Effect of Reaction Temperature and Heat Treatment Time on Electrical and Mechanical Performance of TiB2 Particles and TiB Whiskers Reinforced Copper Matrix Composites

Abstract

:1. Introduction

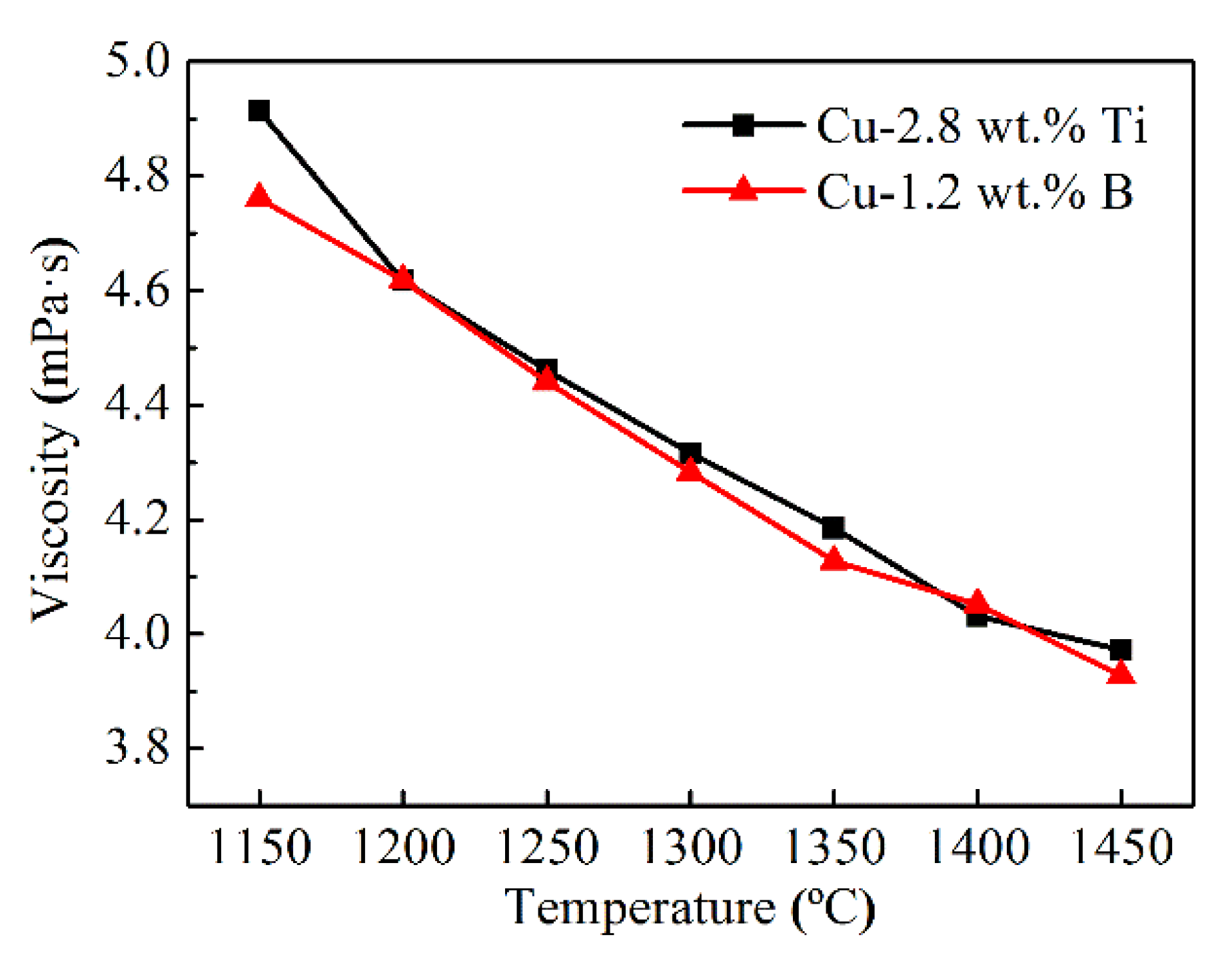

2. Materials and Methods

3. Results and Discussion

3.1. Effect of Reaction Temperature on Microstructures and Properties of Composites

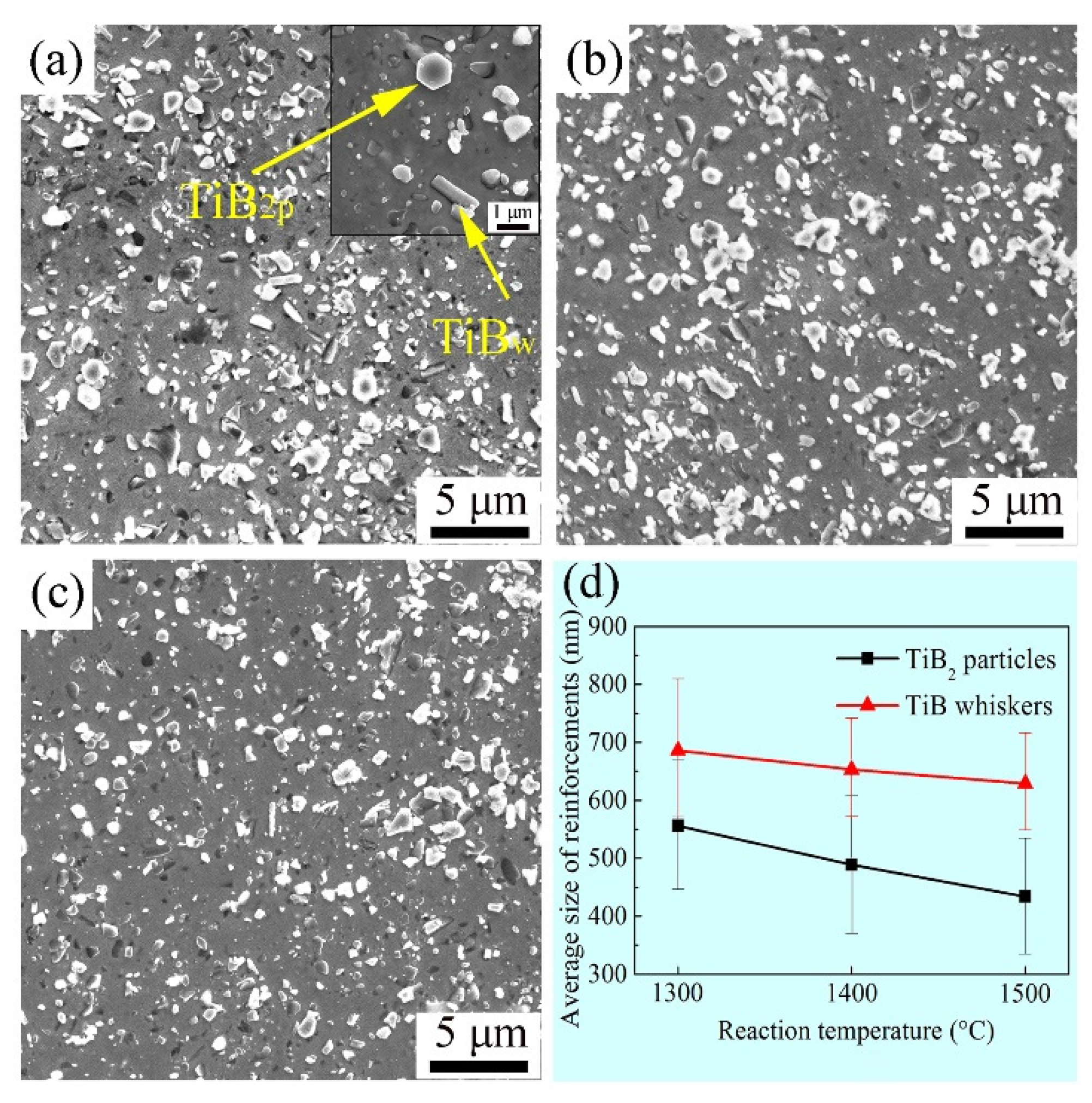

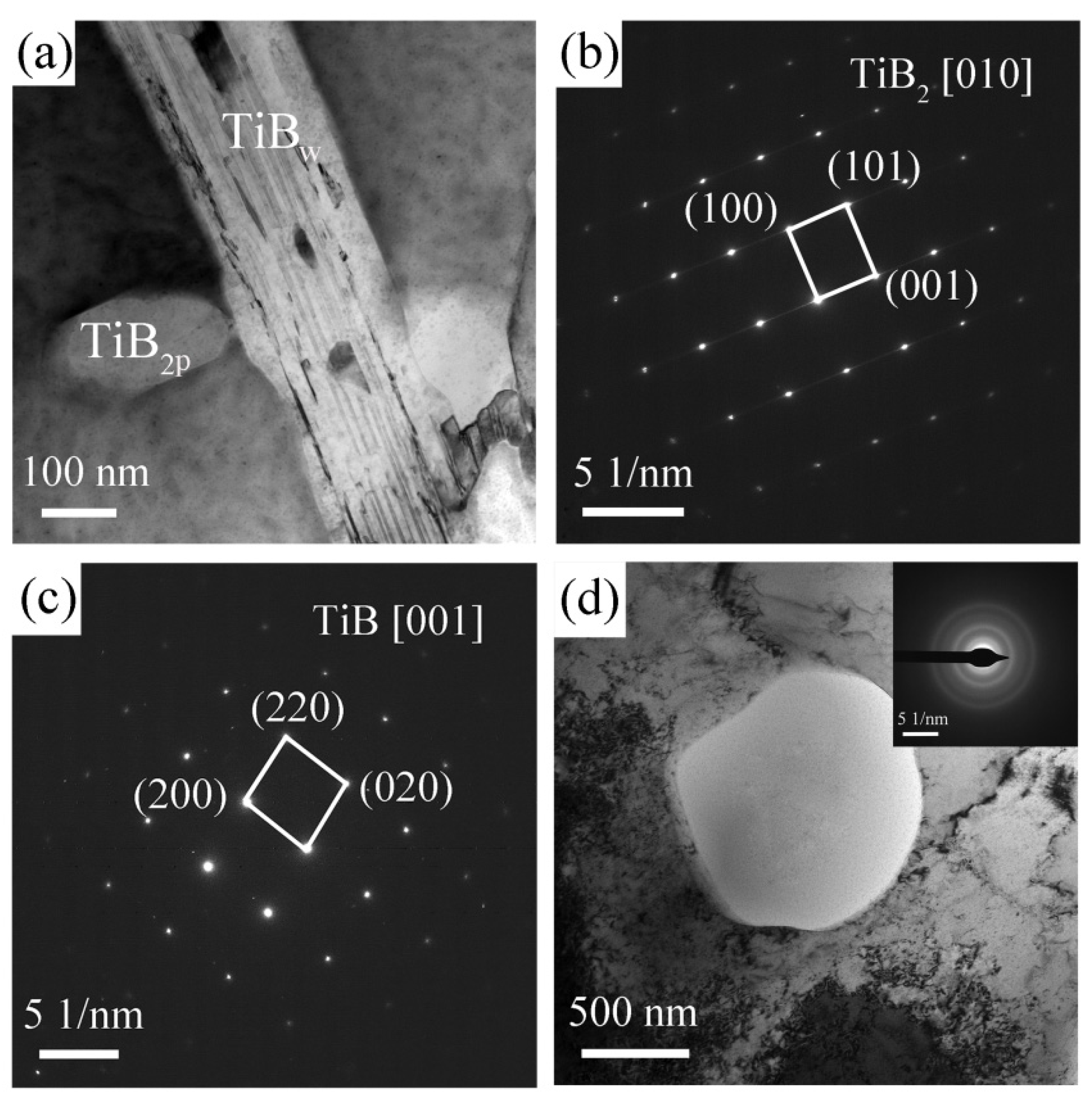

3.1.1. Microstructures of As-Cast Composites

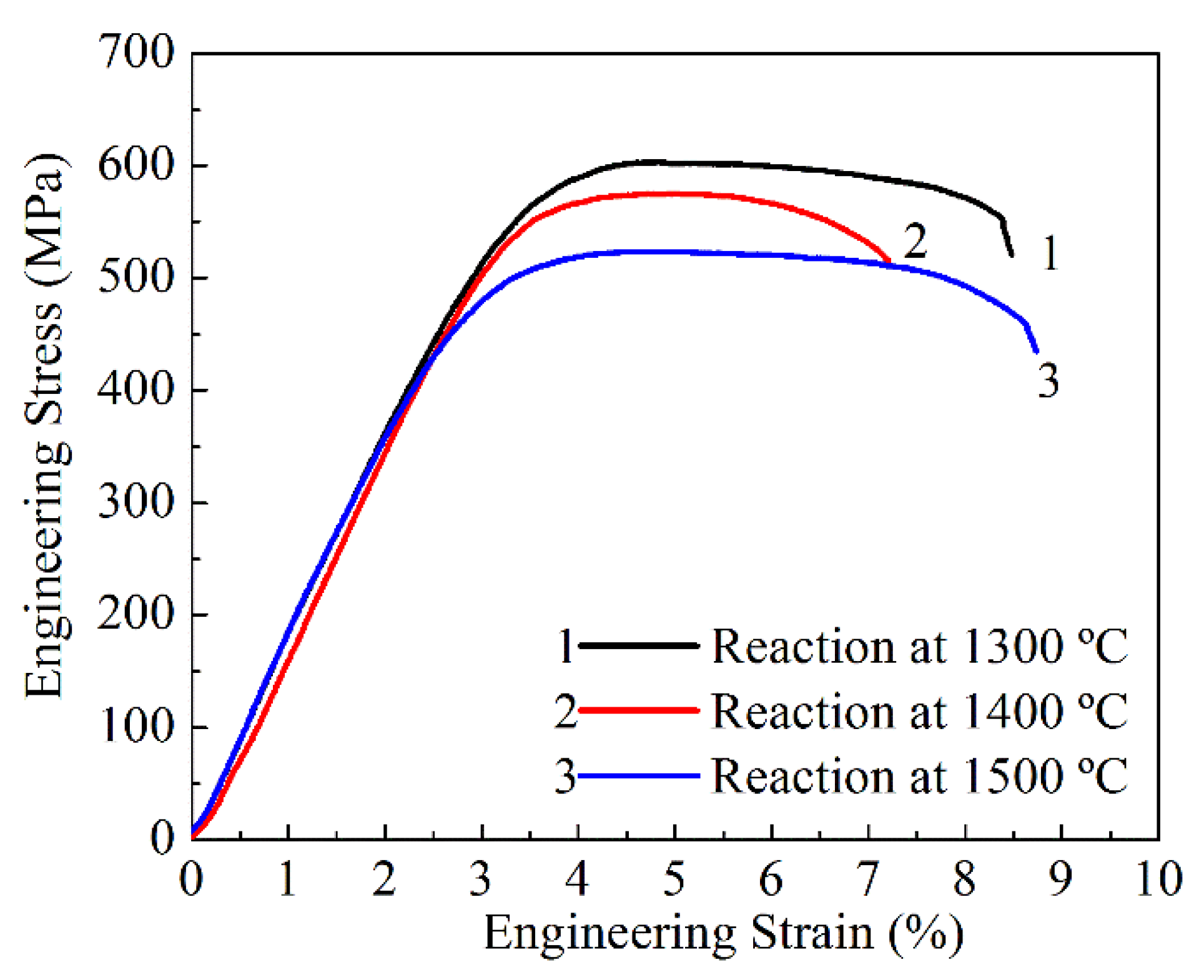

3.1.2. Properties of Composites

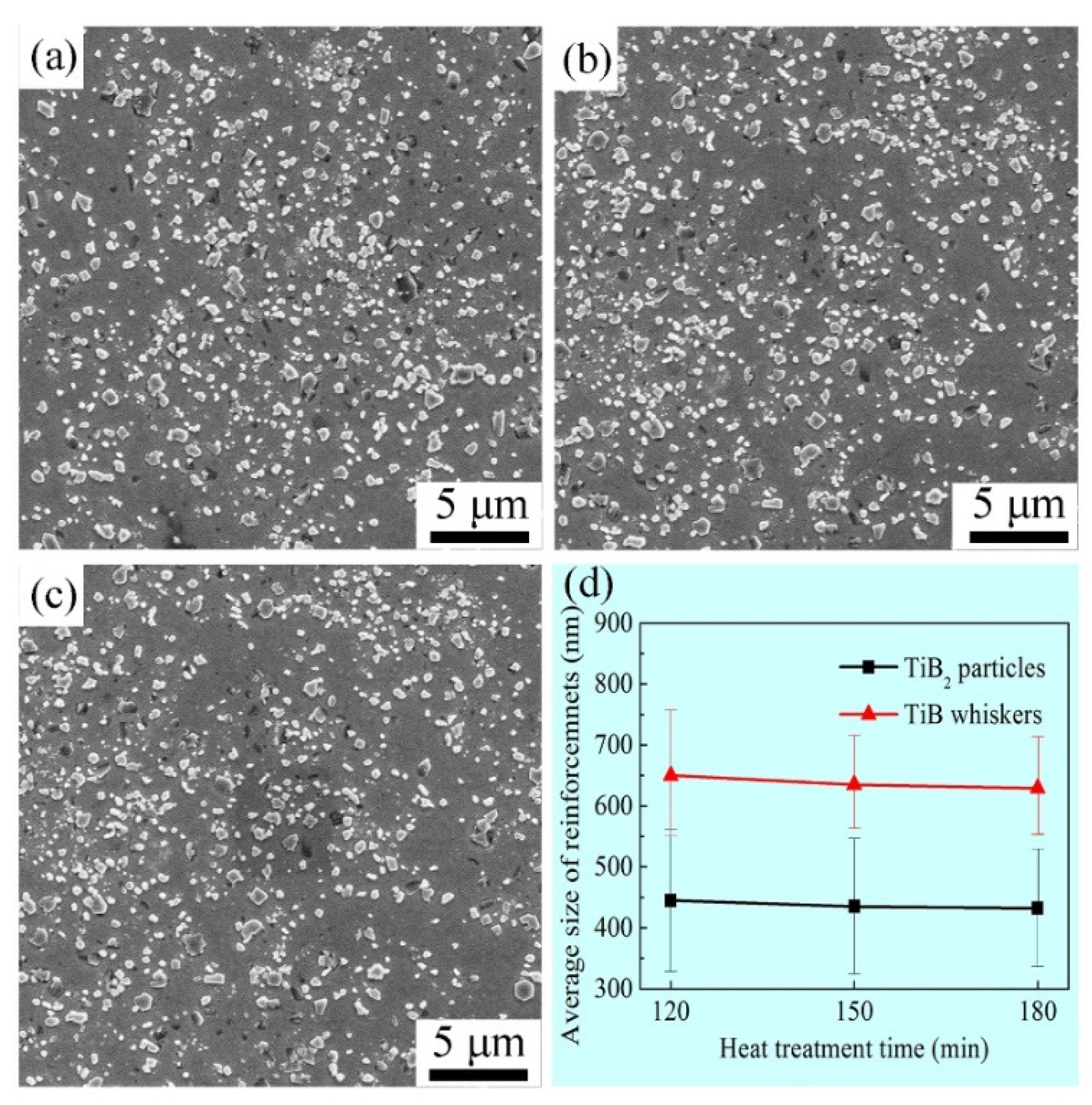

3.2. Effect of Heat Treatment Time on Microstructures and Properties of Composites

3.2.1. Microstructures of Composites

3.2.2. Properties of Composites

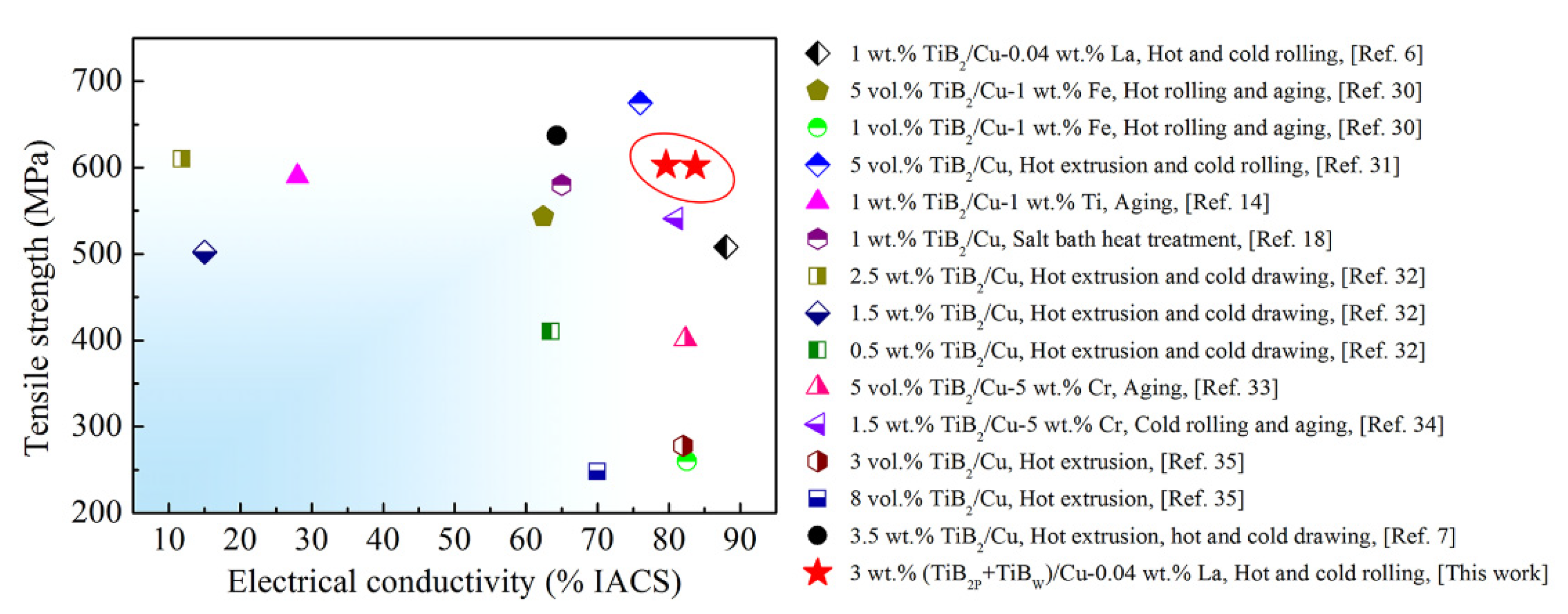

3.3. Optimization of Electrical Conductivity and Tensile Strength

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, H.R.; Guo, X.H.; Song, K.X.; Li, S.L.; Feng, J.; Zhang, X.F.; Feng, M.Q. Synergistic strengthening effect of tungsten carbide (WC) particles and silicon carbide whiskers (SiCw) on mechanical properties of Cu–Al2O3 composite. J. Mater. Res. Technol. 2021, 15, 2837–2847. [Google Scholar] [CrossRef]

- Cao, F.; Dong, G.Z.; Jiang, Y.H.; Xiao, P.; Wang, T.M.; Liang, S.H. Effect of La addition on microstructures and properties of TiB2(-TiB)/Cu hybrid composites prepared by in situ reaction. Mater. Sci. Eng. A 2020, 789, 139605. [Google Scholar] [CrossRef]

- Abdollah, B.; Junko, U.; Ridvan, Y.; Hamidreza, G.; Ammarueda, I.; Bakar, T.A.A.; Katsuyoshi, K. Deformation mechanism and enhanced properties of Cu–TiB2 composites evaluated by the in situ tensile test and microstructure characterization. J. Alloys Compd. 2020, 847, 156555. [Google Scholar]

- Lee, J.; Jung, J.Y.; Lee, E.S.; Park, W.J.; Ahn, S.; Kim, N.J. Microstructure and properties of titanium boride dispersed Cu alloys fabricated by spray forming. Mater. Sci. Eng. A 2000, 277, 274–283. [Google Scholar] [CrossRef]

- Biselli, C.; Morris, D.G.; Randall, N. Mechanical alloying of high-strength copper alloys containing TiB2 and Al2O3 dispersoid particles. Scr. Met. Mater. 1994, 30, 1327–1332. [Google Scholar] [CrossRef] [Green Version]

- Zou, C.L.; Kang, H.J.; Wang, W.; Chen, Z.N.; Li, R.G.; Gao, X.X.; Li, T.J.; Wang, T.M. Effect of La addition on the particle characteristics, mechanical and electrical properties of in situ Cu-TiB2 composites. J. Alloys Compd. 2016, 687, 312–319. [Google Scholar] [CrossRef]

- Tu, J.P.; Wang, N.Y.; Yang, Y.Z.; Qi, W.X.; Liu, F.; Zhang, X.B.; Lu, H.M.; Liu, M.S. Preparation and properties of TiB2 nanoparticle reinforced copper matrix composites by in situ processing. Mater. Lett. 2002, 52, 448–452. [Google Scholar] [CrossRef]

- Guo, M.X.; Shen, K.; Wang, M.P. Effect of in situ reaction conditions on the microstructure changes of Cu–TiB2 alloys by combining in situ reaction and rapid solidification. Mater. Chem. Phys. 2012, 131, 589–599. [Google Scholar] [CrossRef]

- Li, R.G.; Zhang, S.R.; Zou, C.L.; Kang, H.J.; Wang, T.M. The roles of Hf element in optimizing strength, ductility and electrical conductivity of copper alloys. Mater. Sci. Eng. A 2019, 758, 130–138. [Google Scholar] [CrossRef]

- Murray, J.L. The Cu–Ti (Copper–Titanium) System. Bull. Alloy Phase Diagr. 1983, 4, 81–95. [Google Scholar] [CrossRef]

- Chakrabarti, D.J.; Laughlin, D.E. The B–Cu (Boron–Copper) System. Bull. Alloy Phase Diagr. 1982, 3, 45–48. [Google Scholar] [CrossRef]

- Sobhani, M.; Arabi, H.; Mirhabibi, A.; Brydson, R.M.D. Microstructural evolution of copper–titanium alloy during in-situ formation of TiB2 particles. Trans. Nonferrous Met. Soc. China 2013, 23, 2994–3001. [Google Scholar] [CrossRef]

- Jiang, Y.H.; Li, D.; Zhang, X.N.; Zou, J.T.; Xiao, P.; Liang, S.H. Effects of various strengthening methods on the properties of Cu–Ti–B alloys. Mater. Sci. Technol. 2018, 34, 340–346. [Google Scholar] [CrossRef]

- Sobhani, M.; Mirhabibi, A.; Arabi, H.; Brydsonr, M.D. Effects of in situ formation of TiB2 particles on age hardening behavior of Cu–1 wt% Ti–1 wt% TiB2. Mater. Sci. Eng. A 2013, 577, 16–22. [Google Scholar] [CrossRef]

- Zhang, S.-L.; Harper, J.M.E.; D’Heurle, F.M. High conductivity copper-boron alloys obtained by low temperature annealing. J. Electron. Mater. 2001, 30, L1–L5. [Google Scholar] [CrossRef]

- Kumar, P.S.; Lakshminarayanan, P.R.; Varahamoorthi, R. Effect of pouring temperature and holding time on hardness at various locations of Al/TiB2 MMC cast ingot. Int. J. Latest Eng. Res. Appl. 2016, 1, 30–41. [Google Scholar]

- Lawrance, C.A.; Prabhu, P.S. Stir casting of in–situ Al 6061 TiB2 metal matrix composite synthesized with different reaction holding times. Int. J. Eng. Res. Technol. 2015, 4, 449–453. [Google Scholar]

- Sobhani, M.; Arabi, H.; Mirhabibi, A.R. TEM characterization and properties of Cu–1 wt.%TiB2 nanocomposite prepared by rapid solidification and subsequent heat treatment. J. Nanostruct. 2013, 2, 517–524. [Google Scholar]

- Cao, F.; Zhang, X.D.; Jiang, Y.H.; Cai, P.T.; Li, Q.; Wang, T.M.; Dong, G.Z.; Gao, F.; Liang, S.H. Effect of different rare earths on microstructures and tensile strength of in situ hybrid reinforced (TiB2p + TiBw)/Cu composites. Mater. Charact. 2022, 184, 111624. [Google Scholar] [CrossRef]

- Liang, S.H.; Li, W.Z.; Jiang, Y.H.; Cao, F.; Dong, G.Z.; Xiao, P. Microstructures and properties of hybrid copper matrix composites reinforced by TiB whiskers and TiB2 particles. J. Alloys Compd. 2019, 797, 589–594. [Google Scholar] [CrossRef]

- Zhang, S.R.; Kang, H.J.; Li, R.G.; Zou, C.L.; Guo, E.Y.; Chen, Z.N.; Wang, T.M. Microstructure evolution, electrical conductivity and mechanical properties of dual-scale Cu5Zr/ZrB2 particulate reinforced copper matrix composites. Mater. Sci. Eng. A 2019, 762, 138108. [Google Scholar] [CrossRef]

- Wang, Y.D.; Liu, M.; Yu, B.H.; Wu, L.H.; Xue, P.; Ni, D.R.; Ma, Z.Y. Enhanced combination of mechanical properties and electrical conductivity of a hard state Cu-Cr-Zr alloy via one-step friction stir processing. J. Mater. Process. Technol. 2021, 288, 116880. [Google Scholar] [CrossRef]

- Chembarisova, R.G.; Sarkeeva, E.A.; Alexandrov, I.V.; Wei, W. Analysis of the effect of equal-channel angular pressing on the strength and electrical conductivity of low-alloyed alloys of the Cu-Cr-Zr system. J. Phys. Conf. Ser. 2020, 1431, 012065. [Google Scholar] [CrossRef]

- Bozic, D.; Mitkov, M. Strengthening of Cu–Ti alloys by addition of boron. Mater. Sci. Technol. 1992, 8, 1108–1116. [Google Scholar] [CrossRef]

- Bakhtiyarov, S.I.; Overfelt, R.A. Measurement of liquid metal viscosity by rotational technique. Acta Mater. 1999, 47, 4311–4319. [Google Scholar] [CrossRef]

- Rexer, J. Boriding of copper titanium alloys. Mater. Res. Adv. Tech. 1972, 63, 745–751. [Google Scholar]

- Jelena, S.; Boi, D. The effect of in–situ formed TiB2 particles on microstructural and mechanical properties of laser melted copper alloy. Int. J. Mater. Res. 2020, 111, 153–159. [Google Scholar]

- Chmielewski, M.; Pietrzak, K.; Strojny-Nędza, A.; Jarząbek, D.; Nosewicz, S. Investigations of interface properties in copper-silicon carbide composites. Arch. Met. Mater. 2017, 62, 1315–1318. [Google Scholar] [CrossRef] [Green Version]

- Jarząbek, D. The impact of weak interfacial bonding strength on mechanical properties of metal matrix—Ceramic reinforced composites. Compos. Struct. 2018, 201, 352–362. [Google Scholar] [CrossRef]

- Pan, S.H.; Zheng, T.Q.; Yao, G.C.; Chi, Y.T.; Rosa, I.D.; Li, X.C. High–strength and high–conductivity in situ Cu–TiB2 nanocomposites. Mater. Sci. Eng. A 2022, 831, 141952. [Google Scholar] [CrossRef]

- Lee, A.K.; Sanchez-Caldera, L.E.; Chun, J.H.; Suh, N.P. Material with novel compositions and fine microstructures produced via the mixalloy process. Mrs Proc. 1988, 132, 87. [Google Scholar] [CrossRef]

- Tu, J.P.; Rong, W.; Guo, S.Y.; Yang, Y.Z. Dry sliding wear behavior of in situ Cu–TiB2 nanocomposites against medium carbon steel. Wear 2003, 255, 832–835. [Google Scholar] [CrossRef]

- Feng, J.; Liang, S.H.; Song, K.X.; Guo, X.H.; Zhou, Y.J. Micro-nano dual-scale particle-reinforced TiB2/Cu–0.5Cr composites prepared by vacuum arc melting. J. Mater. Eng. Perform. 2020, 29, 3353–3360. [Google Scholar] [CrossRef]

- Zhang, P.C.; Jie, J.C.; Gao, Y.; Li, H.; Cao, Z.Q.; Wang, T.M.; Li, T.J. Preparation and properties of TiB2 particles reinforced Cu–Cr matrix composite. Mater. Sci. Eng. A 2015, 642, 398–405. [Google Scholar] [CrossRef]

- Jung, T.K.; Lim, S.C.; Kwon, H.C.; Kim, M.S. Fabrication and properties of TiB2 reinforced Cu composites by electromagnetic stirring. Mater. Sci. Forum 2004, 449–452, 297–300. [Google Scholar] [CrossRef]

| Reaction Temperature (°C) | Electrical Conductivity (% IACS) | Tensile Strength (MPa) |

|---|---|---|

| 1300 | 73.1 ± 2.1 | 606 ± 3.1 |

| 1400 | 78.5 ± 1.8 | 574 ± 2.2 |

| 1500 | 89.5 ± 1.1 | 525 ± 1.4 |

| Heat Treatment Time (min) | Electrical Conductivity (%IACS) | Tensile Strength (MPa) |

|---|---|---|

| 120 | 64.8 ± 3.1 | 567 ± 2.5 |

| 150 | 66.5 ± 2.2 | 618 ± 8.1 |

| 180 | 89.5 ± 1.1 | 525 ± 1.4 |

| Preparation Process | Electrical Conductivity (%IACS) | Tensile Strength (MPa) |

|---|---|---|

| I | 79.6 ± 1.6 | 603 ± 3.8 |

| II | 83.7 ± 1.3 | 602 ± 2.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, F.; Zhang, X.; Cai, P.; Jiang, Y.; Gao, F.; Liang, S. Effect of Reaction Temperature and Heat Treatment Time on Electrical and Mechanical Performance of TiB2 Particles and TiB Whiskers Reinforced Copper Matrix Composites. Metals 2022, 12, 592. https://doi.org/10.3390/met12040592

Cao F, Zhang X, Cai P, Jiang Y, Gao F, Liang S. Effect of Reaction Temperature and Heat Treatment Time on Electrical and Mechanical Performance of TiB2 Particles and TiB Whiskers Reinforced Copper Matrix Composites. Metals. 2022; 12(4):592. https://doi.org/10.3390/met12040592

Chicago/Turabian StyleCao, Fei, Xingde Zhang, Pengtao Cai, Yihui Jiang, Fan Gao, and Shuhua Liang. 2022. "Effect of Reaction Temperature and Heat Treatment Time on Electrical and Mechanical Performance of TiB2 Particles and TiB Whiskers Reinforced Copper Matrix Composites" Metals 12, no. 4: 592. https://doi.org/10.3390/met12040592

APA StyleCao, F., Zhang, X., Cai, P., Jiang, Y., Gao, F., & Liang, S. (2022). Effect of Reaction Temperature and Heat Treatment Time on Electrical and Mechanical Performance of TiB2 Particles and TiB Whiskers Reinforced Copper Matrix Composites. Metals, 12(4), 592. https://doi.org/10.3390/met12040592