Investigation of Co-Cr-Fe-Mn-Ni Non-Equiatomic High-Entropy Alloy Fabricated by Wire Arc Additive Manufacturing

Abstract

:1. Introduction

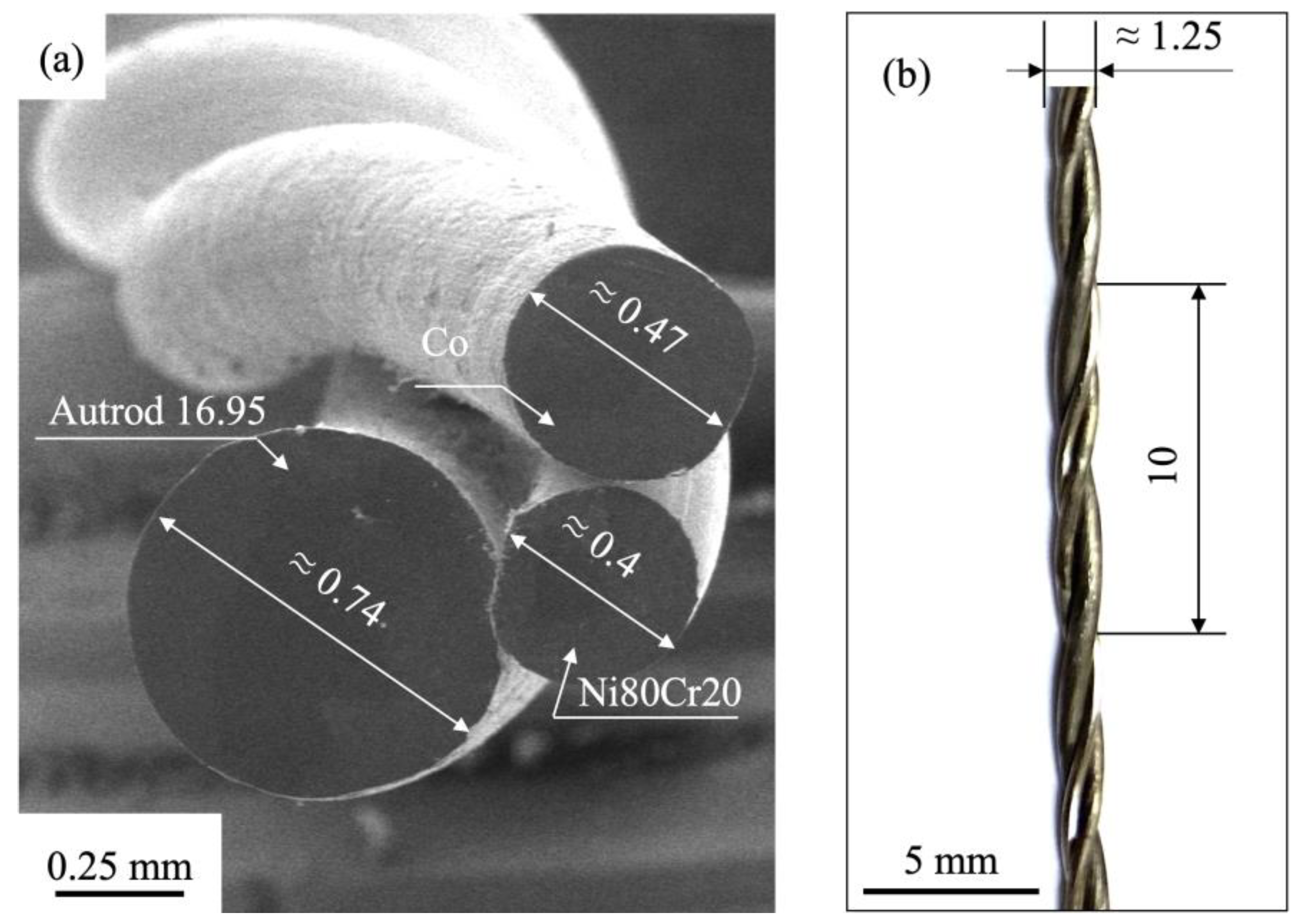

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- Preliminary calculations conducted in this study had an error of not more than 10% for predicting the chemical composition of the principal elements, which confirms the possibility of fabricating HEAs from non-pure wires by wire arc additive manufacturing.

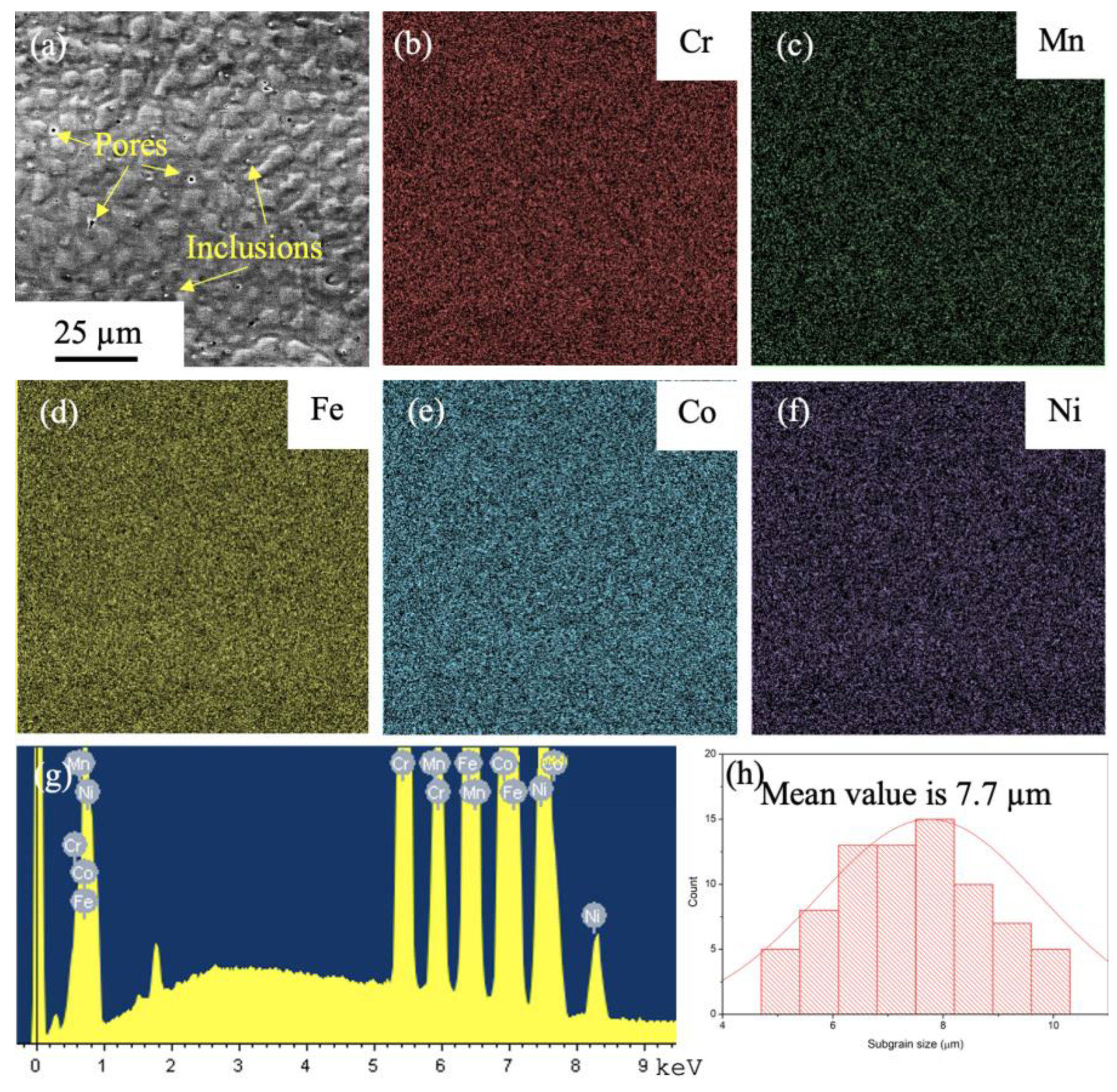

- X-ray diffraction analysis demonstrated that the fabricated Co-Cr-Fe-Mn-Ni HEA showed a single FCC solid solution phase with homogeneous element distribution that correlated with the preliminary calculations of the phase composition.

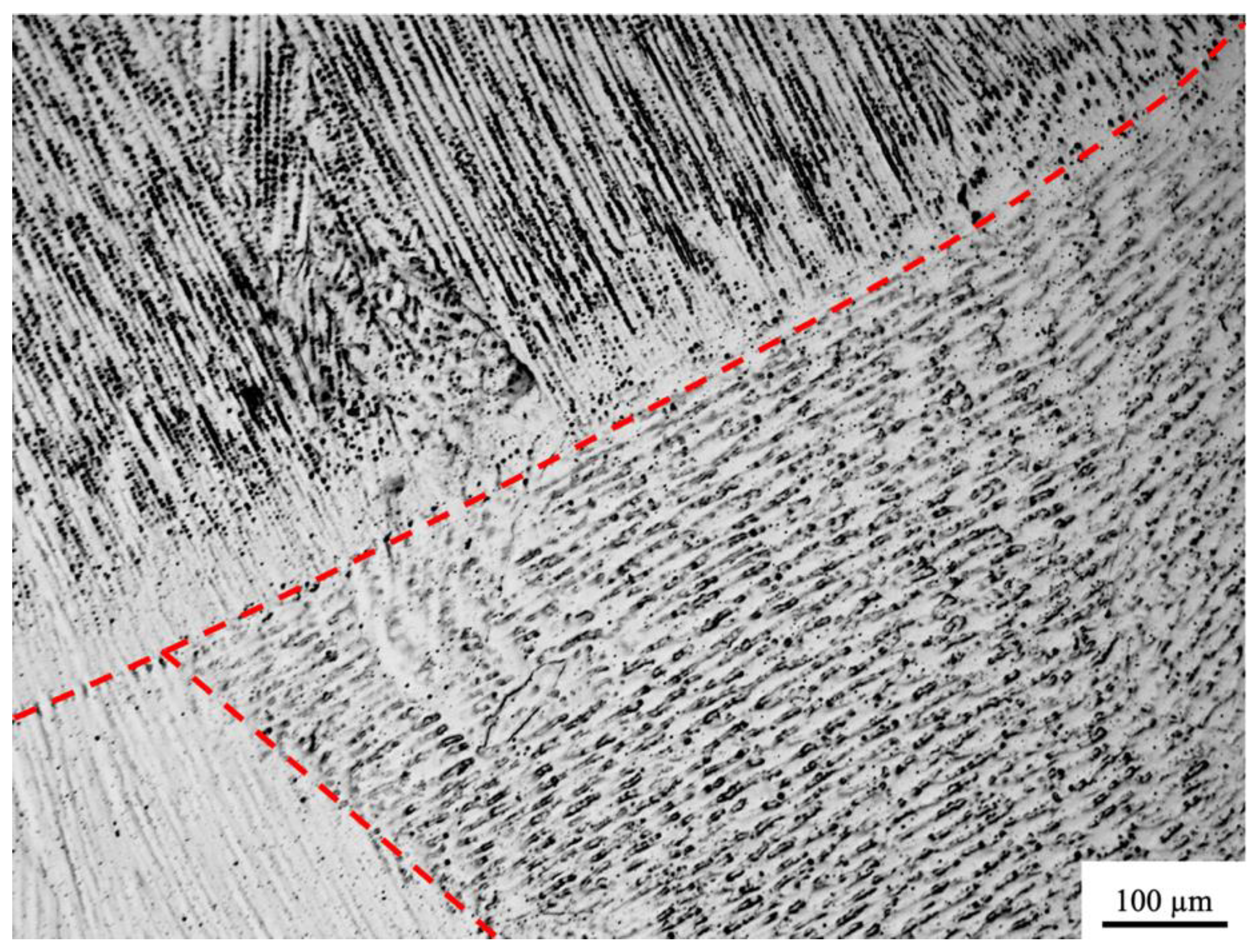

- Optical microscopy showed that the samples’ layers were composed of dendrite grains with a transversal size of 7.7 ± 0.4 µm. These dendrites were oriented along with the cooling directions, most likely because of the high cooling rates typical for WAAM.

- Scanning electron microscopy revealed the presence of defects, such as rounded non-metallic inclusions and micropores. The inclusions contained mostly Al, O, and Mn and had sizes of 1.9 ± 0.3 µm. They were allocated in the microstructure with the number density of 138 mm−2. The pores had the size of 1.9 ± 0.3 µm and were probably formed owing to the gas generation induced by chemical reactions.

- The mechanical tests showed that the as-built alloy has relatively high yield strength ~279 MPa, compared with alloys fabricated by arc melting and laser metal deposition techniques, but lower than the values of the CoCrFeMnNi alloys fabricated by selective laser melting. The ultimate tensile strength (499 ± 74 MPa) is less compared with alloys fabricated by SLM and LMD. Strain before fracture (~63%) is higher than in the CoCrFeMnNi HEAs obtained by selective laser melting, but almost equivalent to as-cast alloys. The average microhardness of the HEA is 153 ± 3 HV1.

- The mechanical properties of the obtained as-deposited HEA showed higher yield strength than the cast and LMD CoCrFeMnNi HEAs, but less than those manufactured by SLM.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miracle, D.B. High entropy alloys as a bold step forward in alloy development. Nat. Commun. 2019, 10, 1805. [Google Scholar] [CrossRef]

- Yeh, J.-W. Recent progress in high-entropy alloys. Ann. Chim. Sci. Des Mater. 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Yeh, J.-W.; Chen, S.-K.; Gan, J.-Y.; Lin, S.-J.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Formation of simple crystal structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V alloys with multiprincipal metallic elements. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2004, 35, 2533–2536. [Google Scholar] [CrossRef]

- Tsai, K.-Y.; Tsai, M.-H.; Yeh, J.-W. Sluggish diffusion in Co–Cr–Fe–Mn–Ni high-entropy alloys. Acta Mater. 2013, 61, 4887–4897. [Google Scholar] [CrossRef]

- Saito, T. Multifunctional Alloys Obtained via a Dislocation-Free Plastic Deformation Mechanism. Science 2003, 300, 464–467. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, H.; Du, X.; He, Y.; Luo, H.; Song, G.; Mao, L.; Zhou, T.; Wang, L. Corrosion resistance enhancement of CoCrFeMnNi high-entropy alloy fabricated by additive manufacturing. Corros. Sci. 2020, 177, 108954. [Google Scholar] [CrossRef]

- Picak, S.; Yilmaz, H.C.; Karaman, I. Simultaneous deformation twinning and martensitic transformation in CoCrFeMnNi high entropy alloy at high temperatures. Scr. Mater. 2021, 202, 113995. [Google Scholar] [CrossRef]

- Wu, Z.; David, S.A.; Leonard, D.N.; Feng, Z.; Bei, H. Microstructures and mechanical properties of a welded CoCrFeMnNi high-entropy alloy. Sci. Technol. Weld. Join. 2018, 23, 585–595. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.; Rolfe, B.; Gibson, I. Additive manufacturing a powerful tool for the aerospace industry. Rapid Prototyp. J. 2021, 28, 87–100. [Google Scholar] [CrossRef]

- Chen, P.; Yang, C.; Li, S.; Attallah, M.M.; Yan, M. In-situ alloyed, oxide-dispersion-strengthened CoCrFeMnNi high entropy alloy fabricated via laser powder bed fusion. Mater. Des. 2020, 194, 108966. [Google Scholar] [CrossRef]

- Zhang, X.; Li, R.; Huang, L.; Amar, A.; Wu, C.; Le, G.; Liu, X.; Guan, D.; Yang, G.; Li, J. Influence of in-situ and ex-situ precipitations on microstructure and mechanical properties of additive manufacturing CoCrFeMnNi high-entropy alloys. Vacuum 2021, 187, 110111. [Google Scholar] [CrossRef]

- Xu, Z.; Zhu, Z.; Wang, P.; Meenashisundaram, G.K.; Nai, S.M.L.; Wei, J. Fabrication of porous CoCrFeMnNi high entropy alloy using binder jetting additive manufacturing. Addit. Manuf. 2020, 35, 101441. [Google Scholar] [CrossRef]

- Lockett, H.; Ding, J.; Williams, S.; Martina, F. Design for wire + Arc additive manufacture: Design rules and build orientation selection. J. Eng. Des. 2017, 28, 568–598. [Google Scholar] [CrossRef] [Green Version]

- Li, J.L.Z.; Alkahari, M.R.; Rosli, N.A.B.; Hasan, R.; Sudin, M.N.; Ramli, F.R. Review of wire arc additive manufacturing for 3d metal printing. Int. J. Autom. Technol. 2019, 13, 346–353. [Google Scholar] [CrossRef]

- Shen, Q.; Kong, X.; Chen, X. Fabrication of bulk Al-Co-Cr-Fe-Ni high-entropy alloy using combined cable wire arc additive manufacturing (CCW-AAM): Microstructure and mechanical properties. J. Mater. Sci. Technol. 2021, 74, 136–142. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.; Du, X.; Tong, Y.; Wang, R.; He, D.; Cai, Z.; Wang, H. Microstructure and mechanical properties of wire arc additively manufactured monbtawti high entropy alloys. Materials 2021, 14, 4512. [Google Scholar] [CrossRef]

- Osintsev, K.; Konovalov, S.; Gromov, V.; Panchenko, I.; Ivanov, Y. Microstructural and mechanical characterisation of non-equiatomic Al 2.1 Co 0.3 Cr 0.5 FeNi 2.1 high-entropy alloy fabricated via wire-arc additive manufacturing. Philos. Mag. Lett. 2021, 101, 353–359. [Google Scholar] [CrossRef]

- Osintsev, K.A.; Konovalov, S.V.; Glezer, A.M.; Gromov, V.E.; Ivanov, Y.F.; Panchenko, I.A.; Sundeev, R.V. Research on the structure of Al2.1Co0.3Cr0.5FeNi2.1 high-entropy alloy at submicro- and nano-scale levels. Mater. Lett. 2021, 294, 129717. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-solution phase formation rules for multi-component alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y. Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 2012, 132, 233–238. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A. Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element. J. Postgrad. Med. Inst. 2016, 30, 80–83. [Google Scholar] [CrossRef] [Green Version]

- Fang, S.; Xiao, X.; Xia, L.; Li, W.; Dong, Y. Relationship between the widths of supercooled liquid regions and bond parameters of Mg-based bulk metallic glasses. J. Non-Cryst. Solids 2003, 321, 120–125. [Google Scholar] [CrossRef]

- Guo, S.; Liu, C.T. Phase stability in high entropy alloys: Formation of solid-solution phase or amorphous phase. Prog. Nat. Sci. Mater. Int. 2011, 21, 433–446. [Google Scholar] [CrossRef] [Green Version]

- Gromov, V.E.; Konovalov, S.V.; Ivanov, Y.F.; Osintsev, K.A. Prediction of Phase Composition of Al-Co-Cr-Fe-Ni System High-Entropy Alloy; Springer International Publishing: Cham, Switzerland, 2021; Volume 107. [Google Scholar]

- Gomez Ortega, A.; Corona Galvan, L.; Deschaux-Beaume, F.; Mezrag, B.; Rouquette, S. Effect of process parameters on the quality of aluminium alloy Al5Si deposits in wire and arc additive manufacturing using a cold metal transfer process. Sci. Technol. Weld. Join. 2018, 23, 316–332. [Google Scholar] [CrossRef] [Green Version]

- Ou, W.; Mukherjee, T.; Knapp, G.L.; Wei, Y.; DebRoy, T. Fusion zone geometries, cooling rates and solidification parameters during wire arc additive manufacturing. Int. J. Heat Mass Transf. 2018, 127, 1084–1094. [Google Scholar] [CrossRef]

- Choi, N.; Lim, K.R.; Na, Y.S.; Glatzel, U.; Park, J.H. Characterization of non-metallic inclusions and their influence on the mechanical properties of a FCC single-phase high-entropy alloy. J. Alloys Compd. 2018, 763, 546–557. [Google Scholar] [CrossRef]

- Yang, X.; Liu, J.; Wang, Z.; Lin, X.; Liu, F.; Huang, W.; Liang, E. Microstructure and mechanical properties of wire and arc additive manufactured AZ31 magnesium alloy using cold metal transfer process. Mater. Sci. Eng. A 2020, 774, 138942. [Google Scholar] [CrossRef]

- Wahab, M.A. Manual Metal Arc Welding and Gas Metal Arc Welding. In Comprehensive Materials Processing; Elsevier: Amsterdam, The Netherlands, 2014; Volume 6, pp. 49–76. ISBN 9780080965338. [Google Scholar]

- Choi, N.; Park, N.; Kim, J.; Karasev, A.V.; Jönsson, P.G.; Park, J.H. Influence of Manufacturing Conditions on Inclusion Characteristics and Mechanical Properties of FeCrNiMnCo Alloy. Metals 2020, 10, 1286. [Google Scholar] [CrossRef]

- Licavoli, J.J.; Gao, M.C.; Sears, J.S.; Jablonski, P.D.; Hawk, J.A. Microstructure and Mechanical Behavior of High-Entropy Alloys. J. Mater. Eng. Perform. 2015, 24, 3685–3698. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Zhu, J.; Zheng, H.; Li, H.; Liu, S.; Cheng, G.J. A review on microstructures and properties of high entropy alloys manufactured by selective laser melting. Int. J. Extrem. Manuf. 2020, 2, 032003. [Google Scholar] [CrossRef]

- Zhong, M.; Liu, W. Laser surface cladding: The state of the art and challenges. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2010, 224, 1041–1060. [Google Scholar] [CrossRef]

- Ma, L.; Li, C.; Jiang, Y.; Zhou, J.; Wang, L.; Wang, F.; Cao, T.; Xue, Y. Cooling rate-dependent microstructure and mechanical properties of Al Si0.2CrFeCoNiCu1−x high entropy alloys. J. Alloys Compd. 2017, 694, 61–67. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef] [Green Version]

- Mittemeijer, E.J. Fundamentals of Materials Science; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 978-3-642-10499-2. [Google Scholar]

- Hackenhaar, W.; Mazzaferro, J.A.E.; Montevecchi, F.; Campatelli, G. An experimental-numerical study of active cooling in wire arc additive manufacturing. J. Manuf. Process. 2020, 52, 58–65. [Google Scholar] [CrossRef]

- Zhao, Y.; Jia, Y.; Chen, S.; Shi, J.; Li, F. Process planning strategy for wire-arc additive manufacturing: Thermal behavior considerations. Addit. Manuf. 2020, 32, 100935. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, L.; Li, H.; Li, C.; Huang, K.; Lu, B. Microstructure Evolution and Mechanical Behavior of 2219 Aluminum Alloys Additively Fabricated by the Cold Metal Transfer Process. Materials 2018, 11, 812. [Google Scholar] [CrossRef] [Green Version]

- Gu, J.; Ding, J.; Williams, S.W.; Gu, H.; Ma, P.; Zhai, Y. The effect of inter-layer cold working and post-deposition heat treatment on porosity in additively manufactured aluminum alloys. J. Mater. Process. Technol. 2016, 230, 26–34. [Google Scholar] [CrossRef]

- He, J.Y.; Liu, W.H.; Wang, H.; Wu, Y.; Liu, X.J.; Nieh, T.G.; Lu, Z.P. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 2014, 62, 105–113. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Shaysultanov, D.G.; Salishchev, G.A.; Tikhonovsky, M.A.; Oleynik, E.E.; Tortika, A.S.; Senkov, O.N. Effect of V content on microstructure and mechanical properties of the CoCrFeMnNiVx high entropy alloys. J. Alloys Compd. 2015, 628, 170–185. [Google Scholar] [CrossRef]

- Li, B.; Zhang, L.; Xu, Y.; Liu, Z.; Qian, B.; Xuan, F. Selective laser melting of CoCrFeNiMn high entropy alloy powder modified with nano-TiN particles for additive manufacturing and strength enhancement: Process, particle behavior and effects. Powder Technol. 2020, 360, 509–521. [Google Scholar] [CrossRef]

| Principal Elements | Impurities | ||||||

|---|---|---|---|---|---|---|---|

| Co | Cr | Fe | Mn | Ni | Al | Si | |

| Co-Cr-Fe-Mn-Ni experimentally obtained by EDS, at. % | 25.2 | 15.1 | 37.8 | 3.4 | 16.3 | 0.8 | 1.4 |

| Co-Cr-Fe-Mn-Ni preliminary calculated, at. % | 25.0 | 14.9 | 37.9 | 3.5 | 17.9 | 0.1 | 0.9 |

| Error. % | 0.8 | 1.7 | 0.2 | 2.2 | 9.8 | 88.0 | 39.3 |

| ΔSmix, kJ/mol | ΔHmix, kJ/mol | δr, % | Ω | VEC | Estimated Phase Composition | ||

|---|---|---|---|---|---|---|---|

| 11.76 | −2.79 | 1.54 | 7.71 | 8.26 | 0.09 | 4.11 | Single-phase FCC crystal structure without presence of Laves and TCP Phases |

| Elements | Co | Cr | Fe | Mn | Ni | Al | Si | O | Mg | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| Inclusion, at. % | 11.0 | 8.0 | 18.7 | 3.2 | 8.0 | 18.3 | 1.1 | 30.5 | 0.8 | 0.3 |

| Type of the Tests | Ultimate Strength, MPa | Yield Strength, MPa | Fracture Strain, % | Hardness, HV | |

|---|---|---|---|---|---|

| WAAM non-equiatomic Co-Cr-Fe-Mn-Ni (this work) | Compressive | 1689 ± 343 | 279 ± 47 | 53 ± 2 | 153 ± 3 |

| Tensile | 499 ± 74 | 279 ± 9 | 63 ± 25 | ||

| Arc-melted equiatomic CoCrFeMnNi [43] | Compressive | 496 | 209 | 75 | 144 |

| Arc-melted equiatomic CoCrFeMnNi [44] | Compressive | Not fractured | 230 | >75 | 176 |

| SLM equiatomic CoCrFeMnNi [45] | Tensile | 601 | ~350 | 30 | - |

| SLM equiatomic CoCrFeMnNi [12] | Tensile | 747 ± 2 | 624 ± 4 | 12.3 ± 0.2 | - |

| LMD equiatomic CoCrFeMnNi [13] | Tensile | 550 | 245 | 52 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osintsev, K.; Konovalov, S.; Zaguliaev, D.; Ivanov, Y.; Gromov, V.; Panchenko, I. Investigation of Co-Cr-Fe-Mn-Ni Non-Equiatomic High-Entropy Alloy Fabricated by Wire Arc Additive Manufacturing. Metals 2022, 12, 197. https://doi.org/10.3390/met12020197

Osintsev K, Konovalov S, Zaguliaev D, Ivanov Y, Gromov V, Panchenko I. Investigation of Co-Cr-Fe-Mn-Ni Non-Equiatomic High-Entropy Alloy Fabricated by Wire Arc Additive Manufacturing. Metals. 2022; 12(2):197. https://doi.org/10.3390/met12020197

Chicago/Turabian StyleOsintsev, Kirill, Sergey Konovalov, Dmitrii Zaguliaev, Yurii Ivanov, Victor Gromov, and Irina Panchenko. 2022. "Investigation of Co-Cr-Fe-Mn-Ni Non-Equiatomic High-Entropy Alloy Fabricated by Wire Arc Additive Manufacturing" Metals 12, no. 2: 197. https://doi.org/10.3390/met12020197

APA StyleOsintsev, K., Konovalov, S., Zaguliaev, D., Ivanov, Y., Gromov, V., & Panchenko, I. (2022). Investigation of Co-Cr-Fe-Mn-Ni Non-Equiatomic High-Entropy Alloy Fabricated by Wire Arc Additive Manufacturing. Metals, 12(2), 197. https://doi.org/10.3390/met12020197