Temperature Field Evolution of Seeding during Directional Solidification of Single-Crystal Ni-Based Superalloy Castings

Abstract

:1. Introduction

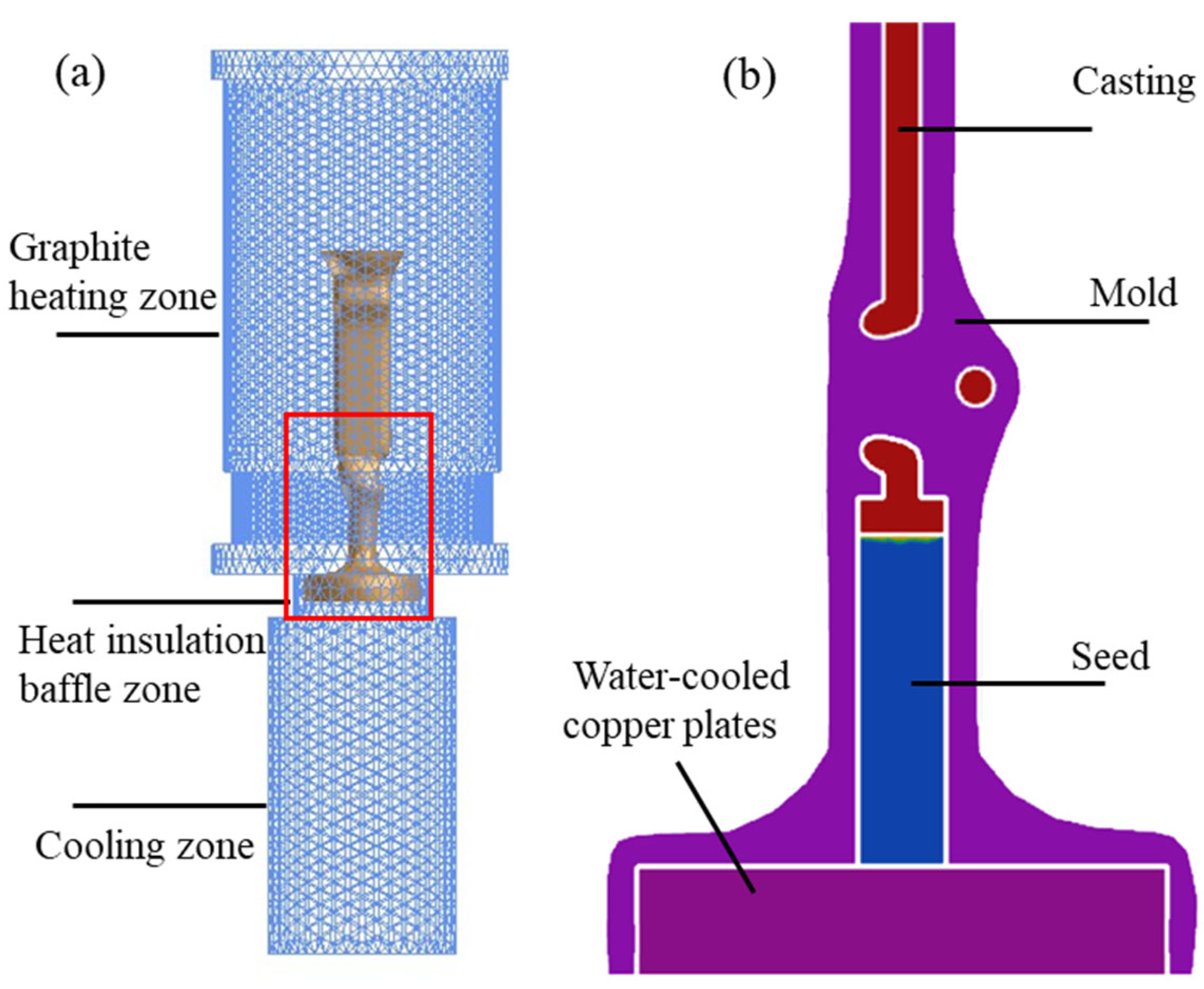

2. Simulation and Experiment

3. Results

3.1. Simulation Results

3.2. Experimental Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Harris, K.; Erickson, G.L.; Schwer, R.E. Metals Handbook, 10th ed.; ASM International: Russell Township, OH, USA, 1990. [Google Scholar]

- Reed, R.C. The Superalloys Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Koff, B.L. Gas turbine technology evolution: A designer’s perspective. J. Propuls. Power 2004, 20, 577–595. [Google Scholar] [CrossRef]

- Kakehi, K. Influence of Primary and Secondary Crystallographic Orientations on Strengths of Nickel-based Superalloy Single Crystals. Mater. Trans. 2004, 45, 1824–1828. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Zhang, J.; Lou, L. Anisotropie Creep Rupture Properties of a Nickel-base Single Crystal Superalloy at High Temperature. J. Mater. Sci. Technol. 2011, 27, 107–112. [Google Scholar] [CrossRef]

- Qiu, W.; He, Z.; Fan, Y.-N.; Shi, H.-J.; Gu, J. Effects of secondary orientation on crack closure behavior of nickel-based single crystal superalloys. Int. J. Fatigue 2016, 83, 335–343. [Google Scholar] [CrossRef]

- Zhou, Z.J.; Wang, L.; Wang, D.; Lou, L.H.; Zhang, J. Effect of secondary orientation on room temperature tensile behaviors of Ni-base single crystal superalloys. Mater. Sci. Eng. A 2016, 659, 130–142. [Google Scholar] [CrossRef]

- Arakere, N.K.; Swanson, G. Effect of Crystal Orientation on Fatigue Failure of Single Crystal Nickel Base Turbine Blade Superalloys. J. Eng. Gas Turbines Power 2002, 124, 161–176. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.C.; Gao, H.S.; Wen, Z.X.; Yang, Y.Q.; Wang, J.J.; Zhang, X.H.; Yue, Z.F. Effect of Orientation Deviation on Resonance Characteristics of Single Crystal Turbine Blades. AIAA J. 2020, 58, 2673–2681. [Google Scholar] [CrossRef]

- Zhang, X.H.; Gao, H.S.; Yu, K.H.; Wen, Z.X.; Zhao, Y.C.; Yue, Z.F. Crystal orientation effect and multi-fidelity optimization of a solid single crystal superalloy turbine blade. Comput. Mater. Sci. 2018, 149, 84–90. [Google Scholar] [CrossRef]

- Pan, D.; Xu, Q.; Liu, B.; Li, J.; Yuan, H.; Jin, H. Modeling of Grain Selection during Directional Solidification of Single Crystal Superalloy Turbine Blade Castings. JOM 2010, 62, 30–34. [Google Scholar] [CrossRef]

- Xiao, J.; Jiang, W.; Han, D.; Li, K.; Lu, Y.; Lou, L. Evolution of crystallographic orientation and microstructure in the triangular adapter of grain continuator of a 3rd-generation single crystal superalloy casting during directional solidification. J. Alloys Compd. 2022, 898, 162782. [Google Scholar] [CrossRef]

- Hallensleben, P.; Schaar, H.; Thome, P.; Jöns, N.; Jafarizadeh, A.; Steinbach, I.; Eggeler, G.; Frenzel, J. On the evolution of cast microstructures during processing of single crystal Ni-base superalloys using a Bridgman seed technique. Mater. Des. 2017, 128, 98–111. [Google Scholar] [CrossRef]

- Xuan, W.; Lan, J.; Liu, H.; Li, C.; Zhong, Y.; Ren, X.; Li, X.; Cao, G.; Ren, Z. A Method of Stray Grain Suppression for Single-Crystal Superalloy During Seed Melt-Back. Metall. Mater. Trans. A 2016, 47, 5691–5697. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, F.; Ma, D.; Buhrig-Polaczek, A. Development of a High-Efficiency Z-Form Selector for Single Crystal Blades and Corresponding Grain Selection Mechanism. Materials 2019, 12, 780. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Liu, L.; Huang, T.; Zhang, J.; Fu, H. The process analysis of seeding-grain selection and its effect on stray grain and orientation control. J. Alloys Compd. 2016, 657, 341–347. [Google Scholar] [CrossRef]

- Liu, G.; Li, T.; Fu, T.; Liu, H.; Deng, X.; Li, J.; Wang, Z.; Wang, G. Morphology and competitive growth during the development of the parallel lamellar structure by self-seeding in directionally solidified Ti-50Al-4Nb alloy. J. Alloys Compd. 2016, 682, 601–609. [Google Scholar] [CrossRef]

- Chen, G.S.; Aimone, P.R.; Ming, G.; Miller, C.D.; Wei, R.P. Growth of nickel-base superalloy bicrystals by the seeding technique with a modified Bridgman method. J. Cryst. Growth 1997, 179, 635–646. [Google Scholar] [CrossRef]

- Zhou, Y. Formation of stray grains during directional solidification of a nickel-based superalloy. Scr. Mater. 2011, 65, 281–284. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, L.; Zhang, J. Investigation of grain competitive growth during directional solidification of single-crystal nickel-based superalloys. Appl. Phys. A 2015, 120, 793–800. [Google Scholar] [CrossRef]

- Petrov, D.A.; Tumanov, T. Device for Making Single-Crystal Products. U.S. Patent 4015657, 5 April 1997. [Google Scholar]

- Stanford, N. Seeding of single crystal superalloys—Role of seed melt-back on casting defects. Scr. Mater. 2004, 50, 159–163. [Google Scholar] [CrossRef]

- Xuan, W.; Liu, H.; Li, C.; Ren, Z.; Zhong, Y.; Li, X.; Cao, G. Effect of a High Magnetic Field on Microstructures of Ni-Based Single Crystal Superalloy During Seed Melt-Back. Metall. Mater. Trans. B 2016, 47, 828–833. [Google Scholar] [CrossRef]

- Yang, X.; Ness, D.; Lee, P.D.; D’Souza, N. Simulation of stray grain formation during single crystal seed melt-back and initial withdrawal in the Ni-base superalloy CMSX4. Mater. Sci. Eng. A 2005, 413–414, 571–577. [Google Scholar] [CrossRef]

- D’Souza, N.; Jennings, P.A.; Yang, X.L.; Lee, P.D.; Mclean, M.; Dong, H.B. Seeding of single-crystal superalloys—Role of constitutional undercooling and primary dendrite orientation on stray-grain nucleation and growth. Metall. Mater. Trans. B 2005, 36, 657–666. [Google Scholar] [CrossRef]

- Yang, X.L.; Lee, P.D.; D’Souza, N. Stray grain formation in the seed region of single-crystal turbine blades. JOM 2005, 57, 40–44. [Google Scholar] [CrossRef]

- Hu, S.; Liu, L.; Yang, W.; Sun, D.; Huo, M.; Li, Y.; Huang, T.; Zhang, J.; Su, H.; Fu, H. Inhibition of stray grains at melt-back region for re-using seed to prepare Ni-based single crystal superalloys. Prog. Nat. Sci.-Mater. Int. 2019, 29, 582–586. [Google Scholar] [CrossRef]

- Yang, W.; Hu, S.; Huo, M.; Sun, D.; Zhang, J.; Liu, L. Orientation controlling of Ni-based single-crystal superalloy by a novel method: Grain selection assisted by un-melted reused seed. J. Mater. Res. Technol. 2019, 8, 1347–1352. [Google Scholar] [CrossRef]

- Salkeld, R.W.; Anderson, N.P.; Giamei, A.F. Control of Seed Melt-Back during Directional Solidification of Metals. U.S. Patent 42412577, 1 November 1983. [Google Scholar]

- Stanford, N.; Djakovic, A.; Shollock, B.; McLean, M.; D’Souza, N.; Jennings, P. Defects grains in the melt-back region of CMSX-4 single crsytal seeds. Superalloy 2004, 2014, 719–726. [Google Scholar]

- Montakhab, M.; Bacak, M.; Balikci, E. Low Melt Height Solidification of Superalloys. Metall. Mater. Trans. A 2016, 47, 3031–3039. [Google Scholar] [CrossRef]

- Szeliga, D.; Kubiak, K.; Burbelko, A.; Motyka, M.; Sieniawski, J. Modeling of Directional Solidification of Columnar Grain Structure in CMSX-4 Nickel-Based Superalloy Castings. J. Mater. Eng. Perform. 2014, 23, 1088–1095. [Google Scholar] [CrossRef] [Green Version]

- Elliott, A.J.; Pollock, T.M. Thermal Analysis of the Bridgman and Liquid-Metal-Cooled Directional Solidification Investment Casting Processes. Metall. Mater. Trans. A 2007, 38, 871–882. [Google Scholar] [CrossRef]

- Wang, N.; Liu, L.; Gao, S.; Zhao, X.; Huang, T.; Zhang, J.; Fu, H. Simulation of grain selection during single crystal casting of a Ni-base superalloy. J. Alloys Compd. 2014, 586, 220–229. [Google Scholar] [CrossRef]

- Wang, F.; Wu, Z.; Huang, C.; Ma, D.; Jakumeit, J.; Buehrig-Polaczek, A. Three-Dimensional Dendrite Growth Within the Shrouds of Single Crystal Blades of a Nickel-Based Superalloy. Metall. Mater. Trans. A 2017, 48, 5924–5939. [Google Scholar] [CrossRef]

- Hu, S.; Yang, W.; Li, Z.; Xu, H.; Huang, T.; Zhang, J.; Su, H.; Liu, L. Formation mechanisms and control method for stray grains at melt-back region of Ni-based single crystal seed. Prog. Nat. Sci.-Mater. Int. 2021, 31, 624–632. [Google Scholar] [CrossRef]

| Material | Liquidus Temperature (°C) | Solidification Temperature (°C) | Density (g (cm3)−1) | Thermal Conductivity (W (m2 K)−1) |

|---|---|---|---|---|

| DD33 | 1401 | 1349 | 8.95 (25 °C)–7.73 (1520 °C) | 10.9 (25 °C)–36.2 (1520 °C) |

| Initial Condition | Value |

|---|---|

| Seed temperature | 25 °C |

| Mold temperature | 25 °C |

| Chill-plate temperature | 40 °C |

| Boundary condition | value |

| Heater temperature | 1520 °C |

| Emissivity | 0.8 |

| Cooler temperature | 25 °C |

| Interface heat transfer coefficients | value |

| Alloy melt and ceramic shell mold | 380–2200 W (m2 K)−1 |

| Alloy melt and water-cooled chill plate | 1000 W (m2 K)−1 |

| Ceramic shell mold and water-cooled chill plate | 50 W (m2 K)−1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, S.; Zhao, Y.; Bai, W.; Wang, X.; Yin, F.; Yang, W.; Liu, L. Temperature Field Evolution of Seeding during Directional Solidification of Single-Crystal Ni-Based Superalloy Castings. Metals 2022, 12, 817. https://doi.org/10.3390/met12050817

Hu S, Zhao Y, Bai W, Wang X, Yin F, Yang W, Liu L. Temperature Field Evolution of Seeding during Directional Solidification of Single-Crystal Ni-Based Superalloy Castings. Metals. 2022; 12(5):817. https://doi.org/10.3390/met12050817

Chicago/Turabian StyleHu, Songsong, Yunsong Zhao, Weimin Bai, Xinming Wang, Fucheng Yin, Wenchao Yang, and Lin Liu. 2022. "Temperature Field Evolution of Seeding during Directional Solidification of Single-Crystal Ni-Based Superalloy Castings" Metals 12, no. 5: 817. https://doi.org/10.3390/met12050817

APA StyleHu, S., Zhao, Y., Bai, W., Wang, X., Yin, F., Yang, W., & Liu, L. (2022). Temperature Field Evolution of Seeding during Directional Solidification of Single-Crystal Ni-Based Superalloy Castings. Metals, 12(5), 817. https://doi.org/10.3390/met12050817