Plastic Deformation Mechanism and Slip Transmission Behavior of Commercially Pure Ti during In Situ Tensile Deformation

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

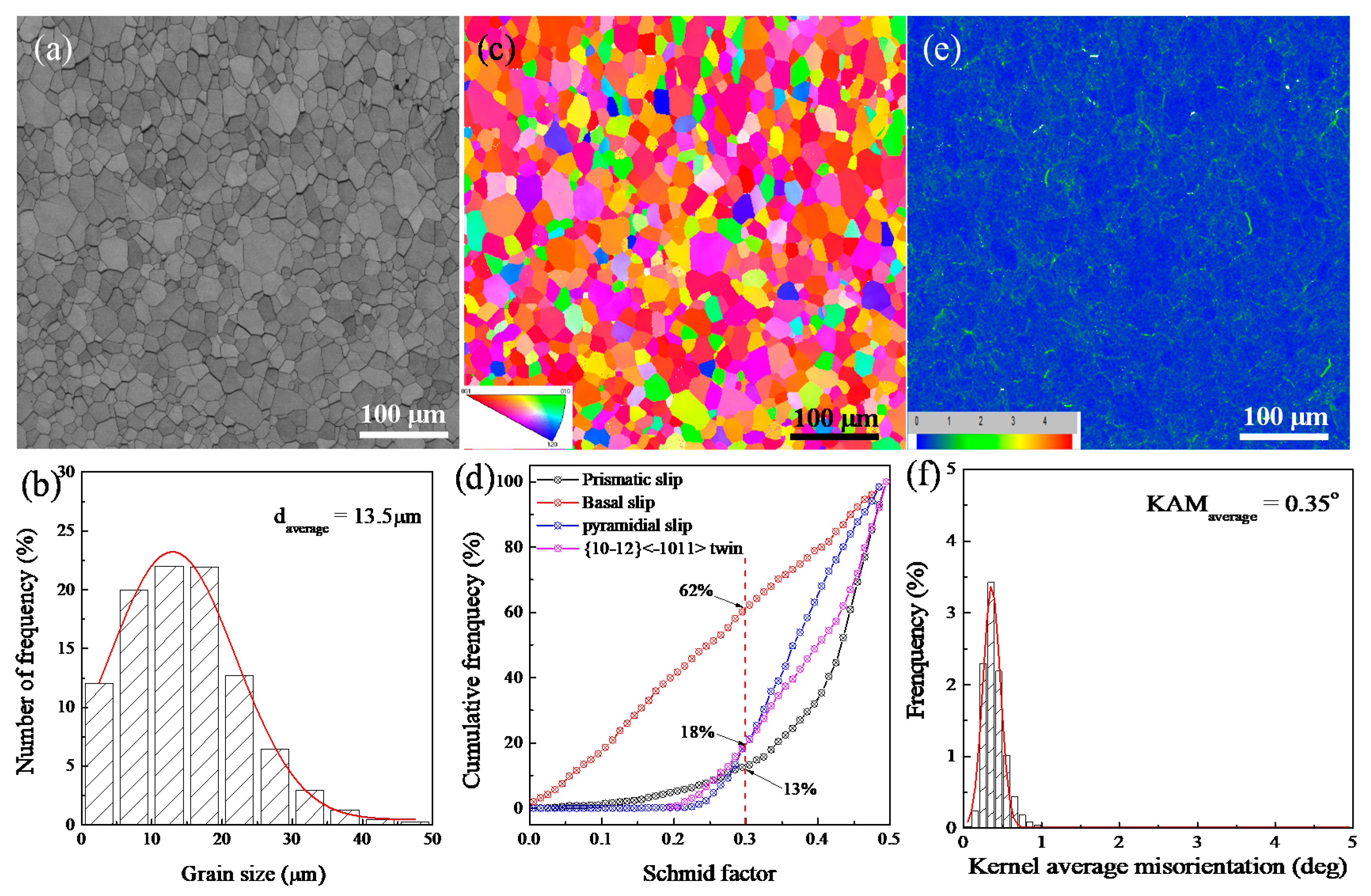

3.1. Initial Microstructure

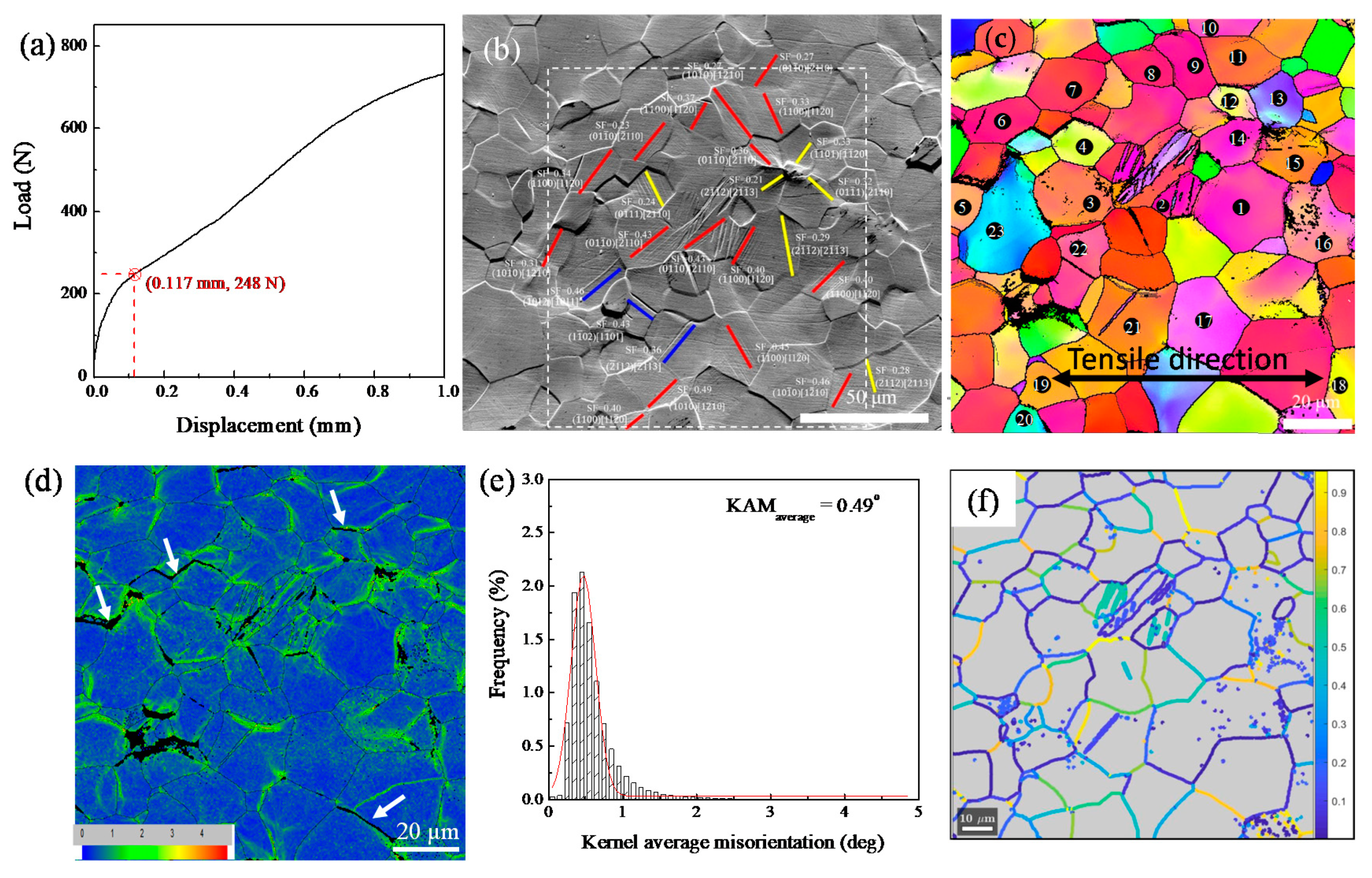

3.2. Dislocation Slip during In Situ Tensile Testing

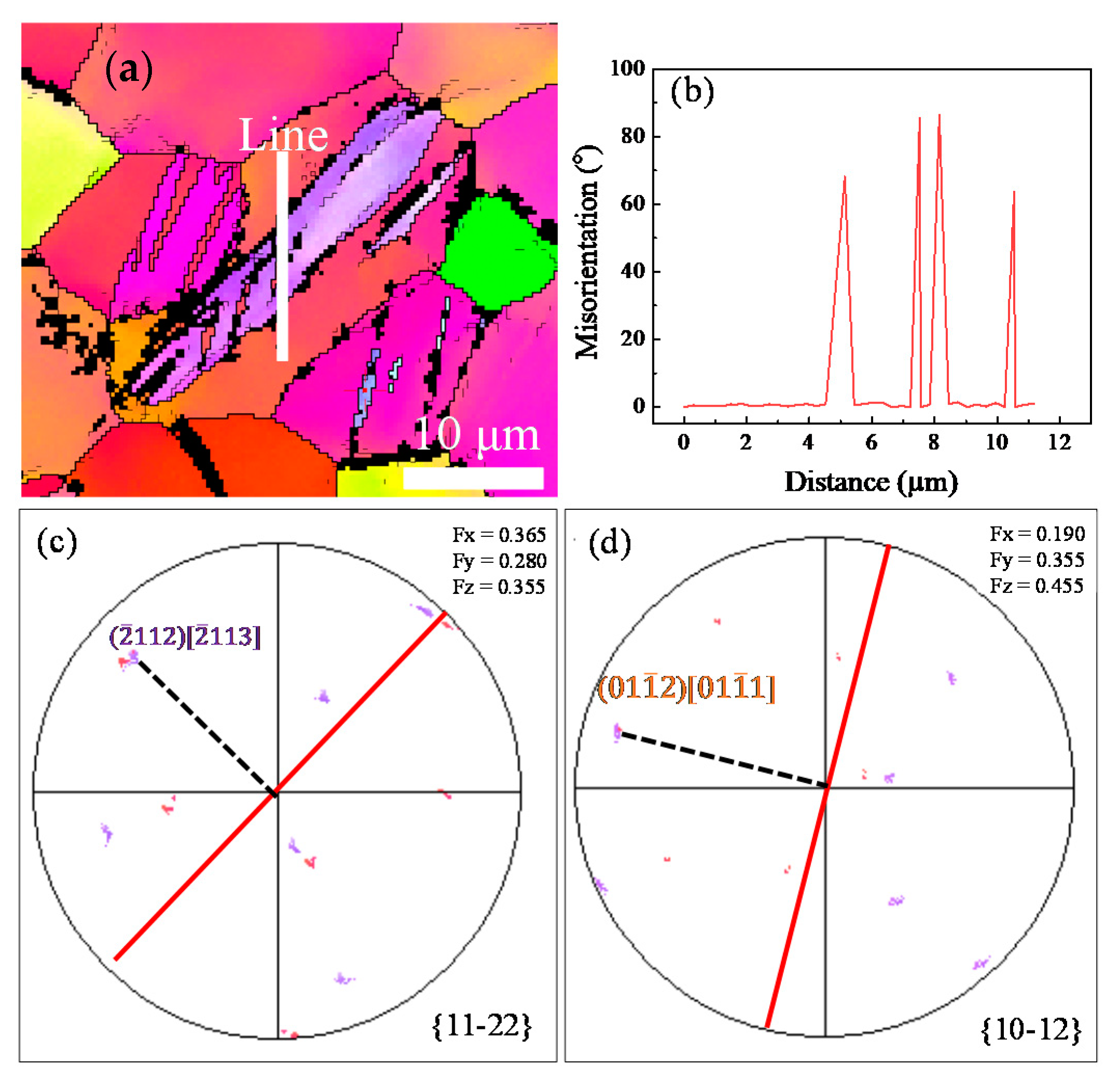

3.3. Deformation Twins during In Situ Tensile Testing

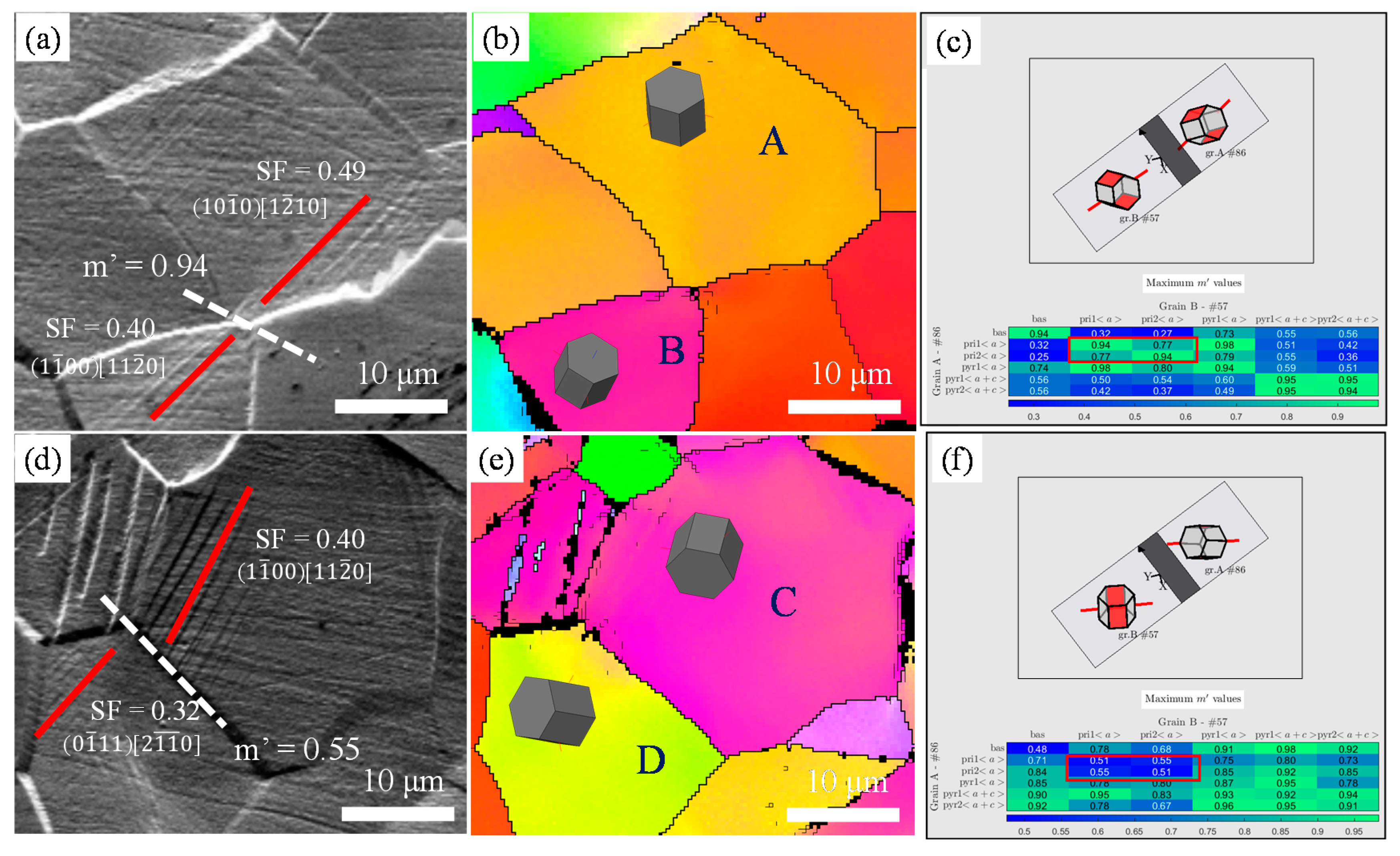

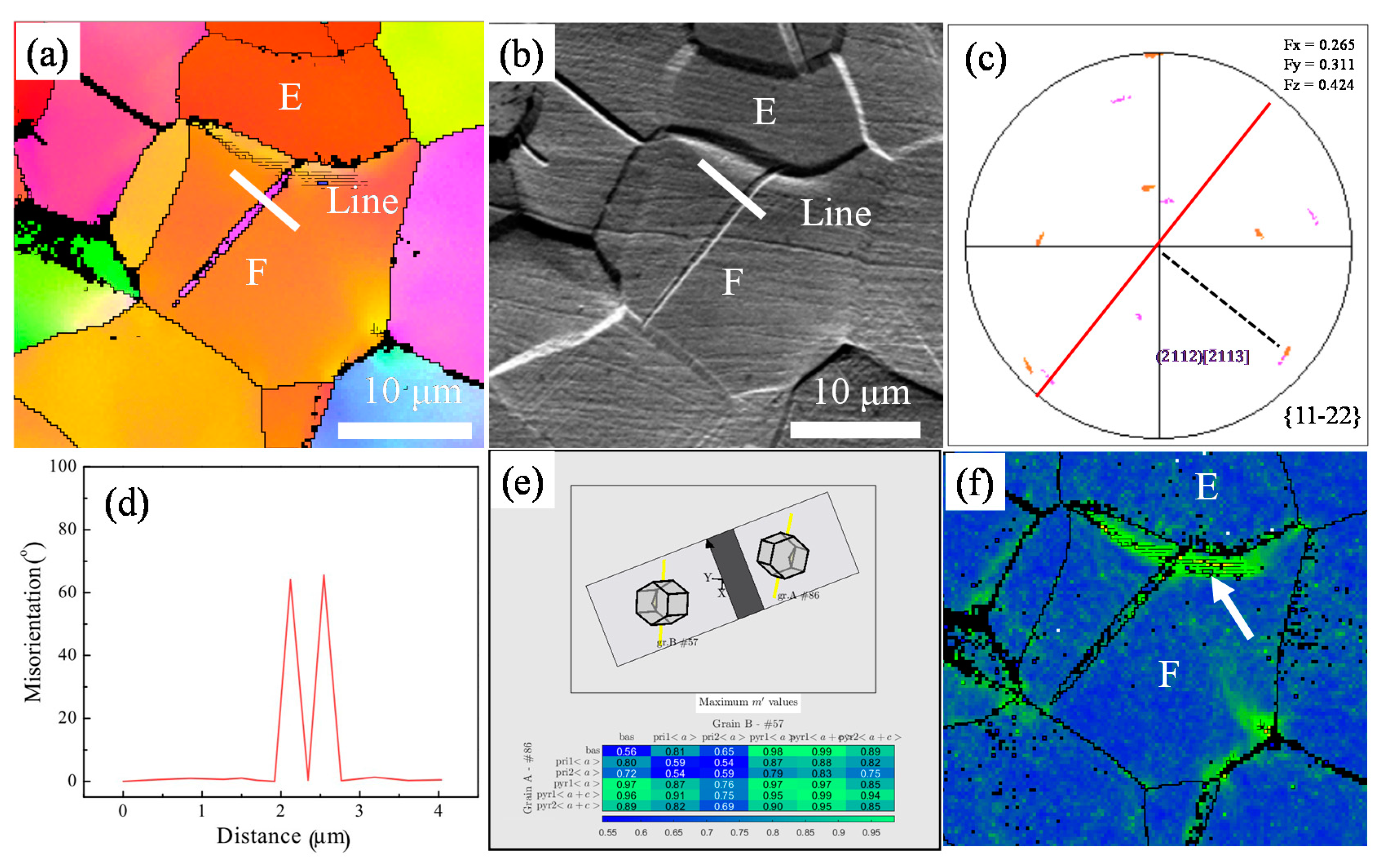

3.4. Slip Transmission Behavior during In Situ Tensile Testing

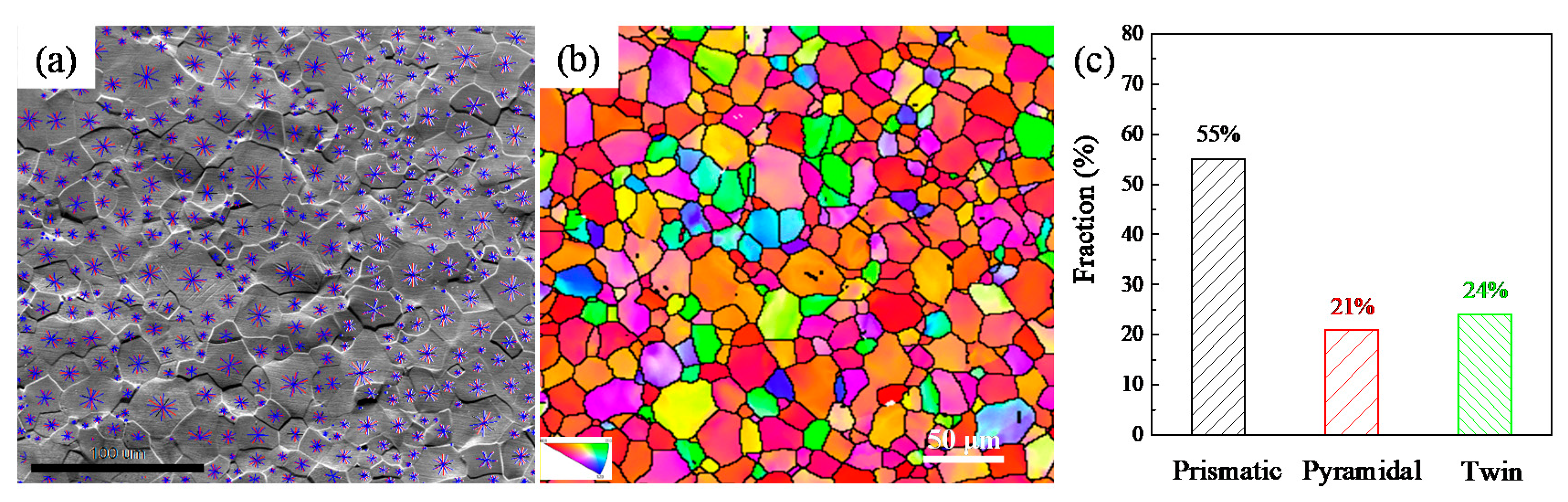

3.5. Surface Topography after In Situ Tensile Testing

4. Conclusions

- (1)

- Based on EBSD characterization and slip trace analysis, the active deformation modes of CP-Ti after an in situ tensile strain of ~2.9% were prismatic slip (55%), pyramidal slip (21%), and deformation twins (24%);

- (2)

- Slip transmission had an obvious influence on the activities of the deformation mode, which were predicted using a geometric compatibility factor. Slip transmission in CP-Ti tended to occur between the same slip types (prismatic slip to prismatic slip). The stress concentration in GBs was released by slip transmission to accommodate coordinated deformation;

- (3)

- Poor geometric compatibility between two adjacent grains led to stress concentration at the GBs, which was conducive to the activity of pyramidal slip or the nucleation of deformation twins.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zeng, L.; Wang, L.; Hua, P.; He, Z.; Zhang, G. In-situ investigation of dwell fatigue damage mechanism of pure Ti using digital image correlation technique. Mater. Charact. 2021, 181, 111466. [Google Scholar] [CrossRef]

- Liu, X.; Gao, H.; Wu, H.; Pan, H.; Shu, B.; Yang, Y.; Liu, H.; Yang, F.; Zhu, X. Microstructure and texture characteristics of pure Ti with a superior combination of strength and ductility. Mater. Sci. Eng. A 2021, 808, 140915. [Google Scholar] [CrossRef]

- Wang, B.; Liu, H.; Zhang, Y.; Zhou, B.; Deng, L.; Wang, C.; Chen, J.; Zhang, Y. Effect of grain size on twinning behavior of pure titanium at room temperature. Mater. Sci. Eng. A 2021, 827, 142060. [Google Scholar] [CrossRef]

- Kishida, K.; Kim, J.G.; Nagae, T.; Inui, H. Experimental evaluation of critical resolved shear stress for the first-order pyramidal c + a slip in commercially pure Ti by micropillar compression method. Acta Mater. 2020, 196, 168–174. [Google Scholar] [CrossRef]

- Gong, J.; Wilkinson, A.J. Anisotropy in the plastic flow properties of single-crystal α titanium determined from micro-cantilever beams. Acta Mater. 2009, 57, 5693–5705. [Google Scholar] [CrossRef]

- Hémery, S.; Tromas, C.; Villechaise, P. Slip-stimulated grain boundary sliding in Ti-6Al-4 V at room temperature. Materialia 2019, 5, 100189. [Google Scholar] [CrossRef]

- Bieler, T.; Eisenlohr, P.; Zhang, C.; Phukan, H.; Crimp, M. Grain boundaries and interfaces in slip transfer. Curr. Opin. Solid State Mater. Sci. 2014, 18, 212–226. [Google Scholar] [CrossRef] [Green Version]

- Zhao, P.Y.; Shen, C.; Savage, M.F.; Li, J.; Niezgoda, S.R.; Mills, M.J.; Wang, Y.Z. Slip transmission assisted by Shockley partials across α/β interfaces in Ti-alloys. Acta Mater. 2019, 171, 291–305. [Google Scholar] [CrossRef]

- Tan, C.; Sun, Q.; Xiao, L.; Zhao, Y.; Sun, J. Slip transmission behavior across α/β interface and strength prediction with a modified rule of mixtures in TC21 titanium alloy. J. Alloys Compd. 2017, 724, 112–120. [Google Scholar] [CrossRef]

- Jiang, S.; Jia, Y.; Wang, X. In-situ analysis of slip transfer and heterogeneous deformation in tension of Mg-5.4Gd-1.8Y-1.5Zn alloy. J. Magnes. Alloys 2020, 8, 1186–1197. [Google Scholar] [CrossRef]

- Joseph, S.; Bantounas, I.; Lindley, T.C.; Dye, D. Slip transfer and deformation structures resulting from the low cycle fatigue of near-alpha titanium alloy Ti-6242Si. Int. J. Plast. 2018, 100, 90–103. [Google Scholar] [CrossRef]

- Luster, J.; Morris, J.M. Compatibility of deformation in two-phase Ti-Al alloys: Dependence on microstructure and orientation relationships. Metall. Mater. Trans. A 1995, 26, 1745–1756. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Y.; Wang, L.; Jia, H.; Zeng, X. The role of grain boundary plane in slip transfer during deformation of magnesium alloys. Acta Mater. 2022, 227, 117662. [Google Scholar] [CrossRef]

- Wei, S.; Zhu, G.; Tasan, C.C. Slip-twinning interdependent activation across phase boundaries: An in-situ investigation of a Ti-Al-V-Fe (α+β) alloy. Acta Mater. 2021, 206, 116520. [Google Scholar] [CrossRef]

- Guan, D.; Wynne, B.; Gao, J.; Huang, Y.; Rainforth, W.M. Basal slip mediated tension twin variant selection in magnesium WE43 alloy. Acta Mater. 2019, 170, 1–14. [Google Scholar] [CrossRef]

- Wang, Q.; Ren, J.; Zhang, B.; Xin, C.; Wu, Y.; Ye, M. Influence of microstructure on the fatigue crack growth behavior of a near-alpha TWIP Ti alloy. Mater. Charact. 2021, 178, 111208. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, P.; Li, L. Fatigue cracking at twin boundaries: Effects of crystallographic orientation and stacking fault energy. Acta Mater. 2012, 60, 3113–3127. [Google Scholar] [CrossRef]

- Zhang, S.; Zeng, W.; Zhao, Q.; Ge, L.; Zhang, M. In situ SEM study of tensile deformation of a near-β titanium alloy. Mater. Sci. Eng. A 2017, 708, 574–581. [Google Scholar] [CrossRef]

- Huang, S.; Zhao, Q.; Lin, C.; Wu, C.; Zhao, Y.; Jia, W.; Mao, C. In-situ investigation of tensile behaviors of Ti–6Al alloy with extra low interstitial. Mater. Sci. Eng. A 2021, 809, 140958. [Google Scholar] [CrossRef]

- Cepeda, C.; Molina, J.; Perez, M. Effect of grain size on slip activity in pure magnesium polycrystals. Acta Mater. 2015, 84, 443–456. [Google Scholar] [CrossRef]

- Dichtl, C.; Lunt, D.; Atkinson, M.; Thomas, R.; Plowman, A.; Barzdajn, B.; Sandala, R.; da Fonseca, J.Q.; Preuss, M. Slip activity during low-stress cold creep deformation in a near-α titanium alloy. Acta Mater. 2022, 229, 117691. [Google Scholar] [CrossRef]

- Bridier, F.; Villechaise, P.; Mendez, J. Analysis of the different slip systems activated by tension in a α/β titanium alloy in relation with local crystallographic orientation. Acta Mater. 2005, 53, 555–567. [Google Scholar] [CrossRef]

- Ren, J.; Wang, Q.; Lu, X.; Liu, W.; Zhang, P.; Zhang, X. Effect of oxygen content on active deformation systems in pure titanium polycrystals. Mater. Sci. Eng. A 2018, 731, 530–538. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, Z.; Phukan, H.; Kenesei, P.; Park, J.-S.; Lind, J.; Suter, R.; Bieler, T. Direct measurement of critical resolved shear stress of prismatic and basal slip in polycrystalline Ti using high energy X-ray diffraction microscopy. Acta Mater. 2017, 132, 598–610. [Google Scholar] [CrossRef]

- Li, H.; Mason, D.; Bieler, T.; Boehlert, C.; Crimp, M. Methodology for estimating the critical resolved shear stress ratios of α-phase Ti using EBSD-based trace analysis. Acta Mater. 2013, 61, 7555–7567. [Google Scholar] [CrossRef]

- Shamsujjoha, M.; Agnew, S.R.; Fitz-Gerald, J.M.; Moore, W.R.; Newman, T.A. High Strength and Ductility of Additively Manufactured 316L Stainless Steel Explained. Met. Mater. Trans. A 2018, 49, 3011–3027. [Google Scholar] [CrossRef]

- Shamsujjoh, M. Evolution of microstructures, dislocation density and arrangement during deformation of low carbon lath martensitic steels. Mater. Sci. Eng. A 2020, 776, 139039. [Google Scholar] [CrossRef]

- Zribi, Z.; Ktari, H.H.; Herbst, F.; Optasanu, V.; Njah, N. EBSD, XRD and SRS characterization of a casting Al-7wt% Si alloy processed by equal channel angular extrusion: Dislocation density evaluation. Mater. Charact. 2019, 153, 190–198. [Google Scholar] [CrossRef]

- Zhang, H.; Wei, B.Q.; Ou, X.Q.; Ni, S.; Yan, H.G.; Song, M. Atomic-level study of {101 1} deformation twinning in pure Ti and Ti-5at.% Al alloy. Int. J. Plast. 2022, 153, 103273. [Google Scholar] [CrossRef]

- Kumar, M.A.; Beyerlein, I.J. Influence of plastic properties on the grain size effect on twinning in Ti and Mg. Mater. Sci. Eng. A 2020, 771, 138644. [Google Scholar] [CrossRef]

- Valeiras, E.; Llorca, J. Criteria for slip transfer across grain and twin boundaries in pure Ni. Materialia 2022, 21, 101303. [Google Scholar] [CrossRef]

- Xu, S.; Zhou, P.; Liu, G.; Xiao, D.; Gong, M.; Wang, J. Shock-induced two types of {101 2} sequential twinning in Titanium. Acta Mater. 2019, 165, 547–560. [Google Scholar] [CrossRef]

- Capolungo, L.; Beyerlein, I.J.; Tomé, C.N. Slip-assisted twin growth in hexagonal close-packed metals. Scr. Mater. 2009, 60, 32–35. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Eisenlohr, P.; Bieler, T.R.; Crimp, M.A.; Mason, D.E. Twin Nucleation by Slip Transfer across Grain Boundaries in Commercial Purity Titanium. Metall. Mater. Trans. A 2010, 41, 421–430. [Google Scholar] [CrossRef]

- Wang, L.; Eisenlohr, P.; Yang, Y.; Bieler, T.R.; Crimp, M.A. Nucleation of paired twins at grain boundaries in titanium. Scr. Mater. 2010, 63, 827–830. [Google Scholar] [CrossRef]

- Guan, B.; Xin, Y.; Huang, X.; Liu, C.; Wu, P.; Liu, Q. The mechanism for an orientation dependence of grain boundary strengthening in pure titanium. Int. J. Plast. 2022, 153, 103276. [Google Scholar] [CrossRef]

| Element | Fe | Si | C | N | H | O | Ti |

|---|---|---|---|---|---|---|---|

| Composition | 0.3 | 0.15 | 0.1 | 0.05 | 0.015 | 0.2 | Balance |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xin, C.; Wang, Q.; Ren, J.; Zhang, Y.; Wu, J.; Chen, J.; Zhang, L.; Sang, B.; Li, L. Plastic Deformation Mechanism and Slip Transmission Behavior of Commercially Pure Ti during In Situ Tensile Deformation. Metals 2022, 12, 721. https://doi.org/10.3390/met12050721

Xin C, Wang Q, Ren J, Zhang Y, Wu J, Chen J, Zhang L, Sang B, Li L. Plastic Deformation Mechanism and Slip Transmission Behavior of Commercially Pure Ti during In Situ Tensile Deformation. Metals. 2022; 12(5):721. https://doi.org/10.3390/met12050721

Chicago/Turabian StyleXin, Chao, Qi Wang, Junqiang Ren, Yonghong Zhang, Jinping Wu, Jie Chen, Liang Zhang, Biao Sang, and Le Li. 2022. "Plastic Deformation Mechanism and Slip Transmission Behavior of Commercially Pure Ti during In Situ Tensile Deformation" Metals 12, no. 5: 721. https://doi.org/10.3390/met12050721

APA StyleXin, C., Wang, Q., Ren, J., Zhang, Y., Wu, J., Chen, J., Zhang, L., Sang, B., & Li, L. (2022). Plastic Deformation Mechanism and Slip Transmission Behavior of Commercially Pure Ti during In Situ Tensile Deformation. Metals, 12(5), 721. https://doi.org/10.3390/met12050721