An Analytical Model for Stress and Curvature Prediction of a Strip Leveling Process

Abstract

1. Introduction

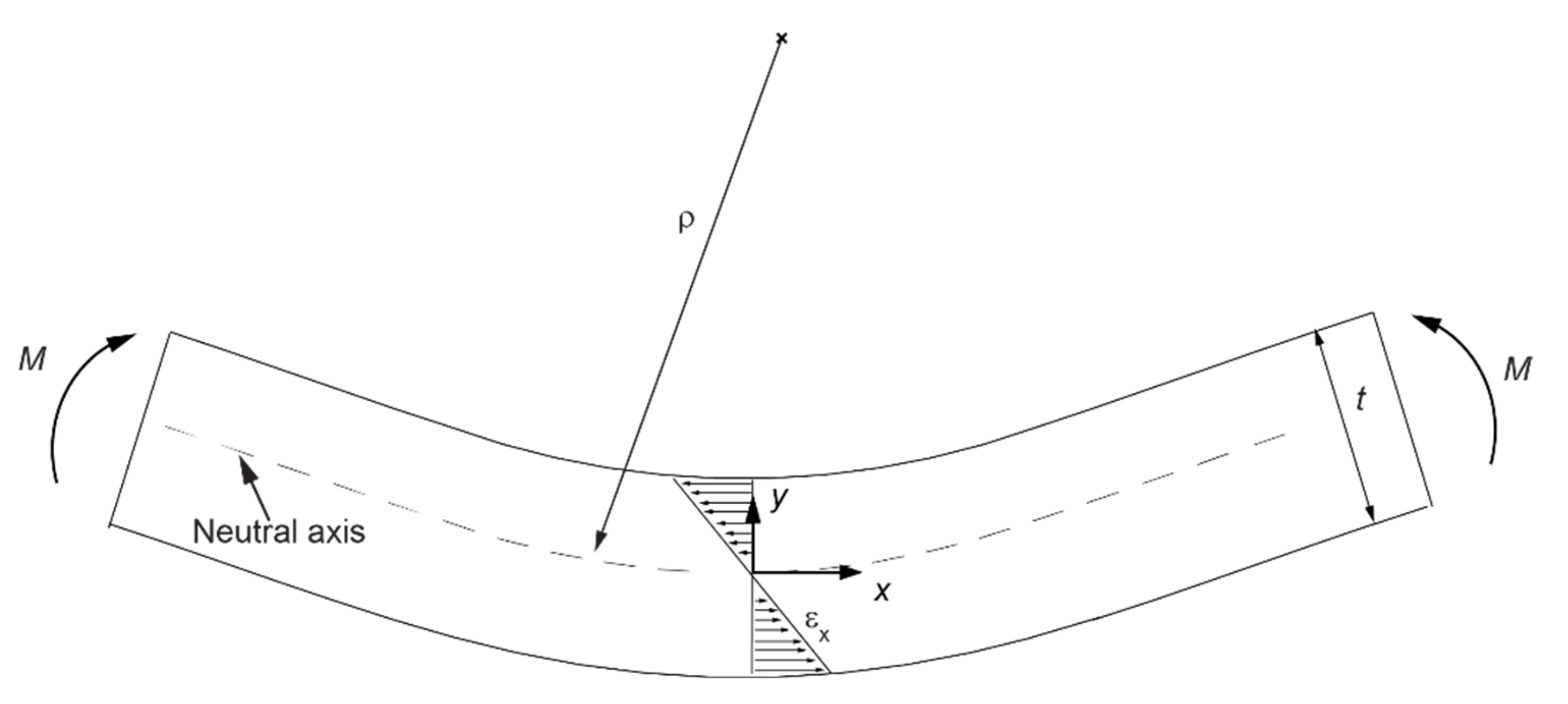

2. Analytical Model

2.1. Material Model

2.2. Contact Model

2.3. Residual Curvature

3. Finite Element Analysis

4. Analyses, Results, and Discussions

4.1. Analysis and Results of the Analytical Model

4.2. Analysis and Results of the Finite Element Model

4.3. Residual Curvature

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amor, A.; Rachik, M.; Sfar, H. Combination of finite-element and semi-analytical models for sheet metal leveling simulation. Key Eng. Mater. 2011, 473, 182–189. [Google Scholar] [CrossRef]

- Li, S.-Z.; Yin, Y.-D.; Xu, J.; Hou, J.-M.; Yoon, J. Numerical simulation of continuous tension leveling process of thin strip steel and its application. J. Iron Steel Res. Int. 2007, 14, 8–13. [Google Scholar] [CrossRef]

- Morris, J.W.; Hardy, S.J.; Lees, A.W.; Thomas, J.T. Some fundamental considerations for the control of residual flatness in tension levelling. J. Mater. Processing Technol. 2002, 120, 385–396. [Google Scholar] [CrossRef]

- Hira, T.; Abe, H.; Azuma, S. Analysis of sheet metal bending deformation behavior in processing lines and its effectiveness. Kawasaki Steel Eng. Rep. 1988, 19, 54–62. [Google Scholar]

- Doege, E.; Menz, R.; Huinink, S. Analysis of the levelling process based upon an analytic forming model. CIRP Ann. Manuf. Technol. 2002, 51, 191–194. [Google Scholar] [CrossRef]

- Behrens, B.-A.; El Nadi, T.; Krimm, R. Development of an analytical 3D-simulation model of the levelling process. J. Mater. Processing Technol. 2011, 211, 1060–1068. [Google Scholar] [CrossRef]

- Dratz, B.; Nalewajk, V.; Bikard, J.; Chaste, Y. Testing and modelling the behavior of steel sheets for roll levelling applications. Int. J. Mater. Form. 2009, 2, 519. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Yan, X. A new model for the plate leveling process based on curvature integration method. Int. J. Mech. Sci. 2012, 54, 213–224. [Google Scholar] [CrossRef]

- Chen, W.-H.; Liu, J.; Cui, Z.-S.; Wang, Y.-J.; Wang, Y.-R. A 2.5-dimensional analytical model of cold leveling for plates with transverse wave defects. J. Iron Steel Res. Int. 2015, 22, 664–671. [Google Scholar] [CrossRef]

- Higo, T.; Matsumoto, H.; Ogawa, S. Influence of delivery-side roll position of roller leveler to plate flatness. In Proceedings of the 2016 AISTech Conference, Pittsburgh, PA, USA, 16–19 May 2016; pp. 2129–2137. [Google Scholar]

- Morris, J.W.; Hardy, S.J.; Lees, A.W.; Thomas, J.T. Formation of residual stresses owing to tension levelling of cold rolled strip. Ironmak. Steelmak. 2001, 28, 44–52. [Google Scholar] [CrossRef]

- Schleinzer, G.; Fischer, F.D. Residual stress formation during the roller straightening of railway rails. Int. J. Mech. Sci. 2001, 43, 2281–2295. [Google Scholar] [CrossRef]

- Park, K.-C.; Hwang, S.-M. Development of a finite element analysis program for roller leveling and application or removing blanking bow defects of thin steel sheet. ISIJ Int. 2002, 42, 990–999. [Google Scholar] [CrossRef][Green Version]

- Huh, H.; Heo, J.H.; Lee, H.W. Optimization of a roller levelling process for Al7001T9 pipes with finite element analysis and Taguchi method. Int. J. Mach. Tools Manuf. 2003, 43, 345–350. [Google Scholar] [CrossRef]

- Roberts, I.; Wang, C.; Mynors, D.; Adams, P.; Lane, K.; Unwin, P. Numerical analysis of strip-roll conformity in tension levelling. In Proceedings of the 10th International Conference of Technology of Plasticity (ICTP 2011), Aachen, Germany, 25–30 September 2011; pp. 315–319. [Google Scholar]

- Jin, H.-R.; Yi, Y.-L.; Han, X.-Y.; Liang, Y. Roller straightening process and FEM simulation for stainless steel clad plate. Open Mech. Eng. J. 2014, 8, 557–561. [Google Scholar]

- Kim, J.; Park, K.-C.; Kim, D.-N. Investigating the fluting defect in v-bending due to the yield-point phenomenon and its reduction via roller-leveling process. J. Mater. Processing Technol. 2019, 270, 59–81. [Google Scholar] [CrossRef]

- Grüber, M.; Kümmelb, L.; Hirt, G. Control of residual stresses by roller leveling with regard to process stability and one-sided surface removal. J. Mater. Processing Technol. 2020, 280, 116600. [Google Scholar] [CrossRef]

- Zhang, D.; Cui, Z.; Ruan, X.; Li, Y. An analytical model for predicting springback and side wall curl of sheet after U-bending. Comput. Mater. Sci. 2007, 38, 707–715. [Google Scholar] [CrossRef]

- Kotov, K.A.; Bolobanova, N.L.; Nushtaev, D.V. Modeling the stress state of a steel strip with a roller leveling machine under cyclic alternating deformations. Steel Transl. 2020, 50, 750–755. [Google Scholar] [CrossRef]

- Müller, U.; Krambeer, H.; Wolff, A.; Viella, A.E.; Richardson, A.D.; Perä, J.-O.; Luoto, P.; Weberm, W. Optimisation of Final Plate Flatness by Set-Up Coordination for Subsequent Manufacturing Process (Final Plate Flatness); Final Report, EUR 25852 EN; Europe Commission: Brussels, Belgium, 2013. [Google Scholar]

- Guan, B.; Zhang, C.; Zang, Y.; Wang, Y. Model for the whole roller leveling process of plates with random curvature distribution based on the curvature integration method. Chin. J. Mech. Eng. 2019, 32, 47. [Google Scholar] [CrossRef]

- Hosford, W.F.; Caddell, R.M. Metal Forming–Mechanics and Metallurgy; Prentice Hall: Hoboken, NJ, USA, 1993. [Google Scholar]

- Guan, B.; Zang, Y.; Wu, D.; Qin, Q. Study on mechanical behavior of thin-walled member during precision straightening process. Sens. Transducers 2014, 179, 36–42. [Google Scholar]

- Guan, B.; Zang, Y.; Wu, D.; Qin, Q. Stress-inheriting behavior of H-beam during roller straightening process. J. Mater. Processing Technol. 2017, 244, 253–272. [Google Scholar] [CrossRef]

- Yonetani, S. The Engender Theory and Countermeasure of Residual Stress; China Machine Press: Beijing, China, 1983. [Google Scholar]

- Smith, R.P. The effect of the number of leveling rolls on the straightening process. Iron Steel Technol. 2007, 4, 57–68. [Google Scholar]

- Yi, G.; Wang, Z.; Hu, Z. A novel modeling method in metal strip leveling based on a roll-strip unit. Math. Probl. Eng. 2020, 2020, 1486864. [Google Scholar] [CrossRef]

- Mathieu, N.; Dimitriou, R.; Parrico, A.; Potier-Ferry, M.; Zahrouni, H. Flatness defects after bridle rolls: A numerical analysis of leveling. Int. J. Mater. Form. 2013, 6, 255–266. [Google Scholar] [CrossRef]

- Carvalho, A.P.; Reis, L.M.; Pinheiro, R.P.R.P.; Pereira, P.H.R.; Langdon, T.G.; Figueiredo, R.B. Using Plane Strain Compression Test to Evaluate the Mechanical Behavior of Magnesium Processed by HPT. Metals 2022, 12, 125. [Google Scholar] [CrossRef]

- Baumgart, M.; Steinboeck, A.; Kiefer, T.; Kugi, A. Modelling and experimental validation of the deflection of a leveler for hot heavy plates. Math. Comput. Model. Dyn. Syst. 2015, 21, 202–227. [Google Scholar] [CrossRef]

- Wang, X.; Li, X. Research on force simulation of main leveler housing and roll cassettes in medium and heavy plate leveling. J. Converg. Inf. Technol. 2012, 7, 153–161. [Google Scholar]

| Property | E (Gpa) | σs (MPa) | Poisson’s Ratio | C (Mpa) | γ | Q∞ (Mpa) | b |

|---|---|---|---|---|---|---|---|

| Value | 219.8 | 329.7 | 0.3 | 44,600.6 | 673.1 | 96.9 | 12.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuo, S.-K.; Ou, Y.-L.; Wang, D.-A. An Analytical Model for Stress and Curvature Prediction of a Strip Leveling Process. Metals 2022, 12, 757. https://doi.org/10.3390/met12050757

Kuo S-K, Ou Y-L, Wang D-A. An Analytical Model for Stress and Curvature Prediction of a Strip Leveling Process. Metals. 2022; 12(5):757. https://doi.org/10.3390/met12050757

Chicago/Turabian StyleKuo, Shih-Kang, Yi-Liang Ou, and Dung-An Wang. 2022. "An Analytical Model for Stress and Curvature Prediction of a Strip Leveling Process" Metals 12, no. 5: 757. https://doi.org/10.3390/met12050757

APA StyleKuo, S.-K., Ou, Y.-L., & Wang, D.-A. (2022). An Analytical Model for Stress and Curvature Prediction of a Strip Leveling Process. Metals, 12(5), 757. https://doi.org/10.3390/met12050757