Effect of Grain Size on Mechanical and Creep Rupture Properties of 253 MA Austenitic Stainless Steel

Abstract

:1. Introduction

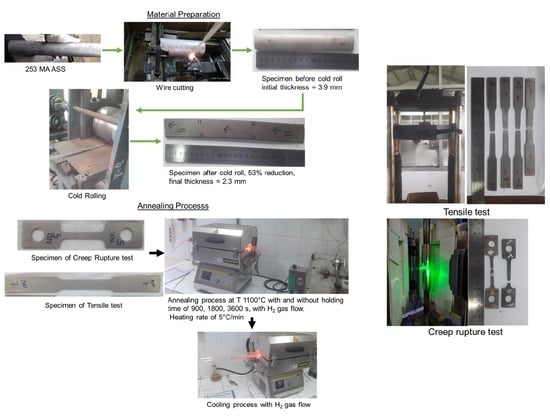

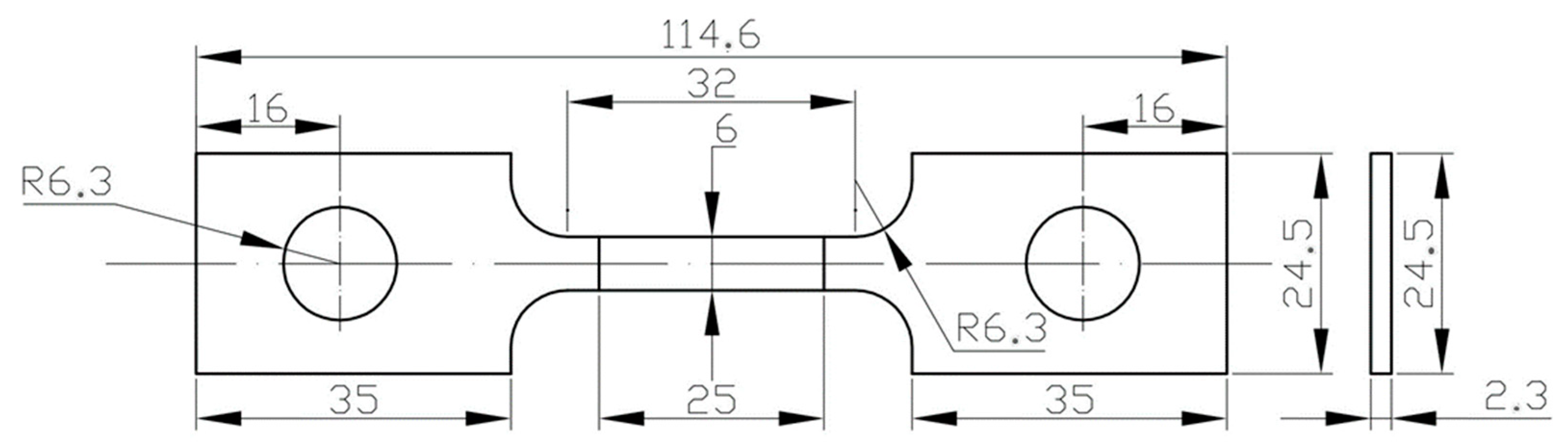

2. Materials and Methods

3. Results and Discussion

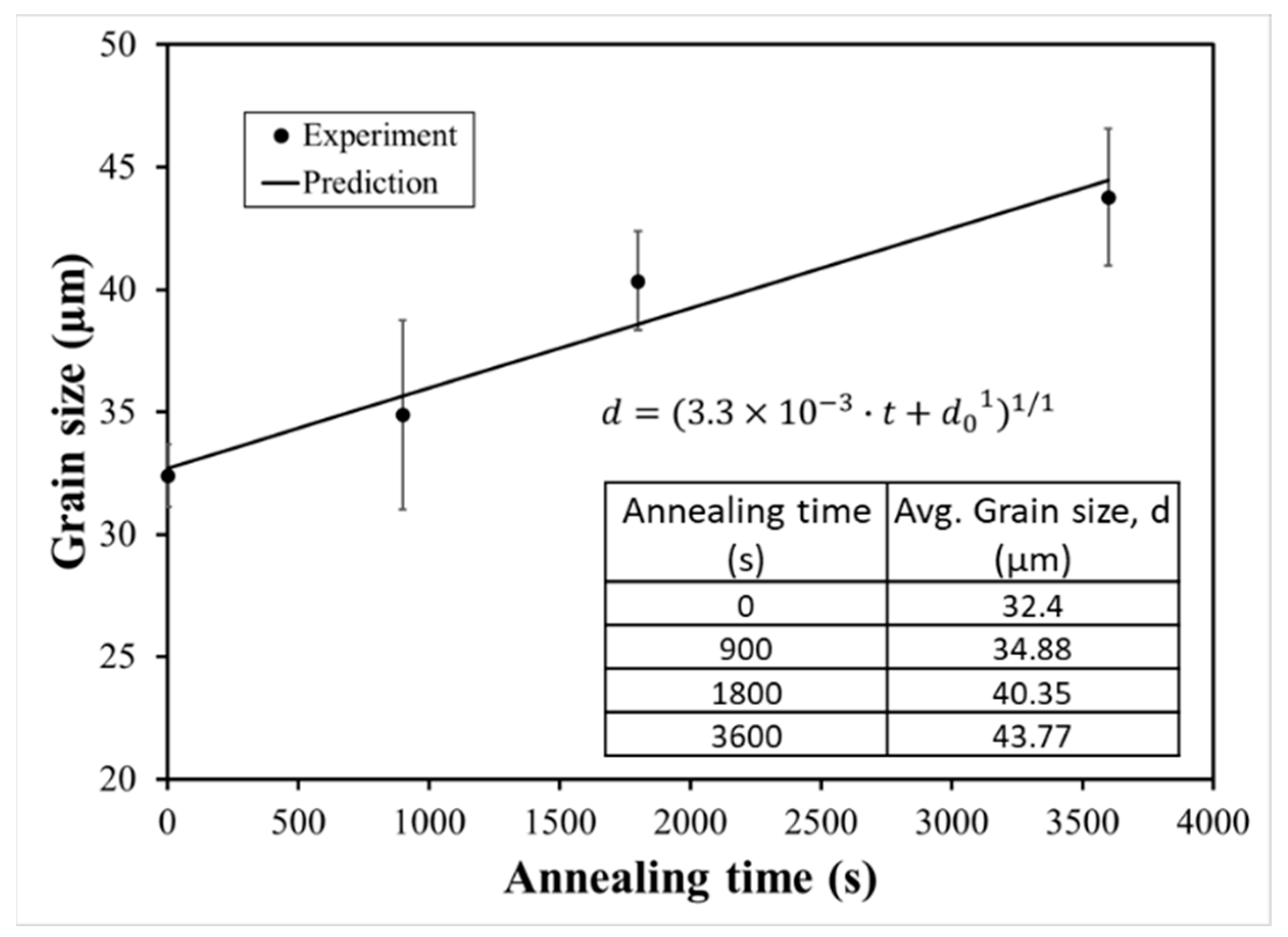

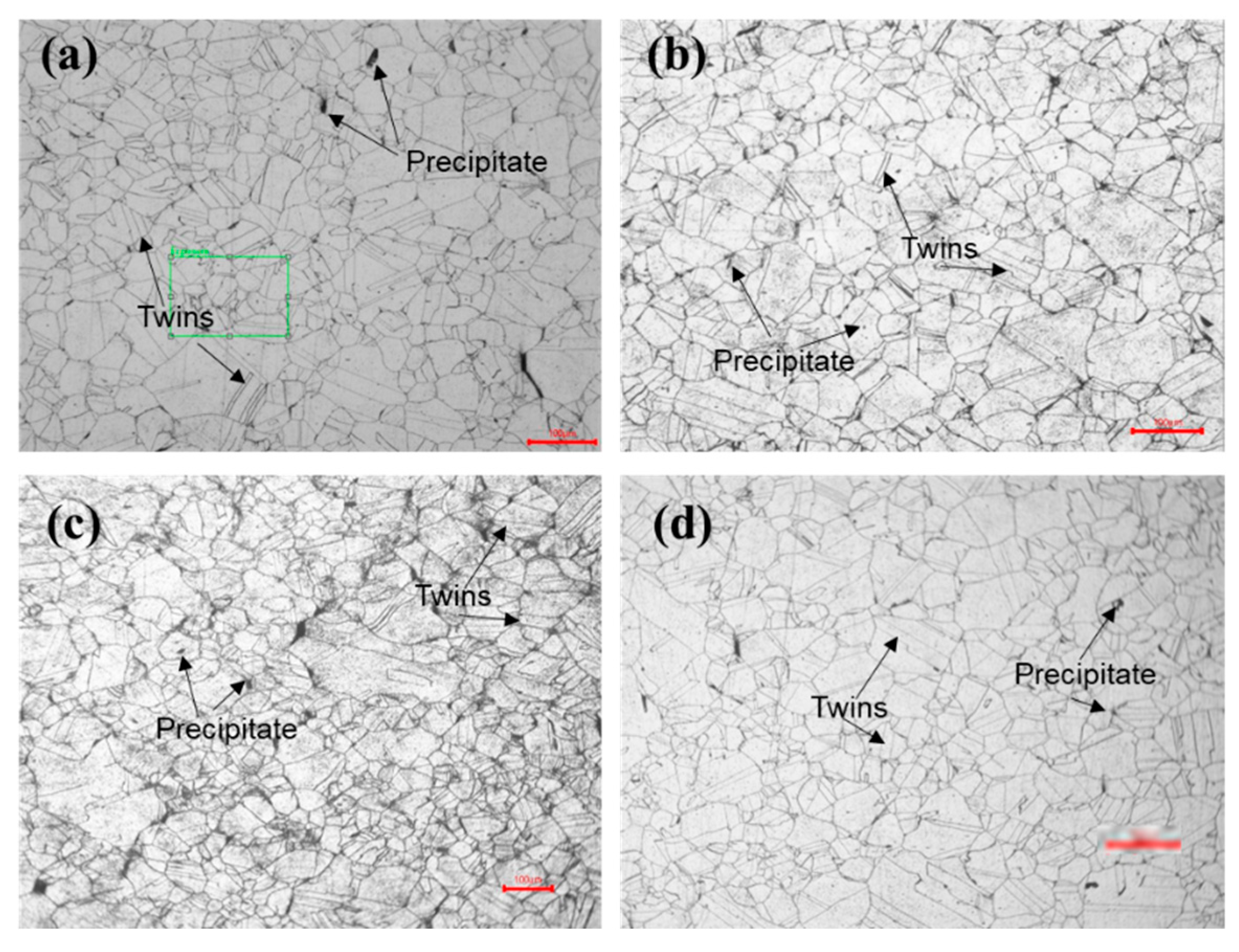

3.1. Grain Growth of 253 MA ASS after 53% Reduction

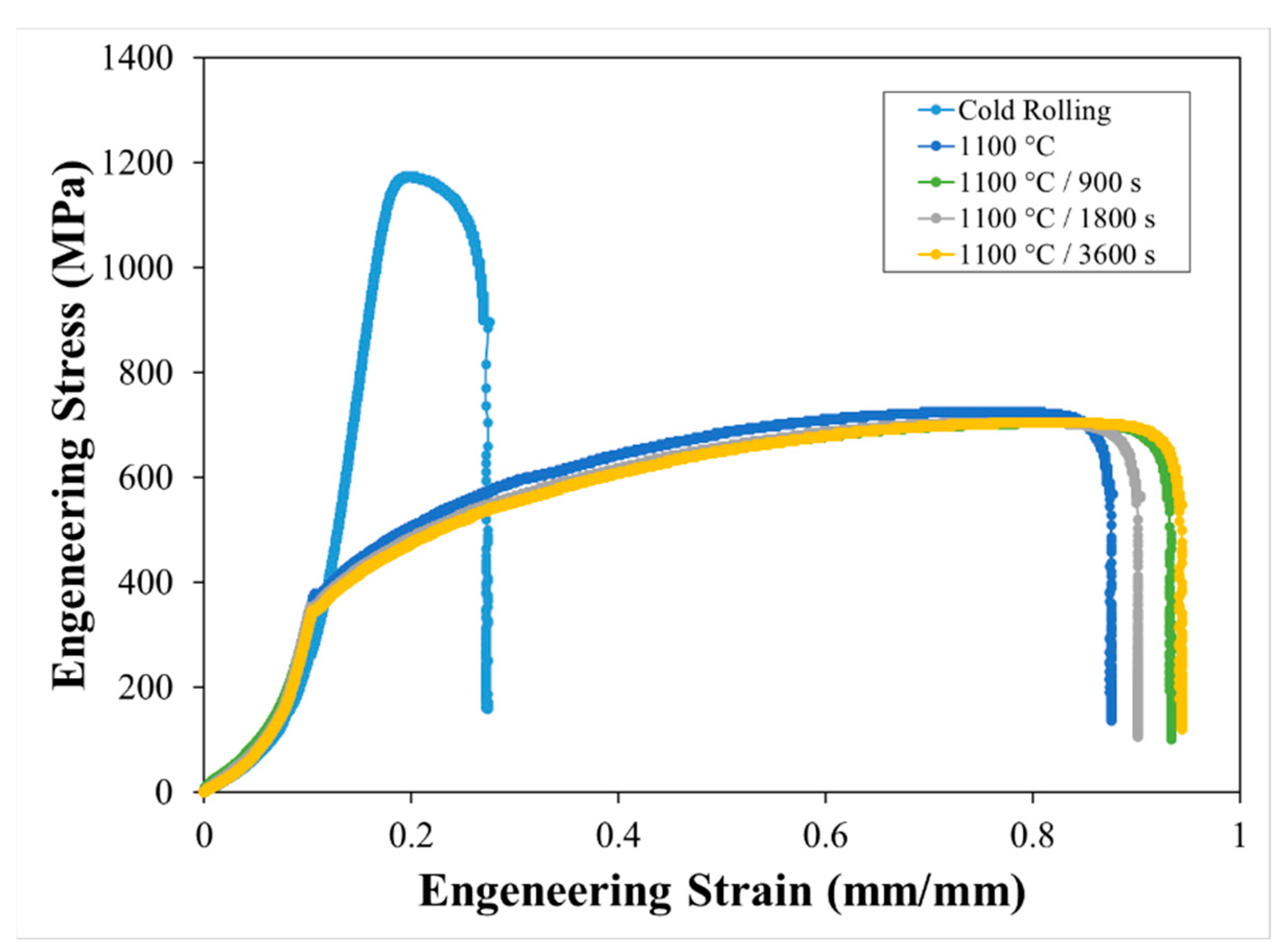

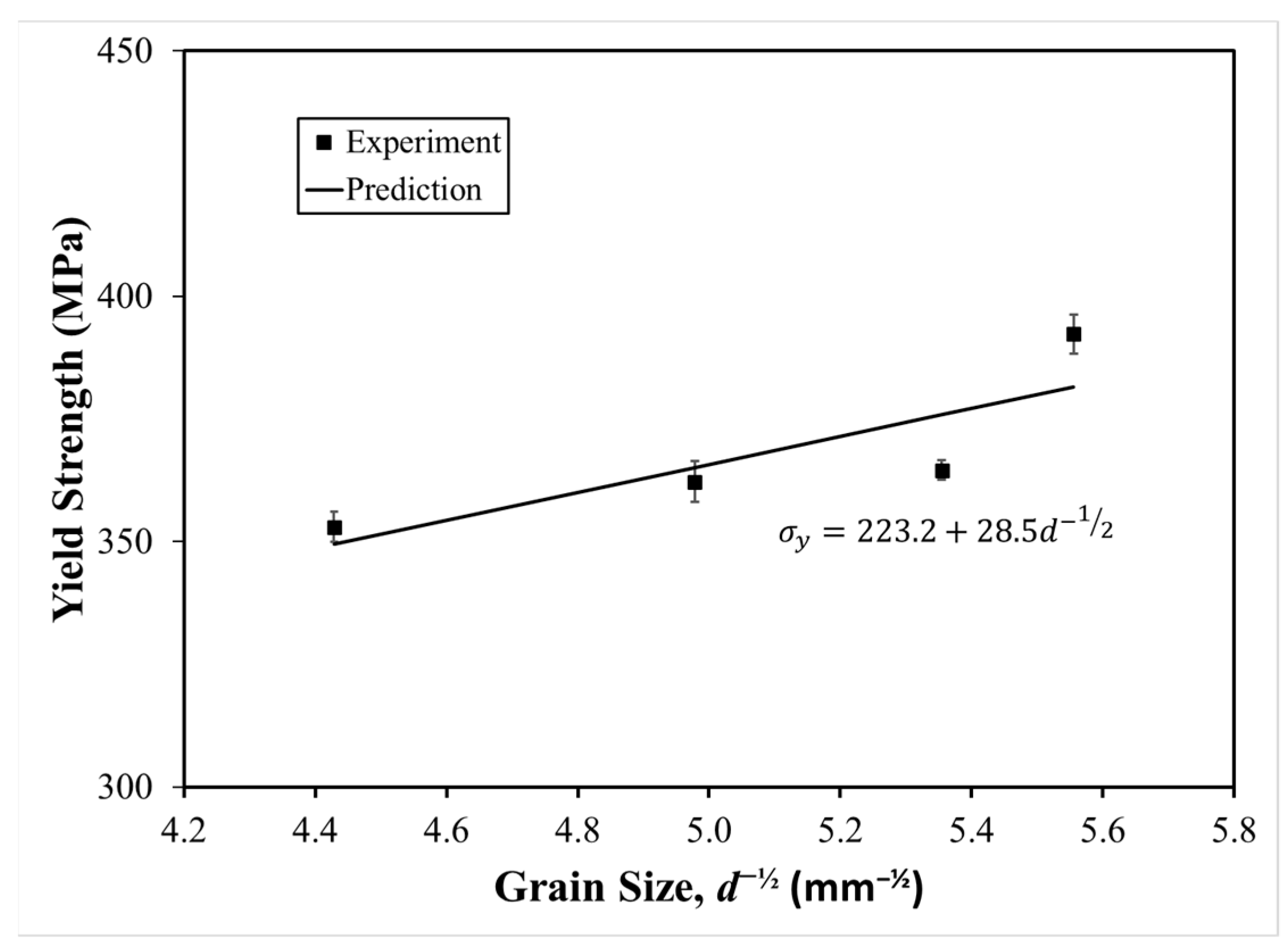

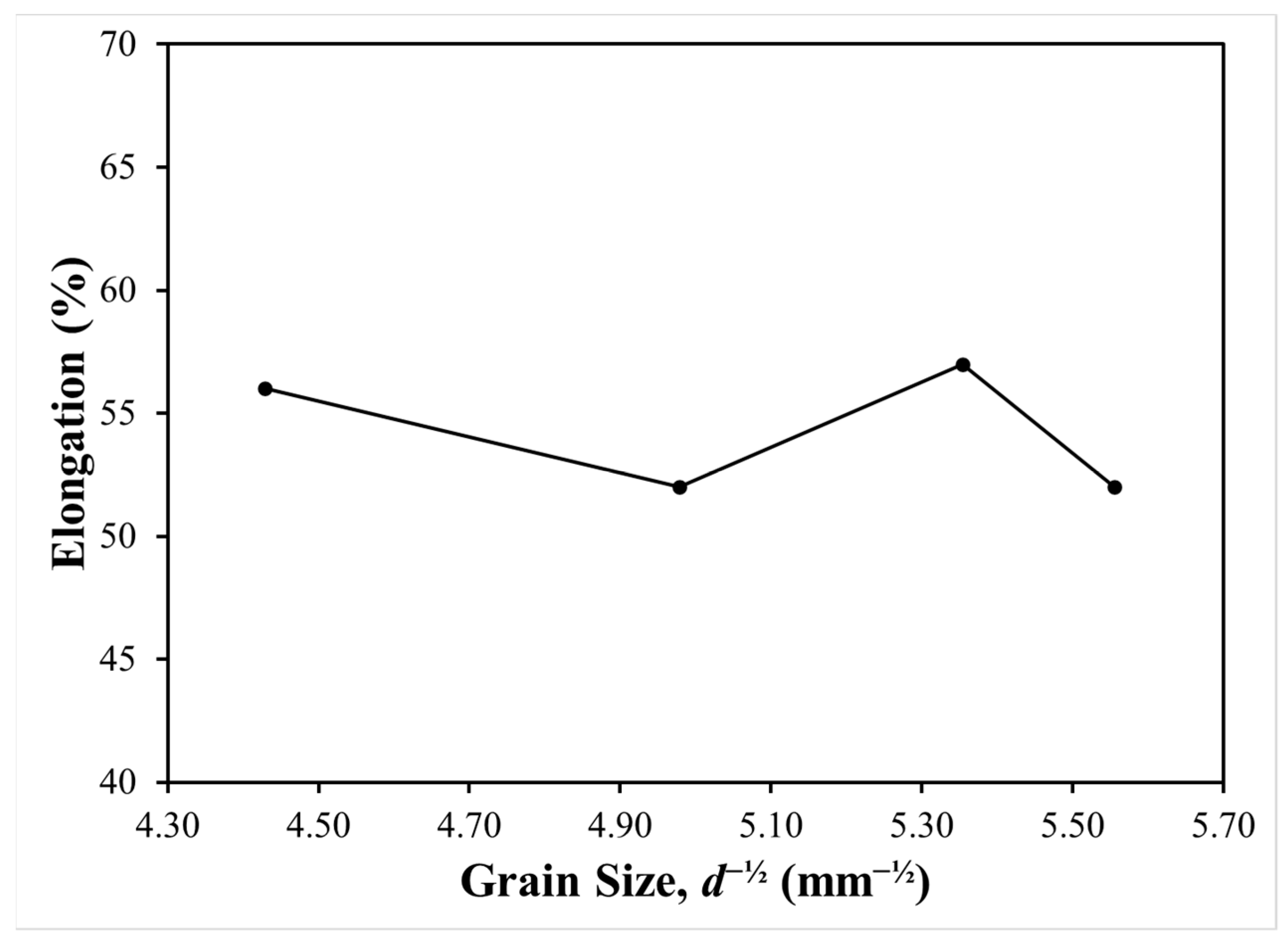

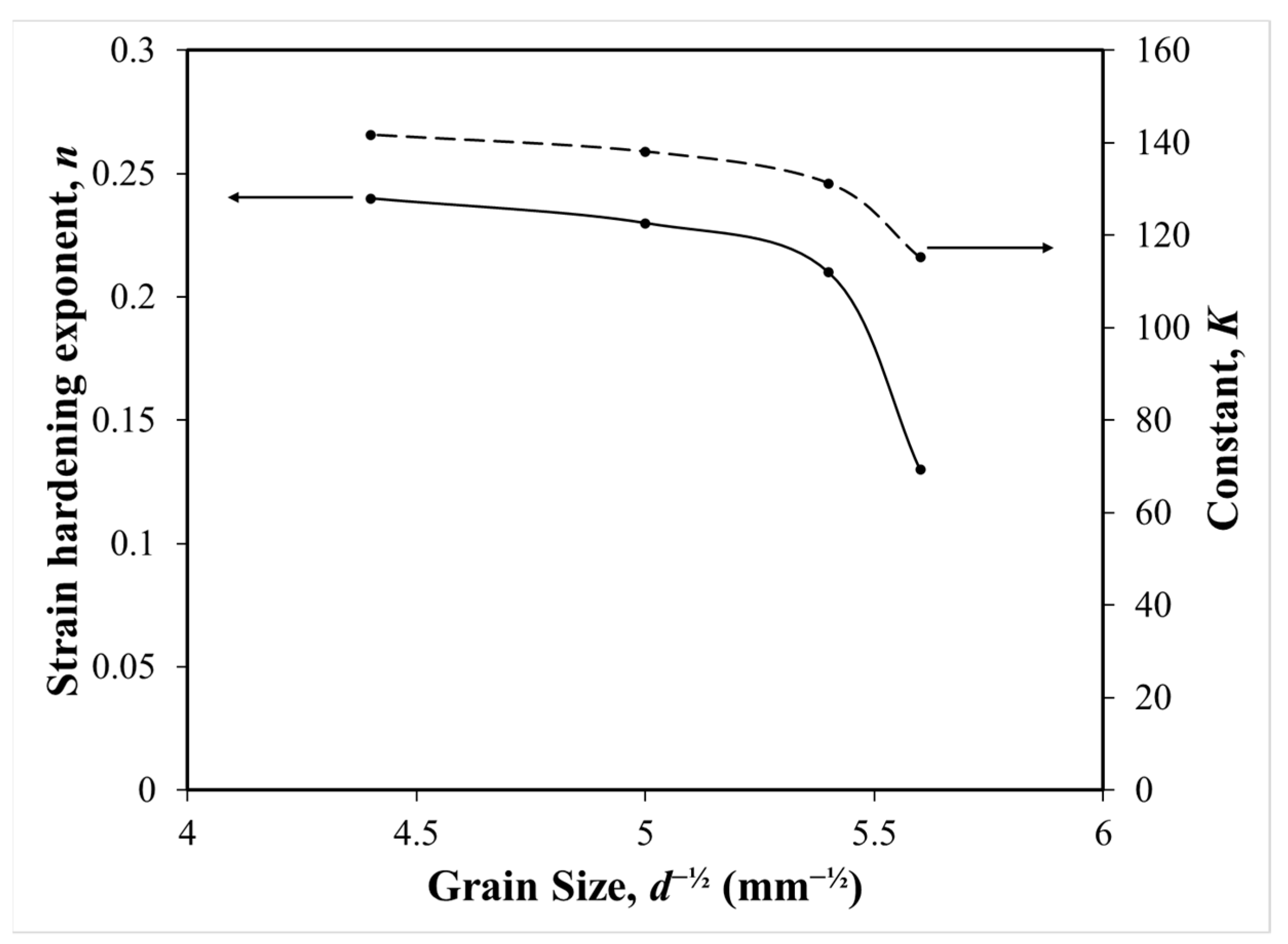

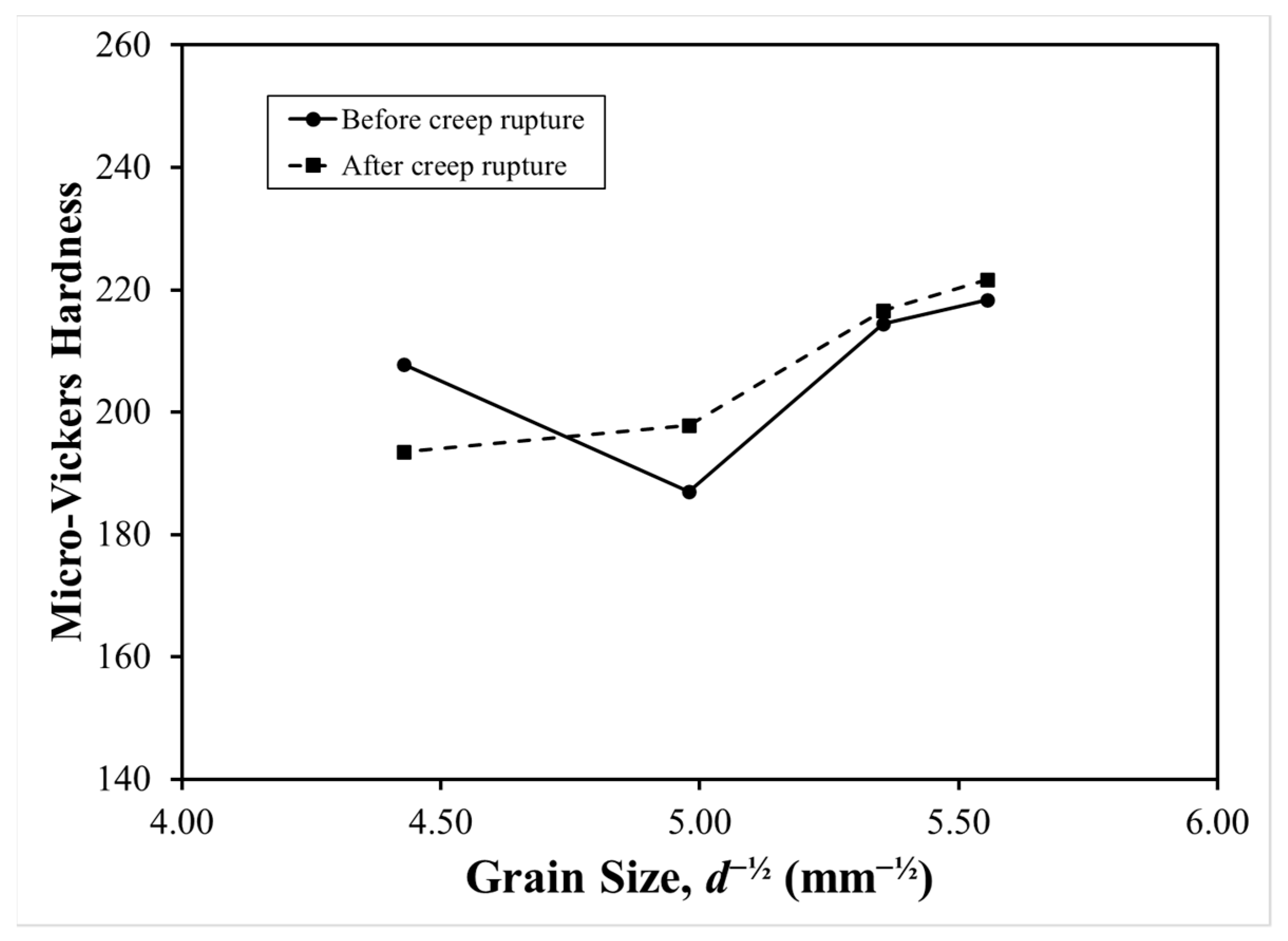

3.2. Effect of Grain Size on the Mechanical Properties

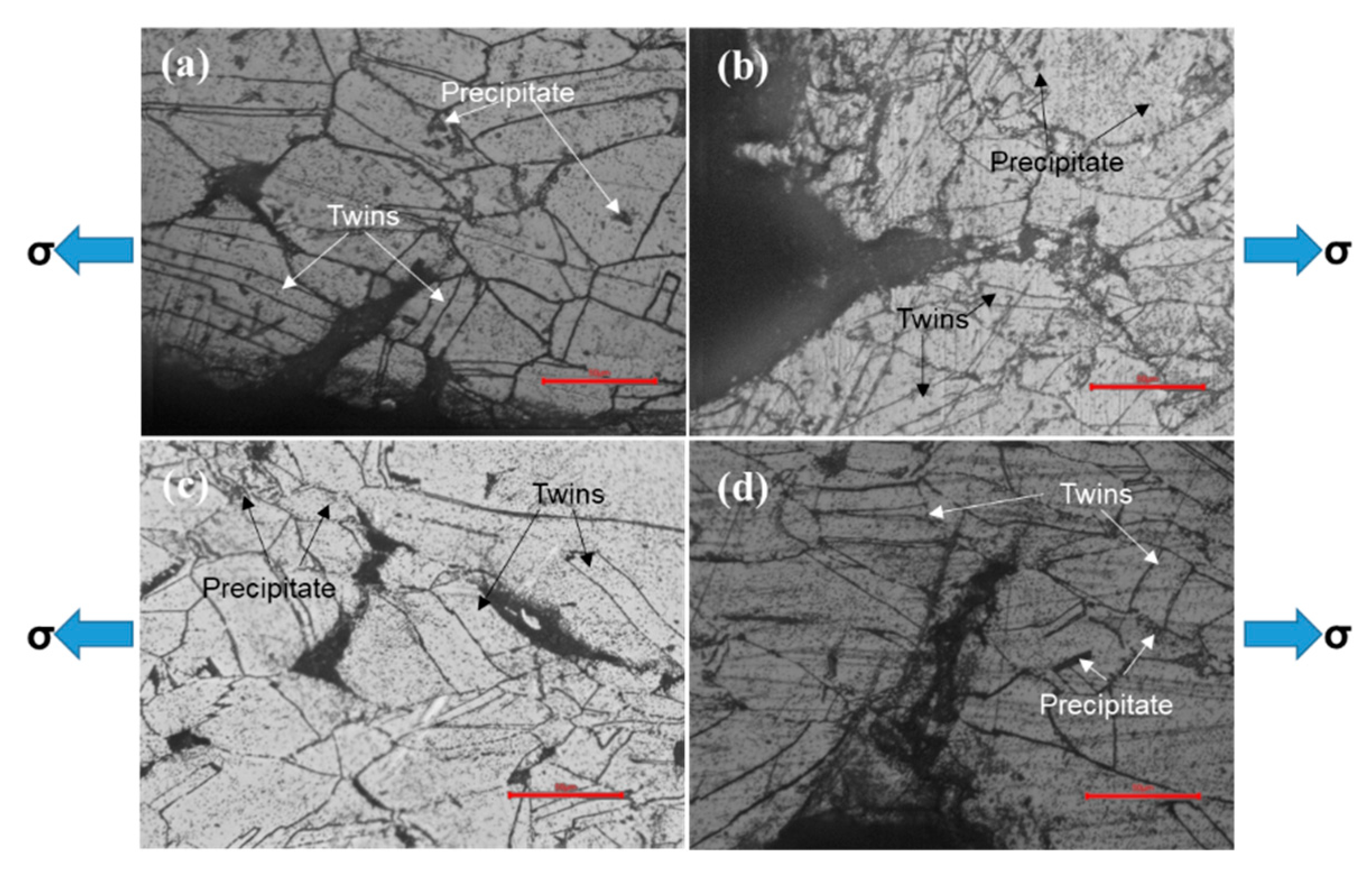

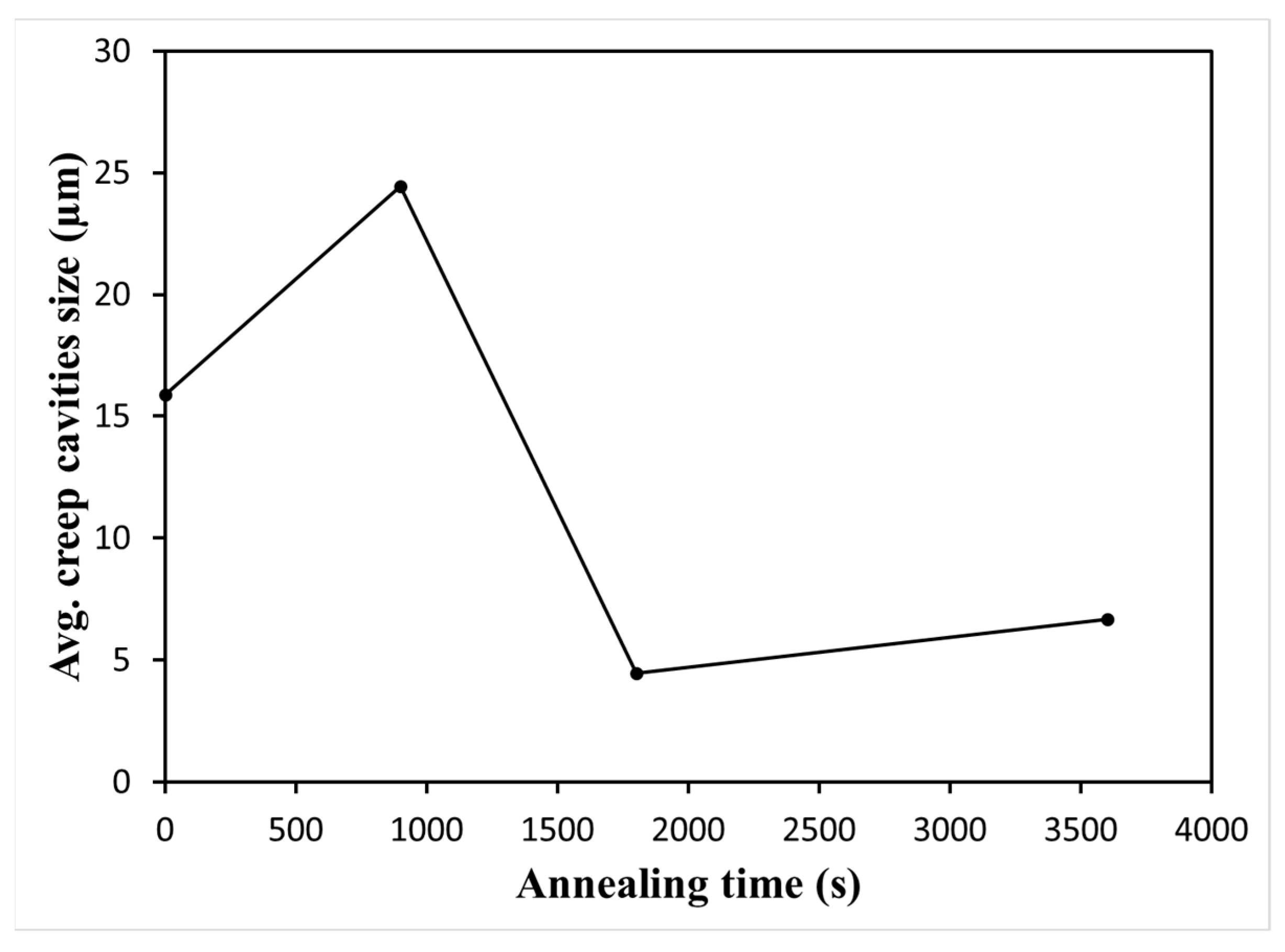

3.3. Effect of Grain Size on Creep Rupture Properties

4. Conclusions

- (1)

- Grain growth at a temperature of 1100 °C showed a slight increase with annealing time. A fine grain size can increase yield strength and hardness, and the ultimate strength was almost constant, with fluctuating elongation and decreased strain hardening;

- (2)

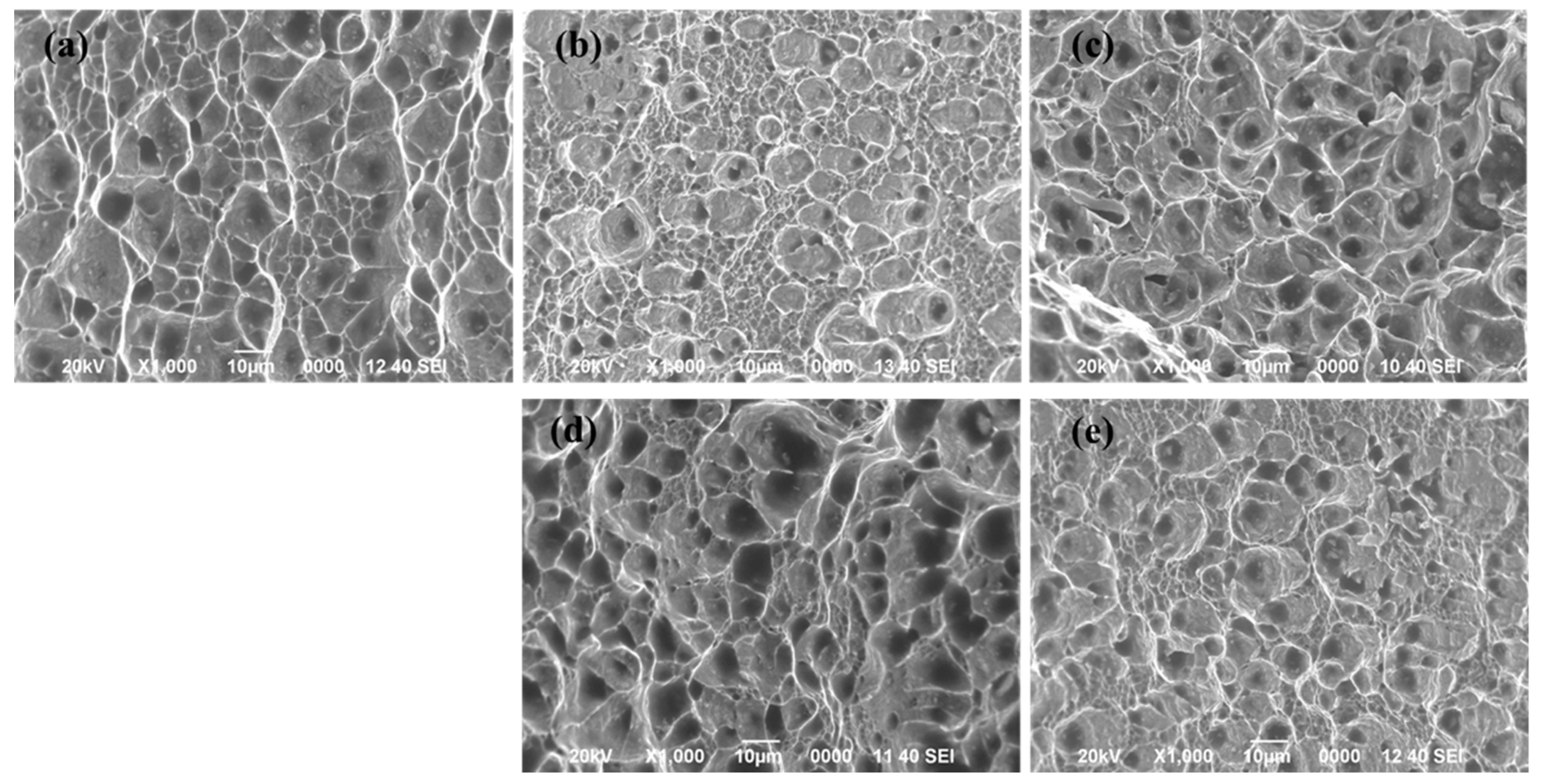

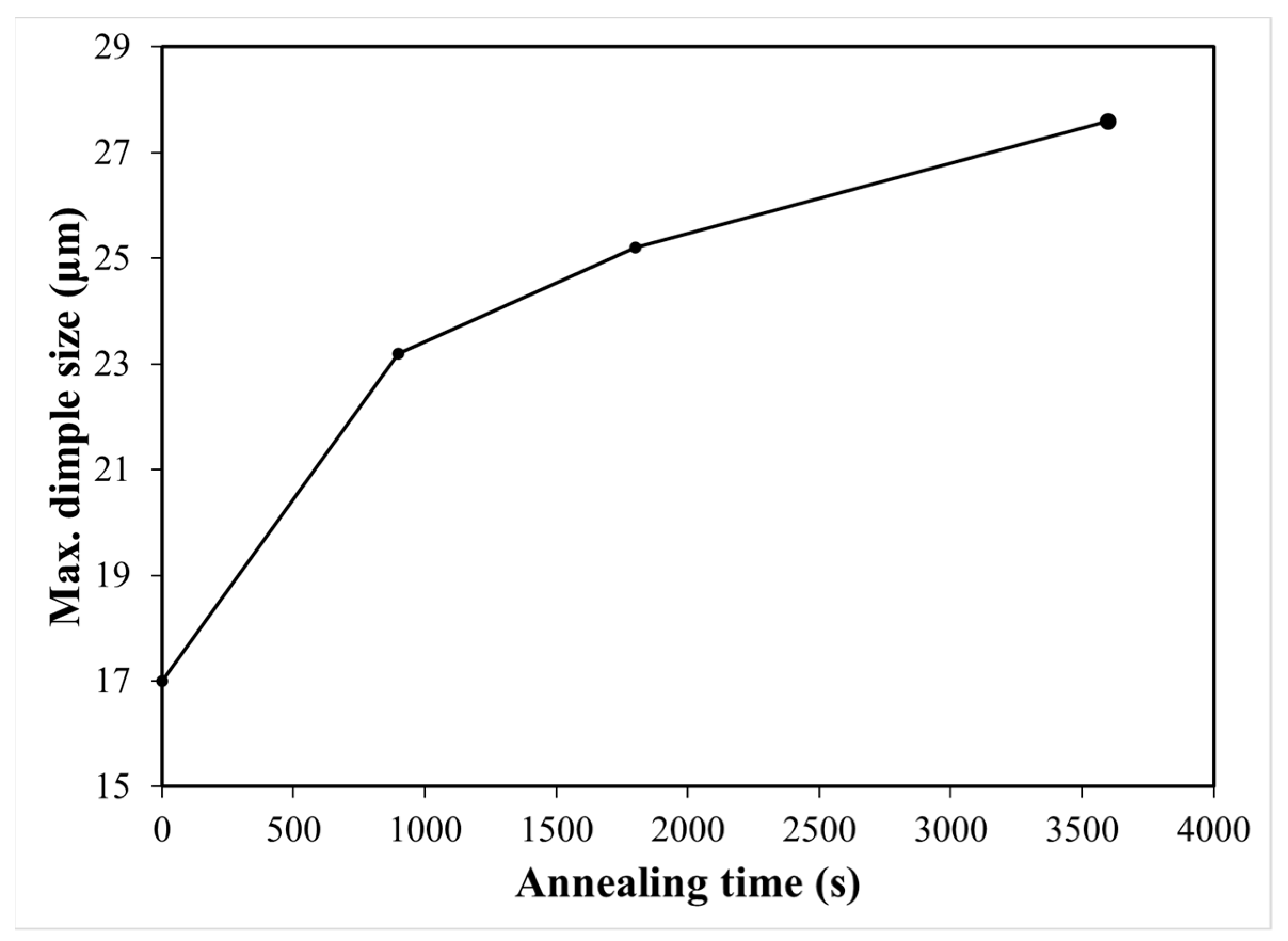

- M23C6 and intermetallic precipitates and micro-alloying in austenite grains resulted in slow grain growth that affected the mechanical properties at room temperature. Ductile fracture occurred in the cold rolling and annealing samples. The grain size influenced the size of the dimple at the fracture surface. The larger the grain size, the larger the resulting dimple size;

- (3)

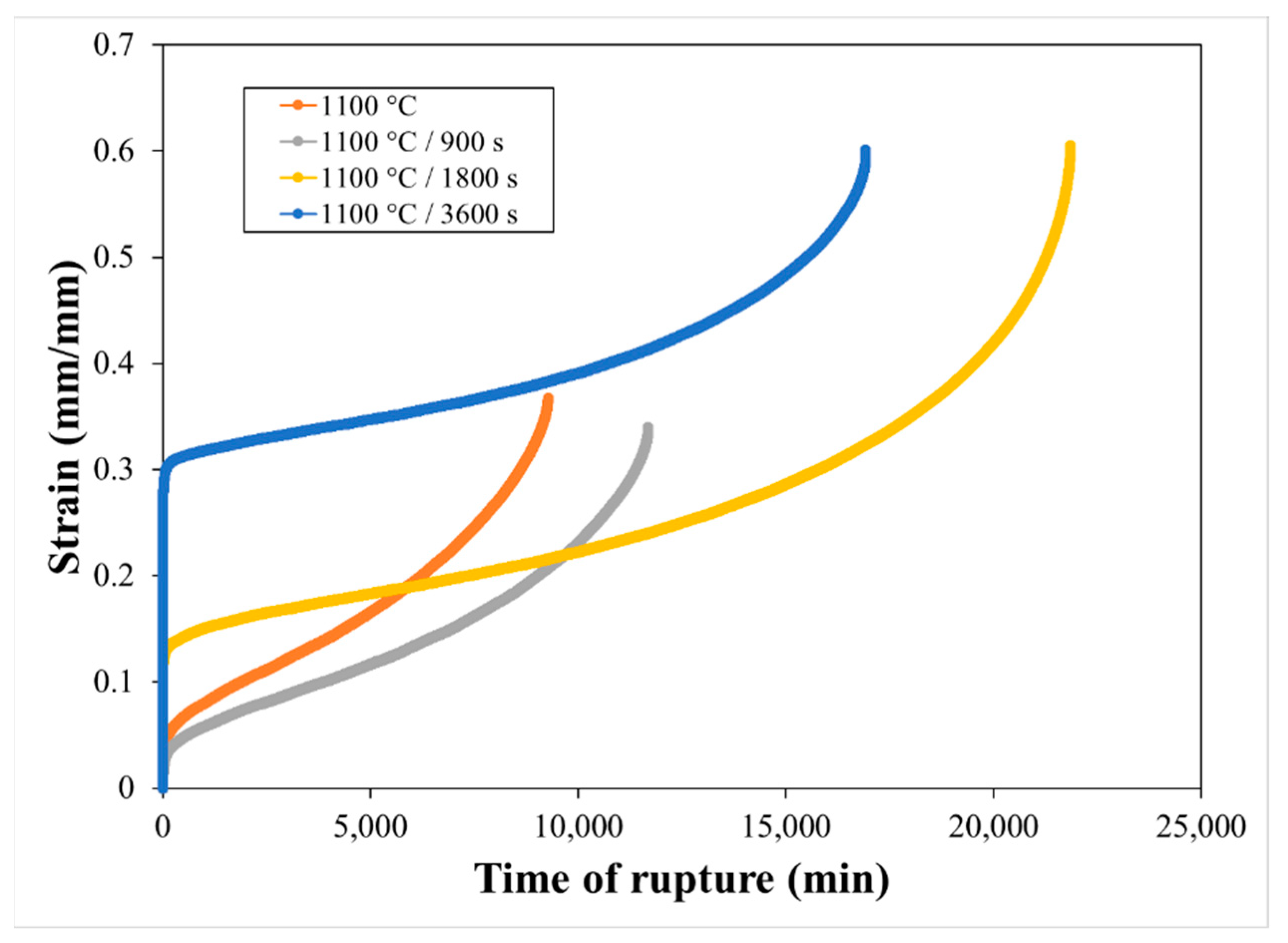

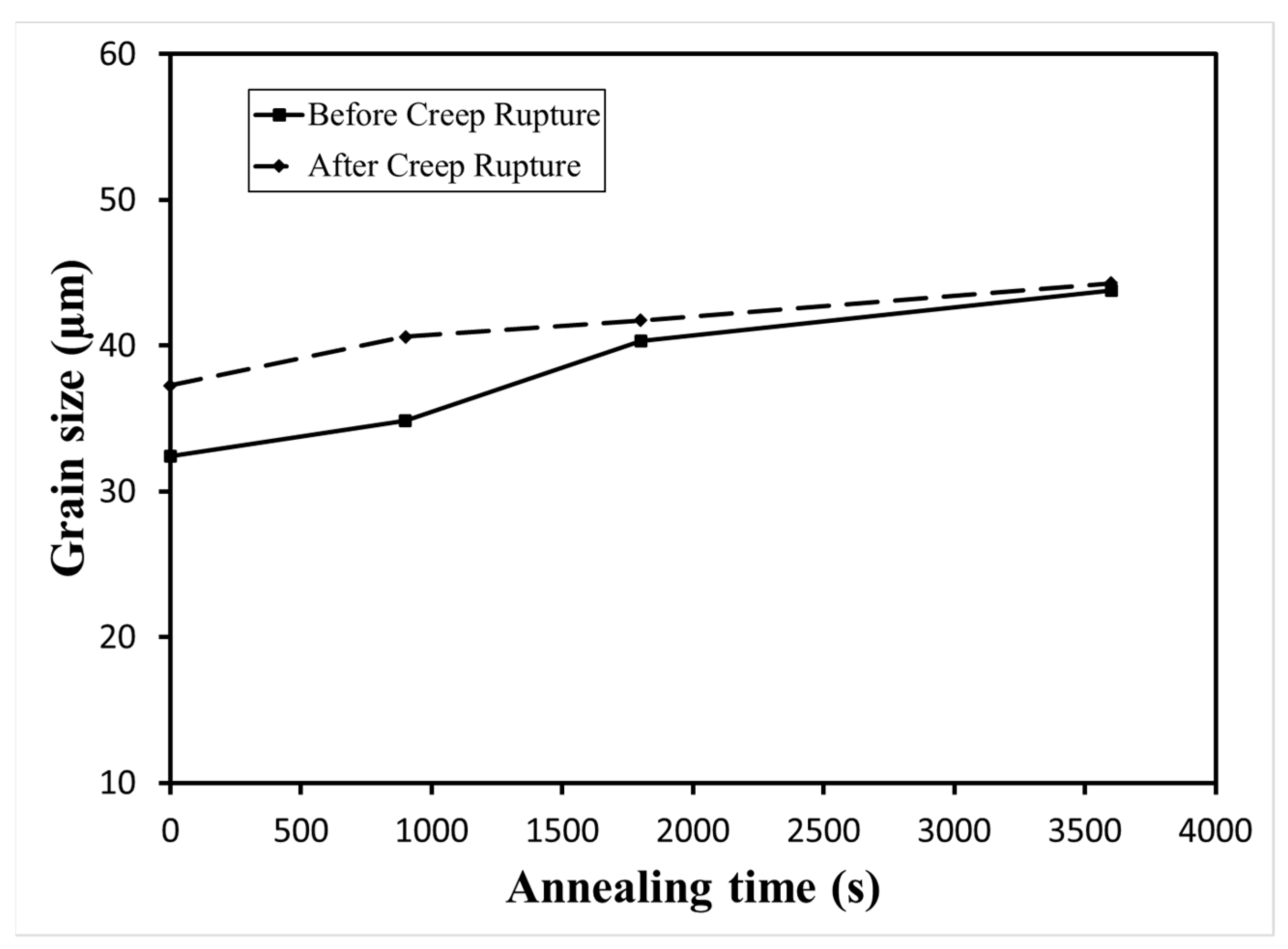

- Creep rupture at a temperature of 700 °C and a load of 150 MPa showed that the austenite grain growth continued even though the difference between the grain size before and after the creep rupture test was not significant;

- (4)

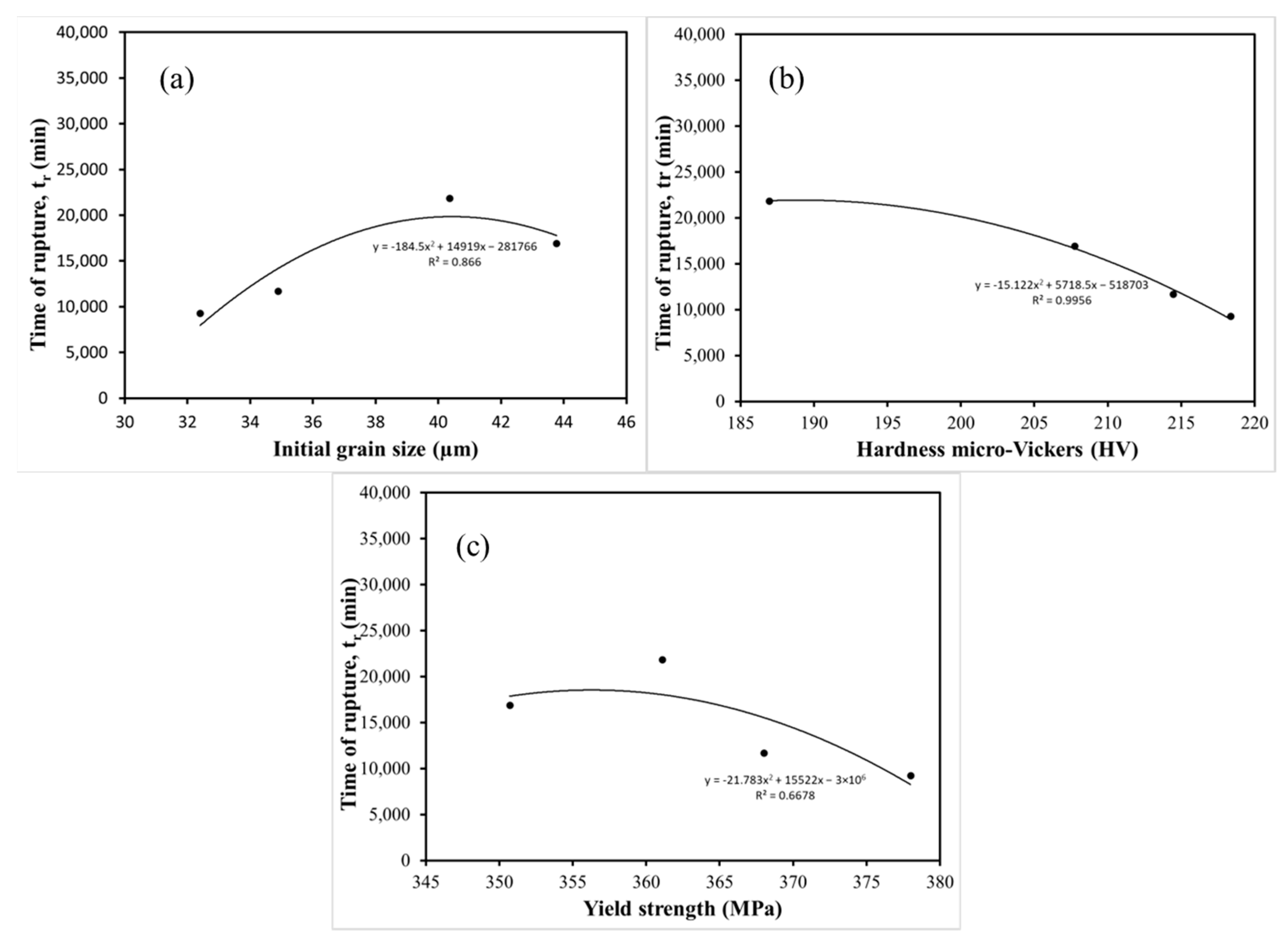

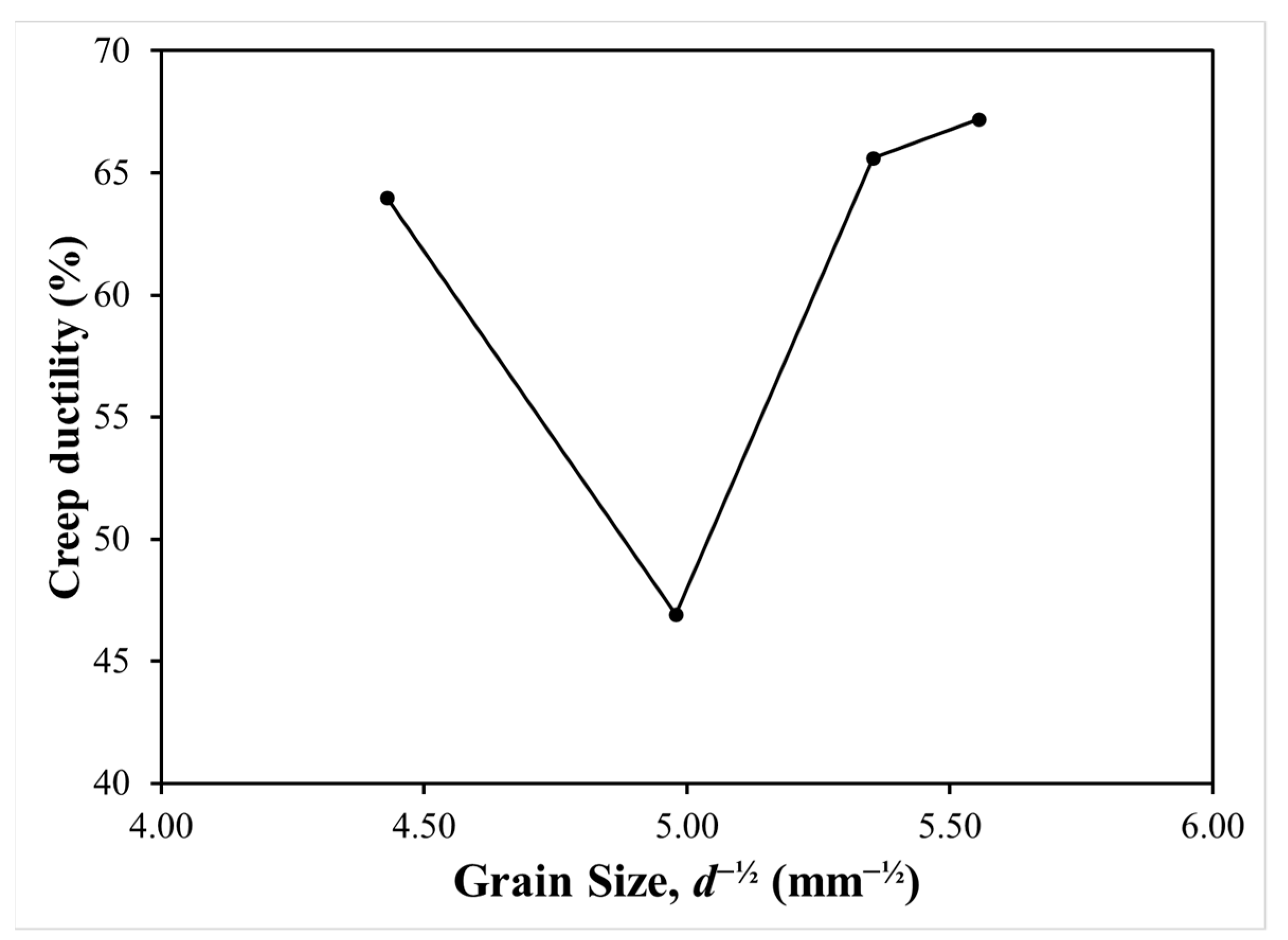

- A higher creep rupture time and a lower creep ductility were found on the grain size of approximately 40 µm. However, this grain size had a low value of hardness and yield strength;

- (5)

- The normal grain size distribution during the creep rupture test resulted in a fast rupture time with intergranular fractures occurring in steels with an initial grain size below 40 µm. In comparison, the bimodal grain size distribution during the creep rupture test increased the rupture time, resulting in mixed-mode intergranular and transgranular fractures in steel with an initial grain size above 40 µm;

- (6)

- The difference in grain size before and after the creep rupture test caused grain boundary hardening, resulting in a higher steel hardness value after the creep rupture test.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Callister, W.D., Jr.; Rethwisch, D.G. Material Science and Engineering an Introduction, 8th ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2009; pp. 212–213. [Google Scholar]

- Naghizadeh, M.; Mirzadeh, H. Effects of grain size on mechanical properties and work-hardening behavior of AISI 304 austenitic stainless steel. Steel Res. Int. 2019, 90, 1900153. [Google Scholar] [CrossRef]

- Järvenpää, A.; Jaskari, M.; Kisko, A.; Karjalainen, P. Processing and properties of reversion-treated austenitic stainless steels. Metals 2020, 10, 281. [Google Scholar] [CrossRef] [Green Version]

- Tikhonova, M.; Belyakov, A.; Kaibyshev, R. Static grain growth in an austenitic stainless steel subjected to intense plastic straining. Mater. Sci. Forum. 2014, 783–786, 1021–1026. [Google Scholar] [CrossRef]

- Gao, S.; Bai, Y.; Zheng, R.; Tian, Y.; Mao, W.; Shibata, A.; Tsuji, N. Mechanism of huge Lüders-type deformation in ultrafine grained austenitic stainless steel. Scr. Mater. 2019, 159, 28–32. [Google Scholar] [CrossRef]

- Kral, P.; Dvorak, J.; Sklenicka, V.; Horita, Z.; Takizawa, Y.; Tang, Y.; Kvapilova, M.; Svobodova, M. Effect of ultrafine-grained microstructure on creep behaviour in 304L austenitic steel. Mater. Sci. Eng. A 2020, 785, 139383. [Google Scholar] [CrossRef]

- Paek, D.S.; Jong, C.B. Investigation of carbide precipitations on microstructure and hardness of medium carbon Cr Ni austenite stainless hardfacing deposit with high wear resistance properties. Weld. World 2022, 66, 1111–1119. [Google Scholar] [CrossRef]

- Wang, C.; Wu, Y.; Guo, Y.; Guo, J.; Zhou, L. Precipitation behavior of sigma phase and its influence on mechanical properties of a Ni-Fe based alloy. J. Alloys Compd. 2019, 784, 266–275. [Google Scholar] [CrossRef]

- Zhou, W.; Zhu, J.; Zhang, Z. Austenite grain growth behaviors of La-microalloyed H13 steel and its effect on mechanical properties. Metall. Mater. Trans. A 2020, 51, 4662–4673. [Google Scholar] [CrossRef]

- Amininejad, A.; Jamaati, R.; Hosseinipour, S.J. Achieving superior strength and high ductility in AISI 304 austenitic stainless steel via asymmetric cold rolling. Mater. Sci. Eng. A 2019, 767, 138433. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, L.; Han, C.; Li, K.; Cai, Z.; Wang, H. Creep rupture mechanisms and life prediction of IN617 for VHTR applications. Mater. Sci. Eng. A 2021, 812, 141151. [Google Scholar] [CrossRef]

- Ruano, O.A.; Wadsworth, J.; Wolfenstine, J.; Sherby, O.D. Evidence for Nabarro-Herring creep in metals: Fiction or reality? Mater. Sci. Eng. A 1993, 165, 133–141. [Google Scholar] [CrossRef]

- Tanaka, M.; Ito, Y.; Kato, R.; Kayama, A. Grain size dependence of creep-rupture properties and fracture mechanism in austenitic SUS304 steel at 973 K. J. Mater. Sci. Lett. 2000, 19, 899–902. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Rae, C. Microstructure-sensitive modelling of dislocation creep in polycrystalline FCC alloys: Orowan theory revisited. Mater. Sci. Eng. A 2016, 651, 116–126. [Google Scholar] [CrossRef]

- Liu, T.; Yang, M.; Wang, J.S.; Dong, J.S.; Wang, L.; Lou, L.H. Effect of heat treatment on microstructure and stress rupture properties of a Ni–Mo–Cr–Fe base corrosion-resistant superalloy. Acta Metall. Sin. 2019, 32, 116–126. [Google Scholar] [CrossRef] [Green Version]

- Morris, D.G.; Harries, D.R. Creep and rupture in Type 316 stainless steel at temperatures between 525 and 900 °C Part II: Rupture and ductility. Met. Sci. J. 1978, 12, 532–541. [Google Scholar] [CrossRef]

- Wei, L.; Zhao, H.; Sun, Y.; Zhang, Y.; Zhao, B.; Liu, Z.; Liang, J.; Yang, Z. Microstructure evolution and stress rupture properties of A286 superalloy in the 600 to 750 °C temperature range. Mater. Res. Express. 2021, 8, 026521. [Google Scholar] [CrossRef]

- SANDVIK 253 MA (Tube and Pipe, Seamless). Available online: https://www.materials.sandvik/en/materials-center/materialdatasheets/ (accessed on 14 April 2020).

- High Temperature Austenitic Stainless Steel. Available online: www.outokumpu.com/stainless (accessed on 24 January 2022).

- Spadaro, L.; Hereñú, S.; Strubbia, R.; Rosas, G.G.; Bolmaro, R.; González, C.R. Effects of laser shock processing and shot peening on 253 MA austenitic stainless steel and their consequences on fatigue properties. Opt. Laser. Technol. 2020, 122, 105892. [Google Scholar] [CrossRef]

- Zhang, J.; Di, H.; Wang, X. Flow softening of 253MA austenitic stainless steel during hot compression at higher strain rates. Mater. Sci. Eng. A 2016, 650, 483–491. [Google Scholar] [CrossRef]

- Maode, Y.; Sandström, R. Influence of cerium on the creep properties of the austenitic stainless steel 253MA. High Temp. Technol. 1988, 6, 153–157. [Google Scholar] [CrossRef]

- Anwar, M.S.; Melinia, R.K.; Pradisti, M.G.; Siradj, E.S. Effect of prior austenite grain size on the annealing twin density and hardness in austenitic stainless steel. Int. J. Technol. 2021, 12, 1149–1160. [Google Scholar] [CrossRef]

- Melinia, R.K.; Anwar, M.S.; Wijaya, R.R.; Siradj, E.S. Grain growth kinetics and hardness empirical model of 253 MA austenitic stainless steel after multi-pass cold rolling. Eng. Appl. Sci. Res. 2022, 49, 425–432. [Google Scholar]

- Hu, J.; Wang, X.; Zhang, J.; Luo, J.; Zhang, Z.; Shen, Z. A general mechanism of grain growth -I. Theory. J. Mater. 2021, 7, 1007–1013. [Google Scholar] [CrossRef]

- Mat, M.F.; Manurung, Y.H.P.; Busari, Y.O.; Adenan, M.S.; Sulaiman, M.S.; Muhammad, N.; Graf, M. Experimental analysis on grain growth kinetics of SS316L austenitic stainless steel. J. Mech. Eng. 2021, 18, 97–111. [Google Scholar]

- Ji, H.C.; Li, Y.M.; Ma, C.J.; Long, H.Y.; Liu, J.P.; Wang, B.Y. Modeling of austenitic grain growth of 21-4N steel. Metalurgija 2019, 58, 83–86. [Google Scholar]

- Quintin, A.P.; Brochet, S.; Vogt, J.B.; Glez, J.C.; Mithieux, J.D. Fine grained austenitic stainless steels: The role of strain induced α’ martensite and the reversion mechanism limitations. ISIJ Int. 2009, 49, 293–301. [Google Scholar]

- Behjati, P.; Kermanpur, A.; Najafizadeh, A.; Baghbadorani, H.S.; Karjalainen, L.P.; Jung, J.G.; Lee, Y.K. effect of nitrogen content on grain refinement and mechanical properties of a reversion-treated Ni-free 18Cr-12Mn austenitic stainless steel. Metall. Mater. Trans. A 2014, 45, 6317–6328. [Google Scholar] [CrossRef]

- Stornelli, G.; Gaggiotti, M.; Mancini, S.; Napoli, G.; Rocchi, C.; Tirasso, C.; Schino, A.D. Recrystallization and grain growth of AISI 904L super-austenitic stainless steel: A multivariate regression approach. Metals 2022, 12, 200. [Google Scholar] [CrossRef]

- Lee, Y.S.; Kim, D.W.; Lee, D.Y.; Ryu, W.S. Effect of grain size on creep properties of Type 316LN stainless steel. Met. Mater. Int. 2001, 7, 107–114. [Google Scholar] [CrossRef]

- Xie, L.; Wang, C.; Wang, Y.; Wu, G.; Huang, X. Grain size effect on the mechanical behavior of metastable Fe-23Cr-8.5Ni alloy. Metals 2019, 9, 734. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Bushby, A.J.; Dunstan, D.J. The Hall–Petch effect as a manifestation of the general size effect. In Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences, London, UK; 2016. [Google Scholar]

- Wang, Y.; Wang, Y.; Wang, Z. Enhancing yield strength of high nitrogen austenitic stainless steel. J. Constr. Steel Res. 2021, 187, 106927. [Google Scholar] [CrossRef]

- Xu, D.M.; Wan, X.L.; Yu, J.X.; Xu, G.; Li, G.Q. Effect of grain refinement on strain hardening and fracture in austenitic stainless steel. Mater. Sci. Technol. 2018, 34, 1344–1352. [Google Scholar] [CrossRef]

- Santella, M.L.; Tortorelli, P.F.; Render, M.; Pint, B.; Wang, H.; Cedro, V.; Chen, X. Effects of applied stress and grain size on creep-rupture lifetime prediction for Haynes 282 alloy. Mater. Sci. Eng. A 2022, 838, 142785. [Google Scholar] [CrossRef]

- Manokaran, M.; Jha, J.S.; Kashinath, A.S.; Toppo, S.P.; Singh, R. Understanding the stress rupture behavior and microstructural changes in austenitic stainless steel SS321. J. Mater. Eng. Perform. 2021, 30, 9165–9180. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Brandão, L.P.M.; Paula, A.d.S.; Elias, C.N.; Pereira, A.C.; Assis, F.S.d.; Almeida, L.H.d.; Araújo, L.S. Creep fracture mechanisms and maps in Aisi Type 316 austenitic stainless steels from distinct origins. Mat. Res. 2017, 20, 892–898. [Google Scholar] [CrossRef] [Green Version]

- Shinya, N.; Tanaka, H.; Murata, M.; Kaise, M.; Yokoi, S. Creep fracture mechanism maps based on creep rupture tests up to about 100 000 h for Type 316 stainless steel. Tetsu Hagane 1985, 71, 114–120. [Google Scholar] [CrossRef] [Green Version]

- Tanaka, M.; Taguchi, J.; Kato, R. Effects of microstructures on the creep-rupture properties and fracture mechanisms in austenitic heat-resistant steels. Mater. Sci. Eng. A 2005, 410–411, 79–84. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, J.; Li, X. Microstructural evolution and change in hardness during creep of NF709 austenitic stainless steel. Acta Metall. Sin. 2011, 24, 220–224. [Google Scholar]

- Sandström, R.; He, J.J. Prediction of creep ductility for austenitic stainless steels and copper. Mater. High Temp. 2022, 1–9. [Google Scholar] [CrossRef]

- Dudrová, E.; Kabátová, M. Fractography of sintered iron and steels. Powder Metall. Prog. 2008, 8, 59–74. [Google Scholar]

| C | Si | Mn | P | S | Cr | Ni | N | Ce | La | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.079 | 1.422 | 0.51 | 0.03 | <0.005 | 22.06 | 10.86 | 0.384 | 0.03 | 0.014 | Bal. |

| No. | Sample | % Atom | |||||||

|---|---|---|---|---|---|---|---|---|---|

| C | O | Si | Cr | Mn | Fe | Ni | Ce | ||

| 1 | Cold Rolled | 33.26 | - | 1.21 | 15.04 | - | 43.76 | 6.73 | - |

| 2 | 1100 °C | 30.7 | 4.42 | 14.71 | 2.09 | 43.1 | 4.97 | - | |

| 3 | 1100 °C—900 s | - | - | - | 24.35 | 1.45 | 65.08 | 9.11 | - |

| 4 | 1100 °C—1800 s | 28.48 | 8.08 | - | 16.02 | - | 42 | 5.45 | - |

| 5 | 1100 °C—3600 s | 27.29 | 6.21 | - | 16.1 | - | 43.21 | 6.27 | 0.45 |

| Creep Parameter | Annealing Time (s) | |||

|---|---|---|---|---|

| 0 | 900 | 1800 | 3600 | |

| εelastic (mm/mm) | 0.055 | 0.039 | 0.135 | 0.306 |

| εfracture (mm/mm) | 0.367 | 0.339 | 0.605 | 0.601 |

| tfracture (min) | 9270.4 | 11,683.6 | 21,846.1 | 16,924.4 |

| Creep rate (s¯¹) | 22.1 × 10−6 | 16.8 × 10−6 | 7.95 × 10−6 | 8.29 × 10−6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anwar, M.S.; Widjaya, R.R.; Prasetya, L.B.A.; Arfi, A.A.; Mabruri, E.; Siradj, E.S. Effect of Grain Size on Mechanical and Creep Rupture Properties of 253 MA Austenitic Stainless Steel. Metals 2022, 12, 820. https://doi.org/10.3390/met12050820

Anwar MS, Widjaya RR, Prasetya LBA, Arfi AA, Mabruri E, Siradj ES. Effect of Grain Size on Mechanical and Creep Rupture Properties of 253 MA Austenitic Stainless Steel. Metals. 2022; 12(5):820. https://doi.org/10.3390/met12050820

Chicago/Turabian StyleAnwar, Mochammad Syaiful, Robert R. Widjaya, Leonardo Bayu Adi Prasetya, Abdul Aziz Arfi, Efendi Mabruri, and Eddy S. Siradj. 2022. "Effect of Grain Size on Mechanical and Creep Rupture Properties of 253 MA Austenitic Stainless Steel" Metals 12, no. 5: 820. https://doi.org/10.3390/met12050820

APA StyleAnwar, M. S., Widjaya, R. R., Prasetya, L. B. A., Arfi, A. A., Mabruri, E., & Siradj, E. S. (2022). Effect of Grain Size on Mechanical and Creep Rupture Properties of 253 MA Austenitic Stainless Steel. Metals, 12(5), 820. https://doi.org/10.3390/met12050820