Magnetostructural Transition and Magnetocaloric Effect with Negligible Magnetic Hysteresis in MnCoGe1.02?xGax Alloys

Abstract

:1. Introduction

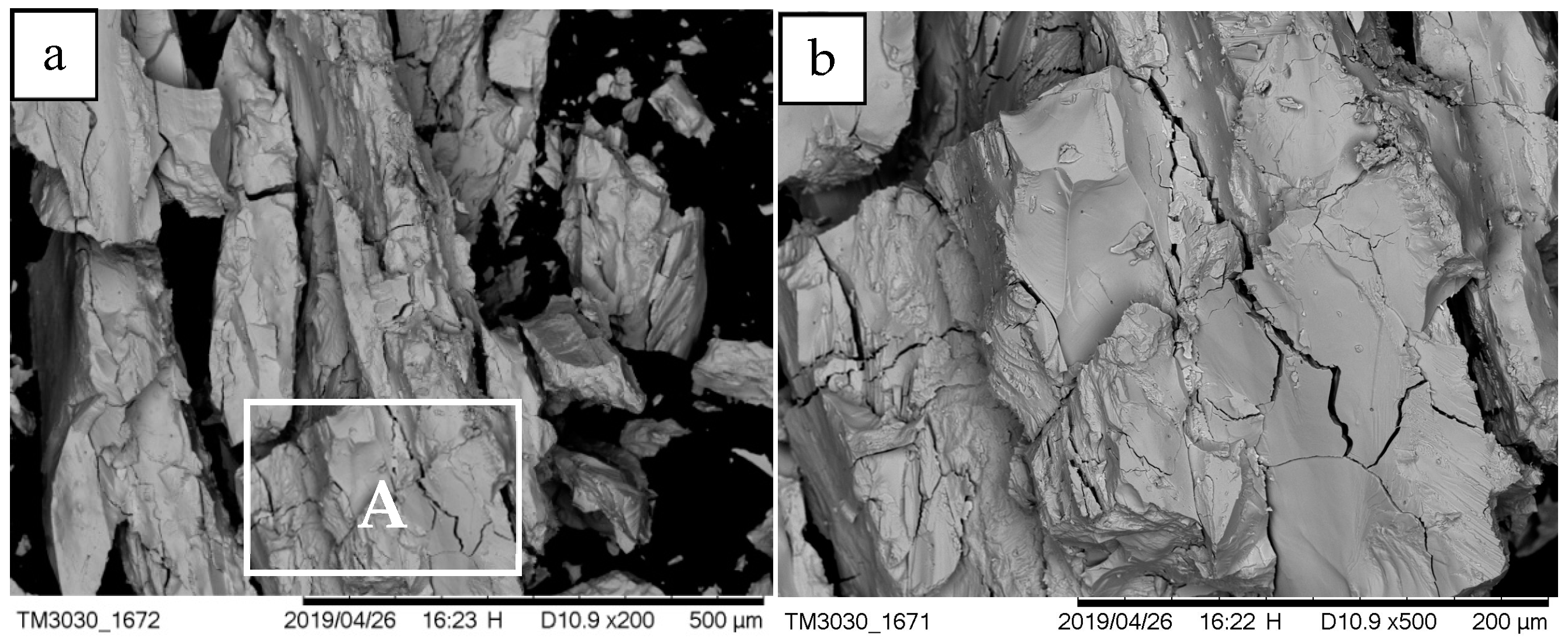

2. Experimental Section

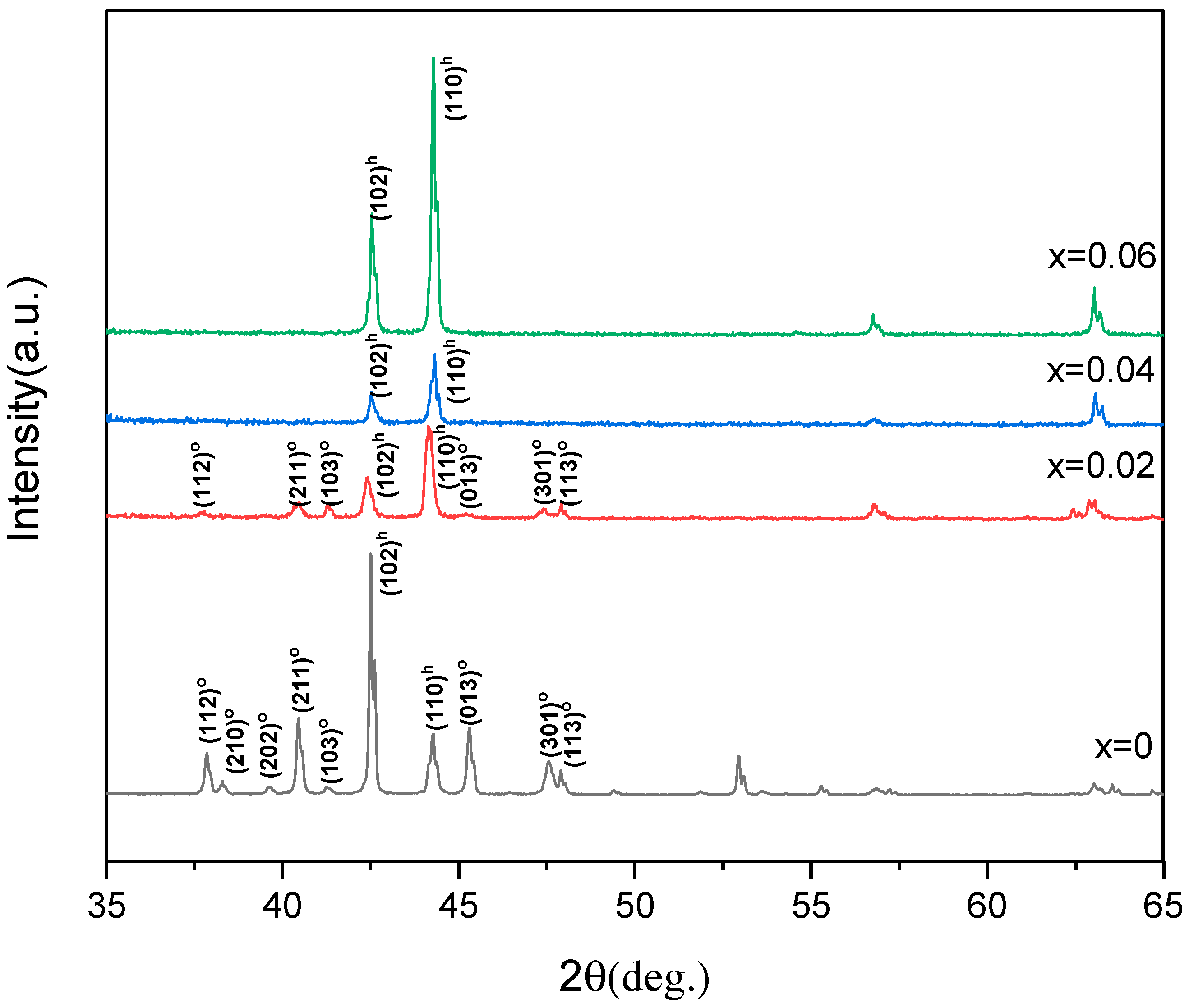

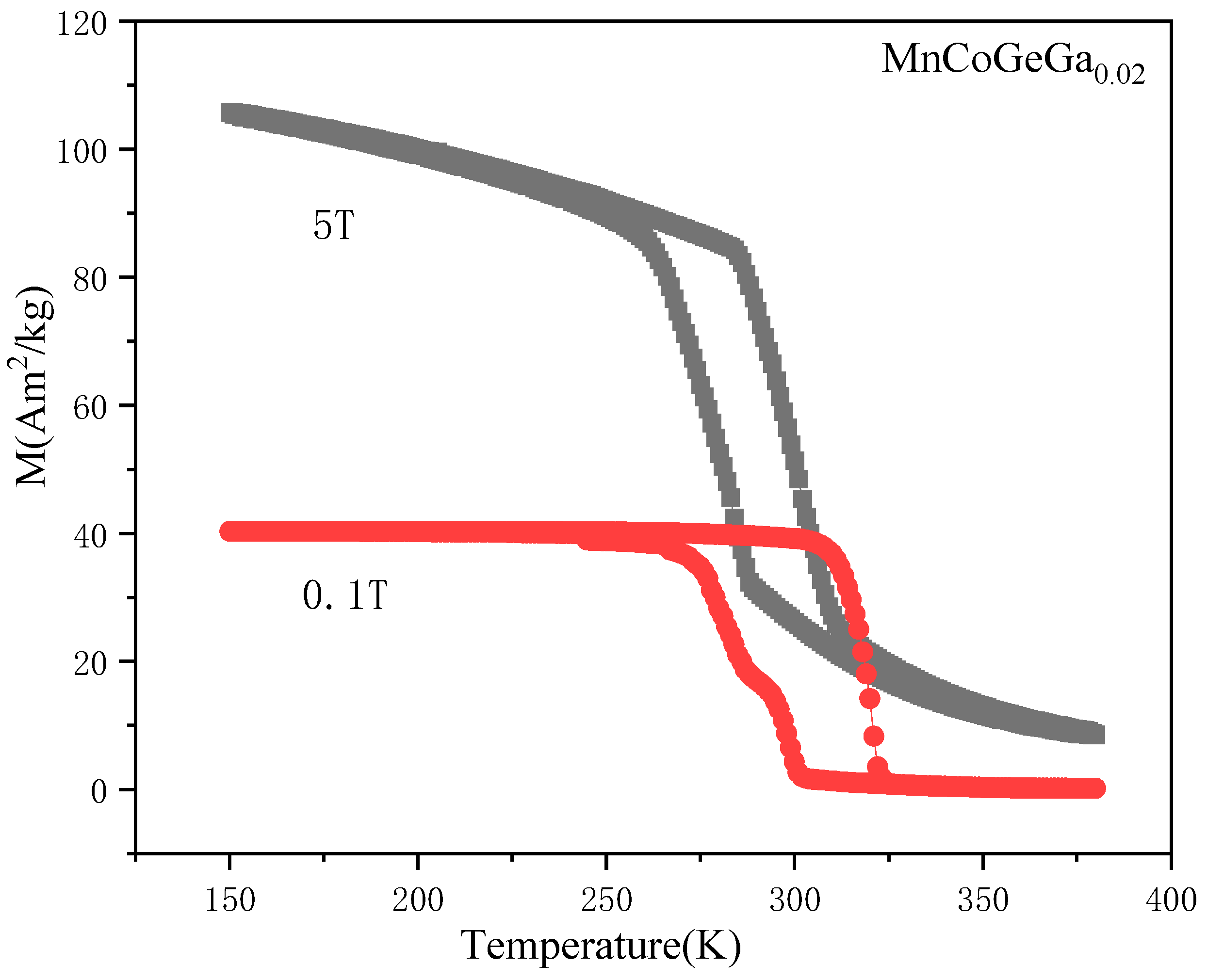

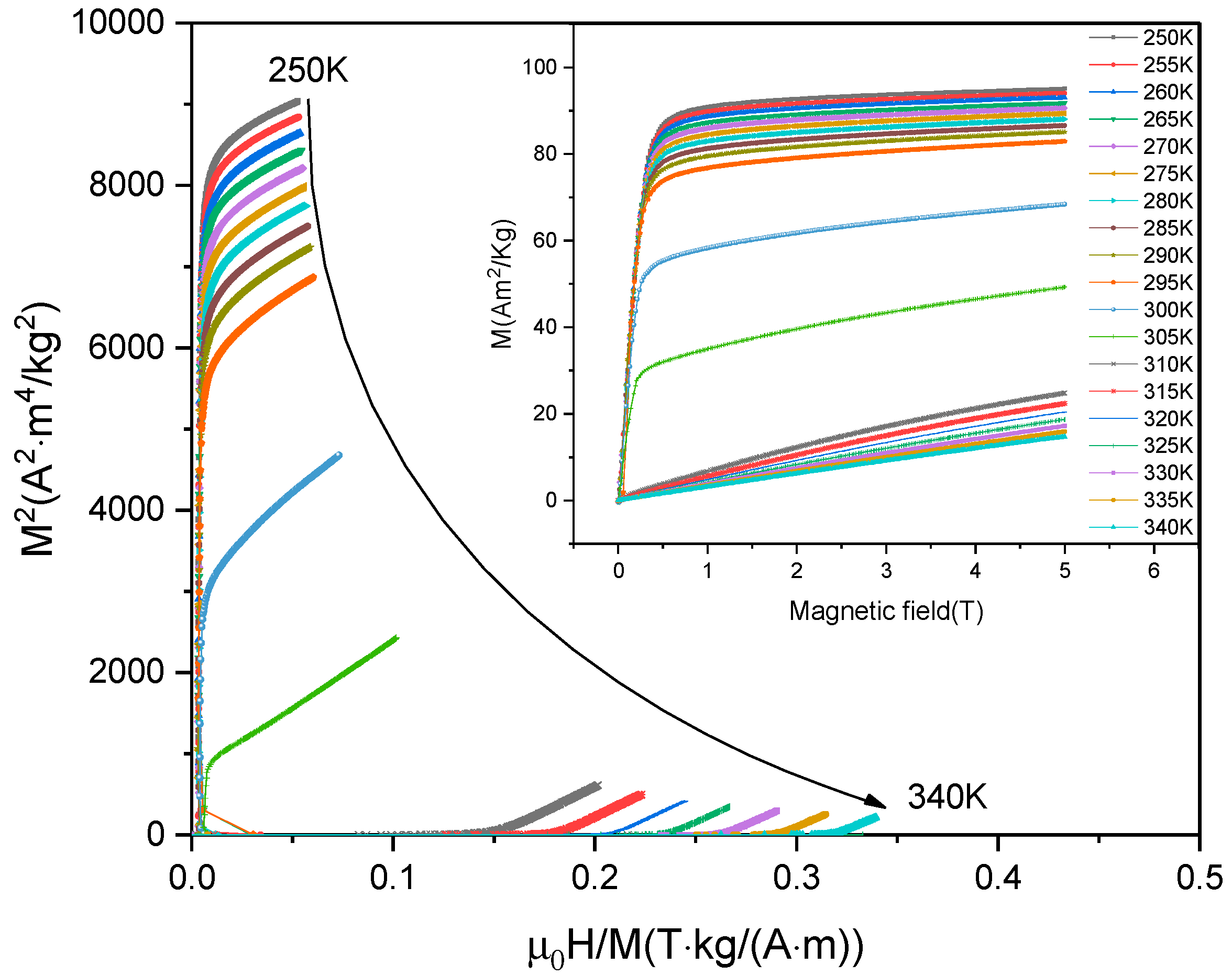

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Phan, M.H.; Yu, S.C. Review of the magnetocaloric effect in manganite materials. J. Magn. Magn. Mater. 2007, 308, 325–340. [Google Scholar] [CrossRef]

- Tegus, O.; Brück, E.; Buschow, K.H.J.; Boer, F.R.D. Transition-metal-based magnetic refrigerants for room-temperature applications. Nature 2002, 415, 150–152. [Google Scholar] [CrossRef]

- Franco, V.; Blázquez, J.S.; Ingale, B.; Conde, A. The Magnetocaloric Effect and Magnetic Refrigeration Near Room Temperature: Materials and Models. Annu. Rev. Mater. Res. 2012, 42, 305–342. [Google Scholar] [CrossRef] [Green Version]

- Provenzano, V.; Shapiro, A.J.; Shull, R.D. corrigendum: Reduction of hysteresis losses in the magnetic refrigerant Gd5Ge2Si2 by the addition of iron. Nature 2004, 429, 853–857. [Google Scholar] [CrossRef]

- Kanomate, T.; Ishigaki, H.; Suzuki, T.; Yoshida, H.; Abe, S.; Kaneko, T. Magneto-volume effect of MnCo1−xGe (0 ≤ x ≤ 0.2). J. Magn. Mater. 1995, 140, 131–132. [Google Scholar] [CrossRef]

- Wang, J.T.; Wang, D.S.; Chen, C.F.; Nashima, O.; Kanomate, T.; Mizuseki, H.; Kawazoe, Y. Vacancy induced structural and magnetic transition in MnCo1−xGe. Appl. Phys. Lett. 2006, 89, 262504. [Google Scholar] [CrossRef]

- Lin, S.; Tegus, O.; Bruck, E.; Dagula, W.; Gortenmulder, T.J.; Buschow, K.H.J. Structural and magnetic properties of MnFe1−xCoxGe compounds. IEEE Trans. Magn. 2006, 42, 3776–3778. [Google Scholar] [CrossRef]

- Hamer, J.B.A.; Daou, R.; Ozcan, S.; Mathur, N.D.; Fray, D.J.; Sandeman, K.G. Phase diagram and magnetocaloric effect of CoMnGe1−xSnx alloys. J. Magn. Mater. 2009, 321, 3535–3540. [Google Scholar] [CrossRef] [Green Version]

- Si, X.D.; Liu, Y.S.; Ma, X.X.; Lin, J.; Yang, J.; Zhou, T. The analysis of magnetic entropy change and long-range ferromagnetic order in Mn12−xAgxCoGe. J. Mater. Sci. 2019, 54, 3196–3210. [Google Scholar] [CrossRef]

- Zhang, C.L.; Nie, Y.G.; Shi, H.F.; Ye, E.J.; Han, Z.D.; Wang, D.H. Tuning magnetostructural transition and the associated giant magnetocaloric effect via thermal treatment in MnCoGe-based alloys. J. Magn. Magn. Mater. 2019, 469, 437–442. [Google Scholar] [CrossRef]

- Imam, H.; Zhang, H.G.; Pan, W.J.; Song, B.T.; Shi, J.H.; Yue, M. Magnetostructural transitions with a critical behavior in Y-doped MnCoGe compounds. Intermetallics 2019, 107, 53–59. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Y.W.; Liu, E.K.; Tao, K.; Wu, M.L.; Wang, Y.X.; Zhou, H.B.; Xue, Y.J.; Cheng, C.; Yan, T.; et al. Multiple magnetic transitions in MnCo1−xCuxGe driven by changes in atom separation and exchange interaction. Mater. Des. 2017, 114, 531–536. [Google Scholar] [CrossRef]

- Hassan, N.U.; Shah, I.A.; Liu, J.; Xu, G.Z.; Gong, Y.Y.; Miao, X.F.; Xu, F. Magnetostructural Coupling and Giant Magnetocaloric Effect in Off-Stoichiometric MnCoGe Alloys. J. Supercond. Nov. Magn. 2018, 31, 3809–3815. [Google Scholar] [CrossRef]

- Pal, S.K.; Frommen, C.; Kumar, S.; Hauback, B.C.; Fjellvåg, H.; Woodcock, T.G.; Nielsch, K.; Helgesen, G. Comparative phase transformation and magnetocaloric effect study of Co and Mn substitution by Cu in MnCoGe compounds. J. Alloys Compd. 2019, 775, 22–29. [Google Scholar] [CrossRef] [Green Version]

- Hassan, N.U.; Chen, F.H.; Zhang, M.G.; Shah, I.A.; Liu, J.; Gong, Y.Y.; Xu, G.Z.; Xu, F. Realisation of magnetostructural coupling and a large magnetocaloric effect in the MnCoGe1+x system. J. Magn. Magn. Mater. 2017, 439, 120–125. [Google Scholar] [CrossRef]

- Ma, S.C.; Zheng, Y.X.; Xuan, H.C.; Shen, L.J.; Cao, Q.Q.; Wang, D.H.; Zhong, Z.C.; Du, Y.W. Large roomtemperature magnetocaloric effect with negligible magnetic hysteresis losses in Mn1−xVxCoGe alloys. J. Magn. Magn. Mater. 2012, 324, 135–139. [Google Scholar] [CrossRef]

- Yildirim, O.; Tozkoparan, O.; Yuzuak, E.; Elerman, Y.; Dincer, I. Magnetocaloric Effect with Very Small Magnetic Hysteresis Losses of CoMn1−xTixGe Alloys. Metals. Mater Trans. A 2017, 48, 5733–5737. [Google Scholar] [CrossRef]

- Zhang, D.L.; Nie, Z.H.; Wang, Z.L.; Huang, L.; Zhang, Q.H.; Wang, Y.D. Giant magnetocaloric effect in MnCoGe with minimal Ga substitution. J. Magn. Magn. Mater. 2015, 387, 107–110. [Google Scholar] [CrossRef]

- Dincer, I.; Yüzüak, E.; Durak, G.; Elerman, Y.; Bell, A.M.T. Ehrenberg. Exploring the details of the martensitic phase transition and magnetocaloric effect of CoMnGe0.95Ga0.05 by synchrotron and magnetic measurements. J. Alloys Compd. 2012, 540, 236–240. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Wang, H.O.; Huo, D.X.; Tan, W.S. Room-temperature magnetoresistive and magnetocaloric effect in La1−xBaxMnO3 compounds: Role of Griffiths phase with ferromagnetic metal cluster above Curie temperature. J. Appl. Phys. 2022, 131, 043901. [Google Scholar] [CrossRef]

- Wang, H.O.; Zhang, H.; Wang, Y.; Tan, W.S.; Huo, D.X. Spin glass feature and exchange bias effect in metallic Pt/antiferromagnetic LaMnO3 heterostructure. J. Phys. Condens. Matter 2021, 33, 285802. [Google Scholar] [CrossRef]

- Liu, K.; Ma, S.C.; Zhang, L.; Huang, Y.L.; Hou, Y.H.; Zhang, G.Q.; Fan, W.B.; Wang, Y.L.; Wang, Y.; Cao, J.; et al. Tuning the magnetic transition and magnetocaloric effect in Mn1−xCrxCoGe alloy ribbons. J. Alloys Compd. 2017, 690, 663–668. [Google Scholar] [CrossRef]

- Sun, X.D.; Jing, C.; Ye, M.F.; Huang, Y.S.; Zhang, Y.L.; Zhang, G.J. The effect of Sb doping for Mn on structure, magnetic properties and magnetocaloric effect of Mn1−xSbxCoGe alloys. J. Mater. Sci. 2019, 30, 6100–6106. [Google Scholar] [CrossRef]

- Bao, L.F.; Wu, R.R.; Zhang, H. Influence of In-substitution for partial Ge on magneto-structural transition and magnetocaloric effect of MnCoGe alloy. Mater. Mech. Eng. 2016, 40, 67–76. [Google Scholar]

| x | a (Å) | b (Å) | c (Å) | Volume (Å3) |

|---|---|---|---|---|

| 0 | 5.95 | 3.82 | 7.04 | 160.21 |

| 0.02 | 4.10 | 4.10 | 5.32 | 77.47 |

| 0.04 | 4.08 | 4.08 | 5.31 | 76.55 |

| 0.06 | 4.09 | 4.09 | 5.31 | 76.93 |

| Materials | −ΔS (J/kg K) | RC (J/kg) | ΔH (T) | Ref. |

|---|---|---|---|---|

| Mn0.97Y0.03CoGe | 13.4 | 132.8 | 3 | [11] |

| Mn0.91Co1.09Ge | 30.8 | 256.87 | 5 | [13] |

| Mn0.17Co0.83Ge | 4.5 | 116.64 | 5 | [13] |

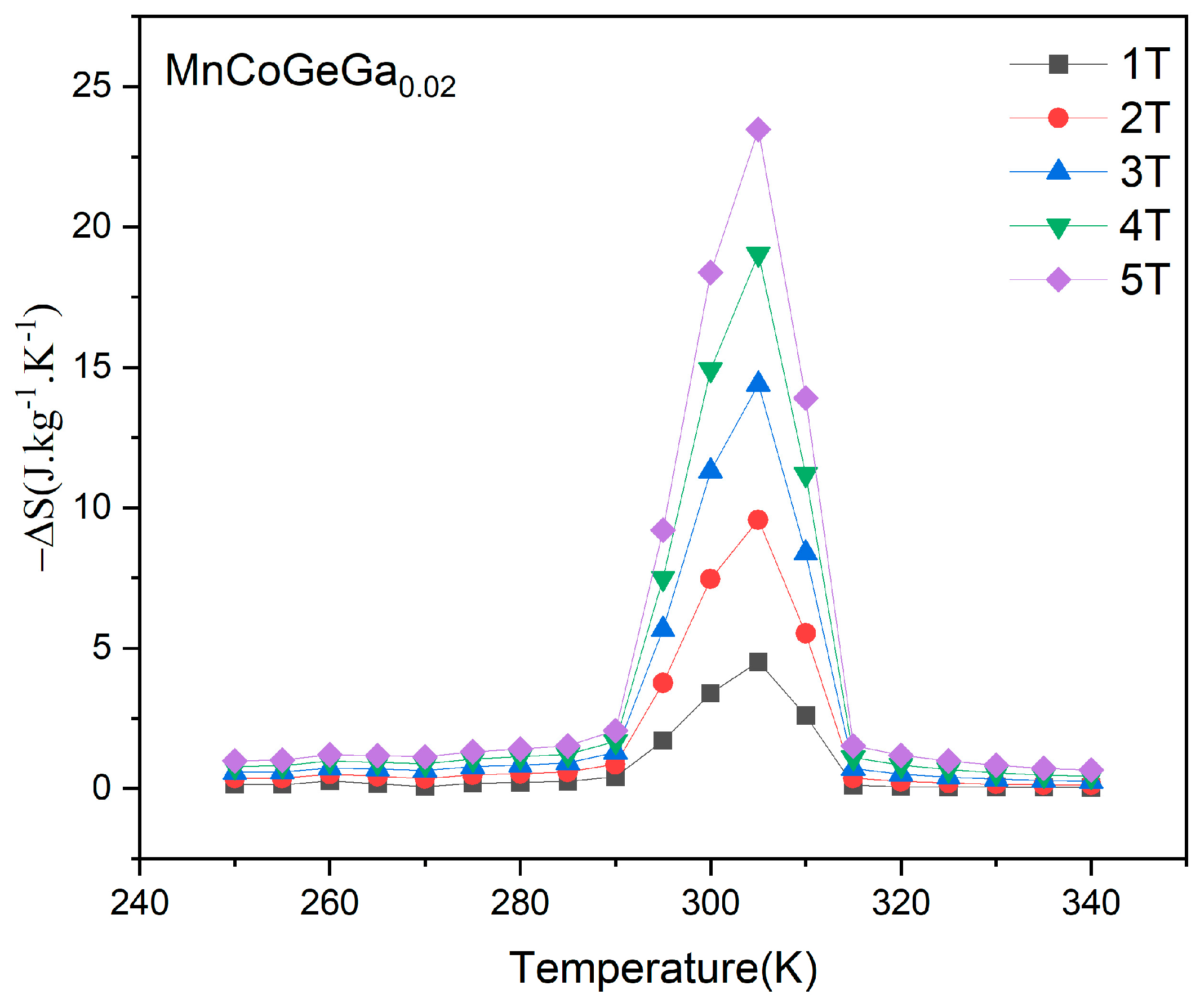

| MnCoGeGa0.02 | 23.47 | 387 | 5 | This work |

| Mn0.98V0.02CoGe | 9.5 | 53 | 1.2 | [16] |

| CoMnGe0.95Ga0.05 | 27.1 | 184 | 5 | [19] |

| Mn0.98Cr0.02CoGe | 13.1 | 76.8 | 2 | [22] |

| Mn0.99Sb0.01CoGe | 17.7 | 204 | 5 | [23] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, L.; Feng, Y.; Hu, S.; Xin, X. Magnetostructural Transition and Magnetocaloric Effect with Negligible Magnetic Hysteresis in MnCoGe1.02?xGax Alloys. Metals 2022, 12, 1143. https://doi.org/10.3390/met12071143

Gao L, Feng Y, Hu S, Xin X. Magnetostructural Transition and Magnetocaloric Effect with Negligible Magnetic Hysteresis in MnCoGe1.02?xGax Alloys. Metals. 2022; 12(7):1143. https://doi.org/10.3390/met12071143

Chicago/Turabian StyleGao, Li, Ying Feng, Shaohui Hu, and Xiangyang Xin. 2022. "Magnetostructural Transition and Magnetocaloric Effect with Negligible Magnetic Hysteresis in MnCoGe1.02?xGax Alloys" Metals 12, no. 7: 1143. https://doi.org/10.3390/met12071143

APA StyleGao, L., Feng, Y., Hu, S., & Xin, X. (2022). Magnetostructural Transition and Magnetocaloric Effect with Negligible Magnetic Hysteresis in MnCoGe1.02?xGax Alloys. Metals, 12(7), 1143. https://doi.org/10.3390/met12071143