The Interaction between He Bubble and Migrating Grain Boundary Induced by Shear Loading

Abstract

1. Introduction

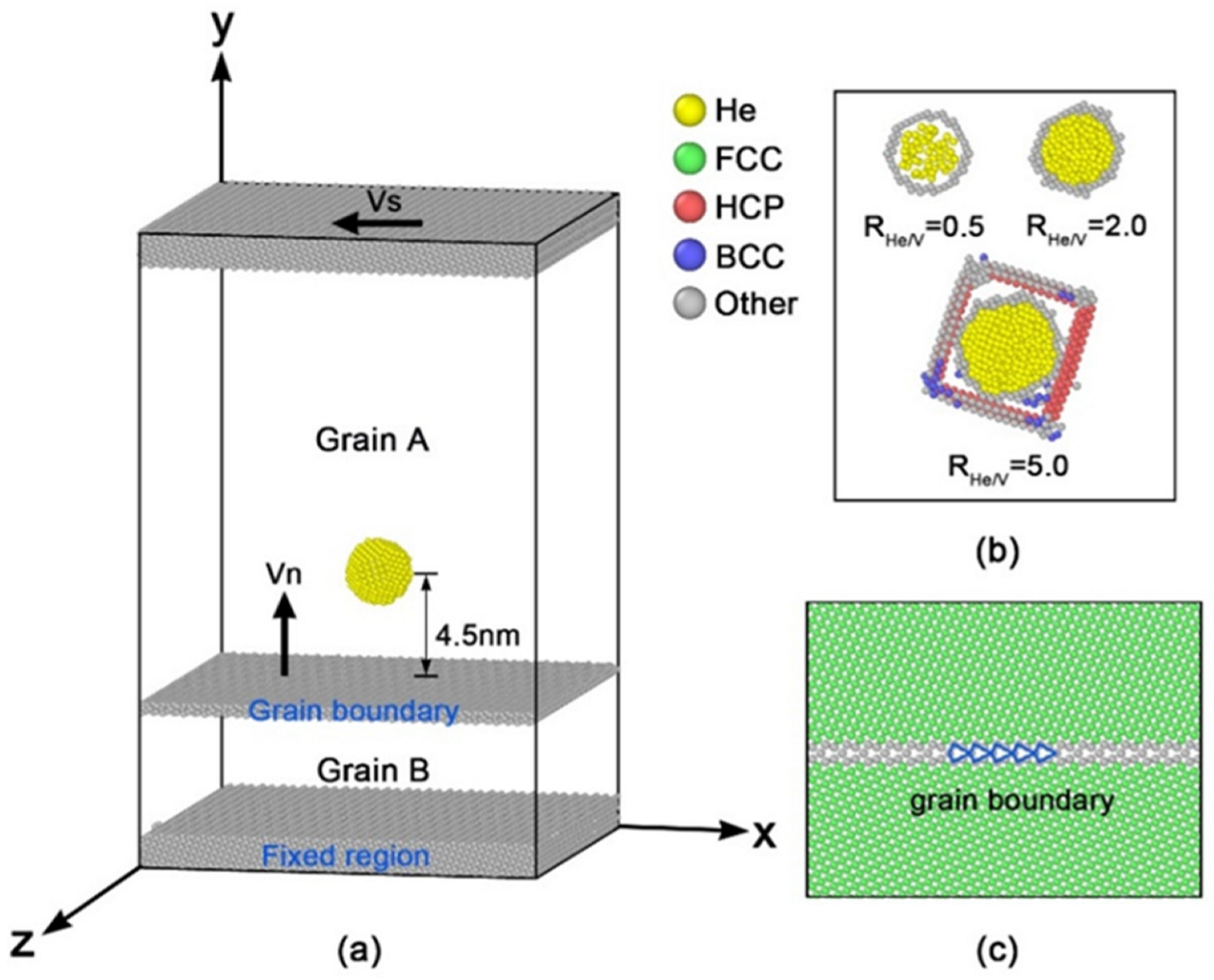

2. Computational Details

3. Results and Discussion

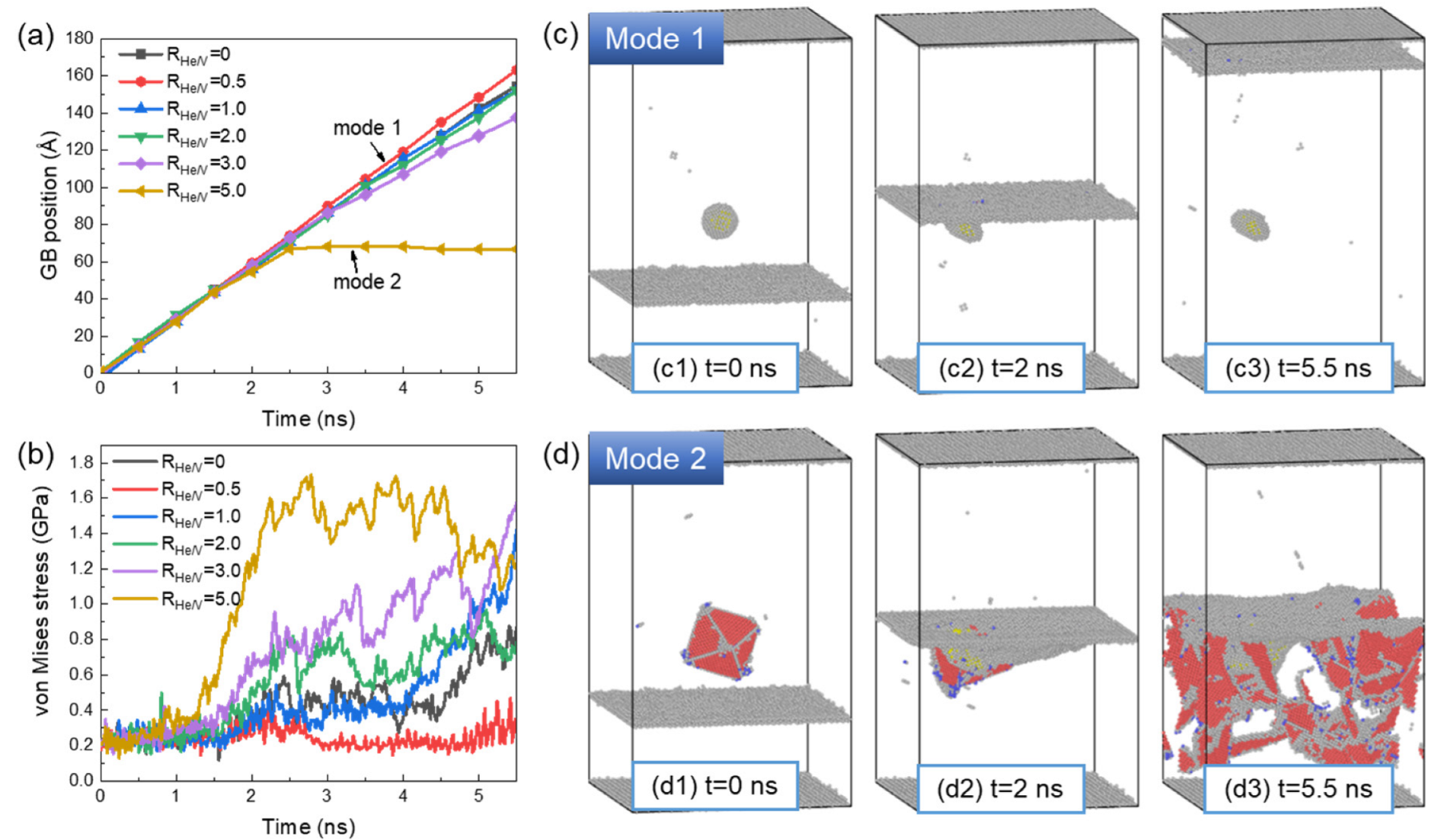

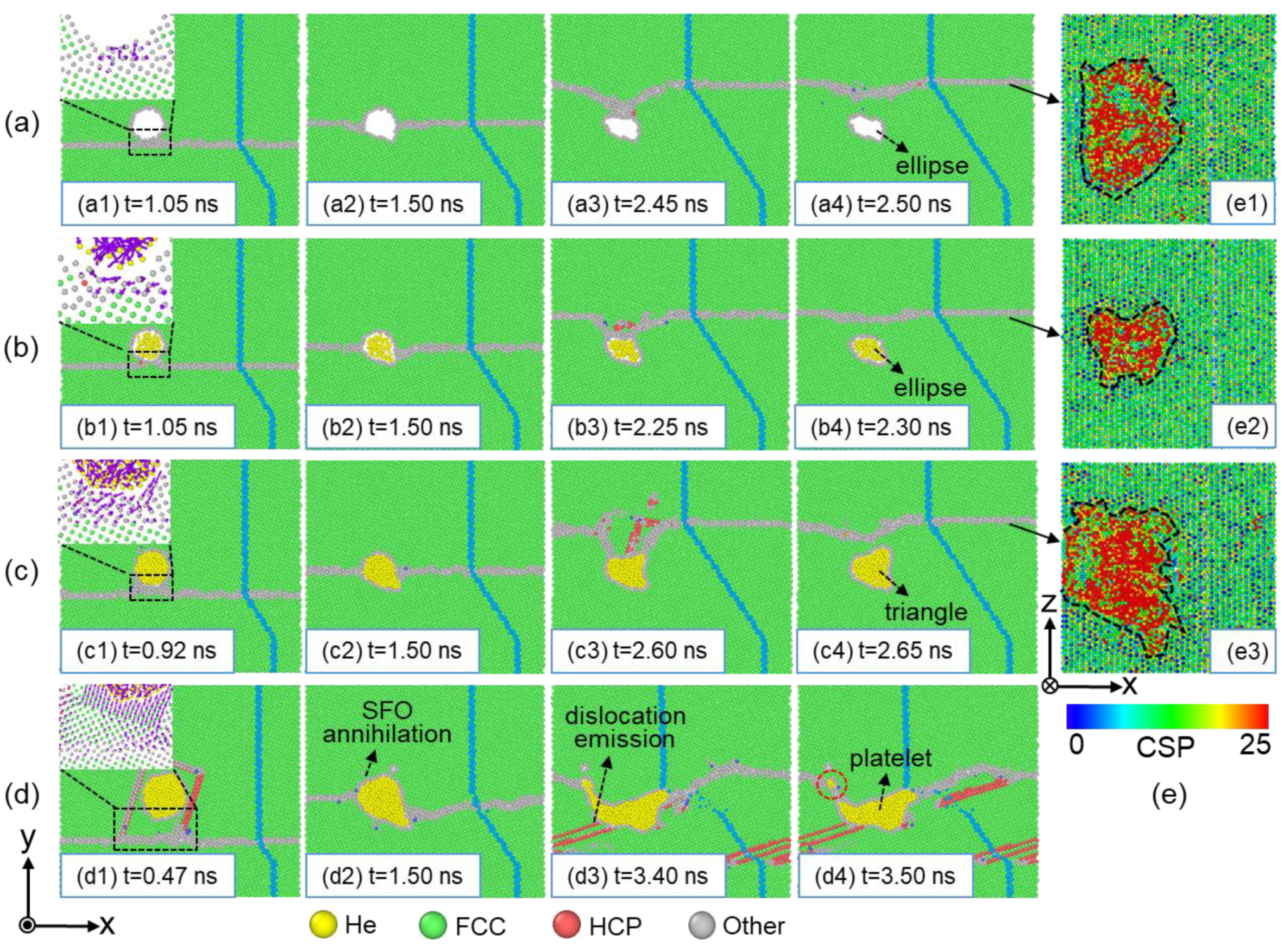

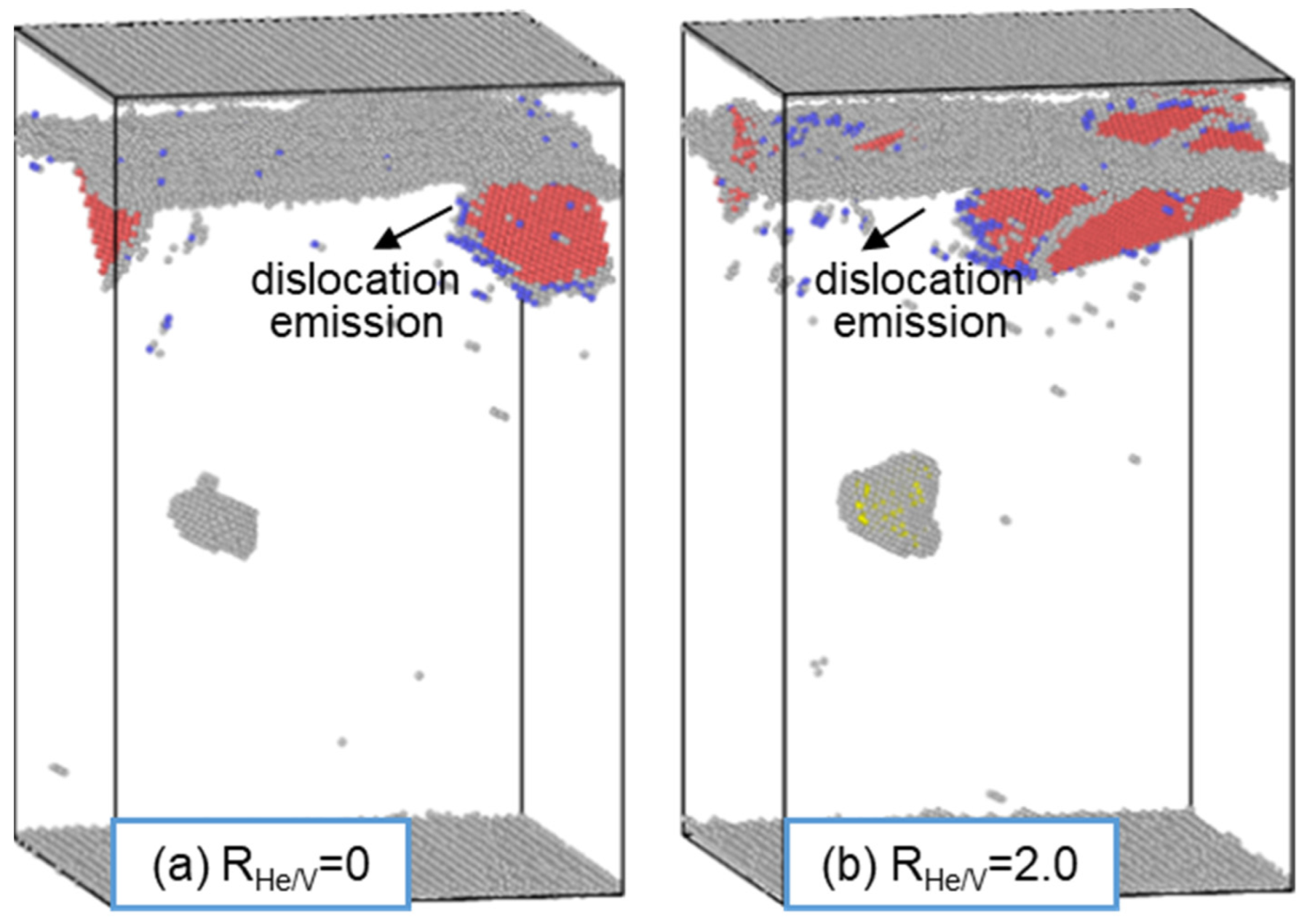

3.1. Effects of He/Vacancy Ratio

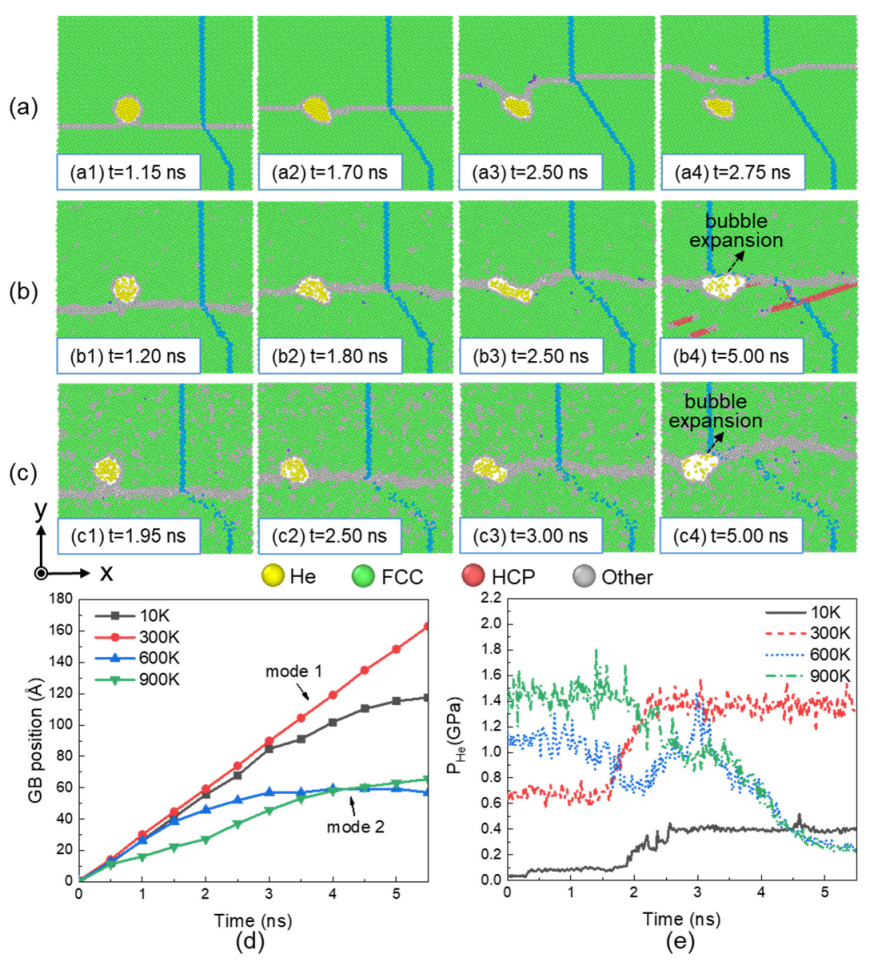

3.2. Effects of Temperature

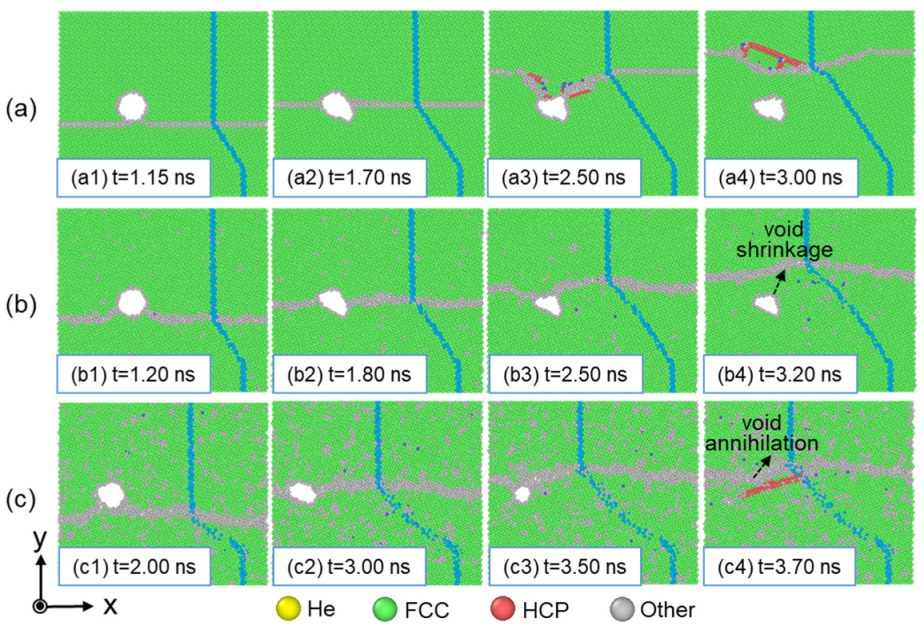

3.3. Effects of Bubble Size

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hashimoto, N.; Byun, T.S.; Farrell, K. Microstructural analysis of deformation in neutron-irradiated fcc materials. J. Nucl. Mater. 2006, 351, 295–302. [Google Scholar] [CrossRef]

- Cui, M.H.; Shen, T.L.; Pang, L.L.; Zhu, Y.B.; Jin, P.; Liu, C.; Fang, X.S.; Wang, Z.G. He ion implantation induced He bubbles and hardness in tungsten. Nucl. Mater. Energy 2018, 15, 232–236. [Google Scholar] [CrossRef]

- Knapp, J.A.; Follstaedt, D.M. Hardening by bubbles in He-implanted Ni. J. Appl. Phys. 2008, 103, 013518. [Google Scholar] [CrossRef]

- Cawthorne, C.; Fulton, E.J. Voids in irradiated stainless steel. Nature 1967, 216, 575–576. [Google Scholar] [CrossRef]

- Briceño, M.; Kacher, J.; Robertson, I.M. Dynamics of dislocation interactions with stacking-fault tetrahedra at high temperature. J. Nucl. Mater. 2013, 433, 390–396. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Busby, J.T. Structural materials for fission & fusion energy. Mater. Today 2009, 12, 12–19. [Google Scholar]

- Osetsky, Y.N.; Stoller, R.E. Atomic-scale mechanisms of helium bubble hardening in iron. J. Nucl. Mater. 2015, 465, 448–454. [Google Scholar] [CrossRef]

- Flanagan, R.M.; Hahn, E.N.; Germann, T.C.; Meyers, M.A.; Fensin, S.J. Molecular dynamics simulations of ejecta formation in helium-implanted copper. Scr. Mater. 2020, 178, 114–118. [Google Scholar] [CrossRef]

- Chen, Z.; Niu, L.-L.; Wang, Z.L.; Tian, L.F.; Kecskes, L.; Zhu, K.G.; Wei, Q.M. A comparative study on the in situ helium irradiation behavior of tungsten: Coarse grain vs. Nanocrystalline grain. Acta Mater. 2018, 147, 100–112. [Google Scholar]

- El-Atwani, O.; Nathaniel, J.E.; Leff, A.C.; Hattar, K.; Taheri, M.L. Direct observation of sinkdependent defect evolution in nanocrystalline iron under irradiation. Sci. Rep. 2017, 7, 1836. [Google Scholar] [CrossRef] [PubMed]

- Kilmametov, A.; Balogh, A.; Ghafari, M.; Gammer, C.; Mangler, C.; Rentenberger, C.; Valiev, R.; Hahn, H. Radiation effects in bulk nanocrystalline FeAl alloy. Radiat. Eff. Defects Solids 2012, 167, 631–639. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Caro, A.; Demkowicz, M.J.; Mara, N.A.; Misra, A.; Uberuaga, B.P. Radiation damage tolerant nanomaterials. Mater. Today 2013, 16, 443–449. [Google Scholar] [CrossRef]

- Cheng, G.M.; Xu, W.Z.; Wang, Y.Q.; Misra, A.; Zhu, Y.T. Grain size effect on radiation tolerance of nanocrystalline Mo. Scr. Mater. 2016, 123, 90–94. [Google Scholar] [CrossRef]

- Liu, H.C.; Huang, J.; Wang, C.X.; Xia, S.Q.; Ge, W.; Liu, Q.Y.; Su, Y.; Gao, Z.Y.; Zhao, S.; Du, C.C.; et al. Effects of grain boundaries and nano-precipitates on helium bubble behaviors in lanthanum-doped nanocrystalline steel. Scr. Mater. 2021, 200, 113900. [Google Scholar] [CrossRef]

- Valles, G.; González, C.; Martin-Bragado, I.; Iglesias, R.; Perlado, J.M.; Rivera, A. The influence of high grain boundary density on helium retention in tungsten. J. Nucl. Mater. 2015, 457, 80–87. [Google Scholar] [CrossRef]

- Aramfard, M.; Deng, C. Interaction of shear-coupled grain boundary motion with crack: Crack healing, grain boundary decohesion, and sub-grain formation. J. Appl. Phys. 2016, 119, 085308. [Google Scholar] [CrossRef]

- Han, W.Z.; Demkowicz, M.J.; Fu, E.G.; Wang, Y.Q.; Misra, A. Effect of grain boundary character on sink efficiency. Acta Mater. 2012, 60, 6341–6351. [Google Scholar] [CrossRef]

- Zhang, C.; Li, H.; Li, M.Q. Interaction mechanism between void and interface grain boundary in diffusion bonding. Sci. Technol. Weld. Join. 2015, 20, 123–129. [Google Scholar] [CrossRef]

- Yu, K.Y.; Bufford, D.; Sun, C.; Liu, Y.; Wang, H.; Kirk, M.A.; Li, M.; Zhang, X. Removal of stacking-fault tetrahedra by twin boundaries in nanotwinned metals. Nat. Commun. 2013, 4, 1377. [Google Scholar] [CrossRef]

- Wu, L.P.; Yu, W.S.; Hu, S.L.; Shen, S.P. Stability of stacking fault tetrahedron in twin boundary bicrystal copper under shear. Int. J. Plast. 2017, 97, 246–258. [Google Scholar] [CrossRef]

- Zhang, L.; Shibuta, Y.; Lu, C.; Huang, X. Interaction between nano-voids and migrating grain boundary by molecular dynamics simulation. Acta Mater. 2019, 173, 206–224. [Google Scholar] [CrossRef]

- Chen, J.; Dang, K.; Vo, H.T.; Hosemann, P.; Fensin, S.J. Associating GB characteristics with its sink efficiency in absorbing Frank loops in Cu. Scr. Mater. 2021, 192, 61–66. [Google Scholar] [CrossRef]

- Bai, X.-M.; Voter, A.F.; Hoagland, R.G.; Nastasi, M.; Uberuaga, B.P. Efficient annealing of radiation damage near grain boundaries via interstitial emission. Science 2010, 327, 1631. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Lu, C.; Tieu, A.K.; Shibuta, Y. Dynamic interaction between grain boundary and stacking fault tetrahedron. Scr. Mater. 2018, 144, 78–83. [Google Scholar] [CrossRef]

- Neogi, A.; Askari, H.; Abdolrahim, N. Atomistic simulations of the strengthening effect of high-density bubble formation in helium irradiated single crystalline copper. Materialia 2018, 1, 139–149. [Google Scholar] [CrossRef]

- Li, S.-H.; Li, J.-T.; Han, W.-Z. Radiation-induced helium bubbles in metals. Materialia 2019, 12, 1036. [Google Scholar] [CrossRef]

- Xie, H.X.; Xu, K.; Lu, G.-H.; Yu, T.; Yin, F.X. Dislocation climbing mechanism for helium bubble growth in tungsten. Scr. Mater. 2018, 147, 98–102. [Google Scholar] [CrossRef]

- Huang, X.; Lv, C.; Chu, H. Anomalous shape effect of nanosized helium bubble on the elastic field in irradiated tungsten. Sci. Rep. 2021, 11, 830. [Google Scholar] [CrossRef]

- Wei, Q.; Li, N.; Sun, K.; Wang, L. The shape of bubbles in He-implanted Cu and Au. Scr. Mater. 2010, 63, 430–433. [Google Scholar] [CrossRef]

- Jin, M.; Gao, Y.; Zhang, Y.; Jiang, C.; Gan, J. Dissociated prismatic loop punching by bubble growth in FCC metals. Sci. Rep. 2021, 11, 12839. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.-D.; Shao, J.-L.; Qie, Y.-H. Atomistic insight into the thermodynamic properties and the surrounding deformation of high-pressurized He bubbles in Al. Comput. Mater. Sci. 2020, 180, 109699. [Google Scholar] [CrossRef]

- Hafez Haghighat, S.M.; Schäublin, R. Influence of the stress field due to pressurized nanometric He bubbles on the mobility of an edge dislocation in iron. Philos. Mag. 2010, 90, 1075–1100. [Google Scholar] [CrossRef]

- Sun, J.; Li, Q.; Tang, H.Y.; Zhang, H.W.; Ye, H.F.; Zheng, Y.G. Helium implantation effects on the tensile response of nano-twinned copper. J. Nucl. Mater. 2020, 541, 152426. [Google Scholar] [CrossRef]

- Ono, K.; Miyamoto, M.; Arakawa, K. Dynamical interaction of helium bubbles with grain boundaries in Fe and Fe–9Cr ferritic alloy. J. Nucl. Mater. 2007, 367−370, 522–526. [Google Scholar] [CrossRef]

- El-Atwani, O.; Hattar, K.; Hinks, J.A.; Greaves, G.; Harilal, S.S.; Hassanein, A. Helium bubble formation in ultrafine and nanocrystalline tungsten under different extreme conditions. J. Nucl. Mater. 2015, 458, 216–223. [Google Scholar] [CrossRef]

- Niu, T.; Li, J.; Zhang, Y.; Cho, J.; Ding, J.; Su, R.; Xue, S.; Fan, C.; Shang, Z.; Chen, D.; et al. In-situ studies on the mechanical properties of He ion irradiated nanotwinned Ag. J. Nucl. Mater. 2020, 540, 152392. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Mishin, Y.; Mehl, M.J.; Papaconstantopoulos, D.A.; Voter, A.F.; Kress, J.D. Structural stability and lattice defects in copper: Ab initio, tight-binding, and embedded-atom calculations. Phys. Rev. B 2001, 63, 224106. [Google Scholar] [CrossRef]

- Zhu, Q.; Shao, J.-L.; Pan, H.; Wang, P. Collapse of stacking fault tetrahedron and dislocation evolution in copper under shock compression. J. Nucl. Mater. 2021, 554, 153081. [Google Scholar] [CrossRef]

- Luo, S.N.; Germann, T.C.; Tonks, D.L.; An, Q. Shock wave loading and spallation of copper bicrystals with asymmetric Σ3<110> tilt grain boundaries. J. Appl. Phys. 2010, 108, 093526. [Google Scholar]

- Wang, L.; Ning, X.J. Molecular dynamics simulations of helium behaviour in copper crystals. Chin. Phys. Lett. 2003, 20, 1416–1419. [Google Scholar]

- Nieminen, R.M. Fundamental Aspects of Inert Gases in Solids; Donnelly, S.E., Evans, J.H., Eds.; Springer: Boston, MA, USA, 1991; Volume 279, pp. 17–25. [Google Scholar]

- Zhu, Q.; Cao, G.; Wang, J.W.; Deng, C.; Li, J.X.; Zhang, Z.; Mao, S.X. In situ atomistic observation of disconnection-mediated grain boundary migration. Nat. Commun. 2019, 10, 156. [Google Scholar] [CrossRef] [PubMed]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Modell. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Ono, K.; Arakawa, K.; Hojou, K.; Oohasi, M.; Birtcher, R.C.; Donnelly, S.E. Quantitative study of Brownian motion of helium bubbles in fcc metals. Microscopy 2002, 51, S245–S251. [Google Scholar] [CrossRef]

- Xia, J.; Hu, W.; Yang, J.; Ao, B.; Wang, X. A study of the behavior of helium atoms at Ni grain boundaries. Phys. Stat. Sol. B 2006, 243, 2702–2710. [Google Scholar] [CrossRef]

- Thompson, A.P.; Plimpton, S.J.; Mattson, W. General formulation of pressure and stress tensor for arbitrary many-body interaction potentials under periodic boundary conditions. J. Chem. Phys. 2009, 131, 154107. [Google Scholar] [CrossRef]

- Barber, C.B.; Dobkin, D.P.; Huhdanpaa, H. The quickhull algorithm for convex hulls. ACM Trans. Math. Softw. 1996, 22, 469–483. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Q.; Shao, J.; Wang, P. The Interaction between He Bubble and Migrating Grain Boundary Induced by Shear Loading. Metals 2022, 12, 2012. https://doi.org/10.3390/met12122012

Zhu Q, Shao J, Wang P. The Interaction between He Bubble and Migrating Grain Boundary Induced by Shear Loading. Metals. 2022; 12(12):2012. https://doi.org/10.3390/met12122012

Chicago/Turabian StyleZhu, Qi, Jianli Shao, and Pei Wang. 2022. "The Interaction between He Bubble and Migrating Grain Boundary Induced by Shear Loading" Metals 12, no. 12: 2012. https://doi.org/10.3390/met12122012

APA StyleZhu, Q., Shao, J., & Wang, P. (2022). The Interaction between He Bubble and Migrating Grain Boundary Induced by Shear Loading. Metals, 12(12), 2012. https://doi.org/10.3390/met12122012