A Smart Digital Twin to Stabilize Return Sand Temperature without Using Coolers

Abstract

:1. Introduction

2. Materials and Methods

- To digitize the process, which is essential in order to digitally represent the manufacturing process that we want to optimize.

- To expand the amount of digitalized information, and therefore, to achieve a representative set for understanding and managing the process to be optimized.

- To generate a robust IIoT (Industrial Internet of Things) system that creates the axes that can be used to correctly define the digital twin.

- To provide a solution that, in addition to describing the current behavior, is capable of providing digitally calculated solutions that improve the real system.

- Identification of the problem and the challenges to be overcome. The purpose of this first step is to extract the background and context of the problem to be solved. In other words, we work to become aware of what we are trying to solve.

- Acquisition of knowledge. The second step is the acquisition of knowledge at a high level, providing the general vision necessary to start the investigation. Later, when we are working on a much more specific topic about the challenge to be faced, we will study that topic in a more specific way.

- Division in challenges. Based on the idea of divisions already mentioned, in this step, we define the challenges to be faced with their specific steps for each of them. In the case of our work, the following challenges have been identified: (i) sensorization and required data, (ii) representation of the digital twin, (iii) uncertainty management and adjustments, (iv) prediction or regression function, (v) management of special cases and (vi) system integration. For each of these challenges, the following subphases are carried out:

- In the acquisition of specific knowledge subphase, once the topic is defined, during this stage, we increase the knowledge to solve this problem. Many times, this acquisition has been directly related to the exploration and learning of the production process that we are optimizing.

- In the definition of the experiment and the techniques to be used subphase, the specific research and experiments are defined for each of the challenges to be faced.

- In the evaluation subphase, we carry out the defined experiment and obtain results of the approximation that has been defined.

- In the analysis subphase, once the previous stage is finished, an analysis process is carried out on the data collected during the specific experimentation designed.

- Interpretation of the results. When each solution for all identified challenges has been created, we combine all of them, and develop a final interpretation based on all the results.

2.1. Sensorizing and Required Data

- Time Shake Out. The data obtained from the database of the molding machine. These data are extracted directly from the manufacturer’s CIM through a monitoring and capture development that had already been carried out. Note that there were certain bugs that had to be handled in the software.

- Pouring time or instant in which each mold is filled. Additional information extracted in the same way as the previous variable. Pouring is sometimes not reported correctly in the manufacturer’s database and, again, some adjustments were needed to ensure the time was set.

- Thickness. This information, similar to the previous variables, is stored in the manufacturer’s database and is extracted by the abovementioned application for monitoring. This value means the thickness of the mold that can vary in each production.

- Compressibility. This is the value that indicates whether the machine is working with or without load. If the value is 0, the machine has work without creating any mold and this translates to a hole created into AMC. If the value is positive, the machine has molded a new mold that it places at the beginning of the molding line and will move with each movement it makes. The compressibility value is also provided by the molding machine database.

- Gross weight of bunches of all references. This information is provided by the engineering department of the foundry; this design data is exported every night and recorded in a database table that the intelligent system can query when needed.

- Mold temperature. This temperature is a reference to determine if the mold is full or empty. According to this measurement, the molds are processed in different ways within the intelligent system.

- Temperature of the sand at the exit of the cooling drum. Temperature information is used to extract the variations that are being reached when the method of adding water is modified. Through this measurement, the algorithm behind the digital twin can be adjusted.

- Operating signals from different equipment. Several situations can occur in the production and demolding process. The digital twin must always know the real state to work on solving the problems detected. Therefore, it is necessary to have the signals that show how the line is working. Some of the most important signals are those that communicate the activation of a by-pass, vibrating device, and cooling drum.

- Temperature sensor at the end of the production line (T0). This sensor is in charge of determining the temperature of the mold cup. Specifically, this sensor provides information about the filling of the mold. If the mold is full, it detects the temperature of the metal. However, if the mold is empty, it detects the temperature of the sand (a much lower temperature).

- Temperature sensor at the entrance of the cooling drum (T1). This installed sensor is proposed to improve the temperature values at the entrance to the cooling drum. Thus, together with the value of the sensor marked as T0, the reality can be better adjusted.

- Temperature sensor at the cooling drum outlet (T2). This sensor captures the temperature of the sand that has been separated and leaves the cooling drum. This sensor can detect the empty belt before the cooling drum stops, therefore, the system must be able to identify this special situation.

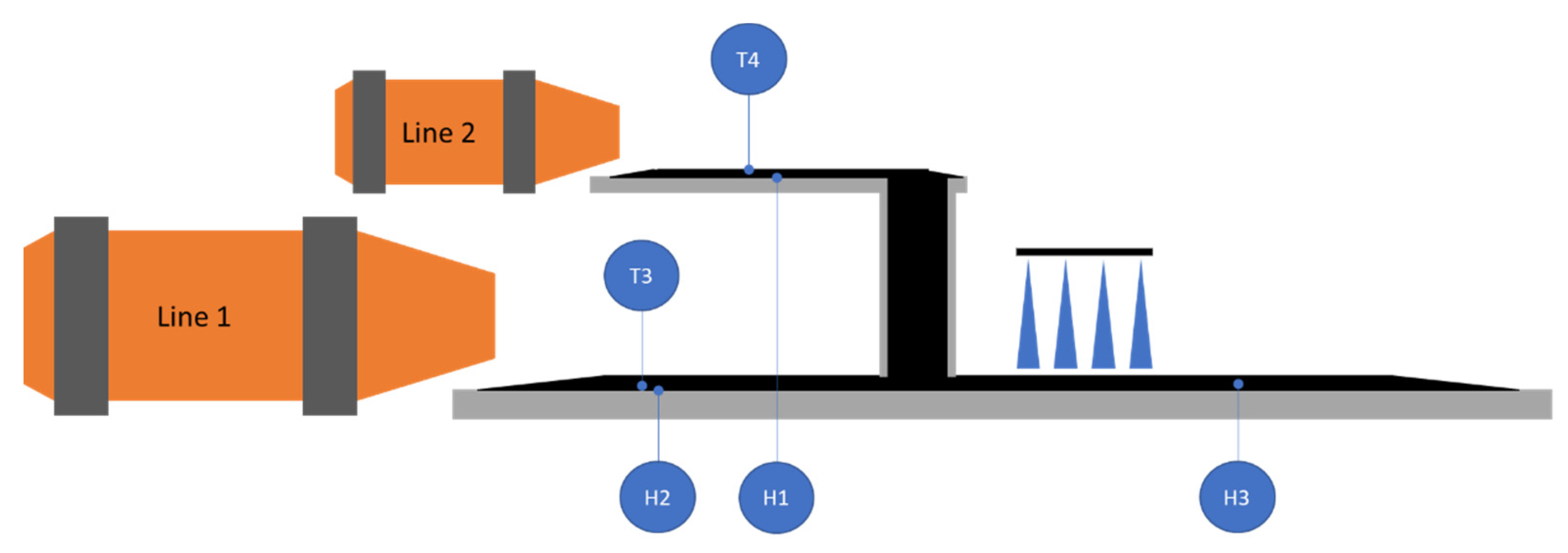

- Temperature and humidity sensors on the conveyor tapes. Temperature sensors (T3 and T4 in Figure 3) and humidity sensors (H1 and H2 in Figure 3) are installed after the sand exits each cooling drum before the unification of the tapes. These sensors stop/restrict the addition of water in the drum if the humidity is too high. Finally, an extra humidity sensor (H3 in Figure 3) is added after some water showers before the sand is transported to the silos.

2.2. Representation of the Digital Twin

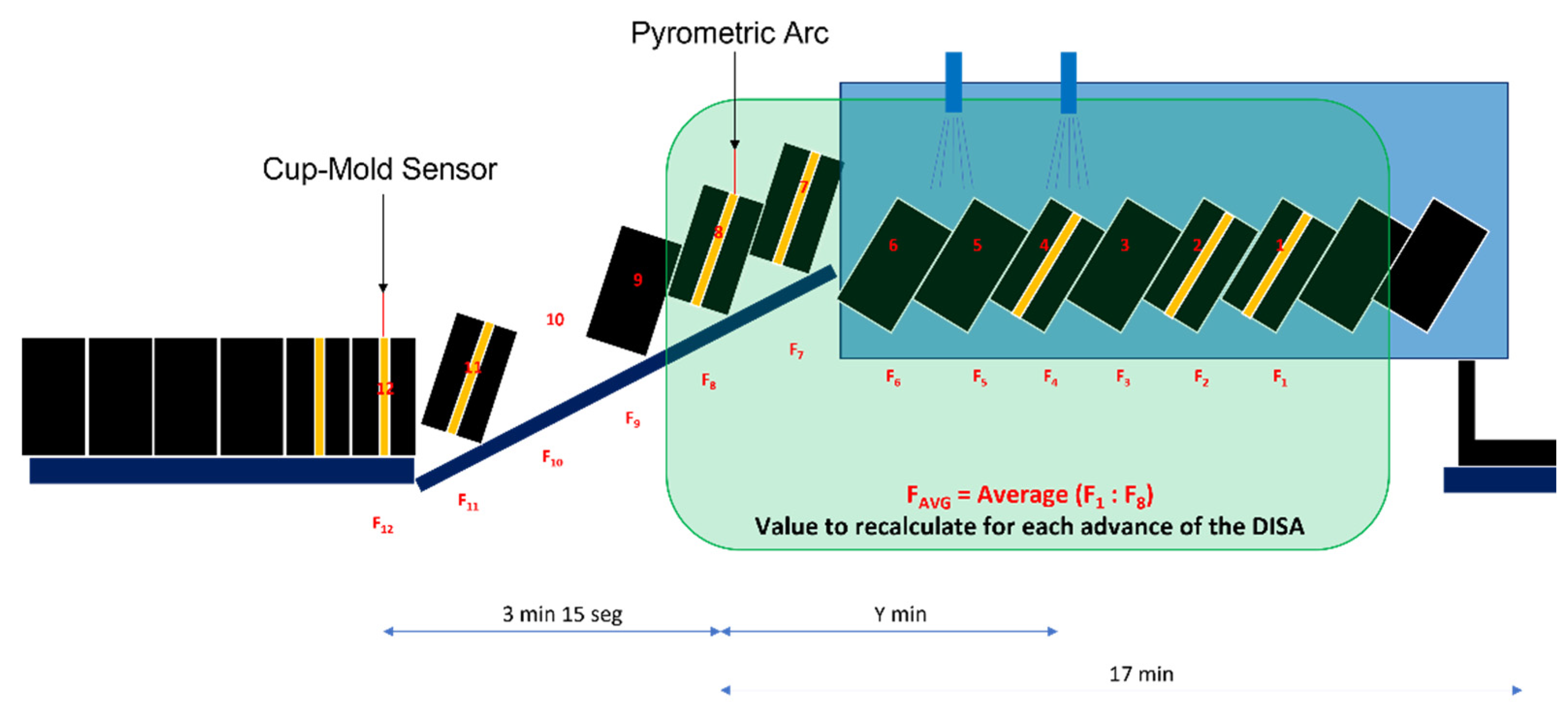

- The first event is the shake out or mold drop. The digital twin has subscribed to the storage (database) of the molds extracted with the sensorics previously mentioned. Once a mold falls from the SBC, it passes from the cooling line to the vibrating device that transports it to the cooling drum. In that moment, the digital twin receives that event from the database and triggers a series of tasks to represent the current state and do the associated calculations. Then, upon this event, the digital twin retrieves the new mold that is under the temperature sensor and advances all the stored molds in its FIFO type queue that represents the end of the SBC.

- Before an advance, if the SBC is full, one of its molds will fall into the vibrating device. Therefore, the digital twin deques a mold from its SBC FIFO queue to enqueue it into its vibrant FIFO queue, moving forward all the molds stored there. To model the advancement of the molds in the cooling drum, real measurements were made on this vibrating device and the time that a mold needs to travel through it. Our measurements indicate that it takes approximately 3 min and 15 s to travel through the entire device. In addition, in the case that concerns this research work, a digital representation of 25 molds was applied to approximate it. These values were prepared to be parameterized and to make it easier to extrapolate the solution to the second line of the plant or to other plants.

- The time elapsed without falling molds is another event. Given all the possible situations during the day-to-day production line, it can be found that the SBC is stopped but the vibrating device and the cooling drum continue working. This situation translates into advances in the content of the vibrating device without being real molds. In other words, it is a creation of empty slots that move the content of the device. Therefore, concurrently with the shake out events, verification processes to manage these movements are maintained. Thus, if a pre-established time passes (in the use case that concerns us, they have been defined as 14 s), the digital twin advances all molds located in the vibrating tape, introducing a blank gap that simulates the real advance.

2.2.1. Dwell Time

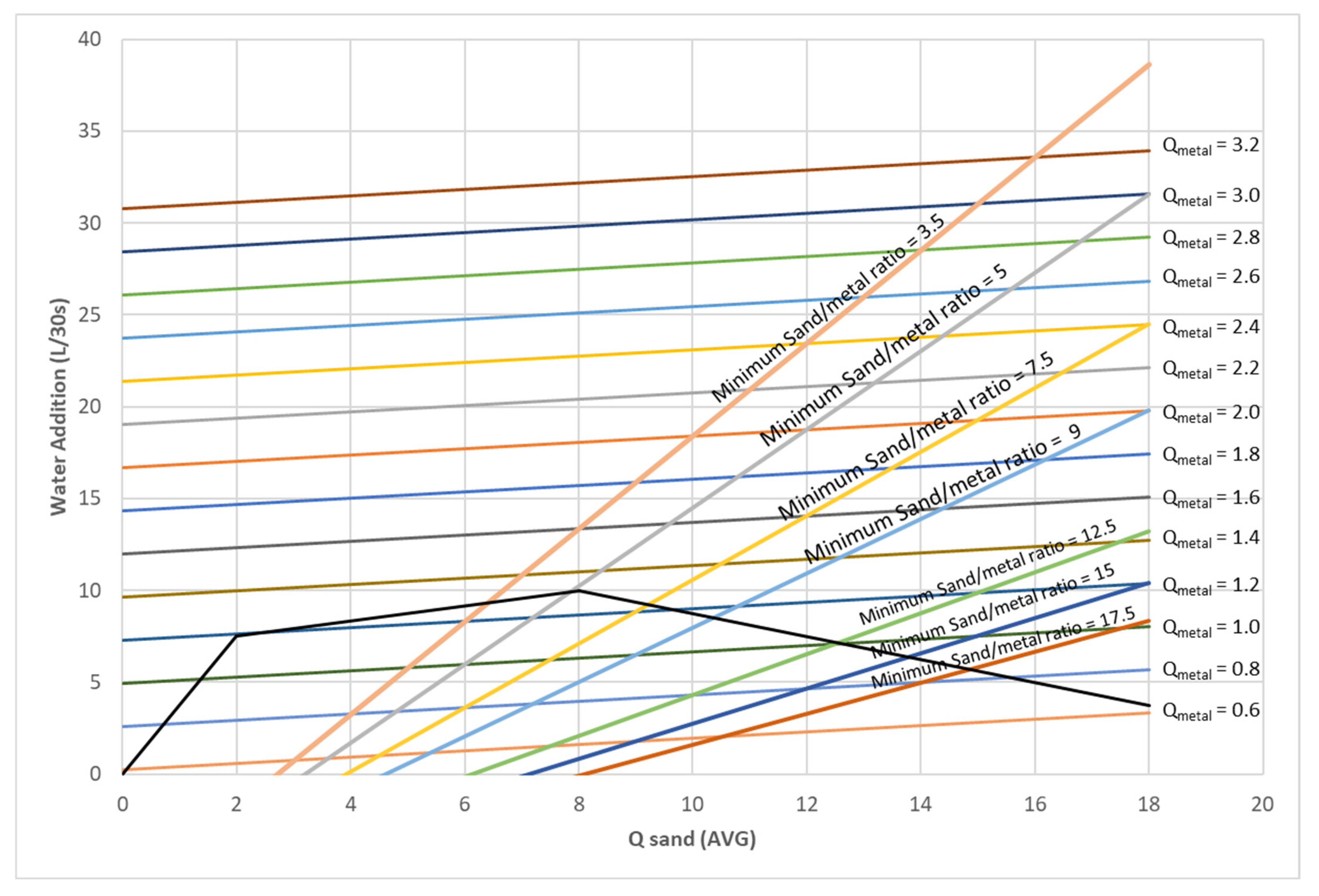

2.2.2. Sand and Metal Flows

2.3. Uncertainty Management and Adjustments

- Lag in the time shake out parameter. During the analysis of how the molding machine works, its behavior, and the information generated, we have detected a lag in the shake out time. Specifically, it is about 9–12 spots. In other words, when a mold falls to the vibrating device, the system indicates that fall between 9 and 12 advances later.

- Error generated by the molding machine due to dimensional variations in the cooling line. This is corrected through a configurable factor in the digital twin itself where, specifically, the fall is made 10 molds later than the molding machine indicates.

- Average of the weights. Although molds come into the cooling drum in sequence, there is uncertainty about the progress of the molds inside the cooling drum. In addition to this unknown, the addition of water is carried out on a series of molds, and not only on one mold. Therefore, researchers have decided to average the flows of a series of molds, which are located in the initial area of the cooling drum. In this way, it is possible to avoid or minimize the possible error that is generated in the assumption of the positioning of molds in the vibrating device and cooling drum.

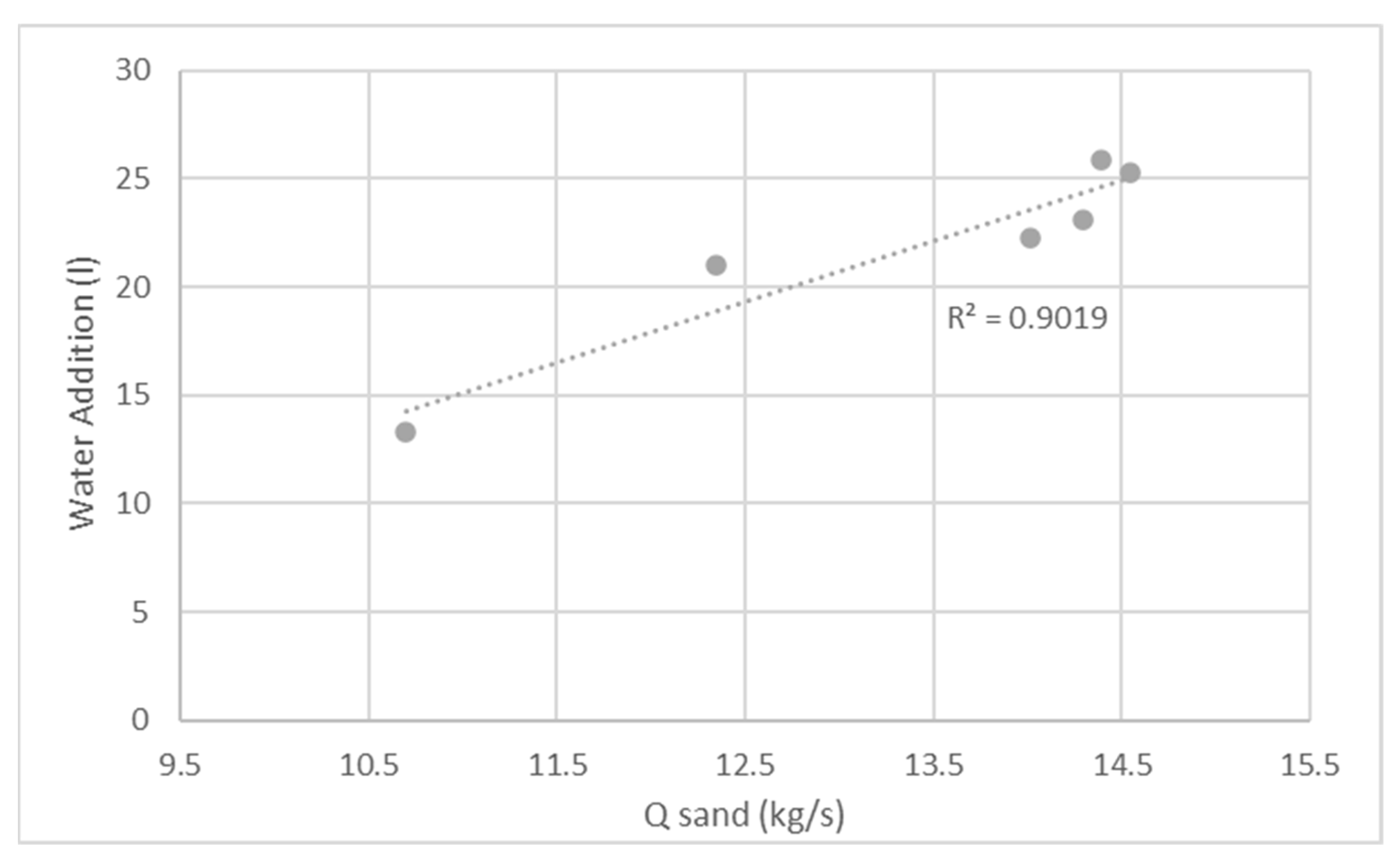

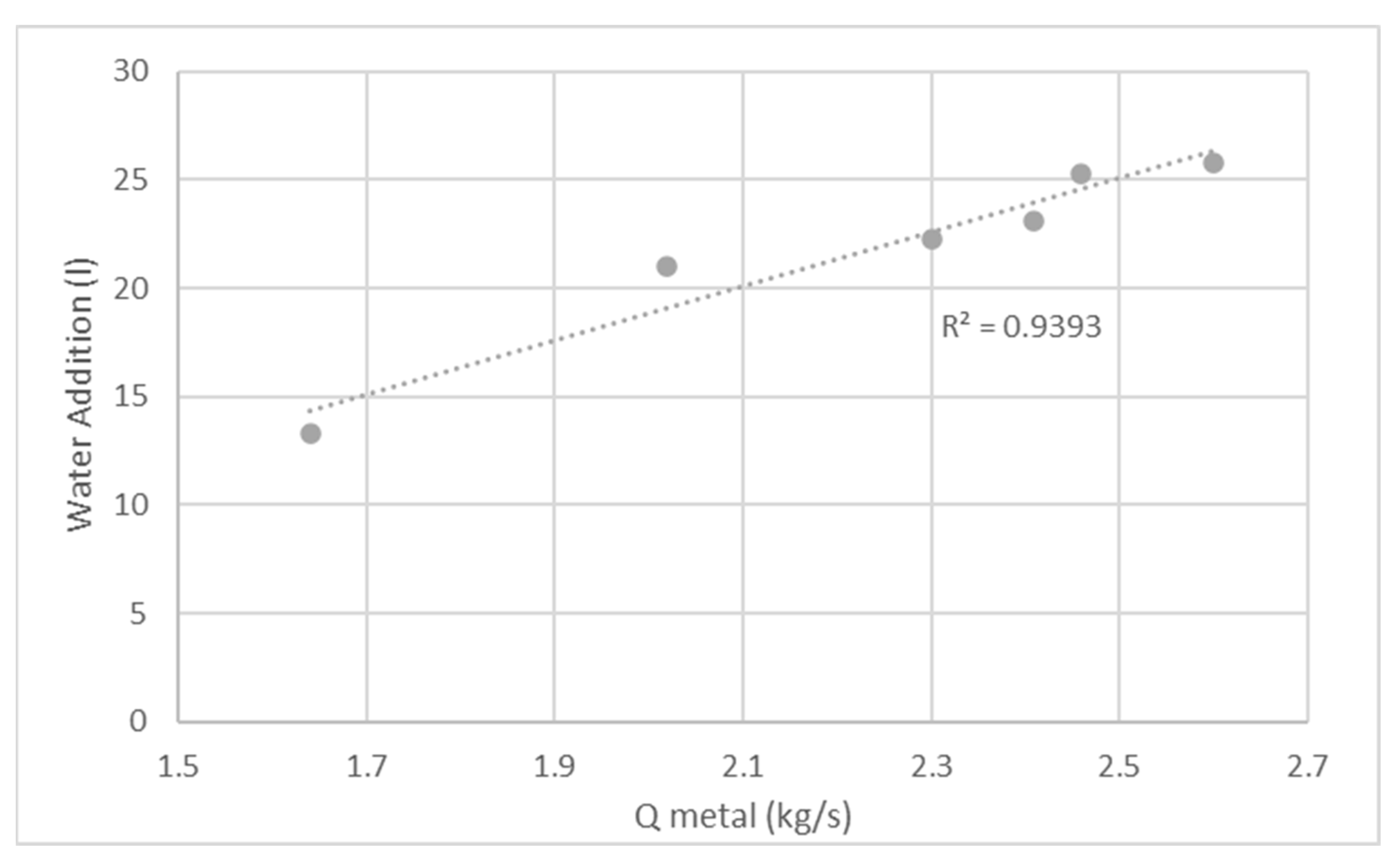

2.4. Prediction or Regression Function

- Coef indicates the estimation of the numbers that accompany the regression;

- Error indicates the variation that the estimation of the coefficient has, which is important when determining the significance;

- r2 indicates how well the model fits; its value range between 0 and 1, and the closer it is to 1, the independent variables explain a greater amount of the variation of the dependent variable;

- Sresidual is also known as the standard error and corresponds to how much the variables deviate from the prediction made by the regression;

- F indicates if all the coefficients of the regression, jointly, are different from zero;

- d.f. is the degree of freedom which is the number of degrees associated with the sources of variance;

- SCReg/SCRef is the relationship between the regression sum of squares and the residual, the lower this ratio, the better the data fit.

2.5. Management of Special Cases

- Vibrating device activated when SBC is stopped. When the vibrating device is activated and the line (the SBC) is stopped, there is a situation in which there is no shake out of molds that fills the queue of the vibrating device. Thus, after determining the status of the line, that is, if the vibrating device is working (capturing the digital signal from the hardware device) and the SBC is stopped (we do not detect shake out events of the molds), a temporary evaluation is carried out (18 s from the last drop of a mold) that determines if we should represent the progress of the vibrating device with a “hole” or “ghost mold” where we do not have sand or metal. Each of these generated holes occupies a segment of the sequence with a sand and metal flow rate of zero.

- By-pass and vibrating device activated. This case is similar to the previous one. When the by-pass is activated, molds are recovered before falling to the vibrating device. Thus, in this case, “holes” are also generated. As in the previous case, these “holes” or “ghost molds” are generated with a flow rate of metal and sand equal to zero.

- Empty molds. The molds considered to be empty at the end of the line do not contain metal, however, they produce a flow of sand. Since this sand is not heated by the pouring of the metal, the mold does not suffer a loss of moisture, therefore, it is not necessary to add more water to it. For this reason, the sand flow of the empty molds is considered to be zero.

- Starting after stops. After a prolonged stop of the molding line (more than 15 min), a situation of excessive drop in temperature in the molds may occur. For this reason, the system determines a restart process making a staggered supply of water. In this way, the digital twin avoids making excessive additions of water. This approach tries to take into consideration the cooling of the equipment and of the sand inside it. This method tries to avoid high humidity and viscosity, letting the sand be filtered through the corresponding holes.The stepwise additions of water were extracted through an empirical process of trial and error. Specifically, Table 2 shows the configuration values.With a stop of 15 to 60 min, the additions of water that are made during the first six molds created, start with a multiplying factor of 0.25. The following additions of the next six molds, start with a factor of 0.50, and finally, the additions of water made during the last six molds, start with a factor of 1.In the case of a long stop (between 60 min and 5 h), the first additions have a starting factor of 0.25 during the first 12 molds, the next 12 molds with 0.50, and finally, the last 12 molds have a starting factor of 1.In cases where the stop is greater than 5 h, the sequence is restarted, and the system must generate the entire sequence of 50 molds again before it begins to provide a value of water to add.Again, all these configuration values were extracted from the digital twin itself in order to be able to be modified, adapted, and adjusted, allowing new deployments of the system that we are presenting in this research paper.

- Molding machine without using sand. When the molding machine works empty, it does not generate any mold, since it executes the cycle without delivering any molds. In these cases, the line advances as if a new mold had been delivered, creating a gap in the molding line. Therefore, the more cycles that are empty, the greater the gap generated in the line. This situation is identified by analyzing the compressibility value provided by the molding machine. When this parameter offers a value of zero, the machine works without load, while a positive value indicates that the machine has pressed the sand during the corresponding cycle. These generated voids are subsequently undone on the line with real machine cycles (compressibility > 0) without the SBC molds advancing. Although these registered gaps appear in the database, the system does not consider this information, since the gaps generated never reach the end of the line. For this reason, the software is designed to avoid this kind of molds. Note that the molding machine usually marks the shake out time of all these molds with compressibility at zero, practically at the same time or does not mark them. This fact facilitates their processing.

2.6. Feedback to the Plant

- Data Storage. Every time there are advances in mold sequences (both in the cooling line and in the vibrating device or cooling drum), the digital twin triggers the calculation process and logs everything into a database. Specifically, there is a table in which the input information used as raw data is recorded (in other words, the information that represents the current state of the process, which has been used for the calculations) in addition to the proposal made by the developed digital system.

- SCADA modifications. The existing SCADA system has been modified. Specifically, it includes a new functionality that allows users to use our new suggestions or those already made by the old system. When the use of the digital twin is activated, the SCADA system accesses the database where the suggestions have been registered and employs them to generate the water additions. Otherwise, it uses its less accurate algorithm to add water.

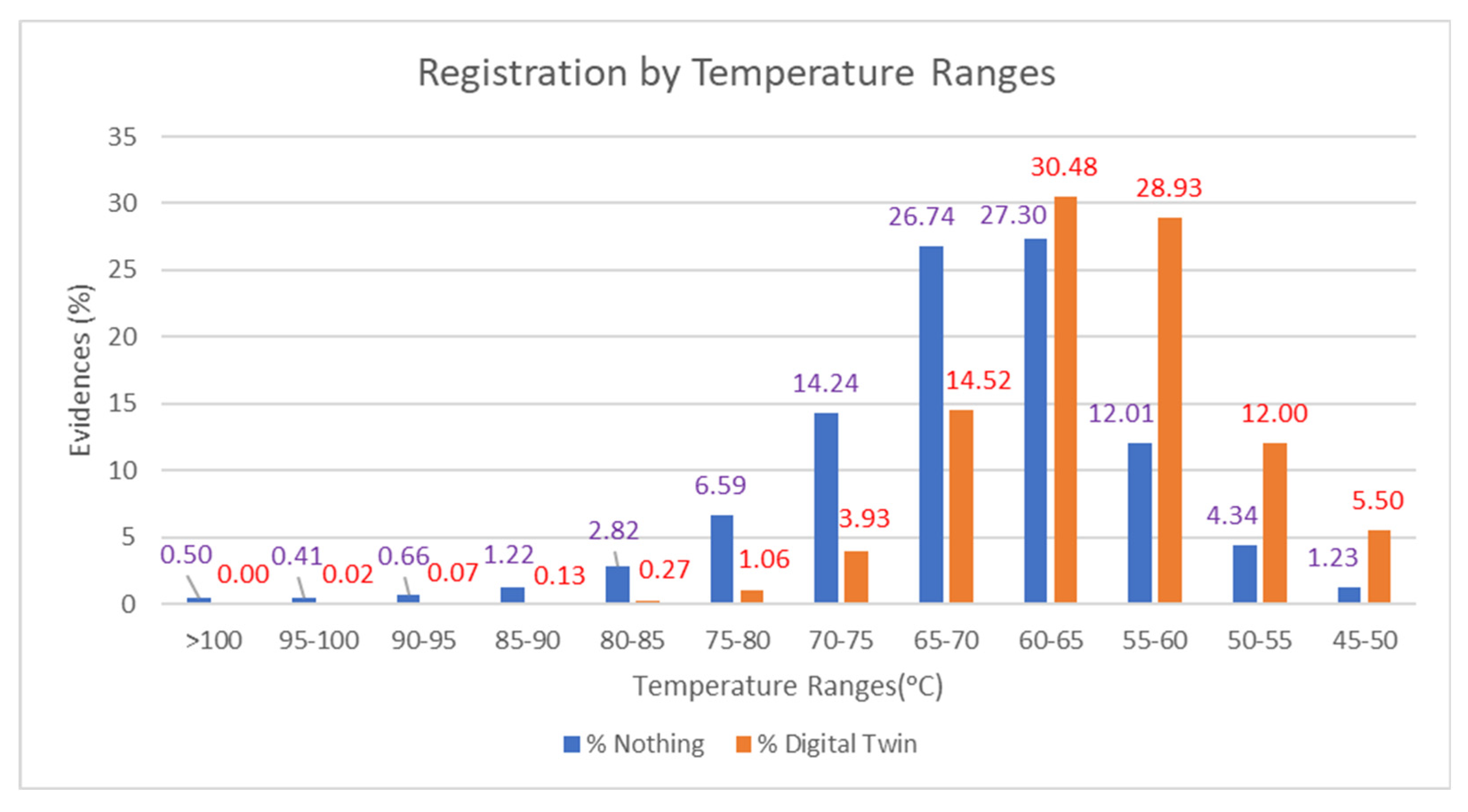

3. Results

4. Discussion and Conclusions

- The time of year causes variations in ambient temperature, humidity, or other atmospheric factors. These changes mean that, given the same addition value, the real system does not behave in the same way. For this reason, an adjustment factor was incorporated. Hence, an operator could manually reduce or increase the calculated addition values. However, as future work, this factor could be calculated automatically. According to each specific time of the year that the environmental values are collected at a plant, this factor should be adjusted.

- The digital twin represents the reality as a sequence of molds. It is true that molds are not kept in a perfect sequence inside the vibrating device, but our approximation works. The current parameterization of the system was carried out for a specific case, however, if there were changes in machinery the system would not be adjusted and would not work properly. Therefore, it is necessary to work on a better digitization that could provide enough information to allow the system to automatically calculate the adjustments of the digital representation.

- These types of systems are sensitive to data. In other words, if the data generated are wrong or contain errors, the system cannot perform its job properly. This can only be solved if data monitoring and validation systems are generated to ensure their quality. Likewise, if there are crashes in the information capture systems or sensor failures, the system would fail, again due to it not representing reality. In fact, maintenance teams take on greater importance to oversee making sure that the complex ecosystem of captors and actuators work properly.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pattnaik, S.; Karunakar, D.B.; Jha, P.K. Developments in investment casting process—A review. J. Mater. Processing Technol. 2012, 212, 2332–2348. [Google Scholar] [CrossRef]

- Fedoryszyn, A. Quality stabilisation of synthetic sand containing bentonite in process lines. Arch. Foundry Eng. 2010, 10, 143–148. [Google Scholar]

- Fedoryszyn, A.; Rudy, C.; Smyksy, K. The rationalization of construction and operation of the equipment for the molding sand preparation. Arch. Metall. Mater. 2013, 58, 915–918. [Google Scholar] [CrossRef] [Green Version]

- Ayani, M.; Ganebäck, M.; Ng, A.H. Digital Twin: Applying emulation for machine reconditioning. Procedia Cirp. 2018, 72, 243–248. [Google Scholar] [CrossRef]

- Kovacevic, L.; Oliveira, R.; Terek, P.; Terek, V.; Pristavec, J.; Škoric, B. i in.: The Direction of Foundry Industry: Toward the Foundry 4.0. J. Mechatron. Autom. Identif. Technol. 2020, 5, 23–28. [Google Scholar]

- Sertucha, J.; Loizaga, A.; Suarez, R. Improvement opportunities for simulation tools. In Proceedings of the 16th European Conference and Exhibition on Digital Simulation for Virtual Engineering (Invited Talk), Toulouse, France, 10–12 October 2006. [Google Scholar]

- He, B.; Bai, K.J. Digital twin-based sustainable intelligent manufacturing: A review. Adv. Manuf. 2021, 9, 1–21. [Google Scholar] [CrossRef]

- Anjos, V.; Vilela, F. The Journey to Olimpo—Description of the work developed by Sakthi Protugal in the pursuit of perfection. In Proceedings of the GIFA 2019 Conference Proceedings. CAEF-Forum (Invited Talk), Sintra, Portugal, 17–19 June 2019. [Google Scholar]

- Kozłowski, J.; Sika, R.; Górski, F.; Ciszak, O. Modeling of foundry processes in the era of industry 4.0. In Design, Simulation, Manufacturing: The Innovation Exchange; Springer: Berlin/Heidelberg, Germany, 2018; pp. 62–71. [Google Scholar]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital twin: Enabling technologies, challenges and open research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Boschert, S.; Rosen, R. Digital Twin—The Simulation Aspect. In Mechatronic Futures Challenges and Solutions for Mechatronic Systems and their Designers; Hehenberger, P., Bradley, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 59–74. [Google Scholar]

- Posner, E.A.; Spier, K.E.; Vermeule, A. Divide and conquer. J. Leg. Anal. 2010, 2, 417–471. [Google Scholar] [CrossRef] [Green Version]

- Mackey, L.; Jordan, M.; Talwalkar, A. Divide-and-conquer matrix factorization. Adv. Neural Inf. Processing Syst. 2011, 24. [Google Scholar]

- Horowitz, E.; Zorat, A. Divide-and-conquer for parallel processing. IEEE Trans. Comput. 1983, 32, 582–585. [Google Scholar] [CrossRef]

- Gruzman, V.M. Foundry production digitalization. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 966, p. 012127. [Google Scholar]

- Doroshenko, V.S.; Tokova, O.V. The Examples of Digitalization of Foundry Production: Virtual Engineering, Digital Twin, Additive Technologies. Control. Syst. Comput. 2020, 5, 64–69. [Google Scholar] [CrossRef]

- Kleeberg, C. MELTING 4.0 “–DIGITALISATION and DIGITAL CONTROL OF THE MELT SHOP OPERATIONS in FOUNDRIES AND STEEL MILLS. Fundid. Fundic. Ferreas Y No Ferreas En Arena Coquilla Y Fundición A Presión 2021, 267, 20–22. [Google Scholar]

- Juran, J.M.; Gryna, F.M. Quality Control Handbook (No. 658.562 Q-1q); McGraw Hill: New York, NY, USA, 1974. [Google Scholar]

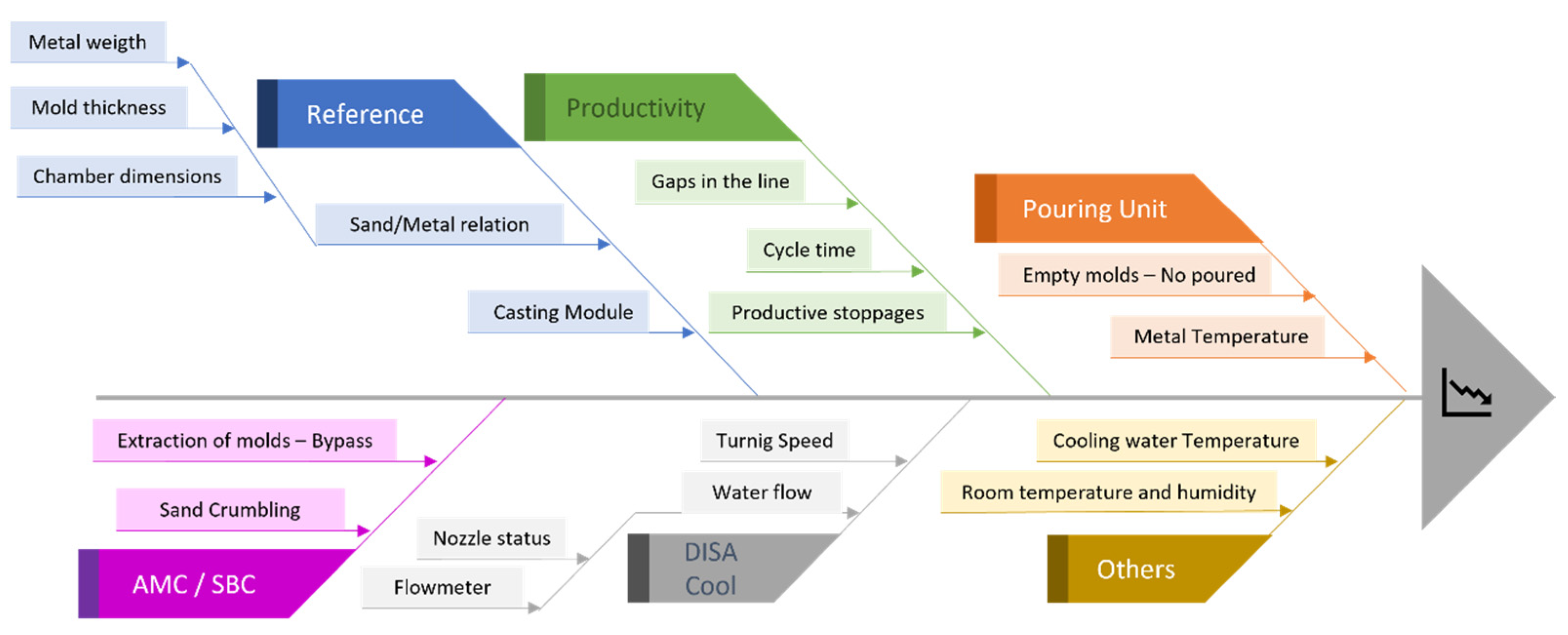

- Chokkalingam, B.; Raja, V.; Anburaj, J.; Immanual, R.; Dhineshkumar, M. Investigation of shrinkage defect in castings by quantitative Ishikawa diagram. Arch. Foundry Eng. 2017, 17, 174–178. [Google Scholar] [CrossRef] [Green Version]

- Chokkalingam, B.; Boovendravarman, S.; Tamilselvan, R.; Raja, V. Application of Ishikawa diagram to investigate significant factors causing rough surface on sand casting. Proc. Eng. Sci. 2020, 2, 353–360. [Google Scholar] [CrossRef]

- Luca, L.; Luca, T.O. Ishikawa diagram applied to identify causes which determines bearings defects from car wheels. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 564, p. 012093. [Google Scholar]

- Beeley, P. Foundry Technology; Elsevier: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Murthy, I.N.; Rao, J.B. Investigations on physical and chemical properties of high silica sand, Fe-Cr slag and blast furnace slag for foundry applications. Procedia Environ. Sci. 2016, 35, 583–596. [Google Scholar] [CrossRef]

| Q Metal | Q Sand | Constant | |

|---|---|---|---|

| Coef. | 11.7584704 | 0.173421604 | −6.84395782 |

| Error | 8.62276505 | 1.96740517 | 8.54667084 |

| R2/SResidual | 0.93941607 | 1.442050501 | - |

| F/d.f | 23.259042 | 3 | - |

| SCReg/ScRef | 96.7348044 | 6.238528944 | - |

| Downtime (tstop) (min) | |||

|---|---|---|---|

| 15 < tstop < 60 | 60 ≤ tstop < 300 | ||

| Multiplier Factor | Number of Molds | Multiplier Factor | Number of Molds |

| 0.25 | 6 | 0.25 | 12 |

| 0.50 | 6 | 0.50 | 12 |

| 0.75 | 6 | 0.75 | 12 |

| 1 | 6 | 1 | 12 |

| Average Temperature | Standard Deviation | Count of Registers with High Temperature (>100 °C) | |

|---|---|---|---|

| Without Digital Twin | 64.796 °C | 9.499 | 9200 |

| With Digital Twin | 60.874 °C | 7.039 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nieves, J.; Bravo, B.; Sierra, D.-C. A Smart Digital Twin to Stabilize Return Sand Temperature without Using Coolers. Metals 2022, 12, 730. https://doi.org/10.3390/met12050730

Nieves J, Bravo B, Sierra D-C. A Smart Digital Twin to Stabilize Return Sand Temperature without Using Coolers. Metals. 2022; 12(5):730. https://doi.org/10.3390/met12050730

Chicago/Turabian StyleNieves, Javier, Beñat Bravo, and David-Ciro Sierra. 2022. "A Smart Digital Twin to Stabilize Return Sand Temperature without Using Coolers" Metals 12, no. 5: 730. https://doi.org/10.3390/met12050730

APA StyleNieves, J., Bravo, B., & Sierra, D.-C. (2022). A Smart Digital Twin to Stabilize Return Sand Temperature without Using Coolers. Metals, 12(5), 730. https://doi.org/10.3390/met12050730