Problems in Welding of High Nitrogen Steel: A Review

Abstract

:1. Introduction

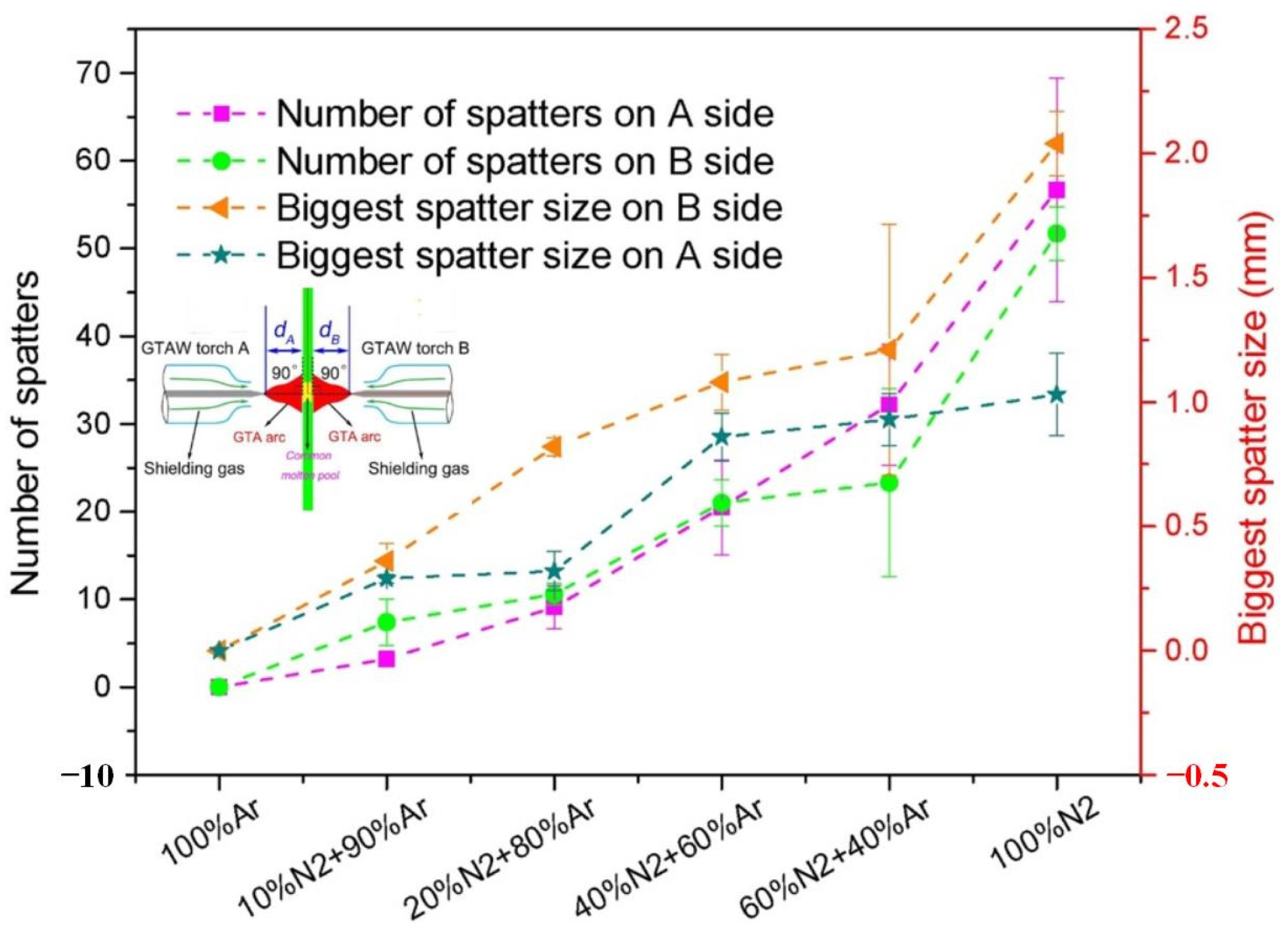

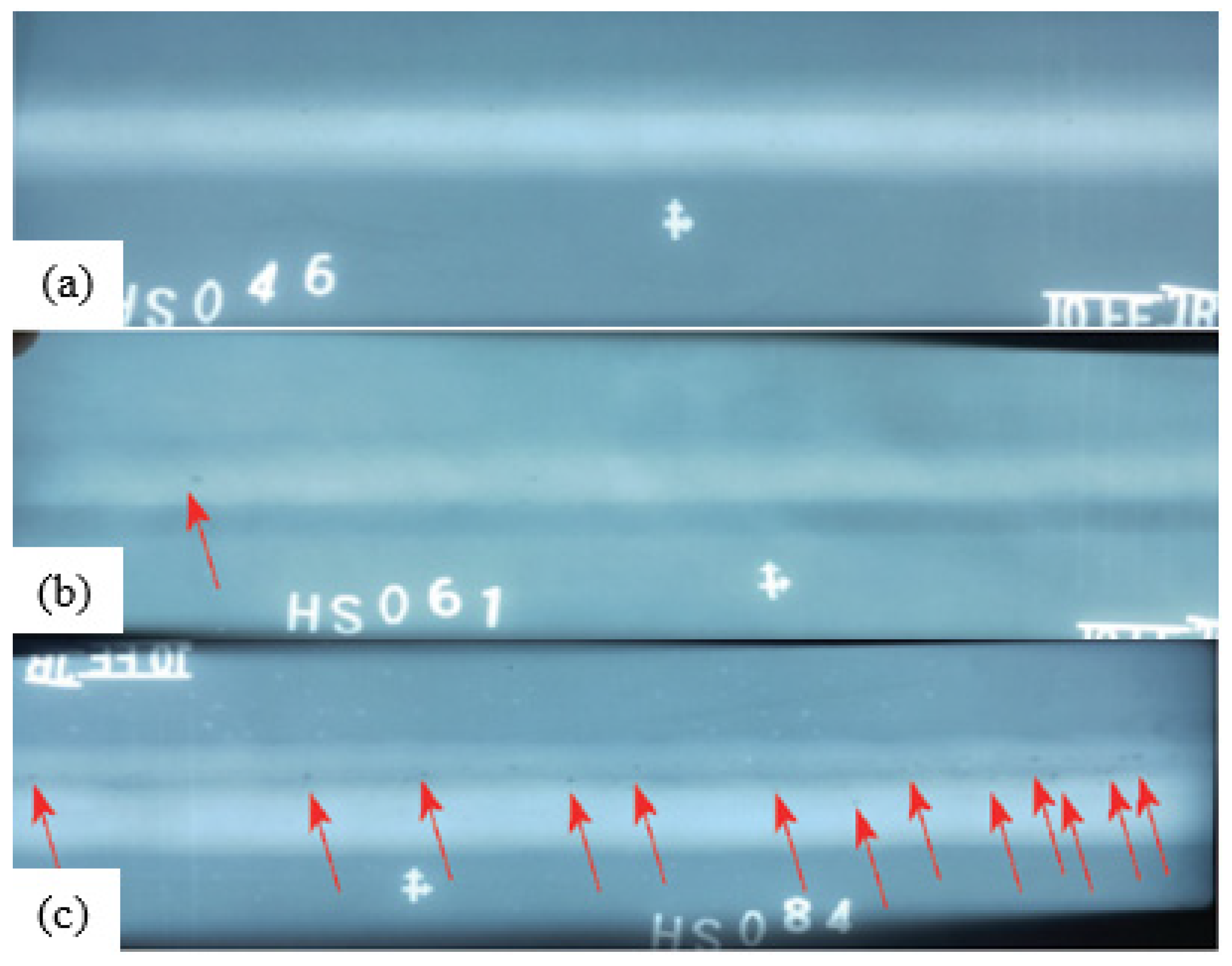

2. Instability of Droplet Transfer

3. Porosity Defect

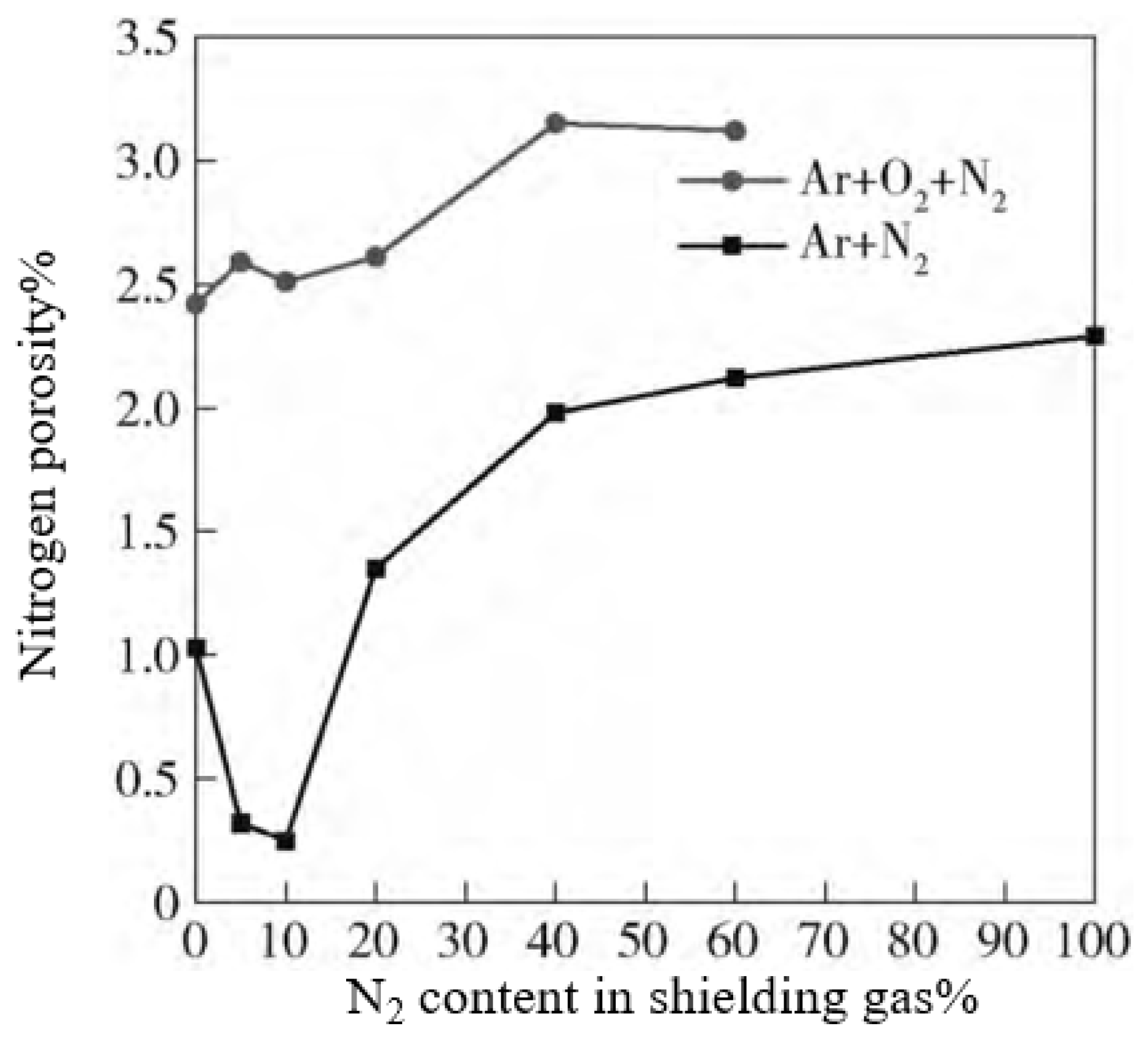

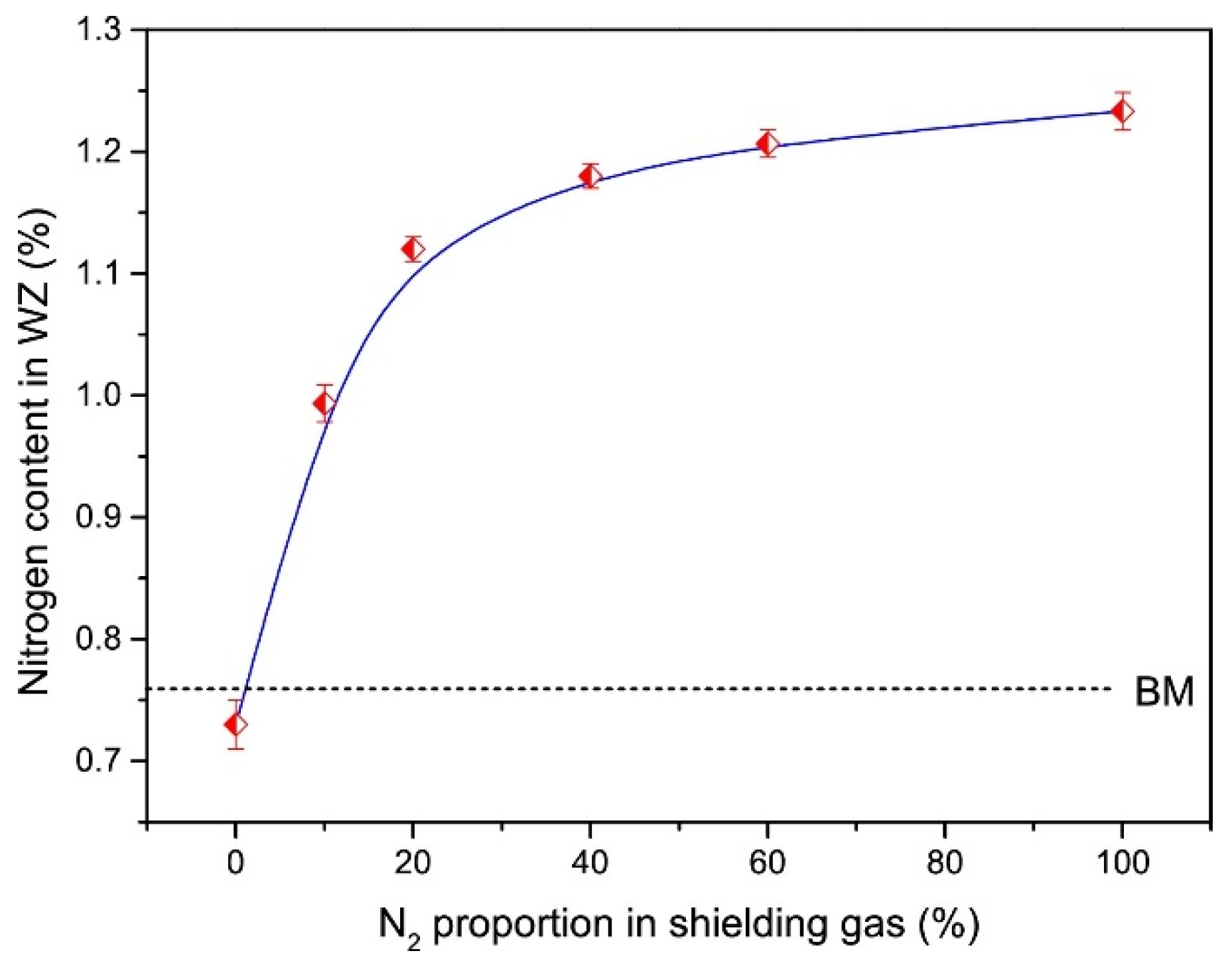

3.1. Effect of the Shielding Gas

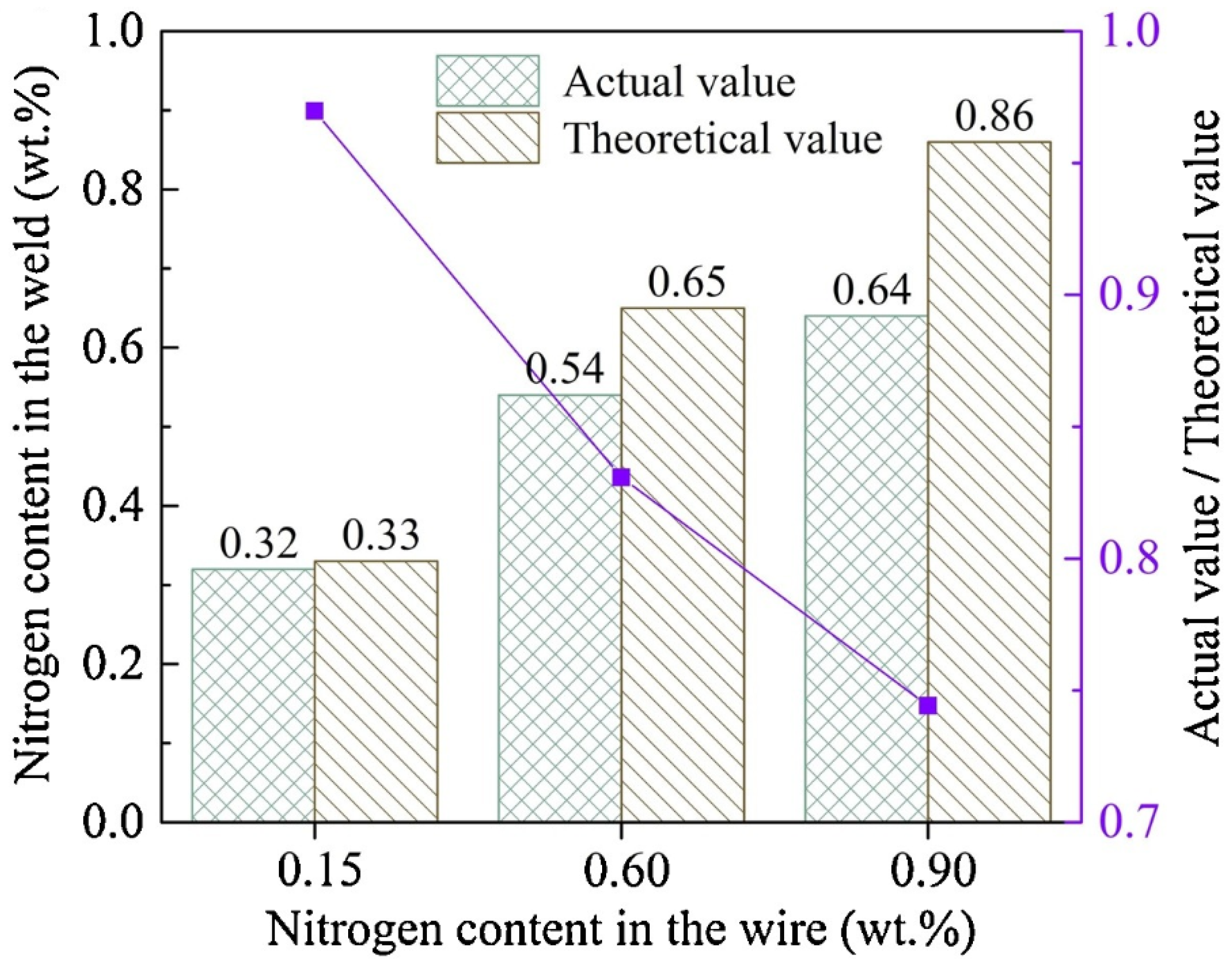

3.2. Effect of Welding Materials

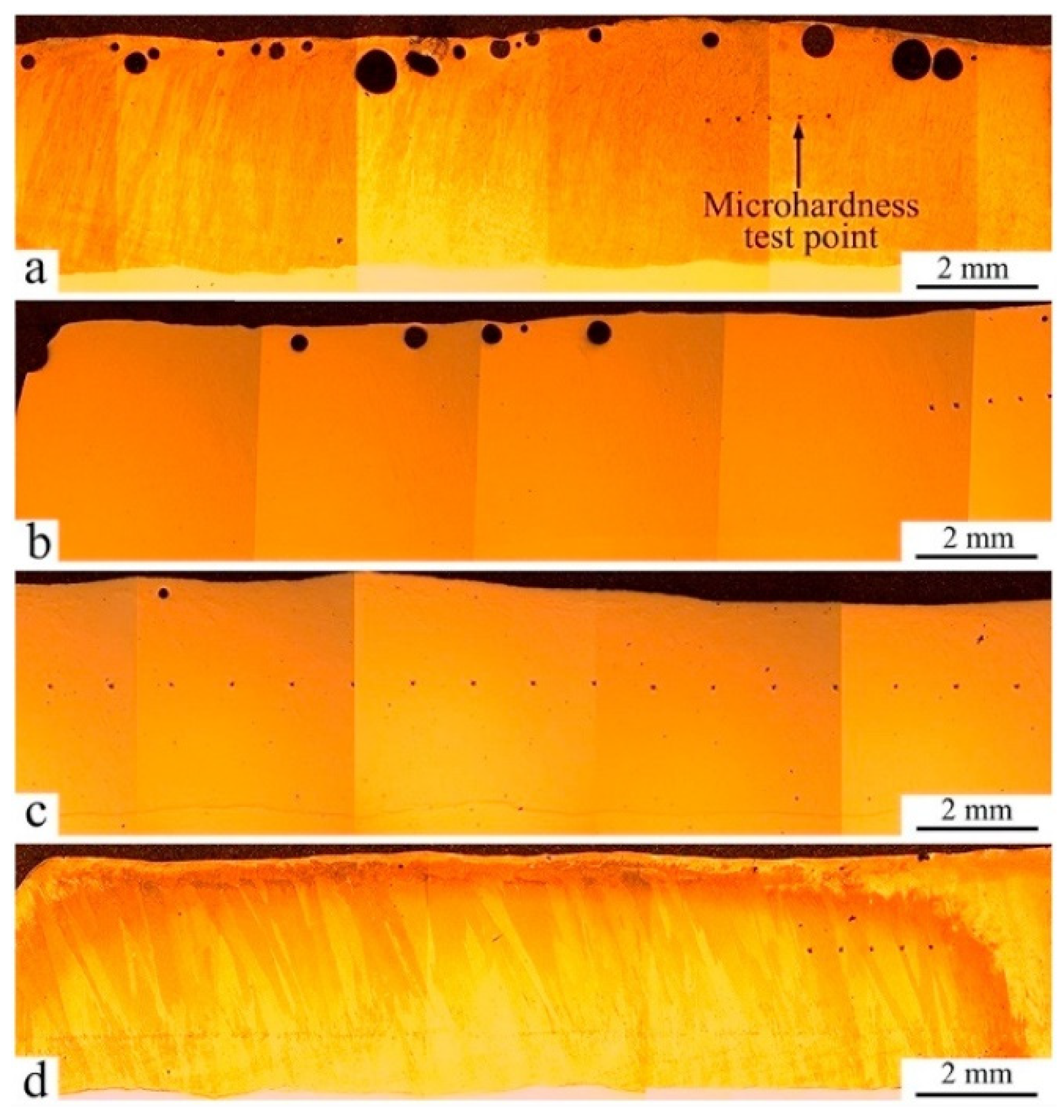

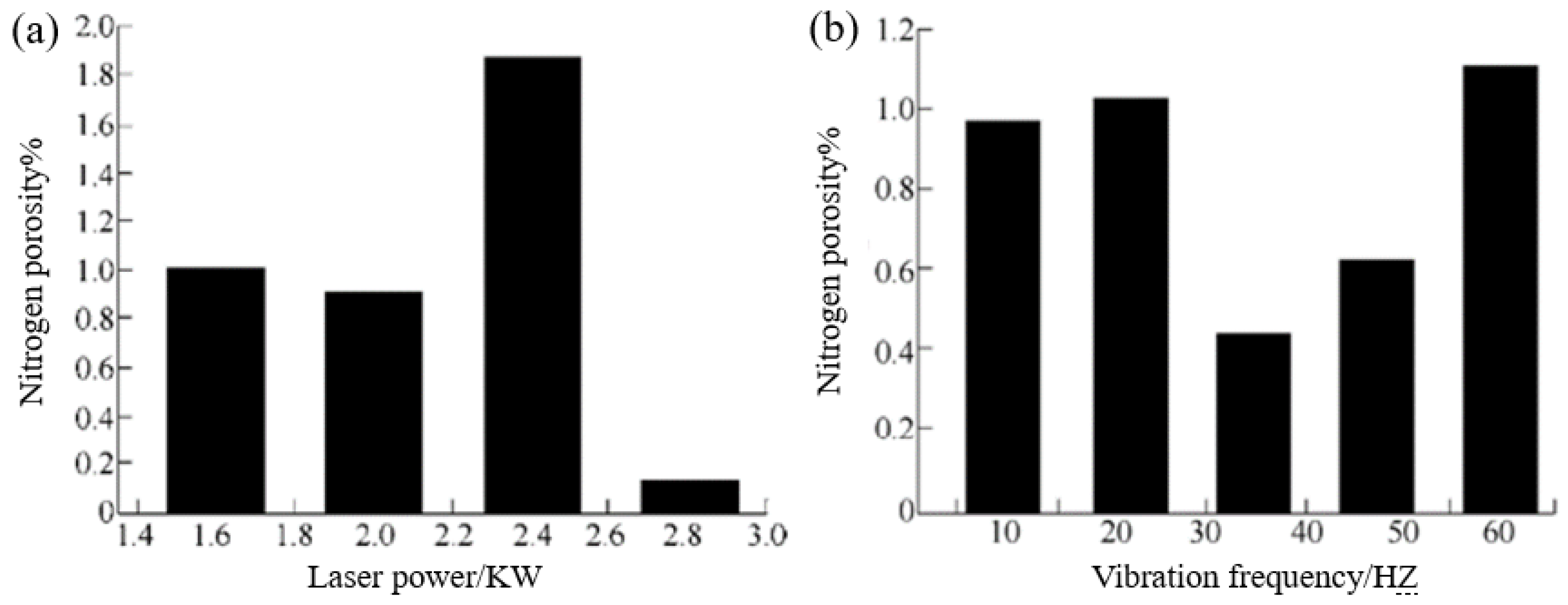

3.3. Effect of Process Parameters

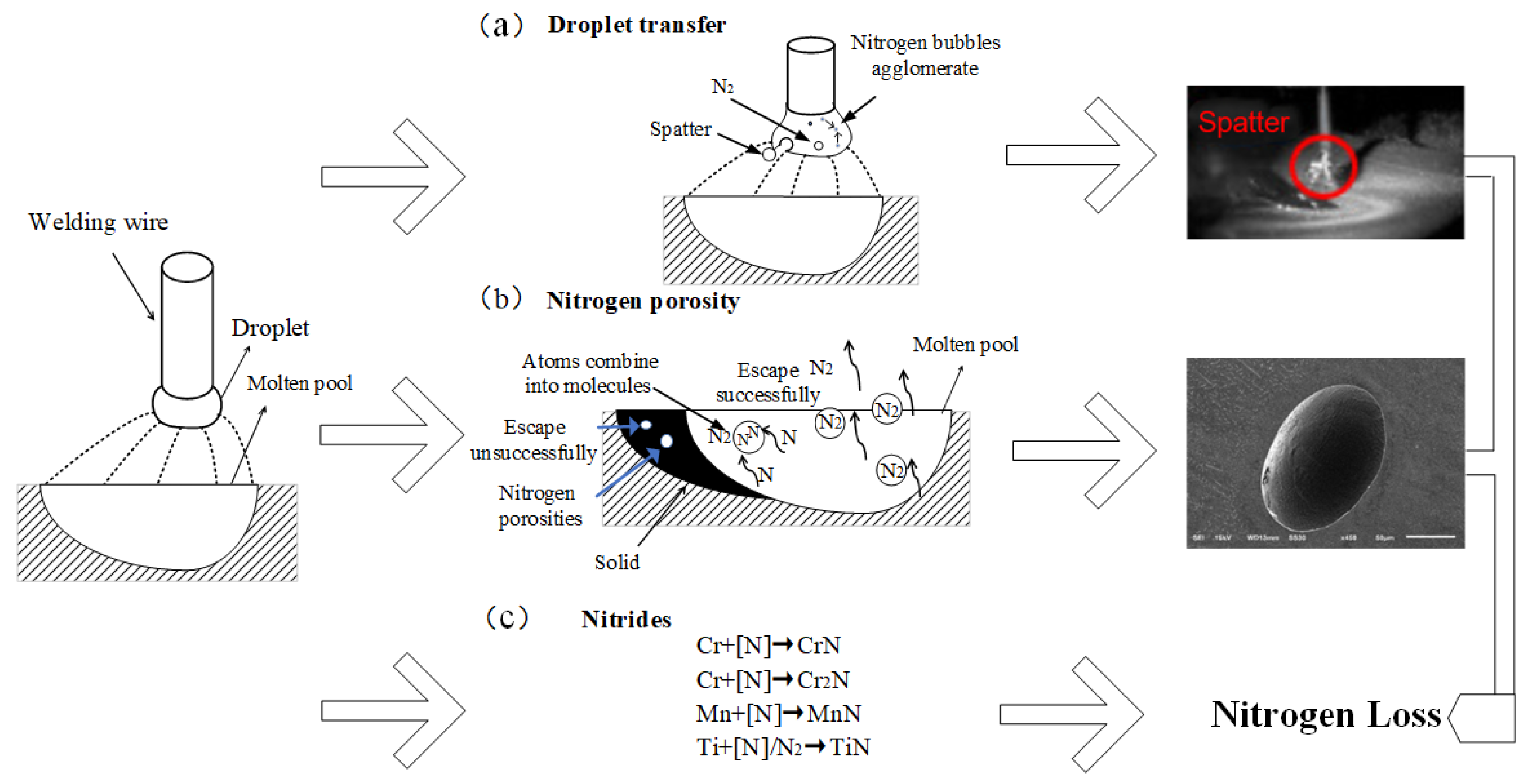

4. Nitrogen Loss

- During the droplet transfer, nitrogen atoms are gathered to form large N2 molecules, which may cause explosions, and the nitrogen in welding materials is lost.

- In the solidification of the molten pool, the nitrogen escapes and the formation of the N2 porosity will cause the loss of nitrogen.

- As the molten pool cools to below 1100 °C, the nitrogen is combined with Mn, Cr, Ti and other alloy elements to form nitrides, resulting in the loss of SSN.

4.1. Effect of the Shielding Gas

4.2. Effect of Welding Materials

5. Mechanical Property

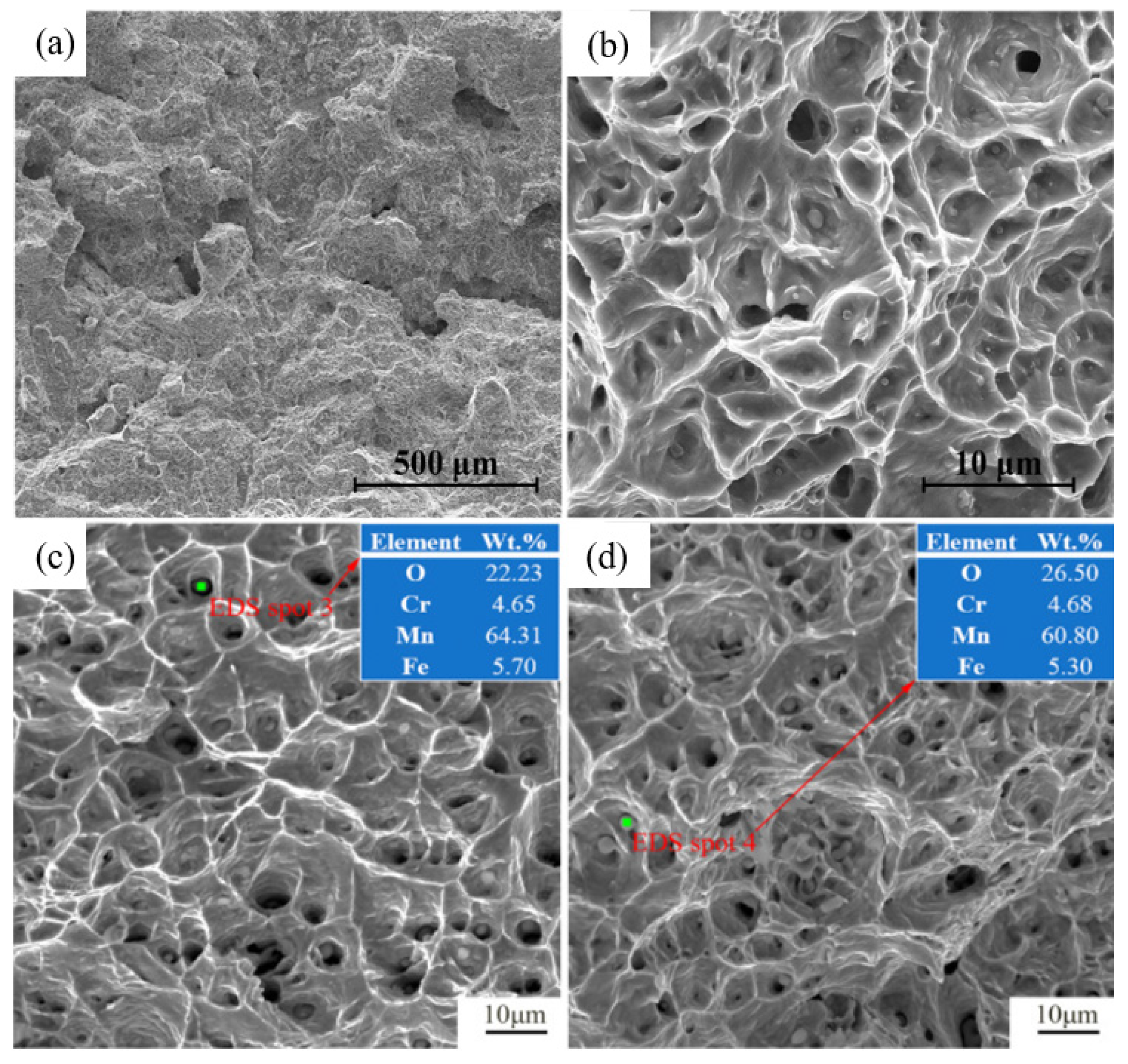

5.1. Fracture Mechanism

5.2. Effect of Welding Methods

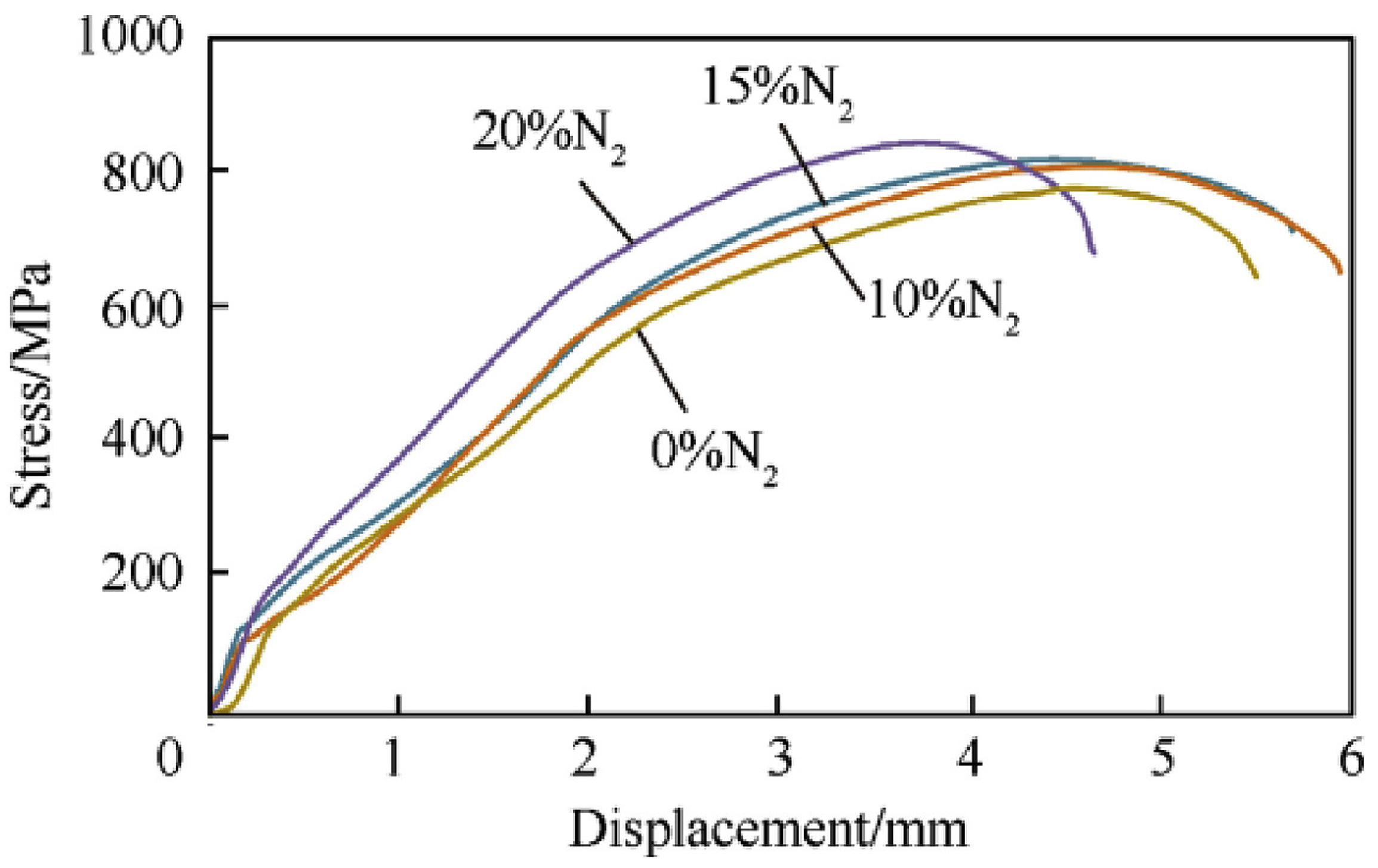

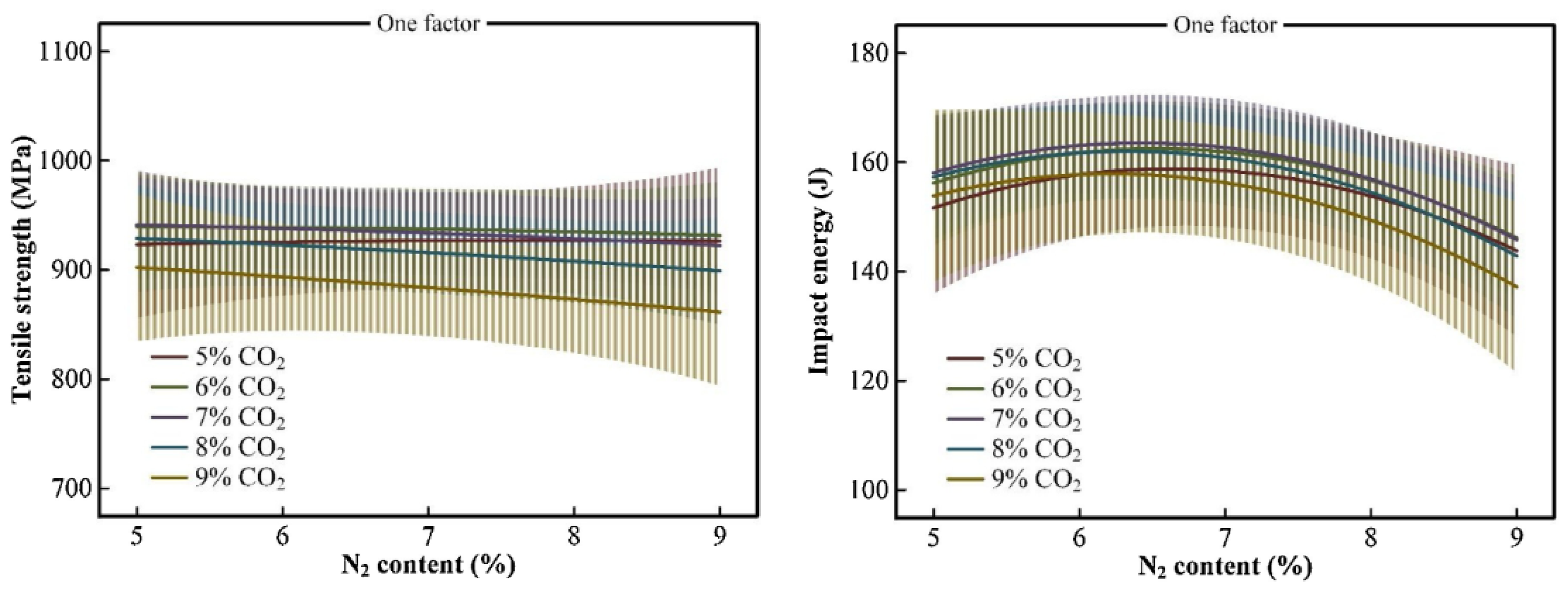

5.3. Effect of the Shielding Gas

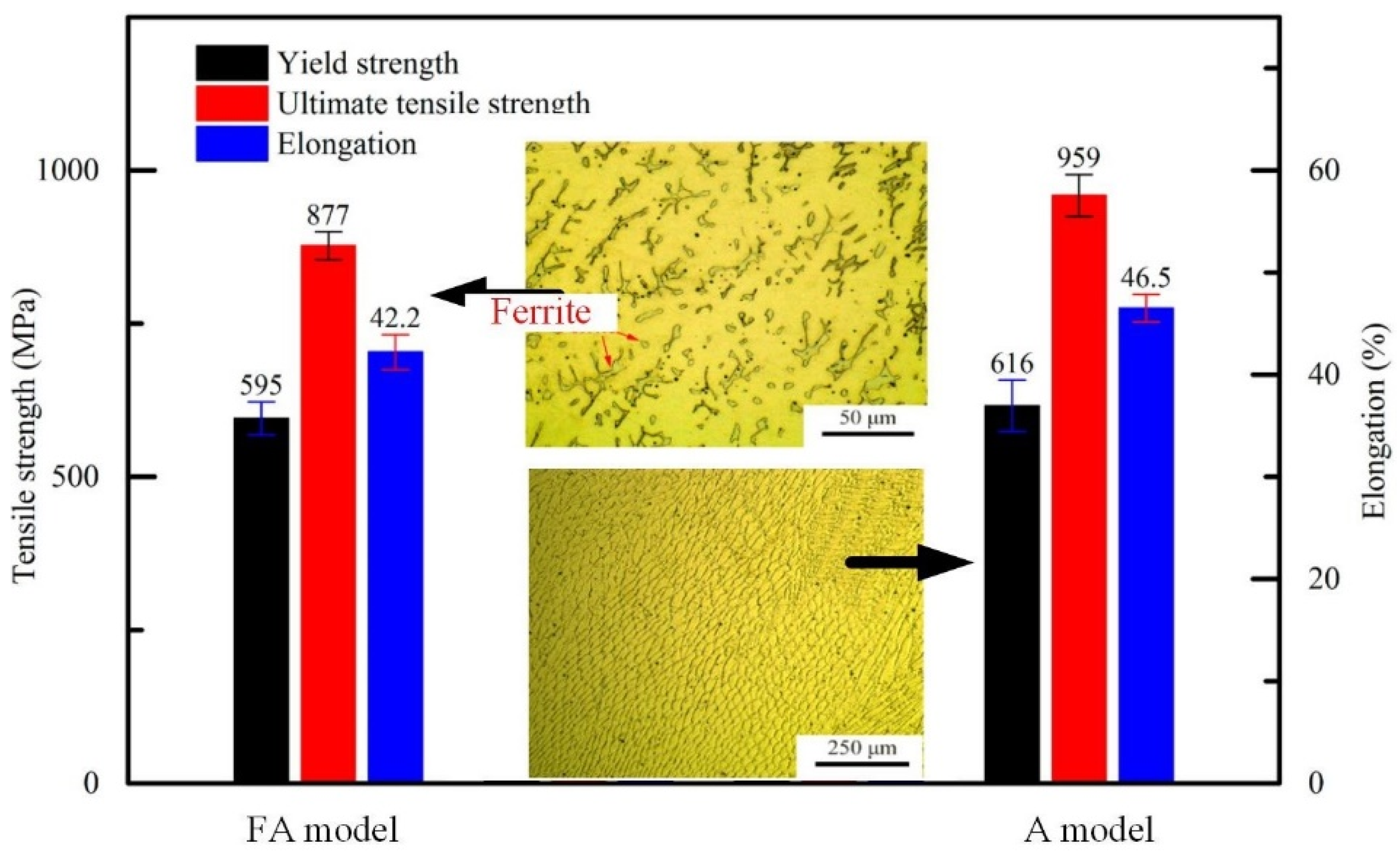

5.4. Effect of Microstructures

5.5. Effect of Welding Materials

6. Conclusions

- During the droplet transfer, many nitrogen atoms gather into the large N2, the droplet transfer becomes unstable, and spatter and splashes may occur. The welding methods with the low heat input, such as CMT, PA and laser arc hybrid welding methods, can be used to keep the droplet transfer stable. Besides, using powder instead of welding wires to fabricate HNS in welding can also avoid the formation of droplets, and improve the explosion problem.

- A large number of nitrogen atoms gather into N2 during the solidification of the molten pool. When the floating speed of N2 is less than the crystallization speed of the molten pool, the N2 porosity will occur. A suitable N2 content in the shielding gas, a suitable nitrogen content in the welding materials, and optimized process parameters can help to avoid the N2 porosities.

- The explosion of molten droplets, the formation of the N2 porosity, and the precipitation of nitrides are the main reasons for the nitrogen loss in the weld, especially the SSN loss. A proper increase in the nitrogen content in the shielding gas and welding materials can effectively ensure the nitrogen content in the weld. Besides, accelerating the cooling rate in the nitride thermal sensitive temperature range can effectively inhibit the precipitation of nitride.

- The mechanical properties of the weld are generally lower than that of the base metal due to the droplet transfer instability, N2 porosities and nitrogen losses in welding. Stabilizing the droplet transfer, inhibiting N2 porosities and reducing nitrogen losses are the means to ensure better mechanical properties. Furthermore, the A solidification mode can promote austenite in the HNS manufacturing structure, which can improve mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Simmons, J.W. Overview: High-Nitrogen Alloying of Stainless Steels. Mater. Sci. Eng. A 1996, 207, 159–169. [Google Scholar] [CrossRef]

- Simmons, J.W. Strain Hardening and Plastic Flow Properties of Nitrogen-Alloyed Fe-17Cr-(8-10)Mn-5Ni Austenitic Stainless Steels. Acta Mater. 1997, 45, 2467–2475. [Google Scholar] [CrossRef]

- Li, M.H.; Wu, D.H.; Wang, Y.; Yi, T.Y.; Gregersen, H.; Zhang, X.J.; Liao, X.L.; Wang, G.X. Immobilization of heparin/poly-l-lysine microspheres on medical grade high nitrogen nickel-free austenitic stainless steel surface to improve the biocompatibility and suppress thrombosis. Mater. Sci. Eng. C 2017, 73, 198–205. [Google Scholar] [CrossRef]

- Lang, Y.-P.; Qu, H.-P.; Chen, H.-T.; Weng, Y.-Q. Research Progress and Development Tendency of Nitrogen-alloyed Austenitic Stainless Steels. J. Iron Steel Res. Int. 2015, 22, 91–98. [Google Scholar] [CrossRef]

- Bhav, B.; Singh KSiva Kumar, V.; Madhu, R.; Arockia, K. Effect of Hot Rolling on Mechanical Properties and Ballistic Performance of High Nitrogen Steel. Procedia Eng. 2017, 173, 926–933. [Google Scholar] [CrossRef]

- Dimitrov, V.I.; Jekov, K.; Avin, A. Prediction of the solubility of nitrogen in steels obtained by pressurised electroslag remelting process. Comput. Mater. Sci. 1999, 15, 400–410. [Google Scholar] [CrossRef]

- He, S.; Yang, D.; Huang, Y.; Wang, K. Effect of the Current Waveform on the Droplet Transfer in CMT Welding High-Nitrogen Steel. J. Manuf. Processes 2022, 75, 41–48. [Google Scholar] [CrossRef]

- Yang, D.; Fang, H.; Peng, Y.; Fan, J.; Huang, Y.; Wang, K.; Yan, D.; Li, D. Investigation of Spatters in Cold Metal Transfer + Pulse-Based Wire and Arc Additive Manufacturing of High Nitrogen Austenitic Stainless Steel. J. Mater. Eng. Perform. 2021, 30, 6881–6894. [Google Scholar] [CrossRef]

- Yang, D.Q.; Xiong, H.Y.; Huang, Y.; Yan, D.J.; Li, D.; Peng, Y.; Wang, K.H. Droplet Transfer Behavior and Weld Formation of Gas Metal Arc Welding for High Nitrogen Austenitic Stainless Steel. J. Manuf. Processes 2021, 65, 491–501. [Google Scholar] [CrossRef]

- Zhang, J.; Li, T.; Yang, D.Q.; Fang, H.; Fan, J.K.; Wang, K.H. Effect of welding wire compositions on welding usability of high nitrogen steel. Acta Armamentarii 2021, 1–7. [Google Scholar] [CrossRef]

- Li, J.; Li, H.; Liang, Y.; Liu, P.; Yang, L.; Wang, Y. Effects of heat input and cooling rate during welding on intergranular corrosion behavior of high nitrogen austenitic stainless steel welded joints. Corros. Sci. 2020, 166, 108445.1–108445.14. [Google Scholar] [CrossRef]

- Qiang, W.; Wang, K. Shielding Gas Effects on Double-Sided Synchronous Autogenous GTA Weldability of High Nitrogen Austenitic Stainless Steel. J. Mater. Processing Technol. 2017, 250, 169–181. [Google Scholar] [CrossRef]

- Wang, J.Y.; Qi, T.; Zhong, C.L.; Zhang, H.; Li, X.R.; Liu, F.D. Study on Seam Nitrogen Behavior of High Nitrogen Steel Hybrid Welding. Optik 2021, 242, 167026. [Google Scholar] [CrossRef]

- Makaya, A.; Fredriksson, H. Study on the Production of Fe–Cr–Mn–C–Si Foam by Nitrogen Solubility Difference between the Liquid and Solid Phases. Mater. Sci. Eng. A 2005, 413–414, 533–537. [Google Scholar] [CrossRef]

- Cui, B.; Zhang, H.; Liu, J.; Liu, F.D.; Zhang, F.L. Study on the Impact of the Shielding Gas on the Droplet Transfer Mode and Blowhole Defect of High Nitrogen Steel Welding. J. Mech. Eng. 2017, 53, 87. [Google Scholar] [CrossRef]

- Zhao, L.; Tian, Z.L.; Peng, Y.; Chang, Q.Y.; Wang, Y.J. Influence of Nitrogen and Heat Input on Weld Metal of Gas Tungsten Arc Welded High Nitrogen Steel. J. Iron Steel Res. Int. 2007, 14, 259–262. [Google Scholar] [CrossRef]

- Cui, B.; Zhang, H.; LIUS, Y.; Liu, F.D. Research on Control Method of Nitrogen Content and Porosity in Hybrid Welding Joint of High Nitrogen Steel. Acta Armamentarii 2019, 40, 2311–2318. [Google Scholar] [CrossRef]

- Yang, D.Q.; Huang, Y.; Fan, J.K.; Jin, M.; Peng, Y.; Wang, K.H. Effect of N2 content in shielding gas on formation quality and microstructure of high nitrogen austenitic stainless steel fabricated by wire and arc additive manufacturing. J. Manuf. Processes 2021, 61, 261–269. [Google Scholar] [CrossRef]

- Zhao, L.; Tian, Z.; Peng, Y. Porosity and Nitrogen Content of Weld Metal in Laser Welding of High Nitrogen Austenitic Stainless Stee. Trans. Iron Steel Inst. Jpn. 2007, 47, 1772–1775. [Google Scholar] [CrossRef] [Green Version]

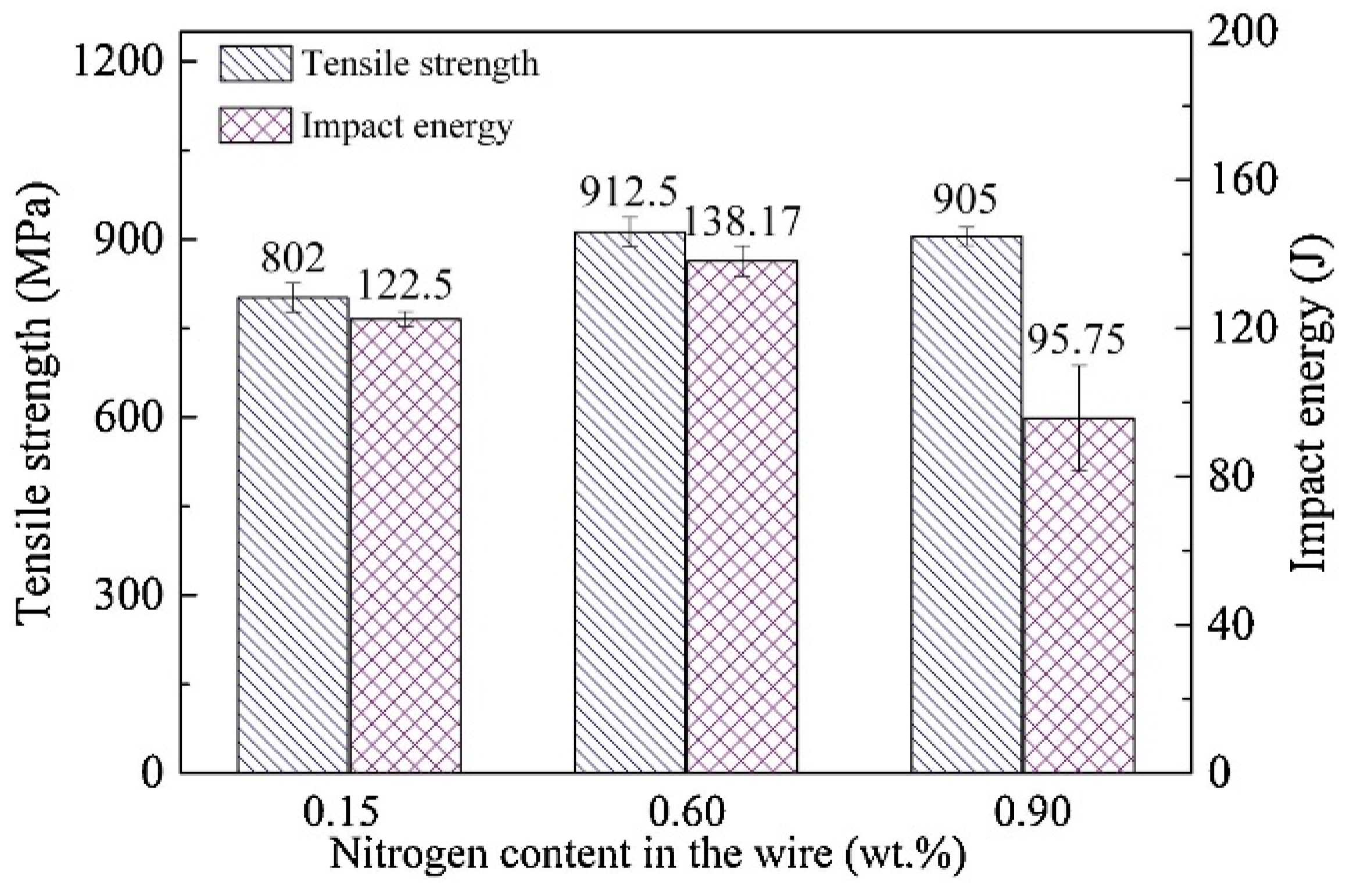

- Ma, L.C.; Wang, D.F.; Ma, B.; Chen, D.G.; Zhang, Y.Y. Microstructure and Mechanical Property of High-nitrogen Steel with GMAW Welding Wires with Different Nitrogen Contents. Acta Armamentarii 2021, 42, 1303. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Wang, K.H.; Zhou, Q.; Peng, Y.; Kong, J.; Huang, Y.; Yang, D.Q. System study of the formability, nitrogen behaviour and microstructure features of the CMT wire and arc additively manufactured high nitrogen Cr-Mn stainless steel. Mater. Today Commun. 2021, 27, 102263. [Google Scholar] [CrossRef]

- Wang, L.F.; Liu, F.D.; Liu, W.N.; Tian, M.Q. Study on Control Methods of Welding Porosity in Laser-arc Hybrid Welding for High Nitrogen Steels. J. Mech. Eng. 2016, 52, 51. [Google Scholar] [CrossRef]

- Cui, B.; Liu, S.; Zhang, F.; Luo, T.; Feng, M. Effect of Welding Heat Input on Pores in Laser-Arc Hybrid Welding of High Nitrogen Steel. Int. J. Adv. Manuf. Technol. 2022, 119, 421–434. [Google Scholar] [CrossRef]

- Li, X.R.; Bai, D.; Liu, F.D.; Zhang, H.; Liu, S.Y. High-nitrogen steel laser-arc hybrid welding in vibration condition. Mater. Sci. Technol. 2019, 36, 434–442. [Google Scholar] [CrossRef]

- Liu, Z.; Fan, C.; Ming, Z.; Chen, C.; Yang, C.; Lin, S.; Wang, L. Optimization of Shielding Gas Composition in High Nitrogen Stainless Steel Gas Metal Arc Welding. J. Manuf. Processes 2020, 58, 19–29. [Google Scholar] [CrossRef]

- Kumar, N.; Arora, N.; Goel, S.; Goel, D. Comparative Study of Microstructure and Mechanical Properties of 21-4-N Steel Weld Joints Using Different Filler Materials—ScienceDirect. Mater. Today Proc. 2018, 5, 17089–17096. [Google Scholar] [CrossRef]

- Liu, Z.; Fan, C.; Chen, C.; Ming, Z.; Yang, C.; Lin, S.; Wang, L. Design and Evaluation of Nitrogen-Rich Welding Wires for High Nitrogen Stainless Steel. J. Mater. Processing Technol. 2021, 288, 116885. [Google Scholar] [CrossRef]

- Wu, T.; Liu, J.; Wang, K.; Wang, L.; Zhang, X. Microstructure and Mechanical Properties of Wire-Powder Hybrid Additive Manufacturing for High Nitrogen Steel. J. Manuf. Processes 2021, 70, 248–258. [Google Scholar] [CrossRef]

- Liu, Z.; Fan, C.; Chen, C.; Ming, Z.; Liu, A.; Yang, C.; Lin, S.; Wang, L. Optimization of the Microstructure and Mechanical Properties of the High Nitrogen Stainless Steel Weld by Adding Nitrides to the Molten Pool. J. Manuf. Processes 2020, 49, 355–364. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, Q.; Wang, K.; Peng, Y.; Ding, J.; Kong, J.; Williams, S. Study on Microstructure and Tensile Properties of High Nitrogen Cr-Mn Steel Processed by CMT Wire and Arc Additive Manufacturing. Mater. Des. 2019, 166, 107611. [Google Scholar] [CrossRef]

- Sun, Y.; Feng, Y.H.; Liu, S.Y.; Wang, K.H. Microstructure and Mechanical Properties of the Large Thickness High Nitrogen Austenitic Stainless Steel Component Deposited by Multilayer and Multi-pass Plasma Arc Additive Manufacturing Process. Mater. Rep. 2020, 34, 6. [Google Scholar] [CrossRef]

- Tang, R.H.; Feng, Y.H.; Liu, S.Y.; Chen, Q. Microstructure and Characteristics of High Nitrogen Austenitic Stainless Steel Component with High-strength and High-hardness Deposited by Double wire Plasma Arc Additive Manufacturing Process. Mater. Rep. 2022, 36, 5. [Google Scholar] [CrossRef]

- Ning, J.; Na, S.J.; Wang, C.H.; Zhang, L.J. A comparison of laser-metal inert gas hybrid welding and metal inert gas welding of high-nitrogen austenitic stainless steel. J. Mater. Res. Technol. 2021, 13, 1841–1854. [Google Scholar] [CrossRef]

- Lei, Z.; Li, B.; Wu, S.; Chen, Y.; Xiong, Y. Effects of MnN Powder on the Microstructure and Properties of High Nitrogen Steel Joint via Laser-Arc Hybrid Welding. Opt. Laser Technol. 2021, 138, 106877. [Google Scholar] [CrossRef]

- Ma, Z.H.; Cheng, D.G.; Liu, H.W.; Guo, H.L.; Yang, W.L. Microstructure and Mechanical Properties of Welded Joints of Mid-thickness High Nitrogen Steel by Laser-MIG Hybrid Welding. Hot Work. Technol. 2014, 43, 194–197. [Google Scholar] [CrossRef]

- Cui, B.; Luo, T.; Feng, M. Effect of Nitrogen Content on the Microstructure and Properties of the Laser-Arc Hybrid Welding Joint of High Nitrogen Steel. Optik 2021, 243, 167478. [Google Scholar] [CrossRef]

- Liu, Z.; Fan, C.; Ming, Z.; Chen, C.; Liu, A.; Yang, C.; Lin, S.; Wang, L. Gas Metal Arc Welding of High Nitrogen Stainless Steel with Ar–N2-O2 Ternary Shielding Gas. Def. Technol. 2021, 17, 923–931. [Google Scholar] [CrossRef]

- Li, J.G.; Li, H.; Liang, Y.; Liu, P.L.; Yang, L.J. The Microstructure and Mechanical Properties of Multi-Strand, Composite Welding-Wire Welded Joints of High Nitrogen Austenitic Stainless Steel. Materials 2019, 12, 2944. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Zhang, H. Analysis of microstructure and properties of welded joint of high nitrogen steel by hybrid welding. Mater. Res. Express 2019, 6, 045602. [Google Scholar] [CrossRef]

- Mohammed, R.; Reddy, G.M.; Rao, K.S. Welding of nickel free high nitrogen stainless steel: Microstructure and mechanical properties. Def. Technol. 2017, 13, 59–71. [Google Scholar] [CrossRef] [Green Version]

- Jacob, G. Prediction of Solidification Phases in Cr-Ni Stainless Steel Alloys Manufactured by Laser Based Powder Bed Fusion Process; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2018. [CrossRef]

- Lippold, J.C.; Kotecki, D.J. Welding Metallurgy and Weldability of Stainless Steels; John Wiley: Hoboken, NJ, USA, 2005; pp. 57–84. [Google Scholar] [CrossRef]

- Jang, A.Y.; Lee, D.J.; Lee, S.H.; Lee, D.J.; Shim, J.H.; Kang, S.W.; Lee, H.W. Effect of Cr/Ni equivalent ratio on ductility-dip cracking in AISI 316L weld metals. Mater. Des. 2011, 32, 371–376. [Google Scholar] [CrossRef]

| No. | Processing Method | Tensile Strength/MPa | Elongation/% | Fracture Location | References |

|---|---|---|---|---|---|

| 1 | MIG | 900 | 14.5 | Weld bead | [20] |

| 2 | MIG | 912.5 | / | Weld bead | [27] |

| 3 | TIG | 956.7 | 6.8 | Weld bead | [29] |

| 4 | TIG | 832 | / | Weld bead | [25] |

| 5 | CMT+P additive manufacturing | 829 | 14.1 | Additive structure | [8] |

| 6 | CMT+P additive manufacturing | 860.6 | 34.9 | Additive structure | [30] |

| 7 | PA additive manufacturing | 1078 | 46.1 | Additive structure | [31] |

| 8 | Double wire filled PA additive manufacturing | 1166 | 51 | Additive structure | [32] |

| 9 | Laser-MIG hybrid welding | 980.15 | / | Weld bead | [34] |

| 10 | Laser-MIG hybrid welding | 923.7 | 16 | Weld bead | [35] |

| 11 | Laser-MIG hybrid welding | 928.9 | 7.3 | Weld bead | [36] |

| 12 | Wire-powder hybrid additive manufacturing | 1014 | 50.8 | Additive structure | [28] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Li, Y.; Ding, J.; Xie, Q.; Zhang, X.; Wang, K. Problems in Welding of High Nitrogen Steel: A Review. Metals 2022, 12, 1273. https://doi.org/10.3390/met12081273

Wang L, Li Y, Ding J, Xie Q, Zhang X, Wang K. Problems in Welding of High Nitrogen Steel: A Review. Metals. 2022; 12(8):1273. https://doi.org/10.3390/met12081273

Chicago/Turabian StyleWang, Lei, Yichen Li, Jialiang Ding, Qiang Xie, Xiaoyong Zhang, and Kehong Wang. 2022. "Problems in Welding of High Nitrogen Steel: A Review" Metals 12, no. 8: 1273. https://doi.org/10.3390/met12081273

APA StyleWang, L., Li, Y., Ding, J., Xie, Q., Zhang, X., & Wang, K. (2022). Problems in Welding of High Nitrogen Steel: A Review. Metals, 12(8), 1273. https://doi.org/10.3390/met12081273