A Prospective Way to Achieve Ballistic Impact Resistance of Lightweight Magnesium Alloys

Abstract

:1. Introduction

2. Proposed Solution and Anticipated Deformation Mechanism

3. Conclusions

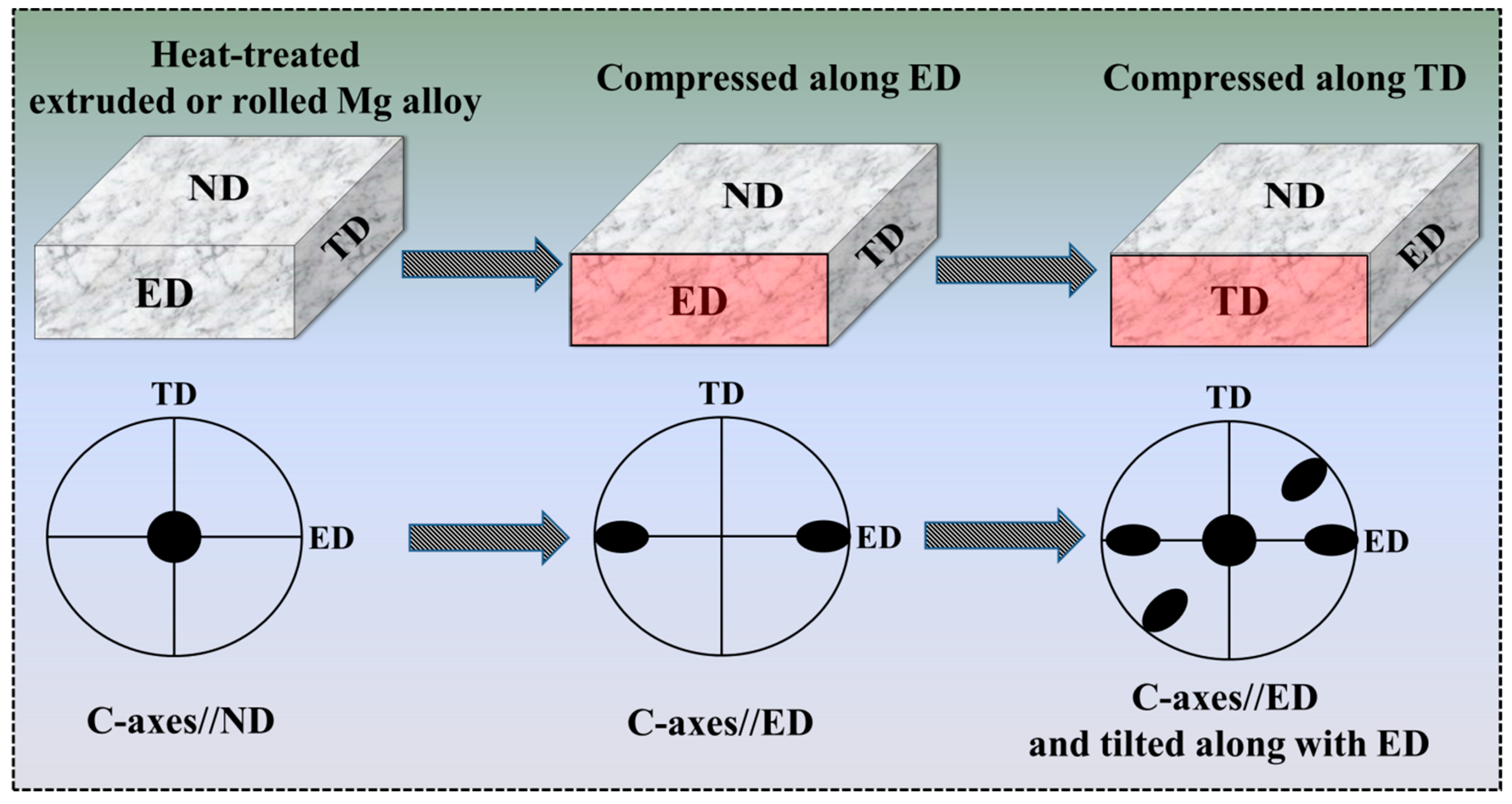

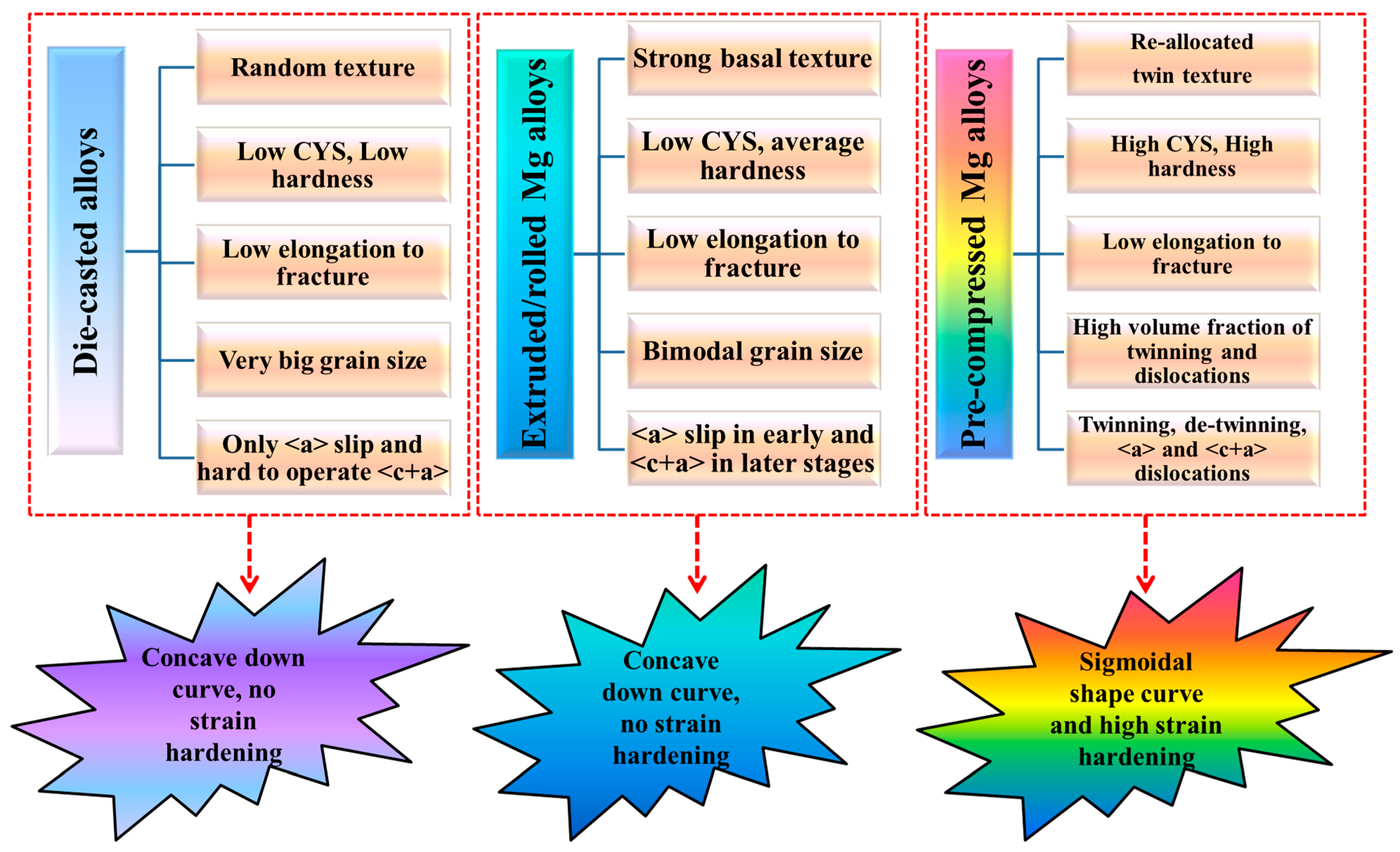

- The typical extruded/rolled texture (c-axes//ND) cannot facilitate a large strain hardening ability, owing to twinning dependencies on the strain path loading. After cross pre-compression, multiple extension twin variants and extension twin types can re-distribute the texture towards and tilted towards the ND. This crystallographic orientation under projectile impact loading along with the normal direction can provide a high strain hardening ability.

- The grain refinement through twinning boundaries can increase the compressive yield strength, ultimate compression strength, and hardness of the Mg alloy. The high ultimate compression strength is the cause of de-twinning and the twin–dislocation interaction.

- The high hardness can control the depth of the penetration, while high mechanical properties can show a high absorption capacity. Consequently, strong resistance against the projectile impact can be offered.

- The re-allocation of non-basal precipitates to the basal plane and vice versa can also take parts to increase the strength. The basal slip activity and non-basal slip activity and its interaction with the pre-induced twinning can lead to a large UFGZ, which can provide more resistance against the next projectile under the impact adjacent to the first crater.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Di Benedetto, G.; Matteis, P.; Scavino, G. Impact behavior and ballistic efficiency of armor-piercing projectiles with tool steel cores. Int. J. Impact Eng. 2018, 115, 10–18. [Google Scholar] [CrossRef]

- Khan, M.A.; Wang, Y.; Cheng, H.; Yasin, G.; Malik, A.; Nazeer, F.; Ahmad, T.; Khan, W.Q.; Kamran, M.; Afifi, M.A. Microstructure evolution of an artificially aged Al-Zn-Mg-Cu alloy subjected to soft- and hard-steel core projectiles. J. Mater. Res. Technol. 2020, 9, 11980–11992. [Google Scholar] [CrossRef]

- Zheng, C.; Wang, F.; Cheng, X.; Liu, J.; Fu, K.; Liu, T.; Zhu, Z.; Yang, K.; Peng, M.; Jin, D. Failure mechanisms in ballistic performance of Ti–6Al–4V targets having equiaxed and lamellar microstructures. Int. J. Impact Eng. 2015, 85, 161–169. [Google Scholar] [CrossRef]

- Malik, A.; Wang, Y.; Huanwu, C.; Bhatti, T.M.; Nazeer, F. Superplastic behavior of fine-grained extruded ZK61 Mg alloy. Results Phys. 2021, 20, 103731. [Google Scholar] [CrossRef]

- Nazeer, F.; Long, J.; Yang, Z.; Li, C. Superplastic deformation behavior of Mg alloys: A-review. J. Magnes. Alloys 2021. [Google Scholar] [CrossRef]

- Park, J.-H.; Kim, S.-H.; Kim, S.-G.; Kim, H.-W.; Lee, J.-C. Improved cryogenic properties of the Al-xMg alloys enabled by twin-roll strip casting. J. Mater. Res. Technol. 2021, 13, 1285–1295. [Google Scholar] [CrossRef]

- Chaudry, U.M.; Hamad, K.; Kim, J.-G. On the ductility of magnesium based materials: A mini review. J. Alloys Compd. 2019, 792, 652–664. [Google Scholar] [CrossRef]

- Malik, A.; Wang, Y.; Nazeer, F.; Khan, M.A.; Sajid, M.; Jamal, S.; Mingjun, W. Deformation behavior of Mg–Zn–Zr magnesium alloy on the basis of macro-texture and fine-grain size under tension and compression loading along various directions. J. Alloys Compd. 2021, 858, 157740. [Google Scholar] [CrossRef]

- Xiong, Y.; Yu, Q.; Jiang, Y. Deformation of extruded ZK60 magnesium alloy under uniaxial loading in different material orientations. Mater. Sci. Eng. A 2018, 710, 206–213. [Google Scholar] [CrossRef]

- Chen, X.; Xiao, L.; Liu, Y.; Xu, M.; Xu, T.; Gao, B.; Hu, Z.; Zhou, H. High strength-ductility of heterogeneous sandwich Mg–Y alloys produced by high pressure torsion. Vacuum 2020, 179, 109568. [Google Scholar] [CrossRef]

- Chaudry, U.M.; Kim, T.H.; Park, S.D.; Kim, Y.S.; Hamad, K.; Kim, J.-G. Effects of calcium on the activity of slip systems in AZ31 magnesium alloy. Mater. Sci. Eng. A 2019, 739, 289–294. [Google Scholar] [CrossRef]

- Chaudry, U.M.; Kim, Y.S.; Hamad, K. Effect of Ca addition on the room-temperature formability of AZ31 magnesium alloy. Mater. Lett. 2019, 238, 305–308. [Google Scholar] [CrossRef]

- Malik, A.; Masood Chaudry, U.; Hamad, K.; Jun, T.-S. Microstructure Features and Superplasticity of Extruded, Rolled and SPD-Processed Magnesium Alloys: A Short Review. Metals 2021, 11, 1766. [Google Scholar] [CrossRef]

- Malik, A.; Wang, Y.; Nazeer, F.; Khan, M.A.; Ali, T.; Ain, Q.T. Effect of pre-straining on twinning, texture and mechanical behavior of magnesium alloys A-review. J. Mater. Res. Technol. 2020, 9, 14478–14499. [Google Scholar] [CrossRef]

- Zang, Q.; Chen, H.; Zhang, J.; Wang, L.; Chen, S.; Jin, Y. Microstructure, mechanical properties and corrosion resistance of AZ31/GNPs composites prepared by friction stir processing. J. Mater. Res. Technol. 2021, 14, 195–201. [Google Scholar] [CrossRef]

- Luo, X.; Feng, Z.; Yu, T.; Luo, J.; Huang, T.; Wu, G.; Hansen, N.; Huang, X. Transitions in mechanical behavior and in deformation mechanisms enhance the strength and ductility of Mg-3Gd. Acta Mater. 2020, 183, 398–407. [Google Scholar] [CrossRef]

- Malik, A.; Wang, Y.; Cheng, H.; Nazeer, F.; Khan, M.A. Microstructure evolution of Mg-Zn-Zr magnesium alloy against soft steel core projectile. J. Mater. Sci. Technol. 2021, 79, 46–61. [Google Scholar] [CrossRef]

- Malik, A.; Yangwei, W.; Huanwu, C.; Khan, M.A.; Nazeer, F.; Rui, A.; Jiawei, B.; Mingjun, W. Fracture behavior of twin induced ultra-fine grained ZK61 magnesium alloy under high strain rate compression. J. Mater. Res. Technol. 2019, 8, 3475–3486. [Google Scholar] [CrossRef]

- Abdullah, M.F.; Abdullah, S.; Omar, M.Z.; Sajuri, Z.; Sohaimi, R.M. Failure observation of the AZ31B magnesium alloy and the effect of lead addition content under ballistic impact. Adv. Mech. Eng. 2015, 7, 1687814015585428. [Google Scholar] [CrossRef]

- Chaudry, U.M.; Kim, T.H.; Kim, Y.S.; Hamad, K.; Ko, Y.G.; Kim, J.-G. Dynamic recrystallization behavior of AZ31-0.5Ca magnesium alloy during warm rolling. Mater. Sci. Eng. A 2019, 762, 138085. [Google Scholar] [CrossRef]

- Zhen, L.; Zou, D.L.; Xu, C.Y.; Shao, W.Z. Microstructure evolution of adiabatic shear bands in AM60B magnesium alloy under ballistic impact. Mater. Sci. Eng. A 2010, 527, 5728–5733. [Google Scholar] [CrossRef]

- Zou, D.L.; Zhen, L.; Xu, C.Y.; Shao, W.Z. Characterization of adiabatic shear bands in AM60B magnesium alloy under ballistic impact. Mater. Charact. 2011, 62, 496–502. [Google Scholar] [CrossRef]

- Zou, D.L.; Zhen, L.; Zhu, Y.; Xu, C.Y.; Shao, W.Z.; Pang, B.J. Deformed microstructure and mechanical properties of AM60B magnesium alloy under hypervelocity impact at a velocity of 4 kms−1. Mater. Sci. Eng. A 2010, 527, 3323–3328. [Google Scholar] [CrossRef]

- Zou, D.L.; Zhen, L.; Zhu, Y.; Xu, C.Y.; Shao, W.Z.; Pang, B.J. Deformed microstructure evolution in AM60B Mg alloy under hypervelocity impact at a velocity of 5 kms−1. Mater. Des. 2010, 31, 3708–3715. [Google Scholar] [CrossRef]

- Zhang, B.; Jiang, J.-T.; Liu, L.; Shao, W.-Z.; Zhen, L. Texture evolution and recrystallization mechanism in a Mg–3Al–1Zn alloy under ballistic impact. J. Alloys Compd. 2020, 816, 152599. [Google Scholar] [CrossRef]

- Zhang, B.; Jiang, J.-T.; Liu, L.; Li, G.-A.; Shao, W.-Z.; Zhen, L. Highly localized shear deformation in a Mg–Al–Mn alloy subjected to ballistic impact. Vacuum 2019, 169, 108868. [Google Scholar] [CrossRef]

- Zhang, W.; Li, K.; Chi, R.; Tan, S.; Li, P. Insights into microstructural evolution and deformation behaviors of a gradient textured AZ31B Mg alloy plate under hypervelocity impact. J. Mater. Sci. Technol. 2021, 91, 40–57. [Google Scholar] [CrossRef]

- Shi, X.; Luo, A.A.; Sutton, S.C.; Zeng, L.; Wang, S.; Zeng, X.; Li, D.; Ding, W. Twinning behavior and lattice rotation in a Mg–Gd–Y–Zr alloy under ballistic impact. J. Alloys Compd. 2015, 650, 622–632. [Google Scholar] [CrossRef]

- Duan, S.; Guo, F.; Zhang, Y.; Chong, K.; Lee, S.; Matsuda, K.; Zou, Y. Effects of texture and precipitates characteristics on anisotropic hardness evolution during artificial aging for an Al–Cu–Li alloy. Mater. Des. 2021, 212, 110216. [Google Scholar] [CrossRef]

- Khan, M.A.; Wang, Y.; Cheng, H.; Nazeer, F.; Yasin, G.; Farooq, M.U.; Malik, A.; Nazir, Z. Ballistic behaviour of spray formed AA7055 aluminum alloy against tungsten core projectile impact. Vacuum 2019, 159, 482–493. [Google Scholar] [CrossRef]

- Khan, M.A.; Wang, Y.; Yasin, G.; Malik, A.; Nazeer, F.; Khan, W.Q.; Zhang, H.; Ahmed, T. Microstructure characteristic of spray formed 7055 Al alloy subjected to ballistic impact by two different steel core projectiles impact. J. Mater. Res. Technol. 2019, 8, 6177–6190. [Google Scholar] [CrossRef]

- Khan, M.A.; Wang, Y.; Malik, A.; Nazeer, F.; Yasin, G.; Khan, W.Q.; Ahmad, T.; Zhang, H. Microstructure characterization of 7055-T6, 6061-T6511 and 7A52-T6 Al alloys subjected to ballistic impact against heavy tungsten alloy projectile. Arch. Civ. Mech. Eng. 2019, 19, 1484–1496. [Google Scholar] [CrossRef]

- Malik, A.; Wang, Y.; Huanwu, C.; Nazeer, F.; Khan, M.A. Post deformation analysis of the ballistic impacted magnesium alloys, a short-review. J. Magnes. Alloys 2021, 9, 1505–1520. [Google Scholar] [CrossRef]

- Malik, A.; Wang, Y.; Nazeer, F. The development of a strong and ductile Mg–Zn–Zr thin sheet through nano precipitates and pre-induced dislocation. Mater. Sci. Eng. A 2021, 817, 141339. [Google Scholar] [CrossRef]

- Malik, A.; Wang, Y.; Nazeer, F.; Khan, M.A. Effect of pre-compression on changes in texture and yielding behavior of ZK61 Mg alloy. Vacuum 2020, 172, 109039. [Google Scholar] [CrossRef]

- Mokdad, F.; Chen, D.; Li, D. Twin-twin interactions and contraction twin formation in an extruded magnesium alloy subjected to an alteration of compressive direction. J. Alloys Compd. 2018, 737, 549–560. [Google Scholar] [CrossRef]

- Malik, A.; Chaudry, U.M.; Yan, T.; Long, J.; Li, C.; Wang, Y. Achieving higher dynamic mechanical response by adjusting texture through twinning in a ZK61 Mg alloy. J. Alloys Compd. 2022, 902, 163755. [Google Scholar] [CrossRef]

- Song, B.; Xin, R.; Zheng, X.; Chen, G.; Liu, Q. Activation of multiple twins by pre-tension and compression to enhance the strength of Mg–3Al–1Zn alloy plates. Mater. Sci. Eng. A 2015, 621, 100–104. [Google Scholar] [CrossRef]

- Sarker, D.; Friedman, J.; Chen, D.L. Influence of pre-deformation and subsequent annealing on strain hardening and anisotropy of AM30 magnesium alloy. J. Alloys Compd. 2014, 611, 341–350. [Google Scholar] [CrossRef]

- Malik, A.; Wang, Y.; Nazeer, F. The both positive and negative effect of pre-strain on the mechanical response of extruded magnesium alloy. Forces in Mechanics 2021, 4, 100031. [Google Scholar] [CrossRef]

- Long, J.; Nazeer, F.; Yang, Z.; Li, C. Compressive properties, mechanical anisotropy and hardness analysis of Mg–Zn alloy under cross pre-compression. Arch. Civ. Mech. Eng. 2021, 21, 156. [Google Scholar] [CrossRef]

- Wang, M.; He, B.B.; Huang, M.X. Strong and ductile Mg alloys developed by dislocation engineering. J. Mater. Sci. Technol. 2019, 35, 394–395. [Google Scholar] [CrossRef]

- Wan, Y.J.; Zeng, Y.; Dou, Y.C.; Hu, D.C.; Qian, X.Y.; Zeng, Q.; Sun, K.X.; Quan, G.F. Improved mechanical properties and strengthening mechanism with the altered precipitate orientation in magnesium alloys. J. Magnes. Alloys 2021. [Google Scholar] [CrossRef]

- Wang, X.J.; Xu, D.K.; Wu, R.Z.; Chen, X.B.; Peng, Q.M.; Jin, L.; Xin, Y.C.; Zhang, Z.Q.; Liu, Y.; Chen, X.H.; et al. What is going on in magnesium alloys? J. Mater. Sci. Technol. 2018, 34, 245–247. [Google Scholar] [CrossRef]

- Yang, Q.; Jiang, B.; Song, B.; Yu, Z.; He, D.; Chai, Y.; Zhang, J.; Pan, F. The effects of orientation control via tension-compression on microstructural evolution and mechanical behavior of AZ31 Mg alloy sheet. J. Magnes. Alloys 2020. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malik, A.; Nazeer, F.; Wang, Y. A Prospective Way to Achieve Ballistic Impact Resistance of Lightweight Magnesium Alloys. Metals 2022, 12, 241. https://doi.org/10.3390/met12020241

Malik A, Nazeer F, Wang Y. A Prospective Way to Achieve Ballistic Impact Resistance of Lightweight Magnesium Alloys. Metals. 2022; 12(2):241. https://doi.org/10.3390/met12020241

Chicago/Turabian StyleMalik, Abdul, Faisal Nazeer, and Yangwei Wang. 2022. "A Prospective Way to Achieve Ballistic Impact Resistance of Lightweight Magnesium Alloys" Metals 12, no. 2: 241. https://doi.org/10.3390/met12020241

APA StyleMalik, A., Nazeer, F., & Wang, Y. (2022). A Prospective Way to Achieve Ballistic Impact Resistance of Lightweight Magnesium Alloys. Metals, 12(2), 241. https://doi.org/10.3390/met12020241