Effect of Quenching and Tempering on Mechanical Properties and Impact Fracture Behavior of Low-Carbon Low-Alloy Steel

Abstract

:1. Introduction

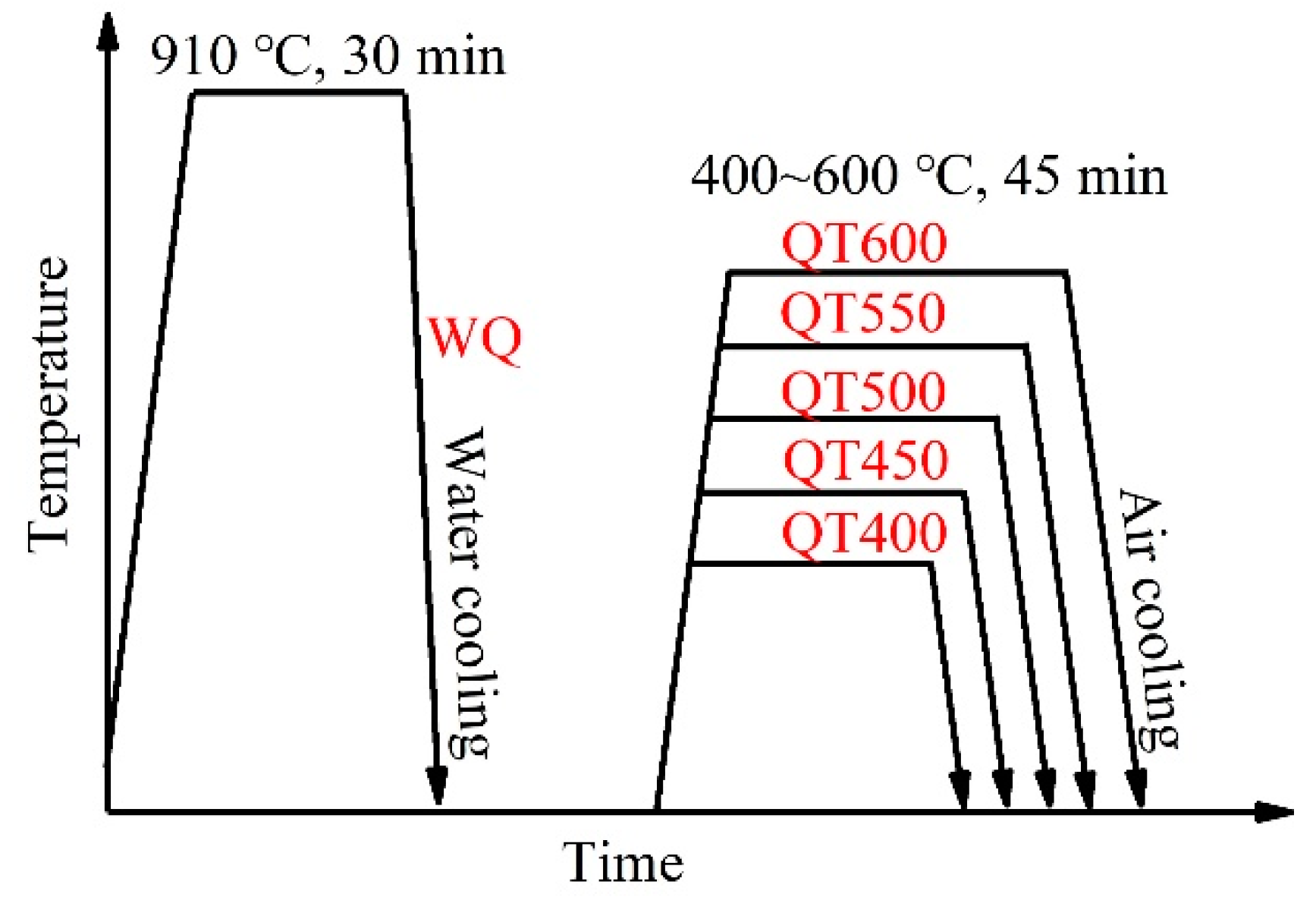

2. Materials and Methods

3. Results

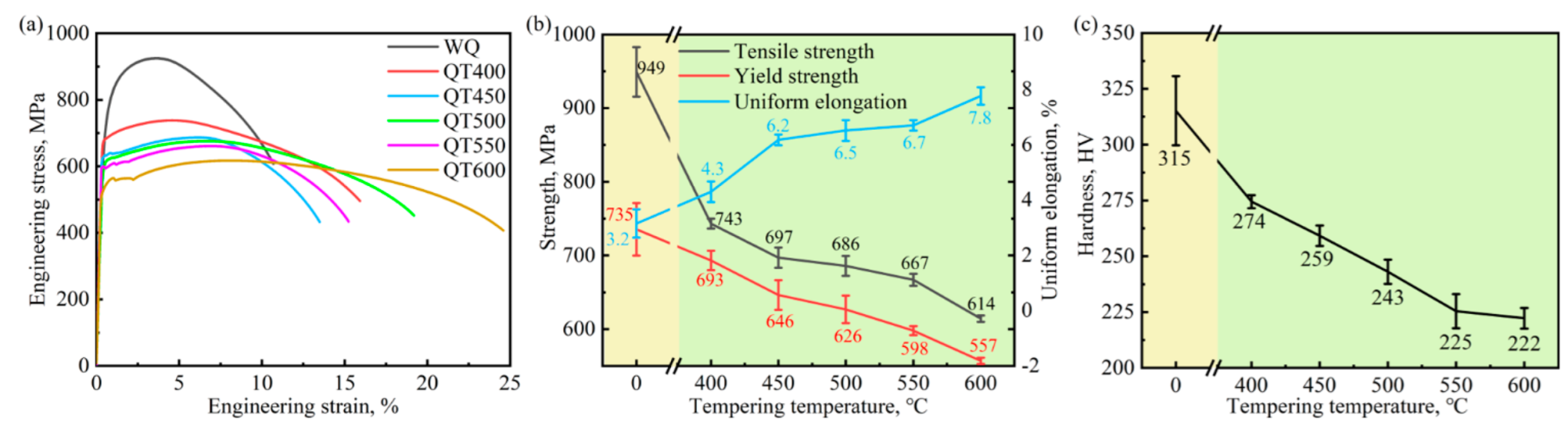

3.1. Mechanical Properties

3.2. Microstructure Characterization

4. Discussion

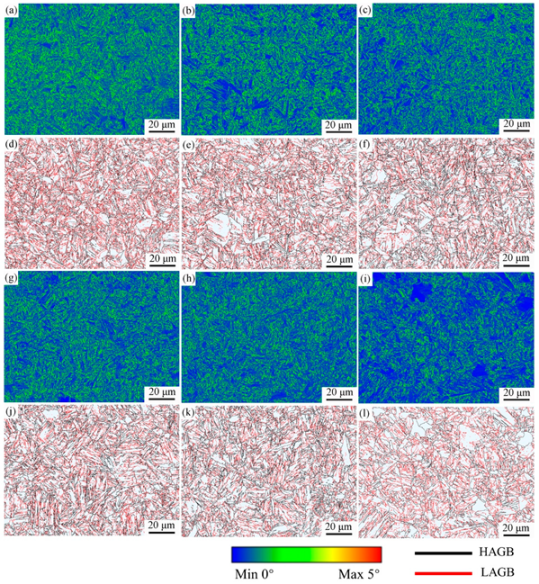

4.1. Effect of Tempering Temperature on Microstructure

4.2. Relationship between Microstructure and Mechanical Properties

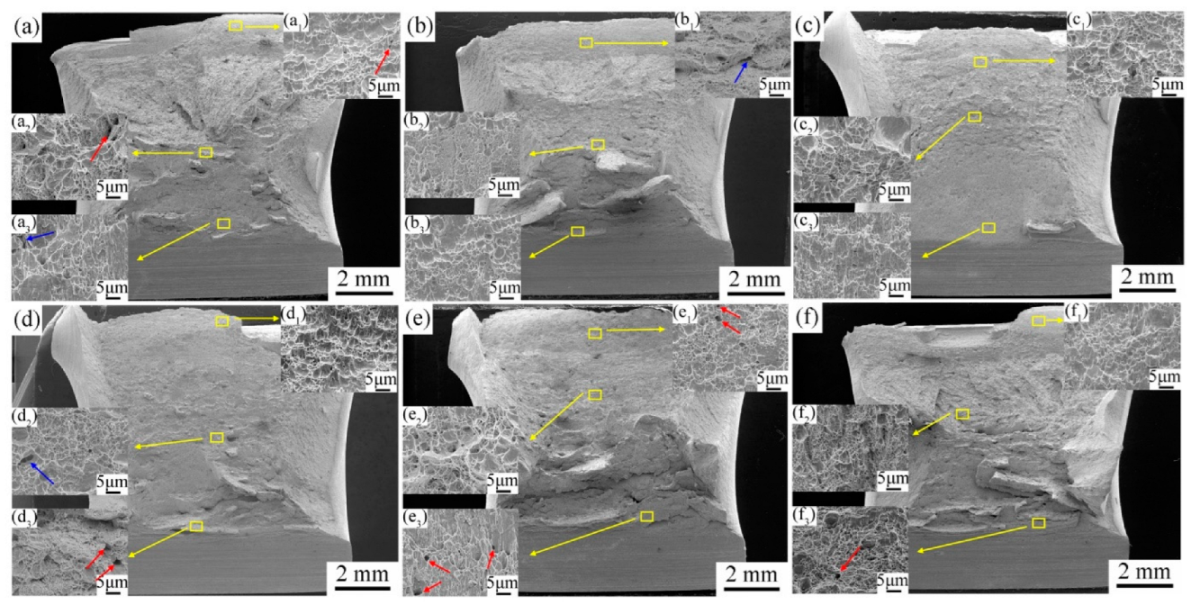

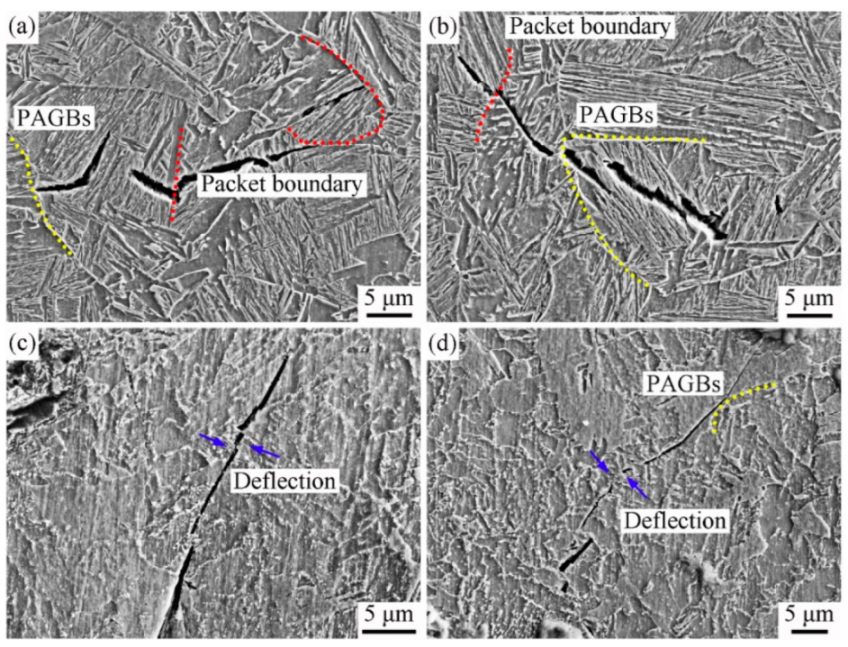

4.3. Impact Fracture Behavior

5. Conclusions

- (1)

- The microstructure of martensite can be regulated by changing tempering temperature. With the increase in tempering temperature, the dislocation density between laths gradually decreased, resulting in a reduction in strength. Meanwhile, martensitic laths gradually merged and coarsened, and a greater transformation between HAGBs and LAGBs occurred. The increase in HAGBs enhanced the toughness of the steel, and the impact energy also increased.

- (2)

- It can be considered that combined with the microstructure and mechanical properties, the optimal strengthening and toughness matching can be achieved at 600 °C tempering. The microstructure was mainly composed of tempered martensite, and the yield strength, the tensile strength and the impact energy were 557 MPa, 614 MPa and 331 J, respectively.

- (3)

- The transformation between LAGBs and LAGBs during tempering also affected the crack propagation. HAGBs effectively deflected and even stopped crack propagation, whereas LAGBs had less influence on crack propagation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, Y.; Jia, T.; Zhang, X.; Liu, Z.; Misra, R.D.K. Microstructure and toughness of the CGHAZ of an offshore platform steel. J. Mater. Process. Technol. 2015, 219, 314–320. [Google Scholar] [CrossRef]

- Zhou, Y.-L.; Chen, J.; Liu, Z.-Y. Corrosion Behavior of Rusted 550 MPa Grade Offshore Platform Steel. J. Iron Steel Res. Int. 2013, 20, 66–73. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, M.; Liu, Y.; Ma, D.; Xu, B.; Huang, M.; Li, D.; Li, Y. Ultrafine-grained dual-phase maraging steel with high strength and excellent cryogenic toughness. Acta Mater. 2021, 211, 116878. [Google Scholar] [CrossRef]

- Tervo, H.; Kaijalainen, A.; Pallaspuro, S.; Anttila, S.; Mehtonen, S.; Porter, D.; Kömi, J. Low-temperature toughness properties of 500 MPa offshore steels and their simulated coarse-grained heat-affected zones. Mater. Sci. Eng. A 2020, 773, 138719. [Google Scholar] [CrossRef]

- Wei, X.; Cao, X.; Luan, J.H.; Jiao, Z.B.; Liu, C.T.; Zhang, Z.W. Synergy of strengthening and toughening of a Cu-rich precipitate-strengthened steel. Mater. Sci. Eng. A 2022, 832, 142487. [Google Scholar] [CrossRef]

- Ning, D.; Dai, C.R.; Wu, J.L.; Wang, Y.D.; Wang, Y.Q.; Jing, Y.; Sun, J. Carbide precipitation and coarsening kinetics in low carbon and low alloy steel during quenching and subsequently tempering. Mater. Charact. 2021, 176, 111111. [Google Scholar] [CrossRef]

- Hutchinson, B.; Hagström, J.; Karlsson, O.; Lindell, D.; Tornberg, M.; Lindberg, F.; Thuvander, M. Microstructures and hardness of as-quenched martensites (0.1–0.5%C). Acta Mater. 2011, 59, 5845–5858. [Google Scholar] [CrossRef]

- Zhao, N.; Zhao, Q.; He, Y.; Liu, R.; Liu, W.; Zheng, W.; Li, L. Strengthening-toughening mechanism of cost-saving marine steel plate with 1000 MPa yield strength. Mater. Sci. Eng. A 2022, 831, 142280. [Google Scholar] [CrossRef]

- Liang, Y.; Long, S.; Xu, P.; Lu, Y.; Jiang, Y.; Liang, Y.; Yang, M. The important role of martensite laths to fracture toughness for the ductile fracture controlled by the strain in EA4T axle steel. Mater. Sci. Eng. A 2017, 695, 154–164. [Google Scholar] [CrossRef]

- Inoue, J.; Sadeghi, A.; Koseki, T. Slip band formation at free surface of lath martensite in low carbon steel. Acta Mater. 2019, 165, 129–141. [Google Scholar] [CrossRef]

- Chen, J.; Li, C.; Ren, J.; Tu, X.; Chen, L. Strength and toughness of Fe-1.2Mn-0.3Cr-1.4Ni-0.4Mo-C tempered steel plate in three cooling processes. Mater. Sci. Eng. A 2019, 754, 178–189. [Google Scholar] [CrossRef]

- Thompson, S.W. Interrelationships between yield strength, low-temperature impact toughness, and microstructure in low-carbon, copper-precipitation-strengthened, high-strength low-alloy plate steels. Mater. Sci. Eng. A 2018, 711, 424–433. [Google Scholar] [CrossRef]

- Morsdorf, L.; Emelina, E.; Gault, B.; Herbig, M.; Tasan, C.C. Carbon redistribution in quenched and tempered lath martensite. Acta Mater. 2021, 205, 116521. [Google Scholar] [CrossRef]

- Gan, X.; Wan, X.; Zhang, Y.; Wang, H.; Li, G.; Xu, G.; Wu, K. Investigation of characteristic and evolution of fine-grained bainitic microstructure in the coarse-grained heat-affected zone of super-high strength steel for offshore structure. Mater. Charact. 2019, 157, 109893. [Google Scholar] [CrossRef]

- Yen, H.; Chiang, M.; Lin, Y.; Chen, D.; Huang, C.; Lin, H. High-Temperature Tempered Martensite Embrittlement in Quenched-and-Tempered Offshore Steels. Metals 2017, 7, 253. [Google Scholar] [CrossRef] [Green Version]

- Sun, C.; Fu, P.; Ma, X.; Liu, H.; Du, N.; Cao, Y.; Liu, H.; Li, D. Effect of matrix carbon content and lath martensite microstructures on the tempered precipitates and impact toughness of a medium-carbon low-alloy steel. J. Mater. Res. Technol. 2020, 9, 7701–7710. [Google Scholar] [CrossRef]

- Long, S.; Liang, Y.; Jiang, Y.; Liang, Y.; Yang, M.; Yi, Y. Effect of quenching temperature on martensite multi-level microstructures and properties of strength and toughness in 20CrNi2Mo steel. Mater. Sci. Eng. A 2016, 676, 38–47. [Google Scholar] [CrossRef]

- Li, C.; Duan, R.; Fu, W.; Gao, H.; Wang, D.; Di, X. Improvement of mechanical properties for low carbon ultra-high strength steel strengthened by Cu-rich multistructured precipitation via modification to bainite. Mater. Sci. Eng. A 2021, 817, 141337. [Google Scholar] [CrossRef]

- Zhao, Y.; Tong, X.; Wei, X.H.; Xu, S.S.; Lan, S.; Wang, X.L.; Zhang, Z.W. Effects of microstructure on crack resistance and low-temperature toughness of ultra-low carbon high strength steel. Int. J. Plast. 2019, 116, 203–215. [Google Scholar] [CrossRef]

- Mao, G.; Cayron, C.; Cao, R.; Logé, R.; Chen, J. The relationship between low-temperature toughness and secondary crack in low-carbon bainitic weld metals. Mater. Charact. 2018, 145, 516–526. [Google Scholar] [CrossRef]

- Yang, G.; Xia, S.L.; Zhang, F.C.; Branco, R.; Long, X.Y.; Li, Y.G.; Li, J.H. Effect of tempering temperature on monotonic and low-cycle fatigue properties of a new low-carbon martensitic steel. Mater. Sci. Eng. A 2021, 826, 141939. [Google Scholar] [CrossRef]

- Mote, V.D.; Purushotham, Y.; Dole, B.N. Williamson-Hall analysis in estimation of lattice strain in nanometer-sized ZnO particles. J. Theor. Appl. Phys. 2012, 6, 6. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Wiskel, J.; Henein, H.; Ivey, D.; Omotoso, O. Characterization of Microstructure in High Strength Microalloyed Steels Using Quantitative X-Ray Diffraction. In Proceedings of the Biennial International Pipeline Conference 2008, Calgary, AB, Canada, 29 September–3 October 2008. [Google Scholar] [CrossRef]

- Xiong, W.; Song, R.; Huo, W.; Yu, P.; Qin, S.; Liu, Z. Microstructure characteristics and impact fracture mechanisms of Nb and V–Ti micro-alloyed offshore platform steels. Vacuum 2022, 195, 110709. [Google Scholar] [CrossRef]

- Ren, J.; Li, C.; Han, Y.; Li, E.; Gao, C.; Qiu, C. Effect of initial martensite and tempered carbide on mechanical properties of 3Cr2MnNiMo mold steel. Mater. Sci. Eng. A 2021, 812, 141080. [Google Scholar] [CrossRef]

- Zhu, W.; Cui, J.; Chen, Z.; Feng, Y.; Zhao, Y.; Chen, L. Design and Performance of 690 MPa Grade Low-Carbon Microalloyed Construction Structural Steel with High Strength and Toughness. Acta Metall. Sin. 2021, 57, 340–352. [Google Scholar] [CrossRef]

- Ghosh, S.; Miettunen, I.; Somani, M.C.; Kömi, J.; Porter, D. Nanolath martensite-austenite structures engineered through DQ&P processing for developing tough, ultrahigh strength steels. Mater. Today Proc. 2021, 46, 2131–2134. [Google Scholar] [CrossRef]

- Wang, J.; Li, W.; Zhu, X.; Zhang, L. Effect of martensite morphology and volume fraction on the low-temperature impact toughness of dual-phase steels. Mater. Sci. Eng. A 2022, 832, 142424. [Google Scholar] [CrossRef]

- Kim, J.; Choi, S.; Park, D.; Lee, J. Charpy impact properties of stainless steel weldment in liquefied natural gas pipelines: Effect of low temperatures. Mater. Des. 2015, 65, 914–922. [Google Scholar] [CrossRef]

- Im, Y.-R.; Oh, Y.J.; Lee, B.-J.; Hong, J.H.; Lee, H.-C. Effects of carbide precipitation on the strength and Charpy impact properties of low carbon Mn-Ni-Mo bainitic steels. J. Nucl. Mater. 2001, 297, 138–148. [Google Scholar] [CrossRef]

- Zhou, Y.; Jia, T.; Zhang, X.; Liu, Z.; Misra, R.D.K. Investigation on tempering of granular bainite in an offshore platform steel. Mater. Sci. Eng. A 2015, 626, 352–361. [Google Scholar] [CrossRef]

- Zhou, C.; Ye, Q.; Hu, J.; Zhao, T.; Gao, X.; Wang, Z. Ultra-high-strength multi-alloyed steel with enhanced cryogenic toughness using thermally stable retained austenite. Mater. Sci. Eng. A 2022, 831, 142356. [Google Scholar] [CrossRef]

- Jia, J.; Liu, Z.; Li, X.; Du, C.; Li, W. Comparative study on the stress corrosion cracking of a new Ni-advanced high strength steel prepared by TMCP, direct quenching, and quenching & tempering. Mater. Sci. Eng. A 2021, 825, 141854. [Google Scholar] [CrossRef]

- Bansal, G.K.; Tripathy, S.; Chandan, A.K.; Rajinikanth, V.; Ghosh, C.; Srivastava, V.C.; Ghosh Chowdhury, S. Influence of quenching strategy on phase transformation and mechanical properties of low alloy steel. Mater. Sci. Eng. A 2021, 826, 141937. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, J.; Han, L. Elemental redistribution and precipitation reactions of 9Cr1.5Mo1CoB(FB2) steel during tempering. Mater. Charact. 2021, 171, 110778. [Google Scholar] [CrossRef]

- Morsdorf, L.; Tasan, C.C.; Ponge, D.; Raabe, D. 3D structural and atomic-scale analysis of lath martensite: Effect of the transformation sequence. Acta Mater. 2015, 95, 366–377. [Google Scholar] [CrossRef]

- Bouissa, Y.; Bohlooli, N.; Shahriari, D.; Champliaud, H.; Morin, J.; Jahazi, M. FEM modeling and experimental validation of quench-induced distortions of large size steel forgings. J. Manuf. Processes 2020, 58, 592–605. [Google Scholar] [CrossRef]

- Chen, K.; Jiang, Z.; Liu, F.; Yu, J.; Li, Y.; Gong, W.; Chen, C. Effect of quenching and tempering temperature on microstructure and tensile properties of microalloyed ultra-high strength suspension spring steel. Mater. Sci. Eng. A 2019, 766, 138272. [Google Scholar] [CrossRef]

- Ghassemi-Armaki, H.; Chen, R.P.; Maruyama, K.; Yoshizawa, M.; Igarashi, M. Static recovery of tempered lath martensite microstructures during long-term aging in 9–12% Cr heat resistant steels. Mater. Lett. 2009, 63, 2423–2425. [Google Scholar] [CrossRef]

- Zhou, T.; Faleskog, J.; Babu, R.P.; Odqvist, J.; Yu, H.; Hedström, P. Exploring the relationship between the microstructure and strength of fresh and tempered martensite in a maraging stainless steel Fe–15Cr–5Ni. Mater. Sci. Eng. A 2019, 745, 420–428. [Google Scholar] [CrossRef]

- Jiang, Z.; Du, J.; Wang, P.; Zheng, J.; Li, D.; Li, Y. Mechanism of Improving the Impact Toughness of SA508-3 Steel Used for Nuclear Power by Pre-Transformation of M-A Islands. Acta Metall. Sin. 2021, 57, 891–902. [Google Scholar] [CrossRef]

- Shi, G.; Zhao, H.; Zhang, S.; Wang, Q.; Zhang, F. Microstructural characteristics and impact fracture behaviors of low-carbon vanadium-microalloyed steel with different nitrogen contents. Mater. Sci. Eng. A 2020, 769, 138501. [Google Scholar] [CrossRef]

- Xiong, Z.; Liu, S.; Wang, X.; Shang, C.; Li, X.; Misra, R.D.K. The contribution of intragranular acicular ferrite microstructural constituent on impact toughness and impeding crack initiation and propagation in the heat-affected zone (HAZ) of low-carbon steels. Mater. Sci. Eng. A 2015, 636, 117–123. [Google Scholar] [CrossRef]

- Rohrer, G.S. Grain boundary energy anisotropy: A review. J. Mater. Sci. 2011, 46, 5881–5895. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Zhang, C.; Jiang, B.; Zhou, L.; Liu, Y. Effect of large-size M23C6-type carbides on the low-temperature toughness of martensitic heat-resistant steels. J. Alloy. Compd. 2016, 685, 248–257. [Google Scholar] [CrossRef]

- Wang, X.L.; Wang, Z.Q.; Dong, L.L.; Shang, C.J.; Ma, X.P.; Subramanian, S.V. New insights into the mechanism of cooling rate on the impact toughness of coarse grained heat affected zone from the aspect of variant selection. Mater. Sci. Eng. A 2017, 704, 448–458. [Google Scholar] [CrossRef]

| C | Si | Mn | Al | Cr | Nb | Ti | Ni | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.08 | 0.18 | 1.61 | 0.03 | 0.16 | 0.037 | 0.013 | 0.26 | 0.2 | Bal. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Yang, J.; Xiao, D.; Luo, D.; Tuo, C.; Wu, H. Effect of Quenching and Tempering on Mechanical Properties and Impact Fracture Behavior of Low-Carbon Low-Alloy Steel. Metals 2022, 12, 1087. https://doi.org/10.3390/met12071087

Zhang Y, Yang J, Xiao D, Luo D, Tuo C, Wu H. Effect of Quenching and Tempering on Mechanical Properties and Impact Fracture Behavior of Low-Carbon Low-Alloy Steel. Metals. 2022; 12(7):1087. https://doi.org/10.3390/met12071087

Chicago/Turabian StyleZhang, Yajing, Jianhua Yang, Daheng Xiao, Deng Luo, Chende Tuo, and Huibin Wu. 2022. "Effect of Quenching and Tempering on Mechanical Properties and Impact Fracture Behavior of Low-Carbon Low-Alloy Steel" Metals 12, no. 7: 1087. https://doi.org/10.3390/met12071087

APA StyleZhang, Y., Yang, J., Xiao, D., Luo, D., Tuo, C., & Wu, H. (2022). Effect of Quenching and Tempering on Mechanical Properties and Impact Fracture Behavior of Low-Carbon Low-Alloy Steel. Metals, 12(7), 1087. https://doi.org/10.3390/met12071087