Estimation Method of Relative Slip in Fretting Fatigue Contact by Digital Image Correlation

Abstract

:1. Introduction

2. Materials and Experiment

2.1. Material and Sample

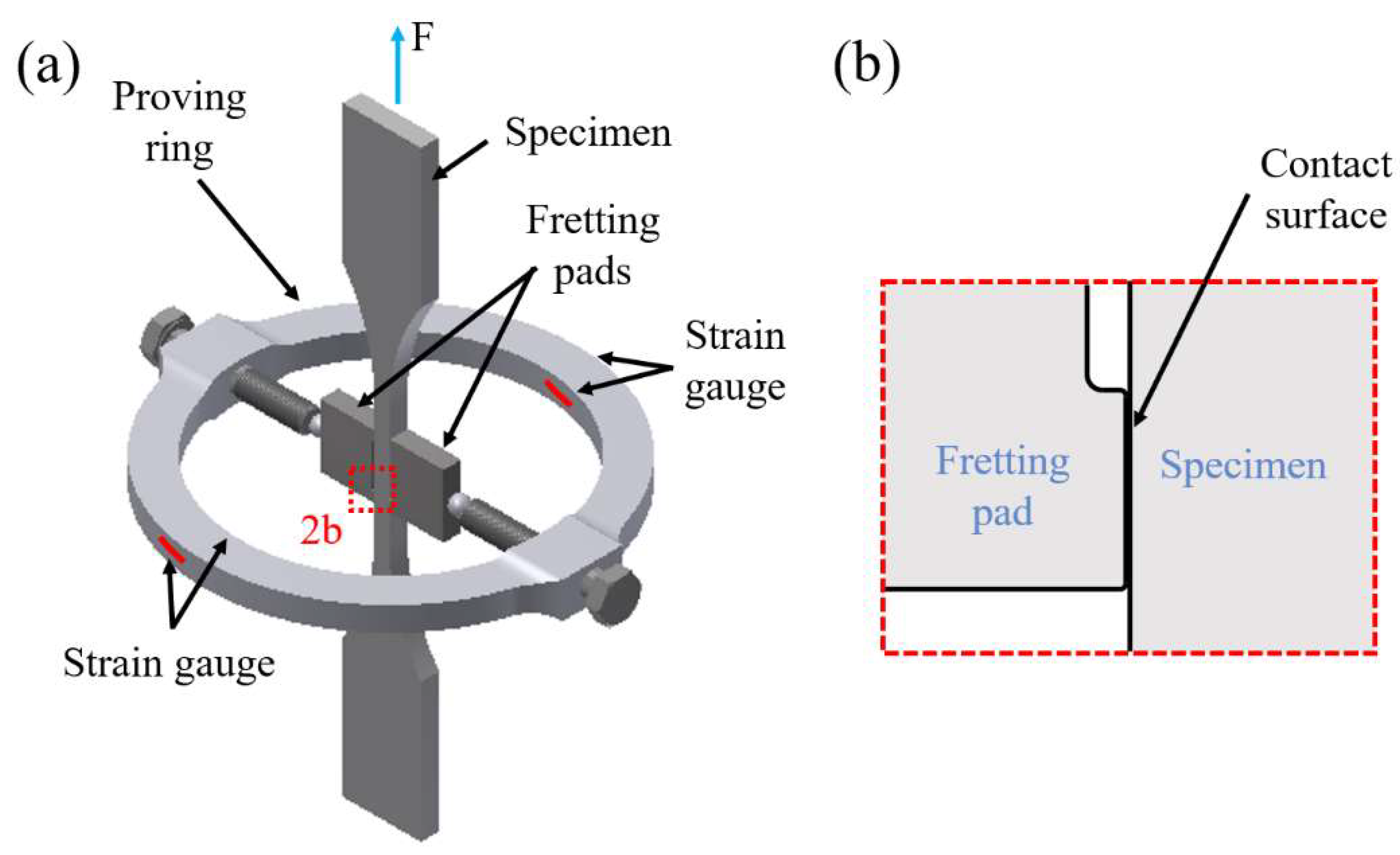

2.2. Fretting Fatigue Test

2.3. Digital Image Correlation (DIC)

3. Experimental Results

3.1. Fretting Scar

3.2. Tangential Force Coefficient

3.3. Displacement Field

3.4. Hysteresis Loops

4. Discussion and Analysis

4.1. Definition of Slip Value and Tangential Stiffness

4.2. Evolution of Relative Slip with the Cycle Number

4.3. Distribution of Relative Slip along the Contact Surface

4.4. Tangential Contact Stiffness

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Waterhouse, R.B. Fretting Fatigue; Elsevier Science & Technology: Amsterdam, The Netherlands, 1981. [Google Scholar]

- Nowell, D. An Analysis of Fretting Fatigue; University of Oxford: Oxford, UK, 1988. [Google Scholar]

- Hills, D.A. Mechanics of fretting fatigue. Wear 1994, 175, 107–113. [Google Scholar] [CrossRef]

- Foletti, S.; Beretta, S.; Gurer, G. Defect acceptability under full-scale fretting fatigue tests for railway axles. Int. J. Fatigue 2016, 86, 34–43. [Google Scholar] [CrossRef]

- Ekberg, A. Fretting fatigue of railway axles—A Review of predictive methods and an outline of a finite element model. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2004, 218, 299–316. [Google Scholar] [CrossRef]

- Moraes, J.; Rao, H.M.; Jordon, J.; Barkey, M. High cycle fatigue mechanisms of aluminum self-piercing riveted joints. Fatigue Fract. Eng. Mater. Struct. 2017, 41, 57–70. [Google Scholar] [CrossRef] [Green Version]

- Huang, L.; Bonnen, J.; Lasecki, J.; Guo, H.; Su, X. Fatigue and fretting of mixed metal self-piercing riveted joint. Int. J. Fatigue 2016, 83, 230–239. [Google Scholar] [CrossRef]

- Oskouei, R.; Ibrahim, R. Improving fretting fatigue behaviour of Al 7075-T6 bolted plates using electroless Ni–P coatings. Int. J. Fatigue 2012, 44, 157–167. [Google Scholar] [CrossRef]

- Peterka, P.; Krešák, J.; Kropuch, S.; Fedorko, G.; Molnar, V.; Vojtko, M. Failure analysis of hoisting steel wire rope. Eng. Fail. Anal. 2014, 45, 96–105. [Google Scholar] [CrossRef]

- Rajasekaran, R.; Nowell, D. Fretting fatigue in dovetail blade roots: Experiment and analysis. Tribol. Int. 2006, 39, 1277–1285. [Google Scholar] [CrossRef]

- Barella, S.; Boniardi, M.; Cincera, S.; Pellin, P.; Degive, X.; Gijbels, S. Failure analysis of a third stage gas turbine blade. Eng. Fail. Anal. 2011, 18, 386–393. [Google Scholar] [CrossRef]

- Su, Y.; Han, Q.N.; Qiu, W.; He, Z.; Shang, Y.B.; Shi, H.J.; Niu, L.S. High temperature in-situ SEM observation and crystal plasticity simulation on fretting fatigue of Ni-based single crystal superalloys. Int. J. Plast. 2019, 127, 102645. [Google Scholar] [CrossRef]

- Han, Q.; Rui, S.; Qiu, W.; Su, Y.; Ma, X.; He, Z.; Cui, H.; Zhang, H.; Shi, H. Subsurface crack formation and propagation of fretting fatigue in Ni-based single-crystal superalloys. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 2520–2532. [Google Scholar] [CrossRef]

- Zhou, Z.; Vincent, L. Mixed fretting regime. Wear 1995, 181–183, 531–536. [Google Scholar] [CrossRef]

- Pasanen, A.; Lehtovaara, A.; Rabb, R.; Riihimäki, P. Friction behavior of quenched and tempered steel in partial and gross slip conditions in fretting point contact. Wear 2009, 267, 2200–2207. [Google Scholar] [CrossRef]

- Sabelkin, V.; Mall, S. Investigation into relative slip during fretting fatigue under partial slip contact condition. Fatigue Fract. Eng. Mater. Struct. 2005, 28, 809–824. [Google Scholar] [CrossRef]

- Fouvry, S.; Kapsa, P.; Vincent, L. Quantification of fretting damage. Wear 1996, 200, 186–205. [Google Scholar] [CrossRef]

- Zhou, Z.; Nakazawa, K.; Zhu, M.; Maruyama, N.; Kapsa, P.; Vincent, L. Progress in fretting maps. Tribol. Int. 2006, 39, 1068–1073. [Google Scholar] [CrossRef]

- Han, Q.N.; Rui, S.S.; Qiu, W.; Ma, X.; Su, Y.; Cui, H.; Zhang, H.; Shi, H. Crystal orientation effect on fretting fatigue induced geometrically necessary dislocation distribution in Ni-based single-crystal superalloys. Acta Mater. 2019, 179, 129–141. [Google Scholar] [CrossRef]

- Vingsbo, O.; Söderberg, S. On fretting maps. Wear 1988, 126, 131–147. [Google Scholar] [CrossRef]

- Jin, O.; Mall, S. Effects of slip on fretting behavior: Experiments and analyses. Wear 2004, 256, 671–684. [Google Scholar] [CrossRef]

- Rengaraj, B.; Baba, S.; Okazaki, M. Influence of Crystal Orientation on Cyclic Sliding Friction and Fretting Fatigue Behavior of Single Crystal Ni-Base Superalloys. In Superalloys 2016: Proceedings of the 13th Intenational Symposium of Superalloys; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016. [Google Scholar]

- Su, Y.; Han, Q.N.; Zhang, C.C.; Shi, H.; Niu, L.S.; Deng, G.J.; Rui, S.S. Effects of secondary orientation and temperature on the fretting fatigue behaviors of Ni-based single crystal superalloys. Tribol. Int. 2018, 130, 9–18. [Google Scholar] [CrossRef]

- Cai, Z.B.; Zhu, M.H.; Yang, S.; Xiao, X.B.; Lin, X.Z.; Yu, H.Y. In situ observations of the real-time wear of PMMA flat against steel ball under torsional fretting. Wear 2011, 271, 2242–2251. [Google Scholar] [CrossRef]

- Han, Q.N.; Qiu, W.; He, Z.; Su, Y.; Ma, X.; Shi, H.J. The effect of crystal orientation on fretting fatigue crack formation in Ni-based single-crystal superalloys: In-situ SEM observation and crystal plasticity finite element simulation. Tribol. Int. 2018, 125, 209–219. [Google Scholar] [CrossRef]

- Wittkowsky, B.U.; Birch, P.R.; Dominguez, J.; Suresh, S. An apparatus for quantitative fretting fatigue testing. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 307–320. [Google Scholar] [CrossRef]

- Popov, V.L. Contact Mechanics and Friction; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Kartal, M.E.; Mulvihill, D.M.; Nowell, D.; Hills, D.A. Determination of the Frictional Properties of Titanium and Nickel Alloys Using the Digital Image Correlation Method. Exp. Mech. 2010, 51, 359–371. [Google Scholar] [CrossRef]

- Kartal, M.; Mulvihill, D.; Nowell, D.; Hills, D. Measurements of pressure and area dependent tangential contact stiffness between rough surfaces using digital image correlation. Tribol. Int. 2011, 44, 1188–1198. [Google Scholar] [CrossRef]

- De Pauw, J.; De Waele, W.; Hojjati-Talemi, R.; De Baets, P. On the use of digital image correlation for slip measurement during coupon scale fretting fatigue experiments. Int. J. Solids Struct. 2014, 51, 3058–3066. [Google Scholar] [CrossRef]

- Ding, J.; Bandak, G.; Leen, S.; Williams, E.; Shipway, P. Experimental characterisation and numerical simulation of contact evolution effect on fretting crack nucleation for Ti–6Al–4V. Tribol. Int. 2009, 42, 1651–1662. [Google Scholar] [CrossRef]

- Pan, B.; Qian, K.; Xie, H.; Asundi, A. Two-dimensional digital image correlation for in-plane displacement and strain measurement: A review. Meas. Sci. Technol. 2009, 20, 062001. [Google Scholar] [CrossRef]

- Blaber, J.; Adair, B.S.; Antoniou, A. Ncorr: Open-Source 2D Digital Image Correlation Matlab Software. Exp. Mech. 2015, 55, 1105–1122. [Google Scholar] [CrossRef]

- Juoksukangas, J.; Lehtovaara, A.; Mäntylä, A. Applying the digital image correlation method to fretting contact for slip measurement. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2016, 231, 509–519. [Google Scholar] [CrossRef]

- Juoksukangas, J.; Lehtovaara, A.; Mäntylä, A. A comparison of relative displacement fields between numerical predictions and experimental results in fretting contact. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2016, 230, 1273–1287. [Google Scholar] [CrossRef]

- De Crevoisier, J.; Swiergiel, N.; Champaney, L.; Hild, F. Identification of in situ frictional properties of bolted assemblies with digital image correlation. Exp. Mech. 2012, 52, 561–572. [Google Scholar] [CrossRef]

- Cuevas Arteaga, C.; Rodríguez, J.A.; Clemente, C.M.; Segura, J.A.; Urquiza, G.; Hamzaoui, Y.E. Estimation of useful life in turbines blades with cracks in corrosive environment. Eng. Fail. Anal. 2013, 35, 576–589. [Google Scholar] [CrossRef]

- ASTM. Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2016; Volume E8/E8M-162016. [Google Scholar]

- JSME. JSME Standard Method of Fretting Fatigue Testing; Japan Society Mechanical Engineers: Tokyo, Janpan, 2002; Volume JSME S 015-20022002. [Google Scholar]

- Nix, K.J.; Lindley, T.C. The Application of Fracture Mechanics to Fretting Fatigue. Fatigue Fract. Eng. Mater. Struct. 1985, 8, 143–160. [Google Scholar] [CrossRef]

- Pan, B. Recent Progress in Digital Image Correlation. Exp. Mech. 2010, 51, 1223–1235. [Google Scholar] [CrossRef]

- Chu, T.C.; Ranson, W.F.; Sutton, M.A. Applications of digital-image-correlation techniques to experimental mechanics. Exp. Mech. 1985, 25, 232–244. [Google Scholar] [CrossRef]

- Massingham, M.; Irving, P. The effect of variable amplitude loading on stress distribution within a cylindrical contact subjected to fretting fatigue. Tribol. Int. 2006, 39, 1084–1091. [Google Scholar] [CrossRef]

- Cortez, R. Investigation of variable amplitude loading on fretting fatigue behavior of Ti-6Al-4V. Int. J. Fatigue 1999, 21, 709–717. [Google Scholar] [CrossRef]

- Mubarak Ali, M.; Ganesh Sundara Raman, S.; Pathak, S.D.; Gnanamoorthy, R. Influence of plasma nitriding on fretting wear behaviour of Ti–6Al–4V. Tribol. Int. 2010, 43, 152–160. [Google Scholar] [CrossRef]

- Madge, J.; Leen, S.; McColl, I.; Shipway, P. Contact-evolution based prediction of fretting fatigue life: Effect of slip amplitude. Wear 2007, 262, 1159–1170. [Google Scholar] [CrossRef]

- Madge, J.; Leen, S.; Shipway, P. The critical role of fretting wear in the analysis of fretting fatigue. Wear 2007, 263, 542–551. [Google Scholar] [CrossRef]

- Allara, M. A model for the characterization of friction contacts in turbine blades. J. Sound Vib. 2008, 320, 527–544. [Google Scholar] [CrossRef]

| Young’s Modulus (GPa) | Proportionality Limit (MPa) | 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | Elongation (%) | Poisson’s Ratio |

|---|---|---|---|---|---|

| 212.31 | 438.29 | 539.52 | 715.44 | 28.78 | 0.26 |

| Stress Ratio | Frequency | Waveform | Cyclic Load Amplitude (Fa) | Average Normal Pressure |

|---|---|---|---|---|

| −1 | 20 Hz | Sine wave | 8.5, 7.3, 6.5 kN | 90 MPa |

| Camera Pixel | Field of View | Sampling Rate | Subset | Step |

|---|---|---|---|---|

| 5 megapixels (2448 × 2050) | 8.8 × 6.6 mm2 | 20 images/cycle | 101 × 101 pixels | 15 pixels |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, Y.; Rui, S.-S.; Han, Q.-N.; Shang, Z.-H.; Niu, L.-S.; Li, H.; Ishikawa, H.; Shi, H.-J. Estimation Method of Relative Slip in Fretting Fatigue Contact by Digital Image Correlation. Metals 2022, 12, 1124. https://doi.org/10.3390/met12071124

Su Y, Rui S-S, Han Q-N, Shang Z-H, Niu L-S, Li H, Ishikawa H, Shi H-J. Estimation Method of Relative Slip in Fretting Fatigue Contact by Digital Image Correlation. Metals. 2022; 12(7):1124. https://doi.org/10.3390/met12071124

Chicago/Turabian StyleSu, Yue, Shao-Shi Rui, Qi-Nan Han, Zhi-Hao Shang, Li-Sha Niu, Hao Li, Hiroshi Ishikawa, and Hui-Ji Shi. 2022. "Estimation Method of Relative Slip in Fretting Fatigue Contact by Digital Image Correlation" Metals 12, no. 7: 1124. https://doi.org/10.3390/met12071124

APA StyleSu, Y., Rui, S.-S., Han, Q.-N., Shang, Z.-H., Niu, L.-S., Li, H., Ishikawa, H., & Shi, H.-J. (2022). Estimation Method of Relative Slip in Fretting Fatigue Contact by Digital Image Correlation. Metals, 12(7), 1124. https://doi.org/10.3390/met12071124