Effect of Shortened Post Weld Heat Treatment on the Laser Welded AA7075 Alloy

Abstract

:1. Introduction

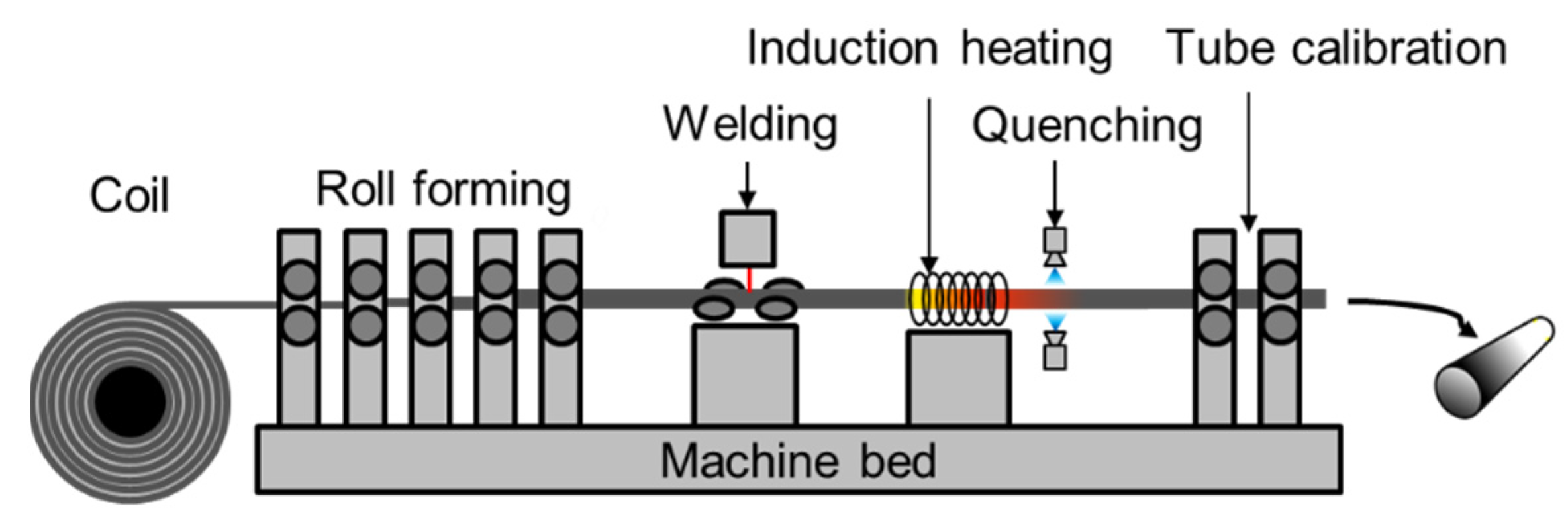

2. Experimental Setup

2.1. Material and Welding Experiments

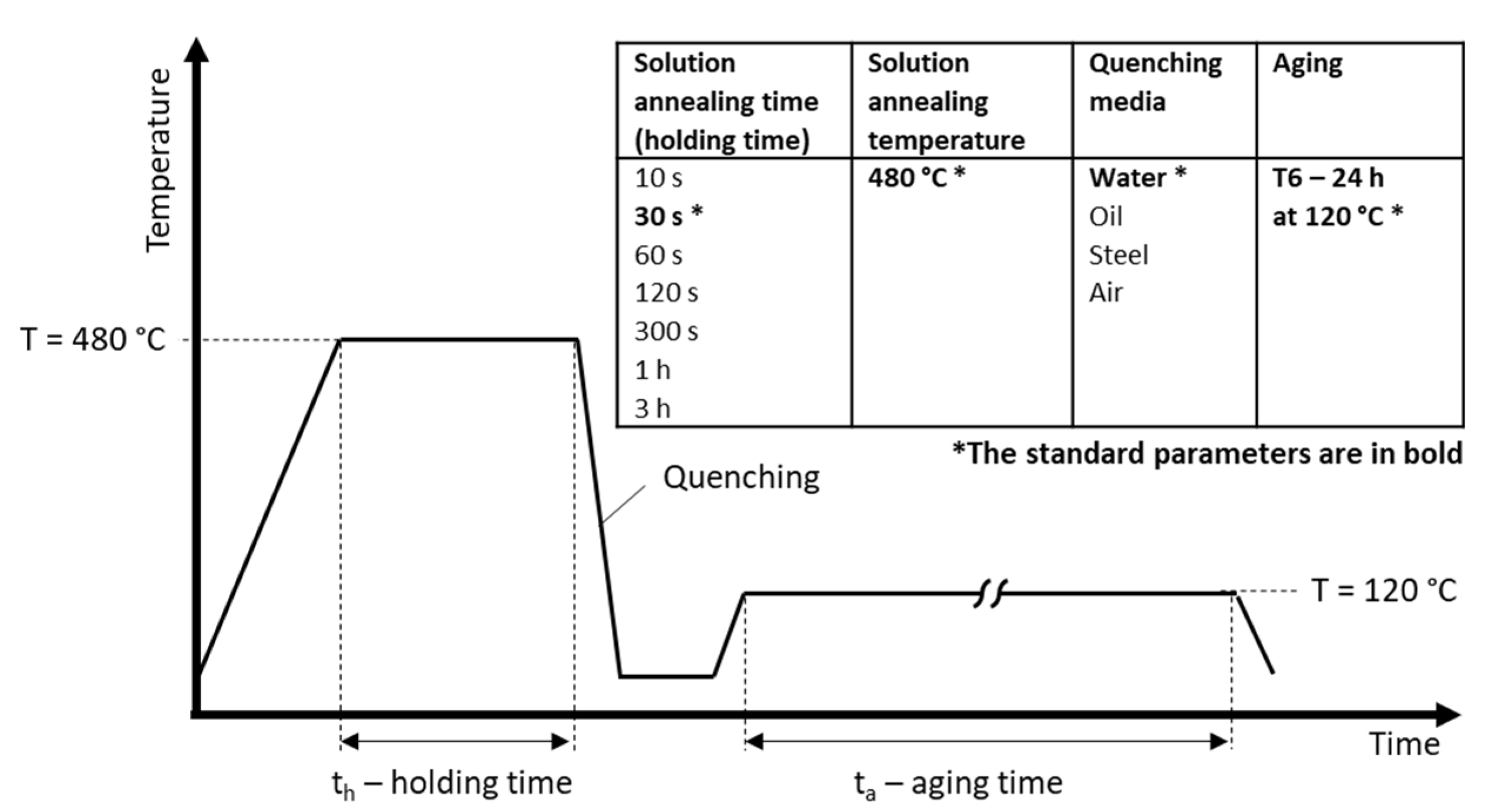

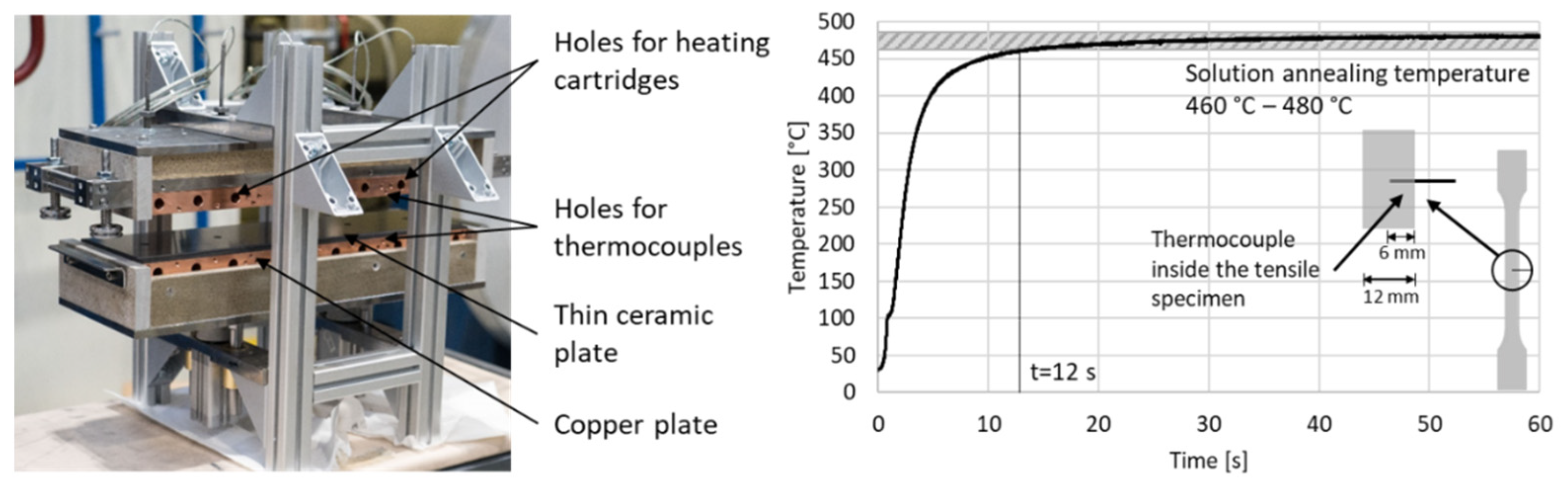

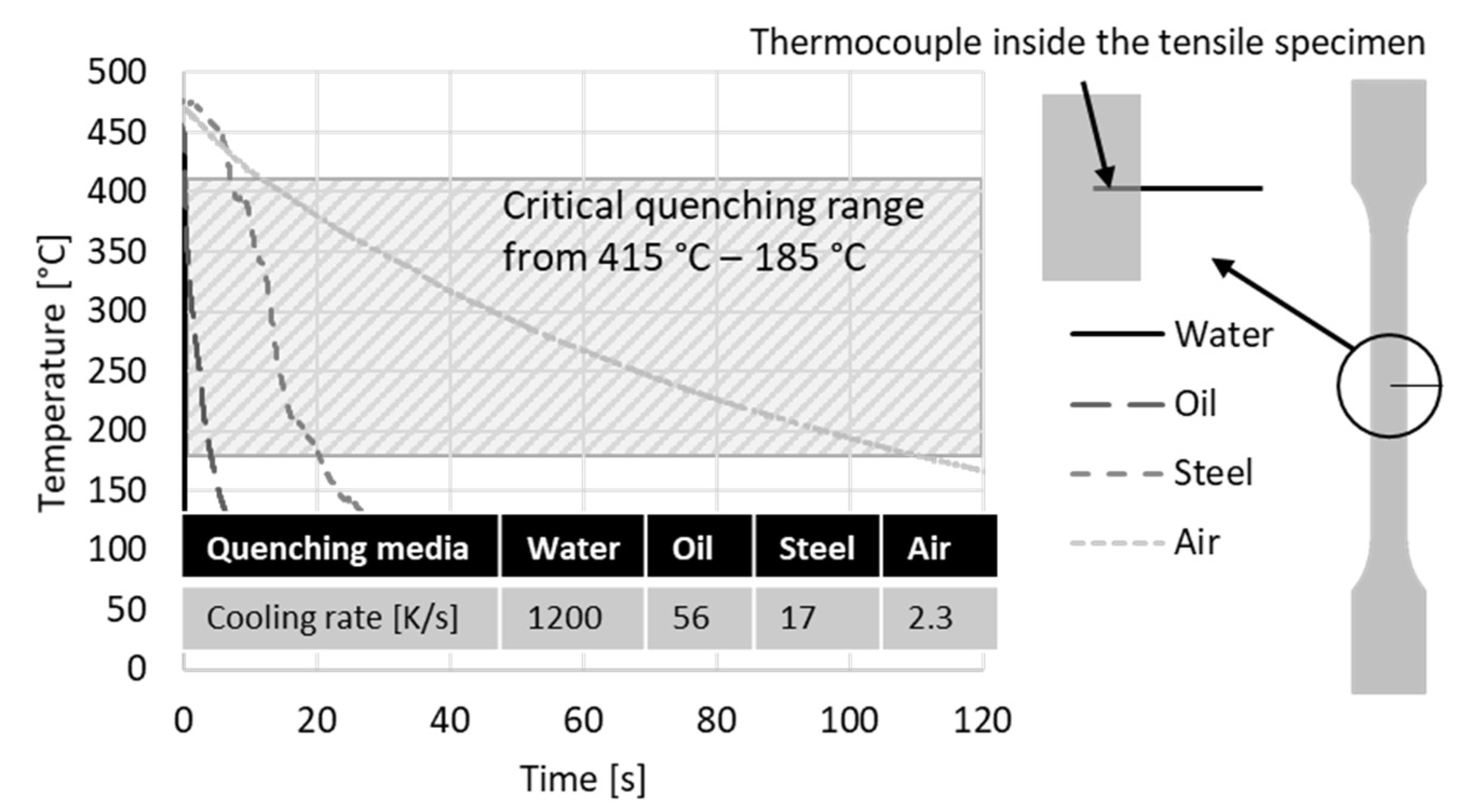

2.2. Post Weld Heat Treatment

3. Results and Discussion

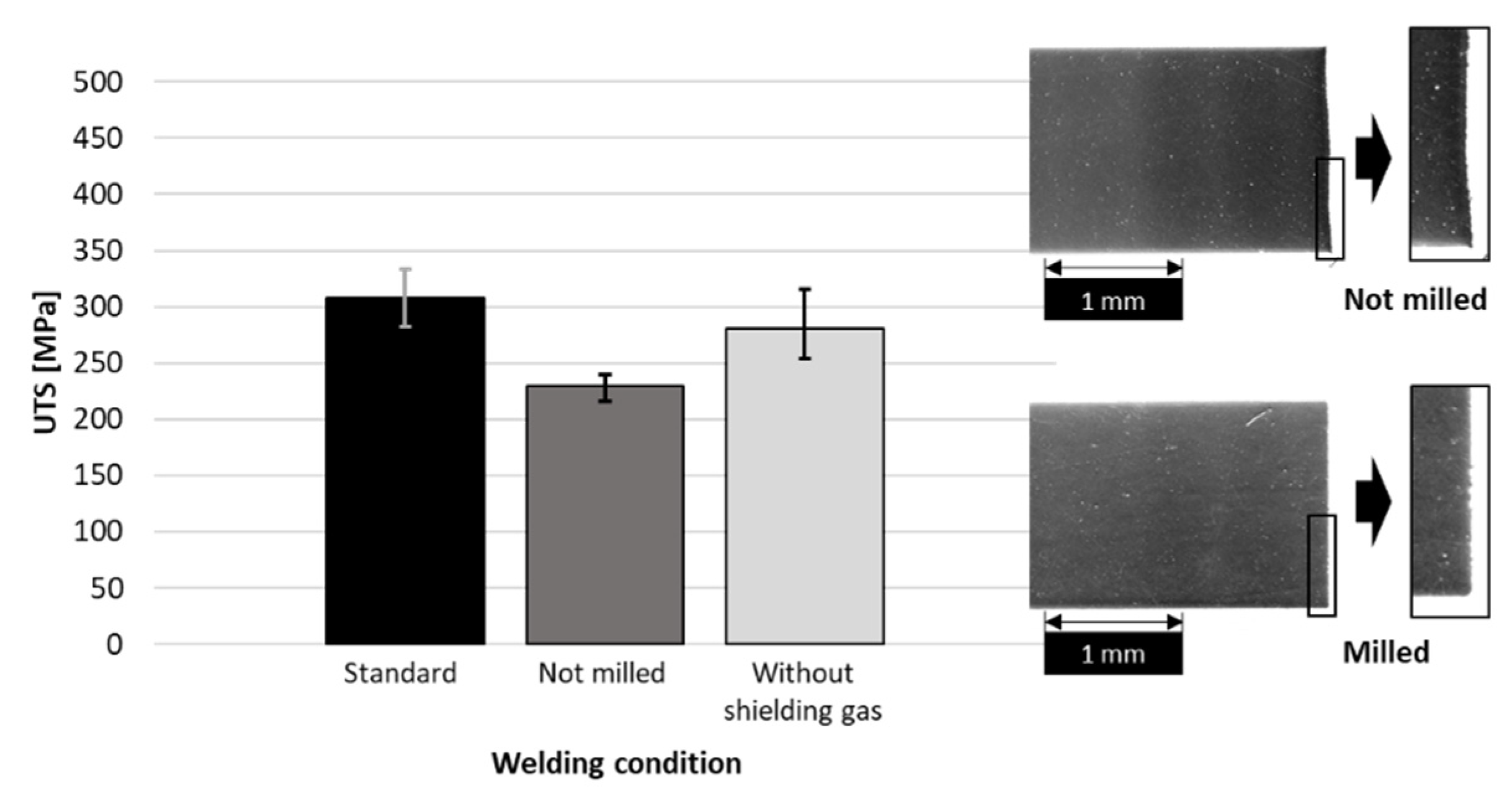

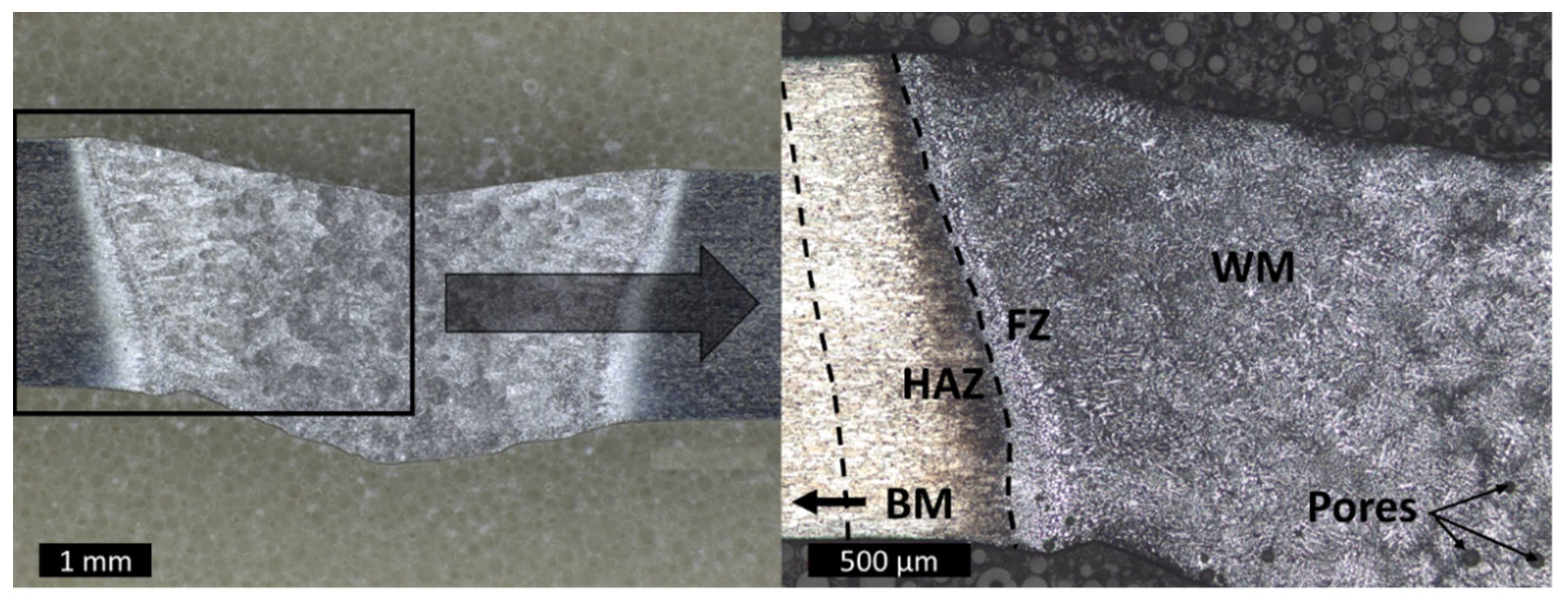

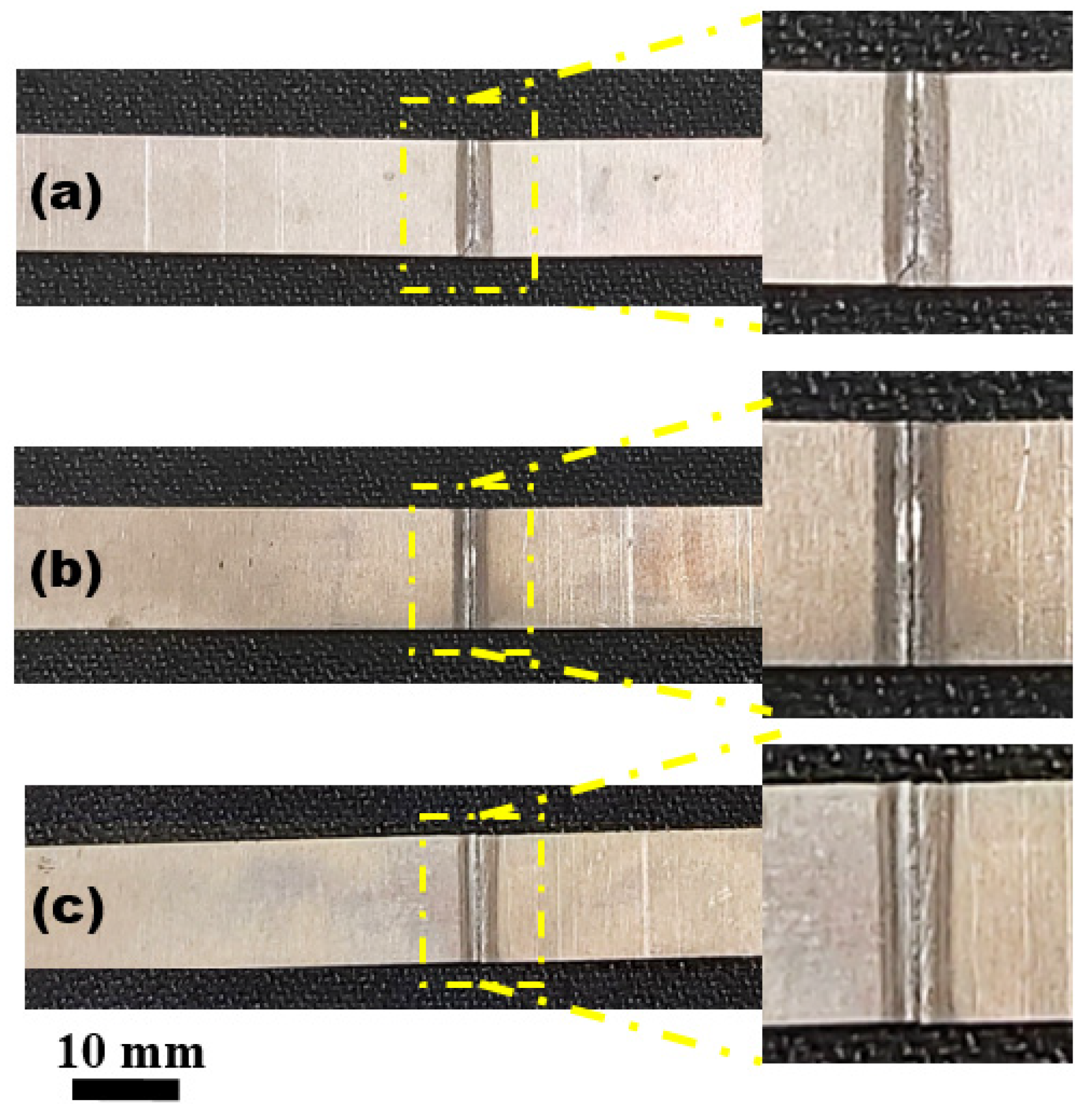

3.1. Influence of the Welding Parameters

3.2. Influence of the Post Weld Heat Treatment

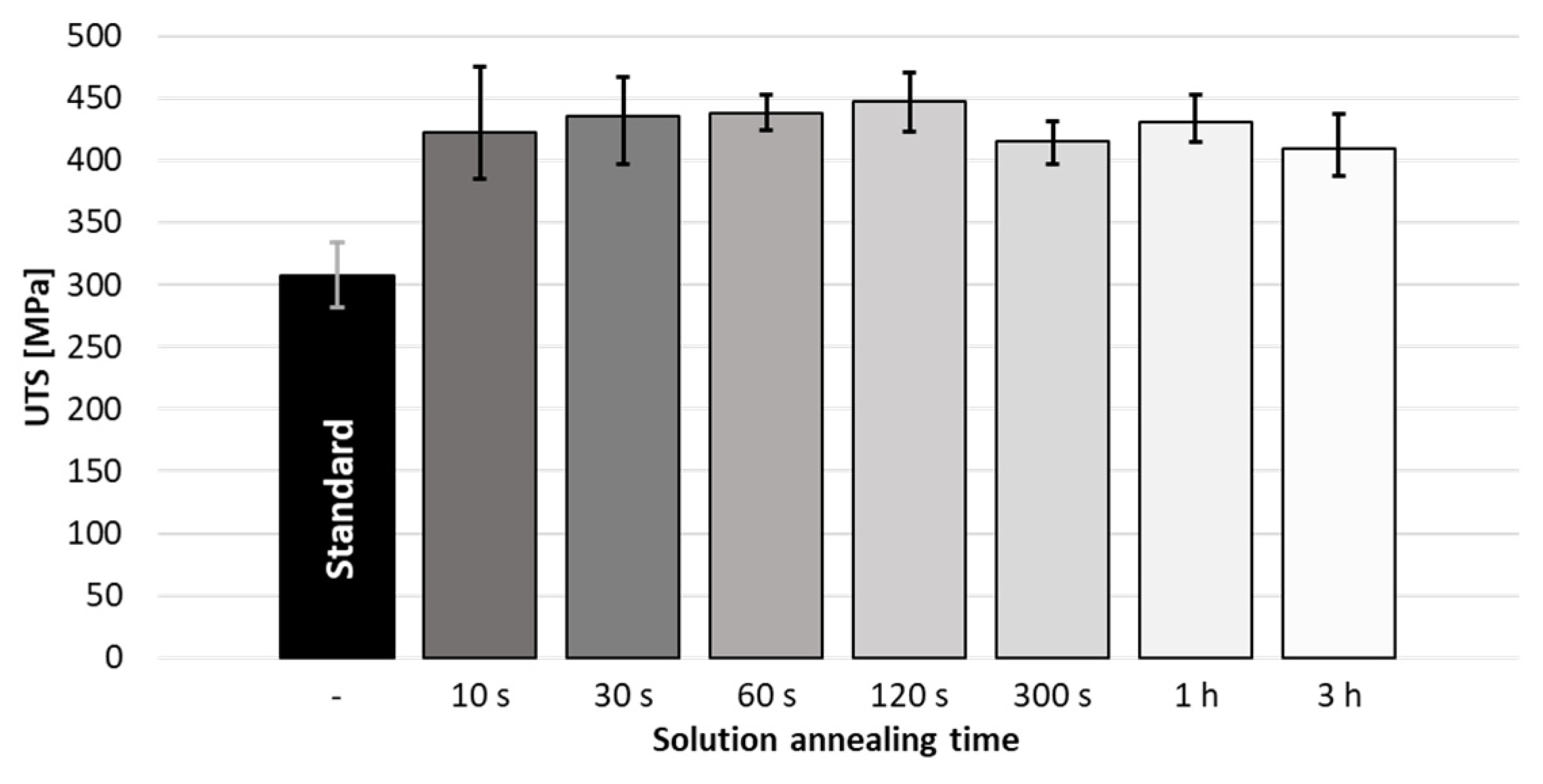

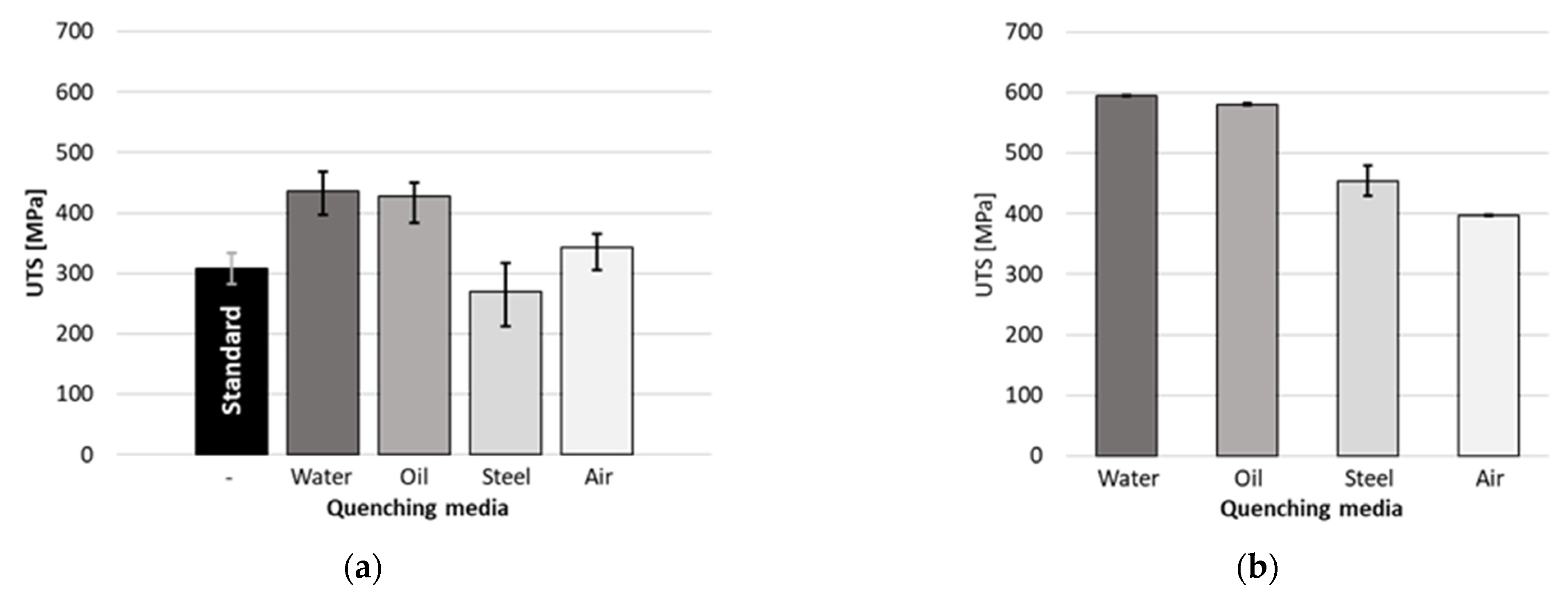

3.2.1. Mechanical Properties from Tensile Tests

3.2.2. Hardness Measurement

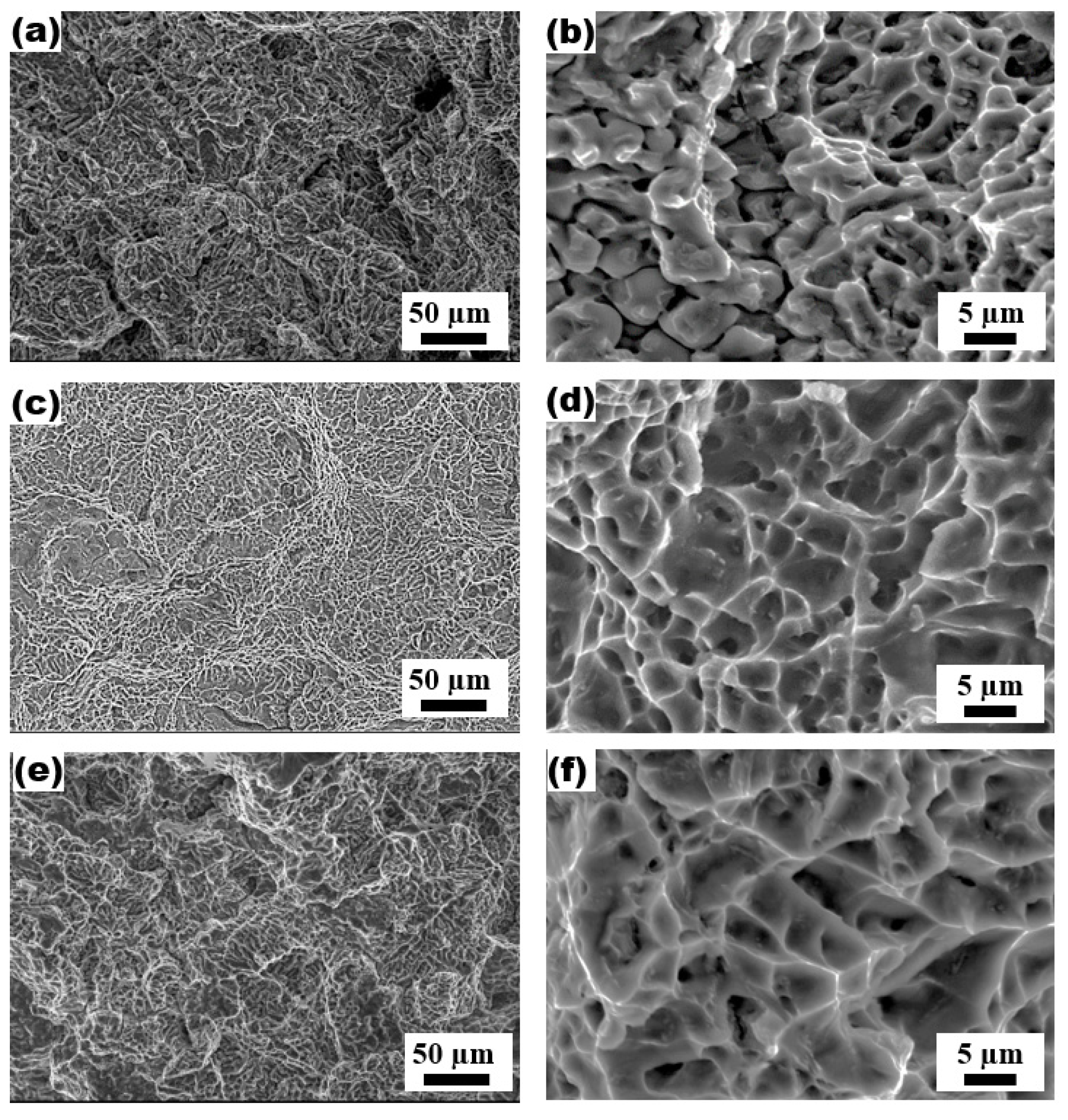

3.2.3. Fracture Surface Analysis

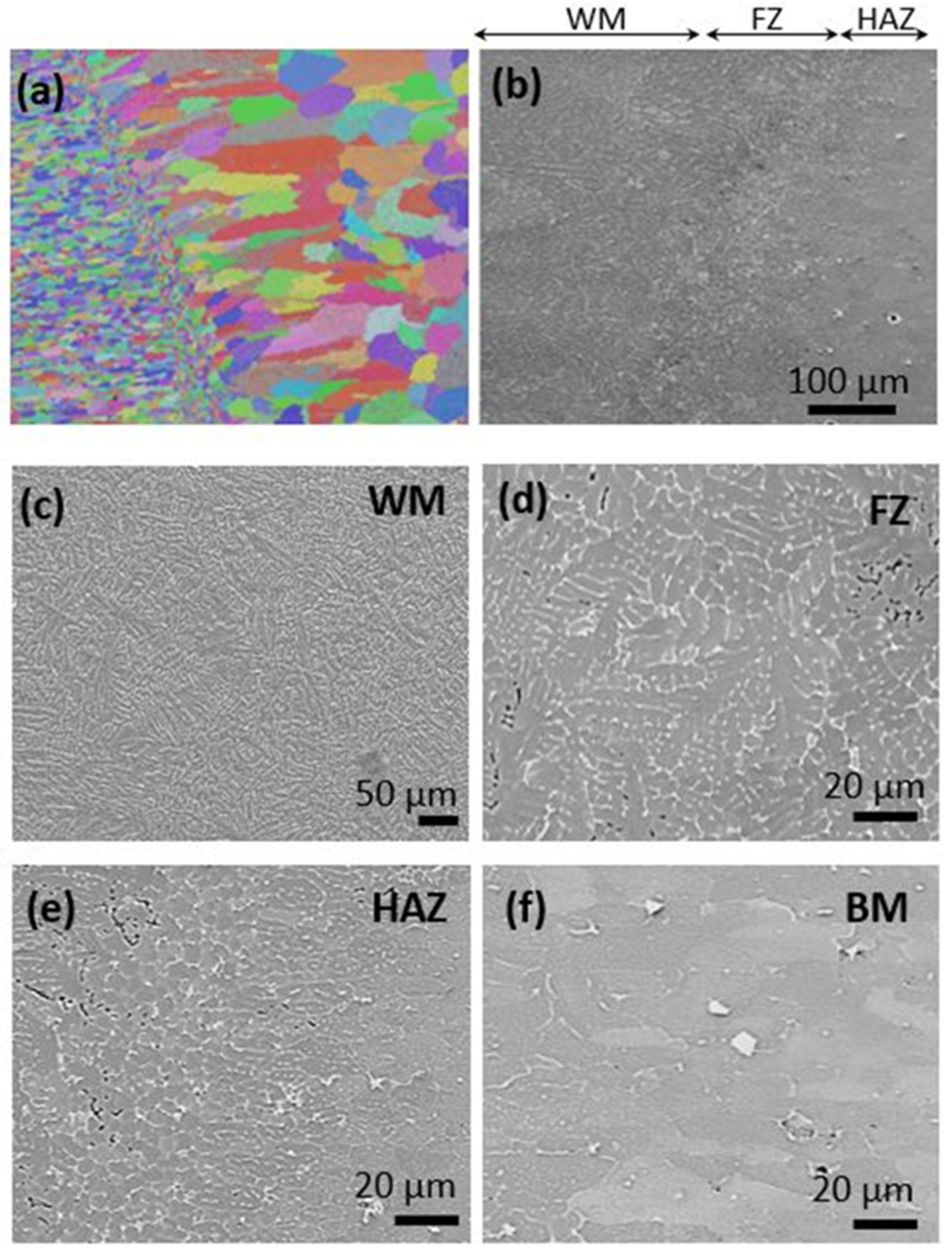

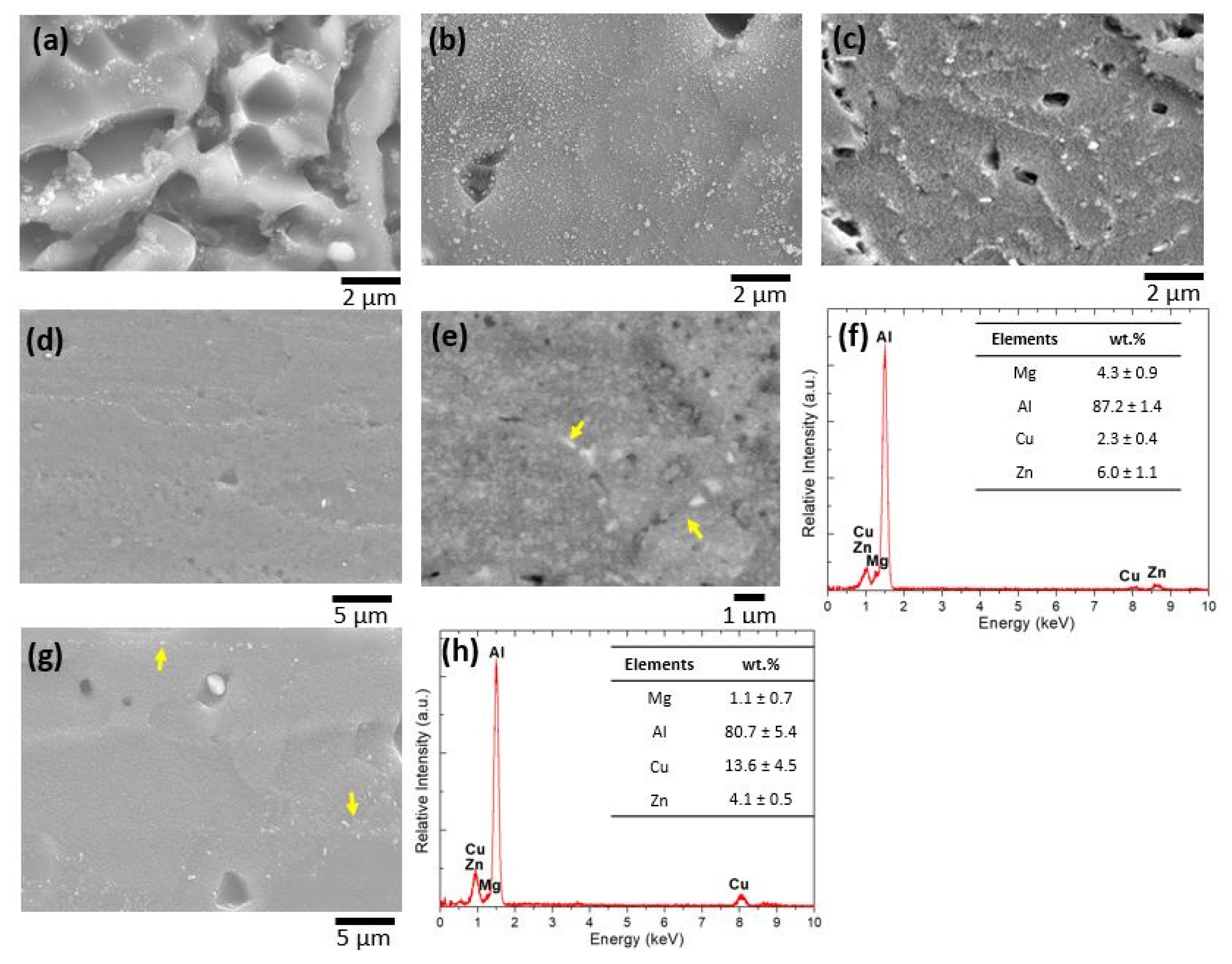

3.2.4. Microstructural Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hügel, H.; Rapp, J. Laserschweißeignung von Aluminiumwerkstoffen für Anwendungen im Leichtbau; Vieweg+Teubner Verlag: Wiesbaden, Germany, 1996; ISBN 978-3-519-06226-4. [Google Scholar]

- Enz, J. Laser Beam Welding of High-Alloyed Aluminium-Zinc Alloys. Ph.D. Thesis, Technische Universität, Hamburg-Harburg, Germany, 2017. [Google Scholar]

- Enz, J.; Riekehr, S.; Ventzke, V.; Kashaev, N. Laser Weldability of Different Al-Zn Alloys and its Improvement. MSF 2015, 828, 389–394. [Google Scholar] [CrossRef] [Green Version]

- Verhaeghe, I.G. Achieving Aerospace Standard Porosity Levels When Welding Thin and Thick-Section Aluminium Using Fibre-Delivered Lasers: Executive Summary. Eng.D. Thesis, University of Warwick, Coventry, UK, 2008. [Google Scholar]

- Rajakumar, S.; Muralidharan, C.; Balasubramanian, V. Influence of friction stir welding process and tool parameters on strength properties of AA7075-T6 aluminium alloy joints. Mater. Des. 2011, 32, 535–549. [Google Scholar] [CrossRef]

- Enz, J.; Riekehr, S.; Ventzke, V.; Huber, N.; Kashaev, N. Fibre laser welding of high-alloyed Al-Zn-Mg-Cu alloys. J. Mater. Processing Technol. 2016, 237, 155–162. [Google Scholar] [CrossRef]

- Liu, C.; Northwood, D.O.; Bhole, S.D. Tensile fracture behavior in CO2 laser beam welds of 7075-T6 aluminum alloy. Mater. Des. 2004, 25, 573–577. [Google Scholar] [CrossRef]

- Holzer, M.; Zapf, K.; Kroberger, S.; Henkelmann, M.; Mann, V.; Hofmann, K.; Roth, S.; Schmidt, M. Influence of Dual Beam on Process Stability in Laser Beam Welding of High Strength Aluminum Alloy AA 7075. In Proceedings of the Lasers in Manufacturing Conference 2017, Munich, Germany, 26–29 June 2017. [Google Scholar]

- Enz, J.; Riekehr, S.; Ventzke, V.; Sotirov, N.; Kashaev, N. Laser Welding of High-strength Aluminium Alloys for the Sheet Metal Forming Process. Procedia CIRP 2014, 18, 203–208. [Google Scholar] [CrossRef] [Green Version]

- Bayazid, S.M.; Farhangi, H.; Asgharzadeh, H.; Radan, L.; Ghahramani, A.; Mirhaji, A. Effect of cyclic solution treatment on microstructure and mechanical properties of friction stir welded 7075 Al alloy. Mater. Sci. Eng. A 2016, 649, 293–300. [Google Scholar] [CrossRef]

- Sajadifar, S.V.; Moeini, G.; Scharifi, E.; Lauhoff, C.; Böhm, S.; Niendorf, T. On the Effect of Quenching on Postweld Heat Treatment of Friction-Stir-Welded Aluminum 7075 Alloy. J. Mater. Eng. Perform. 2019, 28, 5255–5265. [Google Scholar] [CrossRef]

- Sokoluk, M.; Cao, C.; Pan, S.; Li, X. Nanoparticle-enabled phase control for arc welding of unweldable aluminum alloy 7075. Nat. Commun. 2019, 10, 98. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Illia, H.; Viacheslav, B.; Dmytro, R.; Florian, N. Manufacturing of Tailored Tubes with a Process Integrated Heat Treatment. In AIP Conference Proceedings, Proceedings of the 20th International ESAFORM Conference on Material Forming, Dublin, Ireland, 26–28 April 2017; AIP Publishing LLC: Dublin, Ireland, 2017. [Google Scholar]

- Nikanorov, A.; Baake, E.; Neumeyer, J. Numerical Simulation and Investigation of High Frequency Tube Welding Process. AMM 2014, 698, 245–250. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Deutsches Institut für Normung—DIN. Zerstörende Prüfung von Schweißverbindungen an Metallischen Werkstoffen—Querzugversuch; DIN EN ISO 4136; Beuth Verlag GmbH: Berlin, Germany, 2013. [Google Scholar]

- Günzel, J.; Hauβ, J.; Groche, P. Temperature-controlled tools for multi-stage sheet metal forming of high-strength aluminium alloys. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1157, 12086. [Google Scholar] [CrossRef]

- Tekeli, S.; Simsek, I.; Simsek, D.; Ozyurek, D. Effects of Different Solid Solution Temperatures on Microstructure and Mechanical Properties of the AA7075 Alloy After T6 Heat Treatment. High Temp. Mater. Processes 2019, 38, 892–896. [Google Scholar] [CrossRef]

- DIN EN ISO 13919-2; Welding—Electron and Laser Beam Welded Joints—Guidance on Quality Levels for Imperfections—Part 2: Aluminium and Its Weldable Alloys. International Organization for Standardization: Geneva, Switzerland, 2001.

- Zou, X.-L.; Yan, H.; Chen, X.-H. Evolution of second phases and mechanical properties of 7075 Al alloy processed by solution heat treatment. Trans. Nonferrous Met. Soc. China 2017, 27, 2146–2155. [Google Scholar] [CrossRef]

- Deutsches Institut für Normung—DIN. Wärmebehandlung von Aluminium-Knetlegierungen; DIN 29850; Beuth Verlag GmbH: Berlin, Germany, 1989. [Google Scholar]

- Kerstens, N. Nd:YAG Laser Welding of AA7075 High Strength Aluminium; Delft University of Technology: Delft, The Netherlands, 2002. [Google Scholar]

- Liu, S.; Zhong, Q.; Zhang, Y.; Liu, W.; Zhang, X.; Deng, Y. Investigation of quench sensitivity of high strength Al–Zn–Mg–Cu alloys by time–temperature-properties diagrams. Mater. Des. 2010, 31, 3116–3120. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Nie, Z.; Huang, H.; Sun, J. Microstructure and mechanical properties of a new Al–Zn–Mg–Cu alloy joints welded by laser beam. Mater. Des. 2015, 83, 451–458. [Google Scholar] [CrossRef]

- Zhou, M.; Lin, Y.C.; Deng, J.; Jiang, Y.-Q. Hot tensile deformation behaviors and constitutive model of an Al–Zn–Mg–Cu alloy. Mater. Des. 2014, 59, 141–150. [Google Scholar] [CrossRef]

- Ashby, M.F. Mechanisms of Deformation and Fracture. In Advances in Applied Mechanics; Elsevier: Amsterdam, The Netherlands, 1983; Volume 23, pp. 117–177. ISBN 9780120020232. [Google Scholar]

- Hassan, K.A.A.; Norman, A.F.; Price, D.A.; Prangnell, P.B. Stability of nugget zone grain structures in high strength Al-alloy friction stir welds during solution treatment. Acta Mater. 2003, 51, 1923–1936. [Google Scholar] [CrossRef]

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr |

|---|---|---|---|---|---|---|---|---|---|

| Weight [%] | 0.08 | 0.12 | 1.6 | 0.04 | 2.7 | 0.19 | 5.9 | 0.05 | 0.04 |

| Laser | Laser Power | Laser Spot Diameter | Beam Parameter Product | Defocusation | Welding Angle | Shielding Gas |

|---|---|---|---|---|---|---|

| Ytterbium fiber laser | 3.0 kW | 400 µm (in focus) | 8.0 mm × mrad | +14 mm | 6° | Argon |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suckow, T.; Völkers, S.; Bütev Öcal, E.; Grass, M.; Böhm, S.; Groche, P. Effect of Shortened Post Weld Heat Treatment on the Laser Welded AA7075 Alloy. Metals 2022, 12, 393. https://doi.org/10.3390/met12030393

Suckow T, Völkers S, Bütev Öcal E, Grass M, Böhm S, Groche P. Effect of Shortened Post Weld Heat Treatment on the Laser Welded AA7075 Alloy. Metals. 2022; 12(3):393. https://doi.org/10.3390/met12030393

Chicago/Turabian StyleSuckow, Timon, Stephan Völkers, Ezgi Bütev Öcal, Markus Grass, Stefan Böhm, and Peter Groche. 2022. "Effect of Shortened Post Weld Heat Treatment on the Laser Welded AA7075 Alloy" Metals 12, no. 3: 393. https://doi.org/10.3390/met12030393

APA StyleSuckow, T., Völkers, S., Bütev Öcal, E., Grass, M., Böhm, S., & Groche, P. (2022). Effect of Shortened Post Weld Heat Treatment on the Laser Welded AA7075 Alloy. Metals, 12(3), 393. https://doi.org/10.3390/met12030393