Review of Fatigue Assessment Approaches for Welded Marine Joints and Structures

Abstract

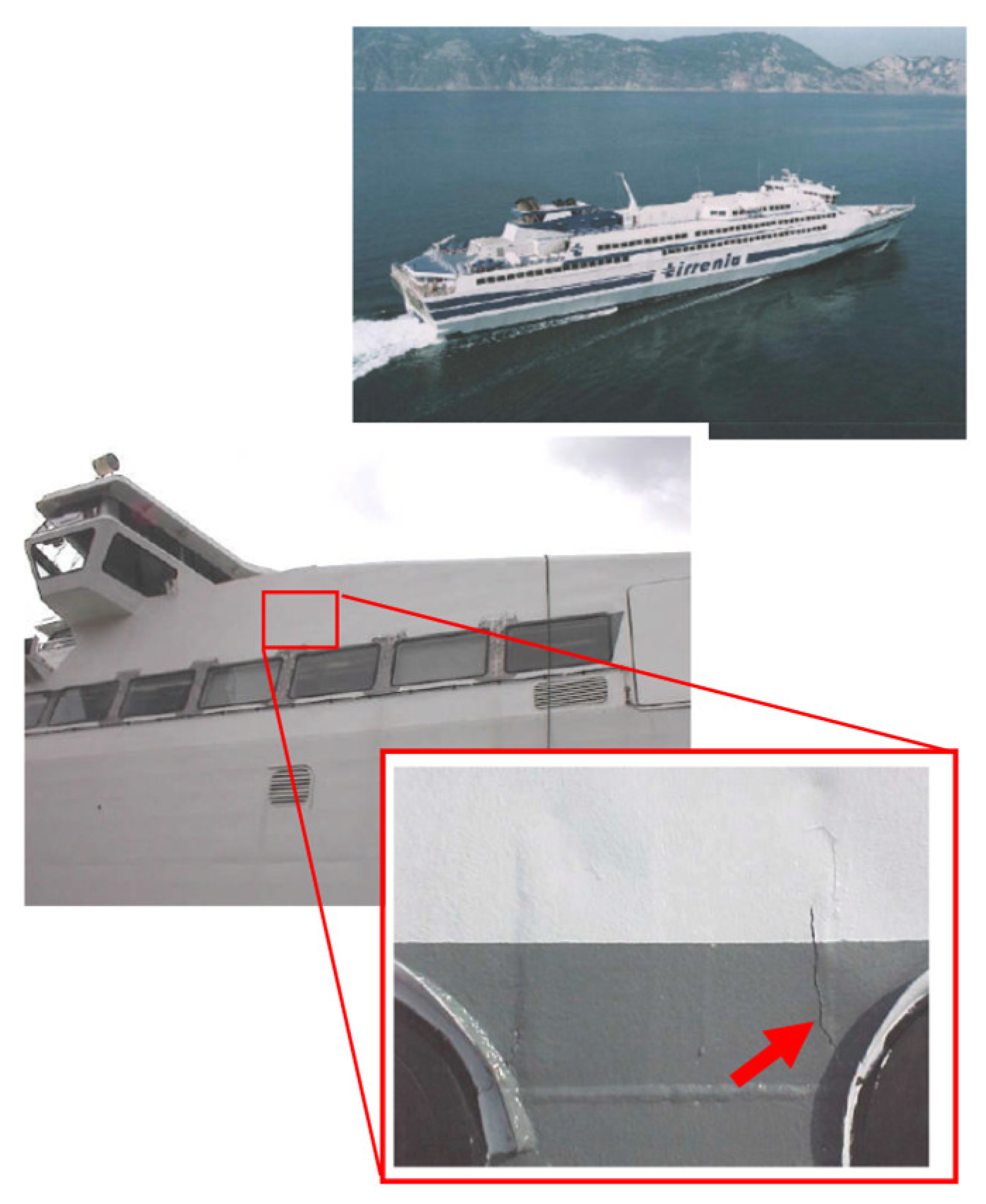

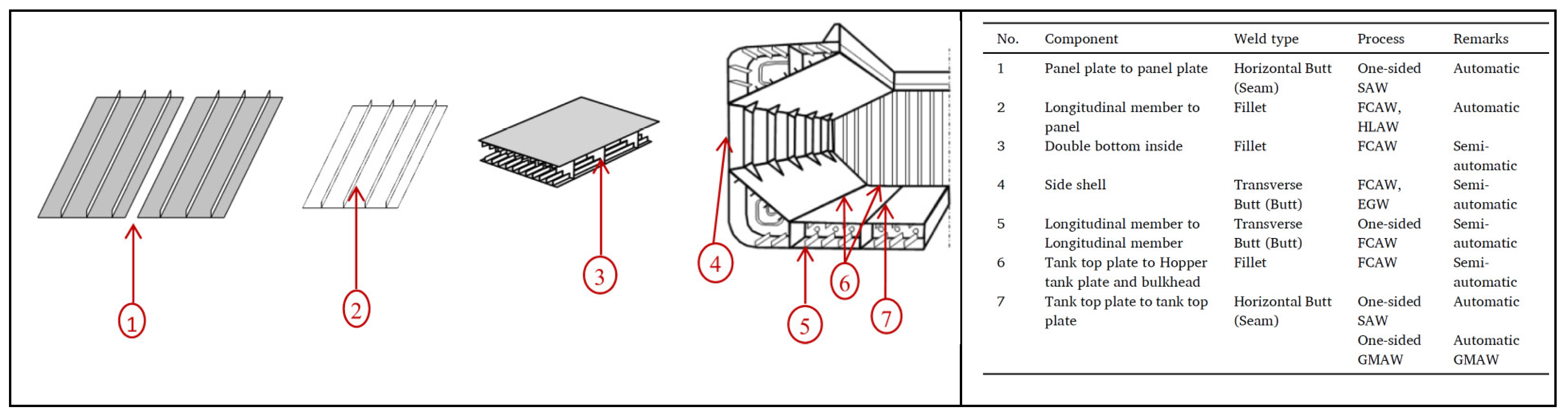

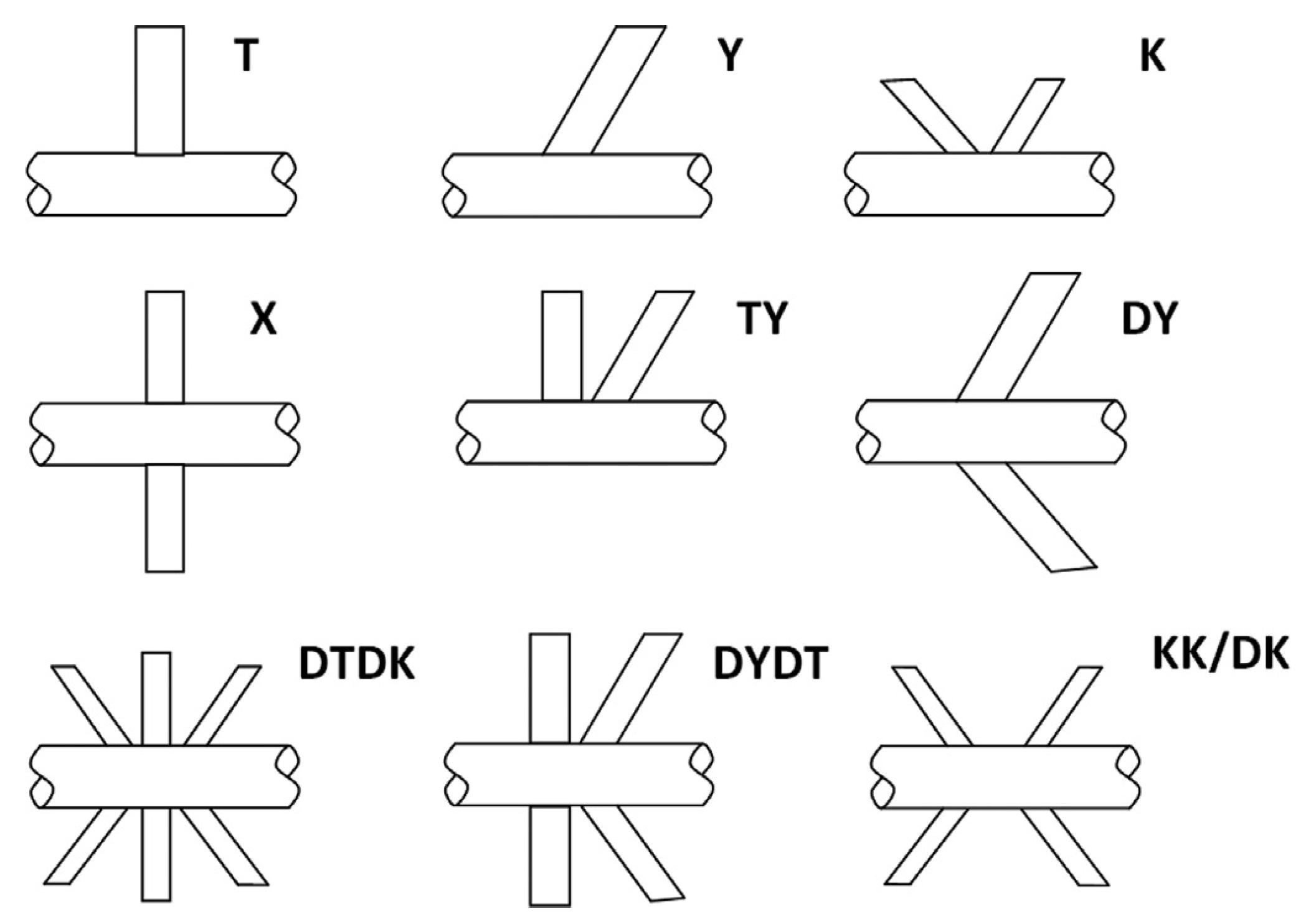

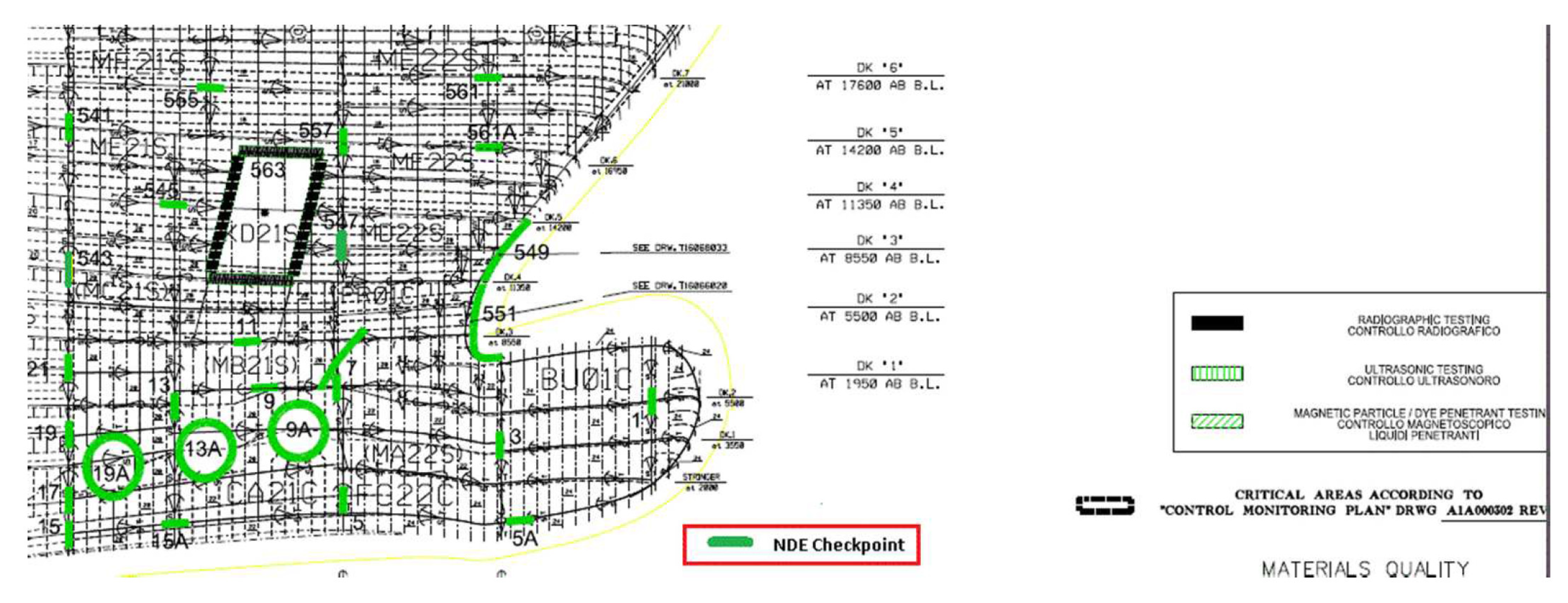

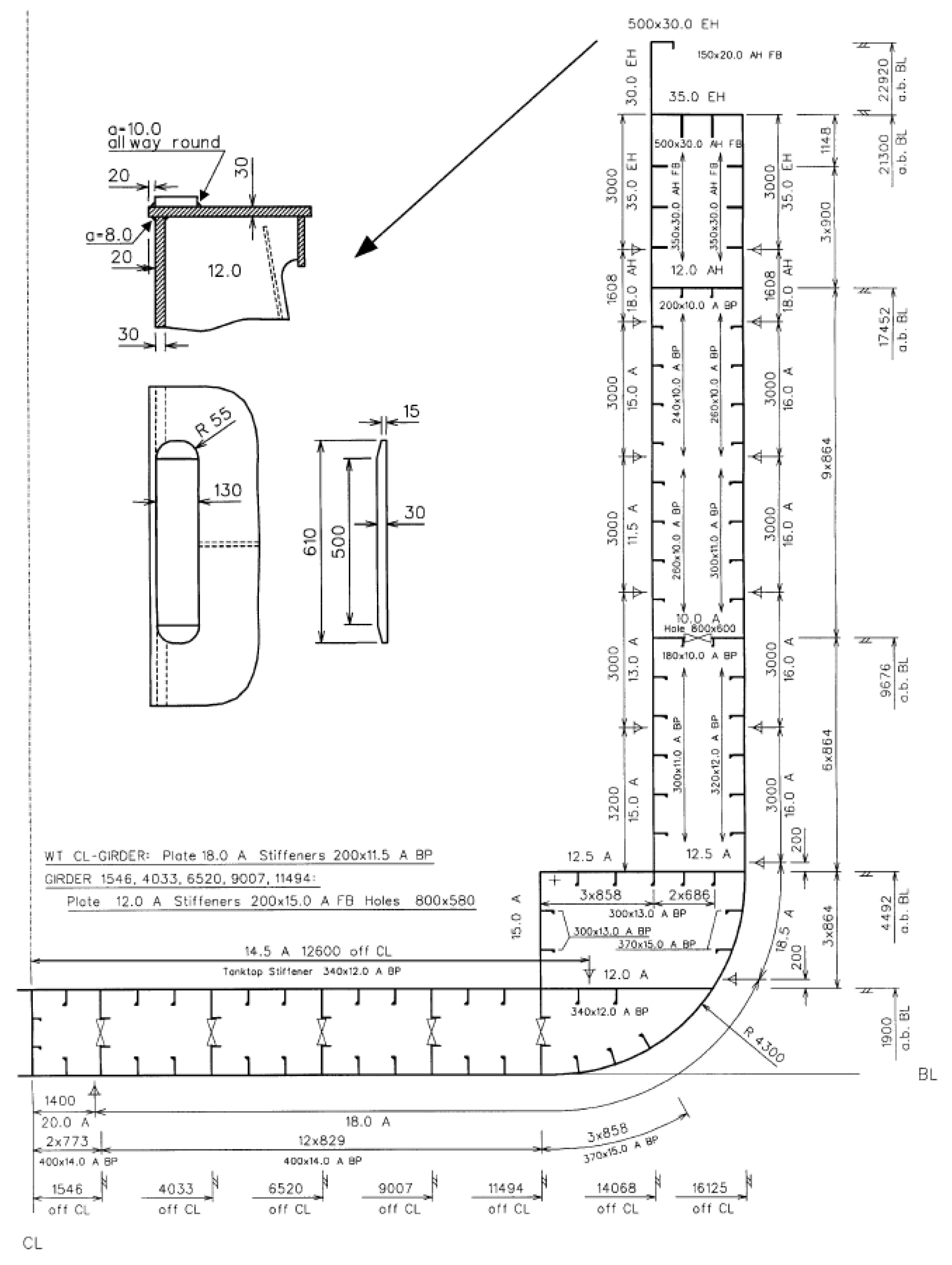

:1. Introduction

- -

- The most common approaches include the following:

- -

- -

- -

- -

- -

- -

- -

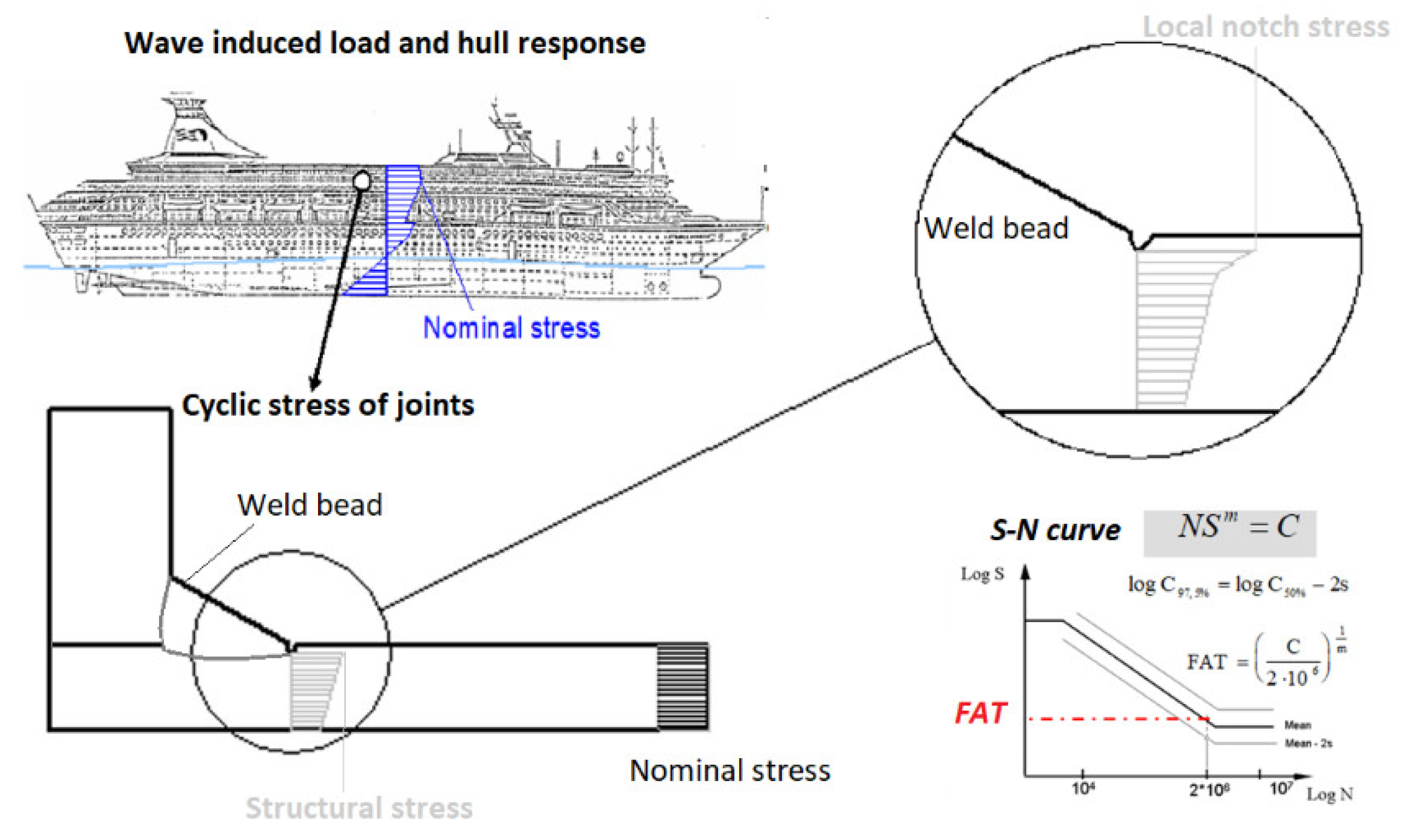

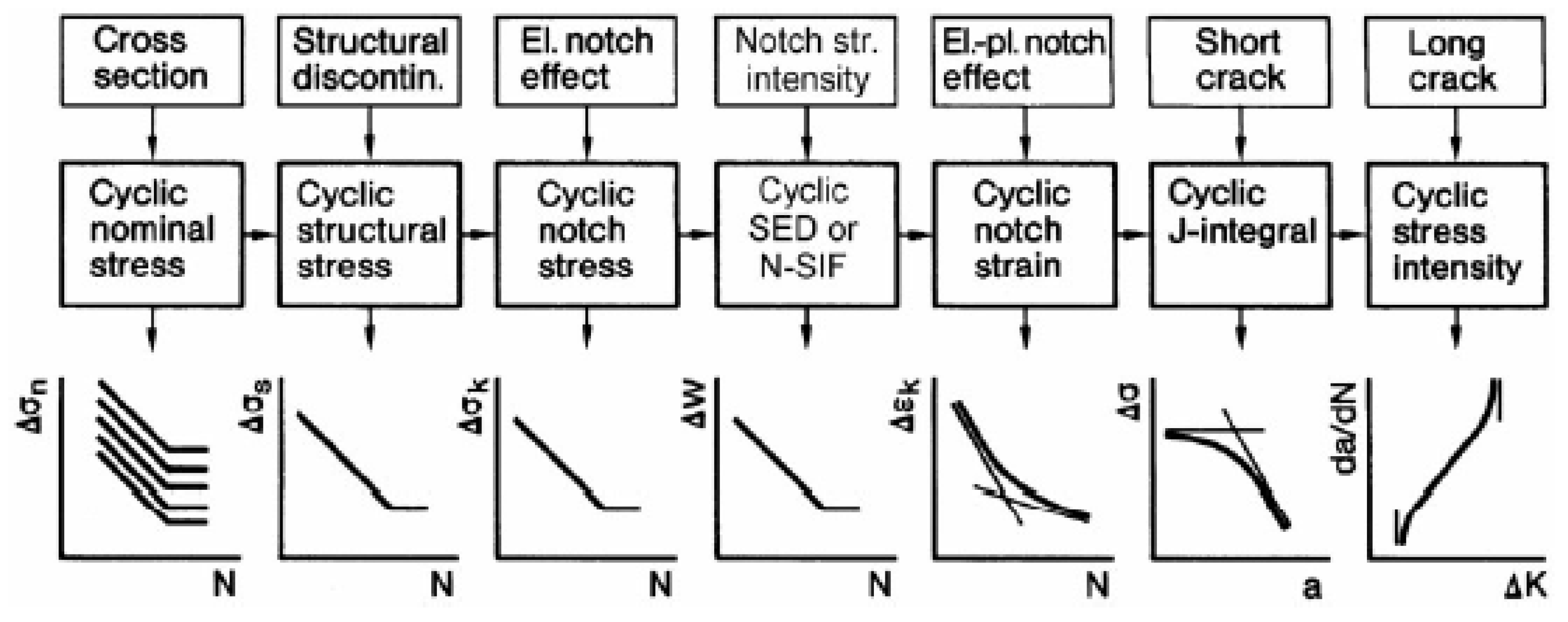

2. Approaches for Fatigue Assessment of Marine Welded Joints

2.1. Nominal Stress Approach

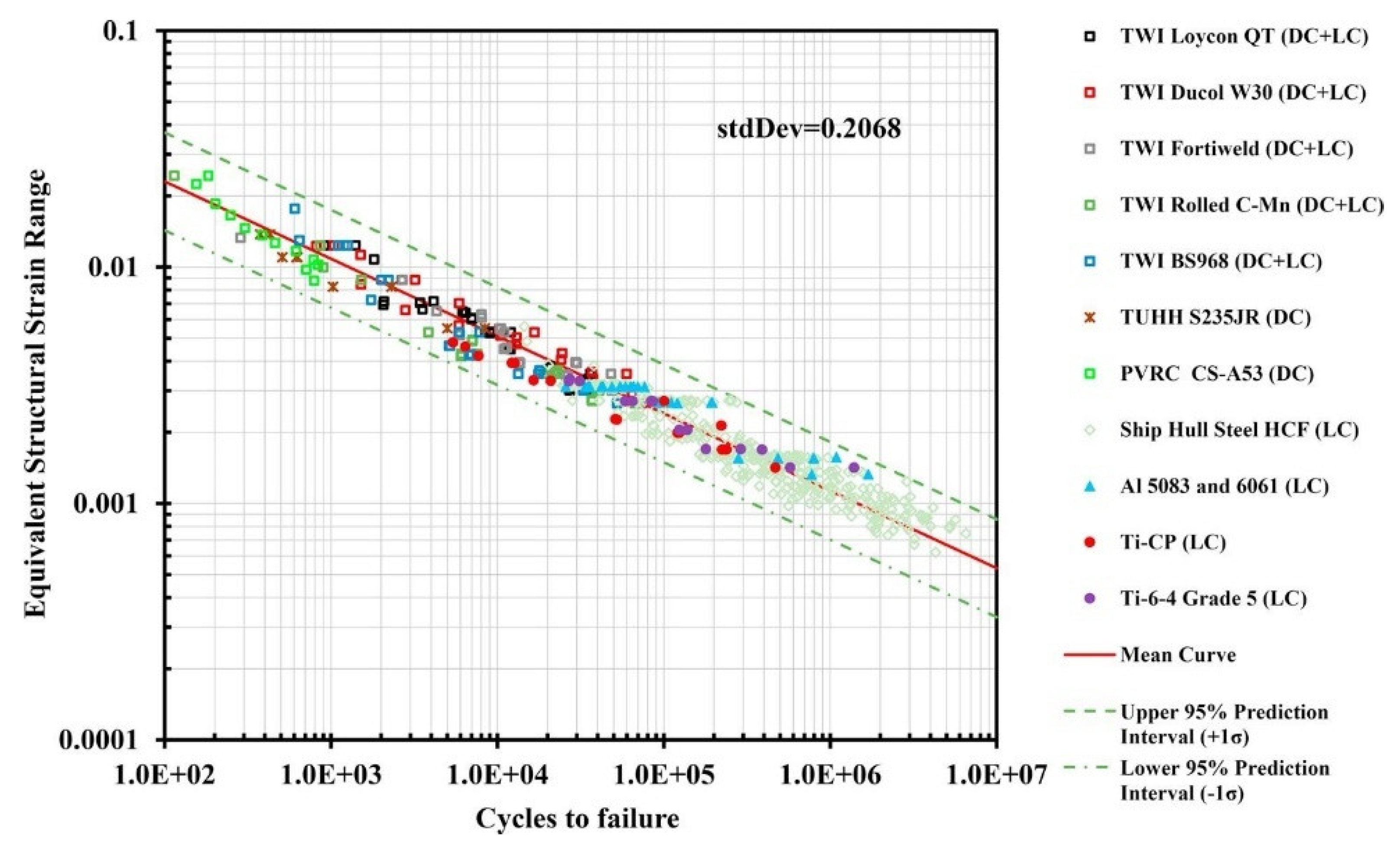

2.2. Structural Approaches

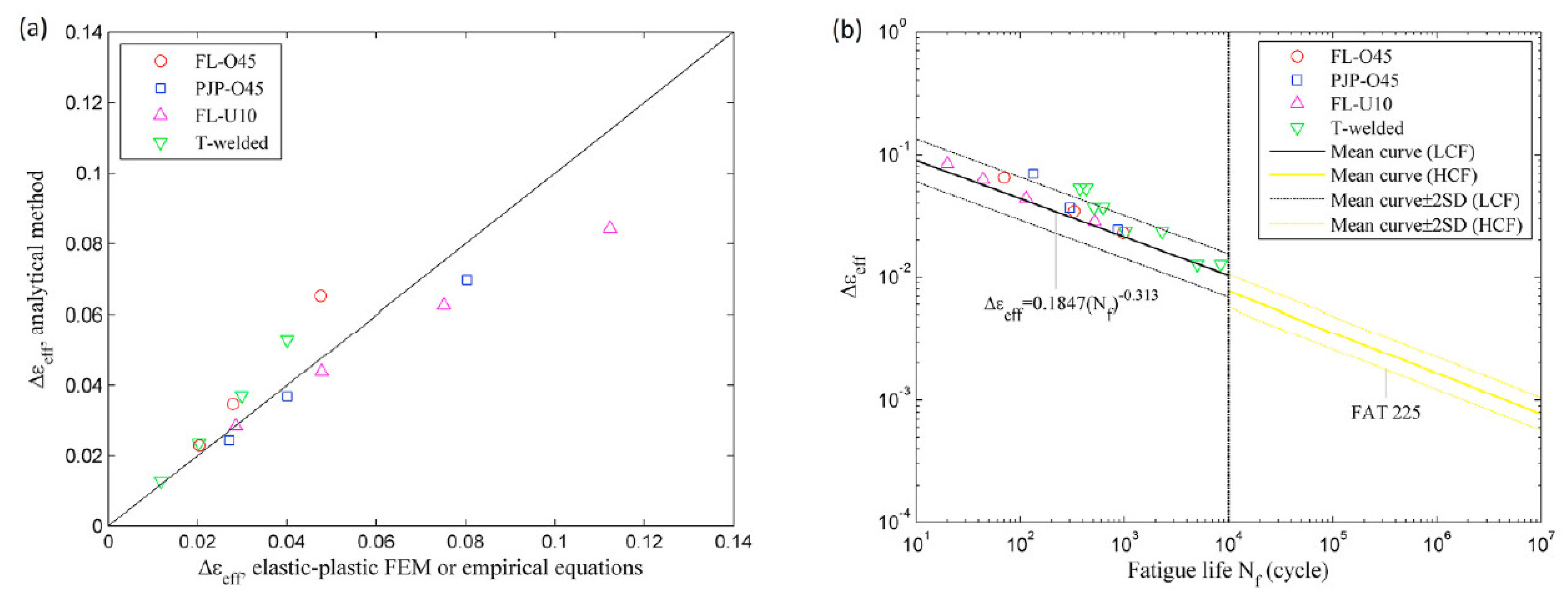

2.3. Local Approaches

2.4. Fracture Mechanics Approaches

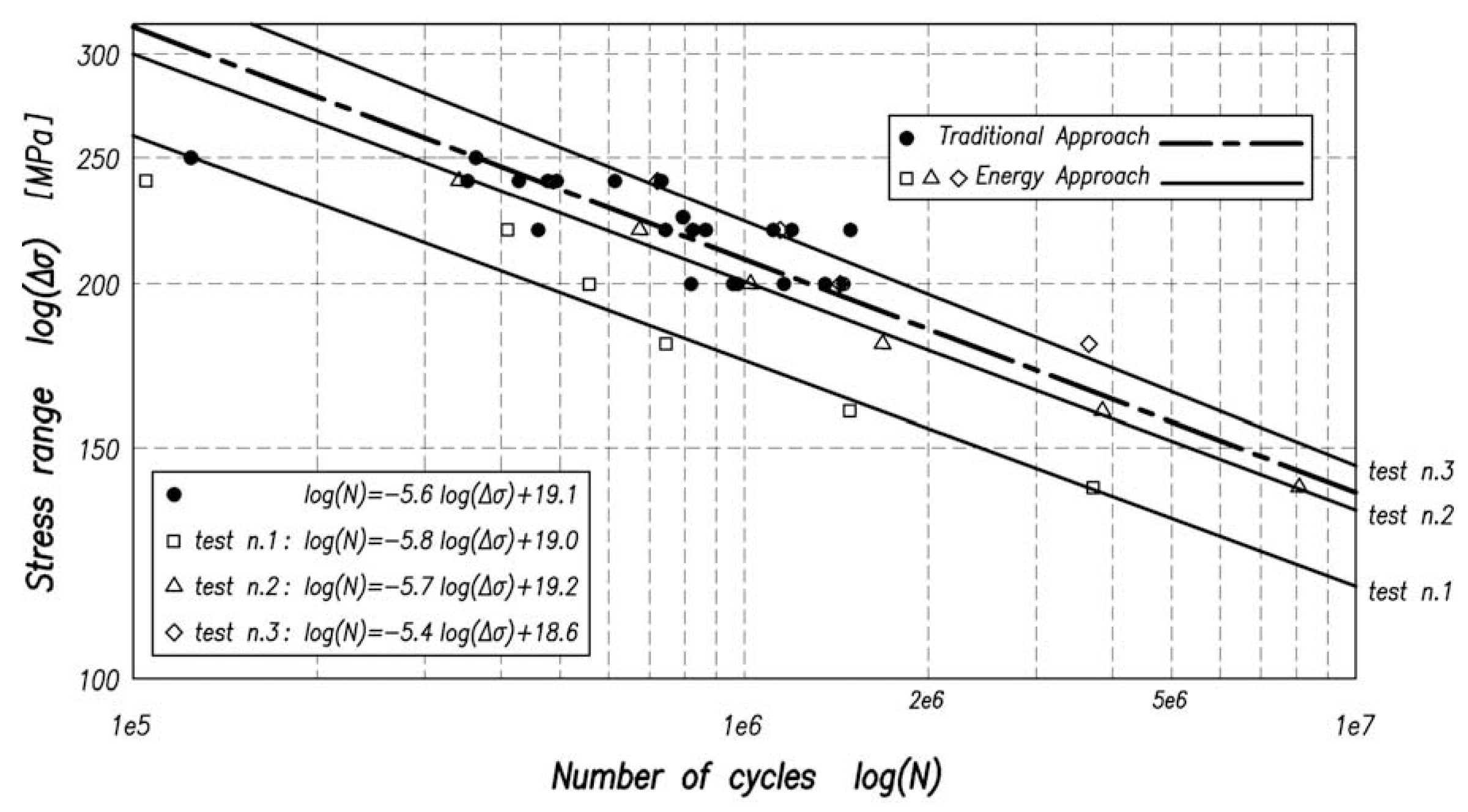

2.5. Energy Approach

2.6. Critical Distance Methods

2.7. Thermal Methods

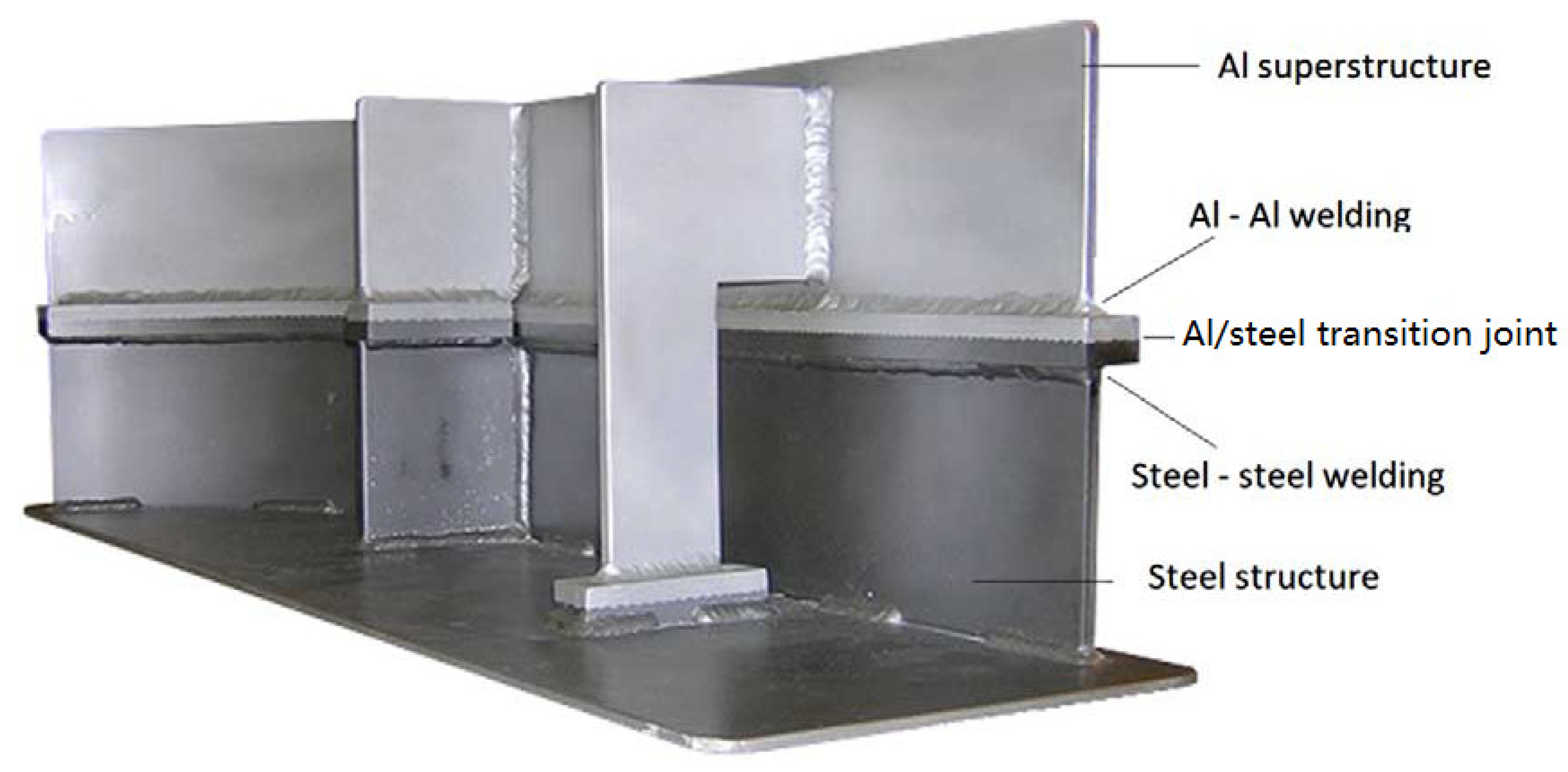

3. Future Developments of Welded Joints in Marine Structures

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hirdaris, S.E.; Bai, W.; Dessi, D.; Ergin, A.; Gu, X.; Hermundstad, O.A.; Huijsmans, R.; Iijima, K.; Nielsen, U.D.; Parunov, J.; et al. Loads for Use in the Design of Ships and Offshore Structures. Ocean Eng. 2014, 78, 131–174. [Google Scholar] [CrossRef]

- Erny, C.; Thevenet, D.; Cognard, J.Y.; Körner, M. Fatigue Life Prediction of Welded Ship Details. Mar. Struct. 2012, 25, 13–32. [Google Scholar] [CrossRef]

- Amirafshari, P.; Barltrop, N.; Wright, M.; Kolios, A. Weld Defect Frequency, Size Statistics and Probabilistic Models for Ship Structures. Int. J. Fatigue 2021, 145, 106069. [Google Scholar] [CrossRef]

- Tveiten, B.W.; Moan, T. Determination of Structural Stress for Fatigue Assessment of Welded Aluminum Ship Details. Mar. Struct. 2000, 13, 189–212. [Google Scholar] [CrossRef]

- Mei, X.; Xiong, M. Effects of Second-Order Hydrodynamics on the Dynamic Responses and Fatigue Damage of a 15 MW Floating Offshore Wind Turbine. J. Mar. Sci. Eng. 2021, 9, 1232. [Google Scholar] [CrossRef]

- Syed Ahmad, S.Z.A.; Abu Husain, M.K.; Mohd Zaki, N.I.; Mukhlas, N.A.; Mat Soom, E.; Azman, N.U.; Najafian, G. Offshore Structural Reliability Assessment by Probabilistic Procedures—A Review. J. Mar. Sci. Eng. 2021, 9, 998. [Google Scholar] [CrossRef]

- Jimenez-Martinez, M. Fatigue of Offshore Structures: A Review of Statistical Fatigue Damage Assessment for Stochastic Loadings. Int. J. Fatigue 2020, 132, 105327. [Google Scholar] [CrossRef]

- Pinheiro, B.d.C.; Pasqualino, I.P. Fatigue Analysis of Damaged Steel Pipelines under Cyclic Internal Pressure. Int. J. Fatigue 2009, 31, 962–973. [Google Scholar] [CrossRef]

- Yang, Q.; Li, G.; Mu, W.; Liu, G.; Sun, H. Identification of Crack Length and Angle at the Center Weld Seam of Offshore Platforms Using a Neural Network Approach. J. Mar. Sci. Eng. 2020, 8, 40. [Google Scholar] [CrossRef] [Green Version]

- Saini, D.S.; Karmakar, D.; Ray-Chaudhuri, S. A Review of Stress Concentration Factors in Tubular and Non-Tubular Joints for Design of Offshore Installations. J. Ocean Eng. Sci. 2016, 1, 186–202. [Google Scholar] [CrossRef] [Green Version]

- Adedipe, O.; Brennan, F.; Kolios, A. Review of Corrosion Fatigue in Offshore Structures: Present Status and Challenges in the Offshore Wind Sector. Renew. Sustain. Energy Rev. 2016, 61, 141–154. [Google Scholar] [CrossRef]

- Albiez, M.; Damm, J.; Ummenhofer, T.; Ehard, H.; Schuler, C.; Kaufmann, M.; Vallée, T.; Myslicki, S. Hybrid Joining of Jacket Structures for Offshore Wind Turbines—Validation under Static and Dynamic Loading at Medium and Large Scale. Eng. Struct. 2022, 252, 112412. [Google Scholar] [CrossRef]

- Corigliano, P.; Crupi, V.; Fricke, W.; Friedrich, N.; Guglielmino, E. Experimental and Numerical Analysis of Fillet-Welded Joints under Low-Cycle Fatigue Loading by Means of Full-Field Techniques. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 1327–1338. [Google Scholar] [CrossRef] [Green Version]

- Schumacher, A.; Borges, L.C.; Nussbaumer, A. A Critical Examination of the Size Effect Correction for Welded Steel Tubular Joints. Int. J. Fatigue 2009, 31, 1422–1433. [Google Scholar] [CrossRef]

- Crupi, V.; Guglielmino, E.; Maestro, M.; Marinò, A. Thinness Effect on the Fatigue Strength of AH36 Steel Plates Used in Shipbuilding. In Proceedings of the NAV 2009, 16th International Conference on Ship and Shipping Research, Messina, Italy, 25 November 2009; pp. 189–197. [Google Scholar]

- Stenberg, T.; Barsoum, Z.; Åstrand, E.; Öberg, A.E.; Schneider, C.; Hedegård, J. Quality Control and Assurance in Fabrication of Welded Structures Subjected to Fatigue Loading. Weld. World 2017, 61, 1003–1015. [Google Scholar] [CrossRef] [Green Version]

- Jonsson, B.; Dobmann, G.; Hobbacher, A.F.; Kassner, M.; Marquis, G. IIW Guidelines on Weld Quality in Relationship to Fatigue Strength; Springer International Publishing: Cham, Switzerland, 2016; ISBN 978-3-319-19197-3. [Google Scholar]

- Amirafshari, P.; Barltrop, N.; Bharadwaj, U.; Wright, M.; Oterkus, S. A Review of Nondestructive Examination Methods for New-Building Ships Undergoing Classification Society Survey. J. Ship Prod. Des. 2017, 34, 9–19. [Google Scholar] [CrossRef]

- Madi, Y.; Matheron, P.; Recho, N.; Mongabure, P. Low Cycle Fatigue of Welded Joints: New Experimental Approach. Nucl. Eng. Des. 2004, 228, 161–177. [Google Scholar] [CrossRef]

- Yan, X.; Huang, X.; Huang, Y.; Cui, W. Prediction of Fatigue Crack Growth in a Ship Detail under Wave-Induced Loading. Ocean Eng. 2016, 113, 246–254. [Google Scholar] [CrossRef]

- Böhm, M.; Kowalski, M. Fatigue Life Estimation of Explosive Cladded Transition Joints with the Use of the Spectral Method for the Case of a Random Sea State. Mar. Struct. 2020, 71, 102739. [Google Scholar] [CrossRef]

- Osawa, N.; De Gracia, L.; Iijima, K.; Yamamoto, N.; Matsumoto, K. Study on Fatigue Strength of Welded Joints Subject to Intermittently Whipping Superimposed Wave Load. In Lecture Notes in Civil Engineering; Springer: Singapore, 2021; Volume 64, pp. 454–472. ISBN 9789811546716. [Google Scholar]

- Woloszyk, K.; Garbatov, Y.; Kłosowski, P. Stress–Strain Model of Lower Corroded Steel Plates of Normal Strength for Fitness-for-Purpose Analyses. Constr. Build. Mater. 2022, 323, 126560. [Google Scholar] [CrossRef]

- Garbatov, Y.; Guedes Soares, C.; Parunov, J. Fatigue Strength Experiments of Corroded Small Scale Steel Specimens. Int. J. Fatigue 2014, 59, 137–144. [Google Scholar] [CrossRef]

- Braun, M.; Ehlers, S. Review of Methods for the High-Cycle Fatigue Strength Assessment of Steel Structures Subjected to Sub-Zero Temperature. Mar. Struct. 2022, 82, 103153. [Google Scholar] [CrossRef]

- Hobbacher, A. Fatigue Design of Welded Joints and Components; Woodhead Publishing: Sawston, UK, 1996; ISBN 1855733153. [Google Scholar]

- Hobbacher, A. Recommendations for fatigue design of welded joints and components; IIW document IIW-1823-07 ex XIII-2151r4-07/XV-1254r4-07; doc. XIII-2151r4-07/XV-1254r4-07; International Institute of Welding: Paris, France, 2008. [Google Scholar]

- EN 1993-1-9; Eurocode 3: Design of Steel Structures—Part 1–9: Fatigue. CEN: Brussels, Belgium, 2005.

- EN 1999-1-3; Eurocode 9: Design of Aluminium Structures—Part 1–3: Structures Susceptible to Fatigue. CEN: Brussels, Belgium, 2011.

- Crupi, V.; Guglielmino, E.; Maestro, M.; Marinò, A. Fatigue Analysis of Butt Welded AH36 Steel Joints: Thermographic Method and Design S-N Curve. Mar. Struct. 2009, 22, 373–386. [Google Scholar] [CrossRef]

- Fricke, W.; Cui, W.; Kierkegaard, H.; Kihl, D.; Koval, M.; Mikkola, T.; Parmentier, G.; Toyosada, M.; Yoon, J.H. Comparative Fatigue Strength Assessment of a Structural Detail in a Containership Using Various Approaches of Classification Societies. Mar. Struct. 2002, 15, 1–13. [Google Scholar] [CrossRef]

- Fricke, W. Recent Developments and Future Challenges in Fatigue Strength Assessment of Welded Joints. Proc. Inst. Mech. Eng. Part C: J. Mech. Eng. Sci. 2015, 229, 1224–1239. [Google Scholar] [CrossRef] [Green Version]

- Radaj, D.; Sonsino, C.M.; Fricke, W. Recent Developments in Local Concepts of Fatigue Assessment of Welded Joints. Int. J. Fatigue 2009, 31, 2–11. [Google Scholar] [CrossRef]

- Dong, P.; Pei, X.; Xing, S.; Kim, M.H. A Structural Strain Method for Low-Cycle Fatigue Evaluation of Welded Components. Int. J. Press. Vessel. Pip. 2014, 119, 39–51. [Google Scholar] [CrossRef]

- Pei, X.; Dong, P. An Analytically Formulated Structural Strain Method for Fatigue Evaluation of Welded Components Incorporating Nonlinear Hardening Effects. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 239–255. [Google Scholar] [CrossRef] [Green Version]

- Han, Q.; Wang, P.; Lu, Y. Path-dependent Multiaxial Fatigue Prediction of Welded Joints Using Structural Strain Method. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 2800–2826. [Google Scholar] [CrossRef]

- Lazzarin, P.; Tovo, R. A Notch Intensity Factor Approach to the Stress Analysis of Welds. Fatigue Fract. Eng. Mater. Struct. 1998, 21, 1089–1103. [Google Scholar] [CrossRef]

- Atzori, B.; Lazzarin, P.; Meneghetti, G.; Ricotta, M. Fatigue Design of Complex Welded Structures. Int. J. Fatigue 2009, 31, 59–69. [Google Scholar] [CrossRef]

- Saiprasertkit, K. Fatigue Strength Assessment of Load-Carrying Cruciform Joints in Low- and High-Cycle Fatigue Region Based on Effective Notch Strain Concept. Weld. World 2014, 58, 455–467. [Google Scholar] [CrossRef]

- Saiprasertkit, K.; Hanji, T.; Miki, C. Local Strain Estimation Method for Low- and High-Cycle Fatigue Strength Evaluation. Int. J. Fatigue 2012, 40, 1–6. [Google Scholar] [CrossRef]

- Meneghetti, G.; Lazzarin, P. Significance of the Elastic Peak Stress Evaluated by FE Analyses at the Point of Singularity of Sharp V-Notched Components. Fatigue Fract. Eng. Mater. Struct. 2007, 30, 95–106. [Google Scholar] [CrossRef]

- Meneghetti, G.; Guzzella, C. The Peak Stress Method to Estimate the Mode I Notch Stress Intensity Factor in Welded Joints Using Three-Dimensional Finite Element Models. Eng. Fract. Mech. 2014, 115, 154–171. [Google Scholar] [CrossRef]

- Chapetti, M.D.; Jaureguizahar, L.F. Fatigue Behavior Prediction of Welded Joints by Using an Integrated Fracture Mechanics Approach. Int. J. Fatigue 2012, 43, 43–53. [Google Scholar] [CrossRef]

- Zerbst, U.; Madia, M. Fracture Mechanics Based Assessment of the Fatigue Strength: Approach for the Determination of the Initial Crack Size. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 1066–1075. [Google Scholar] [CrossRef]

- Lazzarin, P.; Zambardi, R. A Finite-Volume-Energy Based Approach to Predict the Static and Fatigue Behavior of Components with Sharp V-Shaped Notches. Int. J. Fract. 2001, 112, 275–298. [Google Scholar] [CrossRef]

- Livieri, P.; Lazzarin, P. Fatigue Strength of Steel and Aluminium Welded Joints Based on Generalised Stress Intensity Factors and Local Strain Energy Values. Int. J. Fract. 2005, 133, 247–276. [Google Scholar] [CrossRef]

- Taylor, D.; Barrett, N.; Lucano, G. Some New Methods for Predicting Fatigue in Welded Joints. Int. J. Fatigue 2002, 24, 509–518. [Google Scholar] [CrossRef]

- Taylor, D. The Theory of Critical Distances: A New Perspective in Fracture Mechanics; Elsevier: Amsterdam, The Netherlands, 2007; ISBN 9780080554723. [Google Scholar]

- Crupi, G.; Crupi, V.; Guglielmino, E.; Taylor, D. Fatigue Assessment of Welded Joints Using Critical Distance and Other Methods. Eng. Fail. Anal. 2005, 12, 129–142. [Google Scholar] [CrossRef]

- Crupi, V.; Guglielmino, E.; Risitano, A.; Taylor, D. Different Methods for Fatigue Assessment of T Welded Joints Used in Ship Structures. J. Ship Res. 2007, 51, 150–159. [Google Scholar] [CrossRef]

- Fan, J.L.; Guo, X.L.; Wu, C.W.; Zhao, Y.G. Research on Fatigue Behavior Evaluation and Fatigue Fracture Mechanisms of Cruciform Welded Joints. Mater. Sci. Eng. A 2011, 528, 8417–8427. [Google Scholar] [CrossRef]

- Williams, P.; Liakat, M.; Khonsari, M.M.; Kabir, O.M. A Thermographic Method for Remaining Fatigue Life Prediction of Welded Joints. Mater. Des. 2013, 51, 916–923. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.G.; Crupi, V.; Jiang, C.; Guglielmino, E. Quantitative Thermographic Methodology for Fatigue Life Assessment in a Multiscale Energy Dissipation Framework. Int. J. Fatigue 2015, 81, 249–256. [Google Scholar] [CrossRef]

- Wei, W.; Li, C.; Sun, Y.; Xu, H.; Yang, X. Investigation of the Self-Heating of Q460 Butt Joints and an S-N Curve Modeling Method Based on Infrared Thermographic Data for High-Cycle Fatigue. Metals 2021, 11, 232. [Google Scholar] [CrossRef]

- Palumbo, D.; Galietti, U. Characterisation of Steel Welded Joints by Infrared Thermographic Methods. Quant. InfraRed Thermogr. J. 2014, 11, 29–42. [Google Scholar] [CrossRef]

- Al Zamzami, I.; Davison, B.; Susmel, L. Nominal and Local Stress Quantities to Design Aluminium-to-Steel Thin Welded Joints against Fatigue. Int. J. Fatigue 2019, 123, 279–295. [Google Scholar] [CrossRef]

- Al Zamzami, I.; Di Cocco, V.; Davison, J.B.; Iacoviello, F.; Susmel, L. Static Strength and Design of Aluminium-to-Steel Thin Welded Joints. Weld. World 2018, 62, 1255–1272. [Google Scholar] [CrossRef] [Green Version]

- Shen, W.; Yan, R.; He, F.; Wang, S. Multiaxial Fatigue Analysis of Complex Welded Joints in Notch Stress Approach. Eng. Fract. Mech. 2018, 204, 344–360. [Google Scholar] [CrossRef]

- Sonsino, C.M.; Radaj, D.; Brandt, U.; Lehrke, H.P. Fatigue Assessment of Welded Joints in AlMg 4.5Mn Aluminum Alloy (AA 5083) by Local Approaches. Int. J. Fatigue 1999, 21, 985–999. [Google Scholar] [CrossRef]

- Multiaxial Notch Fatigue. Aircr. Eng. Aerosp. Technol. 2009, 81, 24–31. [CrossRef]

- Al Zamzami, I.; Susmel, L. On the Use of Hot-Spot Stresses, Effective Notch Stresses and the Point Method to Estimate Lifetime of Inclined Welds Subjected to Uniaxial Fatigue Loading. Int. J. Fatigue 2018, 117, 432–449. [Google Scholar] [CrossRef]

- Wang, P.; Pei, X.; Dong, P.; Song, S. Traction Structural Stress Analysis of Fatigue Behaviors of Rib-to-Deck Joints in Orthotropic Bridge Deck. Int. J. Fatigue 2019, 125, 11–22. [Google Scholar] [CrossRef]

- Dong, P. A Structural Stress Definition and Numerical Implementation for Fatigue Analysis of Welded Joints. Int. J. Fatigue 2001, 23, 865–876. [Google Scholar] [CrossRef]

- Pei, X.; Dong, P.; Kim, M.H. A Simplified Structural Strain Method for Low-Cycle Fatigue Evaluation of Girth-Welded Pipe Components. Int. J. Fatigue 2020, 139, 105732. [Google Scholar] [CrossRef]

- Pei, X.; Dong, P.; Xing, S. A Structural Strain Parameter for a Unified Treatment of Fatigue Behaviors of Welded Components. Int. J. Fatigue 2019, 124, 444–460. [Google Scholar] [CrossRef]

- Fischer, C.; Fricke, W.; Rizzo, C.M. Review of the Fatigue Strength of Welded Joints Based on the Notch Stress Intensity Factor and SED Approaches. Int. J. Fatigue 2016, 84, 59–66. [Google Scholar] [CrossRef]

- Meneghetti, G.; Campagnolo, A. State-of-the-Art Review of Peak Stress Method for Fatigue Strength Assessment of Welded Joints. Int. J. Fatigue 2020, 139, 105705. [Google Scholar] [CrossRef]

- Song, W.; Liu, X. High Cycle Fatigue Assessment of Steel Load-Carrying Cruciform Welded Joints: An Overview of Recent Results. Frat. Ed Integrita Strutt. 2018, 12, 94–101. [Google Scholar] [CrossRef]

- Meneghetti, G.; Campagnolo, A.; Avalle, M.; Castagnetti, D.; Colussi, M.; Corigliano, P.; De Agostinis, M.; Dragoni, E.; Fontanari, V.; Frendo, F.; et al. Rapid Evaluation of Notch Stress Intensity Factors Using the Peak Stress Method: Comparison of Commercial Finite Element Codes for a Range of Mesh Patterns. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 1044–1063. [Google Scholar] [CrossRef] [Green Version]

- Dong, Y.; Garbatov, Y.; Guedes Soares, C. Improved Effective Notch Strain Approach for Fatigue Reliability Assessment of Load-Carrying Fillet Welded Cruciform Joints in Low and High Cycle Fatigue. Mar. Struct. 2021, 75, 102849. [Google Scholar] [CrossRef]

- Polezhayeva, H.; Toumpis, A.I.; Galloway, A.M.; Molter, L.; Ahmad, B.; Fitzpatrick, M.E. Fatigue Performance of Friction Stir Welded Marine Grade Steel. Int. J. Fatigue 2015, 81, 162–170. [Google Scholar] [CrossRef] [Green Version]

- Van Lieshout, P.S.; Den Besten, J.H.; Kaminski, M.L. Comparative Study of Multiaxial Fatigue Methods Applied to Welded Joints in Marine Structures. Frat. Ed Integrita Strutt. 2016, 10, 173–192. [Google Scholar] [CrossRef] [Green Version]

- Hobbacher, A.F. The New IIW Recommendations for Fatigue Assessment of Welded Joints and Components—A Comprehensive Code Recently Updated. Int. J. Fatigue 2009, 31, 50–58. [Google Scholar] [CrossRef]

- Xiao, Z.G.; Yamada, K. A Method of Determining Geometric Stress for Fatigue Strength Evaluation of Steel Welded Joints. Int. J. Fatigue 2004, 26, 1277–1293. [Google Scholar] [CrossRef]

- Kim, Y.; Oh, J.S.; Jeon, S.H. Novel Hot Spot Stress Calculations for Welded Joints Using 3D Solid Finite Elements. Mar. Struct. 2015, 44, 1–18. [Google Scholar] [CrossRef]

- Maddox, S.J. Review of Fatigue Assessment Procedures for Welded Aluminium Structures. Int. J. Fatigue 2003, 25, 1359–1378. [Google Scholar] [CrossRef]

- Fricke, W. Recommended Hot-Spot Analysis Procedure for Structural Details of Ships and FPSOs Based on Round-Robin FE Analyses. Int. J. Offshore Polar Eng. 2002, 12. [Google Scholar]

- Lee, J.H.; Dong, P.; Kim, M.H. Low-Cycle Fatigue Evaluation for Girth-Welded Pipes Based on the Structural Strain Method Considering Cyclic Material Behavior. Int. J. Nav. Archit. Ocean Eng. 2020, 12, 868–880. [Google Scholar] [CrossRef]

- Yang, H.; Wang, P.; Qian, H.; Dong, P. Fatigue Performance of Different Rib-to-Deck Connections Using Traction Structural Stress Method. Appl. Sci. 2020, 10, 1239. [Google Scholar] [CrossRef] [Green Version]

- Kozy, B. Manual for Design, Construction, and Maintenance of Orthotropic Steel Bridges; FHWA: Washington, DC, USA, 2012. [Google Scholar]

- Ravi, S.K.; Dong, P. A Spectral Fatigue Method Incorporating Non-Proportional Multiaxial Loading. Int. J. Fatigue 2020, 131, 105300. [Google Scholar] [CrossRef]

- Xing, S.; Dong, P.; Threstha, A. Analysis of Fatigue Failure Mode Transition in Load-Carrying Fillet-Welded Connections. Mar. Struct. 2016, 46, 102–126. [Google Scholar] [CrossRef]

- Dong, P.; American Society of Mechanical Engineers. The Master S-N Curve Method: An Implementation for Fatigue Evaluation of Welded Components in the ASME B & PV Code, Section VIII, Division 2 and API 579-1/ASME FFS-1; Welding Research Council: New York, NY, USA, 2010; ISBN 9781581455304. [Google Scholar]

- Corigliano, P.; Crupi, V.; Pei, X.; Dong, P. DIC-Based Structural Strain Approach for Low-Cycle Fatigue Assessment of AA 5083 Welded Joints. Theor. Appl. Fract. Mech. 2021, 116, 103090. [Google Scholar] [CrossRef]

- Corigliano, P. On the Compression Instability during Static and Low-Cycle Fatigue Loadings of AA 5083 Welded Joints: Full-Field and Numerical Analyses. J. Mar. Sci. Eng. 2022, 10, 212. [Google Scholar] [CrossRef]

- Fricke, W. Fatigue and Fracture of Ship Structures. In Encyclopedia of Maritime and Offshore Engineering; John Wiley & Sons, Ltd.: Chichester, UK, 2017; pp. 1–12. [Google Scholar]

- Radaj, D.; Sonsino, C.M.; Fricke, W. Fatigue Assessment of Welded Joints by Local Approaches: Second Edition; Elsevier: Amsterdam, The Netherlands, 2006; ISBN 9781855739482. [Google Scholar]

- Fricke, W. IIW Recommendations for the Fatigue Assessment of Welded Structures By Notch Stress Analysis: IIW-2006-09; Woodhead Publishing: Sawston, UK, 2012; ISBN 9780857098559. [Google Scholar]

- Schijve, J. Fatigue Predictions of Welded Joints and the Effective Notch Stress Concept. Int. J. Fatigue 2012, 45, 31–38. [Google Scholar] [CrossRef]

- Fricke, W.; Kahl, A. Local Stress Analysis and Fatigue Assessment of Bracket Toes Based on Measured Weld Profile; International Institute of Welding: Paris, France, 2007. [Google Scholar]

- Tran Nguyen, K.; Garbatov, Y.; Guedes Soares, C. Fatigue Damage Assessment of Corroded Oil Tanker Details Based on Global and Local Stress Approaches. Int. J. Fatigue 2012, 43, 197–206. [Google Scholar] [CrossRef]

- Sonsino, C.M. Multiaxial Fatigue Assessment of Welded Joints—Recommendations for Design Codes. Int. J. Fatigue 2009, 31, 173–187. [Google Scholar] [CrossRef]

- Nie, J.; Kitazume, D.; Ono, K.; Miyashita, T.; Anami, K.; Matsumura, T. Mechanical Properties and Charpy Absorbed Energy of SBHS400 2019. In Proceedings of the 29th International Ocean and Polar Engineering Conference, Honolulu, HI, USA, 16–21 June 2019. [Google Scholar]

- Saiprasertkit, K.; Sasaki, E.; Miki, C. Fatigue Crack Initiation Point of Load Carrying Cruciform Joints in Low and High Cycle Fatigue Regions. Int. J. Fatigue 2014, 59, 153–158. [Google Scholar] [CrossRef]

- Fricke, W.; Friedrich, N.; Musumeci, L.; Paetzold, H. Low-Cycle Fatigue Analysis of a Web Frame Corner in Ship Structures. Weld. World 2014, 58, 319–327. [Google Scholar] [CrossRef]

- Dong, Y.; Garbatov, Y.; Guedes Soares, C. Strain-Based Fatigue Reliability Assessment of Welded Joints in Ship Structures. Mar. Struct. 2021, 75, 102878. [Google Scholar] [CrossRef]

- Radaj, D. State-of-the-Art Review on Extended Stress Intensity Factor Concepts. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 1–28. [Google Scholar] [CrossRef]

- Han, J.W.; Han, S.H.; Shin, B.C.; Kim, J.H. Fatigue Crack Initiation and Propagation Life of Welded Joints. Key Eng. Mater. 2005, 297–300, 781–787. [Google Scholar] [CrossRef]

- Glen, L.F.; Dinovitzer, A.; Malik, L.; Basu, R.; Yee, R. Guide to Damage Tolerance Analysis of Marine Structures; SSC Report 409; Ship Structure Committee: Washington, DC, USA, 2000. [Google Scholar]

- Qi, T.; Huang, X.; Li, L. Spectral-Based Fatigue Crack Propagation Prediction for Very Large Floating Structures. Mar. Struct. 2018, 57, 193–206. [Google Scholar] [CrossRef]

- Mai, Q.A.; Weijtjens, W.; Devriendt, C.; Morato, P.G.; Rigo, P.; Sørensen, J.D. Prediction of Remaining Fatigue Life of Welded Joints in Wind Turbine Support Structures Considering Strain Measurement and a Joint Distribution of Oceanographic Data. Mar. Struct. 2019, 66, 307–322. [Google Scholar] [CrossRef]

- Meneghetti, G. The Peak Stress Method for Fatigue Strength Assessment of Tube-to-Flange Welded Joints under Torsion Loading. Weld. World 2013, 57, 265–275. [Google Scholar] [CrossRef]

- Gandhi, P.; Ramachandra Murthy, D.S.; Raghava, G.; Madhava Rao, A.G. Fatigue Crack Growth in Stiffened Steel Tubular Joints in Seawater Environment. Eng. Struct. 2000, 22, 1390–1401. [Google Scholar] [CrossRef]

- Sonsino, C.M. Comparison of Different Local Design Concepts for the Structural Durability Assessment of Welded Offshore K-Nodes. Int. J. Fatigue 2012, 34, 27–34. [Google Scholar] [CrossRef]

- Maljaars, J.; Pijpers, R.; Slot, H. Load Sequence Effects in Fatigue Crack Growth of Thick-Walled Welded C–Mn Steel Members. Int. J. Fatigue 2015, 79, 10–24. [Google Scholar] [CrossRef]

- Agerskov, H. Fatigue in Steel Structures under Random Loading. J. Constr. Steel Res. 2000, 53, 283–305. [Google Scholar] [CrossRef]

- Glinka, G. Calculation of Inelastic Notch-Tip Strain-Stress Histories under Cyclic Loading. Eng. Fract. Mech. 1985, 22, 839–854. [Google Scholar] [CrossRef]

- Dong, Y.; Soares, C.G. Estimation of Effective Notch Strain for Fatigue Strength Assessment of Welded Structures under Multiaxial Stress State. In Towards Green Marine Technology and Transport; CRC Press: Boca Raton, FL, USA, 2015; pp. 417–426. [Google Scholar]

- Hanji, T.; Saiprasertkit, K.; Miki, C. Low-And High-Cycle Fatigue Behavior of Load-Carrying Cruciform Joints with Incomplete Penetration and Strength under-Match. Int. J. Steel Struct. 2011, 11, 409–425. [Google Scholar] [CrossRef]

- MENEGHETTI, G. The Peak Stress Method Applied to Fatigue Assessments of Steel and Aluminium Fillet-Welded Joints Subjected to Mode I Loading. Fatigue Fract. Eng. Mater. Struct. 2008, 31, 346–369. [Google Scholar] [CrossRef]

- Lazzarin, P.; Livieri, P. Notch Stress Intensity Factors and Fatigue Strength of Aluminum and Steel Welded Joints. Int. J. Fatigue 2001, 23, 225–232. [Google Scholar] [CrossRef]

- Berto, F.; Lazzarin, P. A Review of the Volume-Based Strain Energy Density Approach Applied to V-Notches and Welded Structures. Theor. Appl. Fract. Mech. 2009, 52, 183–194. [Google Scholar] [CrossRef]

- Berto, F.; Lazzarin, P. Recent Developments in Brittle and Quasi-Brittle Failure Assessment of Engineering Materials by Means of Local Approaches. Mater. Sci. Eng. R Rep. 2014, 75, 1–48. [Google Scholar] [CrossRef]

- Braun, M.; Fischer, C.; Fricke, W.; Ehlers, S. Extension of the Strain Energy Density Method for Fatigue Assessment of Welded Joints to Sub-zero Temperatures. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 2867–2882. [Google Scholar] [CrossRef]

- Susmel, L. The Theory of Critical Distances: A Review of Its Applications in Fatigue. Eng. Fract. Mech. 2008, 75, 1706–1724. [Google Scholar] [CrossRef]

- Susmel, L. Three Different Ways of Using the Modified Wöhler Curve Method to Perform the Multiaxial Fatigue Assessment of Steel and Aluminium Welded Joints. Eng. Fail. Anal. 2009, 16, 1074–1089. [Google Scholar] [CrossRef]

- Feng, E.; Wang, X.; Jiang, C.; Crupi, V. Quantitative Thermographic Method for Fatigue Life Prediction under Variable Amplitude Loading. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 1199–1212. [Google Scholar] [CrossRef]

- la Rosa, G.; Risitano, a. Thermographic Methodology for Rapid Determination of the Fatigue Limit of Materials and Mechanical Components. Int. J. Fatigue 2000, 22, 65–73. [Google Scholar] [CrossRef]

- Fargione, G.; Geraci, a.; la Rosa, G.; Risitano, a. Rapid Determination of the Fatigue Curve by the Thermographic Method. Int. J. Fatigue 2002, 24, 11–19. [Google Scholar] [CrossRef]

- Luong, M.P. Fatigue Limit Evaluation of Metals Using an Infrared Thermographic Technique. Mech. Mater. 1998, 28, 155–163. [Google Scholar] [CrossRef]

- Meneghetti, G. Analysis of the Fatigue Strength of a Stainless Steel Based on the Energy Dissipation. Int. J. Fatigue 2007, 29, 81–94. [Google Scholar] [CrossRef]

- Curà, F.; Curti, G.; Sesana, R. A New Iteration Method for the Thermographic Determination of Fatigue Limit in Steels. Int. J. Fatigue 2005, 27, 453–459. [Google Scholar] [CrossRef]

- De Finis, R.; Palumbo, D.; Ancona, F.; Galietti, U. Fatigue Limit Evaluation of Various Martensitic Stainless Steels with New Robust Thermographic Data Analysis. Int. J. Fatigue 2015, 74, 88–96. [Google Scholar] [CrossRef]

- Amiri, M.; Khonsari, M.M. Rapid Determination of Fatigue Failure Based on Temperature Evolution: Fully Reversed Bending Load. Int. J. Fatigue 2010, 32, 382–389. [Google Scholar] [CrossRef]

- Wang, X.G.; Crupi, V.; Jiang, C.; Feng, E.S.; Guglielmino, E.; Wang, C.S. Energy-Based Approach for Fatigue Life Prediction of Pure Copper. Int. J. Fatigue 2017, 104, 243–250. [Google Scholar] [CrossRef]

- Acosta, R.; Wu, H.; Venkat, R.S.; Weber, F.; Tenkamp, J.; Walther, F.; Starke, P. SteBlife, a New Approach for the Accelerated Generation of Metallic Materials’ Fatigue Data. Metals 2020, 10, 798. [Google Scholar] [CrossRef]

- Guo, S.; Liu, X.; Zhang, H.; Yan, Z.; Fang, H. Fatigue Limit Evaluation of AZ31B Magnesium Alloy Based on Temperature Distribution Analysis. Metals 2020, 10, 1331. [Google Scholar] [CrossRef]

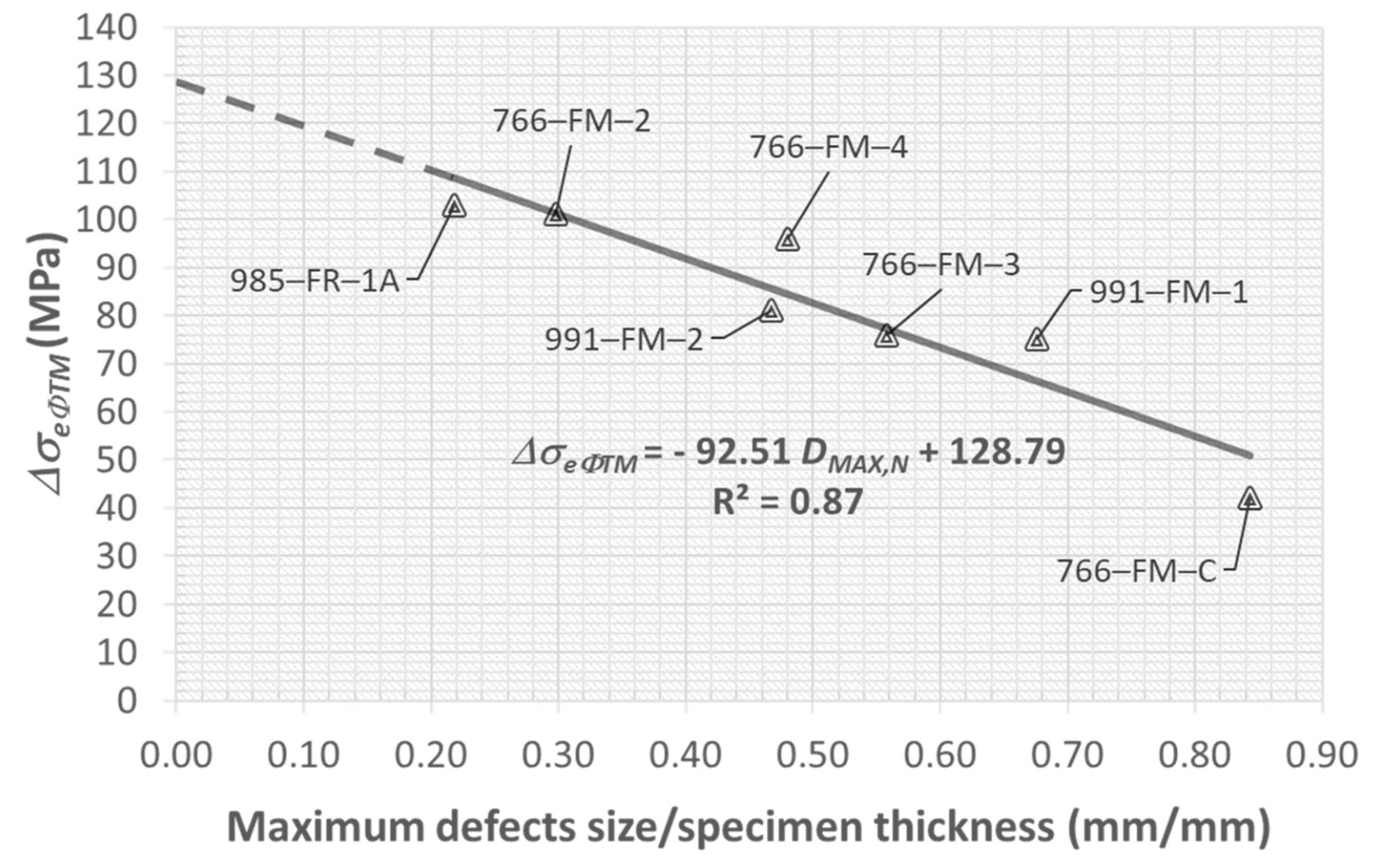

- Crupi, V.; Epasto, G.; Guglielmino, E.; Marinò, A. Influence of Weld-Porosity Defects on Fatigue Strength of AH36 Butt Joints Used in Ship Structures. Metals 2021, 11, 444. [Google Scholar] [CrossRef]

- Corigliano, P.; Epasto, G.; Guglielmino, E.; Risitano, G. Fatigue Analysis of Marine Welded Joints by Means of DIC and IR Images during Static and Fatigue Tests. Eng. Fract. Mech. 2017, 183, 26–38. [Google Scholar] [CrossRef]

- Corigliano, P.; Crupi, V.; Guglielmino, E.; Mariano Sili, A. Full-Field Analysis of AL/FE Explosive Welded Joints for Shipbuilding Applications. Mar. Struct. 2018, 57, 207–218. [Google Scholar] [CrossRef]

- Corigliano, P.; Crupi, V. Fatigue Analysis of TI6AL4V/INCONEL 625 Dissimilar Welded Joints. Ocean Eng. 2021, 221, 108582. [Google Scholar] [CrossRef]

- Micone, N.; de Waele, W. On the Application of Infrared Thermography and Potential Drop for the Accelerated Determination of an S-N Curve. Exp. Mech. 2017, 57, 143–153. [Google Scholar] [CrossRef]

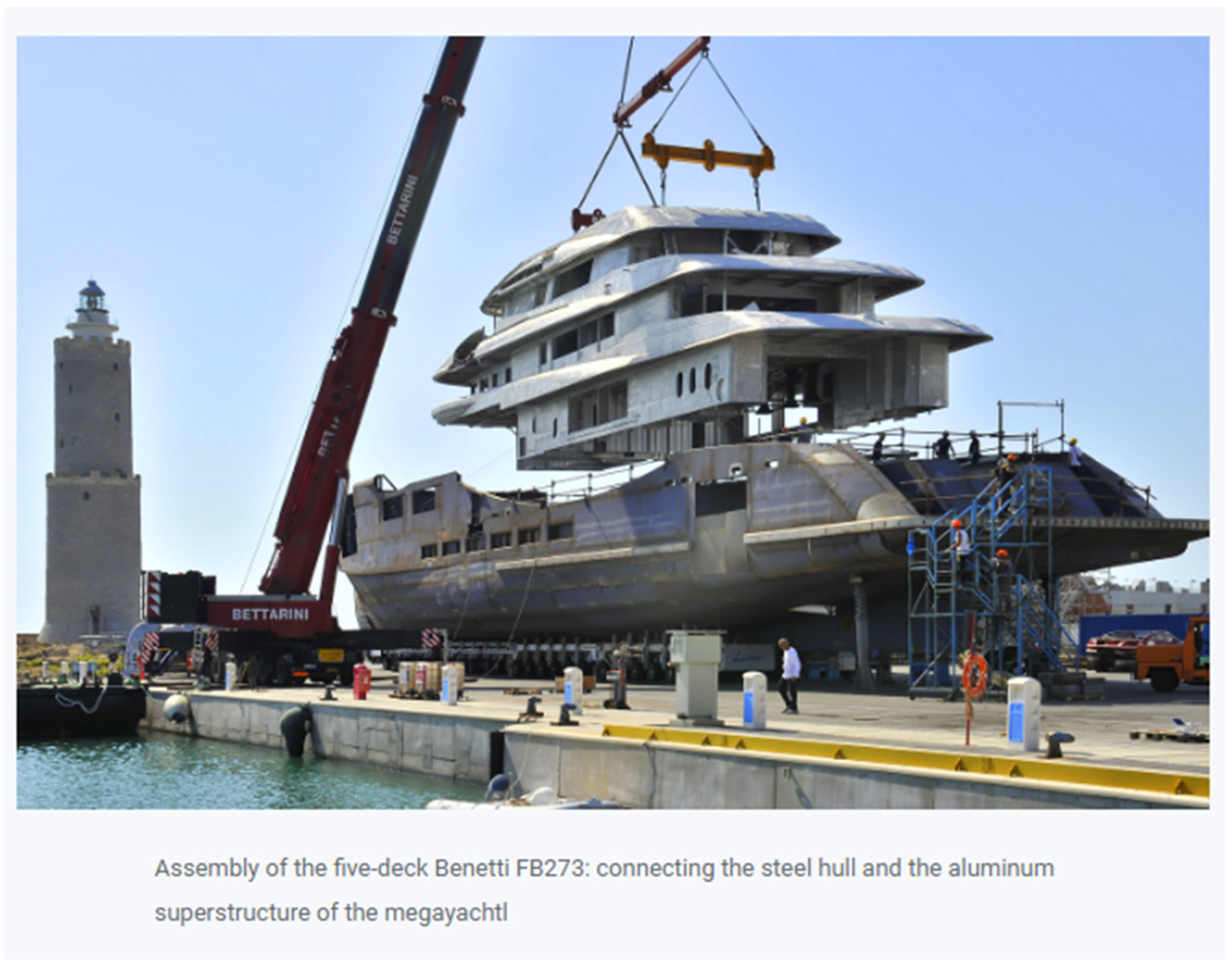

- Benetti 65-Meter Custom Yacht fb274 Takes Shape. Hull and Superstructure Joined Together|Benetti Yachts. Available online: https://www.benettiyachts.it/news-events/benetti-65-meter-custom-yacht-fb274-takes-shape-hull-and-superstructure-joined-together/ (accessed on 26 February 2022).

- 70m Benetti Superyacht FB273 Launched—Luxury Projects. Available online: https://www.luxury-projects.it/70m-benetti-superyacht-fb273-launched/ (accessed on 26 February 2022).

- Kuryntsev, S. A Review: Laser Welding of Dissimilar Materials (Al/Fe, Al/Ti, Al/Cu)—Methods and Techniques, Microstructure and Properties. Materials 2021, 15, 122. [Google Scholar] [CrossRef]

- Fukumoto, S.; Tsubakino, H.; Okita, K.; Aritoshi, M.; Tomita, T. Friction Welding Process of 5052 Aluminium Alloy to 304 Stainless Steel. Mater. Sci. Technol. 1999, 15, 1080–1086. [Google Scholar] [CrossRef]

- Ozaki, H.; Kutsuna, M. Laser-Roll Welding of a Dissimilar Metal Joint of Low Carbon Steel to Aluminium Alloy Using 2 KW Fibre Laser. Weld. Int. 2009, 23, 345–352. [Google Scholar] [CrossRef]

- Boroński, D.; Skibicki, A.; Maćkowiak, P.; Płaczek, D. Modeling and Analysis of Thin-Walled Al/Steel Explosion Welded Transition Joints for Shipbuilding Applications. Mar. Struct. 2020, 74, 102843. [Google Scholar] [CrossRef]

- Findik, F. Recent Developments in Explosive Welding. Mater. Des. 2011, 32, 1081–1093. [Google Scholar] [CrossRef]

- Corigliano, P.; Crupi, V.; Guglielmino, E. Non Linear Finite Element Simulation of Explosive Welded Joints of Dissimilar Metals for Shipbuilding Applications. Ocean Eng. 2018, 160, 346–353. [Google Scholar] [CrossRef]

- Wang, W.; Pei, X. An Analytical Structural Strain Method for Steel Umbilical in Low Cycle Fatigue. J. Offshore Mech. Arct. Eng. 2019, 141, 011605. [Google Scholar] [CrossRef]

- Garbatov, Y. Risk-Based Corrosion Allowance of Oil Tankers. Ocean Eng. 2020, 213, 107753. [Google Scholar] [CrossRef]

- Woloszyk, K.; Garbatov, Y. An Enhanced Method in Predicting Tensile Behaviour of Corroded Thick Steel Plate Specimens by Using Random Field Approach. Ocean Eng. 2020, 213, 107803. [Google Scholar] [CrossRef]

- Iannuzzi, M.; Barnoush, A.; Johnsen, R. Materials and Corrosion Trends in Offshore and Subsea Oil and Gas Production. npj Mater. Degrad. 2017, 1, 1–11. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Jain, A. Materials for Ocean Structures. In Ocean Structures; CRC Press: Taylor & Francis Group: Boca Raton, FL, USA, 2016; pp. 129–194. [Google Scholar]

- Ninomi, M.; Akiyama, S.; Ikeda, M.; Hagiwara, M.; Maruyama The, K. Update and Trends in Titanium Alloy Riser Applications and Technology; Japan Institute of Metals: Sendai, Japan, 2007. [Google Scholar]

- Peacock, D. Titanium for Offshore Applications. Mater. World 1994, 4, 696–698. [Google Scholar]

- Gao, X.L.; Liu, J.; Zhang, L.J. Dissimilar Metal Welding of Ti6Al4V and Inconel 718 through Pulsed Laser Welding-Induced Eutectic Reaction Technology. Int. J. Adv. Manuf. Technol. 2018, 96, 1061–1071. [Google Scholar] [CrossRef]

- Milititsky, M.; Gittos, F.M.; Smith, S.E.; Marques, V. Dissimilar Metals for Sub-Sea Use under Cathodic Protection. In Proceedings of the Materials Science & Technology 2010, Houston, TX, USA, 17–21 October 2010. [Google Scholar]

- Mendoza, B.I.; Maldonado, Z.C.; Albiter, H.A.; Robles, P.E. Dissimilar Welding of Superduplex Stainless Steel/HSLA Steel for Offshore Applications Joined by GTAW. Engineering 2010, 2, 520–528. [Google Scholar] [CrossRef]

- Sadeghian, M.; Shamanian, M.; Shafyei, A. Effect of Heat Input on Microstructure and Mechanical Properties of Dissimilar Joints between Super Duplex Stainless Steel and High Strength Low Alloy Steel. Mater. Des. 2014, 60, 678–684. [Google Scholar] [CrossRef]

- Souza, R.F.; Ruggieri, C.; Zhang, Z. A Framework for Fracture Assessments of Dissimilar Girth Welds in Offshore Pipelines under Bending. Eng. Fract. Mech. 2016, 163, 66–88. [Google Scholar] [CrossRef]

- Orr, R.S.; Dotson, C. Offshore Nuclear Power Plants. Nucl. Eng. Des. 1973, 25, 334–349. [Google Scholar] [CrossRef]

- Briccetti, A.; Buongiorno, J.; Golay, M.; Todreas, N.E. Siting of an Offshore Floating Nuclear Power Plant; Massachusetts Institute of Technology: Cambridge, MA, USA, 2014. [Google Scholar]

- Hänninen, H.; Aaltonen, P.; Brederholm, A.; Ehrnsteń, U.; Gripenberg, H.; Toivonen, A.; Pitkänen, J.; Virkkunen, I. Dissimilar Metal Weld Joints and Their Performance in Nuclear Power Plant and Oil Refinery Conditions; VTT: Espoo, Finland, 2006. [Google Scholar]

- Rooks, B. Robot Welding in Shipbuilding. Ind. Robot 1997, 24, 413–417. [Google Scholar] [CrossRef]

- Sanders, D.; Tewkesbury, G.; Ndzi, D.; Gegov, A.; Gremont, B.; Little, A. Improving Automatic Robotic Welding in Shipbuilding through the Introduction of a Corner-Finding Algorithm to Help Recognise Shipbuilding Parts. J. Mar. Sci. Technol. 2011, 17, 231–238. [Google Scholar] [CrossRef] [Green Version]

- Lee, D.; Ku, N.; Kim, T.W.; Kim, J.; Lee, K.Y.; Son, Y.S. Development and Application of an Intelligent Welding Robot System for Shipbuilding. Robot. Comput.-Integr. Manuf. 2011, 27, 377–388. [Google Scholar] [CrossRef]

- Muhammad, J.; Altun, H.; Abo-Serie, E. Welding Seam Profiling Techniques Based on Active Vision Sensing for Intelligent Robotic Welding. Int. J. Adv. Manuf. Technol. 2016, 88, 127–145. [Google Scholar] [CrossRef]

- Tsai, M.J.; Lee, H.W.; Ann, N.J. Machine Vision Based Path Planning for a Robotic Golf Club Head Welding System. Robot. Comput.-Integr. Manuf. 2011, 27, 843–849. [Google Scholar] [CrossRef]

- Zhang, K.; Yan, M.; Huang, T.; Zheng, J.; Li, Z. 3D Reconstruction of Complex Spatial Weld Seam for Autonomous Welding by Laser Structured Light Scanning. J. Manuf. Processes 2019, 39, 200–207. [Google Scholar] [CrossRef]

- Han, C.; Yang, C.; Kim, H.; Park, S. The Effects of Robot Welding and Manual Welding on the Low- and High-Cycle Fatigue Lives of SM50A Carbon Steel Weld Zones. Adv. Mech. Eng. 2019, 11, 168781401982826. [Google Scholar] [CrossRef] [Green Version]

- Taşdemir, A.; Nohut, S. An Overview of Wire Arc Additive Manufacturing (WAAM) in Shipbuilding Industry. Ships Offshore Struct. 2021, 16, 797–814. [Google Scholar] [CrossRef]

- Astarita, A.; Campatelli, G.; Corigliano, P.; Epasto, G.; Montevecchi, F.; Scherillo, F.; Venturini, G. Microstructure and Mechanical Properties of Specimens Produced Using the Wire-Arc Additive Manufacturing Process. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 1788–1798. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Hari, S.; Amirthalingam, M. Wire Arc Additive Manufacturing of Functionally Graded Material for Marine Risers. Mater. Sci. Eng. A 2020, 792, 139530. [Google Scholar] [CrossRef]

- Spalek, N.; Brunow, J.; Braun, M.; Rutner, M. WAAM-Fabricated Laminated Metal Composites. Metals 2021, 11, 1948. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corigliano, P.; Crupi, V. Review of Fatigue Assessment Approaches for Welded Marine Joints and Structures. Metals 2022, 12, 1010. https://doi.org/10.3390/met12061010

Corigliano P, Crupi V. Review of Fatigue Assessment Approaches for Welded Marine Joints and Structures. Metals. 2022; 12(6):1010. https://doi.org/10.3390/met12061010

Chicago/Turabian StyleCorigliano, Pasqualino, and Vincenzo Crupi. 2022. "Review of Fatigue Assessment Approaches for Welded Marine Joints and Structures" Metals 12, no. 6: 1010. https://doi.org/10.3390/met12061010

APA StyleCorigliano, P., & Crupi, V. (2022). Review of Fatigue Assessment Approaches for Welded Marine Joints and Structures. Metals, 12(6), 1010. https://doi.org/10.3390/met12061010