Benchmarking a 9Cr-2WVTa Reduced Activation Ferritic Martensitic Steel Fabricated via Additive Manufacturing

Abstract

:1. Introduction

- Balancing the Cr and Ni equivalent to prevent the formation of delta ferrite in the weld metal.

- Enhancing tempering by careful control of process parameters.

- Benchmark a 9Cr-2WVTa alloy fabricated via AM and rank its performance with wrought variants of the same alloy;

- Understand the response of the alloy to post-processing heat treatments and compare the performance of similar treatments on wrought counterparts;

- Identify gaps in processing and provide insight into further areas for alloy design and set the stage for future activities in this area.

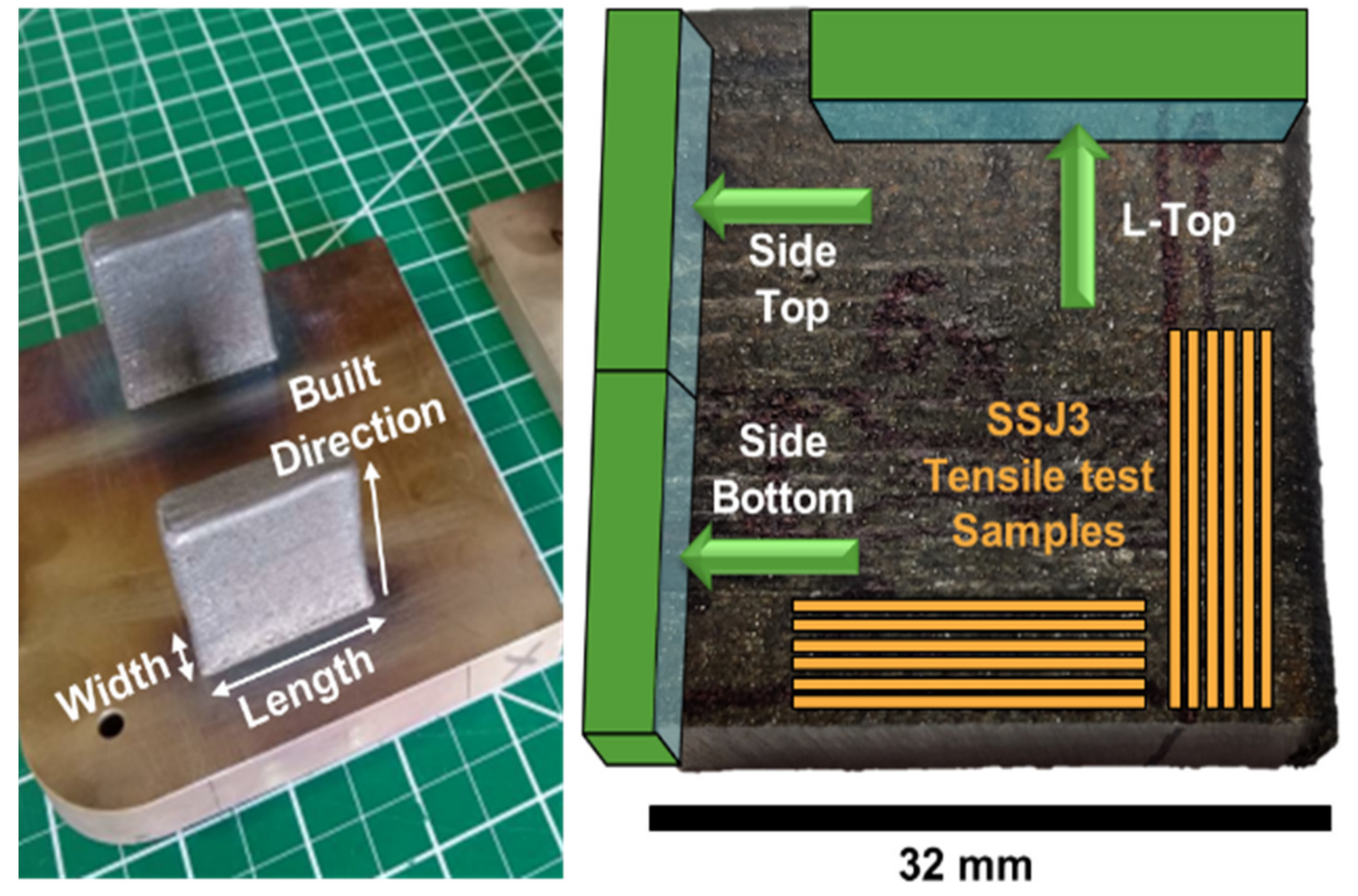

2. Experimental Techniques

- HT-1: 980 °C normalize for 30 min and temper at 750 °C for 120 min;

- HT-2: 1150 °C normalization for 60 min and temper at 750 °C for 60 min;

- HT-3: 1150 °C normalization for 30 min and temper at 750 °C for 30 min.

3. Results

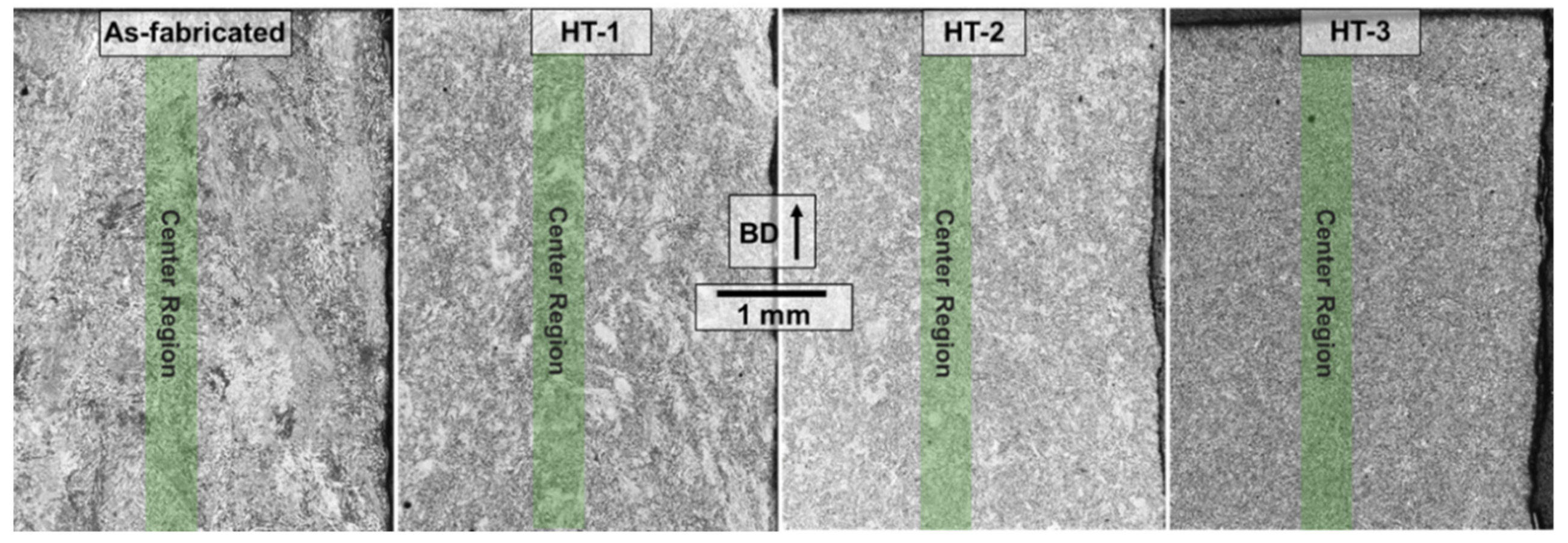

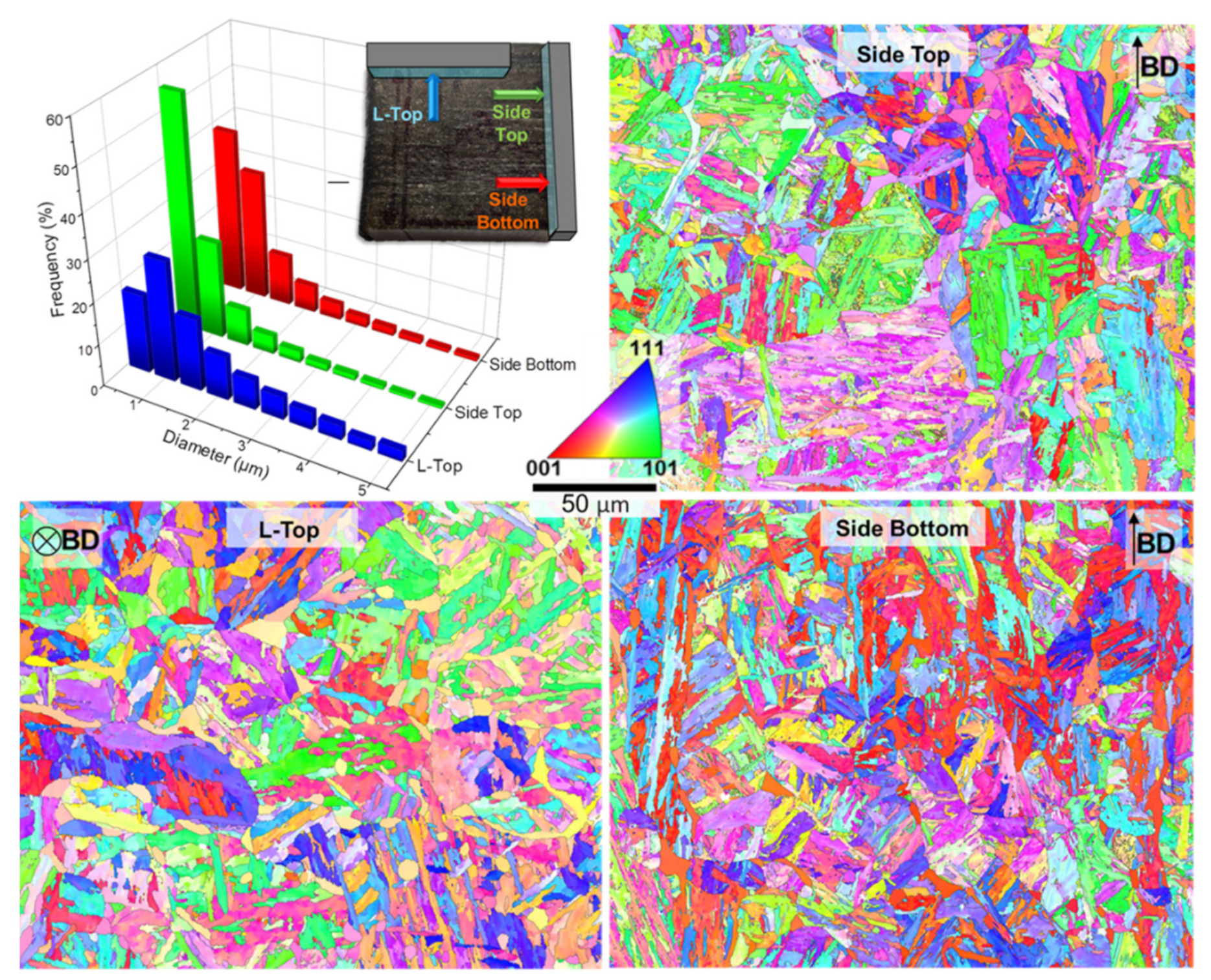

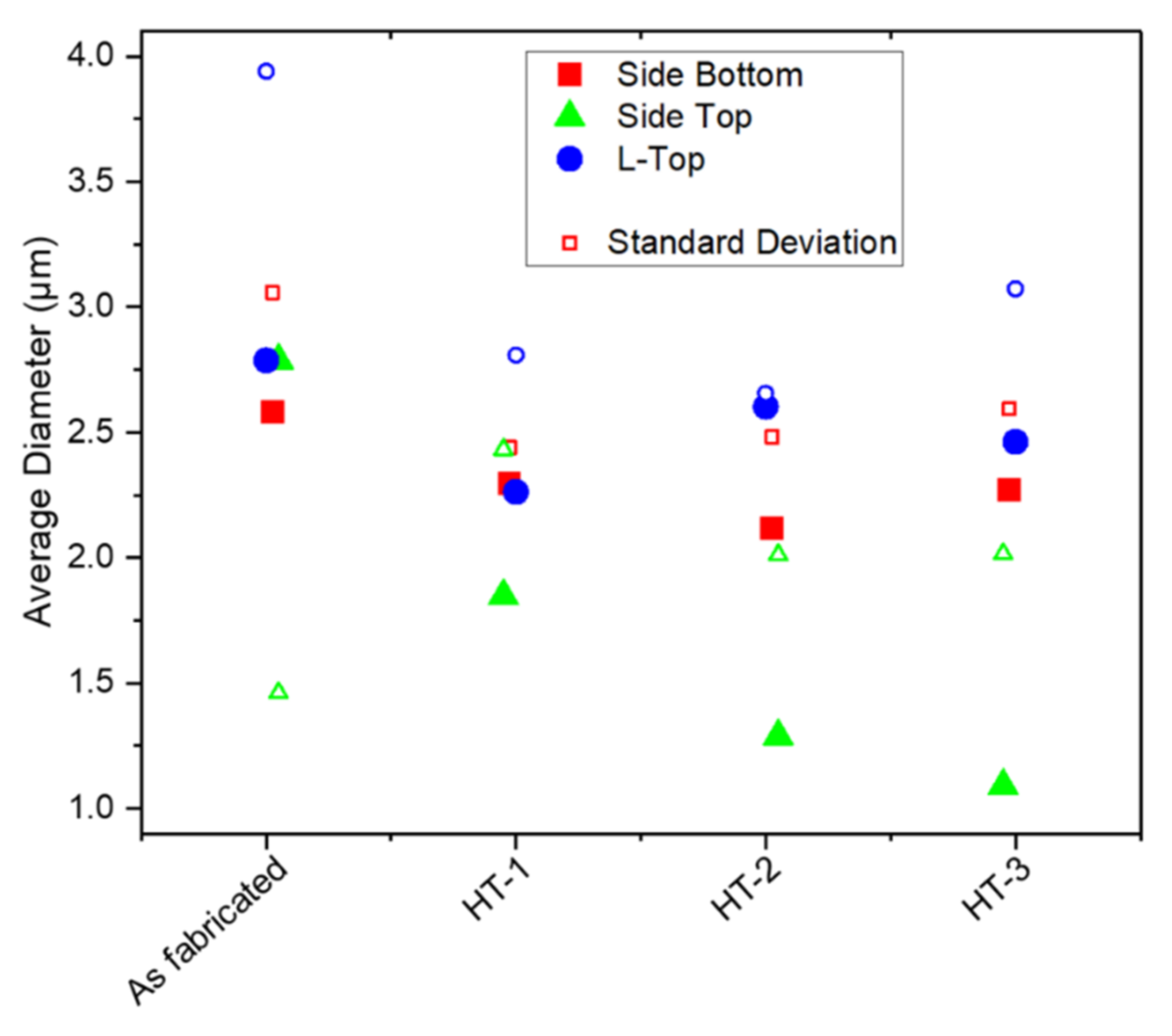

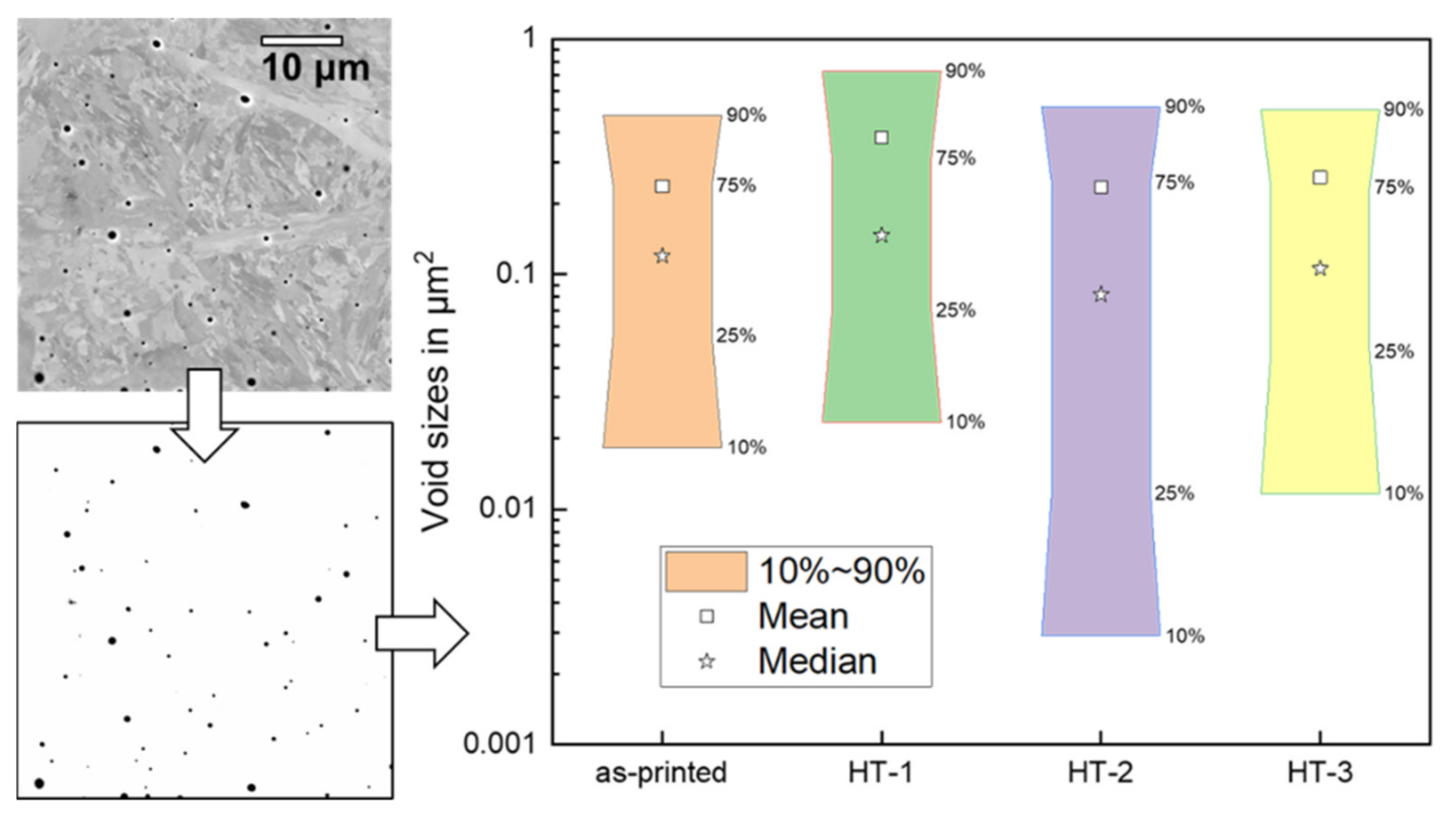

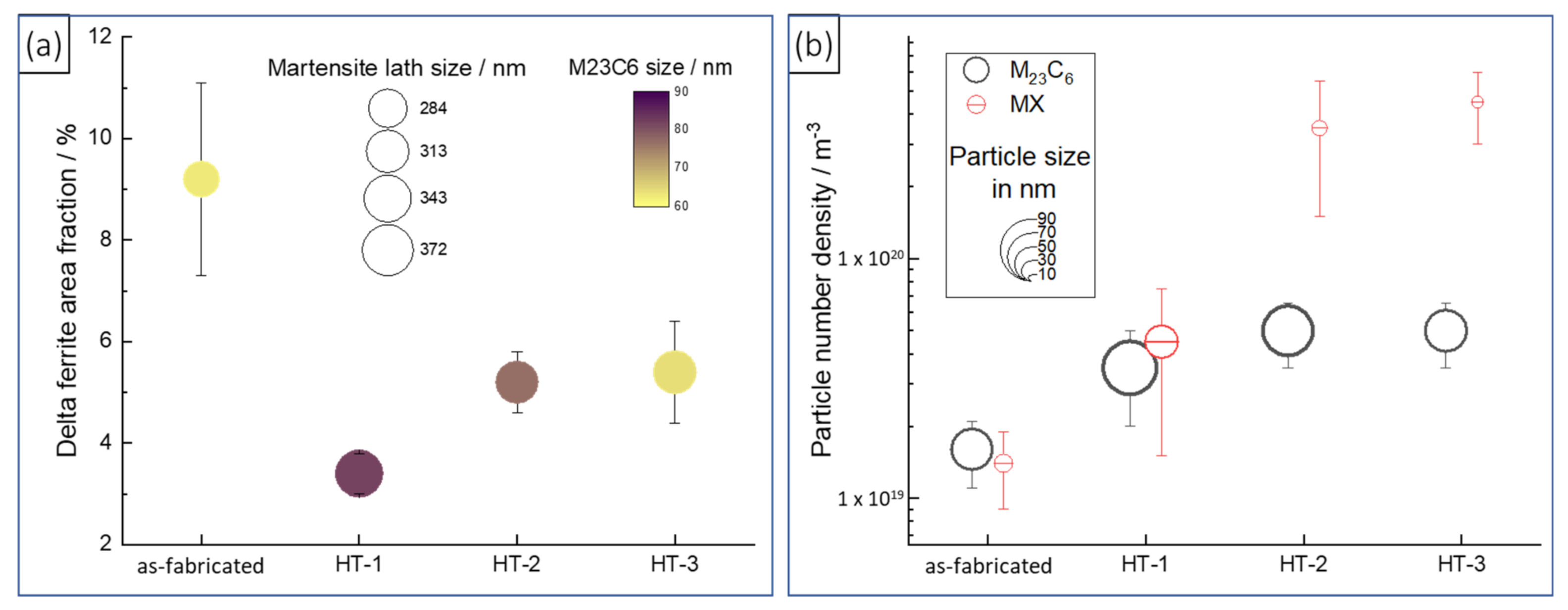

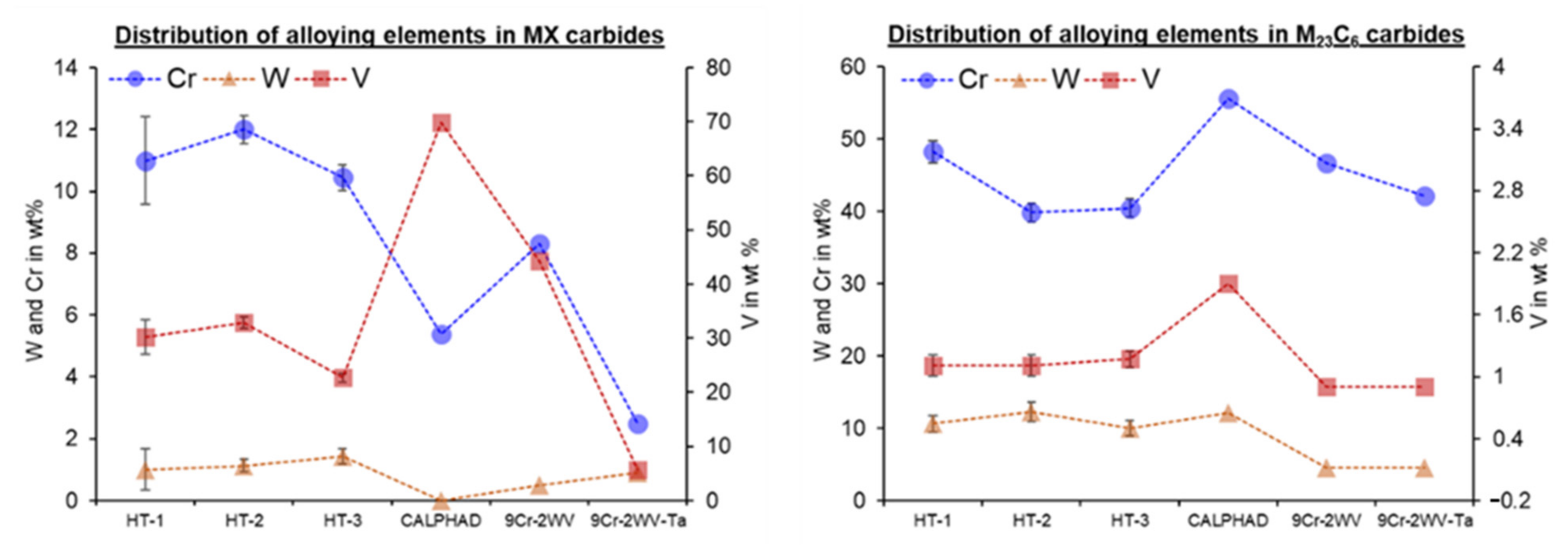

3.1. Microstructure Characterization

3.1.1. Impact of the Investigated Region in the Sample

3.1.2. As-Fabricated Condition

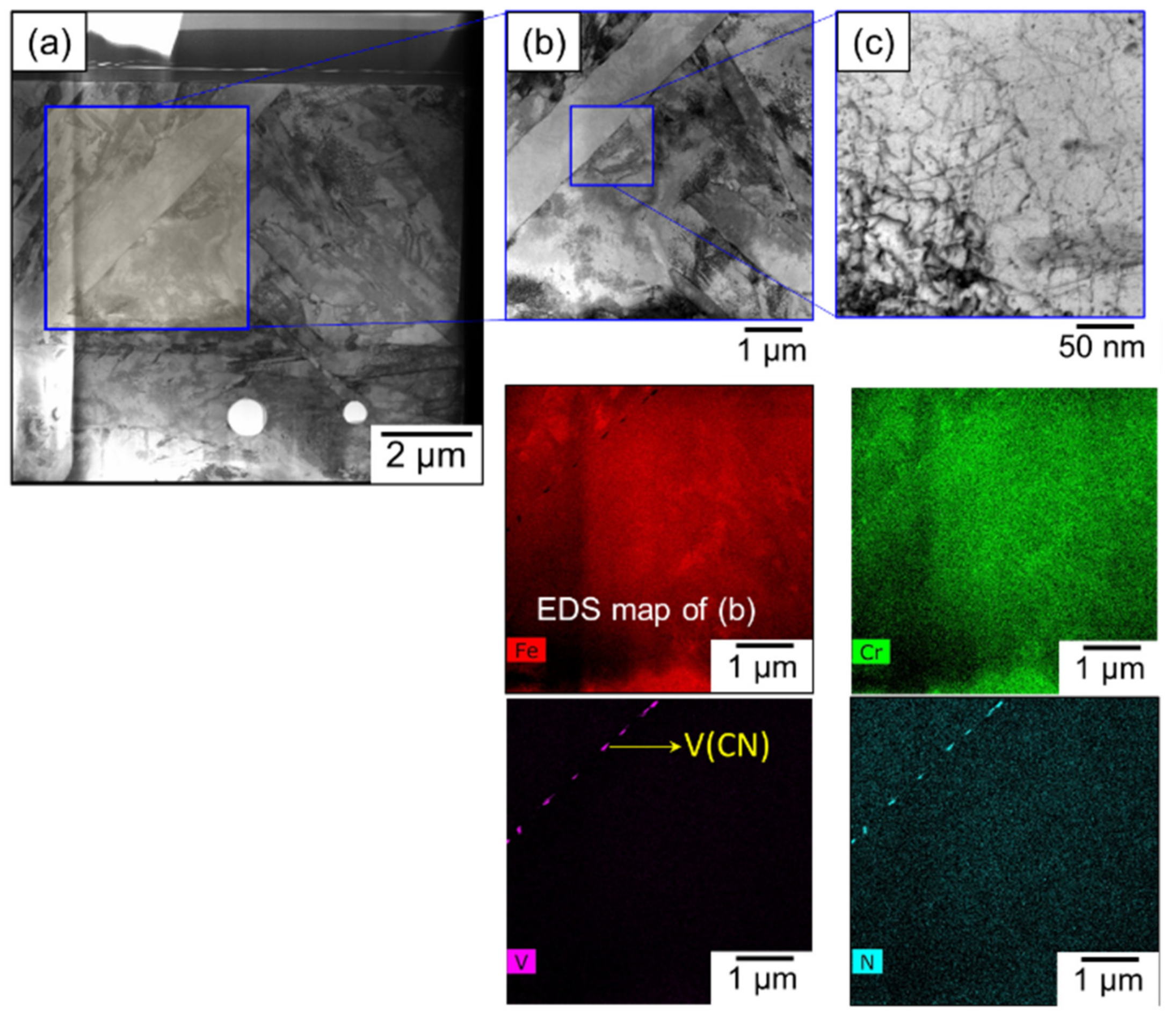

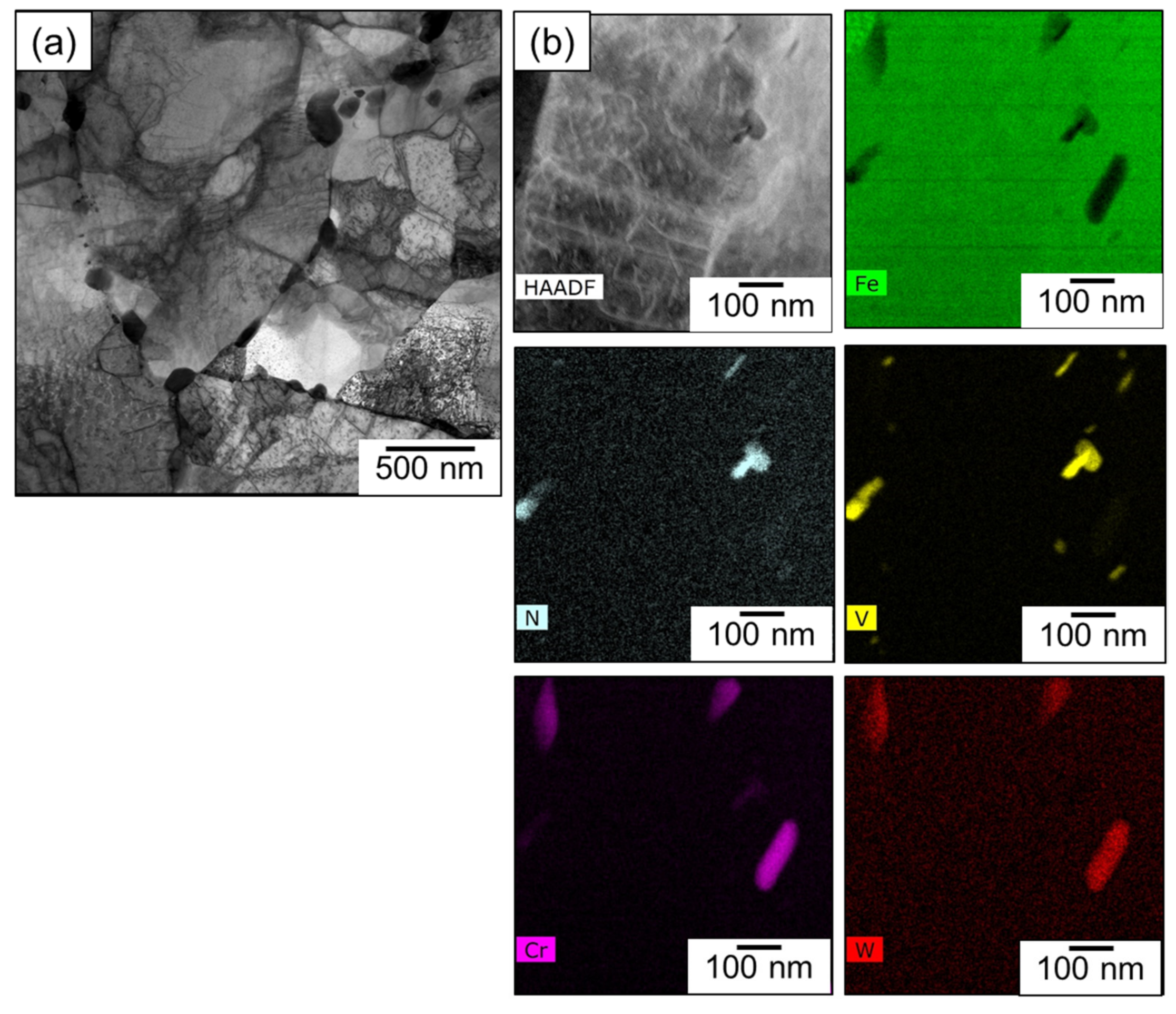

3.1.3. Heat Treatment-1

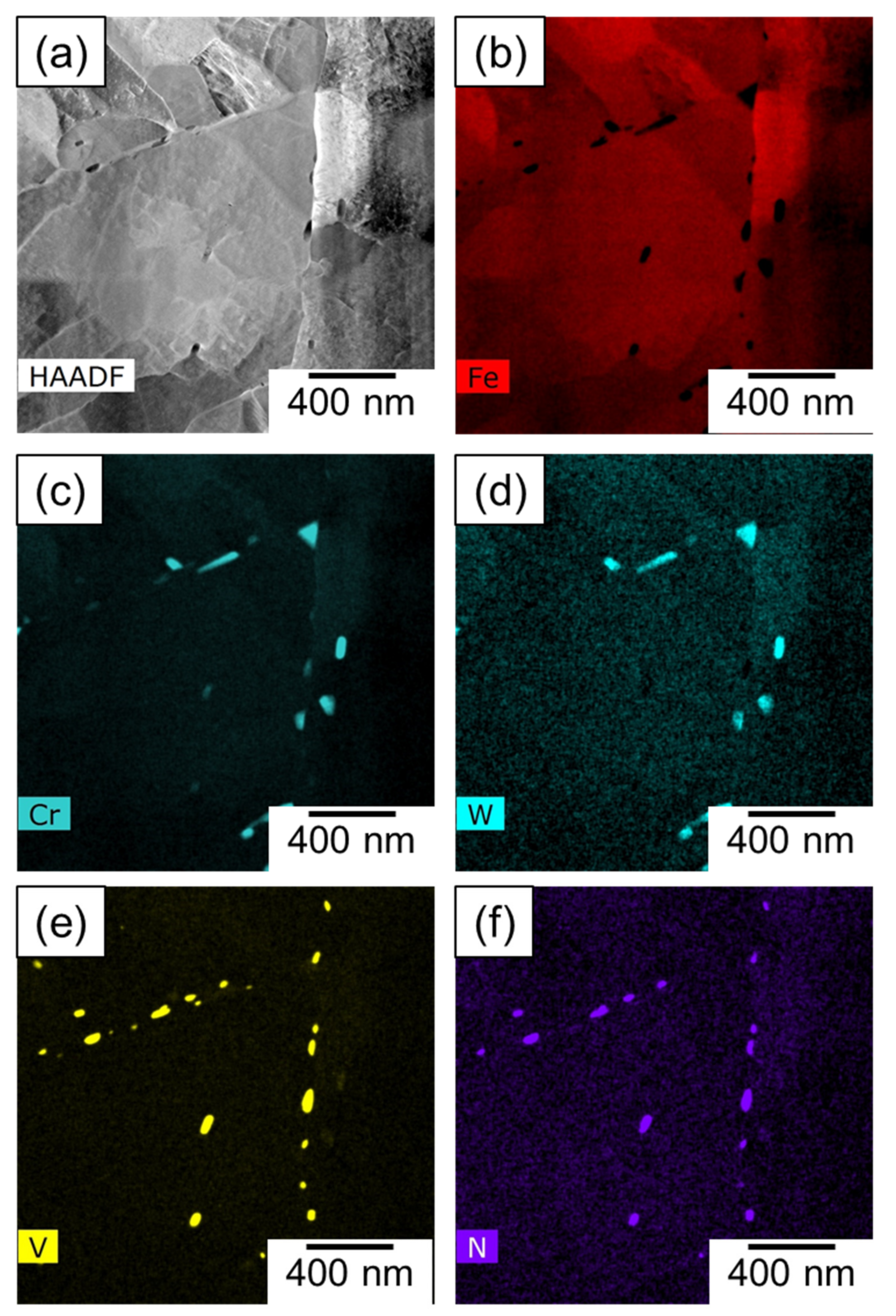

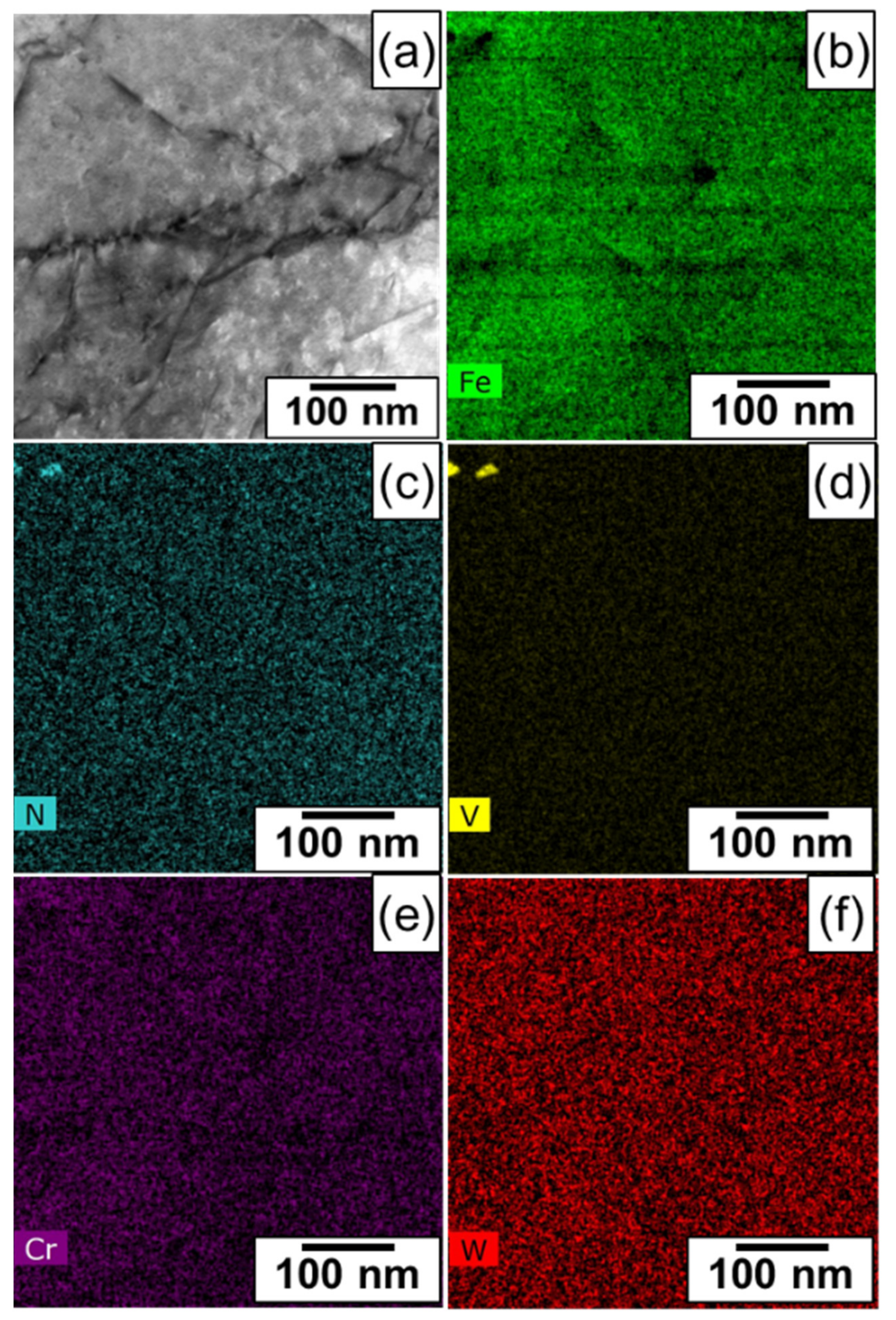

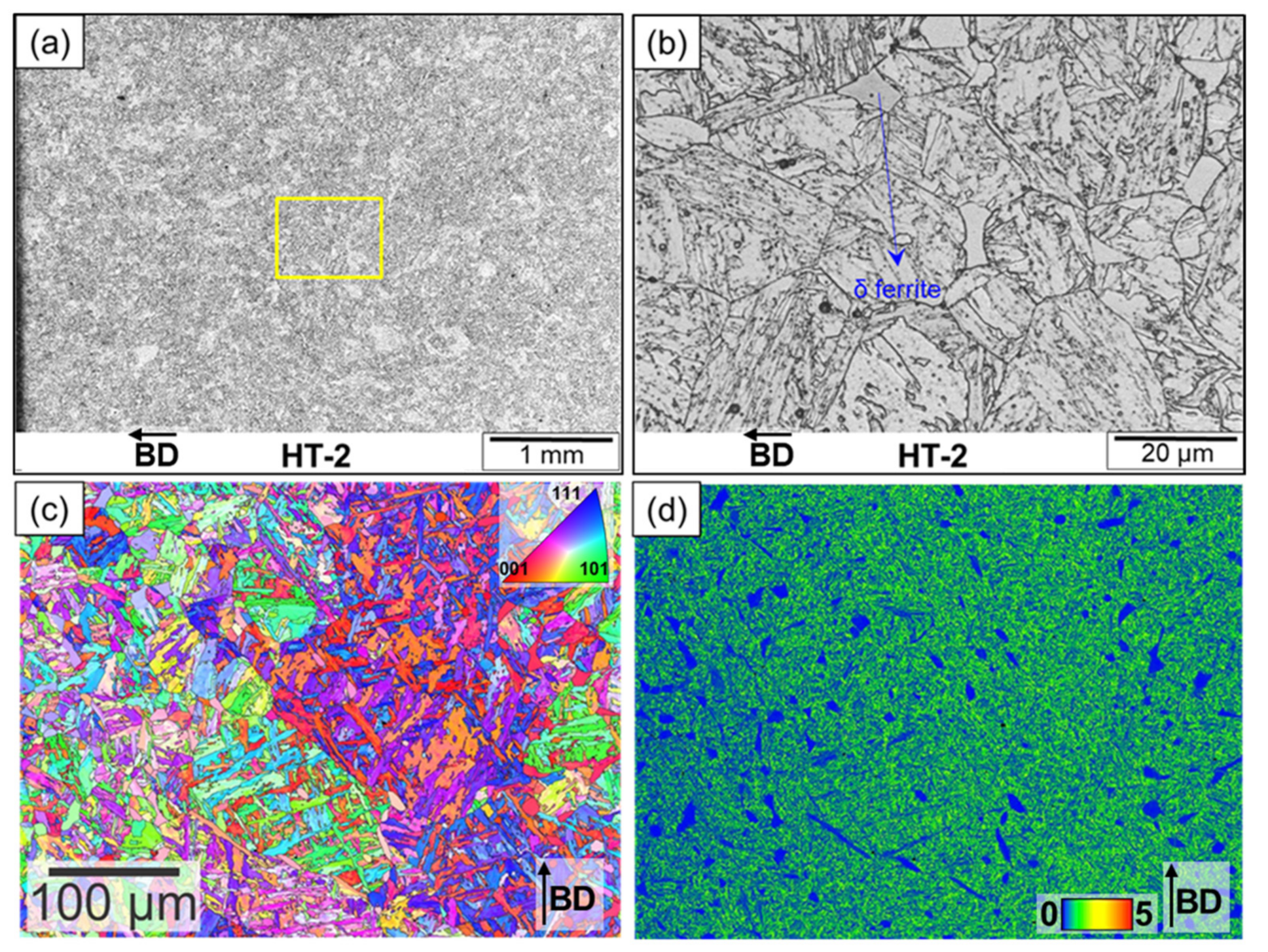

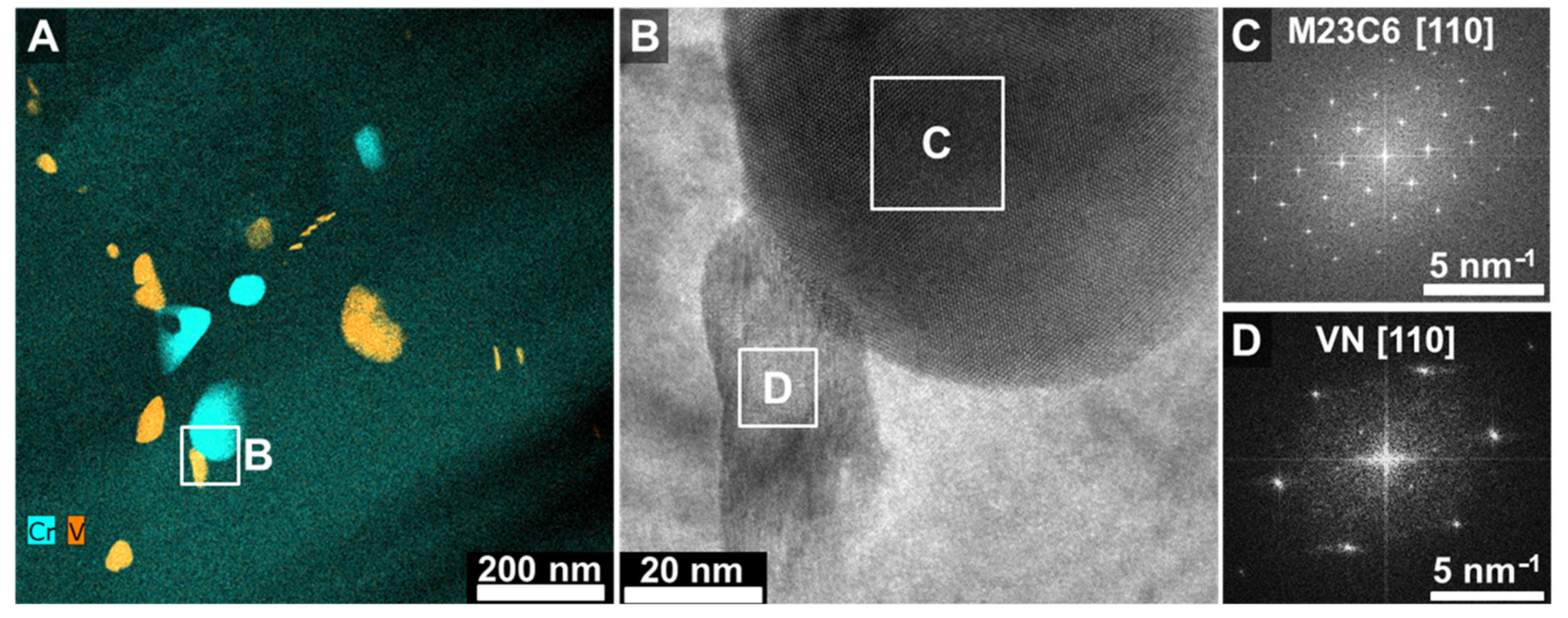

3.1.4. Heat Treatment-2

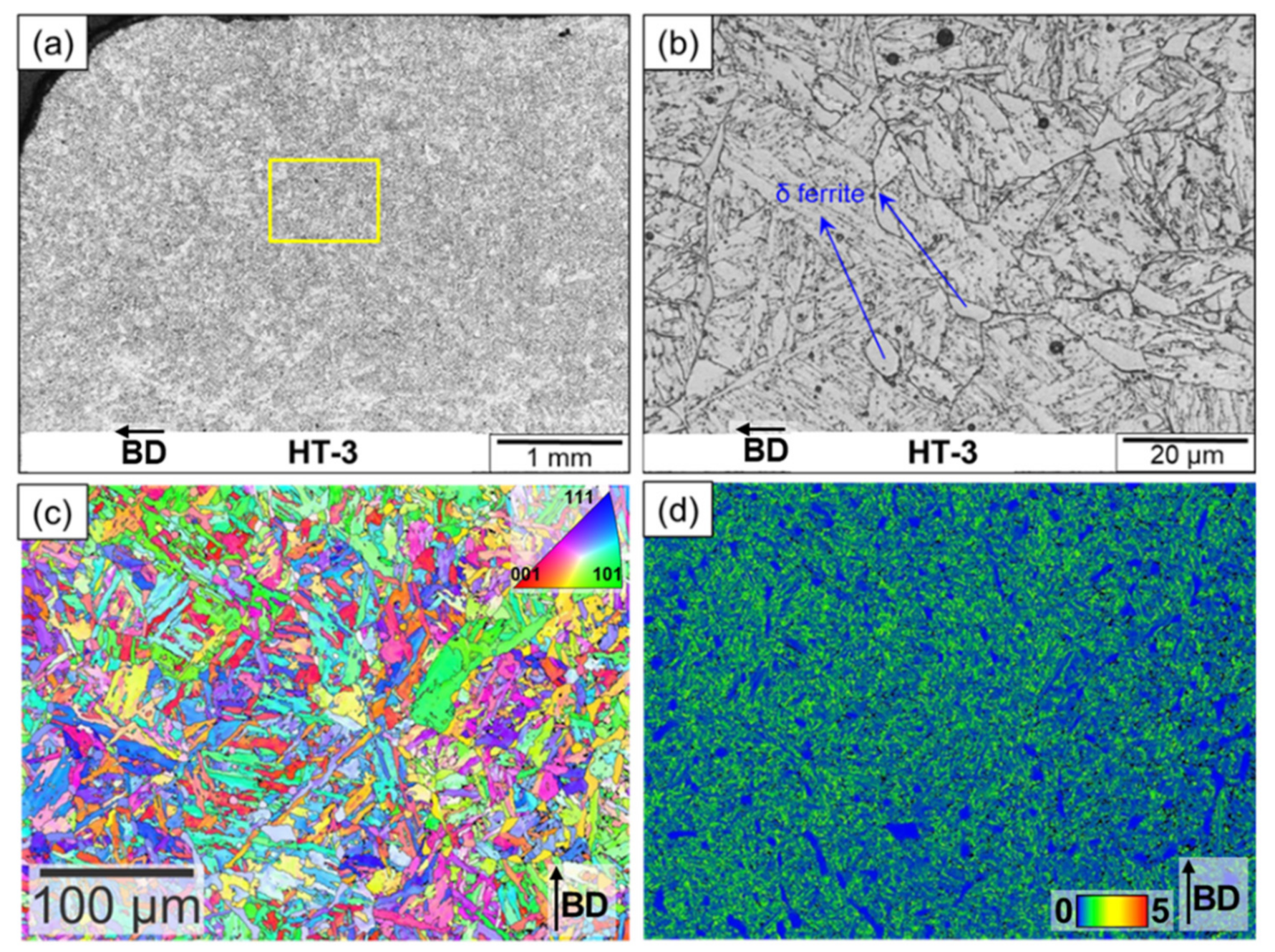

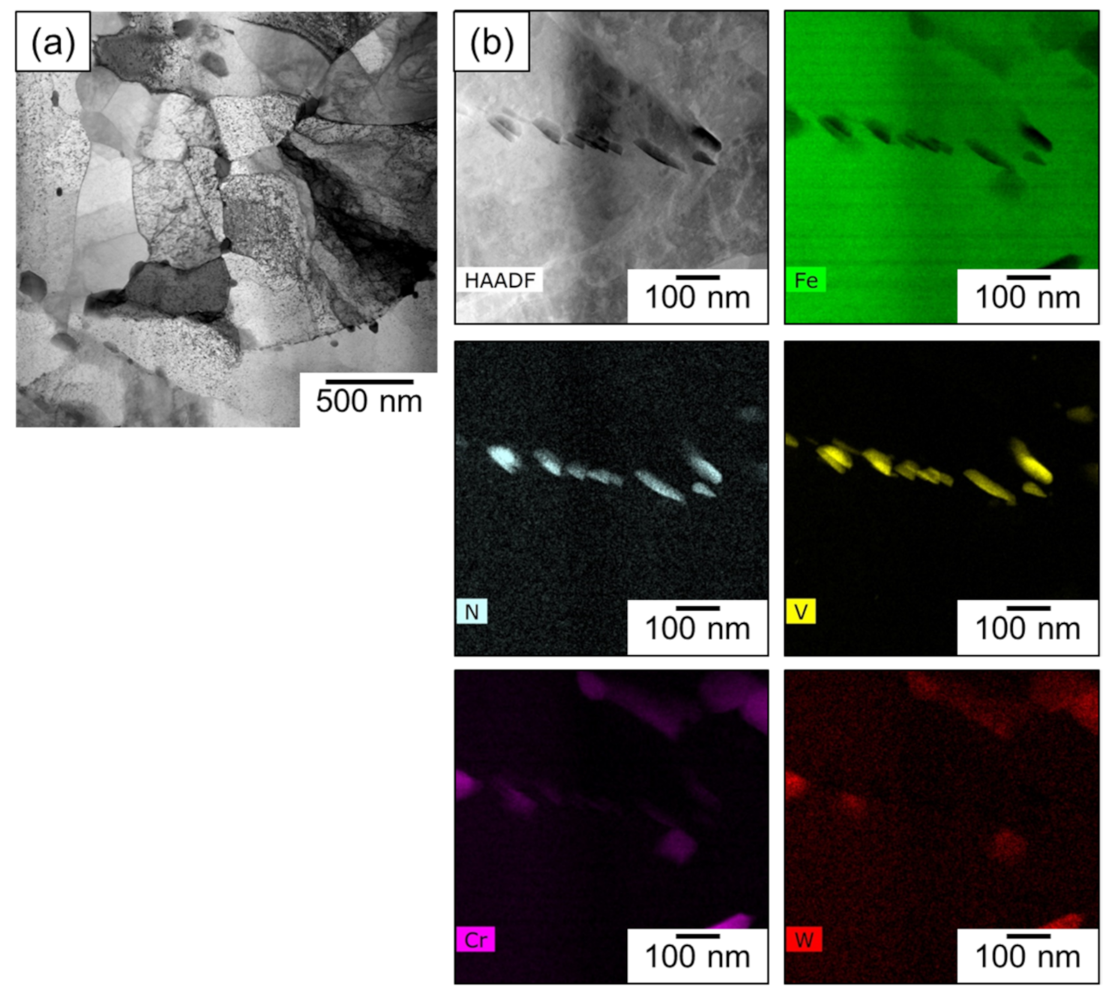

3.1.5. Heat Treatment-3

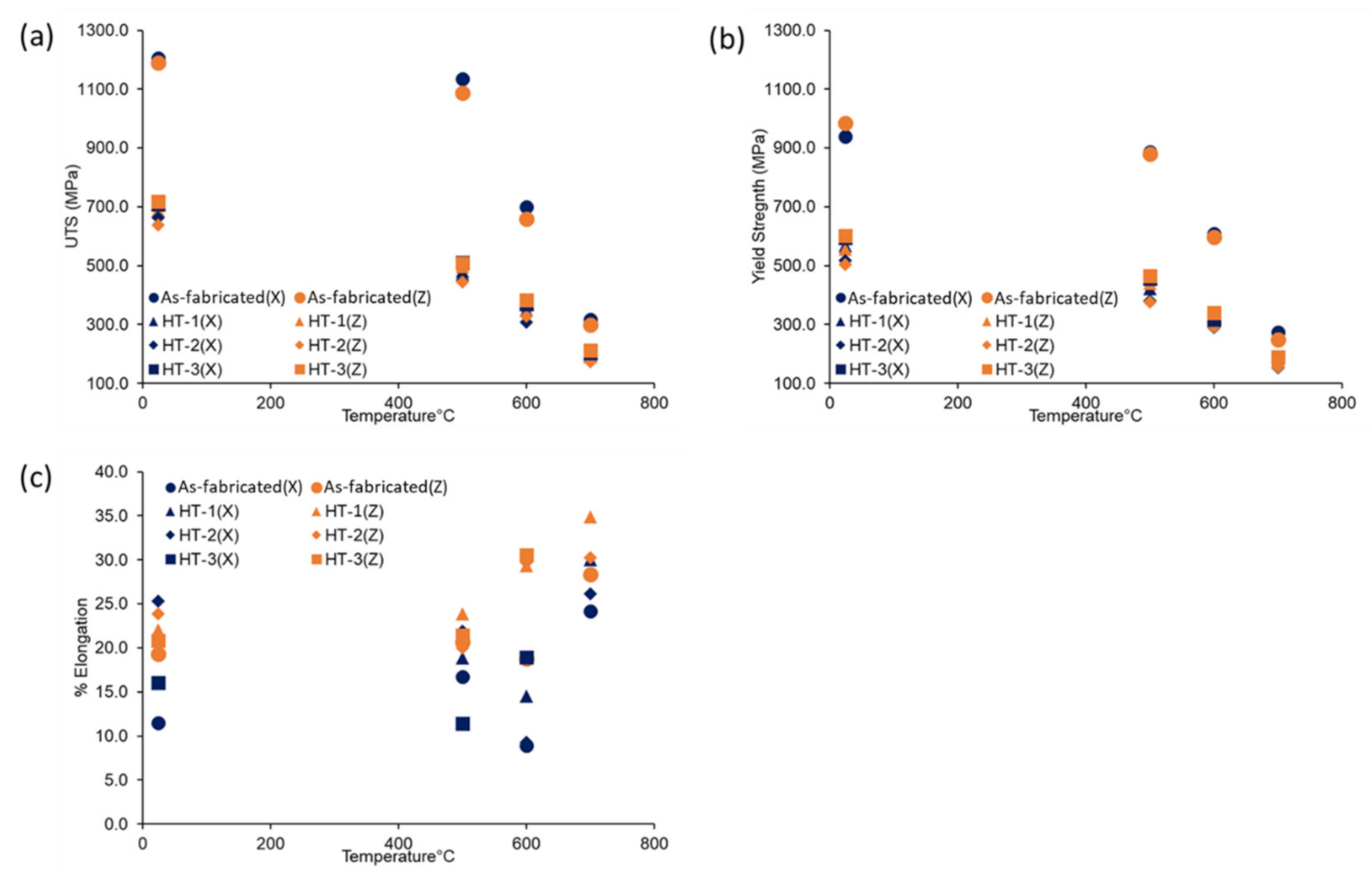

3.2. Mechanical Properties

4. Discussion

- Parameter optimization: The goal of tailoring the process parameters (laser power, travel speed and hatch spacing, in particular) should be geared towards not just eliminating defects, but also to move towards the paradigm of temper bead deposition. Temper bead deposition techniques could ensure that the as-fabricated part can be readily used without the need for any post-processing treatments;

- Alloy design: This is perhaps the greatest challenge for additive manufacturing of these materials. All these materials are designed to be processed using conventional manufacturing. However, far from being equilibrium manufacturing processes, such as AM, they lead complex spatial and temporal changes in the thermal cycles leading to different responses in these conventional alloys. In particular, alloys that can lend themselves to being amenable to temper bead deposition techniques, have low residual stresses by tuning the Ms temperature, and are capable of forming a high density of stable carbo-nitride precipitates, need to be developed and investigated.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sridharan, N.; Field, K. A Road Map for the Advanced Manufacturing of Ferritic-Martensitic Steels. Fusion Sci. Technol. 2019, 75, 264–274. [Google Scholar] [CrossRef]

- Sridharan, N.; Field, K.G. Preliminary Characterization and Mechanical Performance of Additively Manufactured HT9; ORNL: Oak Ridge, TN, USA, 2018. [Google Scholar] [CrossRef]

- Zhong, W.; Sridharan, N.; Isheim, D.; Field, K.G.; Yang, Y.; Terrani, K.; Tan, L. Microstructures and Mechanical Properties of a Modified 9Cr Ferritic-Martensitic Steel in the as-Built Condition after Additive Manufacturing. J. Nucl. Mater. 2020, 545, 152742. [Google Scholar] [CrossRef]

- Klueh, R.; Nelson, A. Ferritic/Martensitic Steels for Next-Generation Reactors. J. Nucl. Mater. 2007, 371, 37–52. [Google Scholar] [CrossRef]

- Klueh, R.L. Elevated Temperature Ferritic and Martensitic Steels and Their Application to Future Nuclear Reactors. Int. Mater. Rev. 2005, 50, 287–310. [Google Scholar] [CrossRef] [Green Version]

- Klueh, R.L.; Harris, D.R. High-Chromium Ferritic and Martensitic Steels for Nuclear Applications; ASTM: Conshohocken, PA, USA, 2001. [Google Scholar]

- David, S.A.; Siefert, J.A.; Feng, Z. Welding and Weldability of Candidate Ferritic Alloys for Future Advanced Ultrasupercritical Fossil Power Plants. Sci. Technol. Weld. Join. 2013, 18, 631–651. [Google Scholar] [CrossRef]

- Klueh, R.; Gelles, D.; Lechtenberg, T. Development of Ferritic Steels for Reduced Activation: The US Program. J. Nucl. Mater. 1986, 141–143, 1081–1087. [Google Scholar] [CrossRef] [Green Version]

- Danon, C.A.; Servant, C. Thermodynamic Modeling in Reduced Activation Steels. ISIJ Int. 2005, 45, 903–912. [Google Scholar] [CrossRef] [Green Version]

- Puype, A.; Bonny, G.; Malerba, L.; Petrov, R.; Sietsma, J. Design of Reduced Activation Ferritic/Martensitic Steels with Improved Creep Resistance by Thermodynamic Modelling. SSRN Electron. J. 2018. [Google Scholar] [CrossRef]

- Hishinuma, A.; Kohyama, A.; Klueh, R.; Gelles, D.; Dietz, W.; Ehrlich, K. Current Status and Future R&D for Reduced-Activation Ferritic/Martensitic Steels. J. Nucl. Mater. 1998, 258–263, 193–204. [Google Scholar] [CrossRef]

- Klueh, R.; Gelles, D.; Jitsukawa, S.; Kimura, A.; Odette, G.; van der Schaaf, B.; Victoria, M. Ferritic/Martensitic Steels—Overview of Recent Results. J. Nucl. Mater. 2002, 307–311, 455–465. [Google Scholar] [CrossRef]

- Kurtz, R.; Alamo, A.; Lucon, E.; Huang, Q.; Jitsukawa, S.; Kimura, A.; Klueh, R.; Odette, G.; Petersen, C.; Sokolov, M.; et al. Recent Progress toward Development of Reduced Activation Ferritic/Martensitic Steels for Fusion Structural Applications. J. Nucl. Mater. 2009, 386–388, 411–417. [Google Scholar] [CrossRef]

- Song, M.; Sun, C.; Fan, Z.; Chen, Y.; Zhu, R.; Yu, K.; Hartwig, K.; Wang, H.; Zhang, X. A Roadmap for Tailoring the Strength and Ductility of Ferritic/Martensitic T91 Steel via Thermo-Mechanical Treatment. Acta Mater. 2016, 112, 361–377. [Google Scholar] [CrossRef] [Green Version]

- Vitek, J.M.; Klueh, R.L. Precipitation Reactions during the Heat Treatment of Ferritic Steels. Metall. Mater. Trans. A 1983, 14, 1047–1055. [Google Scholar] [CrossRef]

- Wang, L.; Felicelli, S.D.; Pratt, P. Residual Stresses in LENS-Deposited AISI 410 Stainless Steel Plates. Mater. Sci. Eng. A 2008, 496, 234–241. [Google Scholar] [CrossRef]

- Klueh, R.L.; King, J.F. Austenitic Stainless Steel-Ferritic Steel Weld Joint Failures. Weld. J. 1982, 61, 302. [Google Scholar]

- Rieth, M.; Rey, J. Specific Welds for Test Blanket Modules. J. Nucl. Mater. 2009, 386–388, 471–474. [Google Scholar] [CrossRef]

- Allen, T.R.; Busby, J.; Klueh, R.L.; Maloy, S.; Toloczko, M.B. Cladding and Duct Materials for Advanced Nuclear Recycle Reactors. JOM 2008, 60, 15–23. [Google Scholar] [CrossRef]

- Dragunov, V.K.; Sliva, A.P.; Goncharov, A.L.; Zhmurko, I.E.; Terent’Ev, E.V.; Sysoev, A.G.; Marchenkov, A.Y. Specific Features of Electron-Beam Welding of ITER Blanket First Wall Components. Therm. Eng. 2020, 67, 387–395. [Google Scholar] [CrossRef]

- Boccaccini, L.V.; Meyder, R.; Fischer, U. Test Strategy for the European HCPB Test Blanket Module in ITER. Fusion Sci. Technol. 2005, 47, 1015–1022. [Google Scholar] [CrossRef]

- Cardella, A.; Rigal, E.; Bedel, L.; Bucci, P.; Fiek, J.; Forest, L.; Boccaccini, L.; Diegele, E.; Giancarli, L.; Hermsmeyer, S.; et al. The Manufacturing Technologies of the European Breeding Blankets. J. Nucl. Mater. 2004, 329–333, 133–140. [Google Scholar] [CrossRef]

- Forest, L.; Aktaa, J.; Boccaccini, L.V.; Emmerich, T.; Eugen-Ghidersa, B.; Fondant, G.; Froio, A.; Puma, A.L.; Namburi, H.; Neuberger, H.; et al. Status of the EU DEMO Breeding Blanket Manufacturing R&D Activities. Fusion Eng. Des. 2020, 152, 111420. [Google Scholar] [CrossRef]

- Manugula, V.L.; Rajulapati, K.V.; Reddy, G.M.; Rao, K.B.S. Role of Evolving Microstructure on the Mechanical Properties of Electron Beam Welded Ferritic-Martensitic Steel in the as-Welded and Post Weld Heat-Treated States. Mater. Sci. Eng. A 2017, 698, 36–45. [Google Scholar] [CrossRef]

- Arivazhagan, B.; Srinivasan, G.; Albert, S.; Bhaduri, A. A Study on Influence of Heat Input Variation on Microstructure of Reduced Activation Ferritic Martensitic Steel Weld Metal Produced by GTAW Process. Fusion Eng. Des. 2011, 86, 192–197. [Google Scholar] [CrossRef]

- Roy, S.; Shassere, B.; Yoder, J.; Nycz, A.; Noakes, M.; Narayanan, B.K.; Meyer, L.; Paul, J.; Sridharan, N. Mitigating Scatter in Mechanical Properties in AISI 410 Fabricated via Arc-Based Additive Manufacturing Process. Materials 2020, 13, 4855. [Google Scholar] [CrossRef]

- Lippold, J.C. Transformation and Tempering Behavior of 12Cr-1Mo-0.3V Martensitic Stainless Steel Weldments. J. Nucl. Mater. 1981, 104, 1127–1131. [Google Scholar] [CrossRef]

- Lippold, J.C. Welding Metallurgy and Weldability; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar] [CrossRef]

- Bhaduri, A.; Rai, S.; Gill, T.; Sujith, S.; Jayakumar, T. Evaluation of Repair Welding Procedures for 2.25Cr–1Mo and 9Cr–1Mo Steel Welds. Sci. Technol. Weld. Join. 2001, 6, 89–93. [Google Scholar] [CrossRef]

- Smith, B.; Ramirez, A.J.; McCracken, S.L.; Tate, S. Investigation of Relationship between Microhardness and Charpy Impact Energy for Temper Bead Welding Qualification: Part 1. In Proceedings of the ASME 2019 Pressure Vessels & Piping Conference, San Antonio, TX, USA, 14–19 July 2019. [Google Scholar] [CrossRef]

- Smith, B.; Ramirez, A.J.; McCracken, S.L.; Tate, S. Investigation of Relationship between Microhardness and Charpy Impact Energy for Temper Bead Welding Qualification: Part 2. In Proceedings of the ASME 2011 Pressure Vessels and Piping Conference: Volume 6, Parts A and B, Virtual, 3 August 2020. [Google Scholar] [CrossRef]

- Sridharan, N.; Chaudhary, A.; Nandwana, P.; Babu, S. Texture Evolution During Laser Direct Metal Deposition of Ti-6Al-4V. JOM 2016, 68, 772–777. [Google Scholar] [CrossRef]

- Sridharan, N.; Noakes, M.W.; Nycz, A.; Love, L.J.; Dehoff, R.R.; Babu, S. On the Toughness Scatter in Low Alloy C-Mn Steel Samples Fabricated Using Wire Arc Additive Manufacturing. Mater. Sci. Eng. A 2018, 713, 18–27. [Google Scholar] [CrossRef]

- Shassere, B.; Nycz, A.; Noakes, M.W.; Masuo, C.; Sridharan, N. Correlation of Microstructure and Mechanical Properties of Metal Big Area Additive Manufacturing. Appl. Sci. 2019, 9, 787. [Google Scholar] [CrossRef] [Green Version]

- Dehoff, R.; Kirka, M.M.; Sames, W.J.; Bilheux, H.; Tremsin, A.; Lowe, L.E.; Babu, S. Site Specific Control of Crystallographic Grain Orientation through Electron Beam Additive Manufacturing. Mater. Sci. Technol. 2015, 31, 931–938. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.; Babu, S. The Metallurgy and Processing Science of Metal Additive Manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Panda, B.; Shankhwar, K.; Garg, A.; Savalani, M.M. Evaluation of Genetic Programming-Based Models for Simulating Bead Dimensions in Wire and Arc Additive Manufacturing. J. Intell. Manuf. 2019, 30, 809–820. [Google Scholar] [CrossRef]

- Kulkarni, J.D.; Goka, S.B.; Parchuri, P.K.; Yamamoto, H.; Ito, K.; Simhambhatla, S. Microstructure Evolution along Build Direction for Thin-Wall Components Fabricated with Wire-Direct Energy Deposition. Rapid Prototyp. J. 2021, 27, 1289–1301. [Google Scholar] [CrossRef]

- Chaturvedi, M.; Scutelnicu, E.; Rusu, C.; Mistodie, L.; Mihailescu, D.; Subbiah, A. Wire Arc Additive Manufacturing: Review on Recent Findings and Challenges in Industrial Applications and Materials Characterization. Metals 2021, 11, 939. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal Additive Manufacturing in Aerospace: A Review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Plotkowski, A.; Ferguson, J.; Stump, B.; Halsey, W.; Paquit, V.; Joslin, C.; Babu, S.; Rossy, A.M.; Kirka, M.; Dehoff, R. A Stochastic Scan Strategy for Grain Structure Control in Complex Geometries Using Electron Beam Powder Bed Fusion. Addit. Manuf. 2021, 46, 102092. [Google Scholar] [CrossRef]

- Zhong, W.; Yang, Y.; Field, K.G.; Sridharan, N.; Terrani, K.; Tan, L. Microstructure and Mechanical Properties of High Mn-Containing Ferritic-Martensitic Alloys Exposed to Cyclical Thermal Treatment. Mater. Sci. Eng. A 2021, 813, 141143. [Google Scholar] [CrossRef]

- Oñoro, J. Martensite Microstructure of 9–12% Cr Steels Weld Metals. J. Mater. Process. Technol. 2006, 180, 137–142. [Google Scholar] [CrossRef]

- Oñoro, J. Weld Metal Microstructure Analysis of 9–12% Cr steels. Int. J. Press. Vessel. Pip. 2006, 83, 540–545. [Google Scholar] [CrossRef]

- Rieth, M.; Schirra, M.; Falkenstein, A.; Graf, P.; Heger, S.; Kempe, H.; Lindau, R.; Zimmermann, H. EUROFER 97. Tensile, Charpy, Creep and Structural Tests; FZKA-6911; KITopen: Karlsruhe, Germany, 2003. [Google Scholar] [CrossRef]

- Schirra, M.; Adelhelm, C.; Graf, P.; Heger, S.; Kempe, H.; Zimmermann, H.; Fernandez, M.; Lapena, J. Arbeiten zur Grundcharakterisierung am Niedrigaktivierenden Stahl F82H-Mod im Vergleich zu OPTIFER; FZKA-6008; KITopen: Karlsruhe, Germany, 1997. [Google Scholar]

- Tan, L.; Katoh, Y.; Snead, L. Development of Castable Nanostructured Alloys as a New Generation RAFM Steels. J. Nucl. Mater. 2018, 511, 598–604. [Google Scholar] [CrossRef]

- Lippold, K.D.J.; John, C. Welding Metallurgy and Weldability of Stainless Steels; John Wiley & Sons: Hoboken, NJ, USA, 2005; Available online: https://app.knovel.com/hotlink/toc/id:kpWMWSS007/welding-metallurgy-weldability/welding-metallurgy-weldability (accessed on 26 December 2021).

- Sridharan, N.; Gussev, M.N.; Field, K.G. Performance of a Ferritic/Martensitic Steel for Nuclear Reactor Applications Fabricated Using Additive Manufacturing. J. Nucl. Mater. 2019, 521, 45–55. [Google Scholar] [CrossRef]

- Abe, F. Precipitate Design for Creep Strengthening of 9% Cr Tempered Martensitic Steel for Ultra-Supercritical Power Plants. Sci. Technol. Adv. Mater. 2008, 9, 013002. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Busby, J. Thermodynamic Modeling and Kinetics Simulation of Precipitate Phases in AISI 316 Stainless Steels. J. Nucl. Mater. 2014, 448, 282–293. [Google Scholar] [CrossRef]

- Sawada, K.; Taneike, M.; Kimura, K.; Abe, F. Effect of Nitrogen Content on Microstructural Aspects and Creep Behavior in Extremely Low Carbon 9Cr Heat-resistant Steel. ISIJ Int. 2004, 44, 1243–1249. [Google Scholar] [CrossRef] [Green Version]

- Tan, L.; Graening, T.; Hu, X.; Zhong, W.; Yang, Y.; Zinkle, S.; Katoh, Y. Effects of Carbonitrides and Carbides on Microstructure and Properties of Castable Nanostructured Alloys. J. Nucl. Mater. 2020, 540, 152376. [Google Scholar] [CrossRef]

- Song, M.; Sun, C.; Jang, J.; Han, C.; Kim, T.; Hartwig, K.; Zhang, X. Microstructure Refinement and Strengthening Mechanisms of a 12Cr ODS Steel Processed by Equal Channel Angular Extrusion. J. Alloy. Compd. 2013, 577, 247–256. [Google Scholar] [CrossRef]

- Moon, J.; Lee, C.-H.; Lee, T.-H.; Kim, H.C. Effect of Heat Input on Microstructure Evolution and Mechanical Properties in the Weld Heat-Affected Zone of 9Cr-2W-VTa Reduced Activation Ferritic-Martensitic Steel for Fusion Reactor. Met. Mater. Trans. A 2014, 46, 156–163. [Google Scholar] [CrossRef]

- Wang, J.; Lu, S.; Rong, L.; Li, D. Thermal Cycling, Microstructure and Mechanical Properties of 9Cr2WVTa Steel Welds. J. Mater. Process. Technol. 2015, 222, 434–443. [Google Scholar] [CrossRef]

- Filacchioni, G.; Montanari, R.; Tata, M.; Pilloni, L. Structural and Mechanical Properties of Welded Joints of Reduced Activation Martensitic Steels. J. Nucl. Mater. 2002, 307–311, 1563–1567. [Google Scholar] [CrossRef]

- Cai, G.-J.; Andrén, H.-O.; Svensson, L.-E. Effect of Cooling after Welding on Microstructure and Mechanical Properties of 12 Pct Cr Steel Weld Metals. Met. Mater. Trans. A 1997, 28, 1417–1428. [Google Scholar] [CrossRef]

- Cai, G.-J.; Lundin, L.; Andrén, H.-O.; Svensson, L.-E. Atom-Probe Investigation of Precipitation in 12% Cr Steel Weld Metals. Appl. Surf. Sci. 1994, 76–77, 248–254. [Google Scholar] [CrossRef]

- Jayaram, R.; Klueh, R.L. Microstructural Characterization of 5 to 9 pct Cr-2 pct W-V-Ta Martensitic Steels. Met. Mater. Trans. A 1998, 29, 1551–1558. [Google Scholar] [CrossRef]

- Babu, S.; Hono, K.; Sakurai, T. Atom Probe Field Ion Microscopy Study of the Partitioning of Substitutional Elements during Tempering of a Low-Alloy Steel Martensite. Met. Mater. Trans. A 1994, 25, 499–508. [Google Scholar] [CrossRef]

- Babu, S.S. Thermodynamic and Kinetic Models for Describing Microstructure Evolution during Joining of Metals and Alloys. Int. Mater. Rev. 2009, 54, 333–367. [Google Scholar] [CrossRef]

| Condition | Fe | Cr | W | V | Ta | C | Mn | N |

|---|---|---|---|---|---|---|---|---|

| ORNL 9Cr-2W alloy (nominal) | Bal | 9.0 | 2.0 | 0.25 | 0.07 | 0.10 | 0.40 | 0.025 |

| Powder chemistry | Bal | 9.57 | 1.94 | 0.36 | 0.05 | 0.076 | 0.36 | 0.041 |

| Deposit chemistry | Bal | 9.61 | 1.98 | 0.30 | 0.03 | 0.070 | 0.36 | 0.01 |

| Program | Steel | C | Si | Mn | Cr | W | V | Ta | N | B |

|---|---|---|---|---|---|---|---|---|---|---|

| Japan | F82H | 0.1 | 0.2 | 0.5 | 8.0 | 2.0 | 0.2 | 0.04 | 0.01 | 0.003 |

| - | JLF-1 | 0.1 | 0.08 | 0.45 | 9.0 | 2.0 | 0.20 | 0.07 | 0.05 | - |

| Europe | OPTIFER I | 0.1 | 0.06 | 0.50 | 9.30 | 1.0 | 0.25 | 0.07 | 0.015 | 0.006 |

| - | OPTIFER II | 0.125 | 0.04 | 0.50 | 9.40 | - | 0.25 | - | 0.015 | 0.006 |

| EUROFER | 0.11 | 0.05 | 0.50 | 8.5 | 1.0 | 0.25 | 0.08 | 0.03 | 0.005 | |

| USA | ORNL9Cr-2WVTa | 0.10 | 0.30 | 0.4 | 9.0 | 2.0 | 0.25 | 0.07 | - | - |

| Processing Condition | Delta Ferrite Area Fraction % | Martensite Lath Size/nm | M23C6 Size/nm | M23C6 Number Density/m−3 | MX Size/nm | MX Number Density/m−3 |

|---|---|---|---|---|---|---|

| As-built | 9.2 ± 1.9 | 284 ± 22 | 63 ± 11 | 1–3 × 1019 | 28 ± 22 | 1–2 × 1019 |

| HT-1 | 3.4 ± 0.4 | 372 ± 19 | 82 ± 43 | 2–5 × 1019 | 51 ± 38 | 2–7 × 1019 |

| HT-2 | 5.2 ± 0.6 | 332 ± 15 | 77 ± 47 | 4–6 × 1019 | 24 ± 21 | 2–5 × 1020 |

| HT-3 | 5.4 ± 1.0 | 341 ± 16 | 64 ± 40 | 4–6 × 1019 | 18 ± 16 | 3–6 × 1020 |

| HT-1: 980 °C Normalize for 30 min + Temper at 750 °C for 2 h | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Phase | Volume % | Fe | Cr | W | Ta | V | C | N | |

| wt.% | M23C6 | 1.85 | 42.91 | 39.86 | 12.26 | 0.31 | 1.11 | 3.29 | 0.23 |

| Std. deviation | 1.38 | 1.28 | 1.32 | 0.1 | 0.1 | 0.21 | |||

| wt.% | (V,Ta)(C,N) | 0.63 | 46.56 | 12 | 1.13 | 0.21 | 32.88 | 0.64 | 6.5 |

| Std. deviation | 1.5 | 0.45 | 0.2 | 0.09 | 1.08 | 0.1 | |||

| wt.% | Ferrite | 98.01 | 86.6 | 8.39 | 2.33 | 0.55 | 0.19 | - | - |

| Std. deviation | 2.62 | 0.28 | 0.26 | 0.08 | 0.03 | - | |||

| HT-2: 1150 °C Normalization for 60 min + Temper at 750 °C for 1 h | |||||||||

| wt.% | M23C6 | 1.95 | 34.50 | 48.25 | 10.65 | 0.06 | 1.11 | 5.43 | - |

| Std. deviation | 1.13 | 1.54 | 1.16 | 0.06 | 0.10 | 0.29 | |||

| wt.% | (V,Ta)(C,N) | 0.19 | 45.47 | 10.99 | 1.01 | 0.03 | 30.25 | 1.68 | 10.51 |

| Std. deviation | 4.59 | 1.41 | 0.68 | 0.01 | 3.16 | 0.60 | |||

| wt.% | Ferrite | 97.86 | 88.95 | 8.79 | 0.87 | - | 0.11 | - | - |

| Std. deviation | 2.69 | 0.29 | 0.11 | 0.03 | - | ||||

| HT-3: 1150 °C Normalization for 30 min + Temper at 750 °C for 30 min | |||||||||

| wt.% | M23C6 | 1.81 | 44.00 | 40.46 | 10.01 | 0.32 | 1.17 | 3.67 | 0.26 |

| Std. deviation | 1.37 | 1.26 | 1.05 | 0.08 | 0.08 | 0.17 | 0.05 | ||

| wt.% | (V,Ta)(C,N) | 0.68 | 55.51 | 10.45 | 1.44 | 0.59 | 22.74 | 0.72 | 7.40 |

| Std. deviation | 1.78 | 0.42 | 0.25 | 0.15 | 0.79 | 0.12 | 0.33 | ||

| wt.% | Ferrite | 97.51 | 85.72 | 8.59 | 2.34 | 1.77 | 0.21 | - | - |

| Std. deviation | 2.6 | 0.28 | 0.26 | 0.2 | 0.03 | - | - | ||

| CALPHAD simulations | |||||||||

| Ferrite | 97.68 | 89.56 | 8.15 | 1.82 | - | 0.13 | - | - | |

| M23C6 | 2.071 | 24.46 | 55.61 | 12.13 | - | 1.9 | 5.09 | - | |

| (V,Ta)(C,N) | 0.202 | 0.23 | 5.38 | - | 6.33 | 69.82 | 2.58 | 15.64 | |

| TaC | 0.044 | - | 0.14 | 1.6 | 88.14 | 3.34 | 6.62 | 0.16 | |

| Literature (9Cr-2WV) [60] | |||||||||

| M23C6 | - | 46.7 | 4.6 | - | 0.9 | - | - | ||

| (V,Ta)(C,N) | - | 8.3 | 0.5 | - | 44.2 | - | - | ||

| Literature (9Cr-2WV-Ta) [60] | |||||||||

| M23C6 | - | 42.1 | 4.6 | - | 0.9 | - | - | ||

| (V,Ta)(C,N) | - | 2.5 | 0.9 | 41.2 | 5.7 | - | - | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gräning, T.; Sridharan, N. Benchmarking a 9Cr-2WVTa Reduced Activation Ferritic Martensitic Steel Fabricated via Additive Manufacturing. Metals 2022, 12, 342. https://doi.org/10.3390/met12020342

Gräning T, Sridharan N. Benchmarking a 9Cr-2WVTa Reduced Activation Ferritic Martensitic Steel Fabricated via Additive Manufacturing. Metals. 2022; 12(2):342. https://doi.org/10.3390/met12020342

Chicago/Turabian StyleGräning, Tim, and Niyanth Sridharan. 2022. "Benchmarking a 9Cr-2WVTa Reduced Activation Ferritic Martensitic Steel Fabricated via Additive Manufacturing" Metals 12, no. 2: 342. https://doi.org/10.3390/met12020342

APA StyleGräning, T., & Sridharan, N. (2022). Benchmarking a 9Cr-2WVTa Reduced Activation Ferritic Martensitic Steel Fabricated via Additive Manufacturing. Metals, 12(2), 342. https://doi.org/10.3390/met12020342