Numerical Analysis of Electron Beam Welding Deformation for the Vacuum Vessel Lower Port Stub of 316L Stainless Steel

Abstract

:1. Introduction

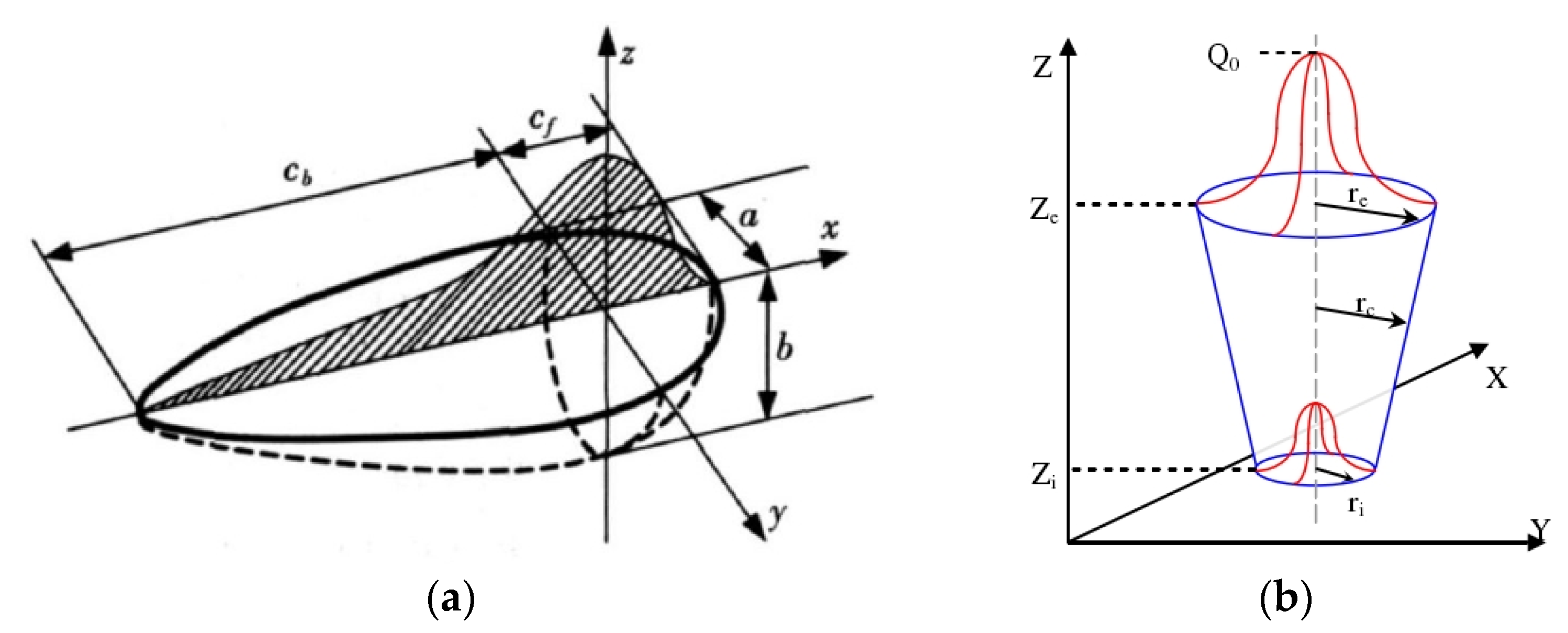

2. Welding Heat Source

2.1. Heat Source Model

2.2. Finite Element Model

2.3. Verification of the Hybrid Heat Source

3. Simulation of the Lower Port Stub

3.1. Calculation Model

3.2. Welding Deformation Analysis

4. Conclusions

- By comparing the temperature cloud diagrams of the simulated and actual weld pools, the hybrid heat source model of EB welding suitable for stainless steel with 50mm thickness was checked.

- Based on the actual manufacturing process of the lower port stub, the welding deformation was analyzed by the thermo-elastic–plastic theory, and the welding fixtures were designed, which effectively reduces the electron beam welding deformation by up to 83%.

- Since the deformation increases after the fixture is removed, natural aging treatment was proposed to reduce the welding residual stress, thereby reducing the welding deformation.

- The analysis results of welding deformation can provide theoretical support for the manufacturing of the lower port stub, and the designed fixtures can be manufactured and applied to the EB welding of the lower port stub.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gao, X.; Wan, B.; Song, Y.; Li, J.; Wan, Y. Progress on CFETR physics and engineering. Sci. Sin. Phys. Mech. Astron. 2018, 49, 045202. [Google Scholar] [CrossRef]

- Kim, H.; Park, C.K.; Kim, G.; Hong, K.; Lee, Y.; Kim, B.; Ahn, H.; Lee, H.; Kim, T.; Lee, J.; et al. Fabrication results of full scale mock-up for ITER VV port in Korea. Fusion Eng. Des. 2014, 89, 1779–1783. [Google Scholar] [CrossRef]

- Giraud, B. ITER Vacuum Vessel Design Description Document (DDD15) ITER; Iter Origanization: Saint-Paul-lez-Durance, France, 2009. [Google Scholar]

- Liu, Z.; Ji, H.; Wu, J.; Wu, H.; Ma, J.; Fan, X.; Wang, R.; Gu, Y.; Lu, K.; Ran, H.; et al. R&D achievements for vacuum vessel towards CFETR construction. Nucl. Fusion 2020, 60, 126024. [Google Scholar] [CrossRef]

- Liu, Z.; Wu, J.; Fan, X.; Xiong, Q.; Ma, J. The key technology research of electron beam welding in CFETR vacuum vessel collar. Fusion Eng. Des. 2018, 139, 14–18. [Google Scholar] [CrossRef]

- Koňár, R.; Mičian, M.; Zrak, A. Lap weld joint modelling and simulation of welding in programme SYSWELD. MATEC Web Conf. 2018, 157, 02018. [Google Scholar] [CrossRef]

- Cui, S.; Pang, S.; Pang, D.; Zhang, Q.; Zhang, Z. Numerical Simulation and Experimental Investigation on 2205 Duplex Stainless Steel K-TIG Welded Joint. Metals 2021, 11, 1323. [Google Scholar] [CrossRef]

- Tao, J.; Wu, J.; Liu, Z.; Ma, J.; Ji, H.; Peng, W.; Sun, S.; Shen, X.; Xia, X.; Zhang, Y.; et al. Simulation and control of welding distortion for the CFETR equatorial port extension mock-up. Fusion Eng. Des. 2021, 172, 112923. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, N.; Lu, F.; Fang, H. Measurement and analysis of welding deformation in arc welded lap joints of thin steel sheets with different material properties. J. Manuf. Process. 2021, 61, 507–517. [Google Scholar] [CrossRef]

- Evdokimov, A.; Doynov, N.; Ossenbrink, R.; Obrosov, A.; Weiß, S.; Michailov, V. Thermomechanical laser welding simulation of dissimilar steel-aluminum overlap joints. Int. J. Mech. Sci. 2020, 190, 106019. [Google Scholar] [CrossRef]

- Rai, R.; Burgardt, P.; Milewski, J.O.; Lienert, T.J.; DebRoy, T. Heat transfer and fluid flow during electron beam welding of 21Cr–6Ni–9Mn steel and Ti–6Al–4V alloy. J. Phys. D Appl. Phys. 2008, 42, 025503. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, S.; Wang, Z.; Zhao, L. Numerical simulation and experimental investigation on electron beam welding of Ti-22Al-25Nb alloy with electron beam oscillation. Mater. Res. Express 2018, 5, 066537. [Google Scholar] [CrossRef]

- Gu, J.C.; Tong, L.G.; Li, L.; Wang, L.; Yin, S.W.; Bai, S.W. Selection criteria of heat source model on the welding numerical simulation. Mater. Rev. 2014, 28, 143–146. [Google Scholar]

- Wang, Y.; Zhao, H.Y.; Wu, S.; Zhang, J.Q.; Liu, D. Shape parameter determination of double ellipsoid heat source model in numerical simulation of high energy beam welding. Hanjie Xuebao (Trans. China Weld. Institu-Tion) 2003, 24, 67–70. [Google Scholar]

- Lu, Y.; Lu, H. Cone-shaped heat source model and parameters for laser welding. Weld. Join. 2012, 11, 24–26. [Google Scholar] [CrossRef]

- RCC-M 2007 Design and construction rules for Mechanical components of nuclear installations, RCC-MR. In French Society for Design and Construction Rules for Nuclear Island Components; AFCEN: Paris, France, 2007.

| No. | A1 | A3 | A5 | A7 | A13 | A9, A10 and A11 | A2 and A4 | A8 and A12 | A6 |

|---|---|---|---|---|---|---|---|---|---|

| Deformation (mm) | 3.38 | 1.16 | 9.62 | 9.74 | 1.78 | 14.63 | 6.72 | 10.98 | 6.97 |

| No | A1 | A3 | A5 | A7 | A13 | A9, A10, and A11 | A2 and A4 | A8 and A12 | A6 |

|---|---|---|---|---|---|---|---|---|---|

| Deformation (mm) | 0.99 | 0.59 | 1.86 | 3.67 | 0.92 | 3.76 | 1.16 | 3.05 | 2.14 |

| Decrease rate | 71% | 49% | 81% | 62% | 48% | 74% | 83% | 72% | 69% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, H.; Tao, J.; Wu, J.; Liu, Z.; Ma, J.; Xia, X.; Lin, X.; Gao, X. Numerical Analysis of Electron Beam Welding Deformation for the Vacuum Vessel Lower Port Stub of 316L Stainless Steel. Metals 2022, 12, 224. https://doi.org/10.3390/met12020224

Ji H, Tao J, Wu J, Liu Z, Ma J, Xia X, Lin X, Gao X. Numerical Analysis of Electron Beam Welding Deformation for the Vacuum Vessel Lower Port Stub of 316L Stainless Steel. Metals. 2022; 12(2):224. https://doi.org/10.3390/met12020224

Chicago/Turabian StyleJi, Haibiao, Jia Tao, Jiefeng Wu, Zhihong Liu, Jianguo Ma, Xiaowei Xia, Xiaodong Lin, and Xiang Gao. 2022. "Numerical Analysis of Electron Beam Welding Deformation for the Vacuum Vessel Lower Port Stub of 316L Stainless Steel" Metals 12, no. 2: 224. https://doi.org/10.3390/met12020224

APA StyleJi, H., Tao, J., Wu, J., Liu, Z., Ma, J., Xia, X., Lin, X., & Gao, X. (2022). Numerical Analysis of Electron Beam Welding Deformation for the Vacuum Vessel Lower Port Stub of 316L Stainless Steel. Metals, 12(2), 224. https://doi.org/10.3390/met12020224