Alloying Effects on the Stability of D022 γ”-Ni3M (M: Nb, Ta, V) Precipitates at Elevated Temperatures in Alloy 718 Type Ni-Based Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

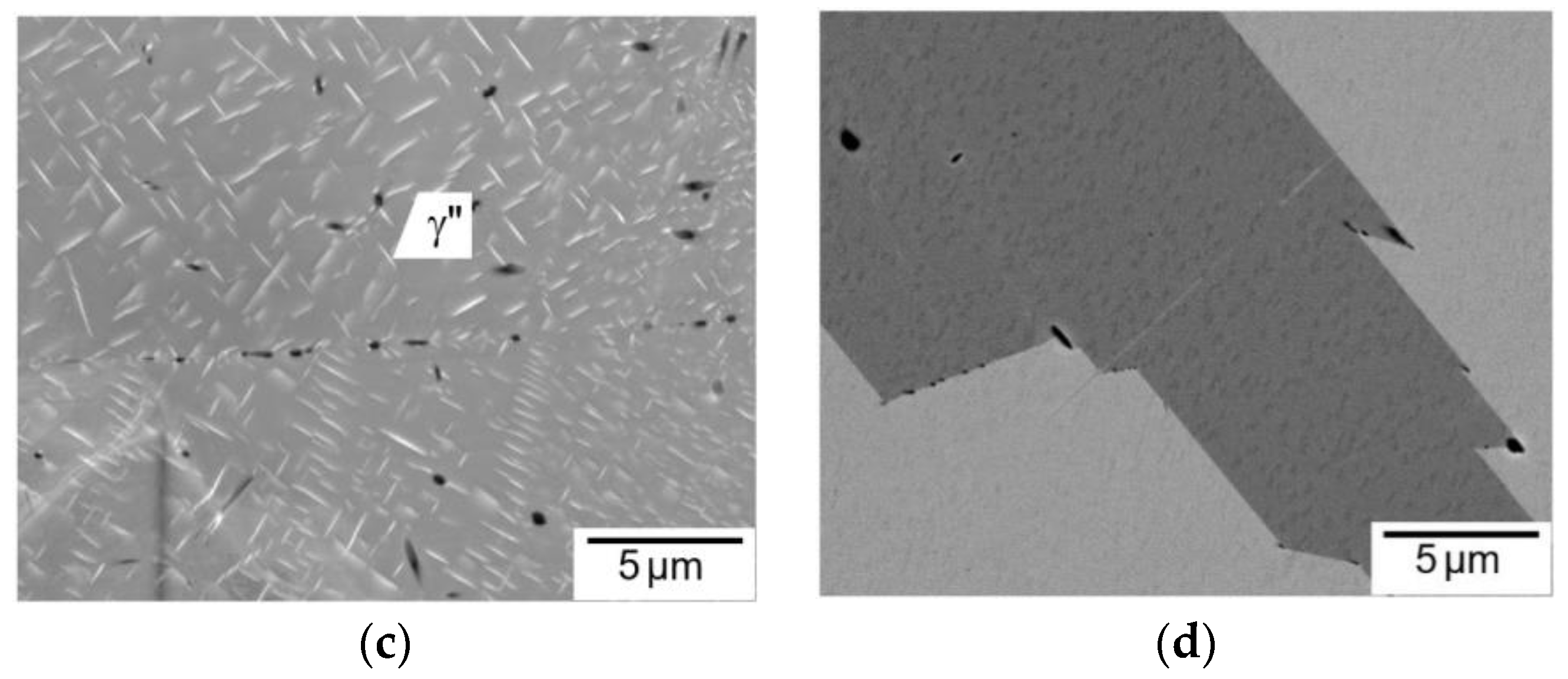

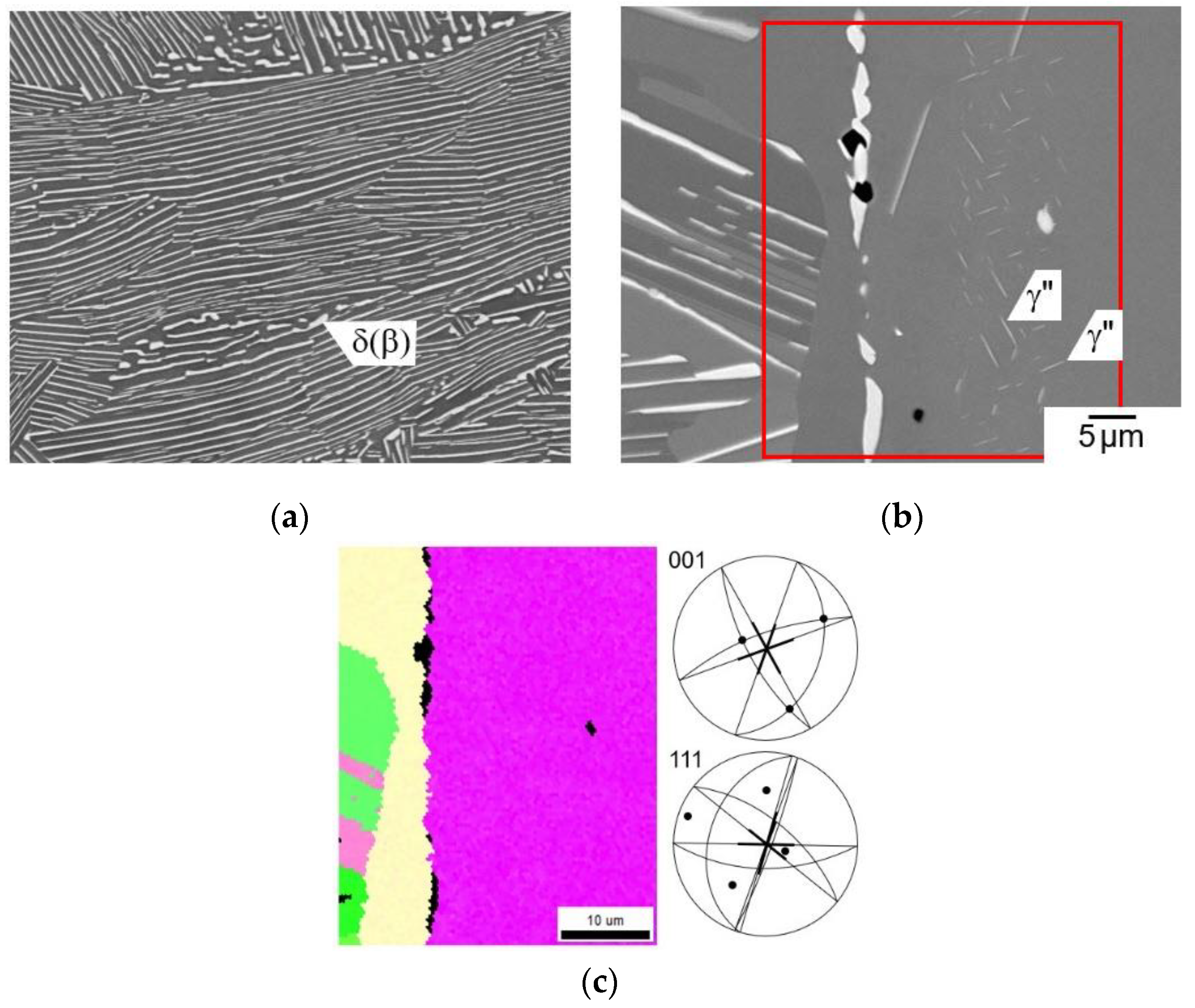

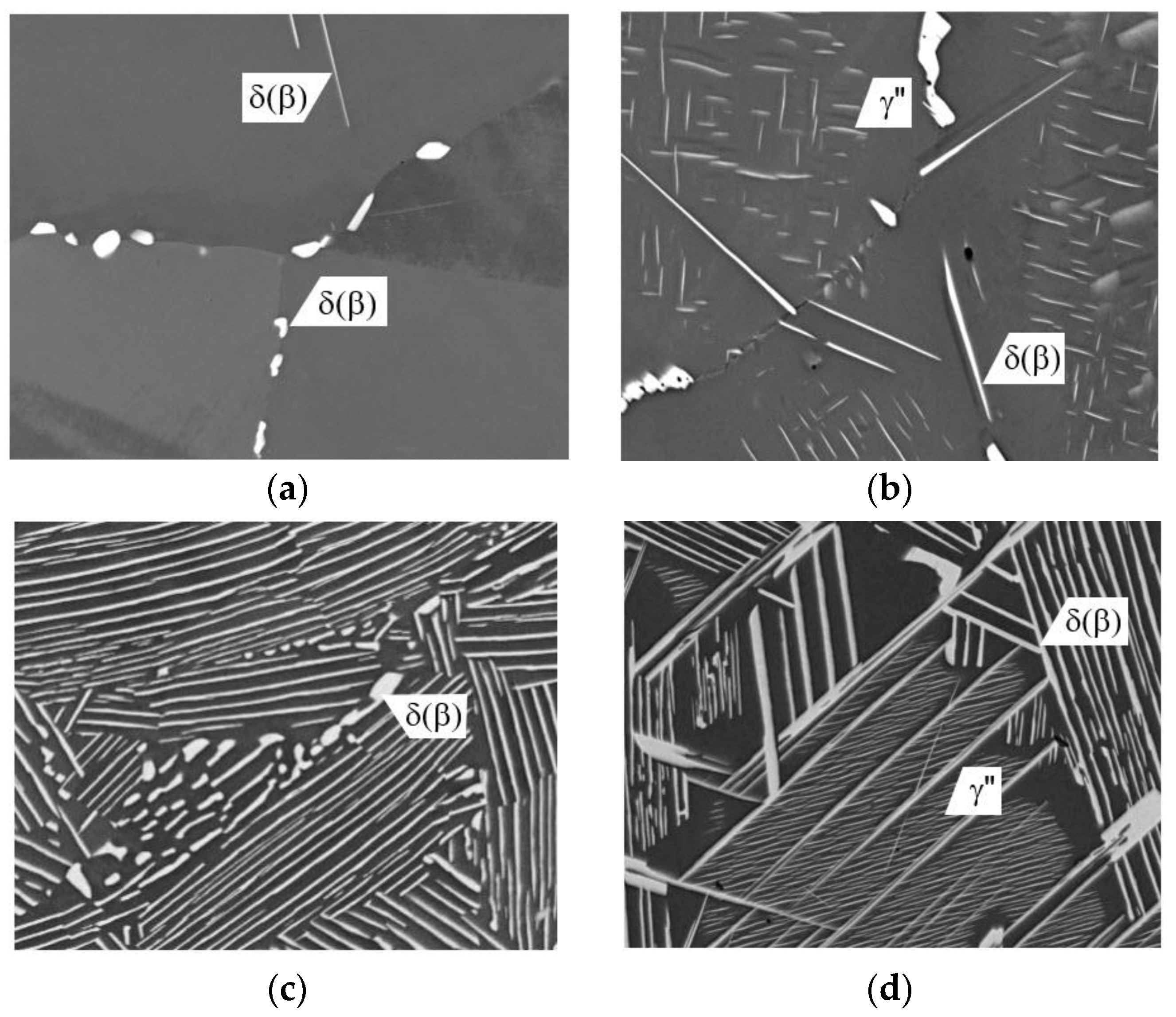

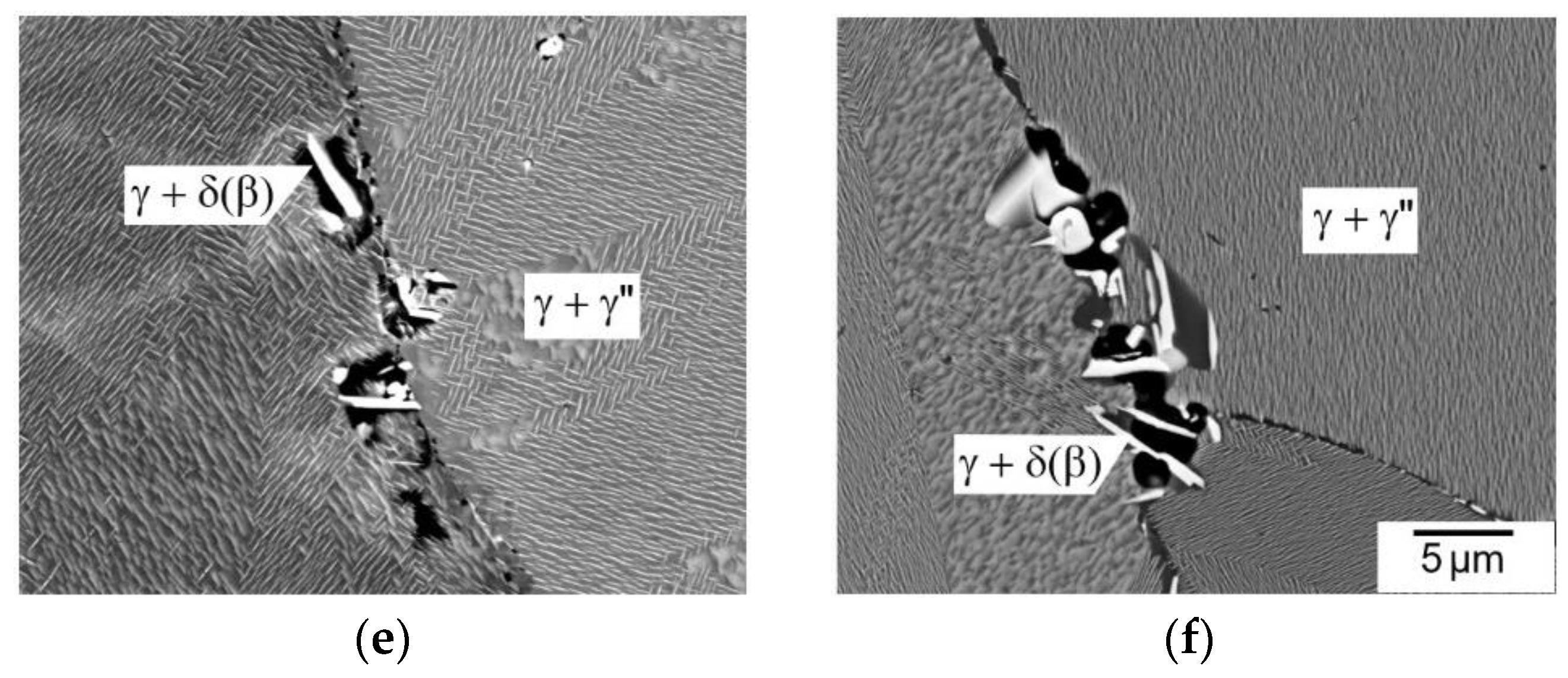

3.1. Microstructures of Diffusion Multiples

3.2. Microstructures of Bulk Alloy Samples

3.3. Chemical Driving Force Consideration

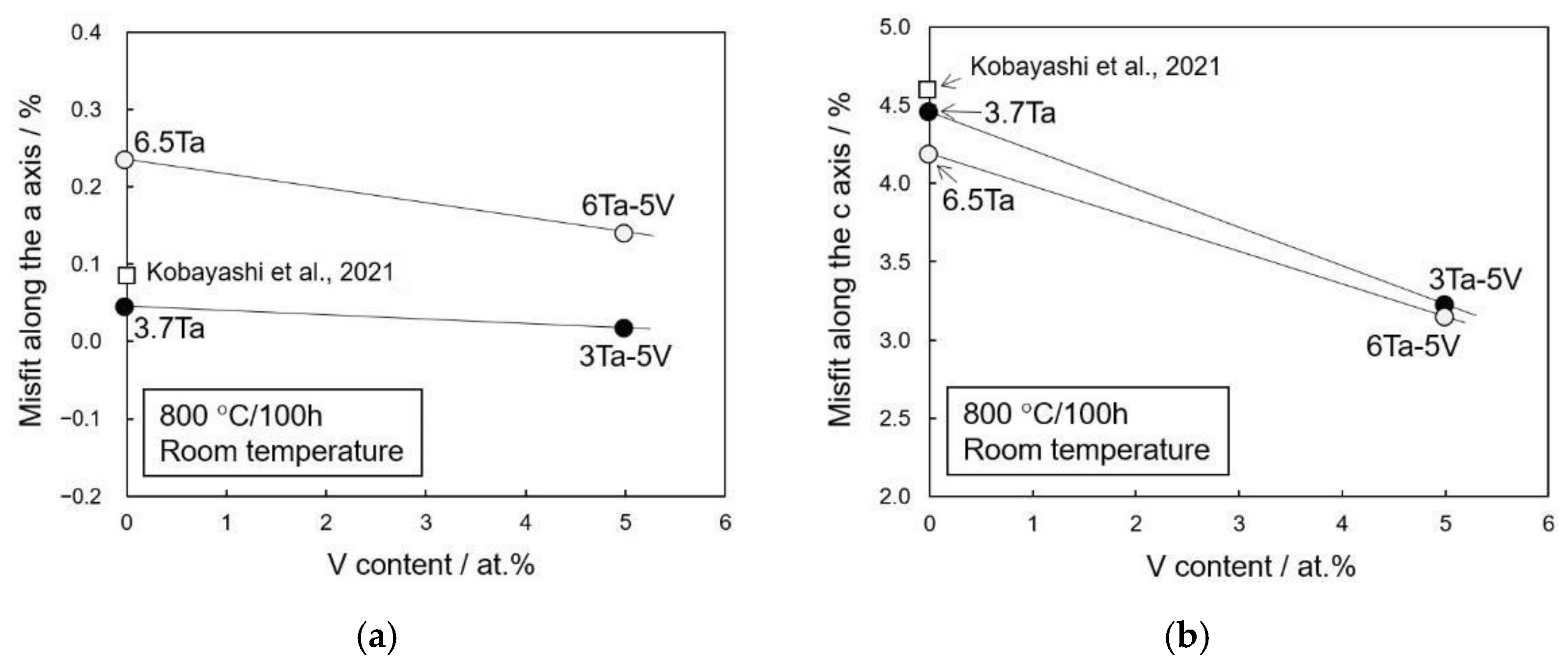

3.4. Misfit Strain Energy Consideration

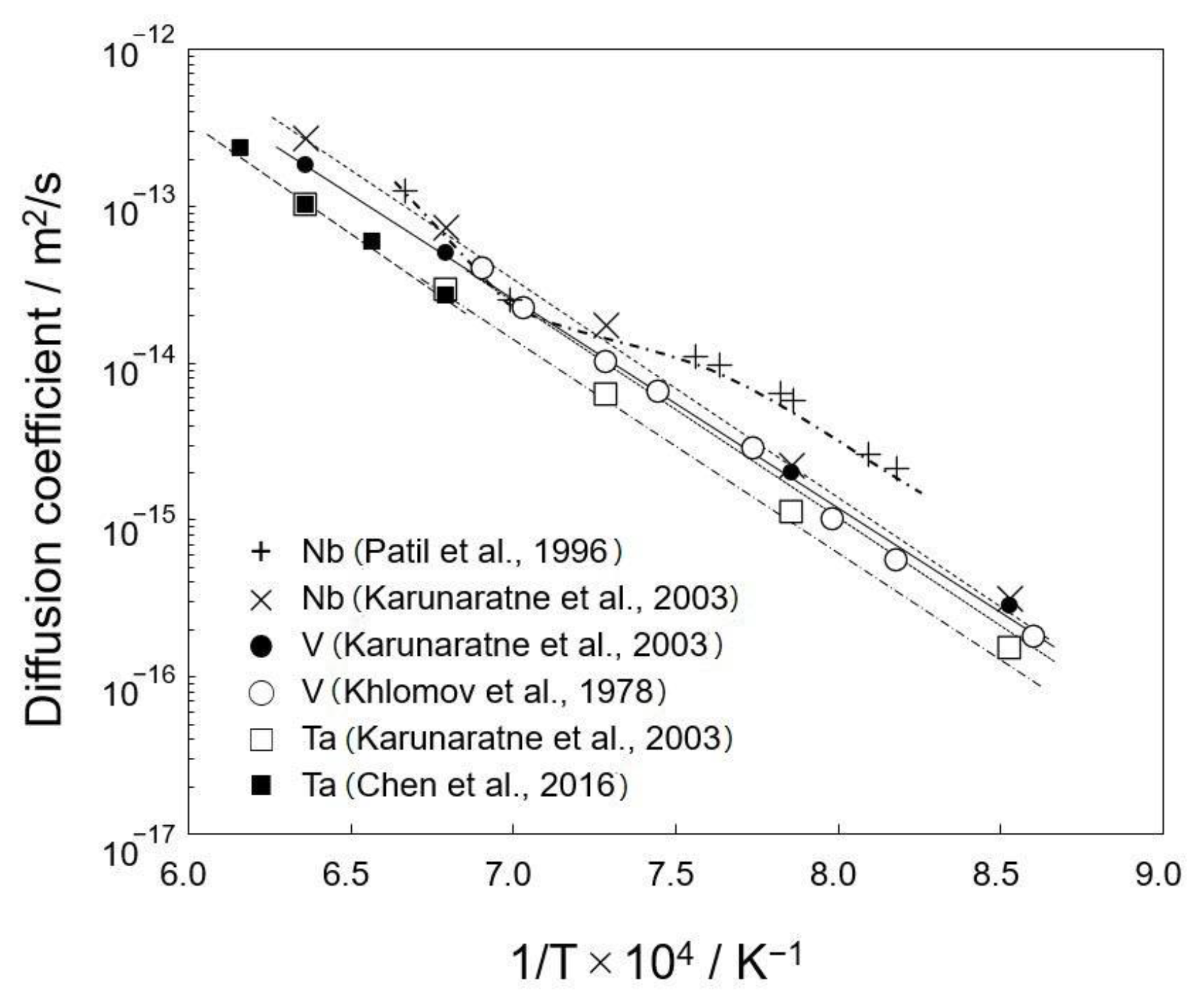

3.5. Diffusion Kinetics Consideration

4. Conclusions

- The microstructural characterization indicated that a complete replacement of Nb with Ta stabilized the γ” precipitates at temperatures up to 800 °C.

- A partial replacement of Ta with V was found to stabilize the precipitates even at 900 °C.

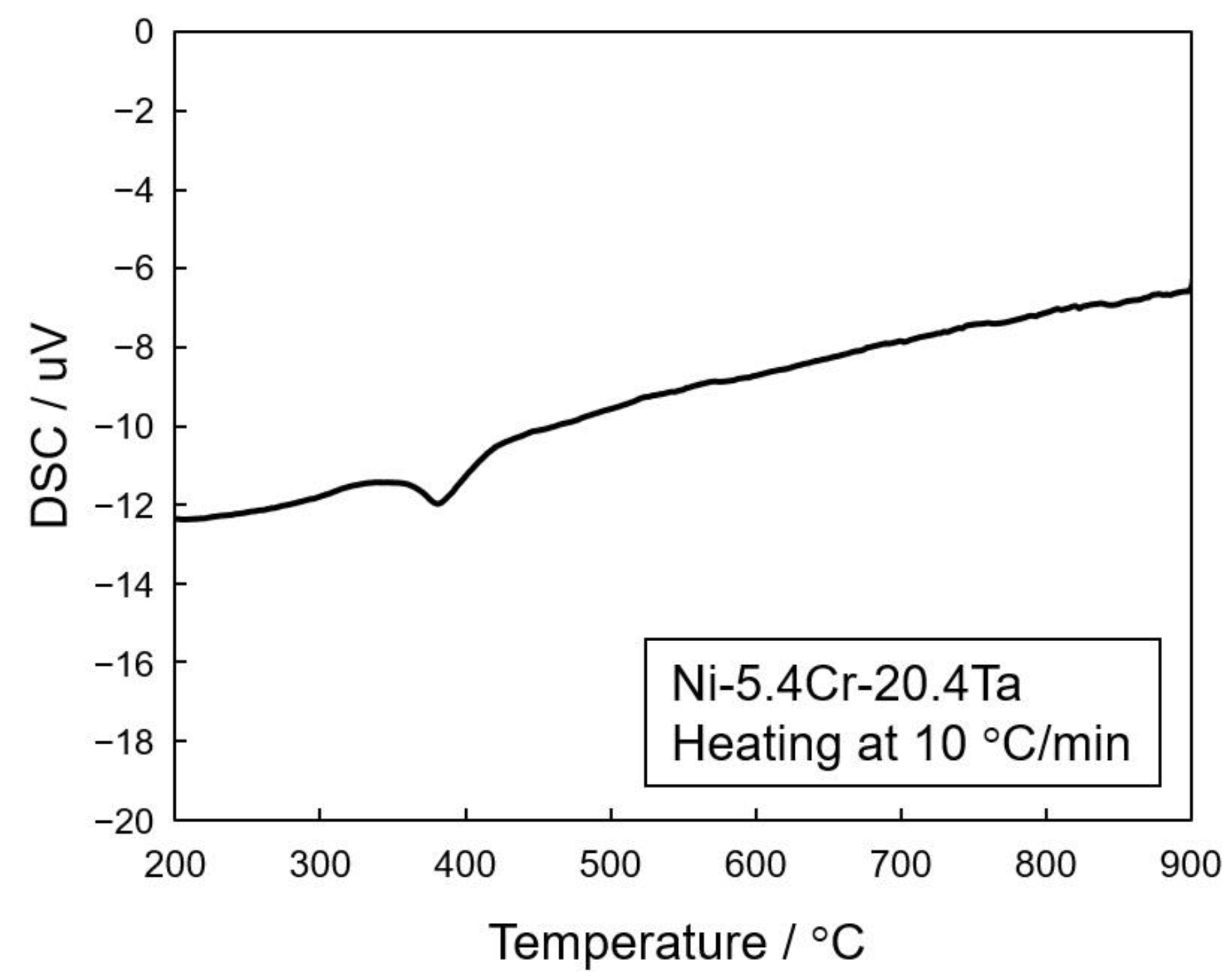

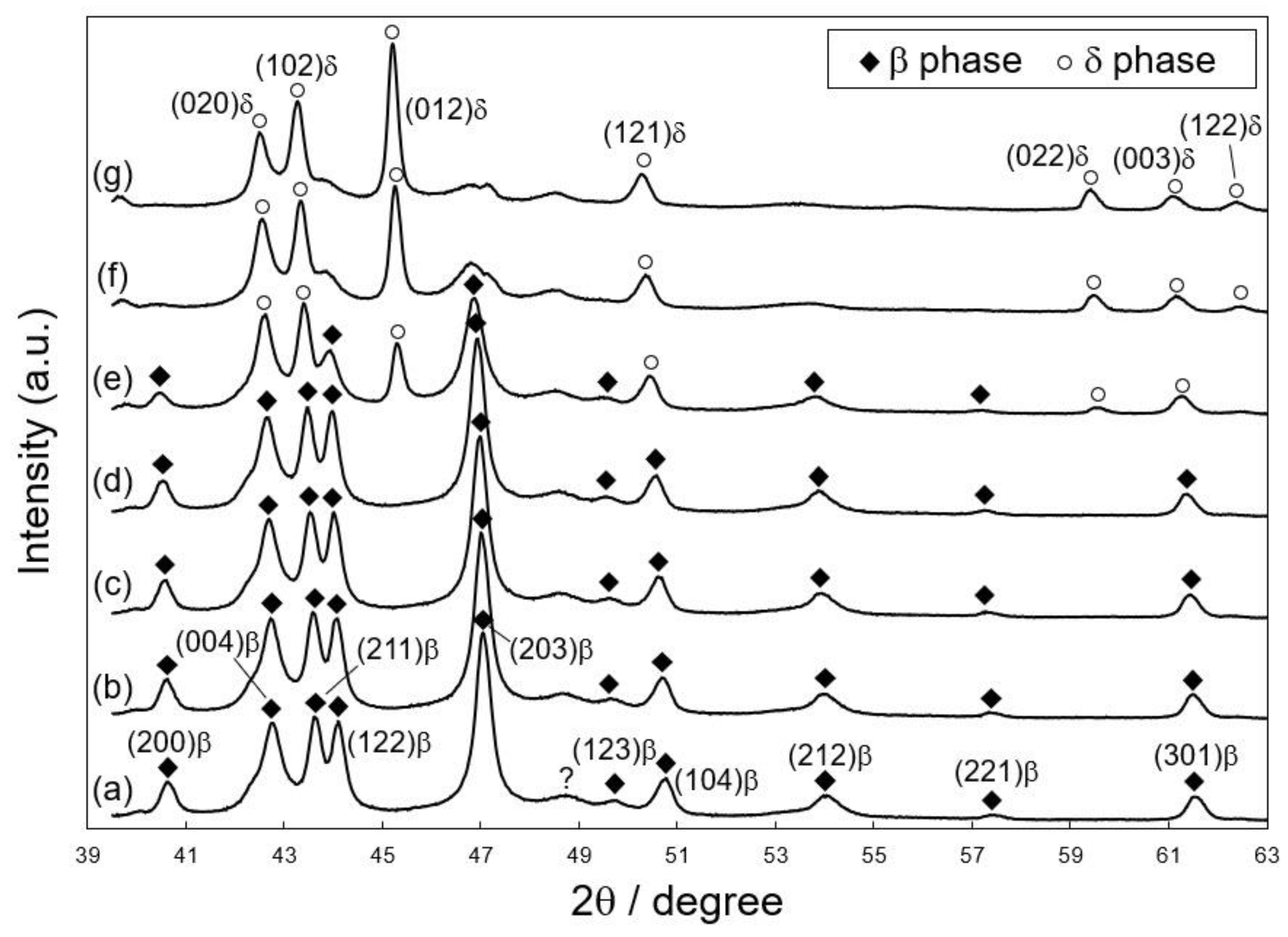

- Differential scanning calorimetry and high-temperature X-ray diffraction experiments demonstrated that the D0a structure, instead of the D022 structure, was stable at elevated temperatures in the Ni-Cr-Ta ternary system.

- Lattice parameter measurements suggested that the partial replacement of Ta with V drastically decreased the lattice misfit between the fcc γ matrix and the γ” precipitate along the two axes of the tetragonal γ” structure.

- A consideration of the chemical driving force, misfit strain, and diffusion kinetics viewpoints may qualitatively suggest that either of the former two factors or both could be important factors for the stability of γ” precipitates at elevated temperatures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- INCONEL® Alloy 718, SPECIAL METALS. Available online: www.specialmetals.com (accessed on 18 June 2022).

- Stoloff, N.S. Metals Handbook; ASM International: Materials Park, OH, USA, 1990; Volume 1, 950p. [Google Scholar]

- Sundraraman, M.; Mukhopadhyay, P.; Banerjee, S. Some aspects of the precipitation of metastable intermetallic phases in Inconel 718. Metall. Trans. A 1988, 19, 453–465. [Google Scholar] [CrossRef]

- Slama, C.; Abdellaoui, M. Structural characterization of the aged Inconel 718. J. Alloys Compd. 2004, 306, 277–284. [Google Scholar] [CrossRef]

- Kennedy, R.L. Allvac® 718plusTM, Superalloy for the Next Forty Years. In Superalloys 718, 625, 706 and Various Derivatives; TMS: Warrendale, PA, USA, 2005; pp. 1–14. 718p. [Google Scholar]

- Collier, J.P.; Song, H.W.; Phillips, J.C.; Tien, J.K. The effect of varying Al, Ti, and Nb content on the phase-stability of Inconel-718. Metall. Trans. 1988, 19, 1657–1666. [Google Scholar] [CrossRef]

- Mignanelli, P.M.; Jones, N.G.; Pickering, E.J.; Messé, O.M.D.M.; Rae, C.M.F.; Hardy, M.C.; Stone, H.J. Gamma-gamma prime-gamma double prime dual-superlattice superalloys. Scr. Mater. 2017, 136, 136–140. [Google Scholar] [CrossRef]

- Loewenkamp, S.A.; Radavich, J.F. Microstructure and properties of Ni-Fe base Ta-718. In Superalloys 1988, Proceedings of the Sixth International Symposium, Champion, PA, USA, 18–22 September 1988; U.S. Department of Energy: Oak Ridge, TN, USA, 1988; pp. 53–61. [Google Scholar]

- Nash, P.; Nash, A. Phase Diagrams of Binary Nickel Alloys; ASM International, The Materials Information Society: Materials Park, OH, USA, 1993. [Google Scholar]

- Firstov, G.S.; Koval, Y.N.; Humbeeck, J.V.; Ochin, P. Martensitic transformation and shape memory effect in Ni3Ta: A novel high-temperature shape memory alloy. Mater. Sci. Eng. A 2008, 481–482, 590–593. [Google Scholar] [CrossRef]

- Cozar, R.; Pineau, A. Morphology of γ’ and γ” precipitates and thermal stability of Inconel 718 type alloys. Metall. Trans. A 1973, 4, 47–59. [Google Scholar] [CrossRef]

- Kirman, I. Precipitation in the Fe-Ni-Cr-Nb System. J. Iron Steel Inst. 1969, 207, 1612–1618. [Google Scholar]

- Williams, D.B.; Butler, E.P. Grain boundary discontinuous precipitation reactions. Int. Met. Rev. 1981, 3, 153–183. [Google Scholar]

- Kobayashi, S.; Otsuka, T.; Watanabe, R.; Sagitani, K.; Okamoto, M.; Tokutomi, K. Alloying Effects on the Competition between Discontinuous Precipitation vs. Continuous Precipitation of δ/η Phases in Model Ni Based Superalloys. In Superalloys 2020, Proceedings of the 14th International Symposium on Superalloys, Online, 13–16 September 2021; Tin, S., Hardy, M., Clews, J., Cormier, J., Feng, Q., Marcin, J., O’Brien, C., Suzuki, A., Eds.; TMS: Warrendale, PA, USA, 2021; pp. 163–170. [Google Scholar]

- Villars, P. Pearson’s Handbook Desk Edition Crystallographic Data for Intermetallic Phases; ASM International, The Materials Information Society: Materials Park, OH, USA, 1997; Volume 2, p. 2555. [Google Scholar]

- Kobayashi, S.; Zaefferer, S. Determination of Phase Equilibria in the Fe3Al-Cr-Mo-C Semi-quaternary System Using a New Diffusion-multiple Technique. J. Alloys Compd. 2008, 452, 67–72. [Google Scholar] [CrossRef]

- Kobayashi, S.; Tsukamoto, Y.; Takasugi, T.; Chinen, H.; Omori, T.; Ishida, K.; Zaefferer, S. Determination of Phase Equilibria in the Co-rich Co–Al–W Ternary System with a Diffusion-Couple Technique. Intermetalics 2009, 17, 1085–1089. [Google Scholar] [CrossRef]

- Kobayashi, S.; Takasugi, T. Mapping of 475 °C embrittlement in ferritic Fe-Cr-Al alloys. Scripta Mater. 2010, 63, 1104–1107. [Google Scholar] [CrossRef]

- Kobayashi, S.; Kimura, K.; Tsuzaki, K. Interphase precipitation of Fe2Hf Laves phase in a Fe-9Cr/Fe-9Cr-Hf diffusion couple. Intermetallics 2014, 46, 80–84. [Google Scholar] [CrossRef]

- Zhou, S.H.; Wang, Y.; Chen, L.Q.; Liu, Z.K.; Napolitano, R.E. Solution-based thermodynamic modeling of the Ni-Ta and Ni-Mo-Ta systems using first principles calculations. CALPHAD 2009, 33, 631–641. [Google Scholar] [CrossRef]

- Zhou, Y.; Wen, B.; Ma, Y.; Melnik, R.; Liu, X. First-principles studies of Ni-Ta intermetallic compounds. J. Solid State Chem. 2012, 187, 211–218. [Google Scholar] [CrossRef]

- Materials Project. Available online: https://materialsproject.org (accessed on 18 June 2022).

- Cullity, B.D. Elements of X-ray Diffraction, 2nd ed.; Agune: Tokyo, Japan, 1979; 332p. (In Japanese) [Google Scholar]

- Patil, R.V.; Kale, G.B. Chemical diffusion of niobium in nickel. J. Nucl. Mater. 1996, 230, 57–60. [Google Scholar] [CrossRef]

- Karunaratne, M.S.A.; Reed, R.C. Interdiffusion of the platinum-group metals in nickel at elevated temperatures. Acta Mater. 2003, 51, 2905–2919. [Google Scholar] [CrossRef]

- Khlomov, V.S.; Pimenov, V.N.; Ugaste, Y.E.; Gurov, K.P. Investigation of mutual diffusion in the system Nickel-Vanadium. Phys. Met. Metallogr. 1978, 46, 188–191. [Google Scholar]

- Chen, J.; Xiao, J.; Zhang, L.; Du, Y. Interdiffusion in fcc Ni-X (X = Rh, Ta, W, Re and Ir) alloys. J. Alloys Compd. 2016, 657, 457–463. [Google Scholar] [CrossRef]

| Sample | Alloy | Alloy Composition (at.%) | ||||

|---|---|---|---|---|---|---|

| Type | Designation | Nb | Ta | V | Cr | Ni |

| DM | 5.5Nb | 5.5 | - | - | 22.0 | Bal. |

| DM | 6.5Ta | - | 6.5 | - | 22.0 | Bal. |

| DM | 10V | - | - | 10.0 | 22.0 | Bal. |

| B | 3.7Ta | - | 3.7 | - | 24.7 | Bal. |

| B | 3Ta-5V | - | 3.0 | 5.0 | 22.0 | Bal. |

| B | 6Ta-5V | - | 6.0 | 5.0 | 22.0 | Bal. |

| B | 20.4Ta | - | 20.4 | - | 5.4 | Bal. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tokutomi, K.; Sagitani, K.; Kobayashi, S. Alloying Effects on the Stability of D022 γ”-Ni3M (M: Nb, Ta, V) Precipitates at Elevated Temperatures in Alloy 718 Type Ni-Based Alloys. Metals 2022, 12, 1251. https://doi.org/10.3390/met12081251

Tokutomi K, Sagitani K, Kobayashi S. Alloying Effects on the Stability of D022 γ”-Ni3M (M: Nb, Ta, V) Precipitates at Elevated Temperatures in Alloy 718 Type Ni-Based Alloys. Metals. 2022; 12(8):1251. https://doi.org/10.3390/met12081251

Chicago/Turabian StyleTokutomi, Kako, Kyosuke Sagitani, and Satoru Kobayashi. 2022. "Alloying Effects on the Stability of D022 γ”-Ni3M (M: Nb, Ta, V) Precipitates at Elevated Temperatures in Alloy 718 Type Ni-Based Alloys" Metals 12, no. 8: 1251. https://doi.org/10.3390/met12081251

APA StyleTokutomi, K., Sagitani, K., & Kobayashi, S. (2022). Alloying Effects on the Stability of D022 γ”-Ni3M (M: Nb, Ta, V) Precipitates at Elevated Temperatures in Alloy 718 Type Ni-Based Alloys. Metals, 12(8), 1251. https://doi.org/10.3390/met12081251