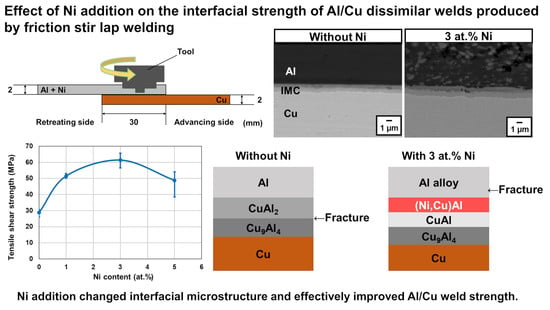

Effect of Ni Addition on the Interfacial Strength of Al/Cu Dissimilar Welds Produced by Friction Stir Lap Welding

Abstract

:1. Introduction

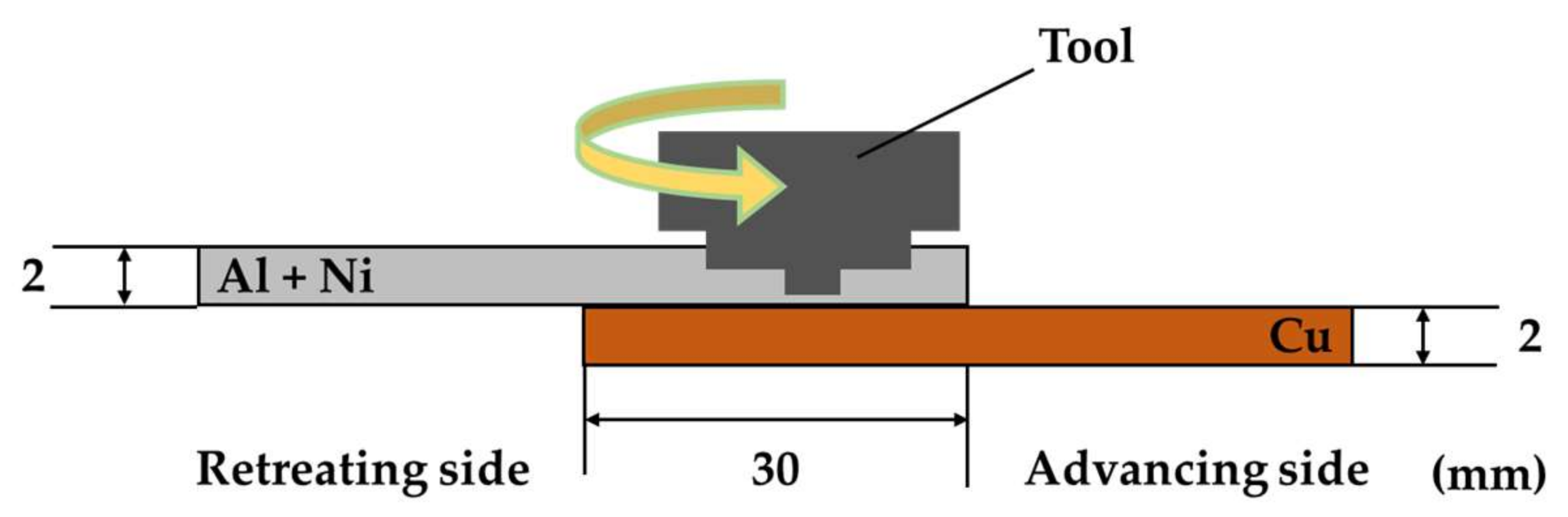

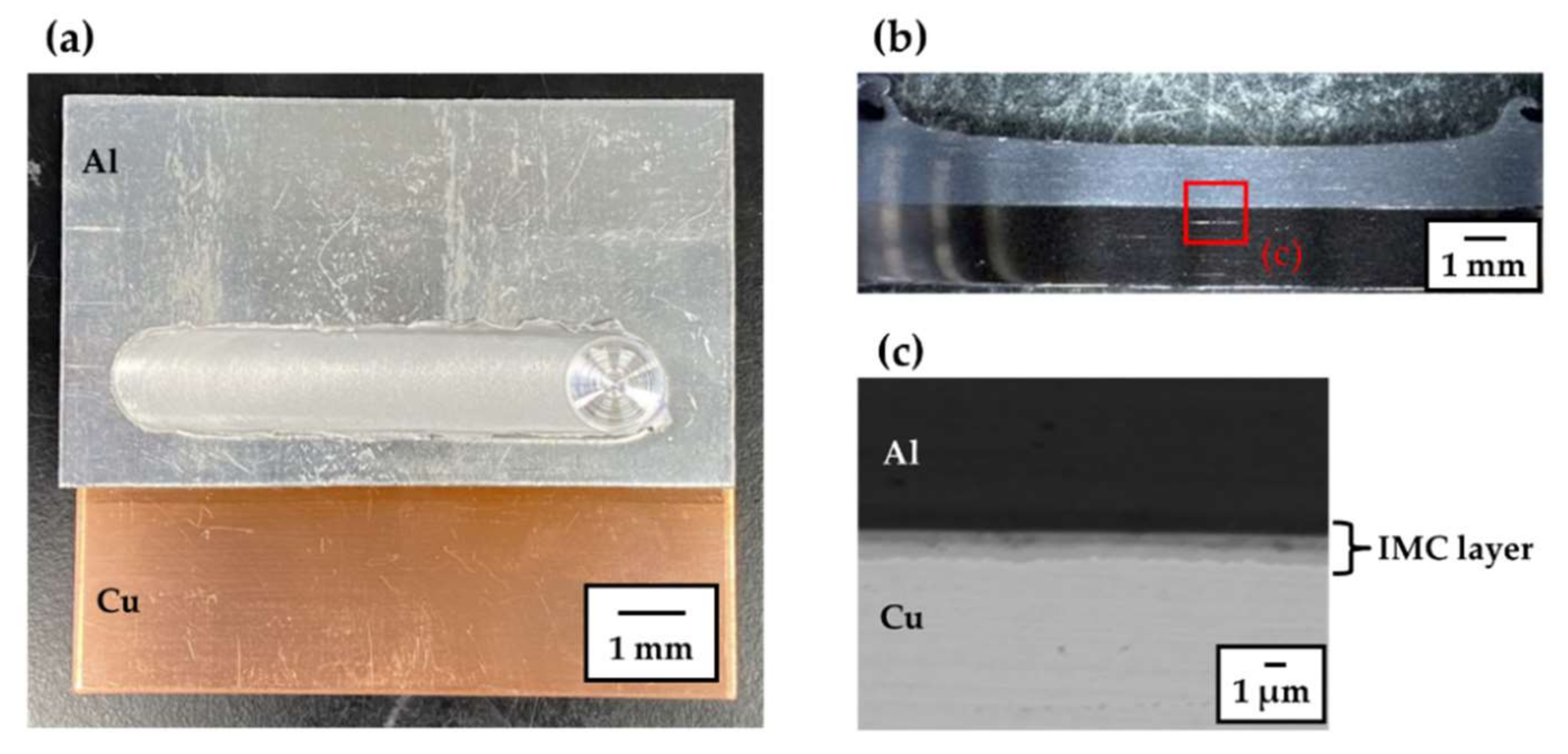

2. Materials and Methods

2.1. Materials

2.2. FSW

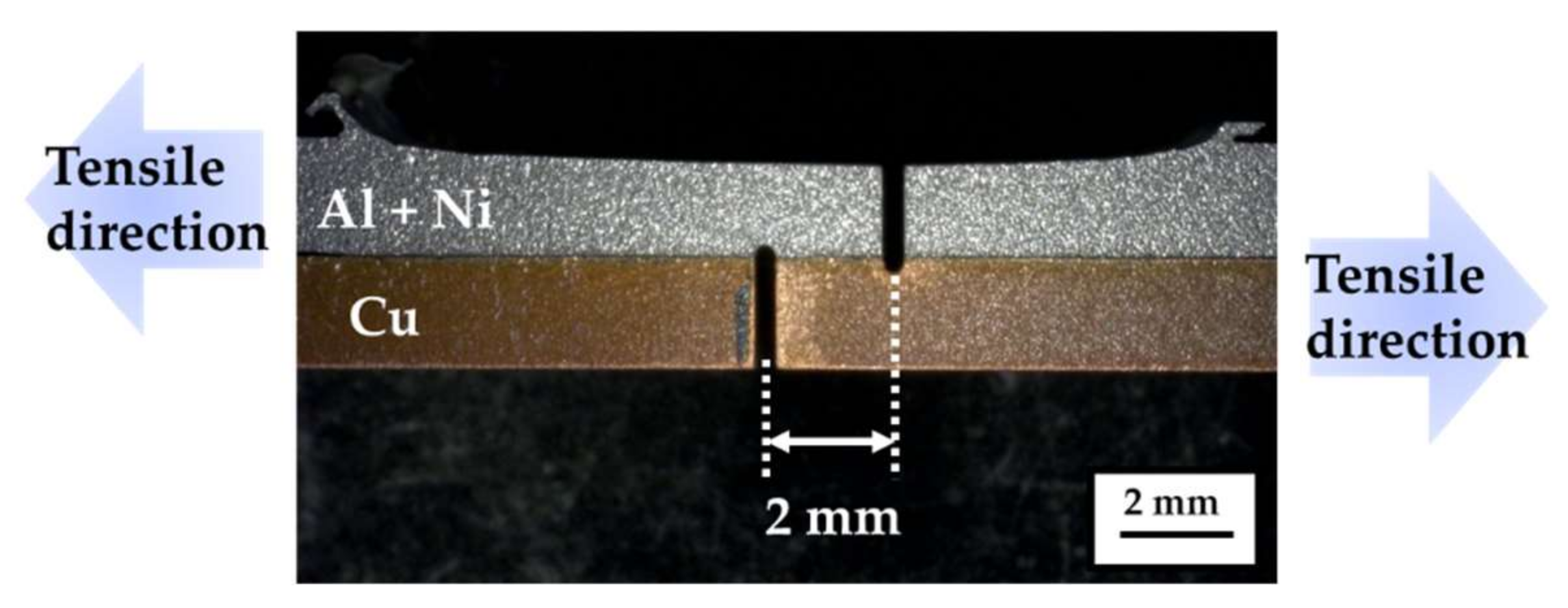

2.3. Tensile Shear Test

2.4. Microstructure Examinations

3. Results and Discussion

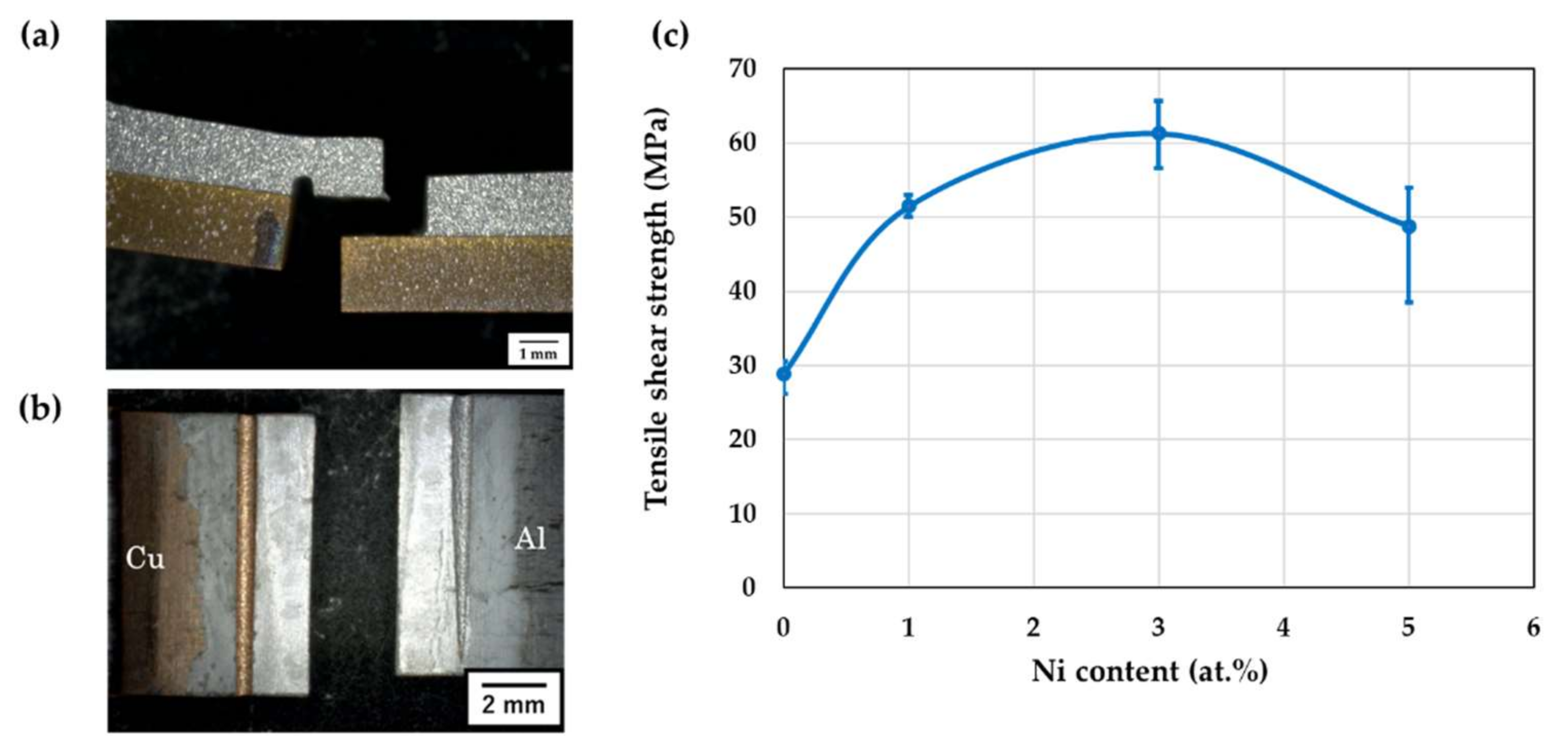

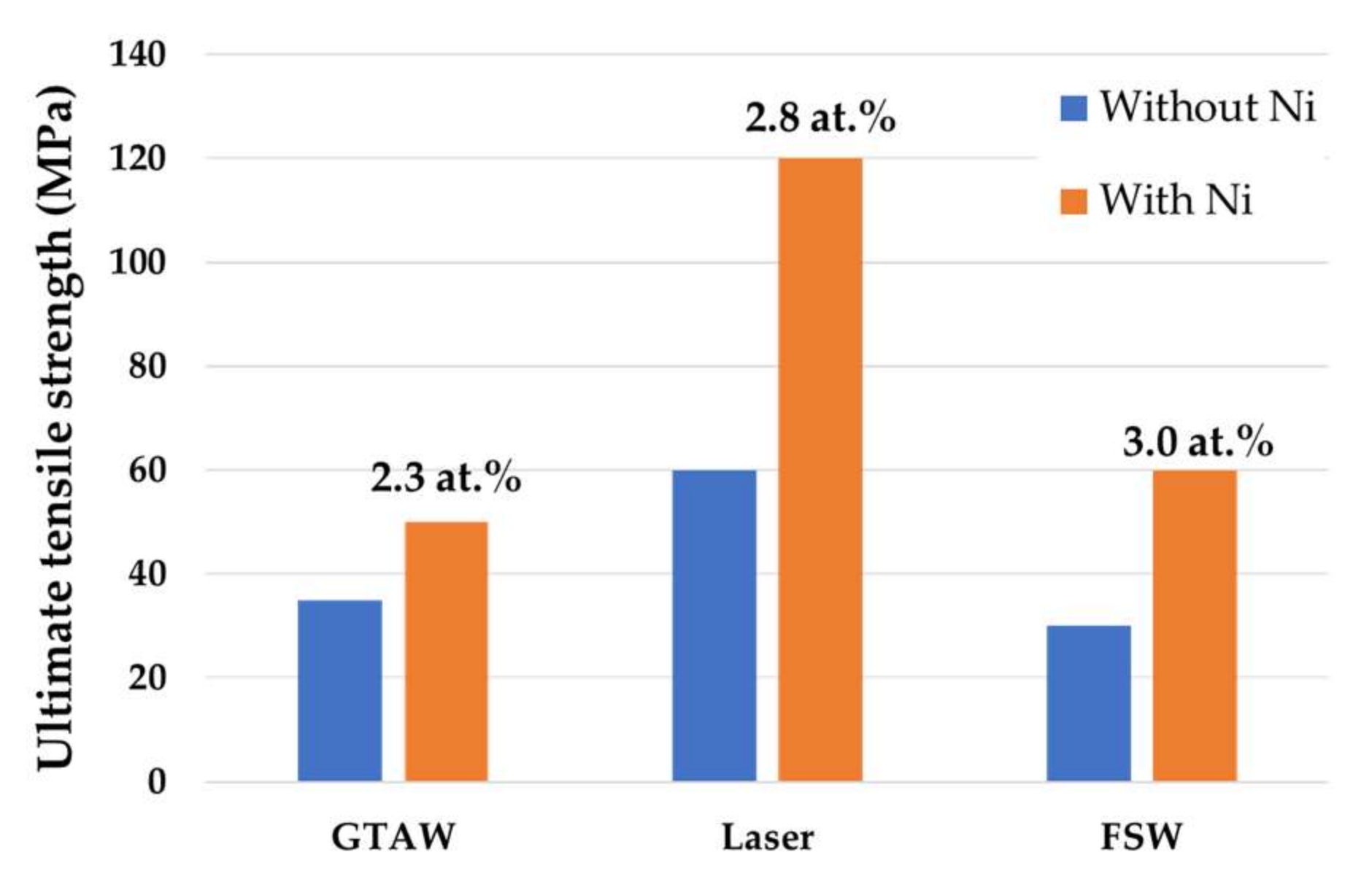

3.1. Weldability and Mechanical Strength of the Joint

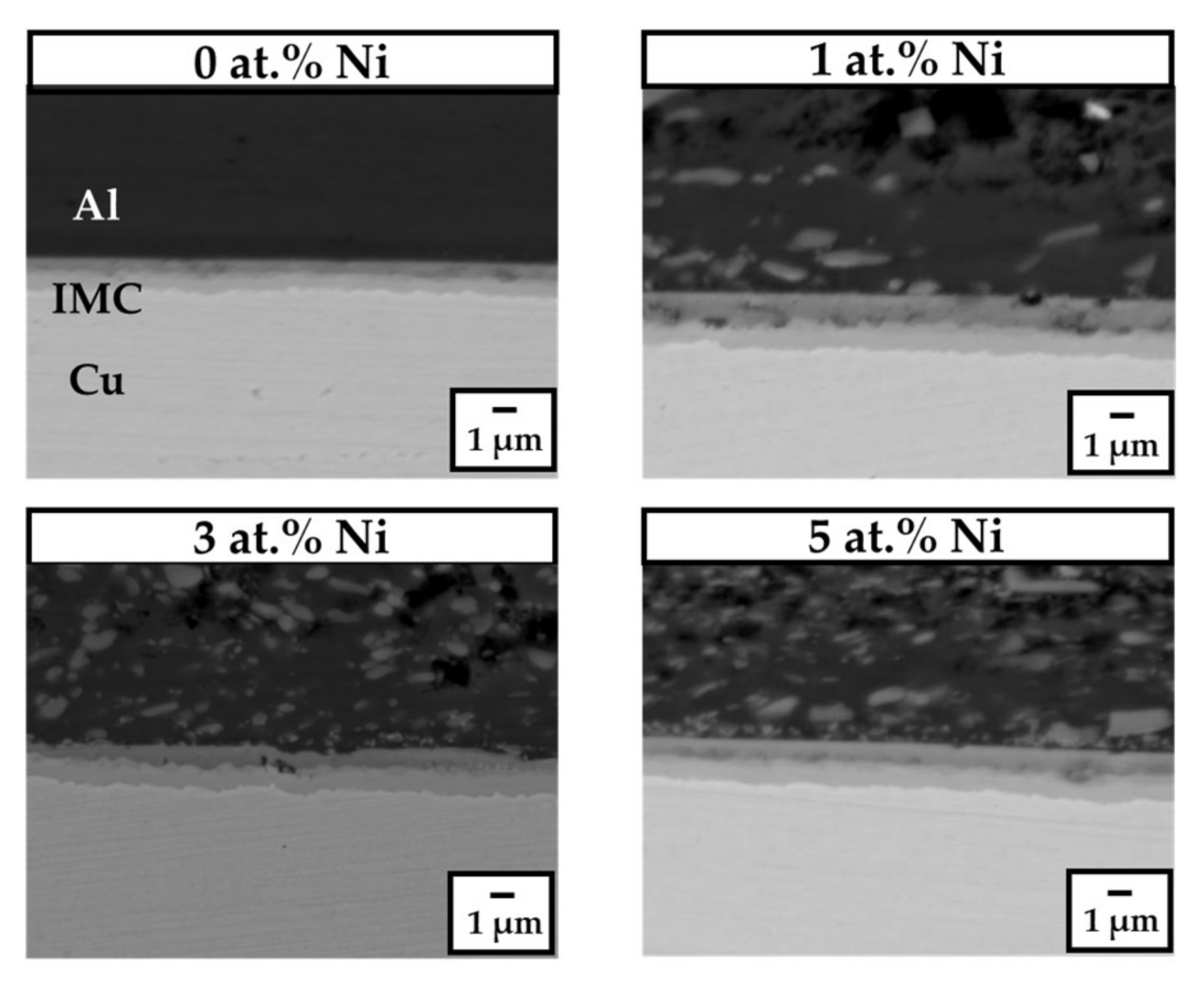

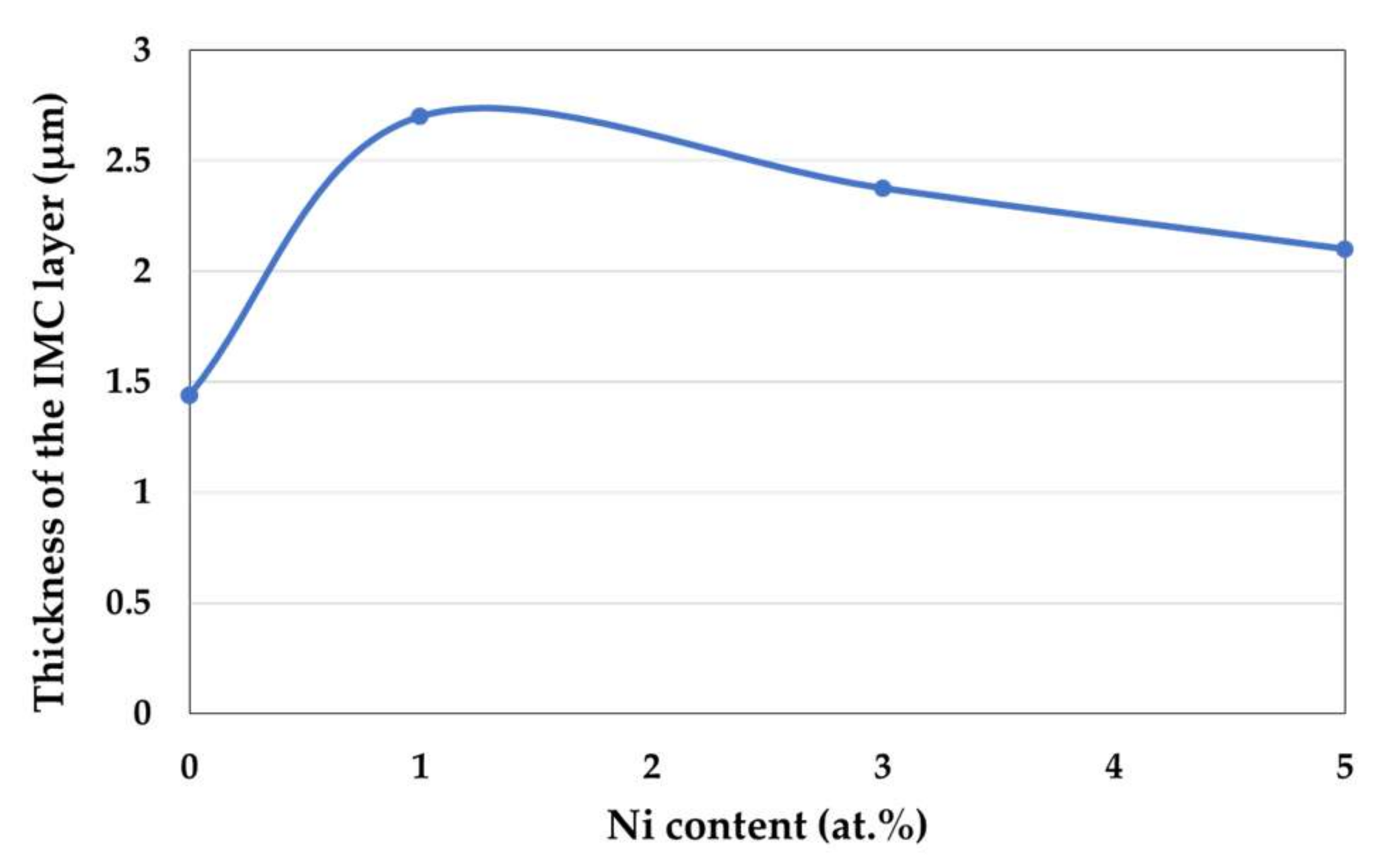

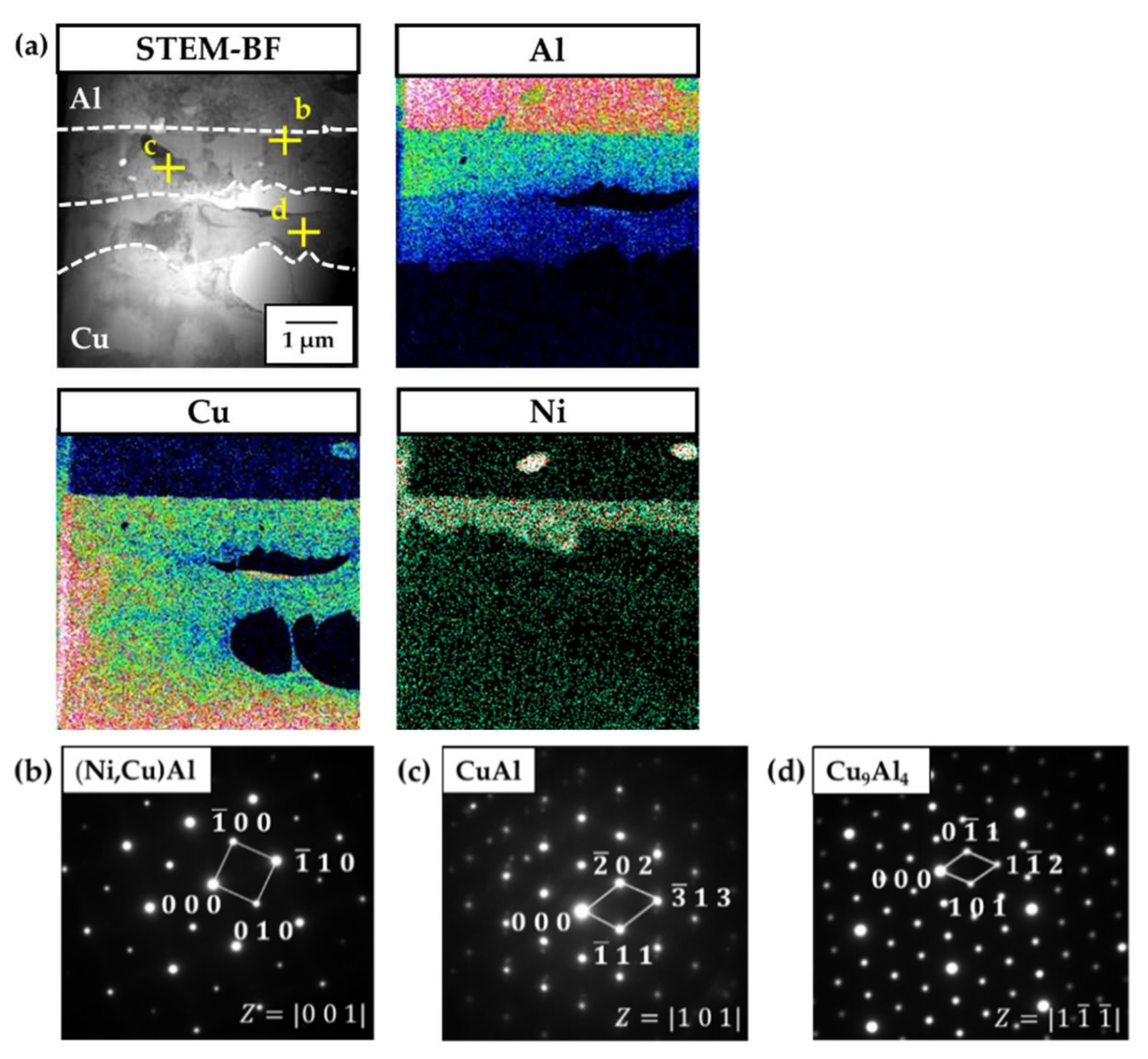

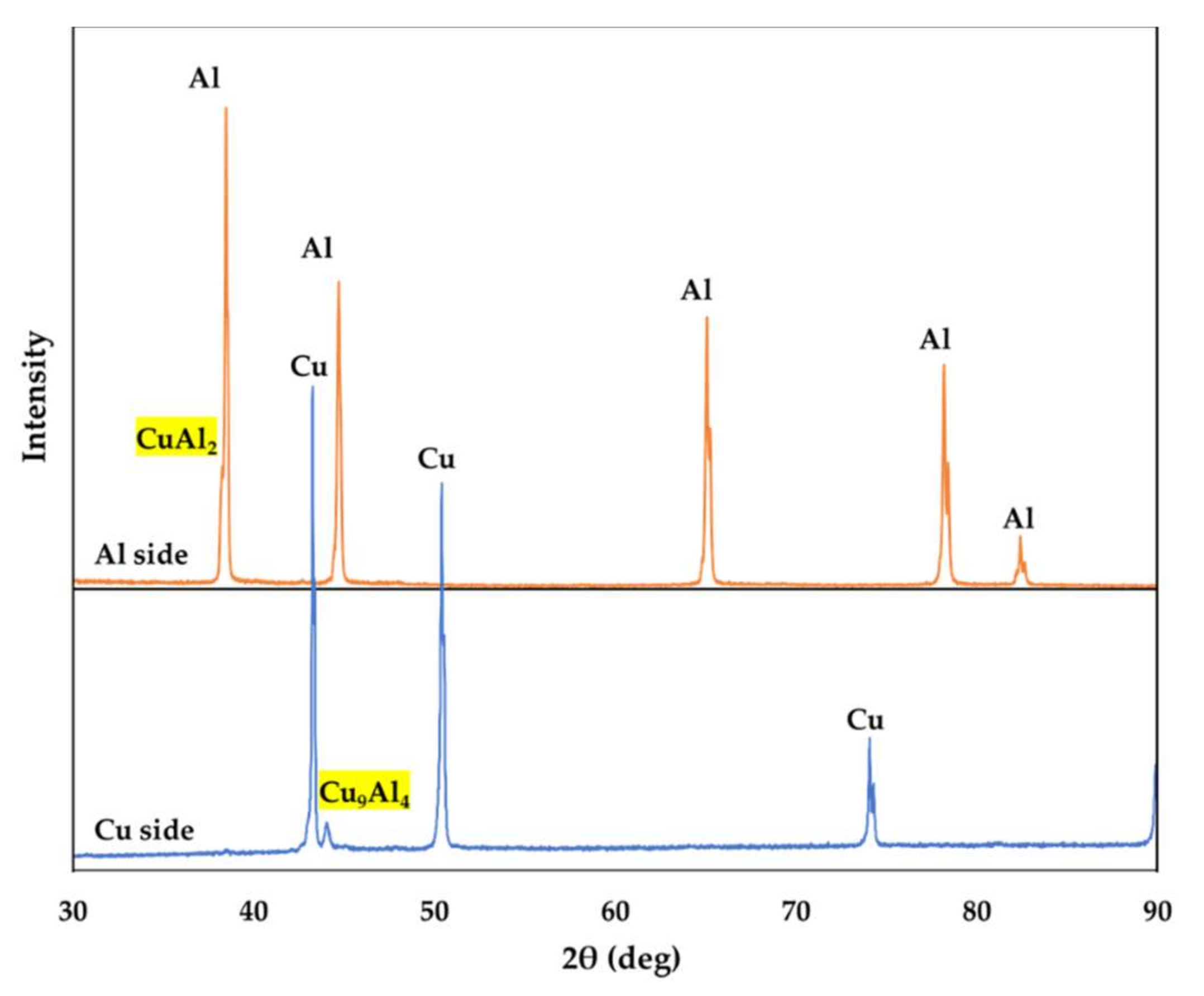

3.2. Interfacial Microstructure

3.3. Examination of Fracture Location

3.4. Mechanism by Which the Addition of Ni Improved the Weld Strength

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, S.; Zhou, B.; Zhang, X.; Sun, T.; Li, G.; Cui, J. Mechanical properties and interfacial microstructures of magnetic pulse welding joints with aluminum to zinc-coated steel. Mater. Sci. Eng. A 2020, 788, 139425. [Google Scholar] [CrossRef]

- Jiang, H.; Liao, Y.; Jing, L.; Gao, S.; Li, G.; Cui, J. Mechanical properties and corrosion behavior of galvanized steel/Al dissimilar joints. Arch. Civ. Mech. Eng. 2021, 21, 168. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, H.; Peng, Y. Metallurgical reaction and joining phenomena in friction welded Al/Fe joints. Int. J. Adv. Manuf. Technol. 2020, 107, 1713–1723. [Google Scholar] [CrossRef]

- Abbasi, M.; Karimi Taheri, A.; Salehi, M.T. Growth rate of intermetallic compounds in Al/Cu bimetal produced by cold roll welding process. J. Alloys Compd. 2001, 319, 233–241. [Google Scholar] [CrossRef]

- Genevois, C.; Girard, M.; Huneau, B.; Sauvage, X.; Racineux, G. Interfacial reaction during friction stir welding of Al and Cu. Metall. Mater. Trans. A 2011, 42, 2290–2295. [Google Scholar] [CrossRef]

- Carlone, P.; Astarita, A.; Palazzo, G.S.; Paradiso, V.; Squillace, A. Microstructural aspects in Al-Cu dissimilar joining by FSW. Int. J. Adv. Manuf. Technol. 2015, 79, 1109–1116. [Google Scholar] [CrossRef]

- Abdollash-Zadeh, A.; Saeid, T.; Sazgari, B. Microstructural and mechanical properties of friction stir welded aluminum/copper lap joints. J. Alloys Compd. 2008, 460, 535–538. [Google Scholar] [CrossRef]

- Chen, J.; Lai, Y.S.; Wang, Y.W.; Kao, C.R. Investigation of growth behavior of Al-Cu intermetallic compounds in Cu wire bonding. Microelectron. Reliab. 2011, 51, 125–129. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.L.; Ma, Z.Y. Effect of interfacial microstructure evolution on mechanical properties and fracture behavior of friction stir-welded Al-Cu joints. Metall. Mater. Trans. A 2015, 46, 3091–3103. [Google Scholar] [CrossRef]

- Dimatteo, V.; Ascari, A.; Fortunato, A. Continuous laser welding with spatial beam oscillation of dissimilar thin sheet materials (Al-Cu and Cu-Al): Process optimization and characterization. J. Manuf. Process. 2019, 44, 158–165. [Google Scholar] [CrossRef]

- Yang, J.W.; Cao, B.; He, X.C.; Luo, H.S. Microstructure evolution and mechanical properties of Cu-Al joints by ultrasonic welding. Sci. Technol. Weld. Join. 2014, 19, 500–504. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, G.; Shi, Y.; Zhu, M.; Yang, F. Microstructures and mechanical behavior of aluminum-copper lap joints. Mater. Sci. Eng. A 2017, 705, 105–113. [Google Scholar] [CrossRef]

- Zare, M.; Pouranvari, M. Metallurgical joining of aluminium and copper using resistance spot welding: Microstructure and mechanical properties. Sci. Technol. Weld. Join. 2021, 26, 461–469. [Google Scholar] [CrossRef]

- Tan, C.W.; Jiang, Z.G.; Li, L.Q.; Chen, Y.B.; Chen, X.Y. Microstructural evolution and mechanical properties of dissimilar Al–Cu joints produced by friction stir welding. Mater. Des. 2013, 51, 466–473. [Google Scholar] [CrossRef]

- Heideman, R.; Johnson, C.; Kou, S. Metallurgical analysis of Al/Cu friction stir spot welding. Sci. Technol. Weld. Join. 2010, 15, 597–604. [Google Scholar] [CrossRef]

- Bergmann, J.P.; Petzoldt, F.; Schürer, R.; Schneider, S. Solid-state welding of aluminum to copper—Case studies. Weld. World 2013, 57, 541–550. [Google Scholar] [CrossRef]

- Shiraly, M.; Shamanian, M.; Toroghinejad, M.R.; Jazani, M.A. Effect of tool rotation rate on microstructure and mechanical behavior of friction stir spot-welded Al/Cu composite. J. Mater. Eng. Perform. 2014, 23, 413–420. [Google Scholar] [CrossRef]

- Zhao, Y.Y.; Li, D.; Zhang, Y.S. Effect of welding energy on interface zone of Al-Cu ultrasonic welded joint. Sci. Technol. Weld. Join. 2013, 18, 354–360. [Google Scholar] [CrossRef]

- Wang, K.; Shang, S.L.; Wang, Y.; Vivek, A.; Daehn, G.; Liu, Z.K.; Li, J. Unveiling non-equilibrium metallurgical phases in dissimilar Al-Cu joints processed by vaporizing foil actuator welding. Mater. Des. 2020, 186, 108306. [Google Scholar] [CrossRef]

- Sahu, P.K.; Pal, S.; Pal, S.K. Al/Cu dissimilar friction stir welding with Ni, Ti, and Zn foil as the interlayer for flow control, enhancing mechanical and metallurgical properties. Metall. Mater. Trans. A 2017, 48, 3300–3317. [Google Scholar] [CrossRef]

- Balasundaram, R.; Patel, V.K.; Bhole, S.D.; Chen, D.L. Effect of zinc interlayer on ultrasonic spot welded aluminum-to-copper joints. Mater. Sci. Eng. A 2014, 607, 277–286. [Google Scholar] [CrossRef]

- Zhou, L.; Luo, L.Y.; Tan, C.W.; Li, Z.Y.; Song, X.G.; Zhao, H.Y.; Huang, Y.X.; Feng, J.C. Effect of welding speed on microstructural evolution and mechanical properties of laser welded-brazed Al/brass dissimilar joints. Opt. Laser Technol. 2018, 98, 234–246. [Google Scholar] [CrossRef]

- Zhang, M. Effects of interfacial reactions on microstructures and mechanical properties of 3003 Al/T2 Cu and 1035 Al/T2 Cu brazed joints. Crystals 2020, 10, 248. [Google Scholar] [CrossRef] [Green Version]

- Feng, J.; Songbai, X.; Wei, D. Reliability studies of Cu/Al joints brazed with Zn–Al–Ce filler metals. Mater. Des. 2012, 42, 156–163. [Google Scholar] [CrossRef]

- Xia, C.; Li, Y.; Puchkov, U.A.; Gerasimov, S.A.; Wang, J. Microstructure and phase constitution near the interface of Cu/Al vacuum brazing using Al–Si filler metal. Vacuum 2008, 82, 799–804. [Google Scholar] [CrossRef]

- Yan, F.; Xu, D.; Wu, S.C.; Sun, Q.; Wang, C.; Wang, Y. Microstructure and phase constitution near the interface of Cu/3003 torch brazing using Al-Si-La-Sr filler. J. Mech. Sci. Technol. 2012, 26, 4089–4096. [Google Scholar] [CrossRef]

- Furuya, H.S.; Sato, Y.S.; Kokawa, H.; Huang, T.; Xiao, R.S. Improvement of interfacial strength with the addition of Ni in Al/Cu dissimilar joints produced via laser brazing. Metall. Mater. Trans. A 2018, 49, 6215–6223. [Google Scholar] [CrossRef]

- Furuya, H.S.; Yabu, S.; Sato, Y.S.; Kokawa, H. Microstructural control of the interface layer for strength enhancement of dissimilar Al/Cu joints via Ni addition during TIG arc brazing. Metals 2021, 11, 491. [Google Scholar] [CrossRef]

- Hou, W.; Oheil, M.; Shen, Z.; Shen, Y.; Jahed, H.; Gerlich, A. Enhanced strength and ductility in dissimilar friction stir butt welded Al/Cu joints by addition of a cold-spray Ni interlayer. J. Manuf. Process. 2020, 60, 573–577. [Google Scholar] [CrossRef]

- Hou, W.; Shen, Z.; Huda, N.; Oheil, M.; Shen, Y.; Jahed, H.; Gerlich, A. Enhancing metallurgical and mechanical properties of friction stir butt welded joints of Al–Cu via cold sprayed Ni interlayer. Mater. Sci. Eng. A 2021, 809, 140992. [Google Scholar] [CrossRef]

- Lee, T.H.; Sim, M.S.; Joo, S.H.; Park, K.T.; Jeong, H.G.; Lee, J.H. Effect of intermetallic compound thickness on anisotropy of Al/Cu honeycomb rods fabricated by hydrostatic extrusion process. Trans. Nonferrous Met. Soc. China 2016, 26, 456–463. [Google Scholar] [CrossRef]

- Pourabbas, M.; Zadeh, A.A.; Sarvari, M.; Alanagh, F.M.; Pouranvari, M. Role of collision angle during dissimilar Al/Cu magnetic pulse welding. Sci. Technol. Weld. Join. 2020, 25, 549–555. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.L.; Ni, D.R.; Ma, Z.Y. Enhanced mechanical properties of friction stir welded dissimilar Al–Cu joint by intermetallic compounds. Mater. Sci. Eng. A 2010, 527, 5723–5727. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, G.; Jin, H.; Shi, Z.; Qiao, G. Intermetallic phase formation in diffusion-bonded Cu/Al laminates. J. Mater. Sci. 2011, 46, 2467–2473. [Google Scholar] [CrossRef]

- Jacobi, H.; Engell, H.J. Defect structure in non-stoichiometric β-(Ni,Cu)Al. Acta Metall. Mater. 1971, 19, 701–711. [Google Scholar] [CrossRef]

- Kainuma, R.; Liu, X.J.; Ohnuma, I.; Hao, S.M.; Ishida, K. Miscibility gap of B2 phase in NiAl to Cu3Al section of the Cu-Al-Ni system. Intermetallics 2005, 13, 655–661. [Google Scholar] [CrossRef]

- Pan, L.; Li, P.; Hao, X.; Zhou, J.; Dong, H. Inhomogeneity of microstructure and mechanical properties in radial direction of aluminum/copper friction welded joints. J. Mater. Process. Technol. 2018, 255, 308–318. [Google Scholar] [CrossRef]

| Element | O | Cu |

|---|---|---|

| wt.% | 0.0001 | 99.99 |

| Element | Si | Fe | Cu | Mn | Ti | Al |

|---|---|---|---|---|---|---|

| wt.% | 0.06 | 0.07 | 0.00 | 0.00 | 0.00 | 99.87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurabayashi, K.; Tokita, S.; Sato, Y.S. Effect of Ni Addition on the Interfacial Strength of Al/Cu Dissimilar Welds Produced by Friction Stir Lap Welding. Metals 2022, 12, 453. https://doi.org/10.3390/met12030453

Kurabayashi K, Tokita S, Sato YS. Effect of Ni Addition on the Interfacial Strength of Al/Cu Dissimilar Welds Produced by Friction Stir Lap Welding. Metals. 2022; 12(3):453. https://doi.org/10.3390/met12030453

Chicago/Turabian StyleKurabayashi, Kota, Shun Tokita, and Yutaka S. Sato. 2022. "Effect of Ni Addition on the Interfacial Strength of Al/Cu Dissimilar Welds Produced by Friction Stir Lap Welding" Metals 12, no. 3: 453. https://doi.org/10.3390/met12030453