Surface Residual Stress Analysis in GMAW and LBW of the Dissimilar TRIP-DP Steels Joint: An Experimental Approach

Abstract

:1. Introduction

2. Materials and Experimental Details

2.1. Materials

2.2. Welding Procedure

2.3. Characterization Techniques

2.4. Residual Stress Measurement

3. Results and Discussion

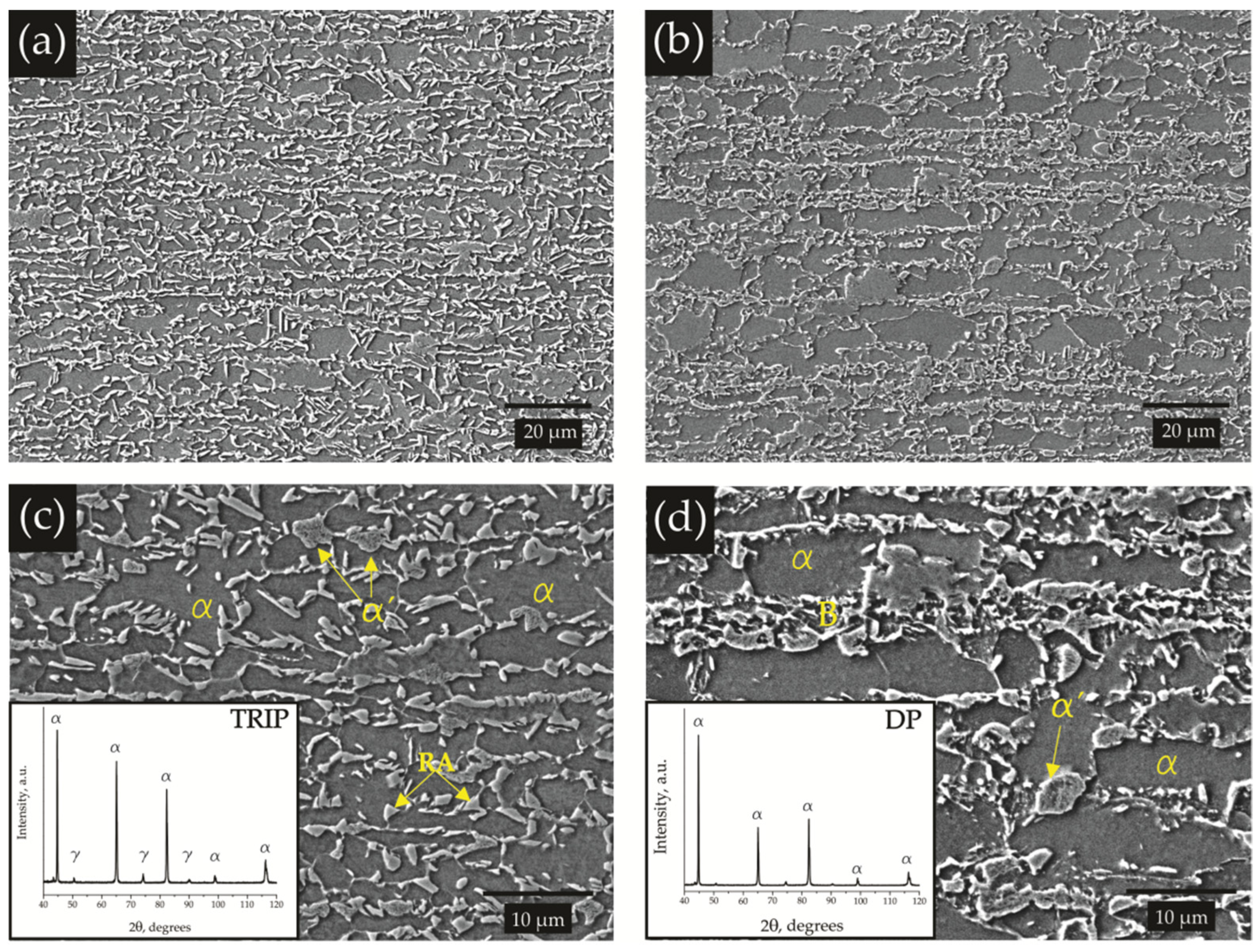

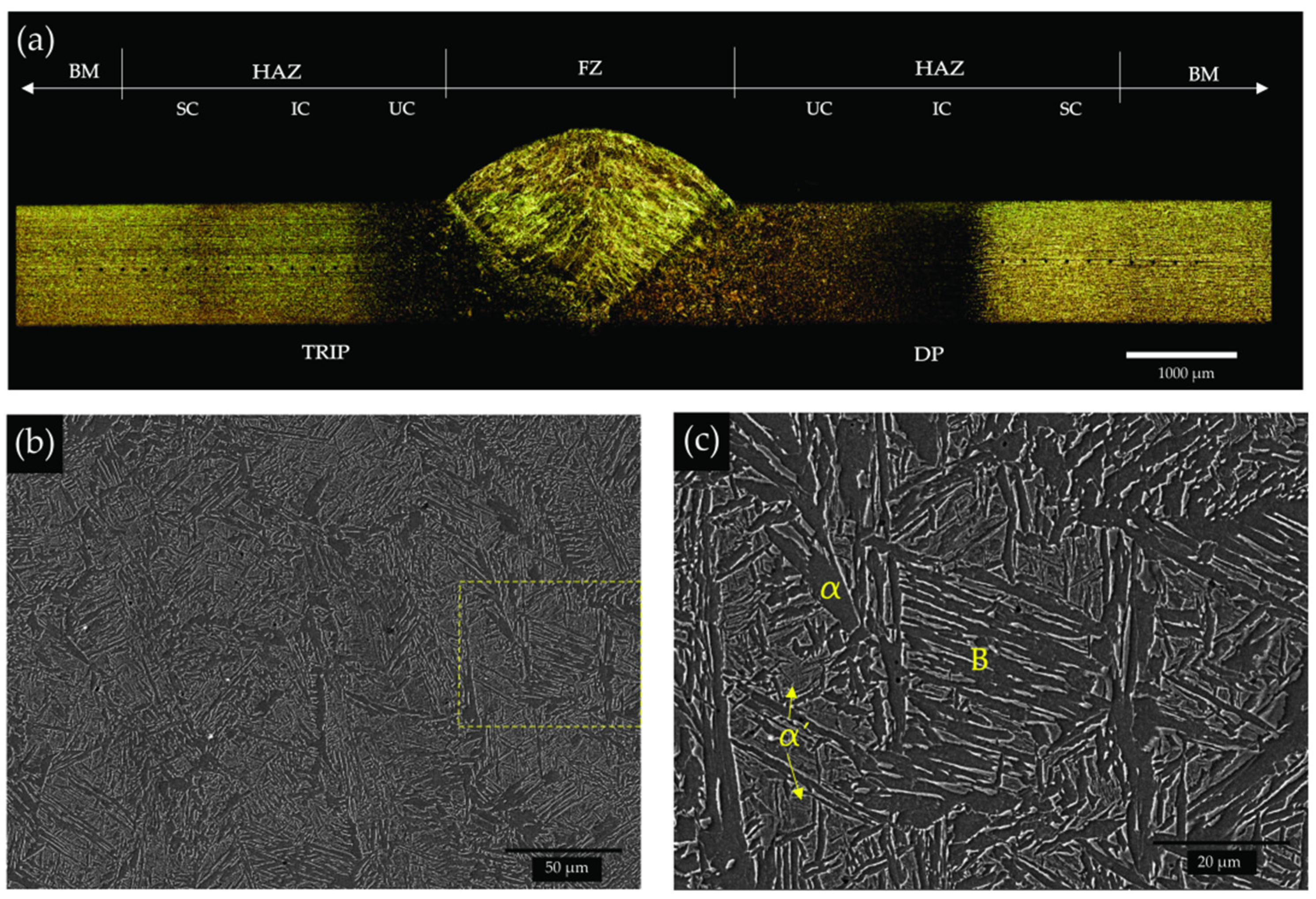

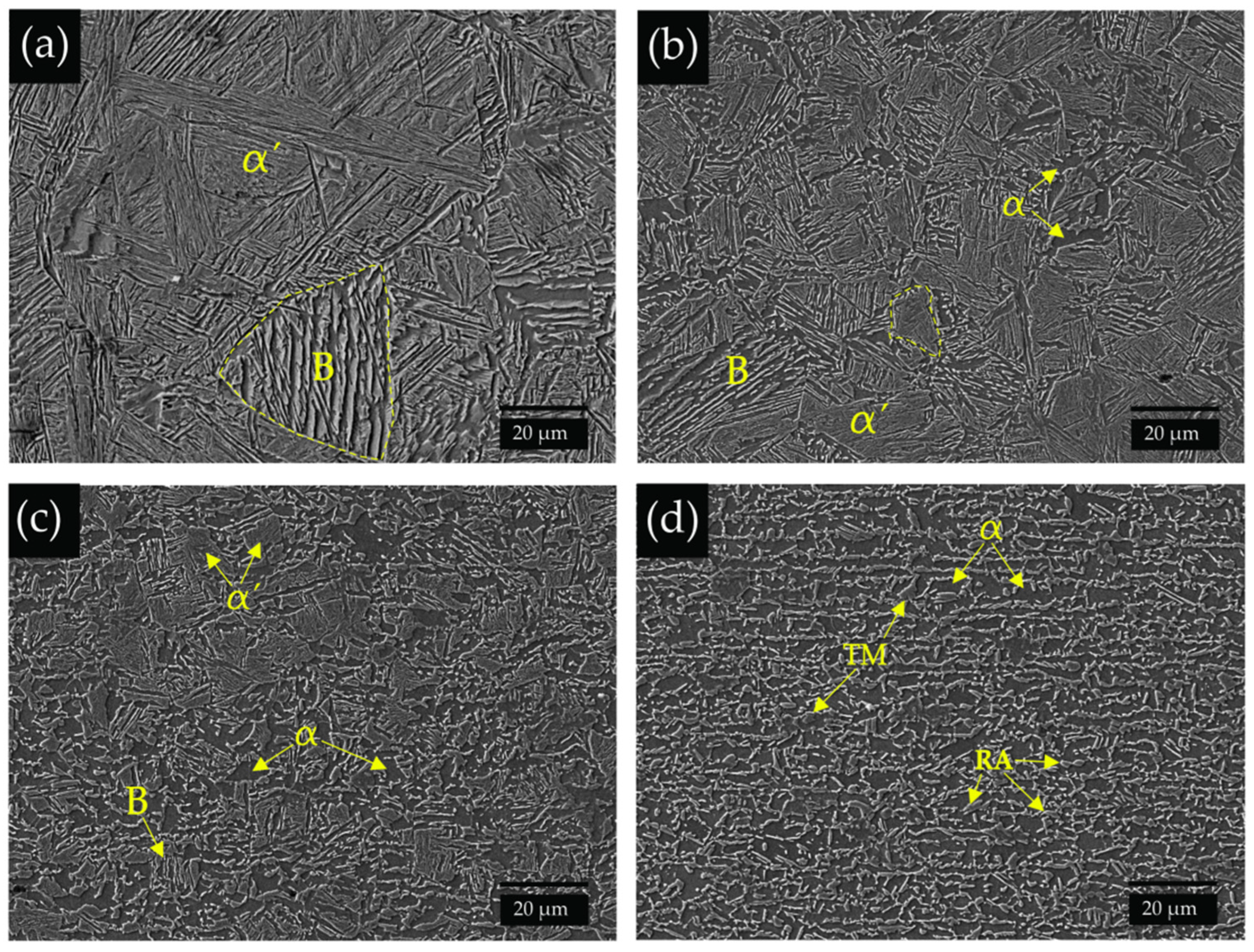

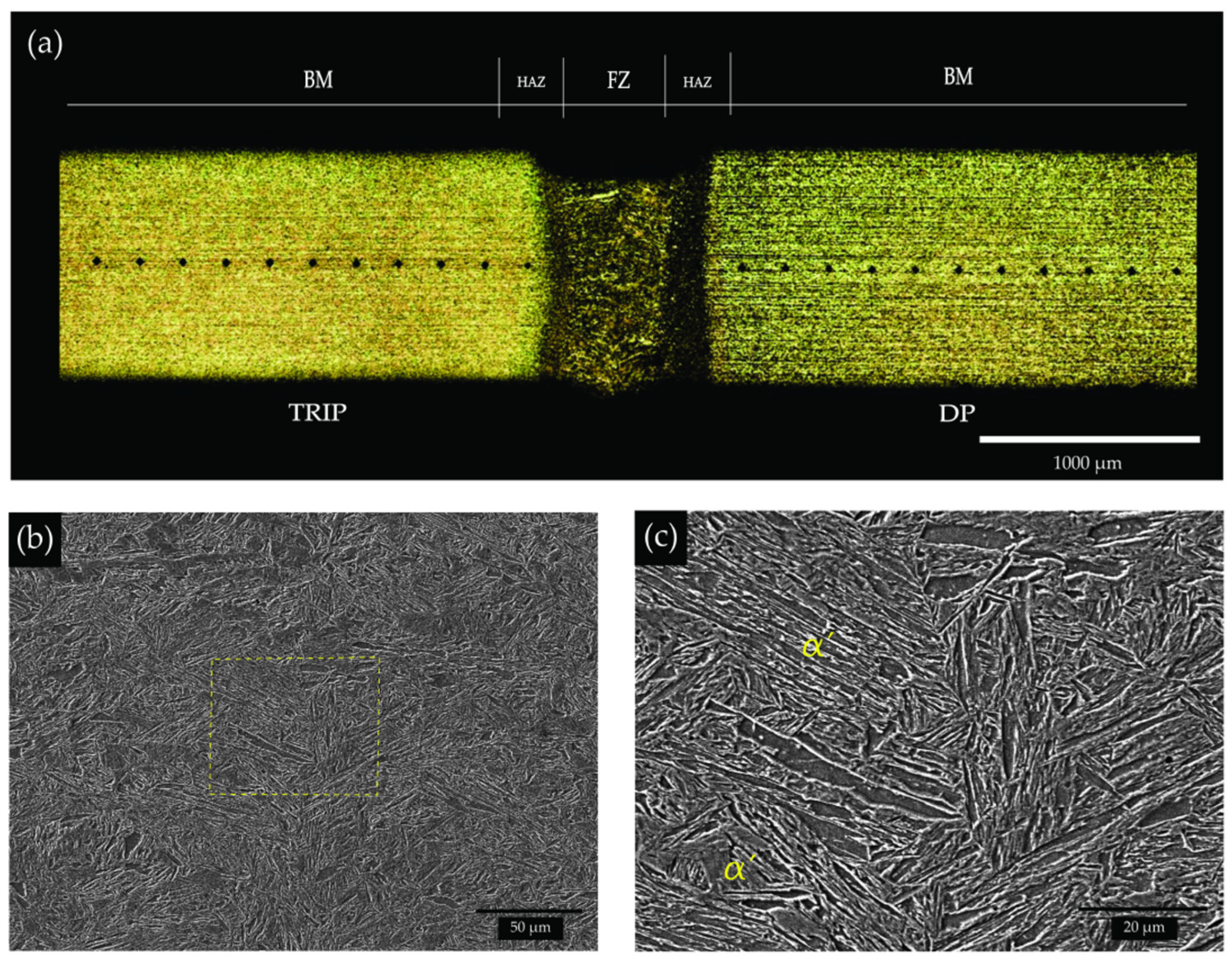

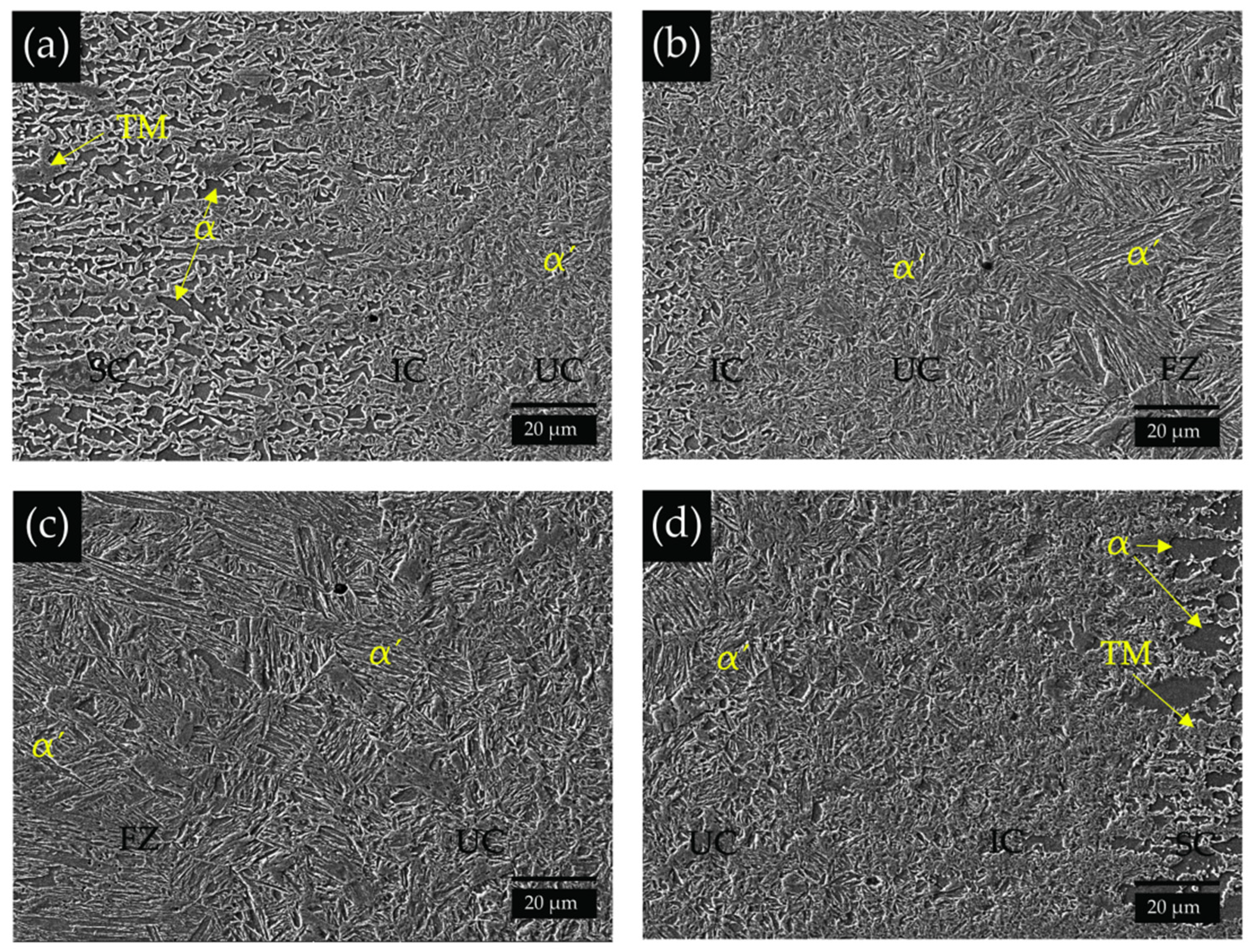

3.1. Microstructure and Hardness

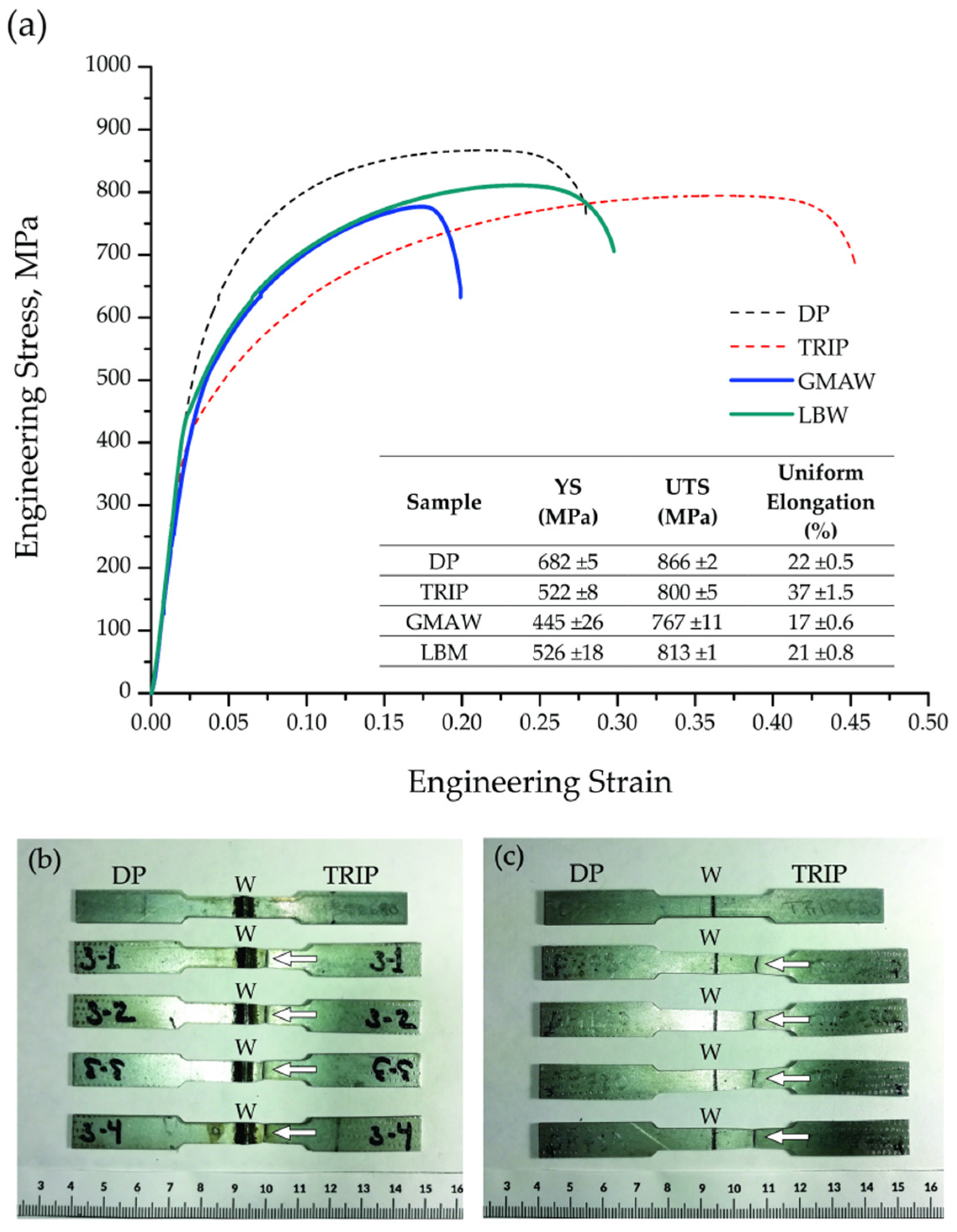

3.2. Uniaxial Tensile Behavior

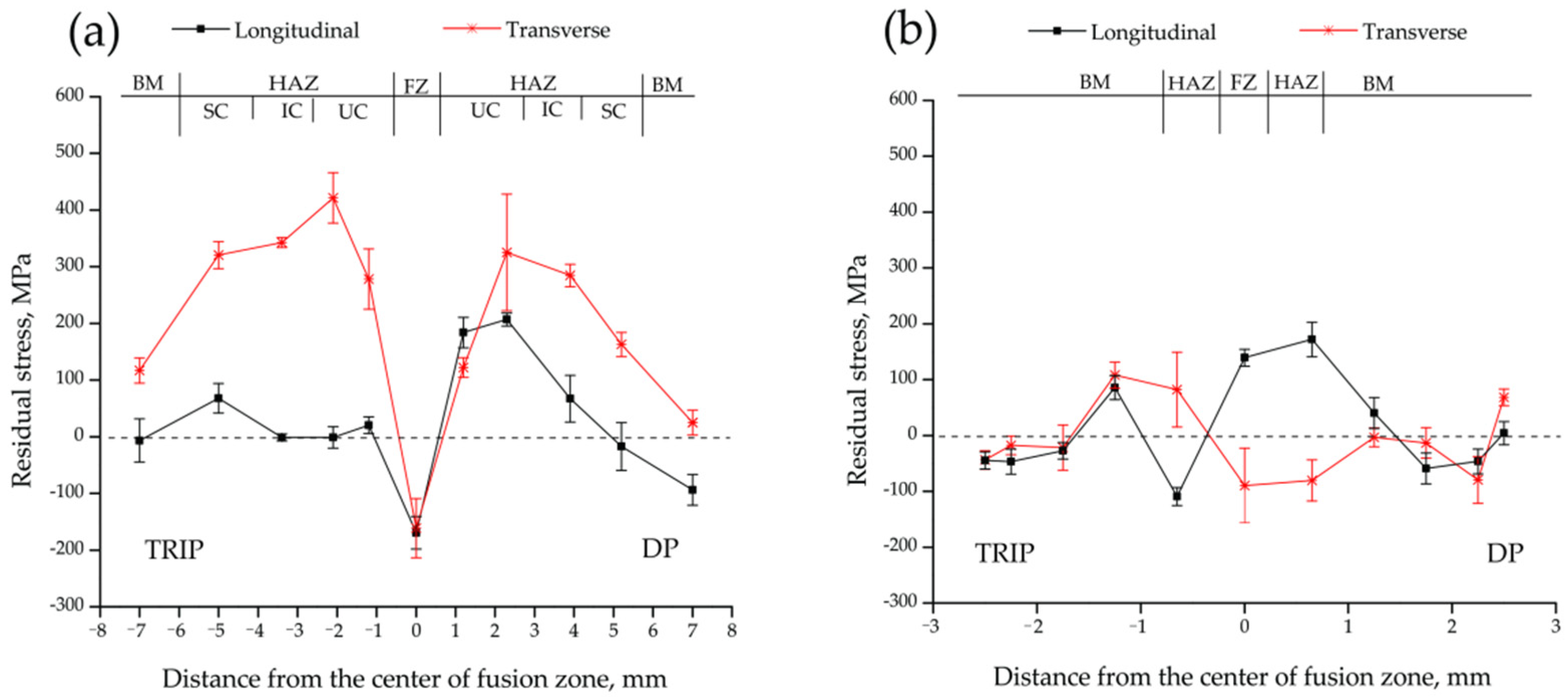

3.3. Residual Stress Analysis

4. Conclusions

- A hard predominant martensite averaging 461 ± 24 HV in the FZ of the LBW specimen contrasts well with the 284 ± 10 HV obtained in the FZ of the GMAW due to the combination of ferrite, bainite, and martensite microstructures promoted by the mix of chemistry between the filler metal and the base material in the latter.

- The peak hardness value (415 HV) measured in the UC-HAZ of the DP steel side in the GMAW specimen clearly contrasted with the peak value (322 HV) on the TRIP steel side due to the presence of a reduced fraction of ferrite located at the prior austenite grain boundary in the latter.

- Although the mechanical behaviors of the base materials are clearly superior, the improved uniaxial tensile weld properties in the LBW specimen (UTS = 813 MPa) contrasted well to the GMAW weldment (UTS = 767 MPa), whereas the failure location was found in the BM in the LBW specimen, and the location of failure was localized in the SC-HAZ of the GMAW specimen. In both cases, the failure resulted on the TRIP steel side.

- In spite of the combination of ferrite, bainite, and martensite microstructures found in the fusion zone of the GMAW specimen, the measured compressive residual stresses cannot be solely attributed to the phase transformation but to other possible factors, such as the material mismatch properties, the reinforcement size, the type of joint, the sheet thickness, and the weld joint restraint.

- The gradual increasing of residual stresses to a maximum value was followed by a steady decrease up to the base metal; the trend ensued: UC-HAZ (maximum) → IC-HAZ (moderated) → SC-HAZ (lowered). That trend was particularly evident in the GMAW specimen.

- The experimental surface residual stress distribution along the weldment measured in the LBW specimen is clearly lower if comparing it to the GMAW specimen. The maximum RS value (172 MPa tensile) was measured in the HAZ of the DP side which clearly contrasts to the maximum value (421 MPa) measured in the HAZ of the TRIP steel in the GMAW specimen.

- The resultant tensile residual stress distribution in both the GMAW and LBW specimens had no direct influence on the uniaxial tensile behavior of the welded specimens due to the failure location in both cases occurring on the TRIP steel side, either in the SC-HAZ in the case of the GMAW or in the BM in the LBW specimen.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jiang, H.; Liao, Y.; Gao, S.; Li, G.; Cui, J. Comparative study on joining quality of electromagnetic driven self-piecing riveting, adhesive and hybrid joints for Al/steel structure. Thin-Walled Struct. 2021, 164, 107903. [Google Scholar] [CrossRef]

- Jiang, H.; Liao, Y.; Jing, L.; Gao, S.; Li, G.; Cui, J. Mechanical properties and corrosion behavior of galvanized steel/Al dissimilar joints. Arch. Civ. Mech. Eng. 2021, 21, 168. [Google Scholar] [CrossRef]

- WorldAutoSteel. AHSS Guidelines. Available online: https://www.worldautosteel.org/projects/advanced-high-strength-steel-application-guidelines/ (accessed on 31 March 2022).

- Hernandez, B.V.H.; Kuntz, M.L.; Khan, M.I.; Zhou, Y. Influence of microstructure and weld size on the mechanical behaviour of dissimilar AHSS resistance spot welds. Sci. Technol. Weld. Join. 2008, 13, 769–776. [Google Scholar] [CrossRef]

- Shome, M.; Tumuluru, M. 1—Introduction to welding and joining of advanced high-strength steels (AHSS). In Welding and Joining of Advanced High Strength Steels (AHSS); Shome, M., Tumuluru, M., Eds.; Woodhead Publishing: Sawston, UK, 2015; pp. 1–8. [Google Scholar] [CrossRef]

- Duchet, M.; Haouas, J.; Gibeau, E.; Pechenot, F.; Honecker, C.; Munier, R.; Weber, B. Improvement of the fatigue strength of welds for lightweight chassis application made of Advanced High Strength Steels. Procedia Struct. Integr. 2019, 19, 585–594. [Google Scholar] [CrossRef]

- John, M.; Kumar, A.; Bhat, U. AHSS welding using undermatching filler wires and process advantages with P-GMAW. Mater. Today Proc. 2022, 49, 1312–1318. [Google Scholar] [CrossRef]

- Kapustka, W.M.a.N. Fatigue of GMAW-P Lap Joints in Advanced High-Strength Steels. In Proceedings of the Sheet Metal Welding Conference XVIII Livonia, Livonia, MI, USA, 17–18 October 2018. [Google Scholar]

- Ahiale, G.K.; Oh, Y.-J. Microstructure and fatigue performance of butt-welded joints in advanced high-strength steels. Mater. Sci. Eng. A 2014, 597, 342–348. [Google Scholar] [CrossRef]

- Svoboda, H.G.; Nadale, H.C. Fatigue Life of GMAW and PAW Welding Joints of Boron Microalloyed Steels. Procedia Mater. Sci. 2015, 9, 419–427. [Google Scholar] [CrossRef] [Green Version]

- Sharifimehr, S.; Fatemi, A.; Cha, S.C.; Bae, M.-K.; Hong, S.-H. Fatigue behavior of AHSS lap shear and butt arc welds including the effect of periodic overloads and underloads. Int. J. Fatigue 2016, 87, 6–14. [Google Scholar] [CrossRef]

- Tong, L.; Niu, L.; Ren, Z.; Zhao, X.-L. Experimental investigation on fatigue behavior of butt-welded high-strength steel plates. Thin-Walled Struct. 2021, 165, 107956. [Google Scholar] [CrossRef]

- Zhang, M.; Li, L.; Fu, R.-y.; Zhang, J.-c.; Wan, Z. Weldability of low carbon transformation induced plasticity steel. J. Iron Steel Res. Int. 2008, 15, 61–65. [Google Scholar] [CrossRef]

- Májlinger, K.; Kalácska, E.; Russo Spena, P. Gas metal arc welding of dissimilar AHSS sheets. Mater. Des. 2016, 109, 615–621. [Google Scholar] [CrossRef]

- Varol, F.; Ferik, E.; Ozsarac, U.; Aslanlar, S. Influence of current intensity and heat input in Metal Inert Gas-brazed joints of TRIP 800 thin zinc coated steel plates. Mater. Des. 2013, 52, 1099–1105. [Google Scholar] [CrossRef]

- Njock Bayock, F.; Kah, P.; Mvola, B.; Layus, P. Effect of Heat Input and Undermatched Filler Wire on the Microstructure and Mechanical Properties of Dissimilar S700MC/S960QC High-Strength Steels. Metals 2019, 9, 883. [Google Scholar] [CrossRef] [Green Version]

- Bandyopadhyay, K.; Panda, S.K.; Saha, P.; Baltazar-Hernandez, V.H.; Zhou, Y.N. Microstructures and failure analyses of DP980 laser welded blanks in formability context. Mater. Sci. Eng. A 2016, 652, 250–263. [Google Scholar] [CrossRef]

- Basak, S.; Katiyar, B.; Orozco-Gonzalez, P.; Baltazar-Hernandez, V.; Arora, K.; Panda, S. Microstructure, forming limit diagram, and strain distribution of pre-strained DP-IF steel tailor–welded blank for auto body application. Int. J. Adv. Manuf. Technol. 2019, 104, 1749–1767. [Google Scholar] [CrossRef]

- Yuce, C.; Tutar, M.; Karpat, F.; Yavuz, N. The Optimization of Process Parameters and Microstructural Characterization of Fiber Laser Welded Dissimilar HSLA and MART Steel Joints. Metals 2016, 6, 245. [Google Scholar] [CrossRef] [Green Version]

- Evin, E.; Tomáš, M. The Influence of Laser Welding on the Mechanical Properties of Dual Phase and Trip Steels. Metals 2017, 7, 239. [Google Scholar] [CrossRef] [Green Version]

- Xue, X.; Pereira, A.; Amorim, J.; Liao, J. Effects of Pulsed Nd:YAG Laser Welding Parameters on Penetration and Microstructure Characterization of a DP1000 Steel Butt Joint. Metals 2017, 7, 292. [Google Scholar] [CrossRef]

- He, H.; Forouzan, F.; Volpp, J.; Robertson, S.M.; Vuorinen, E. Microstructure and Mechanical Properties of Laser-Welded DP Steels Used in the Automotive Industry. Materials 2021, 14, 456. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, S.H.; Kwon, H.S.; Kim, G.S.; Lee, C.S. Laser, tungsten inert gas, and metal active gas welding of DP780 steel: Comparison of hardness, tensile properties and fatigue resistance. Mater. Des. 2014, 64, 559–565. [Google Scholar] [CrossRef]

- Sun, Q.; Di, H.-S.; Li, J.-C.; Wu, B.-Q.; Misra, R.D.K. A comparative study of the microstructure and properties of 800 MPa microalloyed C-Mn steel welded joints by laser and gas metal arc welding. Mater. Sci. Eng. A 2016, 669, 150–158. [Google Scholar] [CrossRef]

- Němeček, S.; Mužík, T.; Míšek, M. Differences between Laser and Arc Welding of HSS Steels. Phys. Procedia 2012, 39, 67–74. [Google Scholar] [CrossRef] [Green Version]

- Guzman-Aguilera, J.J.; Martinez-Gonzalez, C.J.; Baltazar-Hernandez, V.H.; Basak, S.; Panda, S.K.; Razmpoosh, M.H.; Gerlich, A.; Zhou, Y. Influence of SC-HAZ microstructure on the mechanical behavior of Si-TRIP steel welds. Mater. Sci. Eng. A 2018, 718, 216–227. [Google Scholar] [CrossRef]

- Khanna, S.K.; Long, X. Residual stresses in resistance spot welded steel joints. Sci. Technol. Weld. Join. 2008, 13, 278–288. [Google Scholar] [CrossRef]

- Colombo, T.C.A.; Rego, R.R.; Otubo, J.; de Faria, A.R. Mechanical reliability of TWIP steel spot weldings. J. Mater. Process. Technol. 2019, 266, 662–674. [Google Scholar] [CrossRef]

- Shamsujjoha, M.; Enloe, C.M.; Chuang, A.C.; Coryell, J.J.; Ghassemi-Armaki, H. Mechanisms of paint bake response in resistance spot-welded first and third generation AHSS. Materialia 2021, 15, 100975. [Google Scholar] [CrossRef]

- Ren, S.; Ma, N.; Tsutsumi, S.; Watanabe, G.; He, H.; Cao, C.; Huang, L. Post-weld cold working for fatigue strength improvement of resistance spot welded joint of advanced high-strength steel. J. Mater. Process. Technol. 2022, 299, 117364. [Google Scholar] [CrossRef]

- Wu, X.I.N.; Wang, Z.; Yu, Z.; Liu, S.; Bunn, J.R.; Kolbus, L.; Feng, Z. Control of Weld Residual Stress in a Thin Steel Plate through Low Transformation Temperature Welding Consumables. Weld. J. 2020, 99, 124s–134s. [Google Scholar] [CrossRef]

- Kouadri-Henni, A.; Seang, C.; Malard, B.; Klosek, V. Residual stresses induced by laser welding process in the case of a dual-phase steel DP600: Simulation and experimental approaches. Mater. Des. 2017, 123, 89–102. [Google Scholar] [CrossRef] [Green Version]

- Lin, J.; Ma, N.; Lei, Y.; Murakawa, H. Measurement of residual stress in arc welded lap joints by cosα X-ray diffraction method. J. Mater. Process. Technol. 2017, 243, 387–394. [Google Scholar] [CrossRef]

- Kang, H.T.; Lee, Y.-L.; Sun, X.J. Effects of residual stress and heat treatment on fatigue strength of weldments. Mater. Sci. Eng. A 2008, 497, 37–43. [Google Scholar] [CrossRef]

- Kong, F.; Kovacevic, R. Measurement of surface residual stresses and testing mechanical properties of high-strength steel butt joints obtained by hybrid laser/gas metal arc welding. J. Strain Anal. Eng. Des. 2013, 48, 437–445. [Google Scholar] [CrossRef]

- García-García, V.; Mejía, I.; Reyes-Calderón, F.; Benito, J.A.; Cabrera, J.M. FE thermo-mechanical simulation of welding residual stresses and distortion in Ti-containing TWIP steel through GTAW process. J. Manuf. Process. 2020, 59, 801–815. [Google Scholar] [CrossRef]

- Mujica, L.; Weber, S.; Pinto, H.; Thomy, C.; Vollertsen, F. Microstructure and mechanical properties of laser-welded joints of TWIP and TRIP steels. Mater. Sci. Eng. A 2010, 527, 2071–2078. [Google Scholar] [CrossRef]

- Kasuya, T.; Yurioka, N. Determination of Necessary Preheat Temperature to Avoid Cold Cracking under Varying Ambient Temperature. ISIJ Int. 1995, 35, 1183–1189. [Google Scholar] [CrossRef]

- Cullity, B.D. Elements of X-ray Diffraction; Prentice Hall: Hoboken, NJ, USA, 1978; pp. 435–469. [Google Scholar]

- Luo, Q.; Jones, A.H. High-precision determination of residual stress of polycrystalline coatings using optimised XRD-sin2ψ technique. Surf. Coat. Technol. 2010, 205, 1403–1408. [Google Scholar] [CrossRef] [Green Version]

- Ooi, S.W.; Garnham, J.E.; Ramjaun, T.I. Review: Low transformation temperature weld filler for tensile residual stress reduction. Mater. Des. 2014, 56, 773–781. [Google Scholar] [CrossRef]

- Francis, J.A.; Bhadeshia, H.K.D.H.; Withers, P.J. Welding residual stresses in ferritic power plant steels. Mater. Sci. Technol. 2007, 23, 1009–1020. [Google Scholar] [CrossRef]

- Elmesalamy, A.; Francis, J.A.; Li, L. A comparison of residual stresses in multi pass narrow gap laser welds and gas-tungsten arc welds in AISI 316L stainless steel. Int. J. Press. Vessel. Pip. 2014, 113, 49–59. [Google Scholar] [CrossRef]

- Bate, S.K.; Green, D.; Buttle, D. A Review of Residual Stress Distributions in Welded Joints for the Defect Assessment of Offshore Structures; U.S. Department of Energy Office of Scientific and Technical Information: Norwich, UK, 1998; p. 144. ISBN 0717624110.

- Hu, X.; Jiang, H.Y.; Luo, Y.; Jin, Q.; Peng, W.; Yi, C.M. A Study on Microstructure, Residual Stresses and Stress Corrosion Cracking of Repair Welding on 304 Stainless Steel: Part II-Effects of Reinforcement Height. Materials 2020, 13, 2434. [Google Scholar] [CrossRef]

- Venkata Ramana, P.; Madhusudhan Reddy, G.; Mohandas, T.; Gupta, A.V.S.S.K.S. Microstructure and residual stress distribution of similar and dissimilar electron beam welds—Maraging steel to medium alloy medium carbon steel. Mater. Des. 2010, 31, 749–760. [Google Scholar] [CrossRef]

- Sun, J.; Nitschke-Pagel, T.; Dilger, K. Influence of temperature- and phase-dependent yield strength on residual stresses in ultra-high strength steel S960 weldments. J. Mater. Res. Technol. 2021, 15, 1854–1872. [Google Scholar] [CrossRef]

- Balakrishnan, J.; Vasileiou, A.N.; Francis, J.A.; Smith, M.C.; Roy, M.J.; Callaghan, M.D.; Irvine, N.M. Residual stress distributions in arc, laser and electron-beam welds in 30 mm thick SA508 steel: A cross-process comparison. Int. J. Press. Vessel. Pip. 2018, 162, 59–70. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.; Liu, X.; Tong, Y.; Deng, D. A comparative study on welding temperature fields, residual stress distributions and deformations induced by laser beam welding and CO2 gas arc welding. Mater. Des. 2014, 63, 519–530. [Google Scholar] [CrossRef]

- Roshith, P.; Arivarasu, M.; Arivazhagan, N.; Srinivasan, A.; KV, P.P. Investigations on induced residual stresses, mechanical and metallurgical properties of CO2 laser beam and pulse current gas tungsten arc welded SMO 254. J. Manuf. Process. 2019, 44, 81–90. [Google Scholar] [CrossRef]

| Material | C | Mn | P | Si | Cu | Ni | Cr | Mo | Al | CEy |

|---|---|---|---|---|---|---|---|---|---|---|

| TRIP | 0.17 | 1.53 | 0.02 | 0.29 | 0.03 | 0.02 | 0.03 | 0.02 | 1.38 | 0.435 |

| DP | 0.14 | 1.75 | 0.01 | 0.17 | 0.05 | 0.02 | 0.30 | 0.10 | 0.02 | 0.450 |

| ER70S-6 * | 0.06–0.15 | 1.40–1.85 | 0.025 | 0.80–1.15 | 0.50 | 0.15 | 0.15 | 0.15 | - | - |

| GMAW-Parameter | Current (A) | Voltage (V) | Shield Gas | Gas Flow (L/min) | Travel Speed (m/min) |

| 55 | 16.5 | 75% CO2 + 25% Ar | 18 | 0.6 | |

| LBW-Parameter | Laser Power (kW) | Beam Spot Size (µm) | Focal Length (mm) | Gas Flow (L/min) | Travel Speed (m/min) |

| 4 | 600 | 200 | -- | 12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baltazar-Hernández, V.H.; López-Baltazar, E.A.; Alvarado-Hernández, F.; Gómez-Jiménez, S.; Ruiz-Mondragón, J.J.; Biro, E.; Zhou, N. Surface Residual Stress Analysis in GMAW and LBW of the Dissimilar TRIP-DP Steels Joint: An Experimental Approach. Metals 2022, 12, 880. https://doi.org/10.3390/met12050880

Baltazar-Hernández VH, López-Baltazar EA, Alvarado-Hernández F, Gómez-Jiménez S, Ruiz-Mondragón JJ, Biro E, Zhou N. Surface Residual Stress Analysis in GMAW and LBW of the Dissimilar TRIP-DP Steels Joint: An Experimental Approach. Metals. 2022; 12(5):880. https://doi.org/10.3390/met12050880

Chicago/Turabian StyleBaltazar-Hernández, Víctor H., Enrique A. López-Baltazar, Francisco Alvarado-Hernández, Salvador Gómez-Jiménez, José Jorge Ruiz-Mondragón, Elliot Biro, and Norman Zhou. 2022. "Surface Residual Stress Analysis in GMAW and LBW of the Dissimilar TRIP-DP Steels Joint: An Experimental Approach" Metals 12, no. 5: 880. https://doi.org/10.3390/met12050880

APA StyleBaltazar-Hernández, V. H., López-Baltazar, E. A., Alvarado-Hernández, F., Gómez-Jiménez, S., Ruiz-Mondragón, J. J., Biro, E., & Zhou, N. (2022). Surface Residual Stress Analysis in GMAW and LBW of the Dissimilar TRIP-DP Steels Joint: An Experimental Approach. Metals, 12(5), 880. https://doi.org/10.3390/met12050880