Investigation of Laser Butt Welding of AISI 304L and Q235 Steels Based on Numerical and Experimental Analyses

Abstract

:1. Introduction

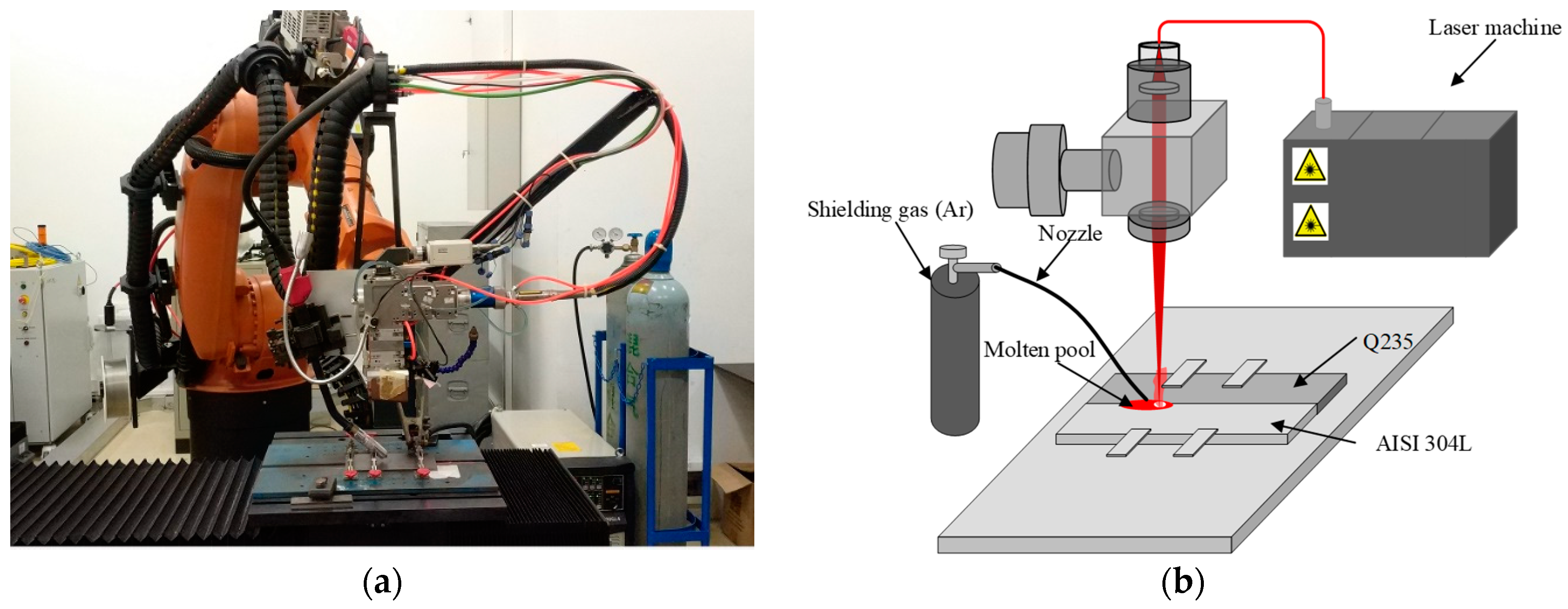

2. Experimental Setup

2.1. Laser Welding Setup

2.2. Materials

3. Numerical Simulation Setup

3.1. Mesh Design and Assumptions in Numerical Simulation

3.2. Modeling of the Laser Beam

3.3. Thermal Properties of the Materials

4. Validation of the Numerical Simulation

5. Results Discussion

5.1. The Shapes of the Welded Joint in the Laser Welding of AISI 304L and Q235 Steels

5.2. The Effect of the Laser Power on the Welded Joint

5.3. The Effects of the Laser Beam Offset on the Welded Joint

6. Conclusions

- (1)

- The numerical simulation with a combined asymmetric heat source implemented in this study agreed well with the experimental results and can be applied to investigate the mechanisms for forming different weld joint shapes in AISI 304L and Q235 steels;

- (2)

- The different shapes of the weld joints resulted from the different thermal conductivity and melting temperatures of the two dissimilar metals;

- (3)

- The effects of the laser beam offset and laser power in dissimilar welding of AISI 304 and low-carbon steel were investigated, proving that a laser power of 2 kW and laser beam offset of 0 mm are the optimum parameters in the laser butt welding of AISI 304L and Q235 plates with an equal thickness of 3 mm.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Riofrío, P.G.; Ferreira, J.A.; Capela, C.A. Imperfections and modelling of the weld bead profile of laser butt joints in HSLA steel thin plate. Metals 2021, 11, 151. [Google Scholar] [CrossRef]

- Cui, L.; Chen, B.; Qian, W.; He, D.; Chen, L. Microstructures and Mechanical Properties of Dissimilar Al/Steel Butt Joints Produced by Autogenous Laser Keyhole Welding. Metals 2017, 7, 492. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; You, D.; Gao, X.; Katayama, S. Online monitoring of welding status based on a DBN model during laser welding. Engineering 2019, 5, 671–678. [Google Scholar] [CrossRef]

- Prabakaran, M.P.; Kannan, G.R. Optimization of laser welding process parameters in dissimilar joint of stainless steel AISI316/AISI1018 low carbon steel to attain the maximum level of mechanical properties through PWHT. Opt. Laser Technol. 2019, 112, 314–322. [Google Scholar] [CrossRef]

- Chen, L.; Wang, C.M.; Zhang, X.; Mi, G.Y. Effect of parameters on microstructure and mechanical property of dissimilar joints between 316L stainless steel and GH909 alloy by laser welding. J. Manuf. Processes 2021, 65, 60–69. [Google Scholar] [CrossRef]

- Zhou, X.F.; Cao, X.B.; Zhang, F.; Duan, J.A. Numerical and experimental investigation of thermal stress distribution in laser lap welding of Ti6Al4V and 2024 alloy plates. Int. J. Adv. Manuf. Technol. 2022, 118, 1427–1440. [Google Scholar] [CrossRef]

- Zhou, X.R.; Ning, J.; Na, S.J.; Zhang, L.J. Microstructures and properties of the dissimilar joint of pure molybdenum/ T2 copper by single-mode laser welding. Int. J. Refract. Met. Hard Mater. 2021, 101, 105667. [Google Scholar] [CrossRef]

- Dak, G.; Pandey, C. A critical review on dissimilar welds joint between martensitic and austenitic steel for power plant application. J. Manuf. Processes 2020, 58, 377–406. [Google Scholar] [CrossRef]

- Kumar, A.; Pandey, C. Autogenous laser-welded dissimilar joint of ferritic/martensitic P92 steel and Inconel 617 alloy: Mechanism, microstructure, and mechanical properties. Arch. Civ. Mech. Eng. 2022, 22, 39. [Google Scholar] [CrossRef]

- Kumar, S.; Yadav, V.K.; Sharma, S.K.; Pandey, C.; Goyal, A.; Kumar, P. Role of dissimilar Ni-based ERNiCrMo-3 filler on the microstructure, mechanical properties and weld induced residual stresses of the ferritic/martensitic P91 steel welds joint. Int. J. Press. Vessel. Pip. 2021, 193, 104443. [Google Scholar] [CrossRef]

- Gao, M.; Zhang, Y.Z.; Meng, Y.F. Interface homogenization and its relationship with tensile properties of laser-arc hybrid welded Al/steel butt-joint via beam oscillation. J. Mater. Sci. 2021, 56, 14126–14138. [Google Scholar] [CrossRef]

- Gao, X.L.; Li, L.K.; Liu, J.; Wang, X.Q.; Yu, H.K. Analysis of Ni interlayer effects on laser beam welding of dissimilar pure Mo alloy to stainless steel. Int. J. Refract. Met. Hard Mater. 2021, 100, 105654. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, W.; Li, Y.; Chen, H. Effect of laser-arc offset and laser-deviation angle on the control of a Ti-Al interlayer. J. Mater. Process. Technol. 2019, 271, 336–345. [Google Scholar] [CrossRef]

- Lei, Z.L.; Zhang, X.R.; Liu, J.G.; Li, P. Interfacial microstructure and reaction mechanism with various weld fillers on laser welding-brazing of Al/Cu lap joint. J. Manuf. Processes 2021, 67, 226–240. [Google Scholar] [CrossRef]

- Meng, Y.F.; Jiang, L.H.; Cen, L.; Gao, M. Improved mechanical properties of laser-arc hybrid welded Al/steel dissimilar butt-joint through beam oscillation. Sci. Technol. Weld. Join. 2021, 26, 487–492. [Google Scholar] [CrossRef]

- Li, L.; Xia, H.; Tan, C.; Ma, N. Effect of groove shape on laser welding-brazing Al to steel. J. Mater. Process. Technol. 2018, 252, 573–581. [Google Scholar] [CrossRef]

- Zhang, M.J.; Chen, G.Y.; Zhang, Y.; Wu, K.R. Research on microstructure and mechanical properties of laser keyhole welding–brazing of automotive galvanized steel to aluminum alloy. Mater. Des. 2013, 45, 24–30. [Google Scholar] [CrossRef]

- Sun, J.H.; Qi, Y.; Li, Z.G.; Hang, J. Effect of bevel angle on microstructure and mechanical property of Al/steel butt joint using laser welding-brazing method. Mater. Des. 2016, 90, 468–477. [Google Scholar] [CrossRef]

- Pereira, A.; Cabrinha, A.; Rocha, F.; Marques, P.; Fernandes, F.; Alves de Sousa, R. Dissimilar Metals Laser Welding between DP1000 Steel and Aluminum Alloy 1050. Metals 2019, 9, 102. [Google Scholar] [CrossRef] [Green Version]

- Perez Zapico, E.; Ascari, A.; Dimatteo, V.; Fortunato, A. Laser dissimilar welding of copper and steel thin sheets for battery production. J. Laser Appl. 2021, 33, 012016. [Google Scholar] [CrossRef]

- Patidar, D.; Rana, R.S. The effect of CO2 laser cutting parameter on Mechanical & Microstructural characteristics of high strength steel—A review. Mater. Today Proc. 2018, 5, 17753–17762. [Google Scholar]

- Bhanu, V.; Fydrych, D.; Gupta, A.; Pandey, C. Study on Microstructure and Mechanical Properties of Laser Welded Dissimilar Joint of P91 Steel and INCOLOY 800HT Nickel Alloy. Materials 2021, 14, 5876. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Li, Z.Y.; Song, X.G.; Tan, C.W.; He, Z.Z.; Huang, Y.X.; Feng, J.C. Influence of laser offset on laser welding-brazing of Al/brass dissimilar alloys. J. Alloys Compd. 2017, 717, 78–92. [Google Scholar] [CrossRef]

- Chen, S.; Li, L.; Chen, Y.; Huang, J. Joining mechanism of Ti/Al dissimilar alloys during laser welding-brazing process. J. Alloys Compd. 2011, 509, 891–898. [Google Scholar] [CrossRef]

- Peng, C.; Cheng, D.H.; Chen, Y.P.; Hu, D. Microstructure and properties of Al/Cu dissimilar materials TIG butt joints with filler wire. Chin. J. Nonferrous Met. 2015, 25, 975–981. [Google Scholar]

- Gao, X.; Ding, D.; Bai, T.; Katayama, S. Weld-pool image centroid algorithm for seam-tracking vision model in arc-welding process. IET Image Process. 2011, 5, 410. [Google Scholar] [CrossRef]

- Zhang, Y.; You, D.; Gao, X.; Zhang, N.; Gao, P.P. Welding defects detection based on deep learning with multiple optical sensors during disk laser welding of thick plates. J. Manuf. Syst. 2019, 51, 87–94. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, X.; You, D.; Zhang, N. Data-Driven Detection of Laser Welding Defects Based on Real-Time Spectrometer Signals. IEEE Sens. J. 2019, 19, 9364–9373. [Google Scholar] [CrossRef]

- Zhang, Y.; You, D.; Gao, X.; Wang, C.; Li, Y.; Gao, P.P. Real-time monitoring of high-power disk laser welding statuses based on deep learning framework. J. Intell. Manuf. 2019, 31, 799–814. [Google Scholar] [CrossRef]

- Zhan, X.H.; Liu, J.Z.; Yan, T.Y.; Kang, X.F.; Zhang, J.H. Study on the grain morphology and fracture performance of T-joints for Ti6Al4V alloy manufactured by dual laser beam bilateral synchronous welding. Opt. Laser Technol. 2021, 141, 107153. [Google Scholar] [CrossRef]

- Zou, J.L.; Han, X.; Zhao, Y.; Wu, Q.; Xiao, R.S. Investigation on plume formation during fiber laser keyhole welding based on in-situ measurement of particles in plume. J. Manuf. Processes 2021, 65, 153–160. [Google Scholar] [CrossRef]

- Gennari, C.; Lago, M.; Bögre, B.; Meszaros, I.; Calliari, I.; Pezzato, L. Microstructural and Corrosion Properties of Cold Rolled Laser Welded UNS S32750 Duplex Stainless Steel. Metals 2018, 8, 1074. [Google Scholar] [CrossRef] [Green Version]

- Huang, R.R.; Tan, C.W.; Sun, Y.M.; Gong, X.T.; Wu, L.J.; Chen, B.; Zhao, H.Y.; Song, X.G. Influence of processing window on laser welding-brazing of Al to press-hardened 22MnB5 steel. Opt. Laser Technol. 2021, 133, 106566. [Google Scholar] [CrossRef]

- Wallerstein, D.; Lusquinos, F.; Comesana, R.; del Val, J.; Riveiro, A.; Badaoui, A.; Pou, J. Dissimilar unbeveled butt joints of AA6061 to S235 structural steel by means of standard single beam fiber laser welding-brazing. J. Mater. Process. Technol. 2021, 291, 116994. [Google Scholar] [CrossRef]

- Song, J.L.; Lin, S.B.; Yang, C.L.; Ma, G.C.; Liu, H. Spreading behavior and microstructure characteristics of dissimilar metals tig welding–brazing of aluminum alloy to stainless steel. Mater. Sci. Eng. A 2009, 509, 31–40. [Google Scholar] [CrossRef]

- Sun, J.H.; Huang, J.; Yan, Q.; Li, Z.G. Fiber laser butt joining of aluminum to steel using welding-brazing method. Int. J. Adv. Manuf. Technol. 2016, 85, 2639–2650. [Google Scholar] [CrossRef]

- Zhu, Z.T.; Wan, Z.D.; Li, Y.X.; Chen, H. Intermediate layer, microstructure and mechanical properties of aluminum alloy/stainless steel butt joint using laser-MIG hybrid welding-brazing method. Int. J. Mod. Phys. B 2017, 31, 1744035. [Google Scholar] [CrossRef]

- Zhang, Y.; Han, S.; Cheon, J.; Na, S.; Gao, X. Effect of joint gap on bead formation in laser butt welding of stainless steel. J. Mater. Process. Technol. 2017, 249, 274–284. [Google Scholar] [CrossRef]

- Cho, W.; Na, S. Impact of Wavelengths of CO2, Disk, and Green Lasers on Fusion Zone Shape in Laser Welding of Steel. J. Weld. Join. 2020, 38, 235–240. [Google Scholar] [CrossRef]

- Pocorni, J.; Han, S.-W.; Cheon, J.; Na, S.; Kaplan, A.F.H.; Bang, H. Numerical simulation of laser ablation driven melt waves. J. Manuf. Processes 2017, 30, 303–312. [Google Scholar] [CrossRef]

- Jiang, M.; Jiang, N.; Chen, X.; Ma, S.; Chen, Y.; Chen, Y.; Lei, Z. Experimental and numerical investigation of single-pass laser welding of 20 mm-thick high-strength steel under reduced ambient pressure. J. Mater. Res. Technol. 2021, 15, 2317–2331. [Google Scholar] [CrossRef]

- Gao, Z.; Jiang, P.; Mi, G.; Cao, L.; Liu, W. Investigation on the weld bead profile transformation with the keyhole and molten pool dynamic behavior simulation in high power laser welding. Int. J. Heat Mass Transf. 2018, 116, 1304–1313. [Google Scholar] [CrossRef]

| Parameter | Laser Power (kW) | Laser Offset on Q235 Side (mm) |

|---|---|---|

| 1 | 2 | 0.15 |

| 2 | 2 | 0.1 |

| 3 | 2 | −0.1 |

| 4 | 2 | 0 |

| 5 | 1 | 0 |

| 6 | 1.5 | 0 |

| 7 | 2.5 | 0 |

| Metal | C | Si | Mn | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| Q235 | 0.17 | 0.1 | 0.44 | 0.03 | 0.03 | 0.7 | - |

| AISI 304L | 0.07 | 0.57 | 1.53 | 0.028 | 0.03 | 17.5 | 8.02 |

| Properties | AISI 304L | Q235 |

|---|---|---|

| Solid density (kg/m3) | 6900 | 6970 |

| Liquid density (kg/m3) | 6900 | 6970 |

| Specific heat of liquid (J/kg K) | 750 | 860 |

| Latent heat of fusion (J/kg) | 2.74 × 105 | 2.5 × 105 |

| Solids temperature (K) | 1655 | 1719 |

| Melting temperature (K) | 1727 | 1789 |

| Temperature (K) | 298 | 523 | 773 | 1023 | 1273 | 1523 | 1773 | 2023 |

|---|---|---|---|---|---|---|---|---|

| Thermal conductivity of AISI 304L (W/m2.K) | 17 | 20 | 23 | 26 | 29 | 31 | 32 | 35 |

| Thermal conductivity of Q235 (W/m2.K) | 57 | 49 | 39 | 28 | 29 | 32 | 34 | 37 |

| Parameters | a1 | a2 | b | c | r | h |

|---|---|---|---|---|---|---|

| AISI 304L (mm) | 0.5 | 1 | 1.1 | 0.29 | 0.2 | 3 |

| Q235 (mm) | 0.5 | 2 | 1 | 0.15 | 0.2 | 3 |

| Points | A1 | A2 | A3 | A4 | A5 | A6 | B1 | B2 | B3 | B4 | B5 | B6 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Highest temperature (K) | 4892 | 4706 | 4236 | 3580 | 2854 | 2392 | 5177 | 4346 | 3363 | 2402 | 1905 | 1831 |

| time (s) | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.41 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.43 |

| Experiment with Laser Beam Offset (mm) | Offset: 0 | Offset: 1 | Offset: 1.5 | Offset: −1 |

|---|---|---|---|---|

| Average hardness (HV) | 404 | 382 | 380 | 422 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Gao, X.; You, D.; Jiang, X.; Ge, W. Investigation of Laser Butt Welding of AISI 304L and Q235 Steels Based on Numerical and Experimental Analyses. Metals 2022, 12, 803. https://doi.org/10.3390/met12050803

Zhang Y, Gao X, You D, Jiang X, Ge W. Investigation of Laser Butt Welding of AISI 304L and Q235 Steels Based on Numerical and Experimental Analyses. Metals. 2022; 12(5):803. https://doi.org/10.3390/met12050803

Chicago/Turabian StyleZhang, Yanxi, Xiangdong Gao, Deyong You, Xiaoming Jiang, and Wenjun Ge. 2022. "Investigation of Laser Butt Welding of AISI 304L and Q235 Steels Based on Numerical and Experimental Analyses" Metals 12, no. 5: 803. https://doi.org/10.3390/met12050803