2. Experimental Part

The object of study was polycrystalline beryllium oxide ceramics with a density of 3.02 g/cm

3 that were obtained by hot-pressing [

26]. The porosity of the ceramics was 2%, and the grain size was no more than 100 nm. The choice of BeO ceramics as objects of study is due to their physicochemical properties, high thermal conductivity, and absorbing characteristics, which make them one of the most promising materials in the field of structural materials for nuclear reactors and a basis for inert nuclear fuel matrices.

The samples were irradiated at a DC-60 heavy ion accelerator located at the Astana branch of the Institute of Nuclear Physics (Nur-Sultan, Kazakhstan). Irradiation of the test samples was carried out in two stages. The first step was to irradiate the samples with heavy Ar

8+, Kr

15+, and Xe

22+ ions with energies of 70, 150, and 230 MeV, respectively. The irradiation fluence for the selected ions was 10

12 ion/cm

2; irradiation was carried out at room temperature, which was maintained during irradiation by using a special target holder with water cooling. The choice of this fluence for irradiation was based on a theoretical analysis of the diameters of damaged areas arising along the trajectory of ion movement in the material [

27]. According to estimates, the diameters of these regions are 7–15 nm, which, taking into account the irradiation density (fluence), indicates the isolation of these regions from each other and the absence of irradiation-caused defect overlapping effect.

The second stage of irradiation was carried out with He

2+ ions with an energy of 40 keV and an irradiation fluence of 5 × 10

17 ion/cm

2. The choice of the irradiation fluence is based on previous studies on helium embrittlement and swelling in oxide and nitride ceramics, according to which it was found that, when this fluence is reached in the structure of ceramics, there is an accumulation of implanted helium, the concentration of which is sufficient for the formation of gas-filled bubbles. At the same time, as was shown in Reference [

26], in the case of irradiation of BeO ceramics with helium ions, at a dose above 10

17 ion/cm

2, the formation of an impurity cubic BeO phase was observed, the presence of which was associated with disordering processes and polymorphic transformations of the BeO-hexagonal→BeO-cubic type.

Table 1 shows the results of simulation of the energy losses of selected ion types in the near-surface layer of BeO ceramics, as performed in the SRIM Pro 2013 program code [

28], as well as the values of atomic displacements at a depth of 300–400 nm. The choice of depth for determining the value of dpa is due to the maximum penetration depth of He

2+ ions in ceramics. It should be mentioned that the calculations of the dpa value for heavy ions were carried out by taking into account the irradiation fluence of 10

12 ion/cm

2; for He

2+ ions, the dpa value was calculated for the irradiation fluence of 5 × 10

17 ion/cm

2. According to the calculations performed, it was found that a change in the type of ions and their energy leads to an increase in the concentration of formed vacancies by a factor of 3.5–4 in the case of Ar

8+ and Kr

15+ ions, and by a factor of 1.5–1.7 in the case of Kr

15+ and Xe

22+ ions. A similar situation occurs with the energy losses of ions that are calculated by taking into account the density of ceramics and the binding energy of atoms. At the same time, the change in the penetration depth with an increase in the energy of incident particles is not significant, and it is no more than 10–15%. In this case, it should be noted that, for heavy ions, the main contribution to structural changes is made by the electron losses of ions during interaction with the crystal structure, the value of which is 2.5–3 orders of magnitude higher than nuclear losses. According to estimates of atomic displacement value calculated at a depth of 300–400 nm for heavy ions, this parameter varies from 0.0001 to 0.0009 dpa, depending on the type and energy of incident ions. Thus, a change in the ion type and their energy at the same irradiation fluences makes it possible to simulate different degrees of structural isolated changes caused by irradiation and to compare their effect on changes in the radiation resistance to helium swelling.

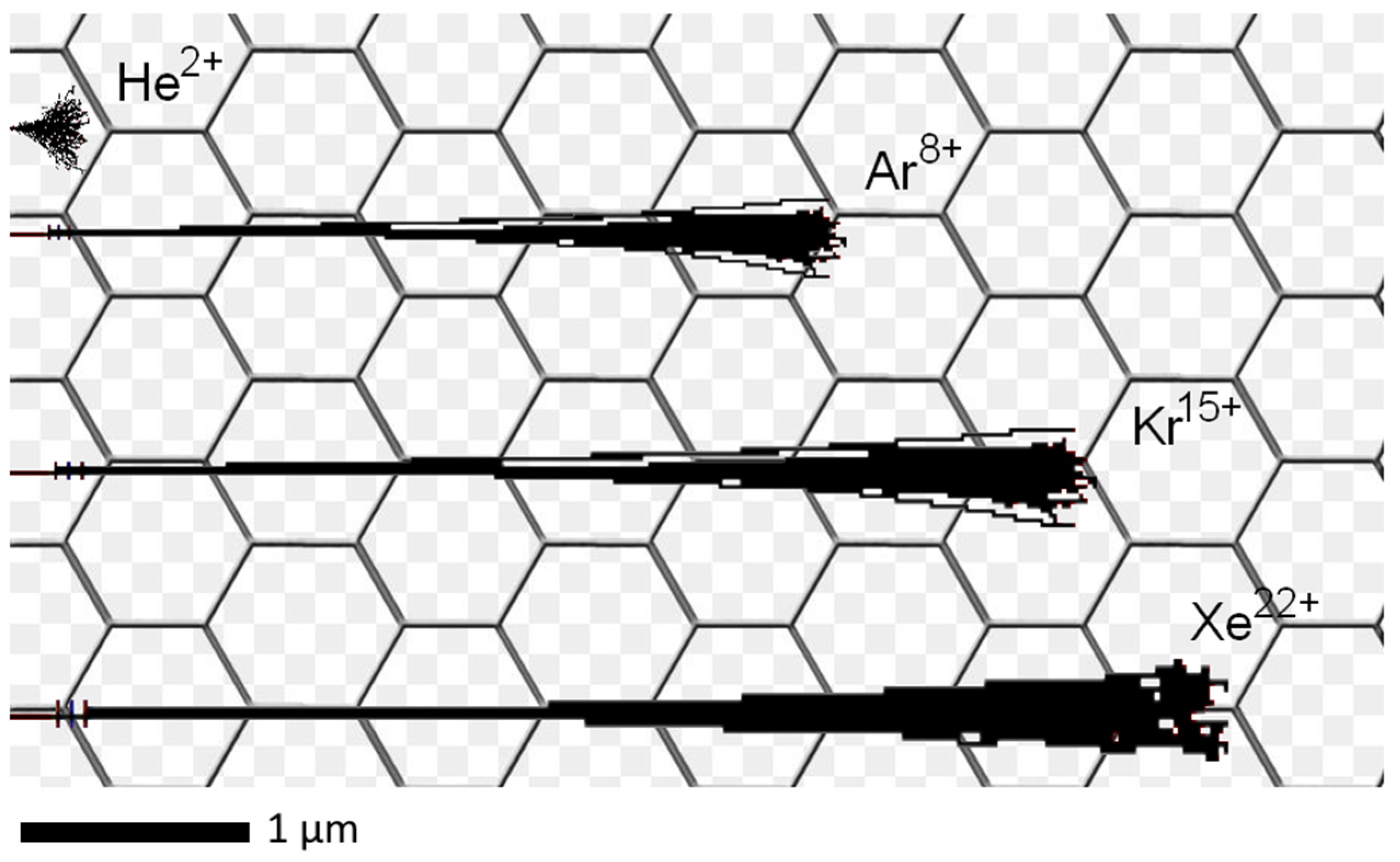

Figure 1 shows a schematic representation of the ion damage trajectories in ceramics caused by various irradiation types.

The study of structural changes caused by various types of radiation, as well as swelling and structural degradation processes, was carried out by using the X-ray structural analysis method. The analysis was carried out by evaluating changes in the parameters and volume of the crystal lattice, as well as crystallite sizes of the samples under study before and after ion irradiation. Calculation of these parameters was carried out on the basis of the data obtained from analysis of X-ray diffraction patterns of the samples. Diffraction patterns were recorded in the Bragg–Brentano geometry, in the angular range of 2θ = 35–75°, with a step of 0.03°. The desired diffraction patterns were obtained on a D8 ADVANCE ECO (Bruker, Karlsruhe, Germany) powder diffractometer.

Mechanical properties were determined by changing the hardness of the near-surface layer at indenter pressure (Vickers pyramid) with a force of 500 N. The studies were carried out on a LECO LM700 (Leco Corporation, St. Joseph, MI, USA) microhardness tester. From the indenter prints obtained, as well as their depth, hardness and softening degrees were determined to characterize the resistance of ceramics to external effects.

The wear resistance of the near-surface layer to mechanical effects was carried out by using the standard tribological method of determining the dry-friction coefficient during 20,000 cycles of tests of rolled metal ball at a load of 200 N. The tests were carried out on a Ducom POD-4.0 (Ducom, New York, NY, USA) instrument. The samples were determined depending on the type of external effects.

3. Results and Discussion

As is known, one of the most informative study methods for structural changes without destroying or externally affecting samples is the X-ray diffraction analysis method, which allows us to assess the structural parameter change kinetics, determining the formation of disordering or amorphization regions of the structure as a result of external influences, etc. At the same time, not only can the basic parameters of the crystal structure be determined from the shape and position of the diffraction lines, but also the effects associated with deformation and distortion of the crystal lattice caused by external influences can be qualitatively described.

Figure 2 shows a series of X-ray diffraction patterns of the samples under study both before and after irradiation, with various types of ions, the main purpose of which is to clearly reflect the structural changes in the samples depending on exposure type.

A full-profile analysis of the initial sample showed that the obtained diffraction pattern with a high probability degree (more than 97%) corresponds to the structure of BeO with a hexagonal crystal lattice and the spatial system P63mc(186) (PDF-00-035-0818). At the same time, the shape of diffraction lines and the ratio of diffraction reflections and background radiation areas, as obtained by approximation with pseudo-Voigt functions of the obtained diffraction patterns, indicate a high structural ordering degree (more than 98%). The crystal lattice parameters of the samples in the initial state were a = 2.6699 Å and c = 4.3369 Å, and the crystal lattice volume was 26.77 Å3.

In the case of irradiation of the initial samples with He

2+ ions with a fluence of 5 × 10

17 ion/cm

2, the main changes in the diffraction pattern consist of a sharp decrease in the intensity of diffraction reflections, their distortion, and also a shift toward small angles, indicating a strong deformation and swelling of the crystal structure. At the same time, our analysis of the shape of the (002) reflection at 2θ = 44–45° showed that the reflection shape is characteristic of the presence of two highly distorted maxima characteristics of the hexagonal BeO and the cubic BeO phases. The presence of this maximum of the BeO-cubic phase indicates the processes of polymorphic transformation of the BeO-hexagonal→BeO-cubic type caused by the cumulative effect of irradiation, as was reported earlier in Reference [

27]. A decrease in the intensity of reflections, as well as a distortion of their shape, indicates not only the crystal lattice deformation, but also the appearance of disordering regions in the structure, leading to its amorphization.

In the case of samples pre-irradiated with heavy Ar8+, Kr15+, and Xe22+ ions, the main structural changes, according to the data obtained, are associated with a change in the intensity of diffraction reflections that indicates the texture reorientation processes, as well as a size factor caused by a change in the shape and size of crystallites. At the same time, a change in the type of ions leads to large changes in the intensities of reflections. This behavior of changes in diffraction reflections is associated with the local nature of structural changes caused by irradiation.

According to the presented X-ray diffraction patterns of modified samples after irradiation with He2+ ions, the structural changes are of a different nature than in the case of irradiation with He2+ ions of the original unmodified samples. First, for the samples modified with heavy ions, the formation of reflections characteristic of cubic-phase impurity inclusions is not observed, thus indicating the absence of polymorphic transformation processes in the amount necessary for possible registration by using the X-ray diffraction method. Second, the change in the position and shape of diffraction reflections is less pronounced than for unmodified samples, thus also indicating that preliminary modification with heavy ions leads to an increase in the stability of the crystal structure to deformation and swelling.

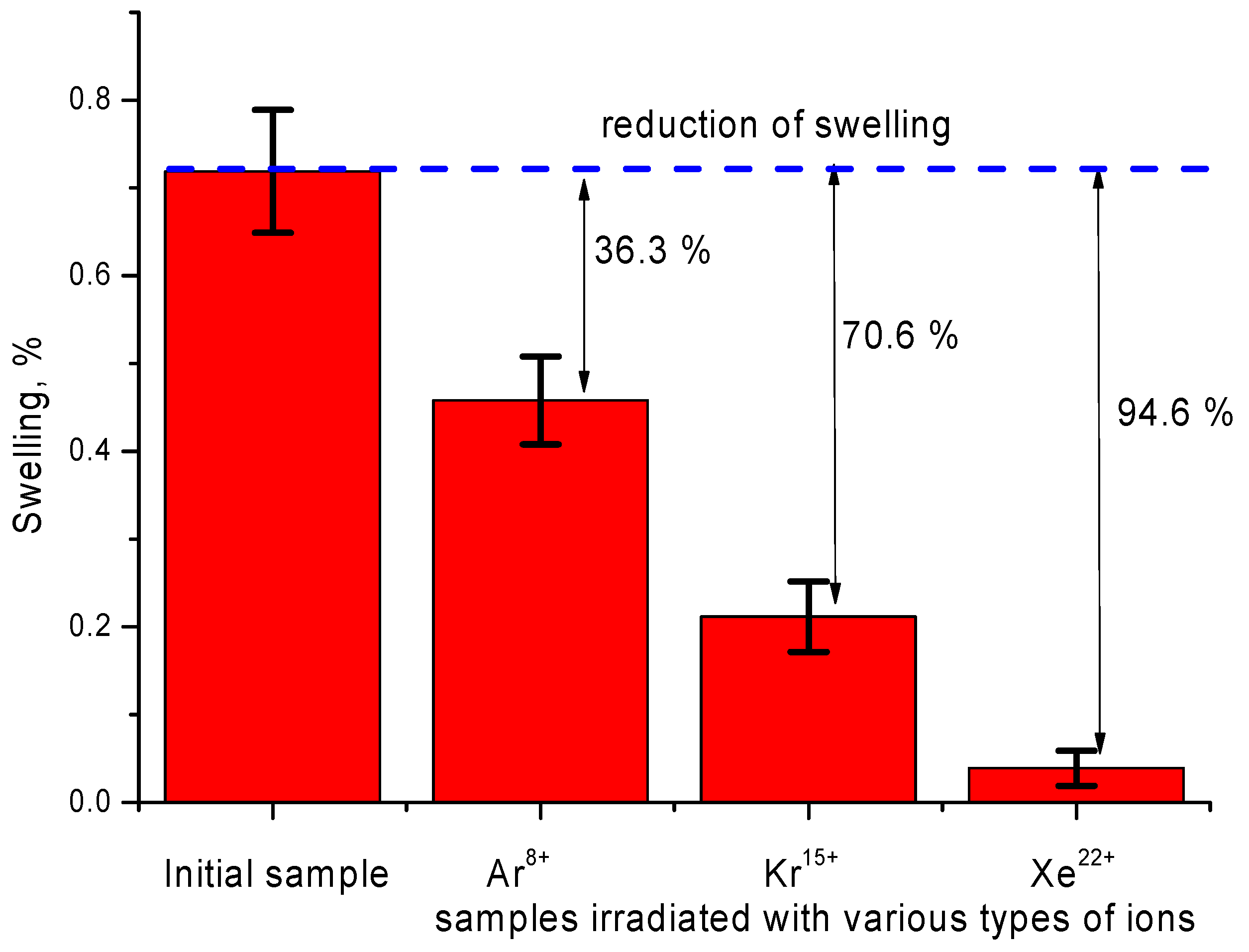

Figure 3 shows the results of changes in the swelling of the crystal lattice after irradiation with He

2+ ions with an irradiation fluence of 5 × 10

17 ion/cm

2. The determination of the swelling value was carried out by using Formula (1):

where

V and

V0 are the crystal lattice volume of the studied samples in the irradiated and initial state. The calculations were carried out on the basis of changes in the structural parameters of the crystal lattice of the studied samples before and after irradiation.

This change characterizes crystal-lattice swelling and deformation as a result of the helium ion accumulation in the surface-layer structure and their subsequent agglomeration into gas-filled bubbles. It should be mentioned that, according to theoretical calculations performed according to the methodology proposed in the work of Egeland et al. [

29], the concentration of implanted helium at a given irradiation fluence is no more than 0.6–0.7 at. %.

According to the data obtained, in the case of unmodified ceramics, the swelling value is 0.7% of the initial volume, and this indicates crystal structure deformation as a result of helium agglomeration in the near-surface layer. For modified ceramics, this swelling value is significantly less, and in the case of modification with heavy Kr

15+ and Xe

22+ ions, the swelling value decreases by 70 and 95%, respectively, in comparison with unmodified ceramics. This change indicates an increase in the resistance of the modified ceramics to helium swelling and subsequent degradation of the crystal structure. This is based on the mechanism of change in the dislocation density in the structure of the surface layer of ceramics exposed to heavy ion irradiation. According to X-ray diffraction data, the dominant contribution to the change in the crystal structure upon irradiation with heavy ions is the size effect associated with a change in the size of crystallites as a result of crushing or their reorientation. This behavior of crystallites is caused by the fact that, when irradiated with heavy ions, the main contribution is made by the electron losses of ions, which, upon interaction, are transformed from kinetic energy into thermal energy, thus leading to the formation of local regions with an increased temperature along the trajectory of ions in the material. The formation of such local regions leads to the appearance of a temperature gradient, which initiates recrystallization processes and crystallite mobility. In this case, the time intervals for which these changes occur are 10

-11-13 s, after which the system stabilizes. As a result, modified local regions appear in the structure of ceramics, and in the case of low fluences, these regions remain isolated, leading to the absence of the effect of overlapping these regions. At the same time, as is known, the sizes of crystallites are related by an inverse quadratic dependence with the dislocation density, and in the case of their decrease, thus leads to an increase in dislocations in the structure of ceramics. The dislocation density was determined by using Formula (2):

where

L is the crystallite size, which was determined from X-ray diffraction data.

Thus, upon irradiation with heavy Ar8+, Kr15+, and Xe22+ ions, the dislocation density was 0.071 × 1010, 0.076 × 1010, and 0.091 × 1010 dislocations/cm2, while, for the initial samples, this value was 0.068 × 1010 dislocations/cm2. As can be seen from the calculations obtained, a change in the type of ions under irradiation leads to an increase in the dislocation density, which is associated with both the energy losses of ions and the amount of energy transferred to the crystal structure, as well as the concentration of vacancy defects formed during the interaction of incident ions with the crystal lattice.

It is also worth noting that, in view of the dielectric nature of ceramics, in contrast to metals and alloys, the change in the electron density as a result of irradiation with heavy ions is associated with its redistribution along the ion trajectory, which also contributes to structural changes.

By analyzing the obtained data on reduction of helium-swelling value and comparing them with the literature data [

15,

16,

17,

19,

20] on other methods of modification and protection against helium embrittlement, the following conclusions can be drawn. As is known from References [

15,

16,

17], one method of increasing swelling resistance and subsequent structure degradation is the method of high-precision pulsed irradiation with electrons and ions. This process is based on the effect of remelting the near-surface layer due to the powerful influence of a pulsed beam of electrons or ions with a high current density (in some cases, the current is μA or mA) in a very short period of time. The result of this action is a rapid heating of the near-surface layer, followed by recrystallization and the creation of a high density of dislocation effects. Previously, in Reference [

15], we showed that the use of such pulsed beams makes it possible to increase the resistance of nitride ceramics to helium swelling by changing the dislocation density and crystallite size in the modified near-surface layer. Another way to reduce the rate of helium accumulation and subsequent swelling is to create multilayer coatings consisting of amorphous and crystalline layers of oxides or nitrides [

21,

22,

23]. This method is based on the effect of the appearance of interfaces between crystalline and amorphous layers, which lead to the retention of implanted helium near the boundaries and a decrease in the rate of its agglomeration. Thus, in all the proposed methods for increasing stability, there is an effect of changing the dislocation density, as well as the structural characteristics of the near-surface layer of ceramics, and this results in the creation of additional obstacles to the agglomeration of implanted helium in the structure. A decrease in the agglomeration rate due to additional defects leads to a decrease in the effect of swelling, and, consequently, to a decrease in the degradation of the strength properties of ceramics.

The study of strength properties, in particular, hardness, resistance to softening, and wear resistance, is presented in

Figure 4 and

Figure 5.

The softening degree (

SD) was determined by the change in hardness in the initial (

H0) and irradiated (

H) states and was calculated by using Formula (3):

This value characterizes the preservation of the stability of the near-surface layer to external influences, as well as crack resistance.

As can be seen from the data presented, in the case of the initial samples, the decrease in the surface layer hardness and the softening degree is more than 30% after irradiation with helium ions and helium accumulation in the structure. This behavior is due to the degradation processes caused by helium implantation, with the subsequent formation of helium bubbles and swelling. In the case of pre-modified ceramics with heavy ions, a decrease in the ceramic strength-degradation degree is observed, and this indicates an increase in the resistance to mechanical damage during irradiation. It should be mentioned that, in the case of irradiation with heavy Xe22+ ions, the softening degree is no more than 5%, thus indicating a high degree of resistance to degradation of the surface layer. An increase in resistance to mechanical damage and external influences for modified samples is due to the fact that, in the case of preliminary irradiation with heavy ions, additional dislocations and grain boundaries are formed in the structure of the surface layer that prevent helium agglomeration and the subsequent formation of helium inclusions and gas-filled regions. Moreover, as shown from the results of X-ray phase analysis, in the case of initial samples, irradiation with He2+ ions at a given dose leads to the initiation of polymorphic transformations of the BeO-hexagonal→BeO-cubic type, resulting in the formation of cubic phase impurity inclusions in the structure. In this case, the analysis of the shape of the diffraction lines for the irradiated samples indicates that, upon irradiation with He2+ ions, the formation of a strong crystal-lattice distortion is observed in the structure, which, in turn, negatively affects the resistance to external influences. For modified samples, the preliminary formation of dislocations, leading to an increase in dislocation density, leads to a significant increase in crack resistance and resistance to softening of the surface layer as a result of external influences.

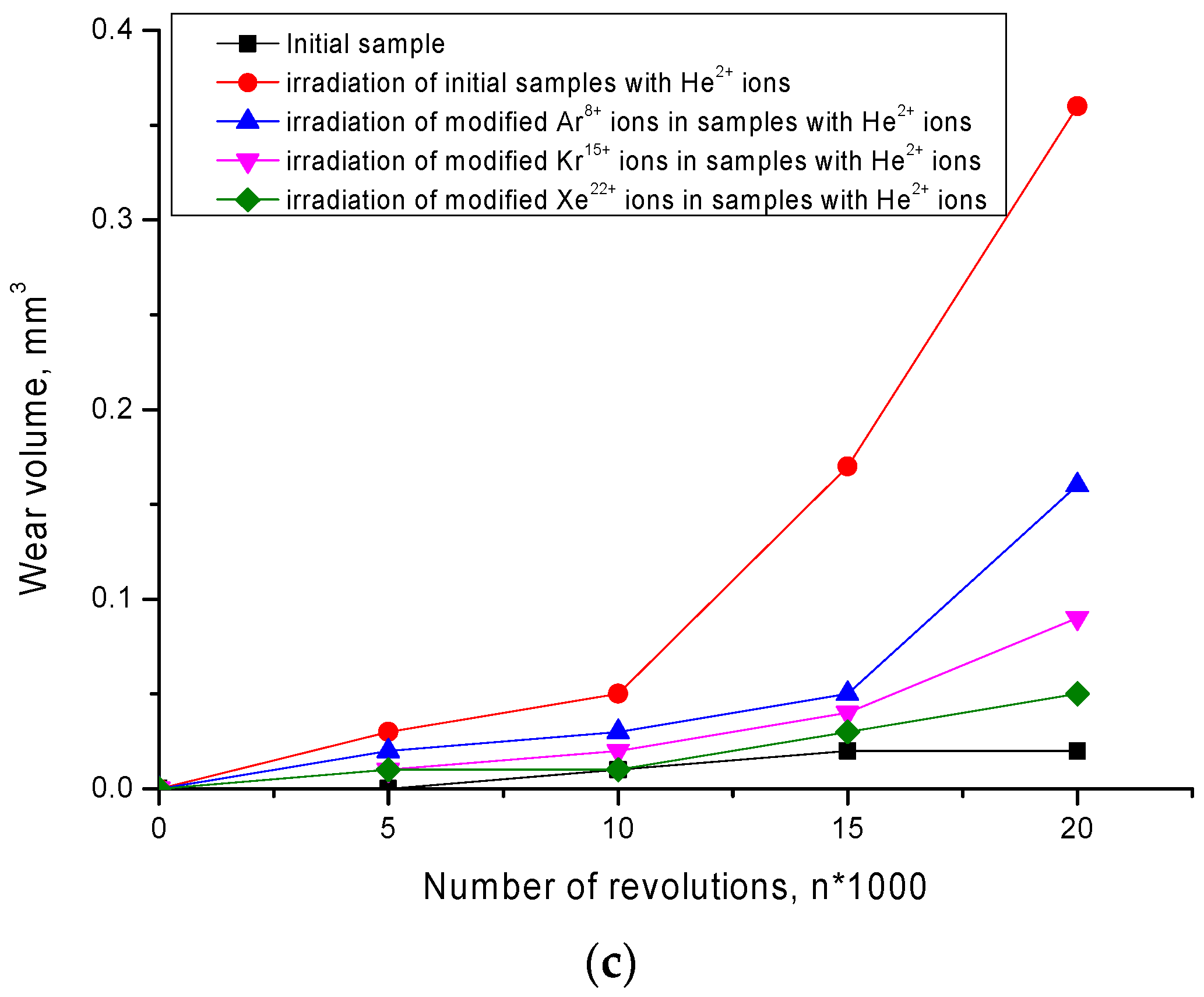

Figure 5 shows the results of changes in the dry-friction coefficient of the studied ceramics after irradiation with He

2+ ions. This value characterizes the stability of the near-surface layer to external mechanical long-term influences, as well as the degree of surface defectiveness as a result of irradiation. As can be seen from the data presented, in the case of the modification of ceramics with heavy Ar

8+, Kr

15+, and Xe

22+ ions, the initial change in the dry-friction coefficient after irradiation with He

2+ ions is insignificant, which indicates the resistance to deformation of the near-surface layer, and this is associated with a decrease in the ceramic swelling value. At the same time, in the case of initial ceramics irradiated with He

2+ ions, the initial change in the dry-friction coefficient is more than 20%, which indicates a strong deformation of the ceramic surface as a result of the radiation-induced damage accumulation and subsequent crystal-structure swelling.

The dynamic indexes of changes in the dry-friction coefficient, indicating a surface deterioration and an increase in friction, show that the main changes associated with an increase in the value of the coefficient are observed after 10,000–12,000 cyclic tests. These changes indicate a fairly high degree of stability and wear resistance of irradiated ceramics to mechanical stress. In the case of unmodified ceramics, the decrease in wear resistance after 20,000 test cycles is more than four times, thus indicating a strong surface degradation and deterioration of the tribological characteristics of the ceramics. At the same time, a sharp decrease in wear resistance for the initial ceramics irradiated with He

2+ ions is observed after 10,000 cyclic tests. For modified specimens after cyclic tests, the dry-friction coefficient changes much less than for unmodified specimens, thus indicating an increase in the friction-resulted wear resistance of ceramics.

Figure 5c shows the results of the change in volume loss as a function of the number of cycles, which also show the efficiency of heavy ion modification and loss reduction in the case of helium swelling of the modified ceramics.