Study of Influence of Aluminum Nitride Nanoparticles on the Structure, Phase Composition and Mechanical Properties of AZ91 Alloy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Powder Mixture

2.2. Obtaining the Mg–AlN Master-Alloy

2.3. Casting Magnesium Alloys

2.4. Characterization

3. Results and Discussion

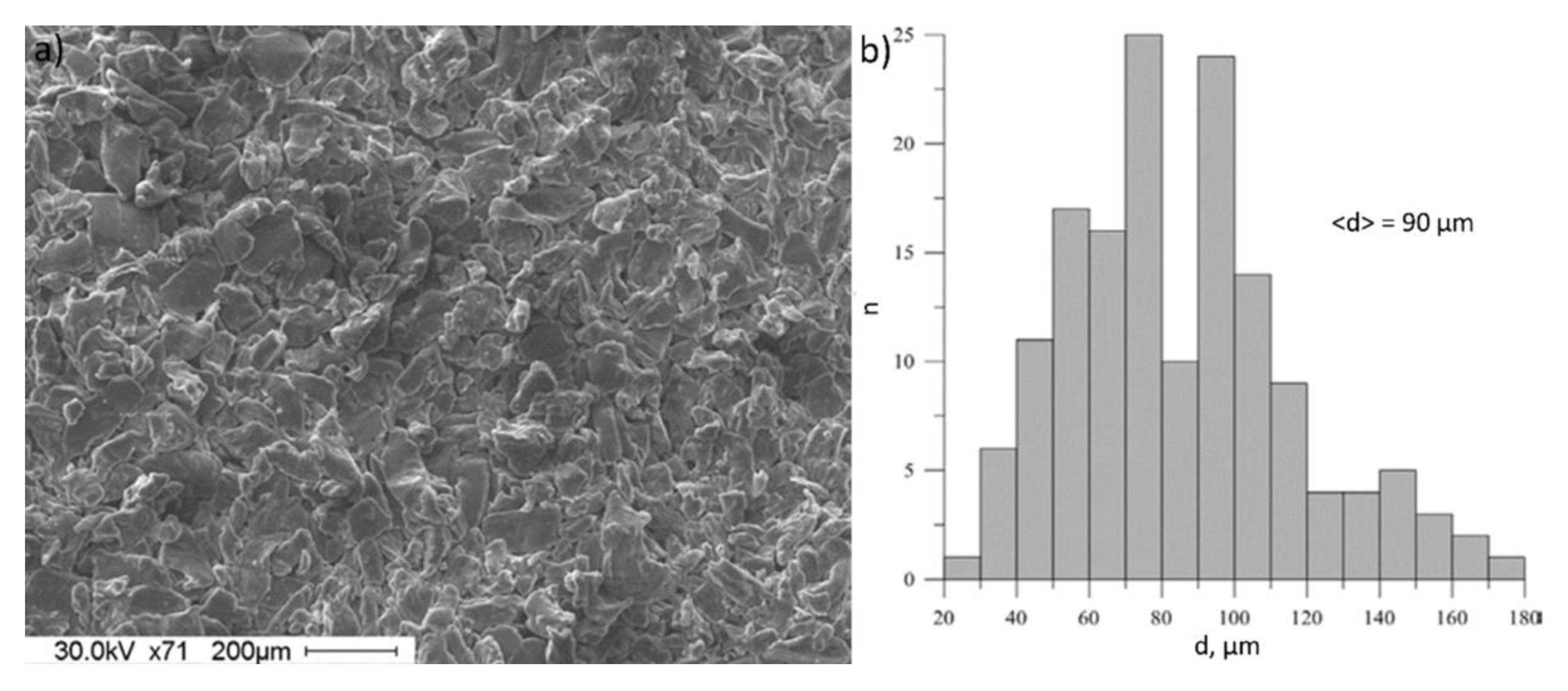

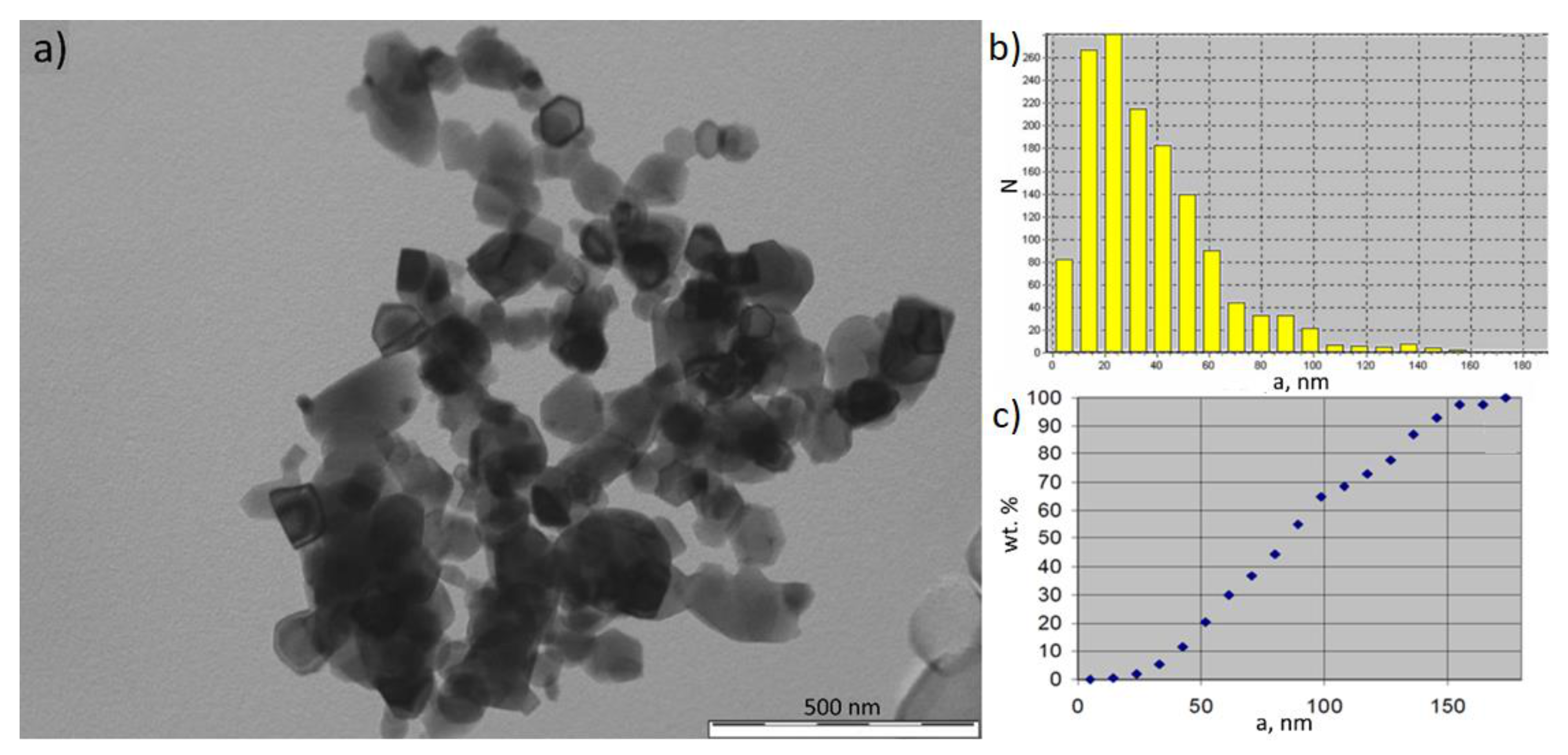

3.1. Initial Powders

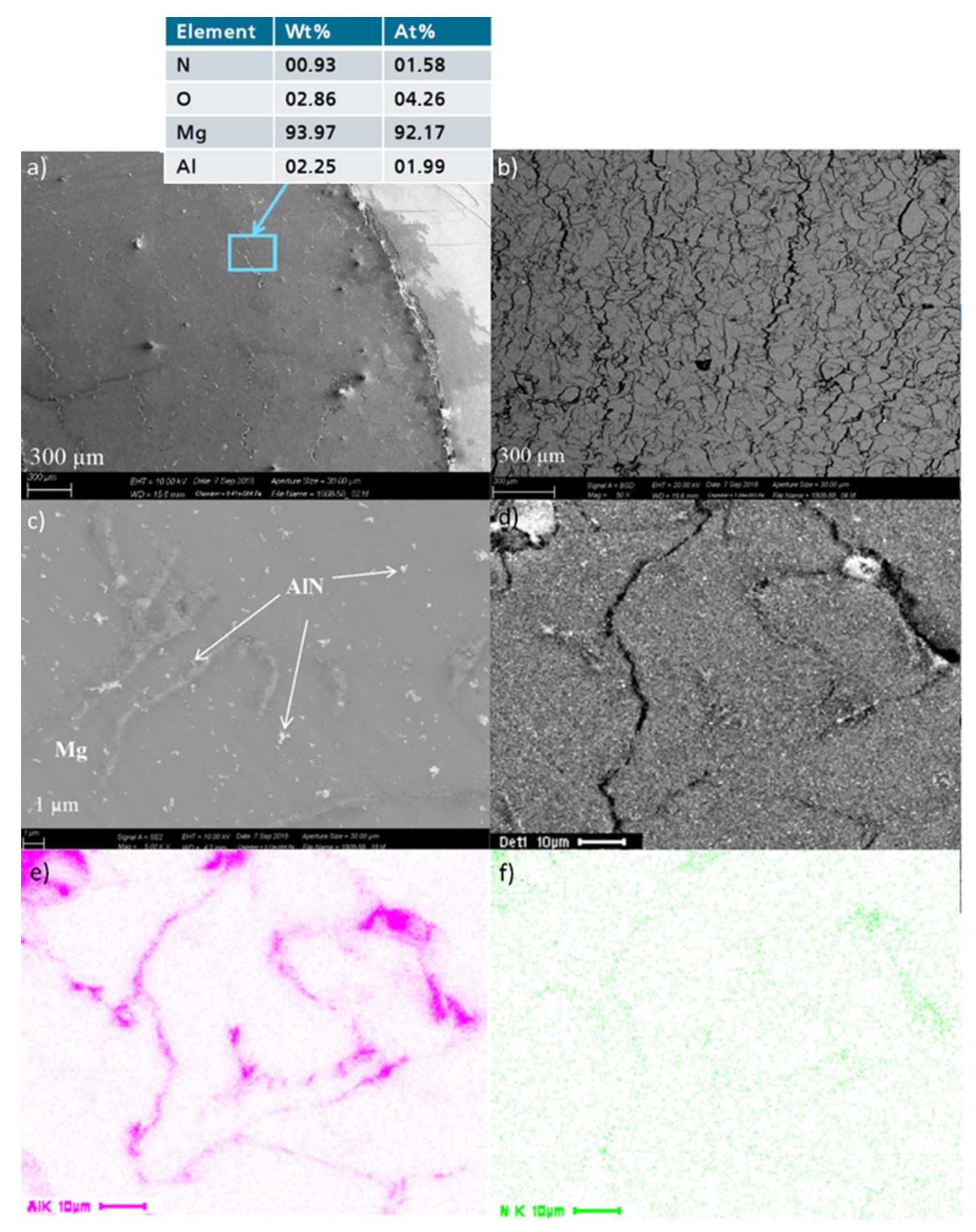

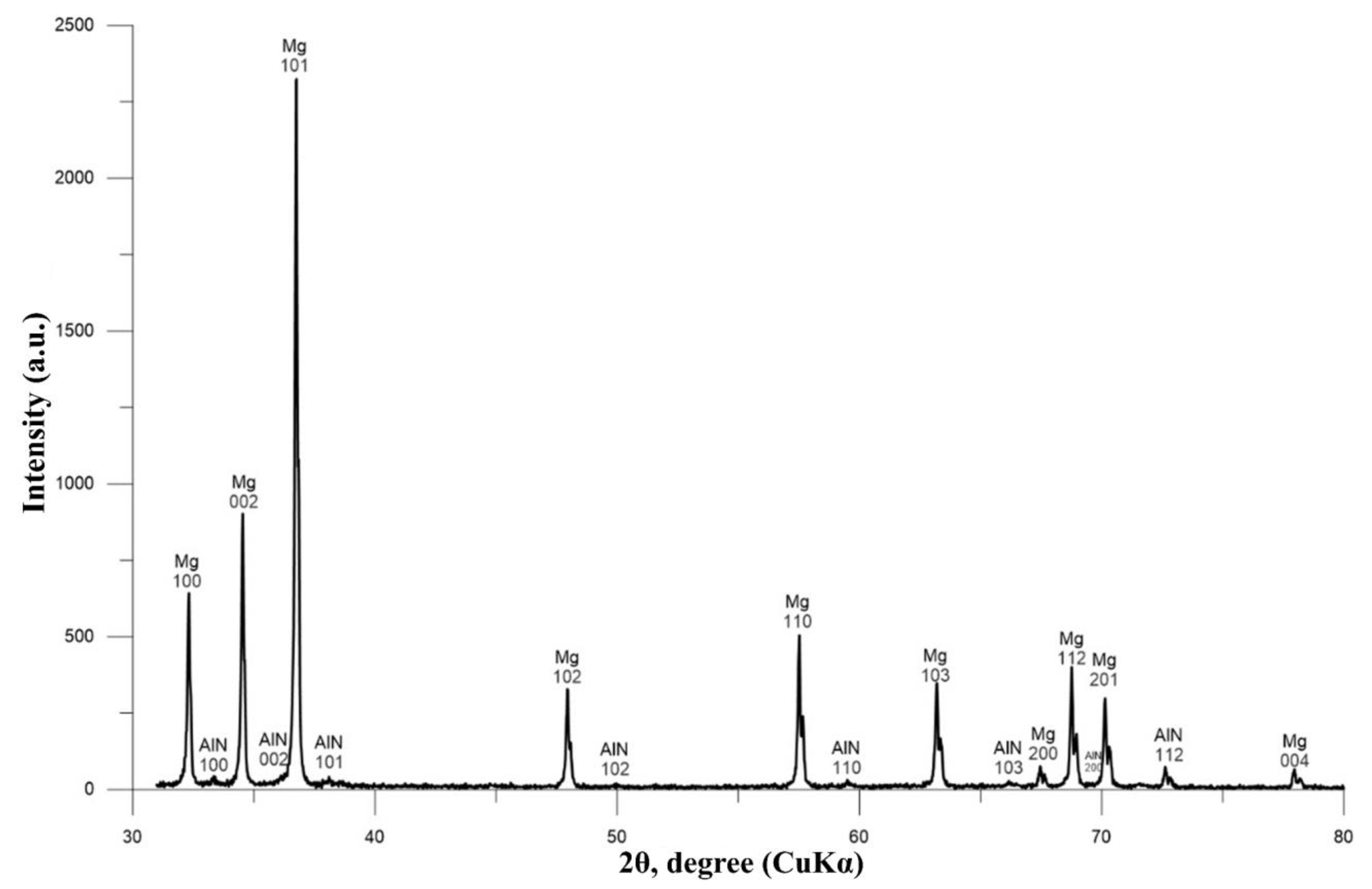

3.2. Mg–AlN Master-Alloy

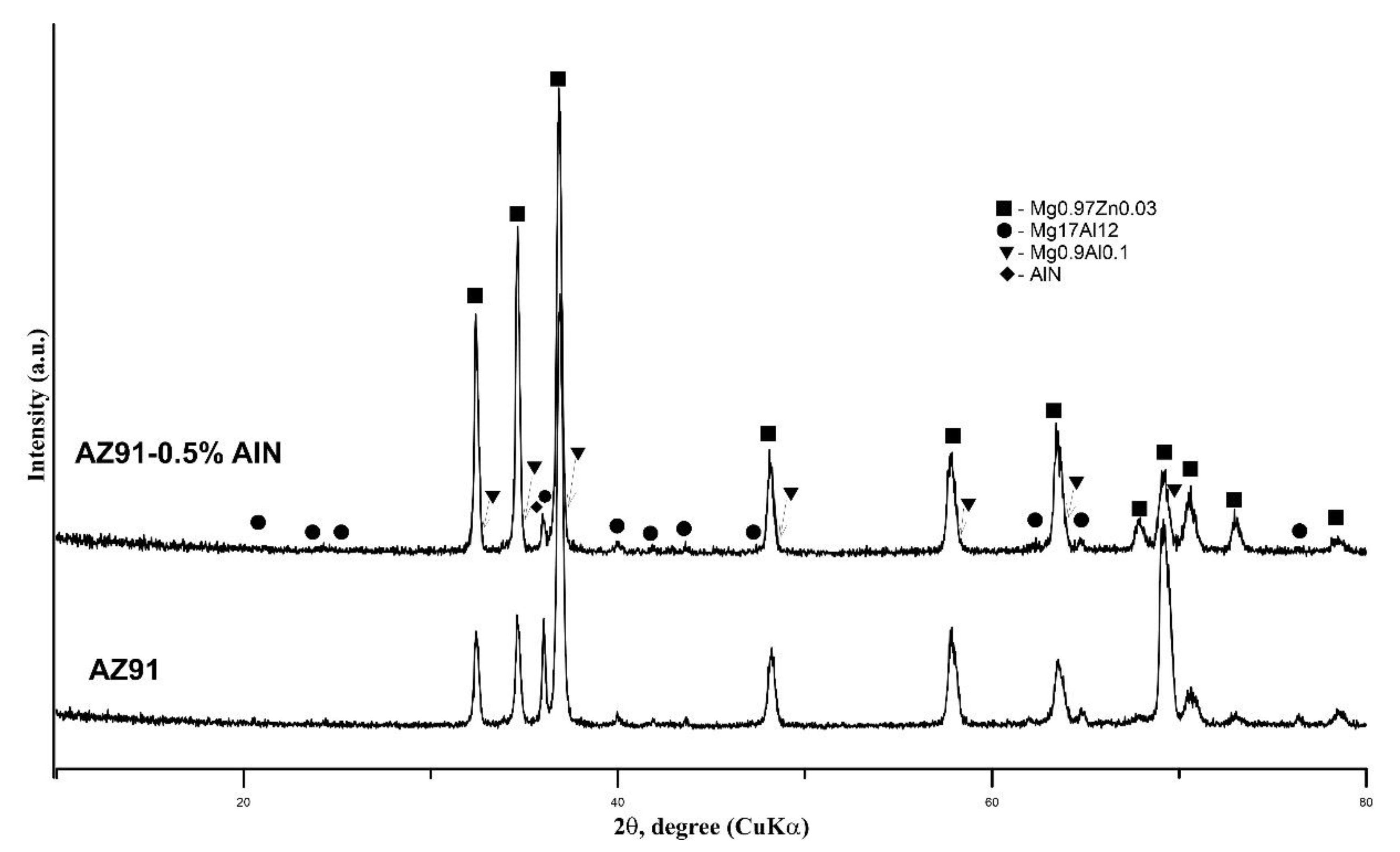

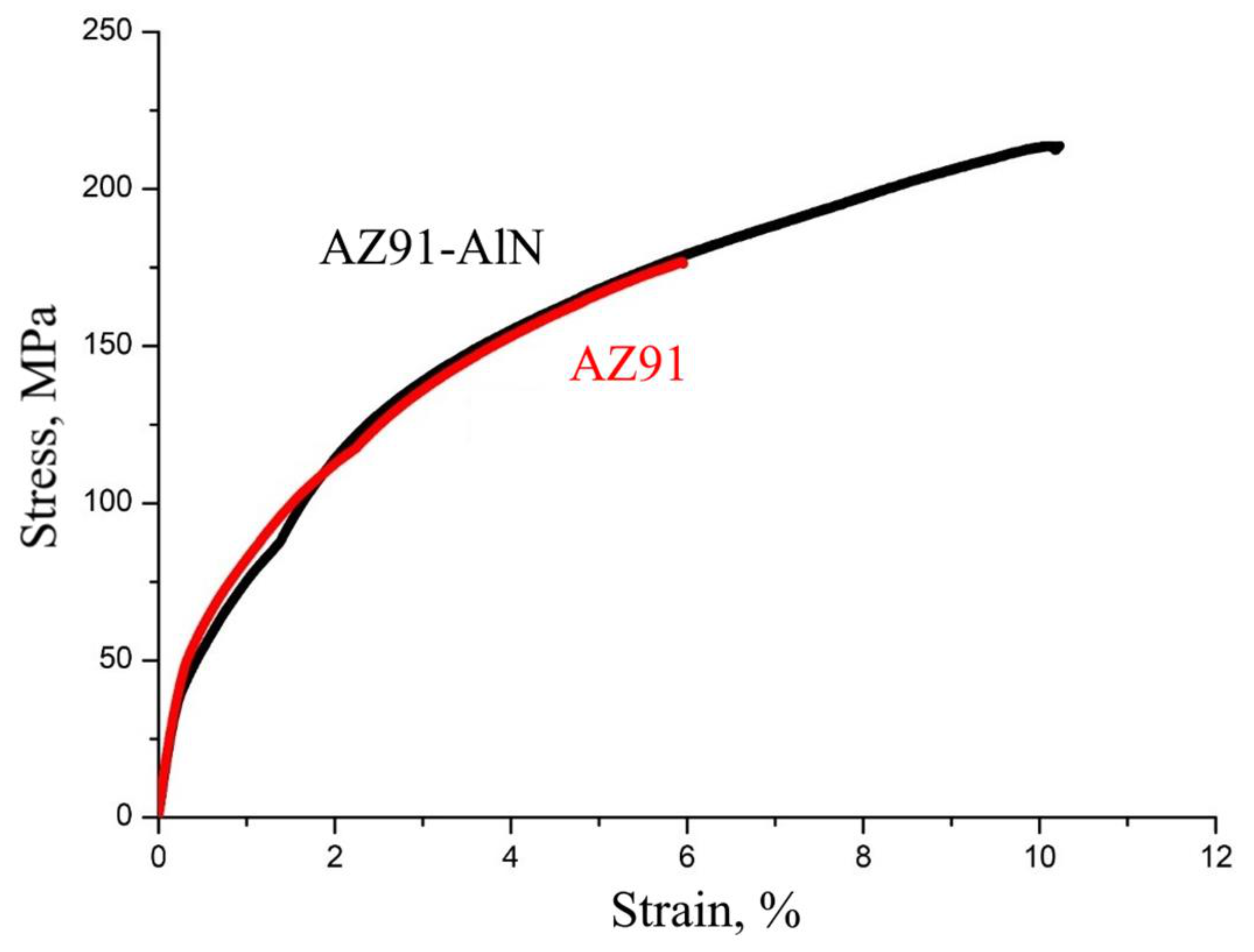

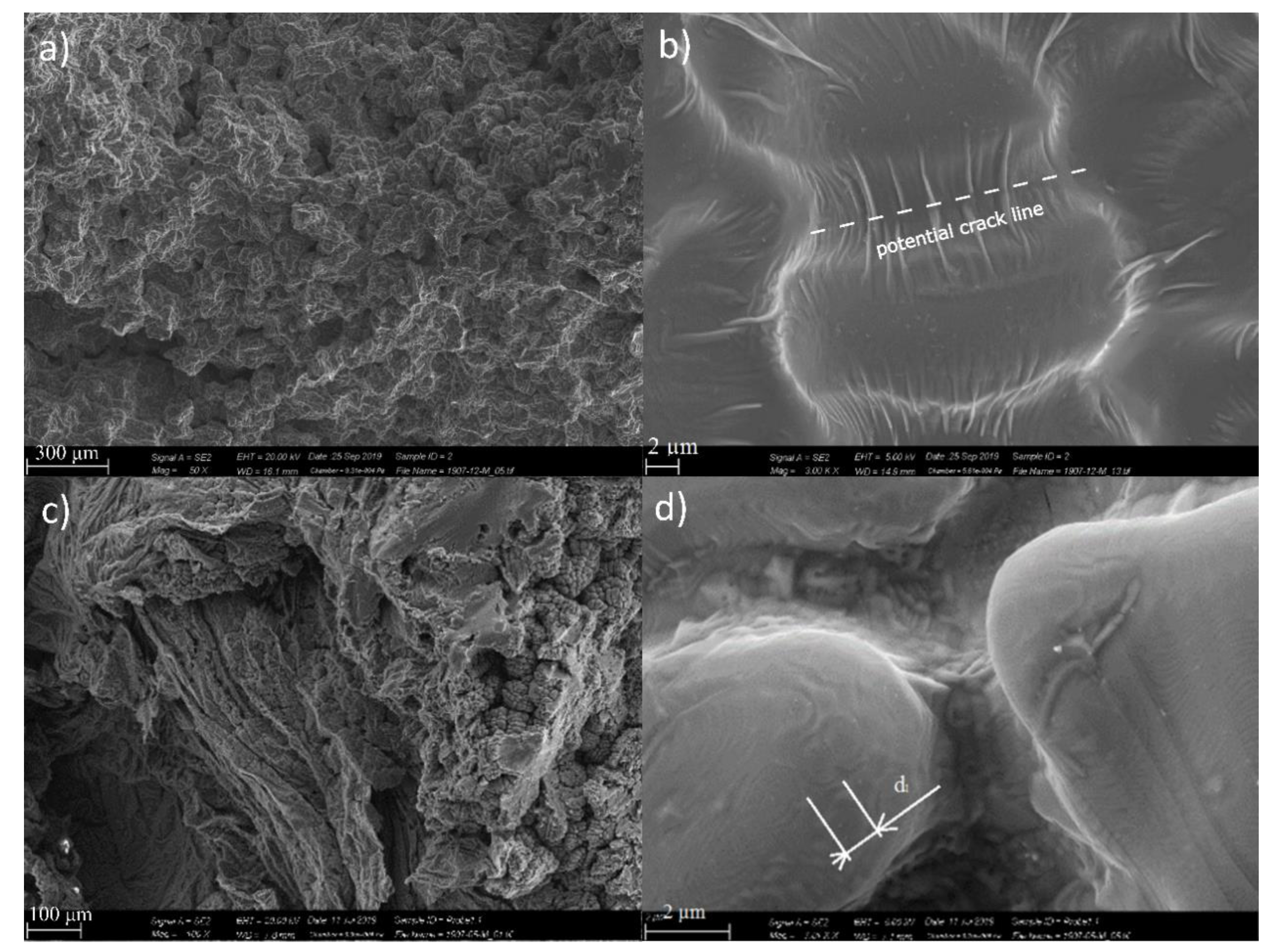

3.3. AZ91–AlN Alloy

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, C.S.; Sohn, I.; Nezafati, M.; Ferguson, J.B.; Schultz, B.F.; Bajestani-Gohari, Z.; Rohatgi, P.K.; Cho, K. Prediction models for the yield strength of particle-reinforced unimodal pure magnesium (Mg) metal matrix nanocomposites (MMNCs). J. Mater. Sci. 2013, 48, 4191. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Schultz, B. Lightweight Metal Matrix Nanocomposites–Stretching the Boundaries of Metals. Mater. Matters 2007, 4, 16–21. [Google Scholar]

- Muley, A.V.; Aravindan, S.; Singh, I.P. Nano and hybrid aluminum based metal matrix composites: An overview. Manuf. Rev. 2015, 2, 15. [Google Scholar] [CrossRef] [Green Version]

- Casati, R.; Vedani, M. Metal Matrix Composites Reinforced by Nano-Particles—A Review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Kurganova, Y.A.; Kolmakov, A.G. Konstrukcionnye Metallomatrichnye Kompozicionnye Materialy: Uchebnoe Posobie; Publishing House of MSTU im. N.E.: Bauman, Moscow, 2015; p. 141. (In Russian) [Google Scholar]

- Ye, H.Z.; Liu, X.Y. Review of recent studies in magnesium matrix composites. J. Mater. Sci. 2004, 39, 6153–6171. [Google Scholar] [CrossRef]

- Khrustalyov, А.P.; Vorozhtsov, S.A.; Zhukov, I.A.; Promakhov, V.V.; Dammer, V.K.; Vorozhtsov, A.B. Structure and mechanical properties of magnesium-based composites reinforced with nitride aluminum nanoparticles. Russ. Phys. J. 2017, 59, 2183–2185. [Google Scholar] [CrossRef]

- Vorozhtsov, S.; Khrustalyov, A.; Khmeleva, M.; Zhukov, I. Structure and deformation characteristics in magnesium alloy ZK51A reinforced with AlN nanoparticles. AIP Conf. Proc. 2016, 1772, 030004. [Google Scholar] [CrossRef] [Green Version]

- Sazonov, M.A.; Chernishova, T.A.; Rokhlin, L.L. Particulate-reinforced magnesium matrix composite: Production and properties (review). Konstr. I Funkc. Mater. 2010, 2, 3–22. (In Russian) [Google Scholar]

- Ferguson, J.B.; Sheykh-Jaberi, F.; Kim, C.S.; Rohatgi, P.K.; Cho, K. On the strength and strain to failure in particle-reinforced magnesium metal-matrix nanocomposites (Mg MMNCs). Mater. Sci. Eng. A 2012, 558, 193–204. [Google Scholar] [CrossRef]

- Gupta, M.; Wong, W.L.E. Magnesium-based nanocomposites: Lightweight materials of the future. Mater. Charact. 2015, 105, 30–46. [Google Scholar] [CrossRef]

- Chen, J.; Bao, C.; Chen, W.; Zhang, L.; Liu, J. Mechanical properties and fracture behavior of Mg-Al/AlN composites with different particle contents. J. Mater. Sci. Technol. 2017, 33, 668–674. [Google Scholar] [CrossRef]

- Vaidya, A.R.; Lewandowski, J.J. Effects of SiCp size and volume fraction on the high cycle fatigue behavior of AZ91D magnesium alloy composites. Mater. Sci. Eng. A 1996, 220, 85–92. [Google Scholar] [CrossRef]

- Luo, A. Development of matrix grain structure during the solidification of a Mg (Az91)/SiCp composite. Scr. Metall. Mater. 1994, 31, 1253. [Google Scholar] [CrossRef]

- Cao, G.; Choi, H.; Oportus, J.; Konishi, H.; Li, X. Study on tensile properties and microstructure of cast AZ91D/AlN nanocomposites. Mater. Sci. Eng. A 2008, 494, 127–131. [Google Scholar] [CrossRef]

- Lerner, M.; Vorozhtsov, A.; Guseinov, S.; Storozhenko, P. Metal Nanopowders: Production Characterization, and Energetic Applications; Gromov, A.A., Teipel, U., Eds.; Wiley-VCH: Weinheim, Germany, 2014; pp. 79–106. [Google Scholar]

- Naydenkin, E.; Mishin, I.; Khrustalyov, A.; Vorozhtsov, S.; Vorozhtsov, A. Influence of Combined Helical and Pass Rolling on Structure and Residual Porosity of an AA6082-0.2 wt% Al2O3 Composite Produced by Casting with Ultrasonic Processing. Metals 2017, 7, 544. [Google Scholar] [CrossRef] [Green Version]

- Vorozhtsov, S.; Minkov, L.; Dammer, V.; Khrustalyov, A.; Zhukov, I.; Promakhov, V.; Vorozhtsov, A.; Khmeleva, M. Ex situ introduction and distribution of nonmetallic particles in aluminum melt: Modeling and experiment. JOM. 2017, 69, 2653–2657. [Google Scholar] [CrossRef]

- Fu, H.M.; Zhang, M.X.; Qiu, D.; Kelly, P.M.; Taylor, J.A. Grain refinement by AlN particles in Mg–Al based alloys. J. Alloys Compd. 2009, 478, 809–812. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Yang, F.; Xi, T.F.; Guo, J.T.; Ye, H.Q. Microstructure evolution and mechanical properties of Ni3Al/Al2O3 composite during self-propagation high-temperature synthesis and hot extrusion. Mater. Sci. Eng. A 2012, 555, 131–138. [Google Scholar] [CrossRef]

- Dieringa, H.; Katsarou, L.; Buzolin, R.; Szakács, G.; Horstmann, M.; Wolff, M.; Mendis, C.; Vorozhtsov, S.; StJohn, D. Ultrasound Assisted Casting of an AM60 Based Metal Matrix Nanocomposite, Its Properties, and Recyclability. Metals 2017, 7, 388. [Google Scholar] [CrossRef] [Green Version]

- Khrustalyov, A.P.; Garkushin, G.V.; Zhukov, I.A.; Razorenov, S.V.; Vorozhtsov, A.B. Quasi-Static and Plate Impact Loading of Cast Magnesium Alloy ML5 Reinforced with Aluminum Nitride Nanoparticles. Metals 2019, 9, 715. [Google Scholar] [CrossRef] [Green Version]

- Sheng, L.Y.; Yang, F.; Guo, J.T.; Xi, T.F.; Ye, H.Q. Investigation on NiAl–TiC–Al2O3 composite prepared by self-propagation high temperature synthesis with hot extrusion. Compos. Part B Eng. 2013, 45, 785–791. [Google Scholar] [CrossRef]

- Petch, N. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

| Phase | Phase Content, wt.% | Lattice Parameters, Ǻ | CSR Size, nm | Δd/d*10−3 |

|---|---|---|---|---|

| Mg | 96 | а = 3.2101 | 86 | 0.5 |

| с = 5.2112 | ||||

| AlN | 4 | а = 3.1103 | 53 | 0.5 |

| с = 4.9848 |

| Alloy | YStension, MPa | UTStension, MPa | δtension, % |

|---|---|---|---|

| AZ91 | 65 ± 4 | 176 ± 6 | 6 ± 0.4 |

| AZ91–AlN | 53 ± 3 | 214 ± 9 | 10 ± 0.5 |

| Alloy | YStorsion, MPa | UTStorsion, MPa | δtorsion, % |

|---|---|---|---|

| AZ91 | 63 ± 7 | 130 ± 9 | 4.6 ± 0.2 |

| AZ91–AlN | 73 ± 4 | 176 ± 8 | 11.3 ± 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khrustalyov, A.; Zhukov, I.; Nikitin, P.; Kolarik, V.; Klein, F.; Akhmadieva, A.; Vorozhtsov, A. Study of Influence of Aluminum Nitride Nanoparticles on the Structure, Phase Composition and Mechanical Properties of AZ91 Alloy. Metals 2022, 12, 277. https://doi.org/10.3390/met12020277

Khrustalyov A, Zhukov I, Nikitin P, Kolarik V, Klein F, Akhmadieva A, Vorozhtsov A. Study of Influence of Aluminum Nitride Nanoparticles on the Structure, Phase Composition and Mechanical Properties of AZ91 Alloy. Metals. 2022; 12(2):277. https://doi.org/10.3390/met12020277

Chicago/Turabian StyleKhrustalyov, Anton, Ilya Zhukov, Pavel Nikitin, Vladislav Kolarik, Friedrich Klein, Anastasia Akhmadieva, and Alexander Vorozhtsov. 2022. "Study of Influence of Aluminum Nitride Nanoparticles on the Structure, Phase Composition and Mechanical Properties of AZ91 Alloy" Metals 12, no. 2: 277. https://doi.org/10.3390/met12020277

APA StyleKhrustalyov, A., Zhukov, I., Nikitin, P., Kolarik, V., Klein, F., Akhmadieva, A., & Vorozhtsov, A. (2022). Study of Influence of Aluminum Nitride Nanoparticles on the Structure, Phase Composition and Mechanical Properties of AZ91 Alloy. Metals, 12(2), 277. https://doi.org/10.3390/met12020277