Effect of Grain Size on the Properties of Aluminum Matrix Composites with Graphene

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

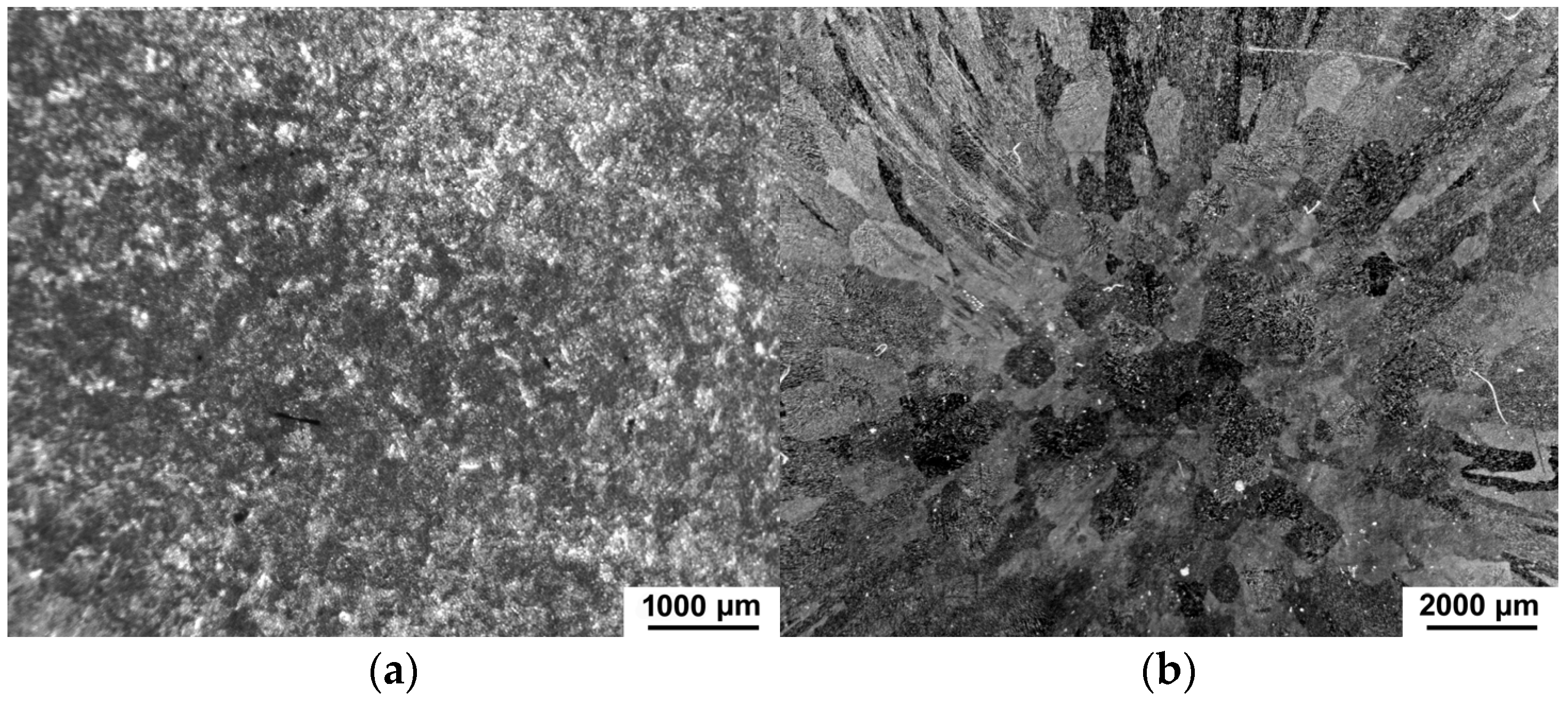

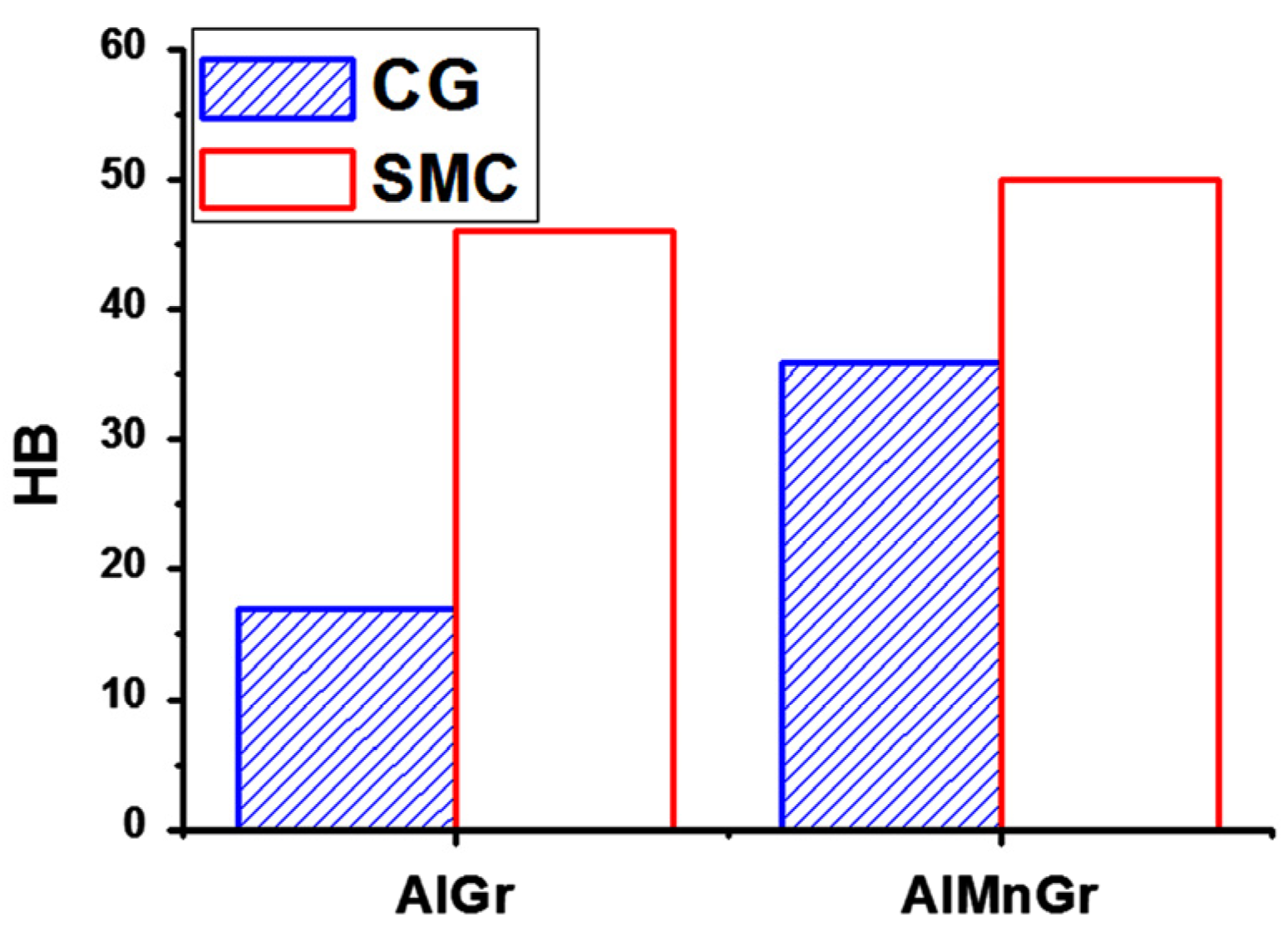

3.1. Structure and Properties of the Composites with Macrocrystalline (Coarse-Grained) Structure

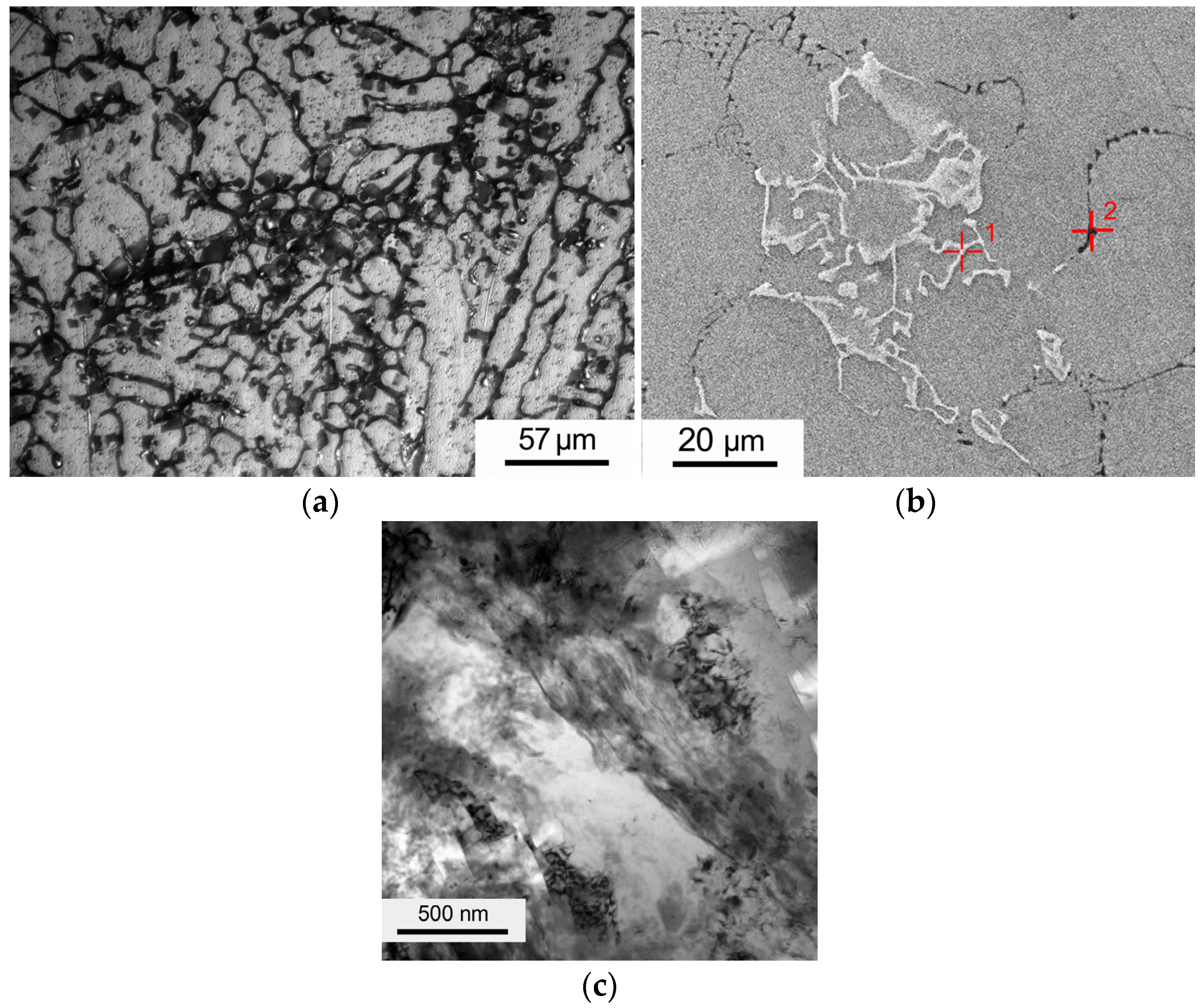

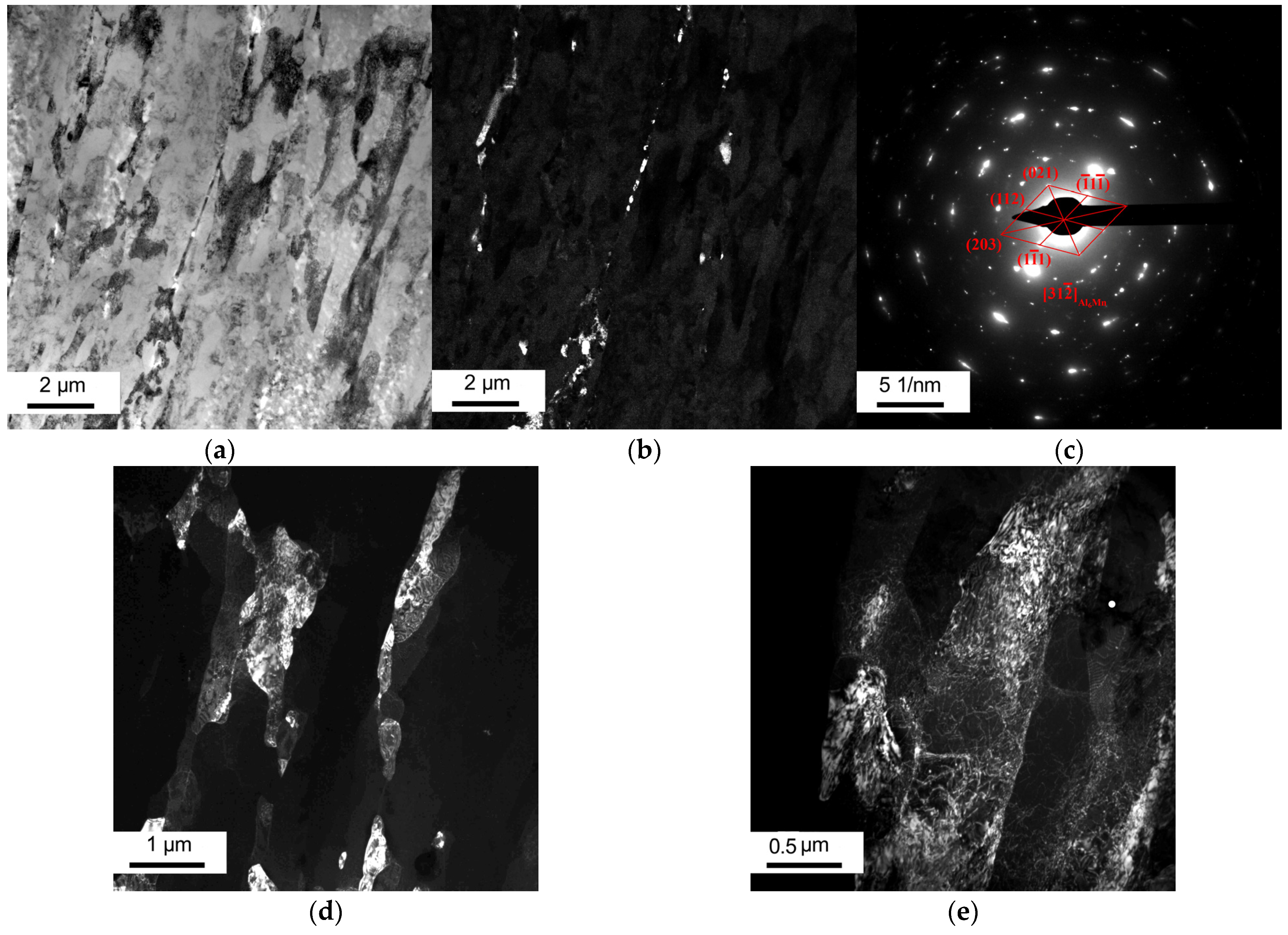

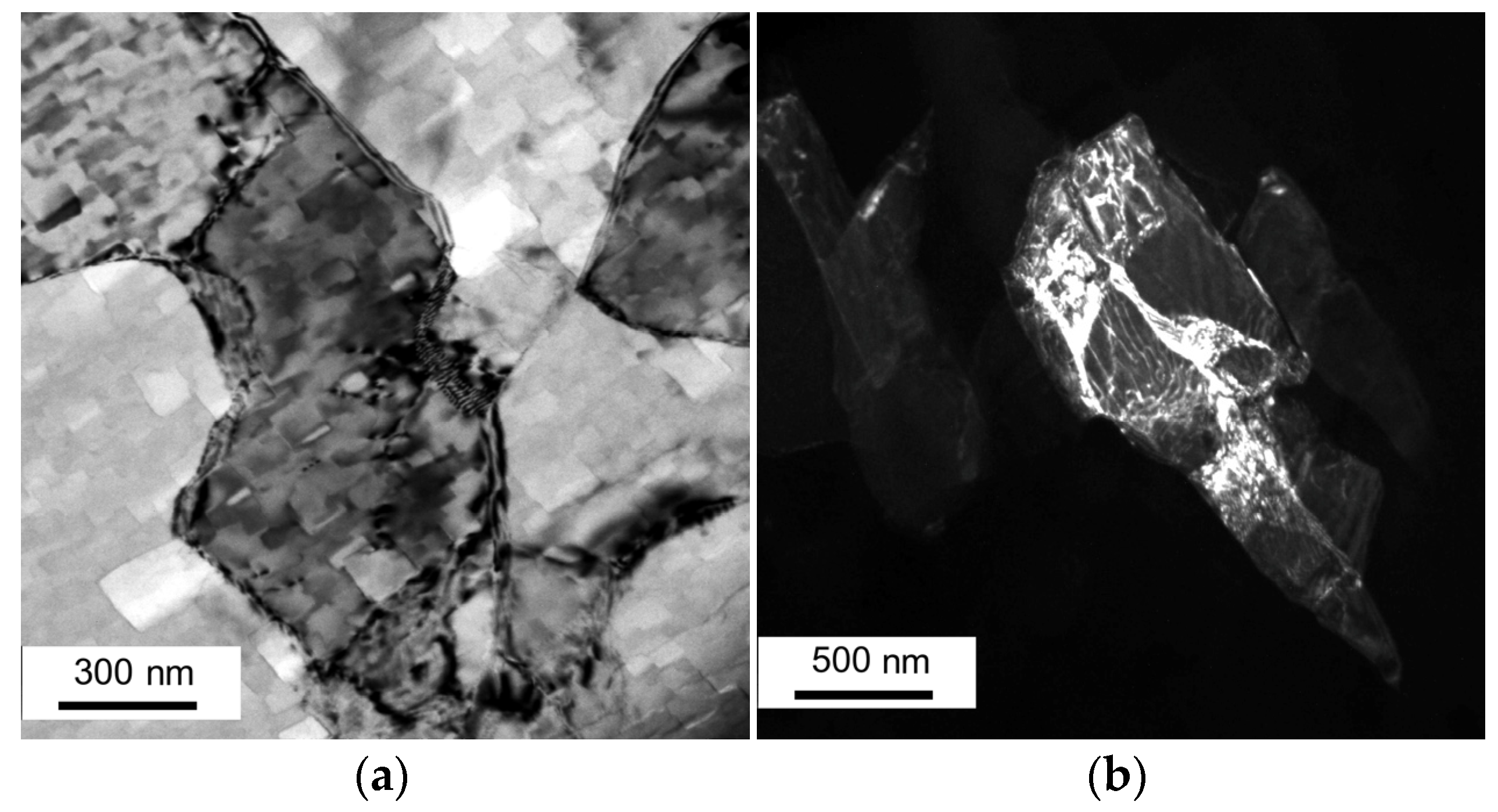

3.2. Structure and Properties of the Composites with Microcrystalline (Fine-Grained) Structure

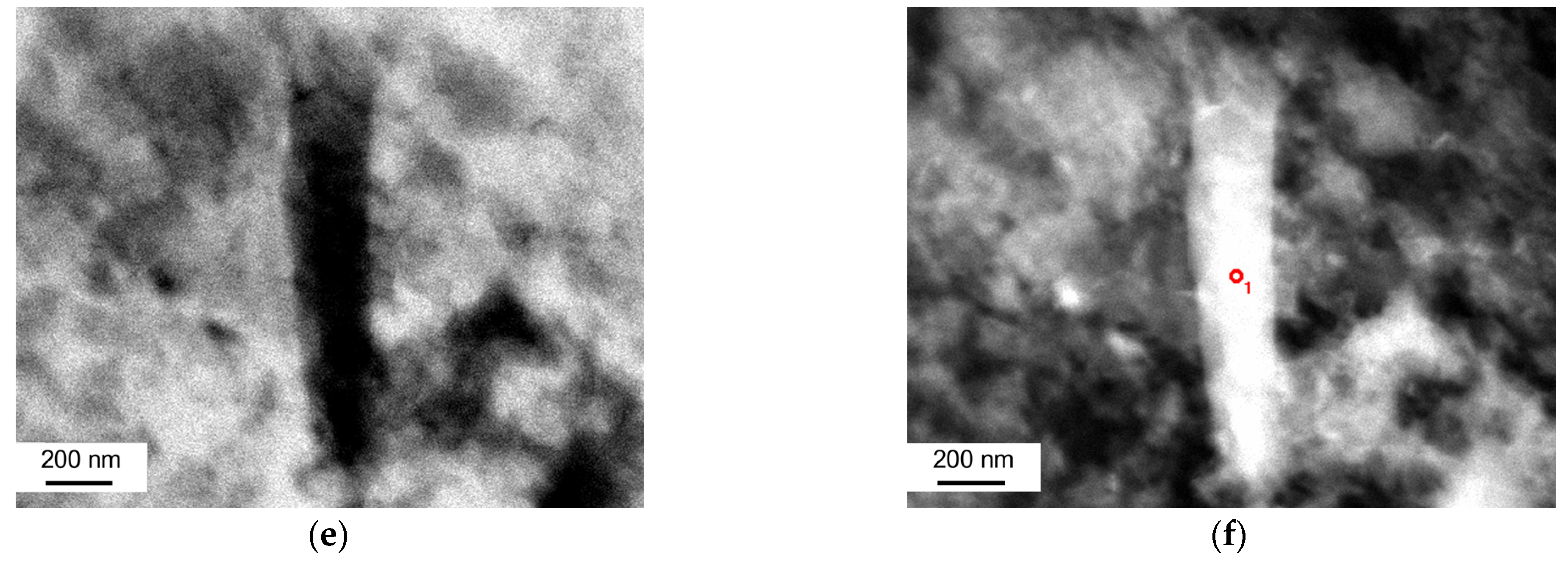

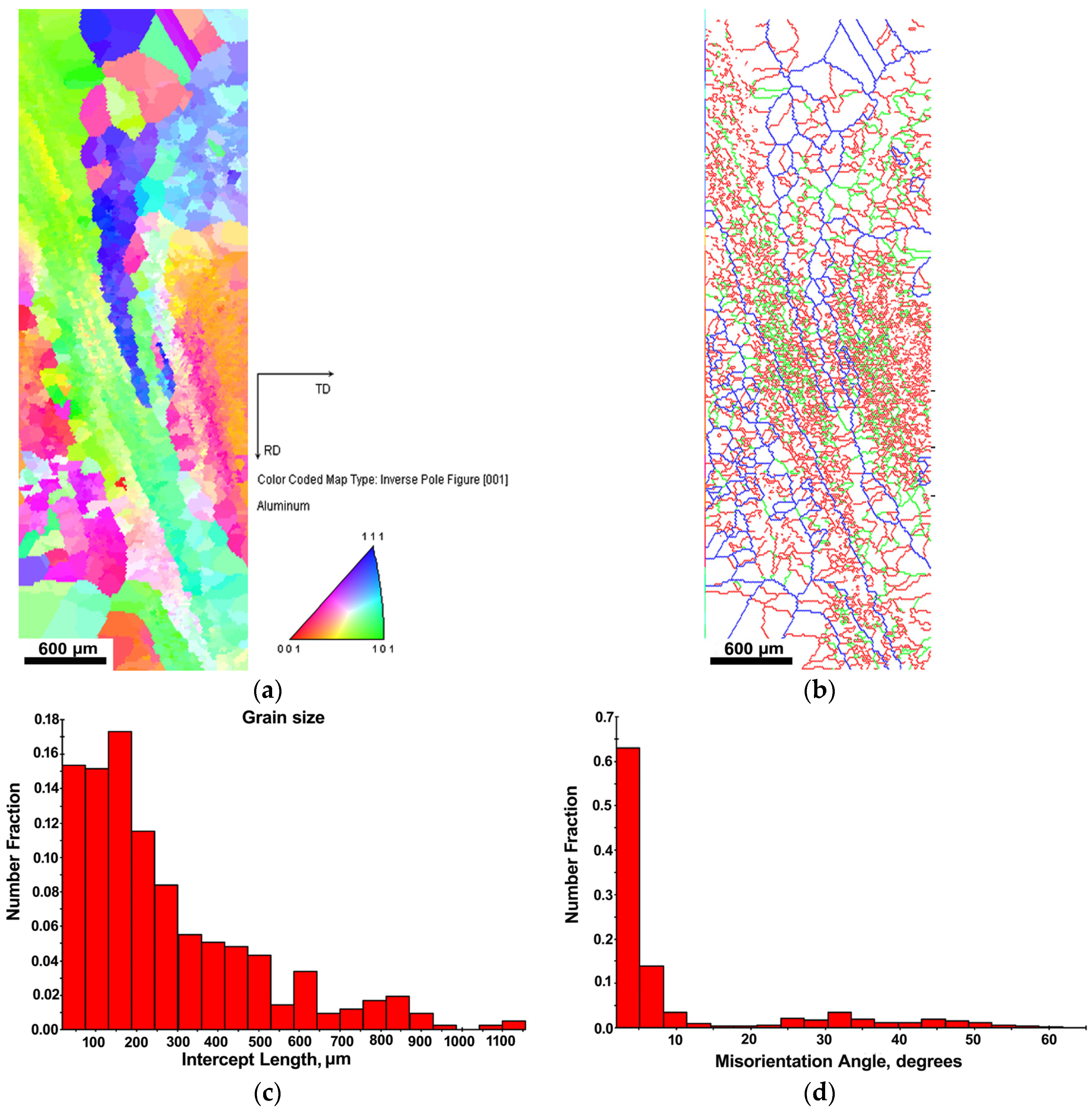

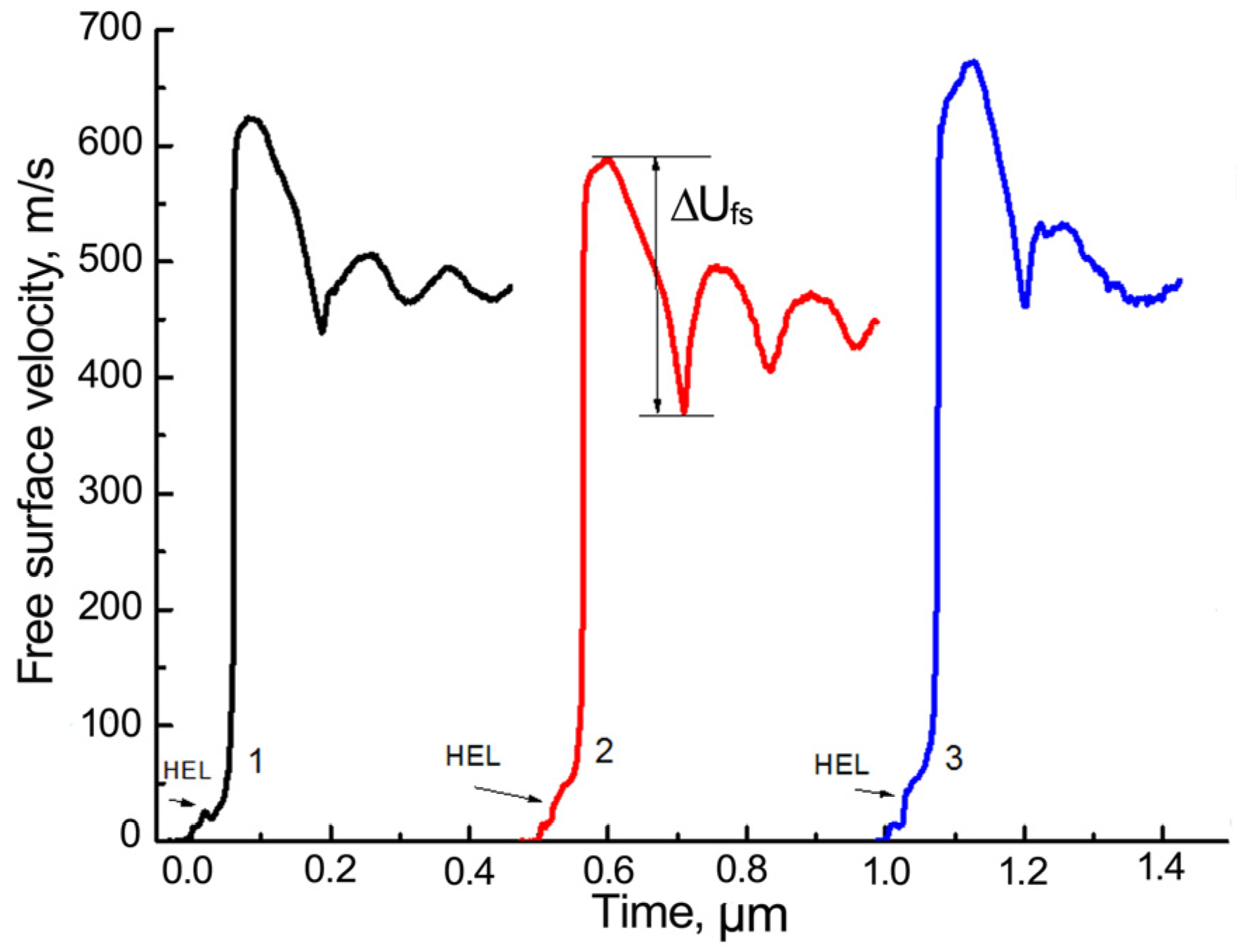

3.3. Structure and Properties of the Composites with Submicrocrystalline Structure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Langdon, T.G. The principles of grain refinement in equal-channel angular pressing. Mater. Sci. Eng. A 2007, 462, 3–11. [Google Scholar] [CrossRef]

- Zehetbauer, M.J.; Valiev, R.Z. Nanomaterials by Severe Plastic Deformation; Wiley: Weinheim, Germany, 2004. [Google Scholar]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Segal, V. Review: Modes and Processes of Severe Plastic Deformation (SPD). Materials 2018, 11, 1175. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mondolfo, L.F. Aluminum Alloys: Structure and Properties; Butterworth & Co.: Oxford, UK, 1976. [Google Scholar]

- Wang, H.; Geng, H.; Liu, C. The influence of SiO2 on the aluminum borate whisker reinforced aluminum phosphate wave-transparent materials. Procedia Eng. 2012, 27, 1222–1227. [Google Scholar] [CrossRef] [Green Version]

- Khrustalev, A.P.; Kozulin, A.A.; Zhukov, I.A.; Khmeleva, M.G.; Vorozhtsov, A.B.; Eskin, D.G.; Chankitmunkong, S.; Platov, V.V.; Vasilev, S.V. Influence of Titanium Diboride Particle Size on Structure and Mechanical Properties of an Al-Mg Alloy. Metals 2019, 9, 1030. [Google Scholar] [CrossRef] [Green Version]

- Das, D.K.; Mishra, P.C.; Singh, S.; Thakur, R.K. Properties of ceramic-reinforced aluminium matrix composites—A review. Int. J. Mech. Mater. Eng. 2014, 9, 12. [Google Scholar] [CrossRef] [Green Version]

- Zhukov, I.A.; Nikitin, P.Y.; Grigoriev, M.V.; Vorozhtsov, A.B. Phase composition and hardness of AlMgB14-based polycrystalline materials. Russ. Phys. J. 2019, 62, 882–885. [Google Scholar] [CrossRef]

- Tjong, S.C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphenenanosheets. Mater. Sci. Eng. R 2013, 74, 281–350. [Google Scholar] [CrossRef]

- Tabandeh-Khorshid, M.; Ajay, K.; Omrani, E.; Kim, C.; Rohatgi, P. Synthesis, characterization, and properties of graphene reinforced metal-matrix nanocomposites. Composites B 2020, 183, 107664. [Google Scholar] [CrossRef]

- Khanna, V.; Kumar, V.; Bansal, S.A. Mechanical properties of aluminium-graphene/carbon nanotubes (CNTs) metal matrix composites: Advancement, opportunities and perspective. Mater. Res. Bull. 2021, 138, 111224. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Lahiri, D.; Agarwal, A. Carbon nanotube reinforced metal matrix composites—A review. Int. Mater. Rev. 2010, 55, 41–64. [Google Scholar] [CrossRef]

- Hu, Z.; Tong, G.; Lin, D.; Chen, C.; Guo, H.; Xu, J.; Zhou, L. Graphene-reinforced metal matrix nanocomposites—A review. Mater. Sci. Technol. 2016, 32, 930–953. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Kinloch, I.A.; Young, R.J. Mechanical properties of graphene and graphene-based nanocomposites. Prog. Mater. Sci. 2017, 90, 75–127. [Google Scholar] [CrossRef]

- Naplocha, K.; Granat, K. Dry sliding wear of Al/Saffil/C hybrid metal matrix composites. Wear 2008, 265, 1734–1740. [Google Scholar] [CrossRef]

- Pérez-Bustamante, R.; Pérez-Bustamante, F.; Estrada-Guel, I.; Santillán-Rodríguez, C.R.; Matutes-Aquino, J.A.; Herrera-Ramírez, J.M. Characterization of Al2024-CNTs composites produced by mechanical alloying. Powder Technol. 2011, 212, 390–396. [Google Scholar] [CrossRef]

- Uglov, V.V.; Cherenda, N.N.; Danilyuk, A.L.; Rauschenbach, B. Structural and phase composition changes in aluminium induced by carbon implantation. Surf. Coat. Technol. 2000, 128–129, 358–363. [Google Scholar] [CrossRef]

- Hu, Z.; Chen, F.; Xu, J.; Nian, Q.; Lin, D.; Chen, C.; Zhu, X.; Chen, Y.; Zhang, M. 3D printing graphene-aluminum nanocomposites. J. Alloys Compd. 2018, 746, 269–276. [Google Scholar] [CrossRef]

- Li, J.L.; Xiong, Y.C.; Wang, X.D.; Yan, S.J.; Yang, C.; He, W.W.; Chen, J.Z.; Wang, S.Q.; Zhang, X.Y.; Dai, S.L. Microstructure and tensile properties of bulk nanostructured aluminum/graphene composites prepared via cryomilling. Mater. Sci. Eng. A 2015, 626, 400–405. [Google Scholar] [CrossRef]

- Yolshina, L.A.; Muradymov, R.V.; Korsun, I.V.; Yakovlev, G.A.; Smirnov, S.V. Novel aluminum–graphene and aluminum–graphite metallic composite materials: Synthesis and properties. J. Alloys Compd. 2016, 663, 449–459. [Google Scholar] [CrossRef]

- Yolshina, V.A.; Yolshina, L.A.; Elterman, V.A.; Vovkotrub, E.G.; Shatunova, A.A.; Pryakhina, V.I.; Khlebnikov, N.A.; Tarakina, N.V. Synthesis of and characterization of freestanding, high-hierarchicallystructured graphene-nanodiamond films. Mater. Des. 2017, 135, 343–352. [Google Scholar] [CrossRef]

- Yolshina, L.A.; Muradymov, R.V.; Vovkotrub, E.G.; Smirnov, S.V. Diamond synthesis in aluminum matrix in molten alkali-halide at ambient pressure. Diam. Relat. Mater. 2015, 55, 1–11. [Google Scholar] [CrossRef]

- Yolshina, L.A.; Vichuzhanin, D.I.; Smirnova, E.O. Enhancement of the Mechanical Properties of Aluminum-Graphene Composites. AIP Conf. Proc. 2016, 1785, 040093. [Google Scholar]

- Yolshina, L.A.; Vovkotrub, E.G.; Shatunova, A.A.; Pryakhina, V.I. Raman spectroscopy study of graphene formed by “in situ” chemical interaction of an organic precursor with a Journal Pre-proof molten aluminium matrix. J. Raman Spectrosc. 2020, 51, 221–231. [Google Scholar] [CrossRef]

- Safina, L.; Baimova, J.; Krylova, K.; Murzaev, R.; Mulyukov, R. Simulation of metal-graphene composites by molecular dynamics: A review. Lett. Mater. 2020, 10, 351–360. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Y.Y.; Zhang, H.N.; Yang, J. Mechanical properties of graphene-reinforced aluminium composite with modified substrate surface: A molecular dynamics study. Nanotechnology 2021, 32, 085712. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Liu, X.; Lei, J.; Yang, Q. Atomic simulations of the formation of twist grain boundary and mechanical properties of graphene/aluminum nanolaminated composites. Comp. Mater. Sci. 2020, 172, 109342. [Google Scholar] [CrossRef]

- Sheinerman, A.G. Mechanical properties of metal matrix composites with graphen and carbon nanotubes. Phys. Met. Metallogr. 2022, 123, 57–84. [Google Scholar] [CrossRef]

- Shirinkina, I.G.; Brodova, I.G.; Rasposienko, D.Y.; Muradymov, R.V.; Yolshina, L.A.; Shorokhov, E.V.; Razorenov, S.V.; Gorkushin, G.V. The effect of graphene additives on the structure and properties of aluminum. Phys. Met. Metallogr. 2020, 121, 1193–1202. [Google Scholar] [CrossRef]

- Brodova, I.G.; Petrova, A.N.; Shirinkina, I.G.; Rasposienko, D.Y.; Yolshina, L.A.; Muradymov, R.V.; Razorenov, S.V.; Shorokhov, E.V. Mechanical properties of submicrocrystallinealuminium matrix composites reinforced by “in situ” graphene through severe plastic deformation processes. J. Alloys Compd. 2021, 859, 158387–158395. [Google Scholar] [CrossRef]

- Wu, H.; Huang, M.; Li Xu Xia, Y.; Wang ZhGuohua, F. Temperature-dependent reversed fracture behavior of multilayered TiBw/Ti–Ti(Al) composites. Int. J. Plast. 2021, 141, 102998. [Google Scholar] [CrossRef]

- Fu, X.; Tan, Z.; Min, X.; Li, Z.; Yue, Z.; Fan, G.; Xiong, D.-B.; Li, Z. Trimodal grain structure enables high-strength CNT/Al-Cu-Mg composites higher ductility by powder assembly & alloying. Mater. Res. Lett. 2020, 9, 50–57. [Google Scholar] [CrossRef]

- Vanin, M.; Mortensen, J.J.; Kelkkanen, A.K.; Garcia-Lastra, J.M.; Thygesen, K.S.; Jacobsen, K.W. Graphene on metals: A van der Waals density functions study. Phys. Rev. B 2010, 87, 081408. [Google Scholar] [CrossRef] [Green Version]

- Sharma, R.; Chadha, N.; Saini, P. Determination of defect density, crystallite size and number of graphene layers in graphene analogues using X-ray diffraction and Raman spectroscopy. Indian J. Pure Appl. Phys. 2017, 55, 625–629. [Google Scholar]

- Shorokhov, E.V.; Zhgilev, I.N.; Valiev, R.Z. Method for Dynamic Deforming of Metals. Abstract of Invention. Patent RU 2283717 C2, 20 September 2006. [Google Scholar]

- Brodova, I.G.; Zel’dovich, V.I.; Khomskaya, I.V. Phase-Structural Transformations and Properties of Non-Ferrous Metals and Alloys under Extreme Conditions. Phys. Met. Metallogr. 2020, 121, 631–663. [Google Scholar] [CrossRef]

- Petrova, A.N.; Brodova, I.G.; Plekhov, O.A.; Naimark, O.B.; Shorokhov, E.V. Mechanical properties and energy dissipation in ultrafine-grained AMts and V95 aluminum alloys during dynamic compression. Tech. Phys. 2014, 59, 989–996. [Google Scholar] [CrossRef]

- Razorenov, S.V.; Garkushin, G.N. Hardening of metals and alloys during shock compression. Tech. Phys. 2015, 60, 1021–1026. [Google Scholar] [CrossRef]

- Brodova, I.G.; Petrova, A.N.; Razorenov, S.V.; Shorokhov, E.V. Resistance of submicrocrystalline aluminum alloys to high-rate deformation and fracture after dynamic channel angular pressing. Phys. Metals Metallogr. 2015, 116, 519–526. [Google Scholar] [CrossRef]

- Razorenov, S.V. Influence of structural factors on the strength properties of aluminum alloys under shock wave loading. Matter Radiat. Extrem. 2018, 3, 1–54. [Google Scholar] [CrossRef] [Green Version]

- Barker, L.M.; Hollenbach, R.E. Laser interferometry for measuring high velocities of any reflecting surface. J. Appl. Phys. 1972, 43, 4669–4675. [Google Scholar] [CrossRef]

- Chen, W.; Yang, T.; Dong, L.; Elmasry, A.; Song, J.; Deng, N.; Elmarakbi, A.; Liu, T.; Bao, L.H.; Qing, F.Y. Advances in graphene reinforced metal matrix nanocomposites: Mechanisms, processing, modelling, properties and applications. Nanotechnol. Precis. Eng. 2020, 3, 189–210. [Google Scholar] [CrossRef]

| Matrix Composition | HB | |

|---|---|---|

| without Graphene | with Graphene | |

| Al | 15 | 17 |

| AlMg | 62 | 64 |

| AlMn | 28 | 30 |

| Composition | LABs (2–5°) | LABs (5–15°) | HABs (>15°) | Average Grain–Subgrain Size, μm | Hardness, MPa |

|---|---|---|---|---|---|

| AlGr | 38 | 8 | 54 | 2.0 | 4.5 |

| AlMgGr | 70 | 14 | 15 | 0.3 | 5.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brodova, I.; Yolshina, L.; Razorenov, S.; Rasposienko, D.; Petrova, A.; Shirinkina, I.; Shorokhov, E.; Muradymov, R.; Garkushin, G.; Savinykh, A. Effect of Grain Size on the Properties of Aluminum Matrix Composites with Graphene. Metals 2022, 12, 1054. https://doi.org/10.3390/met12061054

Brodova I, Yolshina L, Razorenov S, Rasposienko D, Petrova A, Shirinkina I, Shorokhov E, Muradymov R, Garkushin G, Savinykh A. Effect of Grain Size on the Properties of Aluminum Matrix Composites with Graphene. Metals. 2022; 12(6):1054. https://doi.org/10.3390/met12061054

Chicago/Turabian StyleBrodova, Irina, Liudmila Yolshina, Sergey Razorenov, Dmitriy Rasposienko, Anastasia Petrova, Irina Shirinkina, Evgeny Shorokhov, Roman Muradymov, Gennady Garkushin, and Andrey Savinykh. 2022. "Effect of Grain Size on the Properties of Aluminum Matrix Composites with Graphene" Metals 12, no. 6: 1054. https://doi.org/10.3390/met12061054

APA StyleBrodova, I., Yolshina, L., Razorenov, S., Rasposienko, D., Petrova, A., Shirinkina, I., Shorokhov, E., Muradymov, R., Garkushin, G., & Savinykh, A. (2022). Effect of Grain Size on the Properties of Aluminum Matrix Composites with Graphene. Metals, 12(6), 1054. https://doi.org/10.3390/met12061054