Numerical Investigation on the Effects of Impeller Structures in Hot Metal Desulfurization Processes by Mechanical Stirring

Abstract

:1. Introduction

2. Mathematical Method

2.1. Assumptions

- (1)

- The air and hot metal in the ladle were treated as Newtonian fluids with constant physical properties, and the formation of slag in the ladle was ignored [2].

- (2)

- The effect of sulfur content on the interfacial tension was ignored; the constant coefficient of the hot metal-air and molten metal-DA particles interfacial tension was assumed [14].

2.2. Multiple Reference Frame Model

2.3. Continuity, Momentum and Energy Equations Used in the Stationary Reference Frame

2.4. Continuity, Momentum, and Energy Equations Used in the Moving Reference Frame

2.5. Turbulence Model

2.6. VOF Method

2.7. Dispersed Phase Dynamics

2.8. Desulfurization Model

3. Numerical Simulation

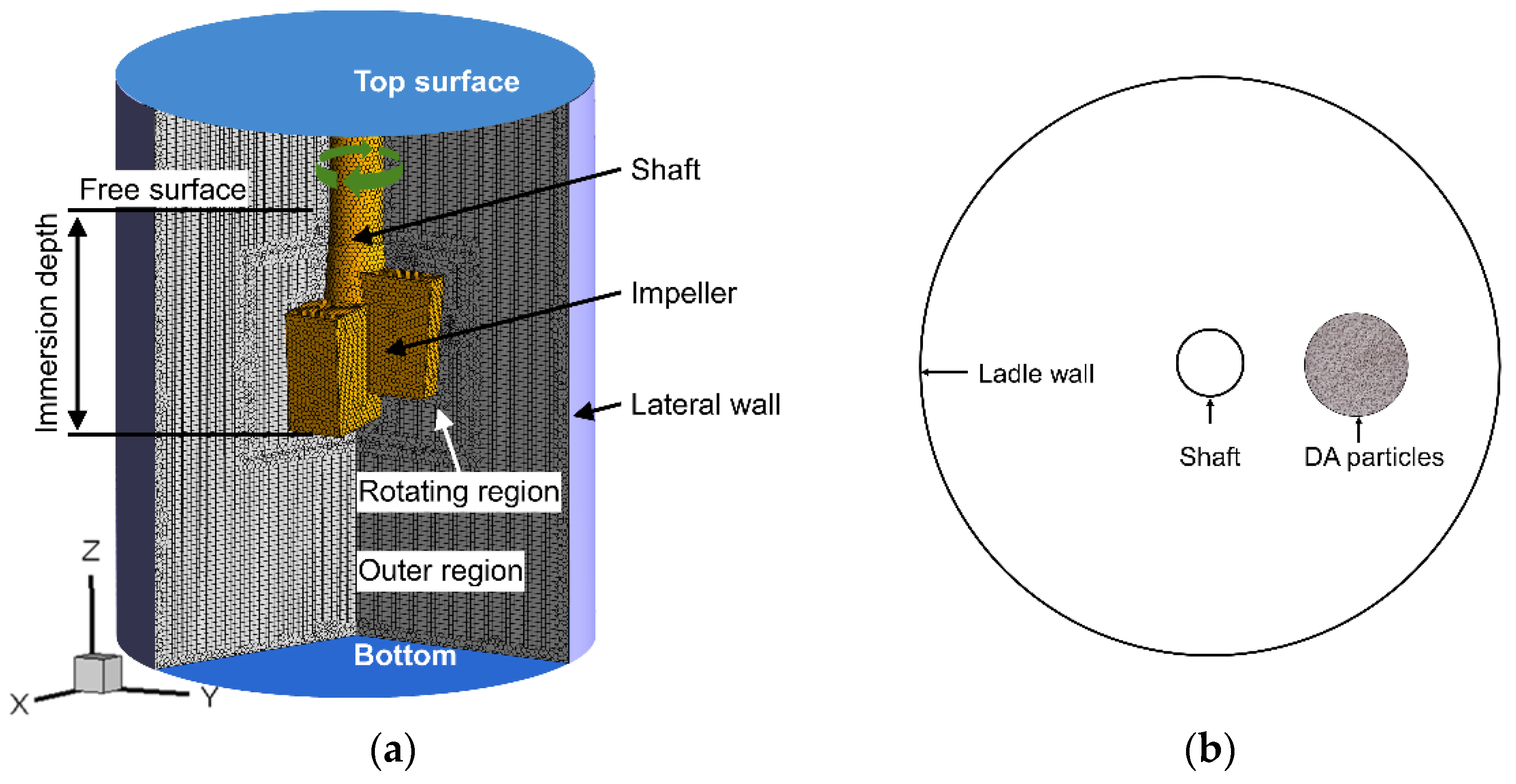

3.1. Impeller Structure

3.2. Initial and Boundary Conditions

3.3. Numerical Procedure

3.4. Model Validation

4. Results and Discussion

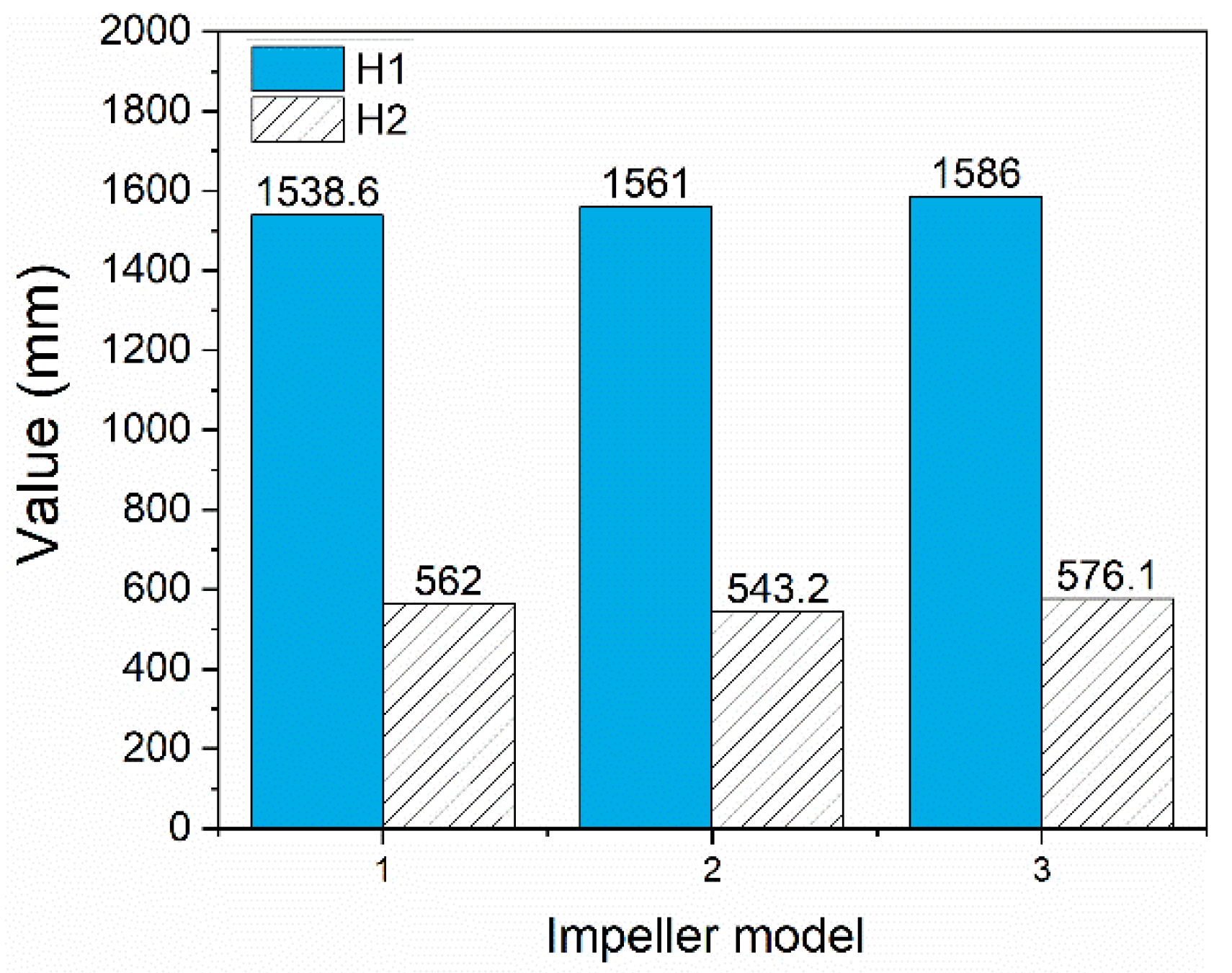

4.1. Characterization of Flow Field

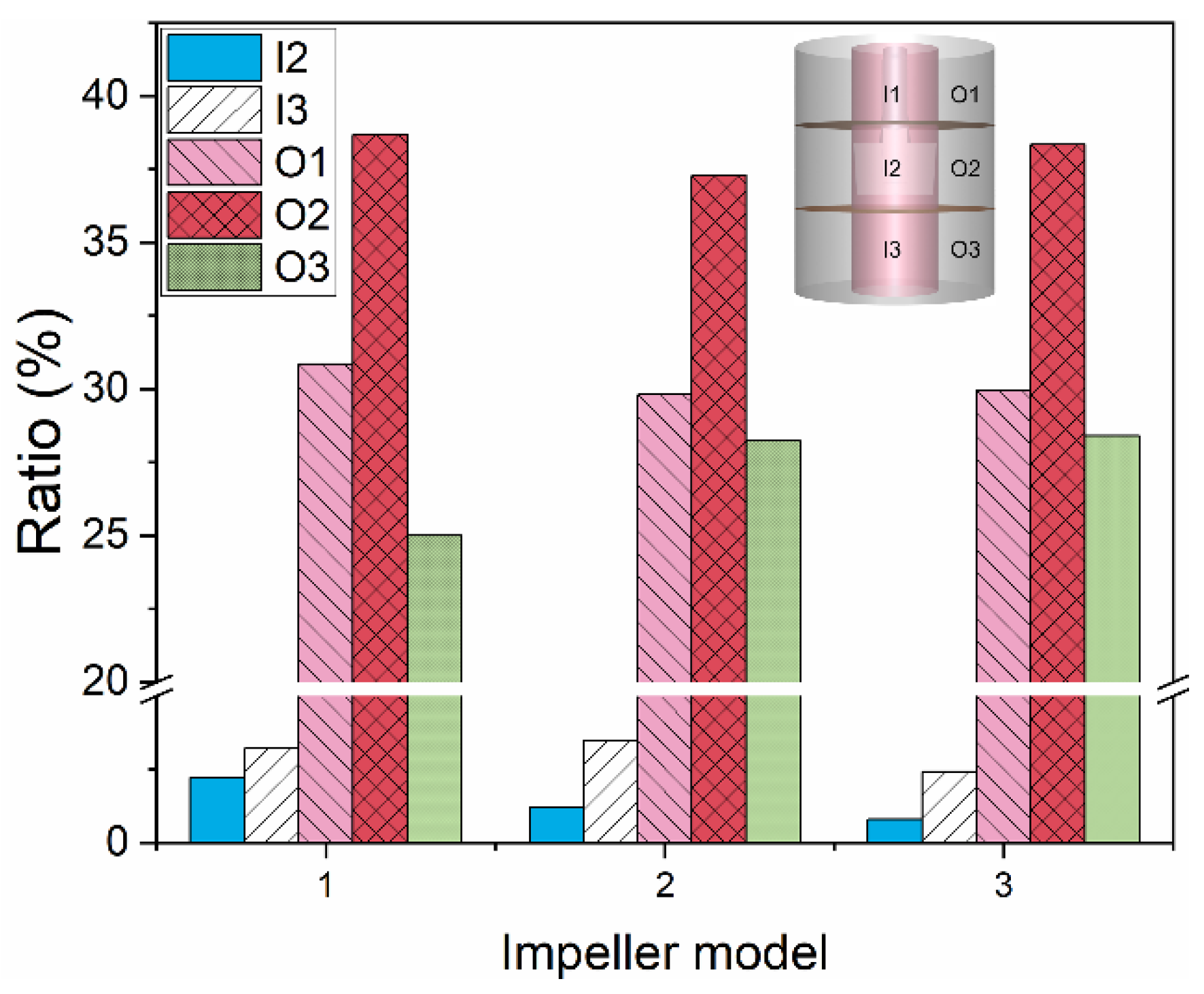

4.2. Distribution of DA Particles in Molten Iron

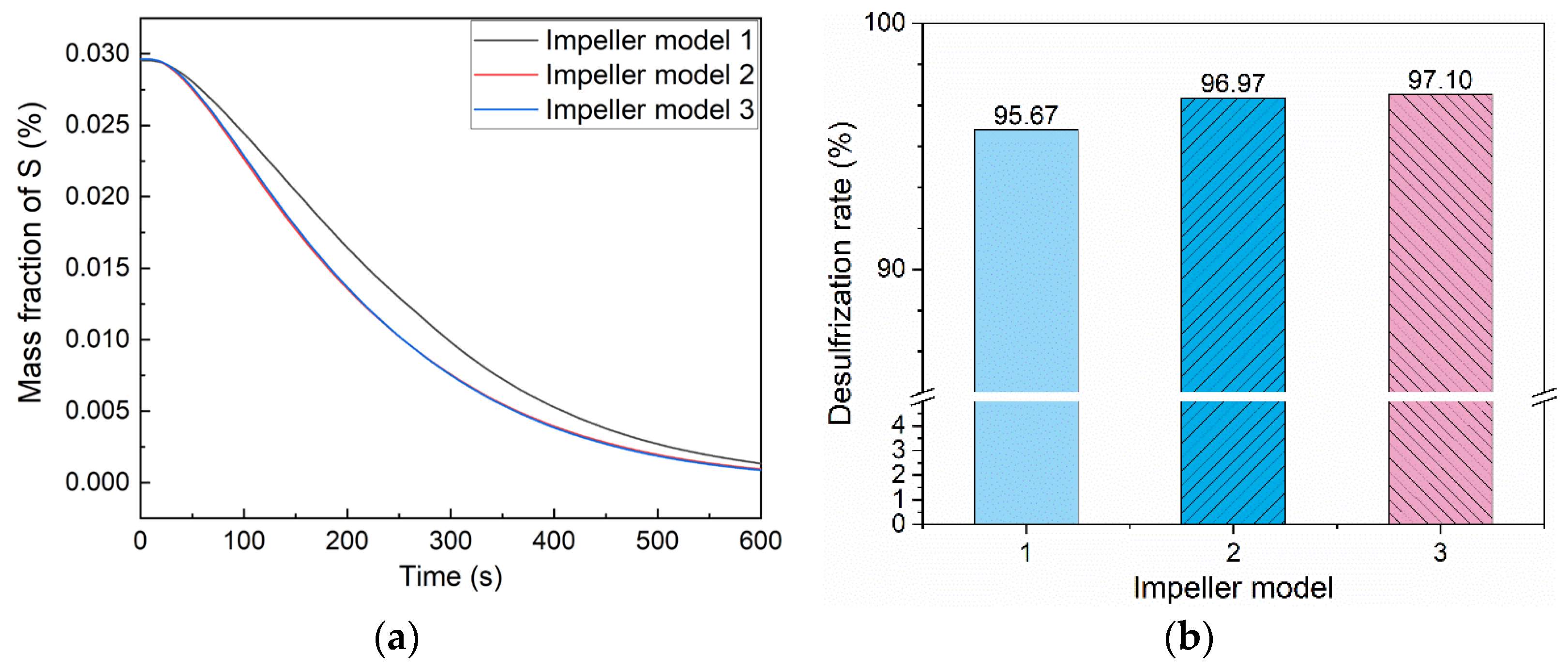

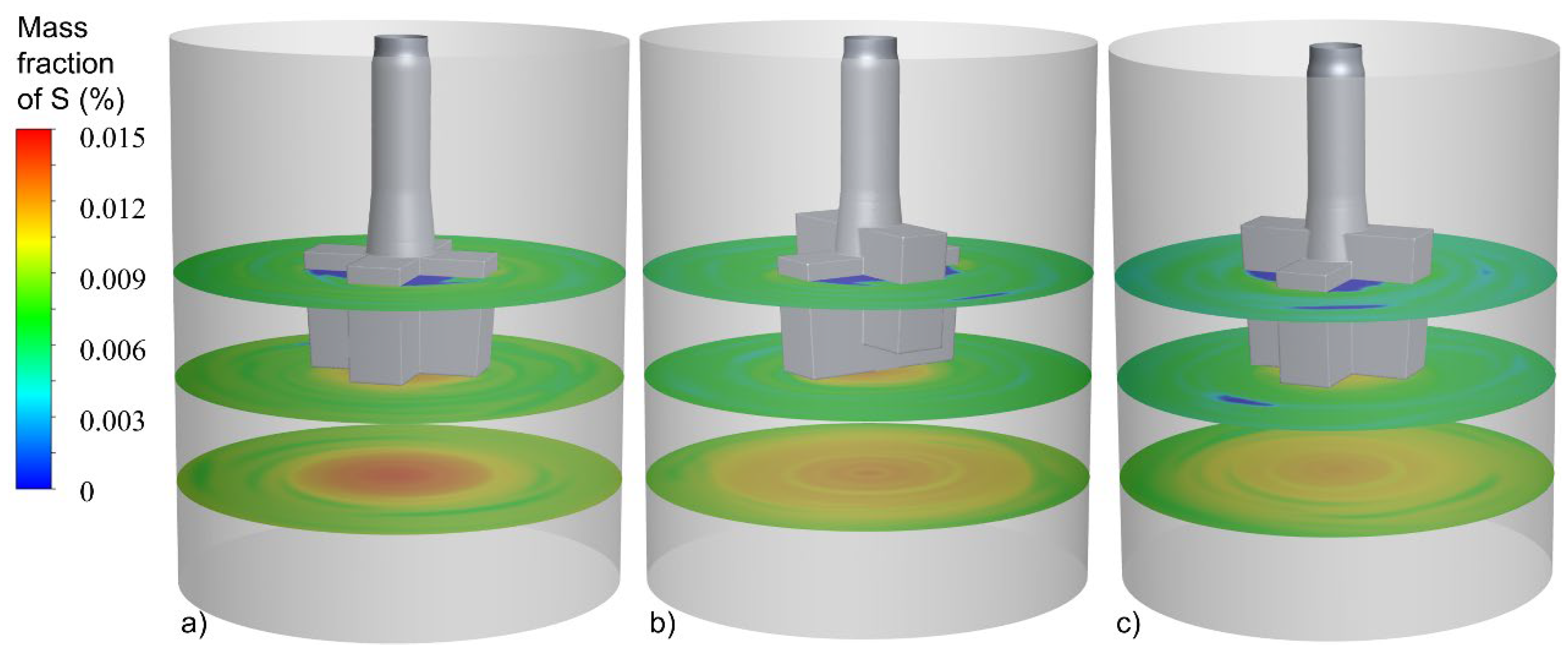

4.3. Distribution of Desulfurizer

5. Conclusions

- The staggered blade structure (impeller models 2 and 3) may improve the desulfurization efficiency of the KR process. Compared with ordinary blades (impeller model 1), the desulfurization rate at 600 s increases from 95.7% to 97.1% when impeller model 3 is used.

- The turbulence intensity of the molten iron, main vortex size and DA particle distributions are enhanced due to the staggered blade structure, which increases the KR desulfurization efficiency.

- Plant tests proved the validity of the developed numerical models and showed that with impeller model 3, the desulfurizer consumption per 1 ppm sulfur was reduced by approximately 8.6% compared with impeller model 1.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, H.L.; Park, S.H. Loading Direction Dependence of Yield-Point Phenomenon and Bauschinger Effect in API X70 Steel Sheet. Met. Mater. Int. 2020, 26, 14–24. [Google Scholar] [CrossRef]

- Saeidi, N.; Jafari, M.; Kim, J.G.; Ashrafizadeh, F.; Kim, H.S. Development of an Advanced Ultrahigh Strength TRIP Steel and Evaluation of Its Unique Strain Hardening Behavior. Met. Mater. Int. 2020, 26, 168–178. [Google Scholar] [CrossRef]

- Visuri, V.V.; Vuolio, T.; Haas, T.; Fabritius, T. A Review of Modeling Hot Metal Desulfurization. Steel Res. Int. 2020, 91, 1900454. [Google Scholar] [CrossRef] [Green Version]

- Holappa, L.E.K. Ladle injection metallurgy. Int. Met. Rev. 1982, 27, 53–76. [Google Scholar] [CrossRef]

- Shao, P.; Liu, S.X.; Miao, X.C. CFD-PBM simulation of bubble coalescence and breakup in top blown-rotary agitated reactor. J. Iron Steel Res. Int. 2021, 28, 1–14. [Google Scholar] [CrossRef]

- Ghosh, A. Secondary Steelmaking: Principles and Applications; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Meichsner, W.; Peters, K.H.; Ullrich, W.; Knahl, H. Desulfurization of hot metal. JOM 1974, 26, 55–58. [Google Scholar] [CrossRef]

- Schrama, F.; Berg, B. Comparison of Kanbara Reactor, magnesium mono-injection and lime: Magnesium co-injection for hot metal desulphurization. Millenn. Steel India 2014, 4, 26–31. [Google Scholar]

- Tripathi, P.; Kumar, D.S.; Sah, R.; Sekhar, V.R. An improved lance design for hot metal de-sulphurisation. Ironmak Steelmak. 2017, 44, 421–429. [Google Scholar] [CrossRef]

- Lindström, D.; Nortier, P.; Sichen, D. Functions of Mg and Mg–CaO Mixtures in Hot Metal Desulfurization. Steel Res. Int. 2014, 85, 76–88. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.; Ma, S.W.; Shen, X.Y.; Li, M.M.; Zou, Z.S. Effects of Impeller Rotational Speed and Immersion Depth on Flow Pattern, Mixing and Interface Characteristics for Kanbara Reactors using VOF-SMM Simulations. Metals 2021, 11, 1596. [Google Scholar] [CrossRef]

- Shiba, R.; Uddin, M.A.; Kato, Y.S.; Kitamura, S.-Y. Solid/liquid mass transfer correlated to mixing pattern in a mechanically-stirred vessel. ISIJ Int. 2014, 54, 2754–2760. [Google Scholar] [CrossRef] [Green Version]

- Ji, J.H.; Liang, R.Q.; He, J.C. Simulation on mixing behavior of desulfurizer and high-sulfur hot metal based on variable-velocity stirring. ISIJ Int. 2016, 56, 794–802. [Google Scholar] [CrossRef] [Green Version]

- He, M.L.; Wang, N.; Chen, M.; Chen, M.; Li, C.F. Distribution and motion behavior of desulfurizer particles in hot metal with mechanical stirring. Power Technol. 2020, 361, 455–461. [Google Scholar] [CrossRef]

- Nakai, Y.; Sumi, I.; Matsuno, H.; Kikuchi, N.; Kishimoto, Y. Effect of flux dispersion behavior on desulfurization of hot metal. ISIJ Int. 2010, 50, 403–410. [Google Scholar] [CrossRef] [Green Version]

- Tong, Z.B.; Ma, G.J.; Cai, X.; Xue, Z.L.; Wang, W.; Zhang, X. Characterization and valorization of Kanbara Reactor desulfurization waste slag of hot metal pretreatment. Waste Biomass Valorization 2016, 7, 1–8. [Google Scholar] [CrossRef]

- Liang, R.Q.; Ji, J.H.; Yan, F.S.; He, J.C. Numerical Study on Flow Characteristics in a Stirring Vessel. Appl. Mech. Mater. 2012, 130–134, 3050–3053. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.M.; Masamichi, S.; Zhang, J.; Shao, P.; Zhang, T.A. Improvement of Impeler Blade Structure for Gas Injection Refining under Mechanical Stirring. J. Iron Steel Res. Int. 2014, 21, 135–143. [Google Scholar] [CrossRef]

- Ji, J.H.; Liang, R.Q.; Feng, Y.T.; He, J.C. Study on the characteristics of fluid flow in stirring vessel of new type stirring of KR desulphurization. J. Iron Steel Res. Int. 2012, S1, 171–174. [Google Scholar]

- Li, Q.; Shen, X.Y.; Guo, S.; Li, M.M.; Zou, Z.S. Computational Investigation on Effect of Impeller Dimension on Fluid Flow and Interface Behavior for Kanbara Reactor Hot Metal Treatment. Steel Res. Int. 2021, 92, 2100239. [Google Scholar] [CrossRef]

- Wang, Q.; Jia, S.Y.; Tan, F.G.; Li, G.Q.; Ouyang, D.G.; Zhu, S.H.; Sun, W.; He, Z. Numerical Study on Desulfurization Behavior During Kanbara Reactor Hot Metal Treatment. Metal Mater. Trans. B 2021, 52, 1085–1094. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, J.L.; Jiao, K.X. Effects of temperature and composition of molten iron on dissolution behavior of carbon brick. Iron Steel 2018, 53, 25–31. [Google Scholar]

- Serra, A.; Campolo, M.; Soldati, A. Time-dependent finite-volume simulation of the turbulent flow in a free-surface CSTR. Chem. Eng. Sci. 2001, 56, 2715–2720. [Google Scholar] [CrossRef]

- Glover, G.M.C.; Fitzpatrick, J.J. Modelling vortex formation in an unbaffled stirred tank reactors. Chem. Eng. J. 2007, 127, 11–22. [Google Scholar] [CrossRef] [Green Version]

- Zhao, H.L.; Lv, C.; Liu, Y.; Zhang, T.A. Process optimization of seed precipitation tank with multiple impellers using computational fluid dynamics. JOM 2015, 67, 1451–1458. [Google Scholar] [CrossRef]

- Haringa, C.; Vandewijer, R.; Mudde, R.F. Inter-compartment interaction in multi-impeller mixing: Part I. Experiments and multiple reference frame CFD. Chem. Eng. Res. Des. 2018, 136, 870–885. [Google Scholar] [CrossRef] [Green Version]

- Franzke, R.; Sebben, S.; Bark, T.; Willeson, E.; Broniewicz, A. Evaluation of the multiple reference frame approach for the modelling of an axial cooling fan. Energies 2019, 12, 2934. [Google Scholar] [CrossRef] [Green Version]

- Launder, B.E.; Spalding, D.B. Lectures in Mathematical Models of Turbulence; Academic Press: London, UK; New York, NY, USA, 1972; p. 157. [Google Scholar]

- Visuri, V.V.; Sulasalmi, P. Hot Metal Desulphurisation Simulator. 2016. Available online: http://cc.oulu.fi/~kamahei/u/res_materials/poster_Visuri-Sulasalmi.pdf (accessed on 1 December 2021).

- Oeters, F.; Strohmenger, P.; Pluschkell, W. Kinetik der Entschwefelung von Roheisenschmelzen mit Kalk und Erdgas. Arch. Für Das Eisenhüttenwesen 1973, 44, 727–733. [Google Scholar] [CrossRef]

- Vuolio, T.; Visuri, V.V.; Tuomikoski, S.; Paananen, T.; Fabritius, T. Data-Driven Mathematical Modeling of the Effect of Particle Size Distribution on the Transitory Reaction Kinetics of Hot Metal Desulfurization. MMTB 2018, 49, 2692–2708. [Google Scholar] [CrossRef] [Green Version]

- Khazam, O.; Kresta, S.M. Mechanisms of solids drawdown in stirred tanks. Can. J. Chem. Eng. 2008, 86, 622–634. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Hot metal density (kg·m−3) | 7036 |

| Hot metal viscosity (Pa·s) | 0.0075 |

| Thermal conductivity of hot metal (W/(m·K)) | 36.3 |

| Specific heat of hot metal (J/(kg·K)) | 1.6 |

| Surface tension coefficient of air and molten iron (N/m) | 1.7 |

| Thermal conductivity of DA particles (W/(m·K)) | 3.5 |

| Ladle diameter (mm) | 3856 |

| Ladle height (mm) | 4700 |

| Initial bath depth (mm) | 3621 |

| Impeller height (mm) | 1000/1250(03) |

| Impeller width (mm) | 1470/1600/1632(03) |

| Impeller immersion depth (mm) | 1833 |

| Impeller rotation rate (rpm) | 80 |

| DA particle density (kg·m−3) | 3000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Jia, S.; He, Z. Numerical Investigation on the Effects of Impeller Structures in Hot Metal Desulfurization Processes by Mechanical Stirring. Metals 2022, 12, 229. https://doi.org/10.3390/met12020229

Wang R, Jia S, He Z. Numerical Investigation on the Effects of Impeller Structures in Hot Metal Desulfurization Processes by Mechanical Stirring. Metals. 2022; 12(2):229. https://doi.org/10.3390/met12020229

Chicago/Turabian StyleWang, Ruizhi, Shuyuan Jia, and Zhu He. 2022. "Numerical Investigation on the Effects of Impeller Structures in Hot Metal Desulfurization Processes by Mechanical Stirring" Metals 12, no. 2: 229. https://doi.org/10.3390/met12020229

APA StyleWang, R., Jia, S., & He, Z. (2022). Numerical Investigation on the Effects of Impeller Structures in Hot Metal Desulfurization Processes by Mechanical Stirring. Metals, 12(2), 229. https://doi.org/10.3390/met12020229