Development of Carbon Nanotube (CNT)-Reinforced Mg Alloys: Fabrication Routes and Mechanical Properties

Abstract

:1. Introduction

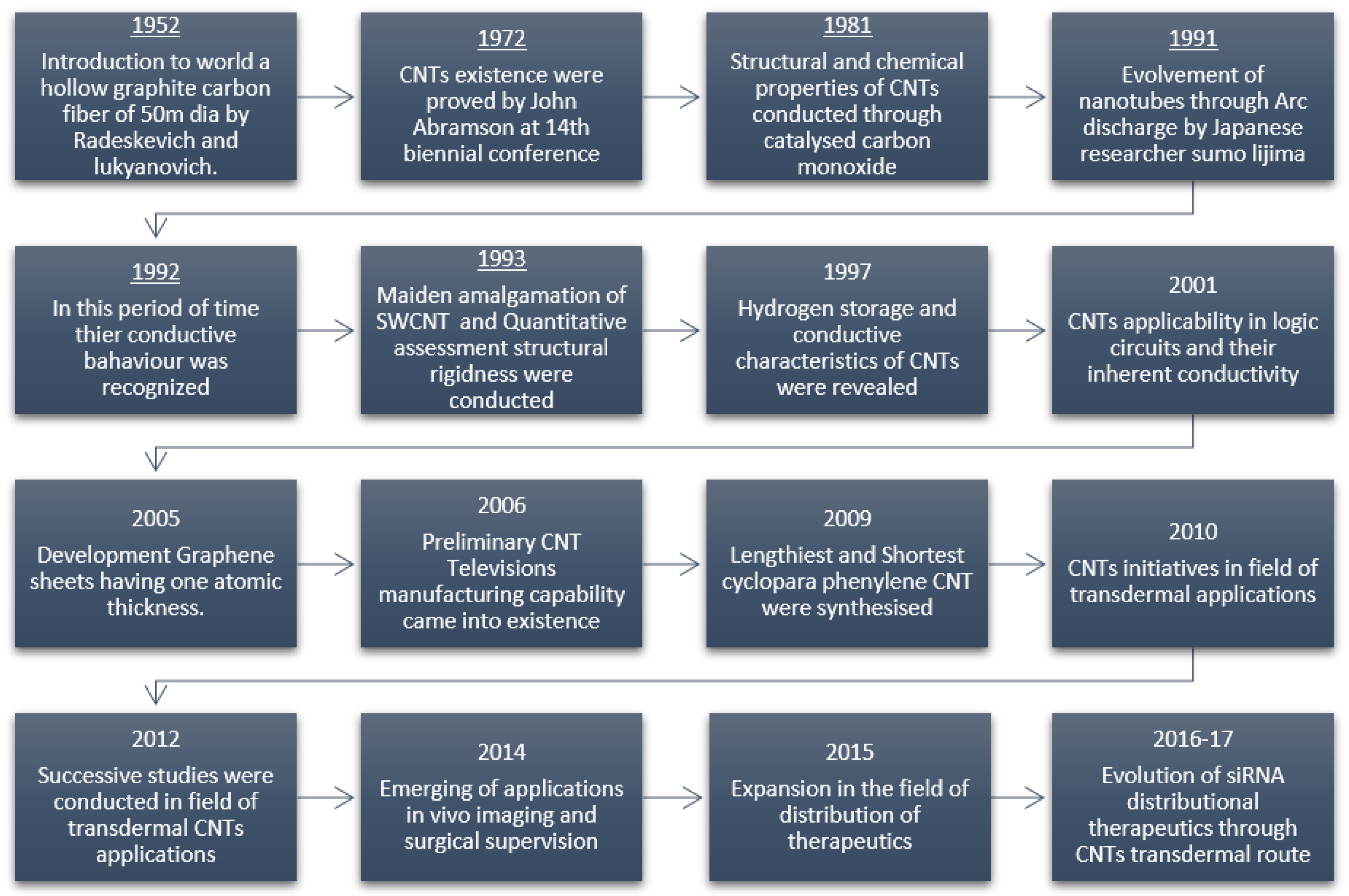

2. Carbon Nanotubes (CNTs)

3. Carbon Nanotube-Reinforced Mg Composites

4. Fabrication Routes to Fabricate Mg-CNTs Composites

4.1. Powder Metallurgy (PM)

4.1.1. Ball Milling (BM)

4.1.2. Ball Milling (BM) Followed by Direct Current Sintering

4.1.3. Pulsed Electric Current Sintering (PECS)

4.2. Semi-Powder Metallurgy (SPM)

4.2.1. Gemini Dispersant

4.2.2. Development of CNT’s Surface Functional Groups

4.3. Extrusion Based on Hot Working

4.4. Metal Fusion and Solidifying Technique

4.4.1. Stir Casting (SC)

4.4.2. Deposition of Disintegrated Melt (DDM)

4.5. Friction Stir Processing (FSP)

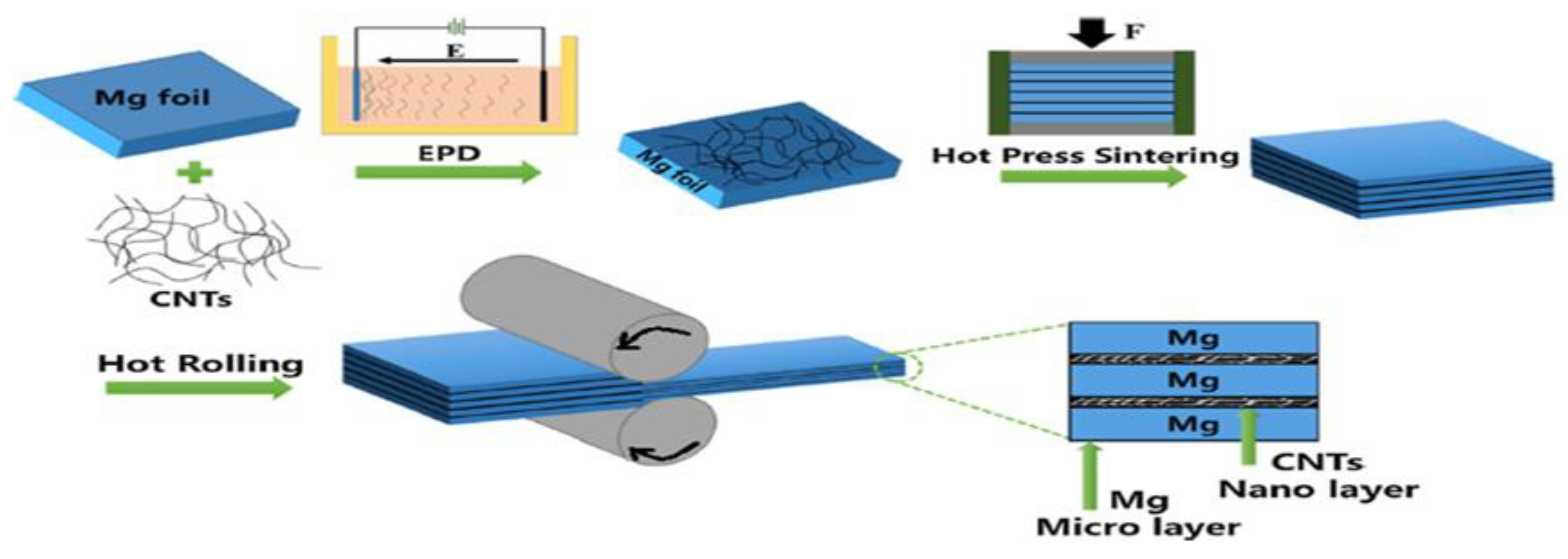

4.6. Spread Dispersion (SD)/Rolling Process

5. Mechanisms Responsible for Strengthening of Nano-Composites

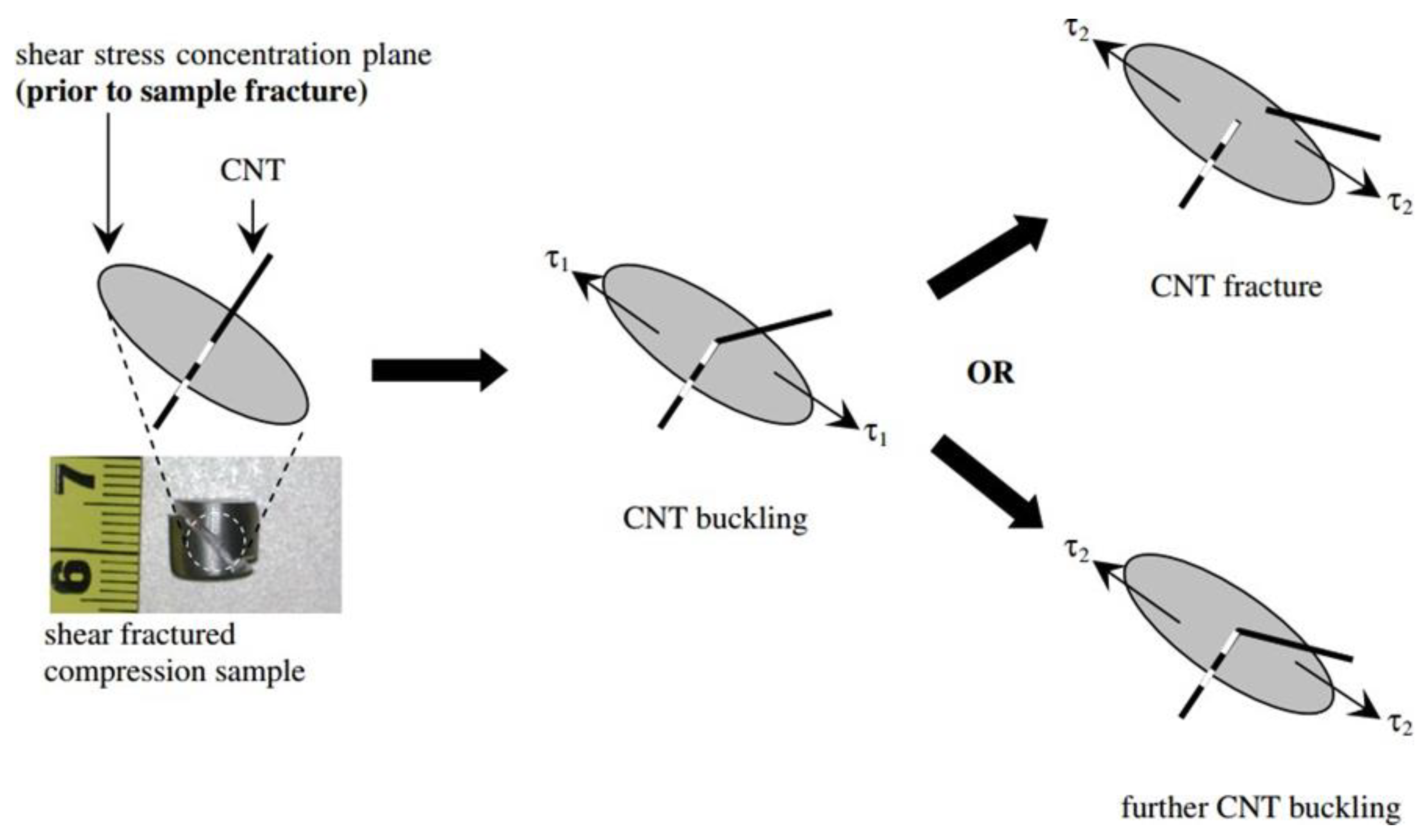

5.1. Load Transfer

5.2. Orowan Mechanism

5.3. Thermal Incongruity

5.4. Grain-Boundary Strengthening

6. Mechanical Properties of Developed Composites Depending on the Production Process

| Sample(s) | Fabrication Method(s) | Young’s Modulus (GPa) | Tensile Proprieties | Compressive Properties | Hardness | Ref. | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.2%TYS (MPa) | UTS (MPa) | Elongation (%) | CYS (MPa) | UCS (MPa) | Failure Strain (%) | |||||

| Mg-1Al | SPM + VS + HTE | ET:12.7 ± 0 EC:5.1 ± 0.2 | 156 ± 3 | 201 ± 3 | 6.8 ± 0.4 | 100 ± 3 | 378 ± 7 | 17 ± 0.4 | 49 ± 3 | [29] |

| Mg-1Al-0.60 GNPs | SPM + VS + HTE | ET: 17.1 ± 0.2 EC: 7.5 ± 0.6 | 202 ± 7 | 263 ± 6 | 4.1 ± 0.7 | 228 ± 4 | 405 ± 4 | 12 ± 0.4 | 62 ± 3 | [29] |

| Mg-1Al-0.60 CNTs | SPM + VS + HTE | ET: 15.5 ± 0.2 EC: 6.6 ± 0.3 | 211 ± 4 | 286 ± 3 | 11 ± 0.2 | 236 ± 3 | 422 ± 3 | 12.3 ± 0.3 | 60 ± 6 | [29] |

| Mg-6Zn-0.5 CNT | BM + ultrasonic treatment + SC | 91 | 193 | - | - | - | - | - | [30] | |

| Mg-1Al-0.60 (1:5) (CNT + GNPs) | SPM + VS + HTE | ET: 15.2 ± 0.3 EC: 6.8 ± 0.3 | 184 ± 5 | 232 ± 5 | 16.1 ± 0.3 | 166 ± 5 | 398 ± 4 | 16 ± 0.3 | 57 ± 4 | [29] |

| Mg (98.5% purity) | MBM + CP + HTE | 126 ± 4 | 203 ± 9 | 8 ± 1 | - | - | - | 47 ± 1 | [31] | |

| Mg-0.06 CNTs | MBM + CP + HTE | 131 ± 3 | 201 ± 3 | 13 ± 1 | - | - | - | 45 ± 1 | [31] | |

| Mg-0.18 CNTs | MBM + CP + HTE | 136 ± 5 | 204 ± 6 | 13 ± 2 | - | - | - | 47 ± 0 | [31] | |

| Mg-0.30 CNTs | MBM + CP + HTE | 147 ± 4 | 212 ± 5 | 7 ± 1 | - | - | - | 46 ± 1 | [31] | |

| AZ91 | SI | 4.8 ± 2 | 82 ± 4 | 204 ± 6 | - | - | - | - | 81 | [32] |

| AZ91-5 MWCNTs | SI | 1.2 ± 2 | 212 ± 11 | 242 ± 9 | - | - | - | - | 151 | [32] |

| AZ91-5 (Si-MWCNTs) | SI | 1.3 ± 2 | 251 ± 11 | 294 ± 9 | - | - | - | - | 159 | [32] |

| AZ91-0.1 MWCNTs | SC | - | - | - | - | 160 ± 4.7 | 414 | 23.6 | [35] | |

| AZ31-0.1 MWCNTs | SC + aged | - | - | - | - | - | - | - | - | [36] |

| AZ31-0.5 MWCNTs | SC + aged | - | - | - | - | - | - | - | - | [36] |

| AZ31-1 MWCNTs | SC + aged | - | - | - | - | - | - | - | - | [36] |

| AZ31-1 CNTs | BM + extrusion + welding | 185 ± 5.7 | 271 ± 7.3 | 7 ± 1.6 | 65 ± 3.5 | [37] | ||||

| Mg-9Al | SPM + HTE | 234 ± 3 | 300 ±4 | 5 ± 1 | 80.2 ± 2.6 | [55] | ||||

| Mg-9Al-0.2 MWCNTs | SPM + HTE | 240 ± 3 | 345 ± 3 | 15 ± 1 | 91.4 ± 1.8 | [55] | ||||

| Mg-9Al 0.4 MWCNTs | SPM + HTE | 247 ± 4 | 354 ± 6 | 14 ± 3 | 94.1 ± 2.6 | [55] | ||||

| Mg-9Al-0.6 MWCNTs | SPM + HTE | 232 ± 3 | 328 ± 2 | 12 ± 1 | 89.3 ± 4.7 | [55] | ||||

| AZ31 | PM + extrusion | 196 ± 5.1 | 284 ± 2.8 | 14.4 ± 1.4 | 161 ± 6.2 | 361 ± 3.4 | 16.2 ± 1.6 | 59 ± 3.1 | [57] | |

| AZ31-0.3 GNP | PM + extrusion | 172 ± 6.3 | 274 ± 5.8 | 21.8 ± 2.7 | 160 ± 4.6 | 396 ± 5.4 | 16.1 ± 1.7 | 70 ± 2.3 | [57] | |

| AZ31-0.3 CNT | PM + extrusion | 211 ± 2.7 | 311 ± 5.2 | 13.2 ± 3.1 | 241 ± 5.6 | 458 ± 6.1 | 14.1 ± 1.2 | 79 ± 2.7 | [57] | |

| Mg- 0.08 CNTs | PM + PECS + HTE | 186 | 237 | 16.2 | [59] | |||||

| AZ81 | DMD + HTE | 224 | 335 | 7.7 | 154 ± 16 | 486 ± 13 | 17.1 ± 0.2 | 118 ± 2 | [62] | |

| AZ81-1.5 CNTs | DMD + HTE | 279 | 391 | 12.7 | 127 ± 18 | 487 ± 11 | 16.2 ± 1.6 | 115 ± 7 | [62] | |

| AZ91 | SPM + HTE | 166 ± 5.0 | 213 ± 6.0 | 6.8 ± 0.2 | 72.1 ± 2.0 | [71] | ||||

| AZ91-1 CNT | SPM + HTE | 172 ± 4.2 | 226 ± 5.2 | 8.4 ± 0.2 | 79.1 ± 2.1 | [71] | ||||

| AZ91-2 CNT | SPM + HTE | 196 ± 4.4 | 262 ± 5.4 | 8.6 ± 0.1 | 87.2 ± 1.6 | [71] | ||||

| AZ91-3 CNT | SPM + HTE | 252 ± 3.6 | 300 ± 4.4 | 9.2 ± 0.2 | 94.2 ± 2.1 | [71] | ||||

| AZ91-4 CNT | SPM + HTE | 188 ± 3.4 | 247 ± 3.8 | 8.4 ± 0.2 | 84.1 ± 1.7 | [71] | ||||

| AZ91-5 CNT | SPM + HTE | 153 ± 4.6 | 227 ± 5.5 | 7.6 ± 0.1 | 80.1 ± 1.6 | [71] | ||||

| AZ91-1(MgO-CNT) | SPM + HTE | 191 ± 3.5 | 261 ± 4.1 | 7.5 ± 0.2 | 80.1 ± 1.6 | [71] | ||||

| AZ91-2(MgO-CNT) | SPM + HTE | 211 ± 5.1 | 293 ± 6.1 | 8.1 ± 0.1 | 89.4 ± 1.1 | [71] | ||||

| AZ91-3(MgO-CNT) | SPM + HTE | 283 ± 4.5 | 330 ± 5.1 | 8.4 ± 0.2 | 96.3 ± 1.1 | [71] | ||||

| AZ91-4(MgO-CNT) | SPM + HTE | 205 ± 3.6 | 271 ± 4.7 | 8.1 ± 0.2 | 86.4 ± 1.1 | [71] | ||||

| AZ91-5(MgO-CNT) | SPM + HTE | 174 ± 5.6 | 254 ± 5.1 | 7.3 ± 0.1 | 83.4 ± 1.4 | [71] | ||||

| Mg | PM + HTE | 104 ± 09 | 238 ± 14 | 19.7 ± 1.6 | 42 ± 4 | [72] | ||||

| Mg-0.5Al-0.18 CNT | PM + HTE | 121 ± 08 | 356 ± 13 | 11.1 ± 1.4 | 51 ± 3 | [72] | ||||

| Mg-1Al-0.18 CNT | PM + HTE | 131 ± 03 | 420 ± 14 | 12.4 ± 1.2 | 57 ± 4 | [72] | ||||

| Mg-1.50Al-0.18 CNT | PM + HTE | 142 ± 06 | 420 ± 10 | 11.1 ± 1.6 | 61 ± 3 | [72] | ||||

| Pure Mg | BM + HPS | 137 | 165 | 72.2 | [73] | |||||

| Mg-(Ni-CNTs) | BM + HPS | 0.43 | 453 | 502 | 10.4 | 503 | [73] | |||

| Mg-0.05 CNT with 20% overall porosity | PM | 71.4 ± 19.3 | [74] | |||||||

| Mg-0.05 CNT with 30% overall porosity | PM | 47 ±19 | [74] | |||||||

| Mg-0.05 CNT with 40% overall porosity | PM | 19 ±9 | [74] | |||||||

| Mg-1 CNT with 20% overall porosity | PM | 87.2 ± 25.7 | [74] | |||||||

| Mg-1 CNT with 30% overall porosity | PM | 51.6 ± 19.4 | [74] | |||||||

| Mg-1 CNT with 40% overall porosity | PM | 24.4 ± 10.6 | [74] | |||||||

| Mg-0.05 CNTs | EPD + HPS + HR | 114 ± 4.1 | 151 ± 4.6 | 4.7 ± 0.8 | [75] | |||||

| Mg-0.10 CNTs | EPD + HPS + HR | 142 ± 7.7 | 173 ± 2.7 | 5.6 ± 0.8 | [75] | |||||

| Mg-2 wt.% CNTs | BM + HPS | 38.7 ± 0.6 | 87 | 141 | 2 | [78] | ||||

| Mg-6Al-0.5 CNT | MBM + CP + HTE | ~161 | ~41 | [96] | ||||||

| Mg-6Al-1 CNT | MBM + CP + HTE | ~141 | ~37 | [96] | ||||||

| Mg-6Al-2 CNT | MBM + CP + HTE | ~106 | ~35 | [96] | ||||||

| Mg-6Al-4 CNT | MBM + CP + HTE | ~77 | ~27 | [96] | ||||||

| AZ91D | SC | 203 | 263 | 73 | [102] | |||||

| AZ91D-2 CNT | SC | 215.13 | 288.22 | 78.48 | [102] | |||||

| AZ91D-3 CNT | SC | 227.24 | 295.46 | 82.77 | [102] | |||||

| AZ91D-4 CNT | SC | 221.19 | 292.36 | 91.87 | [102] | |||||

| AZ91D-2 CNT | SC | 291.2 | 81.21 | [103] | ||||||

| AZ91D-3 CNT | SC | 301.457 | 86.92 | [103] | ||||||

| AZ91D-4 CNT | 294.67 | 92.3 | [103] | |||||||

| ZK60A | DMD | 161 ± 3.2 | 267 ± 2 | 6.7 ± 0.4 | 126 ± 10 | 521 ± 10 | 19.4 ± 0.8 | 138 ± 7 | [105] | |

| ZK60A-1.0 CNT | DMD | 179 ± 5 | 294 ± 7 | 15.2 ± 0.6 | 111 ± 6 | 544 ± 2 | 33.6 ± 6.4 | 113 ± 7 | [105] | |

| Mg-6Zn | As-cast | 71 ± 3.4 | 128 ± 2.5 | 8.2 ± 2.0 | 54 ± 5.9 | [109] | ||||

| Mg-6Zn | FSP | 135 ± 4.7 | 280 ± 4.1 | 18.8 ± 1.2 | 68 ± 3.7 | [109] | ||||

| Mg-6Zn-1.0 CNTs | MBM + SC + FSP | 170 ± 2.1 | 331 ± 5.4 | 15.1 ± 1.3 | 82 ± 7.1 | [109] | ||||

| Mg (98.5% purity) | BM + MS + HTE | 125 ± 2 | 172 ± 4 | 7.7 ± 0.2 | 37 ± 2 | [110] | ||||

| Mg-0.3 CNTs | BM + MS + HTE | 117 ± 3 | 161 ± 6 | 5.5 ± 0.3 | 35 ± 2 | [110] | ||||

| Mg-0.3 (Ni-CNTs) | BM + MS + HTE | 205 ± 3 | 236 ± 2 | 6.3 ± 0.2 | 53 ± 2 | [110] | ||||

| Mg-3Al-1Zn | SPM | 44.2 | 148 | 247 | 15.22 | 47.33 ± 3.4 | [132] | |||

| Mg-3Al-1Zn -0.5 CNTs | SPM | 50.1 | 161 | 268 | 15.93 | 57.31 ± 4.4 | [132] | |||

| Mg-3Al-1Zn -1.0 CNTs | SPM | 55.3 | 185 | 295 | 21.58 | 60.35 ± 2.1 | [132] | |||

| Mg-3Al-1Zn -1.5 CNTs | SPM | 52.3 | 177 | 261 | 21.38 | 60.87 ± 3.2 | [132] | |||

7. Corrosion Properties

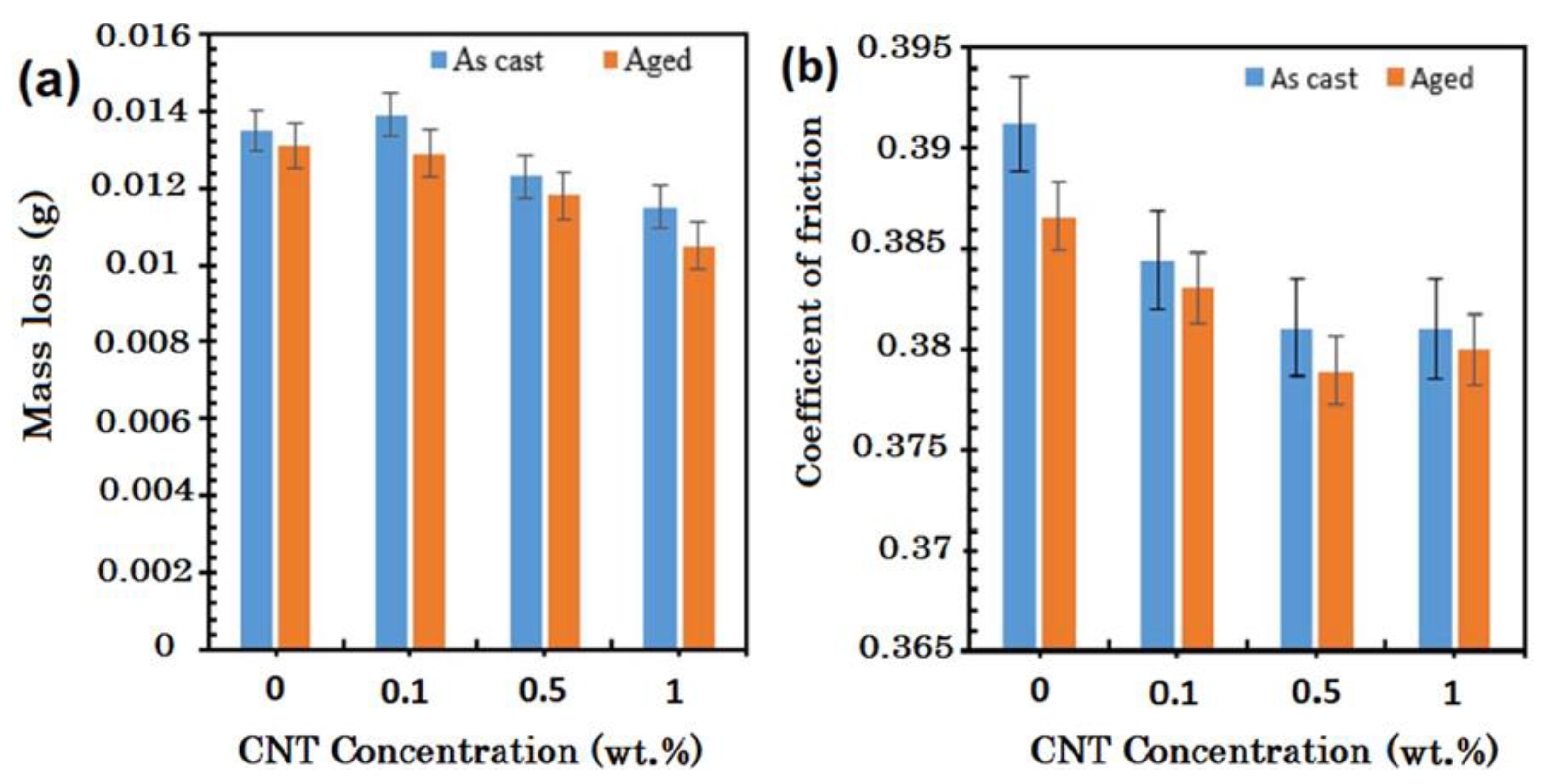

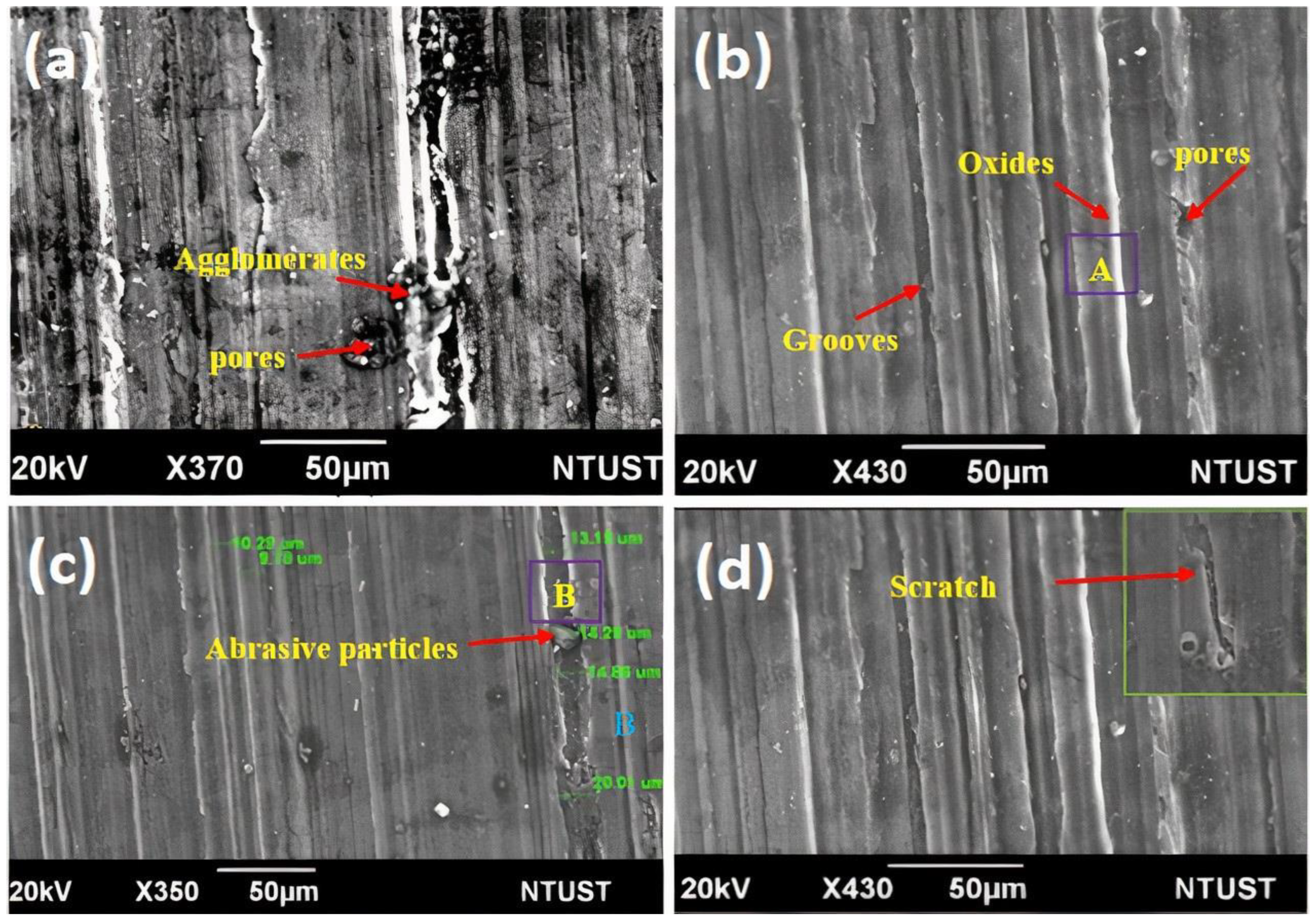

8. Wear and Friction Properties

9. Conclusions

- Due to various obstacles in the fabrication route of CNT-reinforced metal matrix composites (MMCs), inadequate studies have been accomplished in the mentioned domain. Only the fabrication routes pertaining to PM and stirring casting have been comprehensively studied.

- The mechanical characteristics of fabricated Mg/CNT-reinforced composites that have been debated and observed demonstrate that they are broadly altered through the process route adopted to fabricate the composites. Additionally, uniform allocation of CNTs, specifications concerned with CNTs, wt.% of CNTs in matrix material, CNTs’ orientation with matrix material and their in-between interfacial bonding could be the responsible factors for enhancing the mechanical characteristics by an appreciable amount.

- With regard to enhancing the strength of the composites to bear stresses, the load transfer mechanism is expected to happen at the interfaces of the Mg matrix and CNTs in fabricated composites. As a result, the composite will enable the transfer of the stresses to reinforce CNTs more adequately. The interfacial bonding is crucial due to poor wettability between CNTs and the Mg matrix, which arises due to their considerable surface tension difference. This difference in the surface tension prevents the Mg matrix material from being coated with CNTs. This interfacial bonding could be strengthened by enhancing the wettability by incorporating Cu, Ni, or Cr as the coating material for CNTs.

- The mechanism through which the composites were reinforced with CNTs in the Mg matrix that undergoes corrosion is the micro-scale galvanic phenomenon in sodium chloride solution. The CNTs present in the Mg matrix behaved appreciably as cathodes; as a result, increasing the wt.% of CNTs in the Mg matrix could decrease the corrosion resistivity of the fabricated composite.

- The coefficient of friction and wear resistivity of the fabricated composites could be altered according to the fabrication route adopted for fabricating them. Incorporating increased wt.% of CNTs in the Mg matrix could lead to enhanced self-lubrication characteristics, refined mechanical characteristics, low coefficient of friction, and high wear resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ali, Y.; Qiu, D.; Jiang, B.; Pan, F.; Zhang, M.X. Current research progress in grain refinement of cast magnesium alloys: A review article. J. Alloys Compd. 2015, 619, 639–651. [Google Scholar] [CrossRef]

- Saberi, A.; Bakhsheshi-Rad, H.R.; Karamian, E.; Kasiri-Asgarani, M.; Ghomi, H. Magnesium-graphene nano-platelet composites: Corrosion behavior, mechanical and biological properties. J. Alloys Compd. 2020, 821, 153379. [Google Scholar] [CrossRef]

- Chai, F.; Zhang, D.; Zhang, W.; Li, Y. Microstructure evolution during high strain rate tensile deformation of a fine-grained AZ91 magnesium alloy. Mater. Sci. Eng. A 2014, 590, 80–87. [Google Scholar] [CrossRef]

- Pollock, T.M. Weight Loss with Magnesium Alloys. Science 2010, 328, 985–986. [Google Scholar] [CrossRef]

- Barnett, M.R.; Ghaderi, A.; da Fonseca, J.Q.; Robson, J.D. Influence of orientation on twin nucleation and growth at low strains in a magnesium alloy. Acta Mater. 2014, 80, 380–391. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, C.G.; Wang, H.Y.; Nan, X.L.; Liu, G.J.; Jiang, Q.C. Slip-induced texture evolution of rolled Mg–6Al–3Sn alloy during uniaxial tension along rolling and transverse directions. Mater. Sci. Eng. A 2014, 597, 376–380. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, K.; Wang, Z.; Li, S.; Du, W. Microstructure, texture and mechanical properties of as-extruded Mg–Zn–Er alloys containing W-phase. J. Alloys Compd. 2014, 602, 32–39. [Google Scholar] [CrossRef]

- Allen, M.J.; Tung, V.C.; Kaner, R.B. Honeycomb carbon: A review of graphene. Chem. Rev. 2010, 110, 132–145. [Google Scholar] [CrossRef]

- Artiles, M.S.; Rout, C.S.; Fisher, T.S. Graphene-based hybrid materials and devices for biosensing. Adv. Drug Deliv. Rev. 2011, 63, 1352–1360. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Ren, Z.; Chou, T.W. Advances in the science and technology of carbon nanotubes and their composites: A review. Compos. Sci. Technol. 2001, 61, 1899–1912. [Google Scholar] [CrossRef] [Green Version]

- Tjong, S.C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater. Sci. Eng. R Rep. 2013, 74, 281–350. [Google Scholar] [CrossRef]

- Shahin, M.; Munir, K.; Wen, C.; Li, Y. Magnesium matrix nanocomposites for orthopedic applications: A review from mechanical, corrosion, and biological perspectives. Acta Biomater. 2019, 96, 1–19. [Google Scholar] [CrossRef]

- Manchado, M.A.L.; Valentini, L.; Biagiotti, J.; Kenny, J.M. Thermal and mechanical properties of single-walled carbon nanotubes–polypropylene composites prepared by melt processing. Carbon 2005, 43, 1499–1505. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Lahiri, D.; Agarwal, A. Carbon nanotube reinforced metal matrix composites—A review. Int. Mater. Rev. 2010, 55, 41–64. [Google Scholar] [CrossRef]

- Radhamani, A.V.; Lau, H.C.; Ramakrishna, S. CNT-reinforced metal and steel nanocomposites: A comprehensive assessment of progress and future directions. Compos. Part A Appl. Sci. Manuf. 2018, 114, 170–187. [Google Scholar] [CrossRef]

- Yu, F.; Wang, Y.; Liu, Y.; Hui, H.Y.; Wang, F.X.; Li, J.F.; Wang, Q. An aqueous rechargeable zinc-ion battery on basis of an organic pigment. Rare Met. 2022, 41, 2230–2236. [Google Scholar] [CrossRef]

- Fan, W.; Zhang, L.; Liu, T. Graphene-CNT Hybrids for Energy Applications. In Graphene-Carbon Nanotube Hybrids for Energy and Environmental Applications; Springer: Singapore, 2017; pp. 53–90. [Google Scholar] [CrossRef]

- de Vita, A.; Charlier, J.-C.; Blase, X.; Car, R. Electronic structure at carbon nanotube tips. Appl. Phys. A Mater. Sci. Process. 1999, 68, 283–286. [Google Scholar] [CrossRef]

- Popov, V.N. Carbon nanotubes: Properties and application. Mater. Sci. Eng. R: Rep. 2004, 43, 61–102. [Google Scholar] [CrossRef]

- Kuche, K.; Maheshwari, R.; Tambe, V.; Mak, K.K.; Jogi, H.; Raval, N.; Pichika, M.R.; Tekade, R.K. Carbon nanotubes (CNTs) based advanced dermal therapeutics: Current trends and future potential. Nanoscale 2018, 10, 8911–8937. [Google Scholar] [CrossRef]

- Zhao, X.; Song, B.; Fan, W.; Zhang, Y.; Shi, Y. Selective laser melting of carbon/AlSi10Mg composites: Microstructure, mechanical and electronical properties. J. Alloys Compd. 2016, 665, 271–281. [Google Scholar] [CrossRef]

- Huang, Y.; Ouyang, Q.; Zhang, D.; Zhu, J.; Li, R.; Yu, H. Carbon materials reinforced aluminum composites: A review. Acta Metall. Sin. 2014, 27, 775–786. [Google Scholar] [CrossRef]

- Singh, A.; Prabhu, T.R.; Sanjay, A.R.; Koti, V. An Overview of Processing and Properties of CU/CNT Nano Composites. Mater. Today Proc. 2017, 4, 3872–3881. [Google Scholar] [CrossRef]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.J.; Lee, W.R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Cha, S.I.; Kim, K.T.; Arshad, S.N.; Mo, C.B.; Hong, S.H. Extraordinary strengthening effect of carbon nanotubes in metal-matrix nanocomposites processed by molecular-level mixing. Adv. Mater. 2005, 17, 1377–1381. [Google Scholar] [CrossRef]

- Prusty, R.K.; Rathore, D.K.; Ray, B.C. CNT/polymer interface in polymeric composites and its sensitivity study at different environments. Adv. Colloid Interface Sci. 2017, 240, 77–106. [Google Scholar] [CrossRef] [PubMed]

- Neubauer, E.; Kitzmantel, M.; Hulman, M.; Angerer, P. Potential and challenges of metal-matrix-composites reinforced with carbon nanofibers and carbon nanotubes. Compos. Sci. Technol. 2010, 70, 2228–2236. [Google Scholar] [CrossRef] [Green Version]

- Moghadam, A.D.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—A review. Compos. Part B Eng. 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Tang, A.; Asif, M.; Aamir, M. Synergetic effect of graphene nanoplatelets (GNPs) and multi-walled carbon nanotube (MW-CNTs) on mechanical properties of pure magnesium. J. Alloys Compd. 2014, 603, 111–118. [Google Scholar] [CrossRef]

- Shi, H.; Wang, X.; Li, C.; Hu, X.; Ding, C.; Wu, K.; Huang, Y. A novel method to fabricate CNT/Mg-6Zn composites with high strengthening efficiency. Acta Metall. Sin. 2014, 27, 909–917. [Google Scholar] [CrossRef]

- Goh, C.S.; Wei, J.; Lee, L.C.; Gupta, M. Development of novel carbon nanotube reinforced magnesium nanocomposites using the powder metallurgy technique. Nanotechnology 2006, 17, 7–12. [Google Scholar] [CrossRef]

- Park, Y.; Cho, K.; Park, I.; Park, Y. Fabrication and mechanical properties of magnesium matrix composite reinforced with Si coated carbon nanotubes. Procedia Eng. 2011, 10, 1446–1450. [Google Scholar] [CrossRef] [Green Version]

- Morisada, Y.; Fujii, H.; Nagaoka, T.; Fukusumi, M. MWCNTs/AZ31 surface composites fabricated by friction stir processing. Mater. Sci. Eng. A 2006, 419, 344–348. [Google Scholar] [CrossRef]

- Moghadam, A.D.; Schultz, B.F.; Ferguson, J.B.; Omrani, E.; Rohatgi, P.K.; Gupta, N. Functional metal matrix composites: Self-lubricating, self-healing, nanocomposites-an outlook. JOM 2014, 66, 872–881. [Google Scholar] [CrossRef]

- Li, Q.; Viereckl, A.; Rottmair, C.A.; Singer, R.F. Improved processing of carbon nanotube/magnesium alloy composites. Compos. Sci. Technol. 2009, 69, 1193–1199. [Google Scholar] [CrossRef]

- Abbas, A.; Huang, S.J.; Ballóková, B.; Sülleiová, K. Tribological effects of carbon nanotubes on magnesium alloy AZ31 and analyzing aging effects on CNTs/AZ31 composites fabricated by stir casting process. Tribol. Int. 2020, 142, 105982. [Google Scholar] [CrossRef]

- Sabetghadam-Isfahani, A.; Abbasi, M.; Sharifi, S.M.H.; Fattahi, M.; Amirkhanlou, S.; Fattahi, Y. Microstructure and mechanical properties of carbon nanotubes/AZ31 magnesium composite gas tungsten arc welding filler rods fabricated by powder metallurgy. Diam. Relat. Mater. 2016, 69, 160–165. [Google Scholar] [CrossRef]

- Ferguson, J.B.; Sheykh-Jaberi, F.; Kim, C.S.; Rohatgi, P.K.; Cho, K. On the strength and strain to failure in particle-reinforced magnesium metal-matrix nanocomposites (Mg MMNCs). Mater. Sci. Eng. A 2012, 558, 193–204. [Google Scholar] [CrossRef]

- Nanostructured & Amorphous Materials, Inc. (NanoAmor). Available online: https://nanoamor.com/ (accessed on 4 October 2020).

- Lijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar]

- Hashimoto, S.; Iwamoto, T.; Kurachi, D.; Kayahara, E.; Yamago, S. Shortest Double-Walled Carbon Nanotubes Composed of Cycloparaphenylenes. Chempluschem 2017, 82, 1015–1020. [Google Scholar] [CrossRef] [Green Version]

- Lijima, S.; Lchihashi, T. Single-shell carbon nanotubes of 1-nm diameter. Nature 1993, 363, 603–605. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Tabakman, S.; Welsher, K.; Dai, H. Carbon nanotubes in biology and medicine: In vitro and in vivo detection, imaging and drug delivery. Nano Res. 2009, 2, 85–120. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, J.; Zhang, Q.; Gao, L.; Zhong, W.; Sui, G.; Yang, X. Significantly improved electrical and interlaminar mechanical properties of carbon fiber laminated composites by using special carbon nanotube pre-dispersion mixture. Compos. Part A Appl. Sci. Manuf. 2017, 95, 294–303. [Google Scholar] [CrossRef]

- Hu, D.; Xing, Y.; Chen, M.; Gu, B.; Sun, B.; Li, Q. Ultrastrong and excellent dynamic mechanical properties of carbon nanotube composites. Compos. Sci. Technol. 2017, 141, 137–144. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.; Rani, R.; Dilbaghi, N.; Tankeshwar, K.; Kim, K.H. Carbon nanotubes: A novel material for multifaceted applications in human healthcare. Chem. Soc. Rev. 2017, 46, 158–196. [Google Scholar] [CrossRef] [PubMed]

- O’connell, M.J. Carbon Nanotubes: Properties and Applications; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Dong, Z.; Jiang, C.; Cheng, H.; Zhao, Y.; Shi, G.; Jiang, L.; Qu, L. Facile fabrication of light, flexible and multifunctional graphene fibers. Adv. Mater. 2012, 24, 1856–1861. [Google Scholar] [CrossRef]

- Ruoff, R.S.; Qian, D.; Liu, W.K. Mechanical properties of carbon nanotubes: Theoretical predictions and experimental measurements. Comptes Rendus Phys. 2003, 4, 993–1008. [Google Scholar] [CrossRef]

- Abazari, S.; Shamsipur, A.; Bakhsheshi-Rad, H.R.; Ismail, A.F.; Sharif, S.; Razzaghi, M.; Ramakrishna, S.; Berto, F. Carbon nanotubes (CNTs)-reinforced magnesium-based matrix composites: A comprehensive review. Materials 2020, 13, 4421. [Google Scholar] [CrossRef]

- Yu, Y.P. Preparation, purification and properties of carbon nanotubes. Adv. Mater. Res. 2012, 557–559, 472–477. [Google Scholar] [CrossRef]

- Terrones, M. Carbon nanotubes: Synthesis and properties, electronic devices and other emerging applications. Int. Mater. Rev. 2004, 49, 325–377. [Google Scholar] [CrossRef]

- Yang, S.; Yu, S.; Cho, M. Influence of Thrower–Stone–Wales defects on the interfacial properties of carbon nanotube/polypropylene composites by a molecular dynamics approach. Carbon 2013, 55, 133–143. [Google Scholar] [CrossRef]

- Ying, L.S.; Salleh, M.A.b.M.; Yusoff, H.B.M.; Rashid, S.B.A.; Razak, J.B.A. Continuous production of carbon nanotubes—A review. J. Ind. Eng. Chem. 2011, 17, 367–376. [Google Scholar] [CrossRef]

- Hou, J.; Du, W.; Parande, G.; Gupta, M.; Li, S. Significantly enhancing the strength + ductility combination of Mg-9Al alloy using multi-walled carbon nanotubes. J. Alloys Compd. 2019, 790, 974–982. [Google Scholar] [CrossRef]

- Wang, Q.; Du, W.; Liu, K.; Wang, Z.; Li, S.; Wen, K. Microstructure, texture and mechanical properties of as-extruded Mg–Zn–Er alloys. Mater. Sci. Eng. A 2013, 581, 31–38. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Zhang, J.; Asif, M. Use of high energy ball milling to study the role of graphene nanoplatelets and carbon nanotubes reinforced magnesium alloy. J. Alloys Compd. 2015, 646, 223–232. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Asif, M. Exploring mechanical behavior of Mg–6Zn alloy reinforced with graphene nanoplatelets. Mater. Sci. Eng. A 2016, 649, 263–269. [Google Scholar] [CrossRef]

- Han, G.Q.; Shen, J.H.; Ye, X.X.; Chen, B.; Imai, H.; Kondoh, K.; Du, W.B. The influence of CNTs on the microstructure and ductility of CNT/Mg composites. Mater. Lett. 2016, 181, 300–304. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Agarwal, A. An analysis of the factors affecting strengthening in carbon nanotube reinforced aluminum composites. Carbon 2011, 49, 533–544. [Google Scholar] [CrossRef]

- Han, G.; Wang, Z.; Liu, K.; Li, S.; Du, X.; Du, W. Synthesis of CNT-reinforced AZ31 magnesium alloy composites with uniformly distributed CNTs. Mater. Sci. Eng. A 2015, 628, 350–357. [Google Scholar] [CrossRef]

- Paramsothy, M.; Tan, X.H.; Chan, J.; Kwok, R.; Gupta, M. Carbon nanotube addition to concentrated magnesium alloy AZ81: Enhanced ductility with occasional significant increase in strength. Mater. Des. 2013, 45, 15–23. [Google Scholar] [CrossRef]

- Fukuda, H.; Kondoh, K.; Umeda, J.; Fugetsu, B. Interfacial analysis between Mg matrix and carbon nanotubes in Mg–6 wt.% Al alloy matrix composites reinforced with carbon nanotubes. Compos. Sci. Technol. 2011, 71, 705–709. [Google Scholar] [CrossRef]

- Ghali, E.; Dietzel, W.; Kainer, K.U. General and Localized Corrosion of Magnesium Alloys: A Critical Review. J. Mater. Eng. Perform. 2004, 13, 7–23. [Google Scholar] [CrossRef]

- Aung, N.N.; Zhou, W.; Goh, C.S.; Nai, S.M.L.; Wei, J. Effect of carbon nanotubes on corrosion of Mg–CNT composites. Corros. Sci. 2010, 52, 1551–1553. [Google Scholar] [CrossRef]

- Fukuda, H.; Szpunar, J.A.; Kondoh, K.; Chromik, R. The influence of carbon nanotubes on the corrosion behaviour of AZ31B magnesium alloy. Corros. Sci. 2010, 52, 3917–3923. [Google Scholar] [CrossRef]

- Stansbury, E.E.; Buchanan, R.A. Fundamentals of Electrochemical Corrosion; ASM International: Novelty, OH, USA, 2000; ISBN 1615030670. [Google Scholar]

- Li, C.D.; Wang, X.J.; Liu, W.Q.; Shi, H.L.; Ding, C.; Hu, X.S.; Zheng, M.Y.; Wu, K. Effect of solidification on microstructures and mechanical properties of carbon nanotubes reinforced magnesium matrix composite. Mater. Des. 2014, 58, 204–208. [Google Scholar] [CrossRef]

- Honma, T.; Nagai, K.; Katou, A.; Arai, K.; Suganuma, M.; Kamado, S. Synthesis of high-strength magnesium alloy composites reinforced with Si-coated carbon nanofibres. Scr. Mater. 2009, 60, 451–454. [Google Scholar] [CrossRef]

- Liang, J.; Li, H.; Qi, L.; Tian, W.; Li, X.; Zhou, J.; Wang, D.; Wei, J. Influence of Ni-CNTs additions on the microstructure and mechanical properties of extruded Mg-9Al alloy. Mater. Sci. Eng. A 2016, 678, 101–109. [Google Scholar] [CrossRef]

- Yuan, Q.-H.; Zeng, X.-S.; Liu, Y.; Luo, L.; Wu, J.-B.; Wang, Y.-C.; Zhou, G.-H. Microstructure and mechanical properties of AZ91 alloy reinforced by carbon nanotubes coated with MgO. Carbon 2016, 96, 843–855. [Google Scholar] [CrossRef]

- Habibi, M.K.; Paramsothy, M.; Hamouda, A.M.S.; Gupta, M. Enhanced compressive response of hybrid Mg-CNT nano-composites. J. Mater. Sci. 2011, 46, 4588–4597. [Google Scholar] [CrossRef]

- Yuan, Q.H.; Zeng, X.S.; Liu, Y.; Luo, L.; Wu, J.B.; Wang, Y.C.; Zhou, G.H. High performance carbon nanotube-reinforced magnesium nanocomposite. Mater. Sci. Eng. A 2020, 771, 138575. [Google Scholar] [CrossRef]

- Zou, N.; Li, Q. Compressive mechanical property of porous magnesium composites reinforced by carbon nanotubes. J. Mater. Sci. 2016, 51, 5232–5239. [Google Scholar] [CrossRef]

- Xiang, Y.; Wang, X.; Hu, X.; Meng, L.; Song, Z.; Li, X.; Sun, Z.; Zhang, Q.; Wu, K. Achieving ultra-high strengthening and toughening efficiency in carbon nanotubes/magnesium composites via constructing micro-nano layered structure. Compos. Part A Appl. Sci. Manuf. 2019, 119, 225–234. [Google Scholar] [CrossRef]

- Li, Q.; Tian, B. Compression behavior of magnesium/carbon nanotube composites. J. Mater. Res. 2013, 28, 1877–1884. [Google Scholar] [CrossRef]

- Thornby, J.; Harris, A.; Bird, A.; Beake, B.; Manakari, V.; Gupta, M.; Haghshenas, M. Micromechanics and indentation creep of magnesium carbon nanotube nanocomposites: 298 K–573 K. Mater. Sci. Eng. A 2021, 801, 140418. [Google Scholar] [CrossRef]

- Carreño-Morelli, E.; Yang, J.; Couteau, E.; Hernadi, K.; Seo, J.W.; Bonjour, C.; Schaller, R. Carbon nanotube/magnesium composites. Phys. Status Solidi Appl. Res. 2004, 201, R53–R55. [Google Scholar] [CrossRef]

- Endo, M.; Hayashi, T.; Itoh, I.; Kim, Y.A.; Shimamoto, D.; Muramatsu, H.; Shimizu, Y.; Morimoto, S.; Terrones, M.; Iinou, S.; et al. An anticorrosive magnesium/carbon nanotube composite. Appl. Phys. Lett. 2008, 92, 063105. [Google Scholar] [CrossRef] [Green Version]

- Fukuda, H.; Kondoh, K.; Umeda, J.; Fugetsu, B. Fabrication of magnesium based composites reinforced with carbon nanotubes having superior mechanical properties. Mater. Chem. Phys. 2011, 127, 451–458. [Google Scholar] [CrossRef]

- Hulbert, D.M.; Anders, A.; Andersson, J.; Lavernia, E.J.; Mukherjee, A.K. A discussion on the absence of plasma in spark plasma sintering. Scr. Mater. 2009, 60, 835–838. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Asif, M.; Tang, A. Powder metallurgy of Mg–1%Al–1%Sn alloy reinforced with low content of graphene nanoplatelets (GNPs). J. Ind. Eng. Chem. 2014, 20, 4250–4255. [Google Scholar] [CrossRef]

- Kondoh, K.; Fukuda, H.; Umeda, J.; Imai, H.; Fugetsu, B.; Endo, M. Microstructural and mechanical analysis of carbon nanotube reinforced magnesium alloy powder composites. Mater. Sci. Eng. A 2010, 527, 4103–4108. [Google Scholar] [CrossRef]

- Suslick, K.S.; Hammerton, D.A.; Cline, R.E. Sonochemical Hot Spot; McGraw-Hill: New York, NY, USA, 1986. [Google Scholar]

- Abazari, S.; Shamsipur, A.; Bakhsheshi-Rad, H.R.; Berto, F. Functionalized carbon nanotube-encapsulated magnesium-based nanocomposites with outstanding mechanical and biological properties as load-bearing bone implants. Mater. Des. 2022, 213, 110354. [Google Scholar] [CrossRef]

- Matsuda, T.; Minami, D.; Khoerunnisa, F.; Sunaga, M.; Nakamura, M.; Utsumi, S.; Itoh, T.; Fujimori, T.; Hayashi, T.; Hattori, Y.; et al. Aqueous Nanosilica Dispersants for Carbon Nanotube. Langmuir 2015, 31, 3194–3202. [Google Scholar] [CrossRef] [PubMed]

- O’Connell, M.J.; Bachilo, S.M.; Huffman, C.B.; Moore, V.C.; Strano, M.S.; Haroz, E.H.; Rialon, K.L.; Boul, P.J.; Noon, W.H.; Kittrell, C.; et al. Band gap fluorescence from individual single-walled carbon nanotubes. Science 2002, 297, 593–596. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- di Crescenzo, A.; Cambré, S.; Germani, R.; di Profio, P.; Fontana, A. Dispersion of SWCNTs with imidazolium-rich surfactants. Langmuir 2014, 30, 3979–3987. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yu, L.; Zhang, S.; Yuan, J.; Shi, L.; Zheng, L. Dispersion of multiwalled carbon nanotubes by ionic liquid-type Gemini imidazolium surfactants in aqueous solution. Colloids Surf. A Physicochem. Eng. Asp. 2010, 359, 66–70. [Google Scholar] [CrossRef]

- Chen, L.; Xie, H. Properties of carbon nanotube nanofluids stabilized by cationic gemini surfactant. Thermochim. Acta 2010, 506, 62–66. [Google Scholar] [CrossRef]

- Hou, J.; Du, W.; Meng, F.; Zhao, C.; Du, X. Effective dispersion of multi-walled carbon nanotubes in aqueous solution using an ionic-gemini dispersant. J. Colloid Interface Sci. 2018, 512, 750–757. [Google Scholar] [CrossRef]

- Goh, C.S.; Wei, J.; Lee, L.C.; Gupta, M. Simultaneous enhancement in strength and ductility by reinforcing magnesium with carbon nanotubes. Mater. Sci. Eng. A 2006, 423, 153–156. [Google Scholar] [CrossRef]

- Aydin, F.; Ayday, A.; Turan, M.E.; Zengin, H. Role of graphene additive on wear and electrochemical corrosion behaviour of plasma electrolytic oxidation (PEO) coatings on Mg–MWCNT nanocomposite. Surf. Eng. 2020, 36, 791–799. [Google Scholar] [CrossRef]

- Kumar, H.P.; Xavior, M.A. Graphene Reinforced Metal Matrix Composite (GRMMC): A Review. Procedia Eng. 2014, 97, 1033–1040. [Google Scholar] [CrossRef] [Green Version]

- Shimizu, Y.; Miki, S.; Soga, T.; Itoh, I.; Todoroki, H.; Hosono, T.; Sakaki, K.; Hayashi, T.; Kim, Y.; Endo, M.; et al. Multi-walled carbon nanotube-reinforced magnesium alloy composites. Scr. Mater. 2008, 58, 267–270. [Google Scholar] [CrossRef] [Green Version]

- Mindivan, H.; Efe, A.; Kosatepe, A.H.; Kayali, E.S. Fabrication and characterization of carbon nanotube reinforced magnesium matrix composites. Appl. Surf. Sci. 2014, 318, 234–243. [Google Scholar] [CrossRef]

- Goh, C.S.; Wei, J.; Lee, L.C.; Gupta, M. Ductility improvement and fatigue studies in Mg-CNT nanocomposites. Compos. Sci. Technol. 2008, 68, 1432–1439. [Google Scholar] [CrossRef]

- Li, Q.; Rottmair, C.A.; Singer, R.F. CNT reinforced light metal composites produced by melt stirring and by high pressure die casting. Compos. Sci. Technol. 2010, 70, 2242–2247. [Google Scholar] [CrossRef] [Green Version]

- Gupta, M.; Sharon, N.M.L. Magnesium, Magnesium Alloys, Magnesium Composites; John Wiley & Sons: Hoboken, NJ, USA, 2011; ISBN 1118102703. [Google Scholar]

- Tun, K.S.; Gupta, M. Improving mechanical properties of magnesium using nano-yttria reinforcement and microwave assisted powder metallurgy method. Compos. Sci. Technol. 2007, 67, 2657–2664. [Google Scholar] [CrossRef]

- Sherif, E.-S.M.; Latief, F.H.; Junaedi, H.; Almajid, A.A. Influence of Exfoliated Graphite Nanoplatelets Particles Additions and Sintering Temperature on the Mechanical Properties of Aluminum Matrix Composites. Int. J. Electrochem. Sci. 2012, 7, 4352–4361. [Google Scholar]

- Kumar, S.P.; Selvamani, S.T.; Vigneshwar, M.; Hariharan, S.J. Tensile, Microhardness, and Microstructural Analysis on Mg-CNT Nano Composites. Mater. Today Proc. 2018, 5, 7882–7888. [Google Scholar] [CrossRef]

- Selvamani, S.T.; Premkumar, S.; Vigneshwar, M.; Hariprasath, P.; Palanikumar, K. Influence of carbon nano tubes on mechanical, metallurgical and tribological behavior of magnesium nanocomposites. J. Magnes. Alloy. 2017, 5, 326–335. [Google Scholar] [CrossRef]

- Yuan, Q.H.; Liao, L.; Zhou, G.H.; Liu, Z.Y. ZM1 magnesium alloy reinforced by carbon nanotubes using an improved casting process. Rare Met. 2021, 40, 1275–1283. [Google Scholar] [CrossRef]

- Paramsothy, M.; Chan, J.; Kwok, R.; Gupta, M. Addition of CNTs to enhance tensile/compressive response of magnesium alloy ZK60A. Compos. Part A Appl. Sci. Manuf. 2011, 42, 180–188. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Sharma, S.; Handa, A.; Singh, S.S.; Verma, D. Influence of tool rotation speeds on mechanical and morphological properties of friction stir processed nano hybrid composite of MWCNT-Graphene-AZ31 magnesium. J. Magnes. Alloy. 2019, 7, 487–500. [Google Scholar] [CrossRef]

- Jamshidijam, M.; Akbari-Fakhrabadi, A.; Masoudpanah, S.M.; Hasani, G.H.; Mangalaraja, R.v. Wear Behavior of Multiwalled Carbon Nanotube/AZ31 Composite Obtained by Friction Stir Processing. Tribol. Trans. 2013, 56, 827–832. [Google Scholar] [CrossRef]

- Huang, Y.; Li, J.; Wan, L.; Meng, X.; Xie, Y. Strengthening and toughening mechanisms of CNTs/Mg-6Zn composites via friction stir processing. Mater. Sci. Eng. A 2018, 732, 205–211. [Google Scholar] [CrossRef]

- Nai, M.H.; Wei, J.; Gupta, M. Interface tailoring to enhance mechanical properties of carbon nanotube reinforced magnesium composites. Mater. Des. 2014, 60, 490–495. [Google Scholar] [CrossRef]

- Clyne, T.W.; Withers, P.J. An Introduction to Metal Matrix Composites; Cambridge University Press: Cambridge, UK, 1995; ISBN 0521483573. [Google Scholar]

- Nardone, V.C.; Prewo, K.M. On the strength of discontinuous silicon carbide reinforced aluminum composites. Scr. Metall. 1986, 20, 43–48. [Google Scholar] [CrossRef]

- Chen, B.; Shen, J.; Ye, X.; Jia, L.; Li, S.; Umeda, J.; Takahashi, M.; Kondoh, K. Length effect of carbon nanotubes on the strengthening mechanisms in metal matrix composites. Acta Mater. 2017, 140, 317–325. [Google Scholar] [CrossRef]

- Chen, B.; Shen, J.; Ye, X.; Imai, H.; Umeda, J.; Takahashi, M.; Kondoh, K. Solid-state interfacial reaction and load transfer efficiency in carbon nanotubes (CNTs)-reinforced aluminum matrix composites. Carbon 2017, 114, 198–208. [Google Scholar] [CrossRef]

- Chen, B.; Li, S.; Imai, H.; Jia, L.; Umeda, J.; Takahashi, M.; Kondoh, K. Load transfer strengthening in carbon nanotubes reinforced metal matrix composites via in-situ tensile tests. Compos. Sci. Technol. 2015, 113, 1–8. [Google Scholar] [CrossRef]

- Xiang, S.; Wang, X.; Gupta, M.; Wu, K.; Hu, X.; Zheng, M. Graphene nanoplatelets induced heterogeneous bimodal structural magnesium matrix composites with enhanced mechanical properties. Sci. Rep. 2016, 6, 38824. [Google Scholar] [CrossRef]

- Landis, C.M.; McMeeking, R.M. A shear-lag model for a broken fiber embedded in a composite with a ductile matrix. Compos. Sci. Technol. 1999, 59, 447–457. [Google Scholar] [CrossRef]

- Li, P.; Tan, W.; Gao, M.; Shi, K. Strengthening of the magnesium matrix composites hybrid reinforced by chemically oxidized carbon nanotubes and in situ Mg2Sip. J. Alloys Compd. 2021, 858, 158673. [Google Scholar] [CrossRef]

- Park, J.G.; Keum, D.H.; Lee, Y.H. Strengthening mechanisms in carbon nanotube-reinforced aluminum composites. Carbon 2015, 95, 690–698. [Google Scholar] [CrossRef]

- Mirza, F.A.; Chen, D.L. A unified model for the prediction of yield strength in particulate-reinforced metal matrix nanocomposites. Materials 2015, 8, 5138–5153. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ma, P.; Jia, Y.; Gokuldoss, P.K.; Yu, Z.; Yang, S.; Zhao, J.; Li, C. Effect of Al2O3 nanoparticles as reinforcement on the tensile behavior of Al-12Si composites. Metals 2017, 7, 359. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Liu, B.; Fang, Q.H.; Huang, Z.W.; Liu, Y.W. Atomic-scale strengthening mechanism of dislocation-obstacle interaction in silicon carbide particle-reinforced copper matrix nanocomposites. Ceram. Int. 2017, 43, 3839–3846. [Google Scholar] [CrossRef]

- Zhao, X.; Lu, C.; Tieu, A.K.; Pei, L.; Zhang, L.; Cheng, K.; Huang, M. Strengthening mechanisms and dislocation processes in <111> textured nanotwinned copper. Mater. Sci. Eng. A 2016, 676, 474–486. [Google Scholar] [CrossRef]

- Kim, K.T.; Eckert, J.; Menzel, S.B.; Gemming, T.; Hong, S.H. Grain refinement assisted strengthening of carbon nanotube reinforced copper matrix nanocomposites. Appl. Phys. Lett. 2008, 92, 12. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.-C.; Zhang, Z.-H.; Sun, Y.-J.; Liu, Y.; Hu, Z.-Y.; Wang, H.; Korznikov, A.V.; Korznikova, E.; Liu, Z.-F.; Osamu, S. Rapid and low temperature spark plasma sintering synthesis of novel carbon nanotube reinforced titanium matrix composites. Carbon 2015, 95, 396–407. [Google Scholar] [CrossRef]

- George, R.; Kashyap, K.T.; Rahul, R.; Yamdagni, S. Strengthening in carbon nanotube/aluminium (CNT/Al) composites. Scr. Mater. 2005, 53, 1159–1163. [Google Scholar] [CrossRef]

- Zeng, X.; Zhou, G.H.; Xu, Q.; Xiong, Y.; Luo, C.; Wu, J. A new technique for dispersion of carbon nanotube in a metal melt. Mater. Sci. Eng. A 2010, 527, 5335–5340. [Google Scholar] [CrossRef]

- Liu, S.Y.; Gao, F.P.; Zhang, Q.Y.; Zhu, X.; Li, W.Z. Fabrication of carbon nanotubes reinforced AZ91D composites by ultrasonic processing. Trans. Nonferrous Met. Soc. China 2010, 20, 1222–1227. [Google Scholar] [CrossRef]

- Sun, F.; Shi, C.; Rhee, K.Y.; Zhao, N. In situ synthesis of CNTs in Mg powder at low temperature for fabricating reinforced Mg composites. J. Alloys Compd. 2013, 551, 496–501. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.W. Nanotube buckling in aligned multi-wall carbon nanotube composites. Carbon 2004, 42, 3015–3018. [Google Scholar] [CrossRef]

- Namilae, S.; Chandra, N. Role of atomic scale interfaces in the compressive behavior of carbon nanotubes in composites. Compos. Sci. Technol. 2006, 66, 2030–2038. [Google Scholar] [CrossRef] [Green Version]

- Wu, L.; Wu, R.; Hou, L.; Zhang, J.; Sun, J.; Zhang, M. Microstructure and Mechanical Properties of CNT-Reinforced AZ31 Matrix Composites Prepared Using Hot-Press Sintering. J. Mater. Eng. Perform. 2017, 26, 5495–5500. [Google Scholar] [CrossRef]

- Hamdy, A.S.; Alfosail, F.; Gasem, Z. Electrochemical behavior of a discontinuously A6092/SiC/17.5p metal matrix composite in chloride containing solution. Electrochim. Acta 2013, 88, 129–134. [Google Scholar] [CrossRef]

- Abhijeet, S.B.; Balasubramaniam, R.; Gupta, M. Corrosion behaviour of Mg–Cu and Mg–Mo composites in 3.5% NaCl. Corros. Sci. 2008, 50, 2423–2428. [Google Scholar] [CrossRef]

- Bakkar, A.; Neubert, V. Corrosion characterisation of alumina–magnesium metal matrix composites. Corros. Sci. 2007, 49, 1110–1130. [Google Scholar] [CrossRef]

- Tiwari, S.; Balasubramaniam, R.; Gupta, M. Corrosion behavior of SiC reinforced magnesium composites. Corros. Sci. 2007, 49, 711–725. [Google Scholar] [CrossRef]

- Turhan, M.C.; Li, Q.; Jha, H.; Singer, R.F.; Virtanen, S. Corrosion behaviour of multiwall carbon nanotube/magnesium composites in 3.5% NaCl. Electrochim. Acta 2011, 56, 7141–7148. [Google Scholar] [CrossRef]

- Li, Q.; Turhan, M.C.; Rottmair, C.A.; Singer, R.F.; Virtanen, S. Influence of MWCNT dispersion on corrosion behaviour of their Mg composites. Mater. Corros. 2012, 63, 384–387. [Google Scholar] [CrossRef]

- Aung, N.N.; Zhou, W. Effect of grain size and twins on corrosion behaviour of AZ31B magnesium alloy. Corros. Sci. 2010, 52, 589–594. [Google Scholar] [CrossRef]

- Zhou, W.; Aung, N.N.; Sun, Y. Effect of antimony, bismuth and calcium addition on corrosion and electrochemical behaviour of AZ91 magnesium alloy. Corros. Sci. 2009, 51, 403–408. [Google Scholar] [CrossRef]

- Aung, N.N.; Zhou, W. Effect of heat treatment on corrosion and electrochemical behaviour of AZ91D magnesium alloy. J. Appl. Electrochem. 2002, 32, 1397–1401. [Google Scholar] [CrossRef]

- Shi, J.; Ming, J.; Sun, W. Passivation and chloride-induced corrosion of a duplex alloy steel in alkali-activated slag extract solutions. Constr. Build. Mater. 2017, 155, 992–1002. [Google Scholar] [CrossRef]

- Jia, J.X.; Atrens, A.; Song, G.; Muster, T.H. Simulation of galvanic corrosion of magnesium coupled to a steel fastener in NaCI solution. Mater. Corros. 2005, 56, 468–474. [Google Scholar] [CrossRef]

- Andreatta, F.; Apachitei, I.; Kodentsov, A.A.; Dzwonczyk, J.; Duszczyk, J. Volta potential of second phase particles in extruded AZ80 magnesium alloy. Electrochim. Acta 2006, 51, 3551–3557. [Google Scholar] [CrossRef]

- Ali, M.; Hussein, M.A.; Al-Aqeeli, N. Magnesium-based composites and alloys for medical applications: A review of mechanical and corrosion properties. J. Alloys Compd. 2019, 792, 1162–1190. [Google Scholar] [CrossRef]

- Zhang, T.; Shao, Y.; Meng, G.; Wang, F. Electrochemical noise analysis of the corrosion of AZ91D magnesium alloy in alkaline chloride solution. Electrochim. Acta 2007, 53, 561–568. [Google Scholar] [CrossRef]

- Biezma, M.V. The role of hydrogen in microbiologically influenced corrosion and stress corrosion cracking. Int. J. Hydrogen. Energy 2001, 26, 515–520. [Google Scholar] [CrossRef]

- Saikrishna, N.; Reddy, G.P.K.; Munirathinam, B.; Dumpala, R.; Jagannatham, M.; Sunil, B.R. An investigation on the hardness and corrosion behavior of MWCNT/Mg composites and grain refined Mg. J. Magnes. Alloy. 2018, 6, 83–89. [Google Scholar] [CrossRef]

- Funatsu, K.; Fukuda, H.; Takei, R.; Umeda, J.; Kondoh, K. Quantitative evaluation of initial galvanic corrosion behavior of CNTs reinforced Mg–Al alloy. Adv. Powder Technol. 2013, 24, 833–837. [Google Scholar] [CrossRef]

- Say, Y.; Guler, O.; Dikici, B. Carbon nanotube (CNT) reinforced magnesium matrix composites: The effect of CNT ratio on their mechanical properties and corrosion resistance. Mater. Sci. Eng. A 2020, 798, 139636. [Google Scholar] [CrossRef]

- Daavari, M.; Atapour, M.; Mohedano, M.; Sánchez, H.M.; Rodríguez-Hernández, J.; Matykina, E.; Arrabal, R.; Taherizadeh, A. Quasi-in vivo corrosion behavior of AZ31B Mg alloy with hybrid MWCNTs-PEO/PCL based coatings. J. Magnes. Alloy. 2021, 2213–9567. [Google Scholar] [CrossRef]

- Kumar, A.M.; Hassan, S.F.; Sorour, A.A.; Paramsothy, M.; Gupta, M. Investigation on the Controlled Degradation and Invitro Mineralization of Carbon Nanotube Reinforced AZ31 Nanocomposite in Simulated Body Fluid. Met. Mater. Int. 2019, 25, 105–116. [Google Scholar] [CrossRef]

- Turan, M.E.; Sun, Y.; Aydin, F.; Zengin, H.; Turen, Y.; Ahlatci, H. Effects of carbonaceous reinforcements on microstructure and corrosion properties of magnesium matrix composites. Mater. Chem. Phys. 2018, 218, 182–188. [Google Scholar] [CrossRef]

- Al-Qutub, A.M.; Khalil, A.; Saheb, N.; Hakeem, A.S. Wear and friction behavior of Al6061 alloy reinforced with carbon nanotubes. Wear 2013, 297, 752–761. [Google Scholar] [CrossRef]

- Choi, H.J.; Lee, S.M.; Bae, D.H. Wear characteristic of aluminum-based composites containing multi-walled carbon nanotubes. Wear 2010, 270, 12–18. [Google Scholar] [CrossRef]

- Taltavull, C.; Rodrigo, P.; Torres, B.; López, A.J.; Rams, J. Dry sliding wear behavior of AM50B magnesium alloy. Mater. Des. 2014, 56, 549–556. [Google Scholar] [CrossRef]

- Wu, J.B.; Zeng, X.S.; Luo, L.; Yuan, Q.H. Friction and wear properties of Carbon Nanotubes/AZ91 composites. Master Sci. Mech. 2015, 39, 101–105. [Google Scholar]

- Habibnejad-Korayem, M.; Mahmudi, R.; Ghasemi, H.M.; Poole, W.J. Tribological behavior of pure Mg and AZ31 magnesium alloy strengthened by Al2O3 nano-particles. Wear 2010, 268, 405–412. [Google Scholar] [CrossRef]

- Zhang, J.; Alpas, A.T. Transition between mild and severe wear in aluminium alloys. Acta Mater. 1997, 45, 513–528. [Google Scholar] [CrossRef]

- Faruk, M.E.R.T. Wear behaviour of hot rolled AZ31B magnesium alloy as candidate for biodegradable implant material. Trans. Nonferrous Met. Soc. China 2017, 27, 2598–2606. [Google Scholar] [CrossRef]

| Samples | Reinforcement | Processing Route | Reinforcement Particle Size | Corrosion Medium | Icorr. (µA·cm−2) | Ecorr. (V vs. SCE) | Corrosion Rate (mm/year) | Rp (Ω·cm2) | Ref. | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Non-Polarized | Polarized | ||||||||||

| Immersion Time (h) | HE or WL | PDP | |||||||||

| Mg | CNT (0.3 wt.%) | DMD | Average diameter: 20 nm and length: less than 100 µm | 3.5 wt.% NaCl | 57 | –1.56 | - | - | - | - | [63] |

| CNT (1.3 wt.%) | 571 | –1.51 | - | - | - | - | |||||

| Mg | MWCNTs (0.5 wt.%) | SPM | - | 3.5 wt.% NaCl | 578.2 µA | –1.541 | - | - | 24.60 mm/year | - | [93] |

| Mg | MWCNTs (0.5 wt.%) | SPM + PEO | - | 129.6 µA | –1.399 | - | - | 14.76 mm/year | - | ||

| Mg-0.5 MWCNT | GNP | SPM + PEO (coating with graphene addition) | - | 100.9 µA | –1.421 | - | - | 14.47 mm/year | - | ||

| Mg–6Al | CNT (4 wt.%) | MBM + CP + HTE | Average diameter: 9.5 nm; average length: 1.5 µm | 3.5% NaCl | 4 | –1.53 | [96] | ||||

| Mg | MWCNTs (0.1 wt.%)-Dispersed during melt stirring process (0 h) | MS | - | 3.5% NaCl | 97 | –1.616 | - | - | 4.4 mm/year | 367 | [137] |

| MWCNTs (0.1 wt.%)- Dispersed during melt stirring process (6 h) | - | 279 | –1.519 | - | - | 12.6 mm/year | 331 | ||||

| AZ91 | MWCNTs (1 wt.%) | MS | - | 3.5% NaCl | - | - | - | - | 4–8 gm−2 day−1 | - | [138] |

| MWCNTs (5 wt.%) | - | - | - | - | - | 18–23 gm−2 day−1 | - | ||||

| AZ31 | - | DMD | - | SBF | 93.71 | –1.543 | 1 | 2.177 mm/year | - | - | [152] |

| - | 44.21 | –1.440 | 23 | 1.018 mm/year | - | - | |||||

| - | 212.44 | –1.401 | 337 | 4.907 mm/year | - | - | |||||

| AZ31 | CNT (1 wt.%) | - | 87. 63 | –1.501 | 1 | 2.012 mm/year | - | - | |||

| - | 16.41 | –1.407 | 23 | 0.399 mm/year | - | - | |||||

| - | 8.31 | –1.372 | 334 | 0.211 mm/year | - | - | |||||

| AZ91 | GNPs (0.5 wt.%) | SPM | Diameter: 5 and 8 nm; surface area: 750 m2/g | 3.5 wt.% NaCl | 324.901 µA | –1.447 | - | - | 4.11 mm/year | - | [153] |

| MWCNT (0.5 wt.%) C60 (0.5 wt.%) | Diameter: 8 nm; surface area: 250 m2/g | 387.430 µA | –1.490 | - | - | 4.91 mm/year | - | ||||

| Average thickness: 1–2 nm | 211.136 µA | –1.507 | - | - | 2.69 mm/year | - | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Upadhyay, G.; Saxena, K.K.; Sehgal, S.; Mohammed, K.A.; Prakash, C.; Dixit, S.; Buddhi, D. Development of Carbon Nanotube (CNT)-Reinforced Mg Alloys: Fabrication Routes and Mechanical Properties. Metals 2022, 12, 1392. https://doi.org/10.3390/met12081392

Upadhyay G, Saxena KK, Sehgal S, Mohammed KA, Prakash C, Dixit S, Buddhi D. Development of Carbon Nanotube (CNT)-Reinforced Mg Alloys: Fabrication Routes and Mechanical Properties. Metals. 2022; 12(8):1392. https://doi.org/10.3390/met12081392

Chicago/Turabian StyleUpadhyay, Gaurav, Kuldeep K. Saxena, Shankar Sehgal, Kahtan A. Mohammed, Chander Prakash, Saurav Dixit, and Dharam Buddhi. 2022. "Development of Carbon Nanotube (CNT)-Reinforced Mg Alloys: Fabrication Routes and Mechanical Properties" Metals 12, no. 8: 1392. https://doi.org/10.3390/met12081392