Incremental Capacity Curve Health-Indicator Extraction Based on Gaussian Filter and Improved Relevance Vector Machine for Lithium–Ion Battery Remaining Useful Life Estimation

Abstract

:1. Introduction

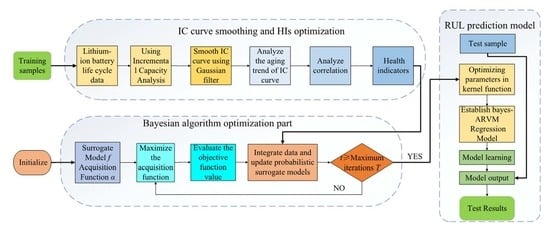

2. IC Curve Smoothing and HI Extraction

2.1. Experimental Dataset Analysis

2.2. IC Curve Extraction and Smoothing

2.3. Health Indicators Extraction and Correlation Analysis

3. Improved Adaptive RVM Model Based on Bayesian Optimization

3.1. Relevance Vector Machine Regression Model

3.2. Adaptive Kernel Function Based on Bayesian Optimization Algorithm

3.2.1. Analysis and Selection of Kernel Functions

3.2.2. Bayesian Optimization Algorithm

3.3. Adaptive RVM Prediction Model Based on Bayesian Algorithm Optimization

4. Experimental Results and Discussion

4.1. Short–Term Prediction Experiments

4.2. Long–Term Prediction Experiments

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, M.; Liu, K.; Dutta, S.; Daniel, S.A.; Rinklebe, J.; Ok, Y.S.; Daniel, C.W.T. Recycling of lithium iron phosphate batteries: Status, technologies, challenges, and prospects. Renew. Sustain. Energy Rev. 2022, 163, 112515. [Google Scholar] [CrossRef]

- Tian, H.; Qin, P.; Li, K.; Zhao, Z. A review of the state of health for lithium-ion batteries: Research status and suggestions. J. Clean. Prod. 2020, 261, 120813. [Google Scholar] [CrossRef]

- Hu, X.; Xu, L.; Lin, X.; Pecht, M. Battery Lifetime Prognostics. Joule 2020, 4, 310–346. [Google Scholar] [CrossRef]

- Ge, M.-F.; Liu, Y.; Jiang, X.; Liu, J. A review on state of health estimations and remaining useful life prognostics of lithium-ion batteries. Measurement 2021, 174, 109057. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, C.; Jiang, J.; Zhang, W.; Zhang, L.; Wang, Y. Review on state-of-health of lithium-ion batteries: Characterizations, estimations and applications. J. Clean. Prod. 2021, 314, 128015. [Google Scholar] [CrossRef]

- Meng, H.; Li, Y.-F. A review on prognostics and health management (PHM) methods of lithium-ion batteries. Renew. Sustain. Energy Rev. 2019, 116, 109405. [Google Scholar] [CrossRef]

- Pan, W.; Luo, X.; Zhu, M.; Ye, J.; Gong, L.; Qu, H. A health indicator extraction and optimization for capacity estimation of Li-ion battery using incremental capacity curves. J. Energy Storage 2021, 42, 103072. [Google Scholar] [CrossRef]

- Qiu, J.; Fan, Y.; Wang, S.; Yang, X.; Qiao, J.; Liu, D. Research on the remaining useful life prediction method of lithium-ion batteries based on aging feature extraction and multi-kernel relevance vector machine optimization model. Int. J. Energy Res. 2022, 46, 13931–13946. [Google Scholar] [CrossRef]

- Guo, P.; Cheng, Z.; Yang, L. A data-driven remaining capacity estimation approach for lithium-ion batteries based on charging health feature extraction. J. Power Sources 2019, 412, 442–450. [Google Scholar] [CrossRef]

- Pang, X.; Liu, X.; Jia, J.; Wen, J.; Shi, Y.; Zeng, J.; Zhao, Z. A lithium-ion battery remaining useful life prediction method based on the incremental capacity analysis and Gaussian process regression. Microelectron. Reliab. 2021, 127, 114405. [Google Scholar] [CrossRef]

- Zhang, S.; Guo, X.; Dou, X.; Zhang, X. A rapid online calculation method for state of health of lithium-ion battery based on coulomb counting method and differential voltage analysis. J. Power Sources 2020, 479, 228740. [Google Scholar] [CrossRef]

- Wang, L.; Qiao, S.; Lu, D.; Zhang, Y.; Pan, C.; He, Z.; Zhao, X.; Wang, R. State of health estimation of lithium-ion battery in wide temperature range via temperature-aging coupling mechanism analysis. J. Energy Storage 2022, 47, 103618. [Google Scholar] [CrossRef]

- Dubarry, M.; Beck, D. Big data training data for artificial intelligence-based Li-ion diagnosis and prognosis. J. Power Sources 2020, 479, 228806. [Google Scholar] [CrossRef]

- Lin, H.; Kang, L.; Xie, D.; Linghu, J.; Li, J. Online State-of-Health Estimation of Lithium-Ion Battery Based on Incremental Capacity Curve and BP Neural Network. Batteries 2022, 8, 29. [Google Scholar] [CrossRef]

- Zhou, R.; Zhu, R.; Huang, C.-G.; Peng, W. State of health estimation for fast-charging lithium-ion battery based on incremental capacity analysis. J. Energy Storage 2022, 51, 104560. [Google Scholar] [CrossRef]

- Li, Y.; Abdel-Monem, M.; Gopalakrishnan, R.; Berecibar, M.; Nanini-Maury, E.; Omar, N.; van den Bossche, P.; Van Mierlo, J. A quick on-line state of health estimation method for Li-ion battery with incremental capacity curves processed by Gaussian filter. J. Power Sources 2018, 373, 40–53. [Google Scholar] [CrossRef]

- He, J.; Wei, Z.; Bian, X.; Yan, F. State-of-Health Estimation of Lithium-Ion Batteries Using Incremental Capacity Analysis Based on Voltage–Capacity Model. IEEE Trans. Transp. Electrif. 2020, 6, 417–426. [Google Scholar] [CrossRef]

- Tang, X.; Liu, K.; Lu, J.; Liu, B.; Wang, X.; Gao, F. Battery incremental capacity curve extraction by a two-dimensional Luenberger–Gaussian-moving-average filter. Appl. Energy 2020, 280, 115895. [Google Scholar] [CrossRef]

- Zheng, Y.; Cui, Y.; Han, X.; Dai, H.; Ouyang, M. Lithium-ion battery capacity estimation based on open circuit voltage identification using the iteratively reweighted least squares at different aging levels. J. Energy Storage 2021, 44, 103487. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Wang, J.; Zhang, T. State-of-health estimation for lithium-ion batteries by combining model-based incremental capacity analysis with support vector regression. Energy 2022, 239, 121986. [Google Scholar] [CrossRef]

- Maleki, S.; Ray, B.; Hagh, M.T. Hybrid framework for predicting and forecasting State of Health of Lithium-ion batteries in Electric Vehicles. Sustain. Energy Grids Netw. 2022, 30, 100603. [Google Scholar] [CrossRef]

- Tipping, M.E. Sparse bayesian learning and the relevance vector machine. J. Mach. Learn. Res. 2001, 1, 211–244. [Google Scholar] [CrossRef]

- Chen, Z.; Shi, N.; Ji, Y.; Niu, M.; Wang, Y. Lithium-ion batteries remaining useful life prediction based on BLS-RVM. Energy 2021, 234, 121269. [Google Scholar] [CrossRef]

- Guo, W.; He, M. An optimal relevance vector machine with a modified degradation model for remaining useful lifetime prediction of lithium-ion batteries. Appl. Soft Comput. 2022, 124, 108967. [Google Scholar] [CrossRef]

- Liu, D.; Zhou, J.; Pan, D.; Peng, Y.; Peng, X. Lithium-ion battery remaining useful life estimation with an optimized Relevance Vector Machine algorithm with incremental learning. Measurement 2015, 63, 143–151. [Google Scholar] [CrossRef]

- Kim, J.; Chun, H.; Baek, J.; Han, S. Parameter identification of lithium-ion battery pseudo-2-dimensional models using genetic algorithm and neural network cooperative optimization. J. Energy Storage 2022, 45, 103571. [Google Scholar] [CrossRef]

- Yao, F.; He, W.; Wu, Y.; Ding, F.; Meng, D. Remaining useful life prediction of lithium-ion batteries using a hybrid model. Energy 2022, 248, 123622. [Google Scholar] [CrossRef]

- Wang, H.; Song, W.; Zio, E.; Kudreyko, A.; Zhang, Y. Remaining useful life prediction for Lithium-ion batteries using fractional Brownian motion and Fruit-fly Optimization Algorithm. Measurement 2020, 161, 107904. [Google Scholar] [CrossRef]

- Jiang, B.; Berliner, M.D.; Lai, K.; Asinger, P.A.; Zhao, H.; Herring, P.K.; Bazant, M.Z.; Braatz, R.D. Fast charging design for Lithium-ion batteries via Bayesian optimization. Appl. Energy 2022, 307, 118244. [Google Scholar] [CrossRef]

- Doose, S.; Mayer, J.; Michalowski, P.; Kwade, A. Challenges in Ecofriendly Battery Recycling and Closed Material Cycles: A Perspective on Future Lithium Battery Generations. Metals 2021, 11, 291. [Google Scholar] [CrossRef]

- Deng, Z.; Lin, X.; Cai, J.; Hu, X. Battery health estimation with degradation pattern recognition and transfer learning. J. Power Sources 2022, 525, 231027. [Google Scholar] [CrossRef]

- Brochu, E.; Brochu, T.; Freitas, N.D. A Bayesian Interactive Optimization Approach to Procedural Animation Design; The Eurographics Association: Chicago, IL, USA, 2010; pp. 103–112. [Google Scholar] [CrossRef]

- Snoek, J.; Larochelle, H.; Adams, R.P. Practical Bayesian Optimization of Machine Learning Algorithms. Adv. Neural Inf. Process. Syst. 2012, 4, 1–11. [Google Scholar] [CrossRef]

- Lyu, Z.; Wang, G.; Tan, C. A novel Bayesian multivariate linear regression model for online state-of-health estimation of Lithium-ion battery using multiple health indicators. Microelectron. Reliab. 2022, 131, 114500. [Google Scholar] [CrossRef]

| Battery Number | Ambient Temperature | Rated Capacity | Discharge Current | Cut off Voltage | EOL |

|---|---|---|---|---|---|

| CS2–35 | 24 °C | 1.1 Ah | 1.1 A | 2.7 V | 0.9 Ah |

| CS2–36 | 0.85 Ah | ||||

| CS2–37 | 0.9 Ah | ||||

| CS2–38 | 0.9 Ah |

| HIs | I Peak Value | I Peak Position | II Peak Value | II Peak Position |

|---|---|---|---|---|

| CS2–35 | 0.8019 | −0.4759 | 0.9555 | −0.9147 |

| CS2–36 | 0.8759 | −0.8370 | 0.9579 | −0.9196 |

| CS2–37 | 0.7751 | −0.5186 | 0.9608 | −0.8718 |

| CS2–38 | 0.7494 | −0.7507 | 0.9567 | −0.2942 |

| HIs1 | HIs2 | HIs3 | |

|---|---|---|---|

| CS2–35 | I peak value | II peak value | II peak position |

| CS2–36 | I peak value | II peak value | II peak position |

| CS2–37 | I peak value | II peak value | II peak position |

| CS2–38 | I peak value | I peak position | II peak position |

| Short–Term Prediction Experiments | Long–Term Prediction Experiments | |||

|---|---|---|---|---|

| Training Data Length | Test Data Length | Training Data Length | Test Data Length | |

| CS2–35 | 60% (360 cycle) | 40% (140 cycle) | 30% (180 cycle) | 70% (420 cycle) |

| CS2–36 | ||||

| CS2–37 | ||||

| CS2–38 | ||||

| Battery Number | EOL | RT | SP | Algorithm | RP | RE | MAE | R2 |

|---|---|---|---|---|---|---|---|---|

| CS2–35 | 0.9 Ah | 531 | 360 | C2 | 523 | 8 | 0.0081 | 0.9204 |

| C3 | 593 | 62 | 0.0146 | 0.6781 | ||||

| CS2–36 | 0.85 Ah | 525 | 360 | C2 | 516 | 9 | 0.0118 | 0.9312 |

| C3 | 486 | 39 | 0.0371 | 0.7123 | ||||

| CS2–37 | 0.9 Ah | 550 | 360 | C2 | 554 | 4 | 0.0074 | 0.8196 |

| C3 | 496 | 54 | 0.0325 | 0.5716 | ||||

| CS2–38 | 0.9 Ah | 578 | 360 | C2 | 577 | 1 | 0.006 | 0.8474 |

| C3 | 404 | 174 | 0.0444 | 0.3776 |

| Battery Number | EOL | RT | SP | Algorithm | RP | RE | MAE | R2 |

|---|---|---|---|---|---|---|---|---|

| CS2–35 | 0.9 Ah | 531 | 180 | C2 | 543 | 13 | 0.0089 | 0.9145 |

| C3 | 461 | 70 | 0.0334 | 0.7077 | ||||

| CS2–36 | 0.85 Ah | 525 | 180 | C2 | 520 | 5 | 0.0128 | 0.9516 |

| C3 | 406 | 119 | 0.1044 | 0.4705 | ||||

| CS2–37 | 0.9 Ah | 550 | 180 | C2 | 543 | 7 | 0.0105 | 0.9153 |

| C3 | 361 | 189 | 0.0529 | 0.5676 | ||||

| CS2–38 | 0.9 Ah | 578 | 180 | C2 | 549 | 29 | 0.0114 | 0.8916 |

| C3 | 309 | 269 | 0.0421 | 0.6034 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Y.; Qiu, J.; Wang, S.; Yang, X.; Liu, D.; Fernandez, C. Incremental Capacity Curve Health-Indicator Extraction Based on Gaussian Filter and Improved Relevance Vector Machine for Lithium–Ion Battery Remaining Useful Life Estimation. Metals 2022, 12, 1331. https://doi.org/10.3390/met12081331

Fan Y, Qiu J, Wang S, Yang X, Liu D, Fernandez C. Incremental Capacity Curve Health-Indicator Extraction Based on Gaussian Filter and Improved Relevance Vector Machine for Lithium–Ion Battery Remaining Useful Life Estimation. Metals. 2022; 12(8):1331. https://doi.org/10.3390/met12081331

Chicago/Turabian StyleFan, Yongcun, Jingsong Qiu, Shunli Wang, Xiao Yang, Donglei Liu, and Carlos Fernandez. 2022. "Incremental Capacity Curve Health-Indicator Extraction Based on Gaussian Filter and Improved Relevance Vector Machine for Lithium–Ion Battery Remaining Useful Life Estimation" Metals 12, no. 8: 1331. https://doi.org/10.3390/met12081331

APA StyleFan, Y., Qiu, J., Wang, S., Yang, X., Liu, D., & Fernandez, C. (2022). Incremental Capacity Curve Health-Indicator Extraction Based on Gaussian Filter and Improved Relevance Vector Machine for Lithium–Ion Battery Remaining Useful Life Estimation. Metals, 12(8), 1331. https://doi.org/10.3390/met12081331