Process Optimization of Inconel 718 Alloy Produced by Laser Powder Bed Fusion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Optimization of the LPBF Process

2.1.1. Experimental Design

2.1.2. Single-Objective Optimization Analysis

2.1.3. Multiobjective Optimization Analysis

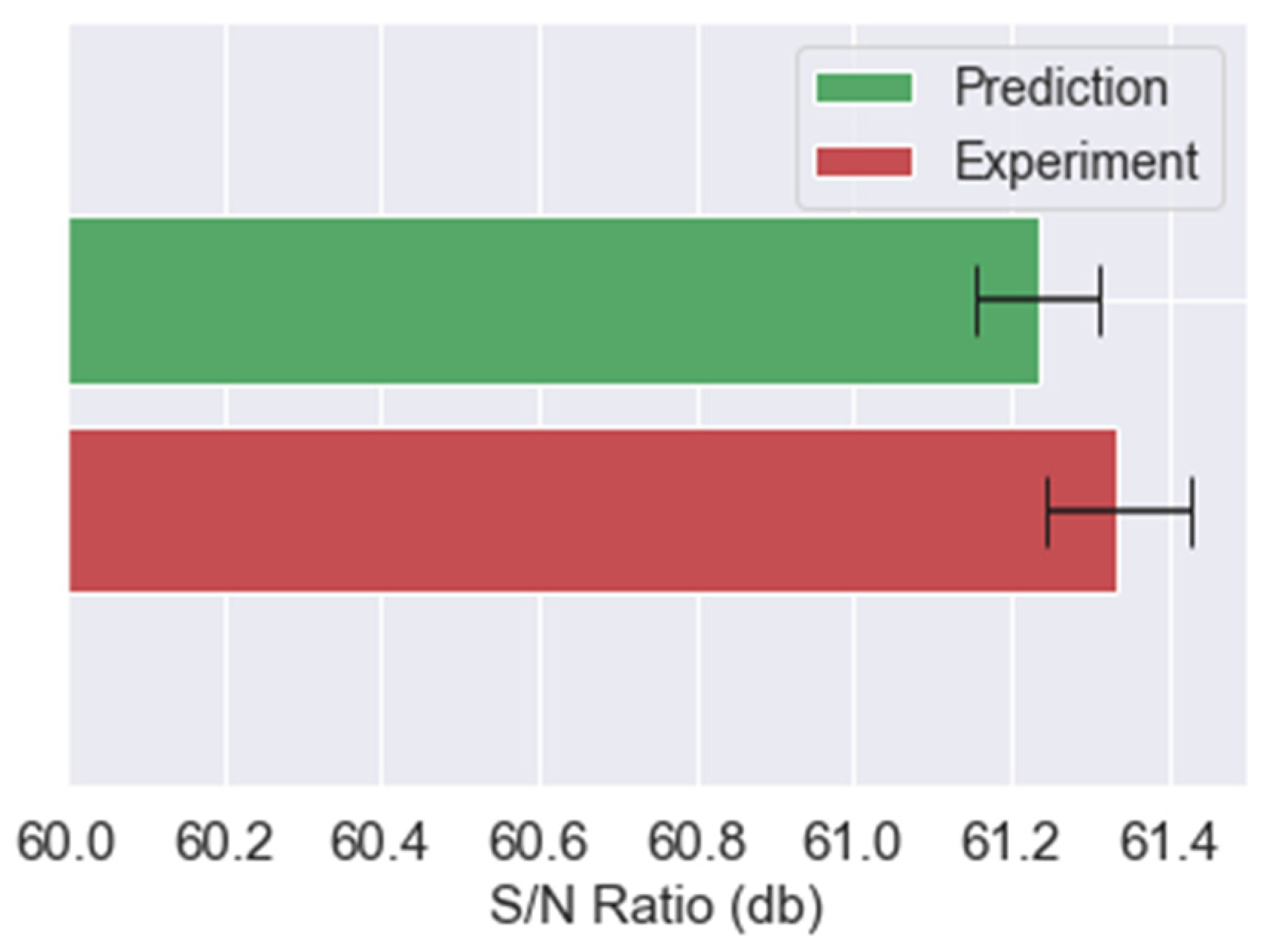

2.1.4. Verification of Optimization Parameters

2.2. Experimental Procedure

2.2.1. Specimen Production

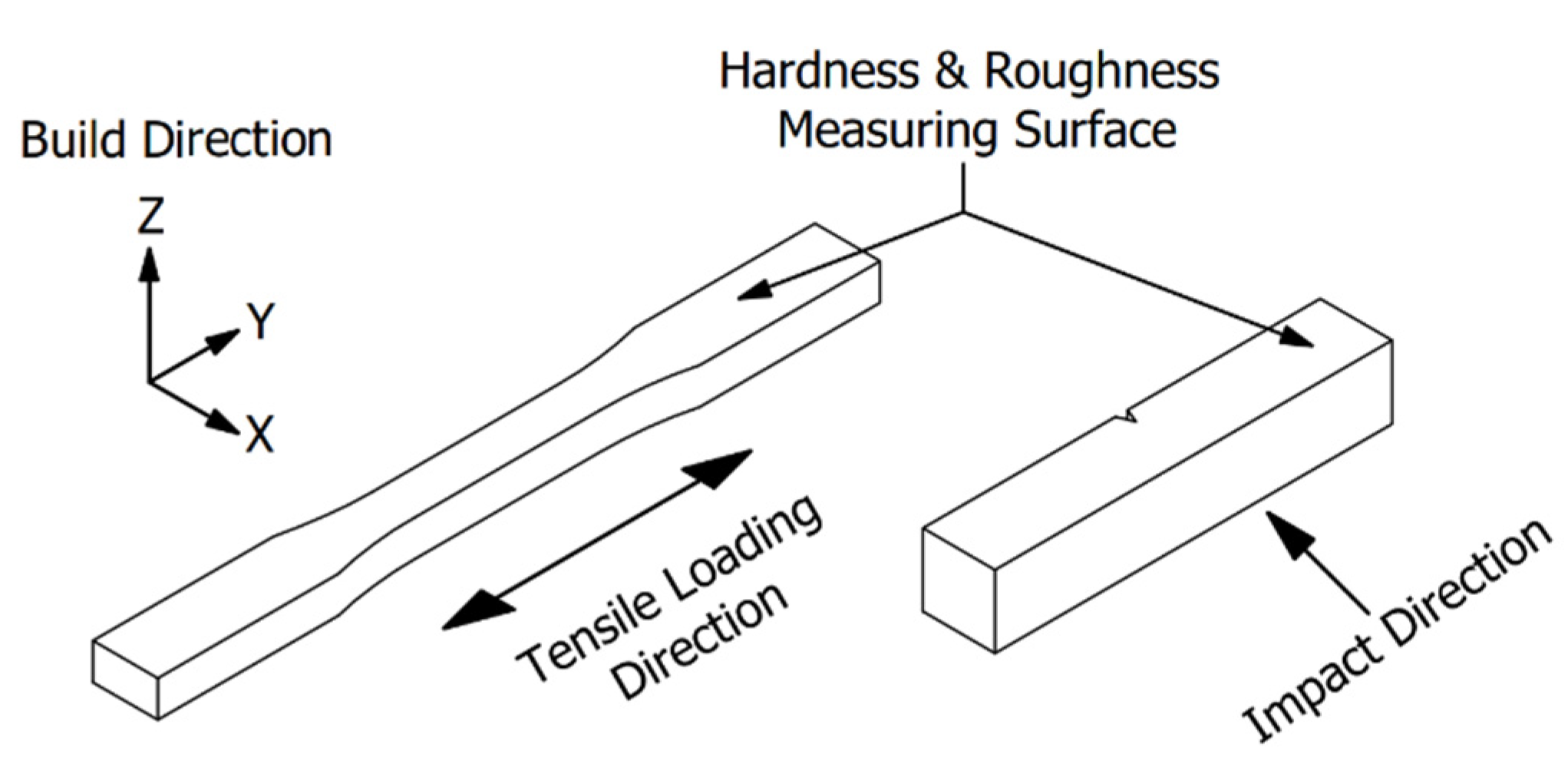

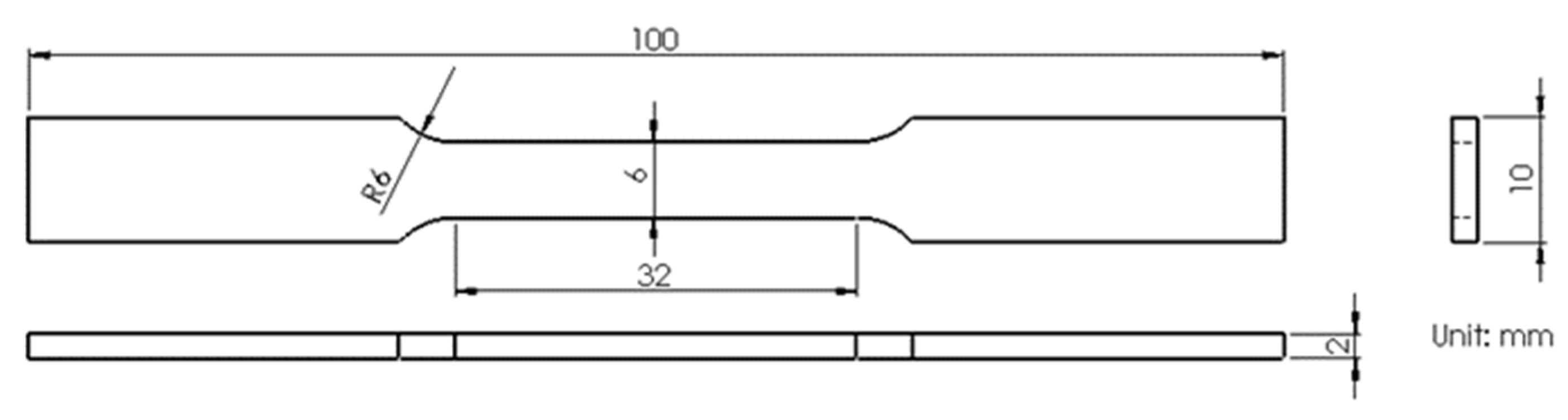

2.2.2. Mechanical Property Testing

2.2.3. Metallographic and Fractographic Examination

3. Results and Discussion

3.1. Mechanical Properties

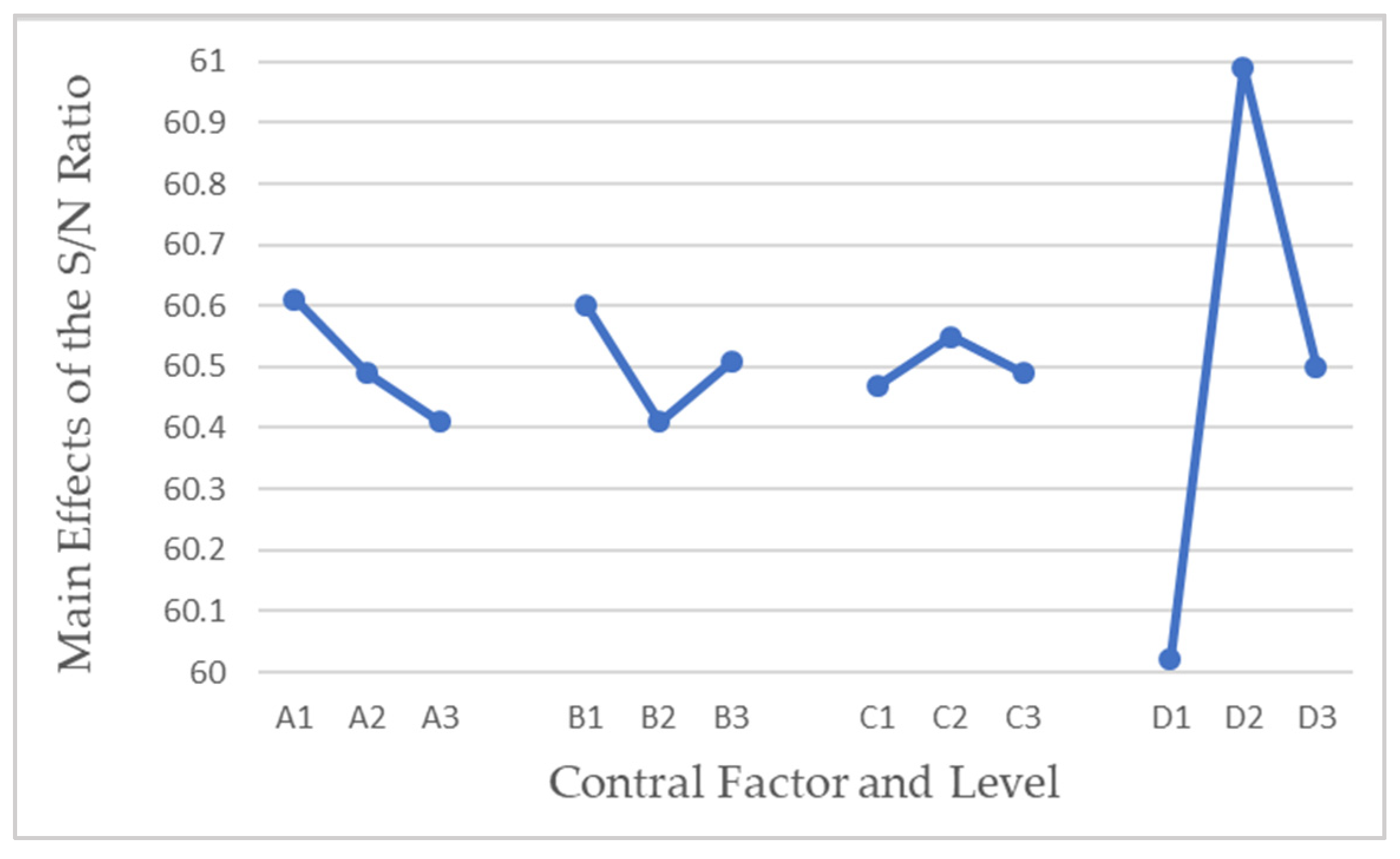

3.2. Single-Objective Optimization Analysis

3.3. Multiobjective Optimization Analysis

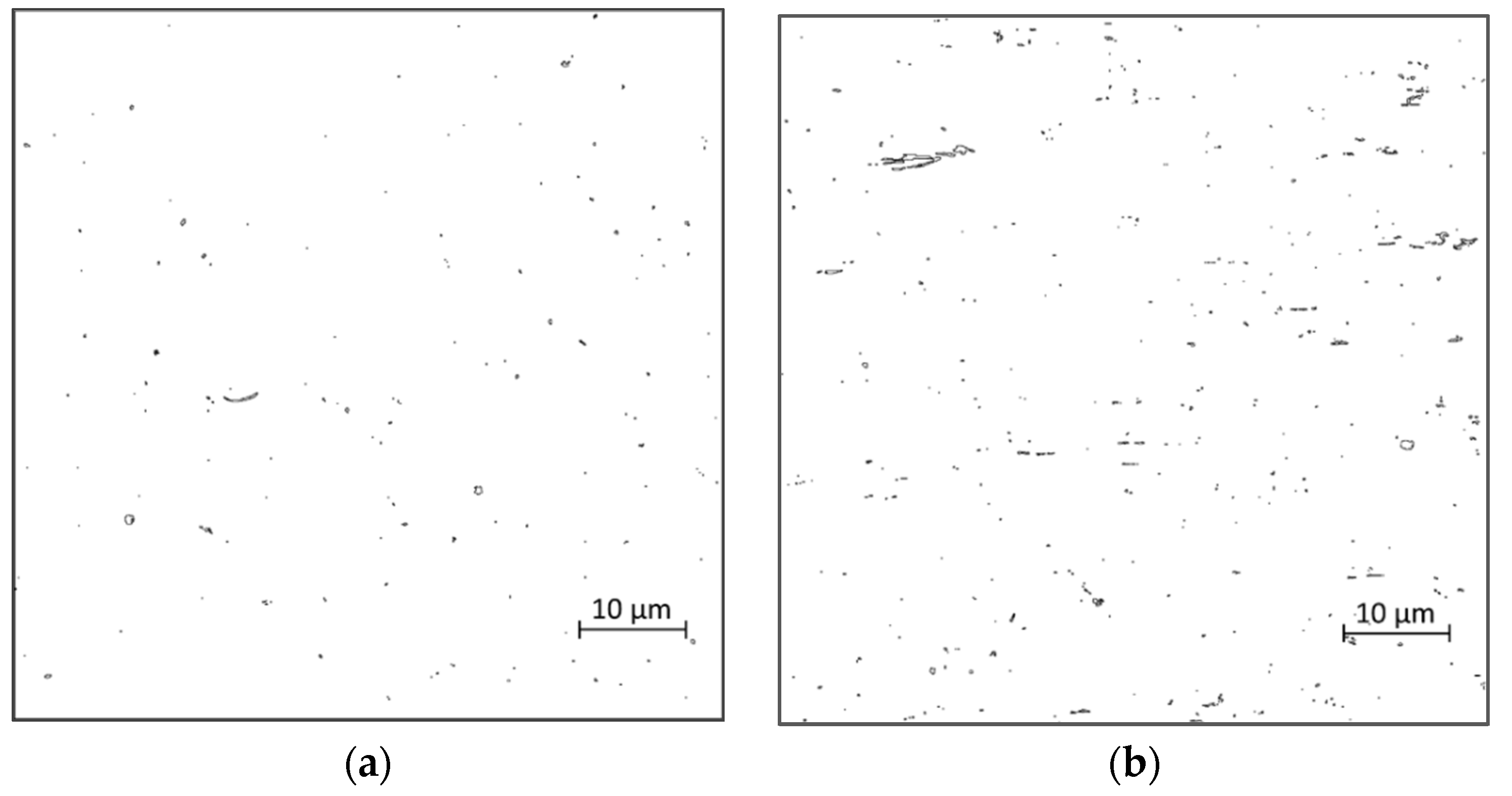

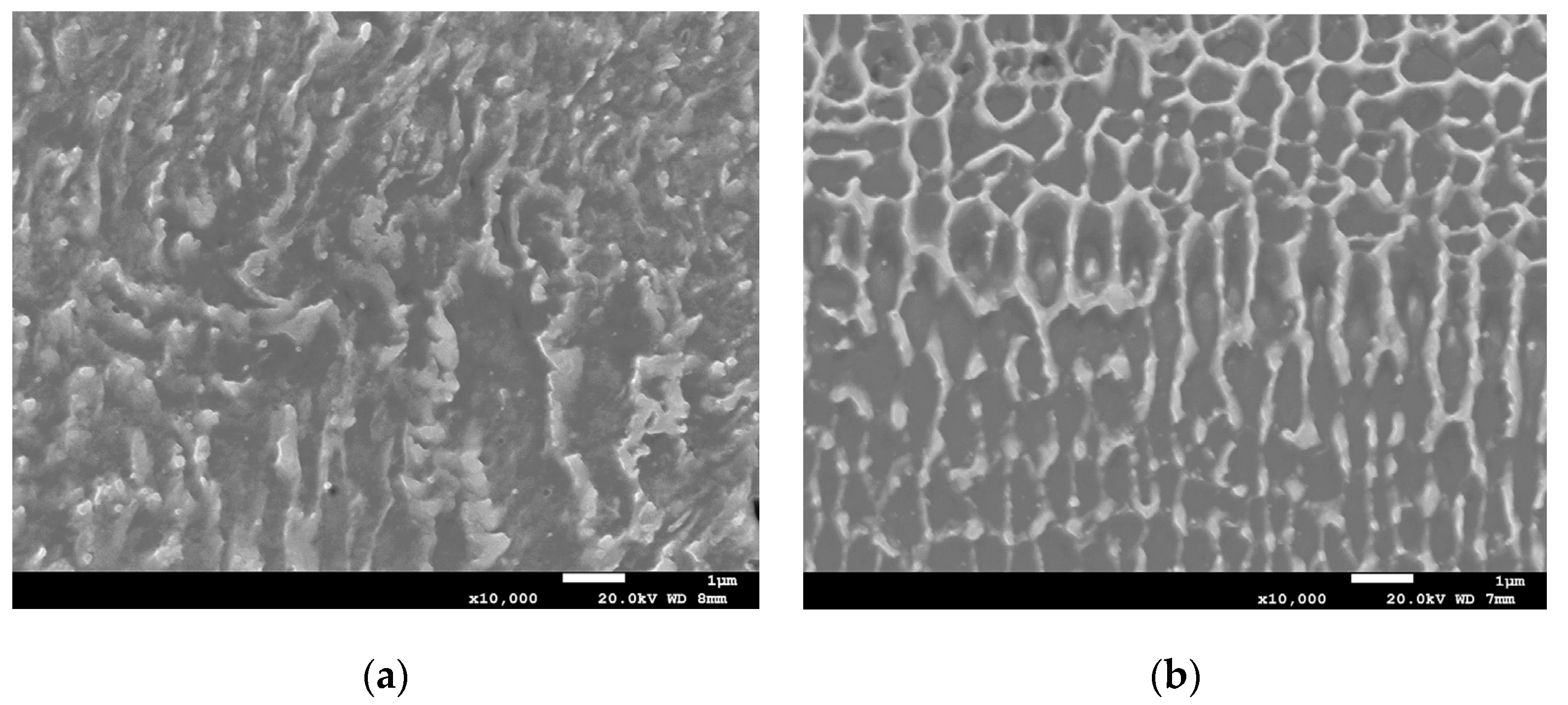

3.4. Porosity and Microstructures

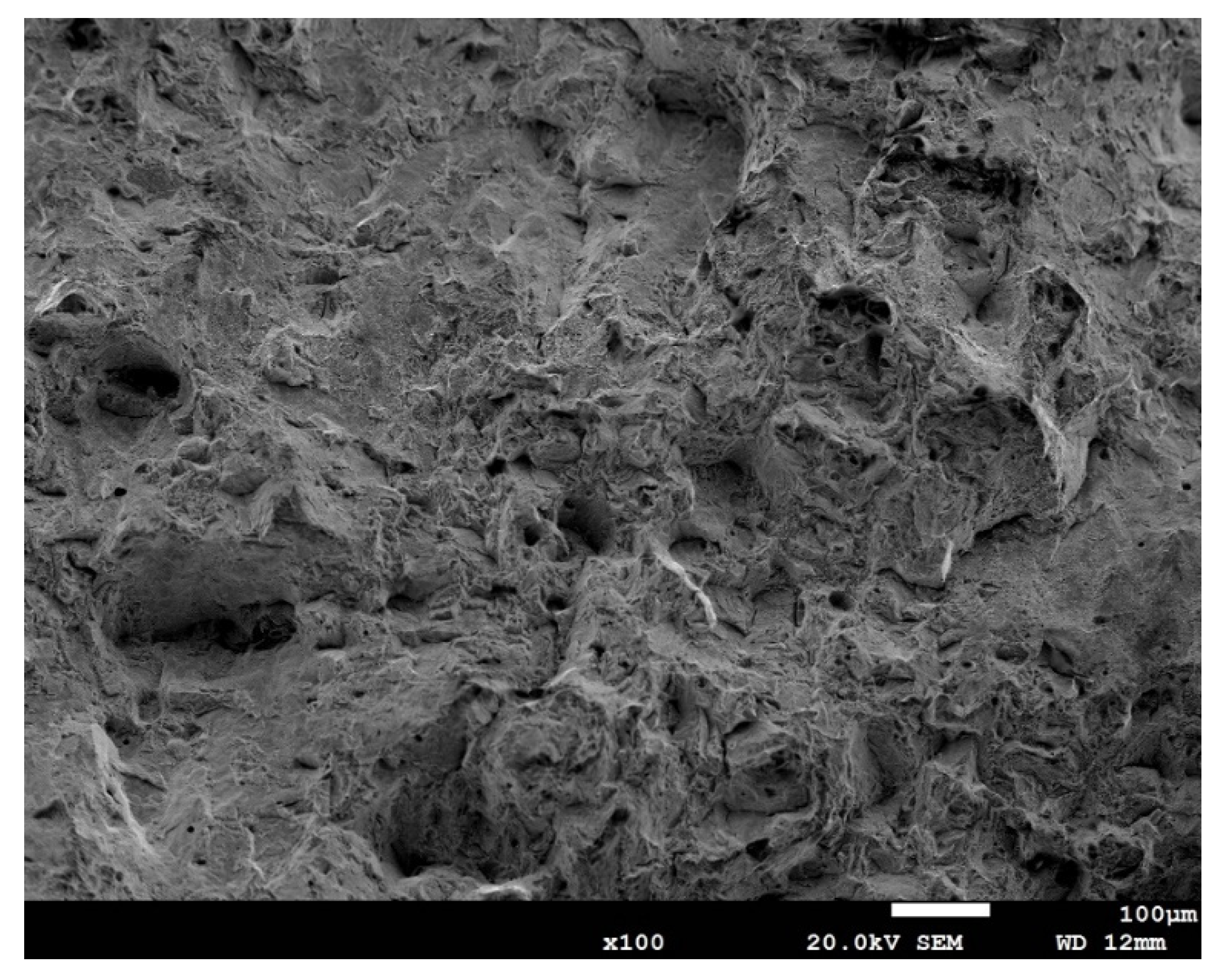

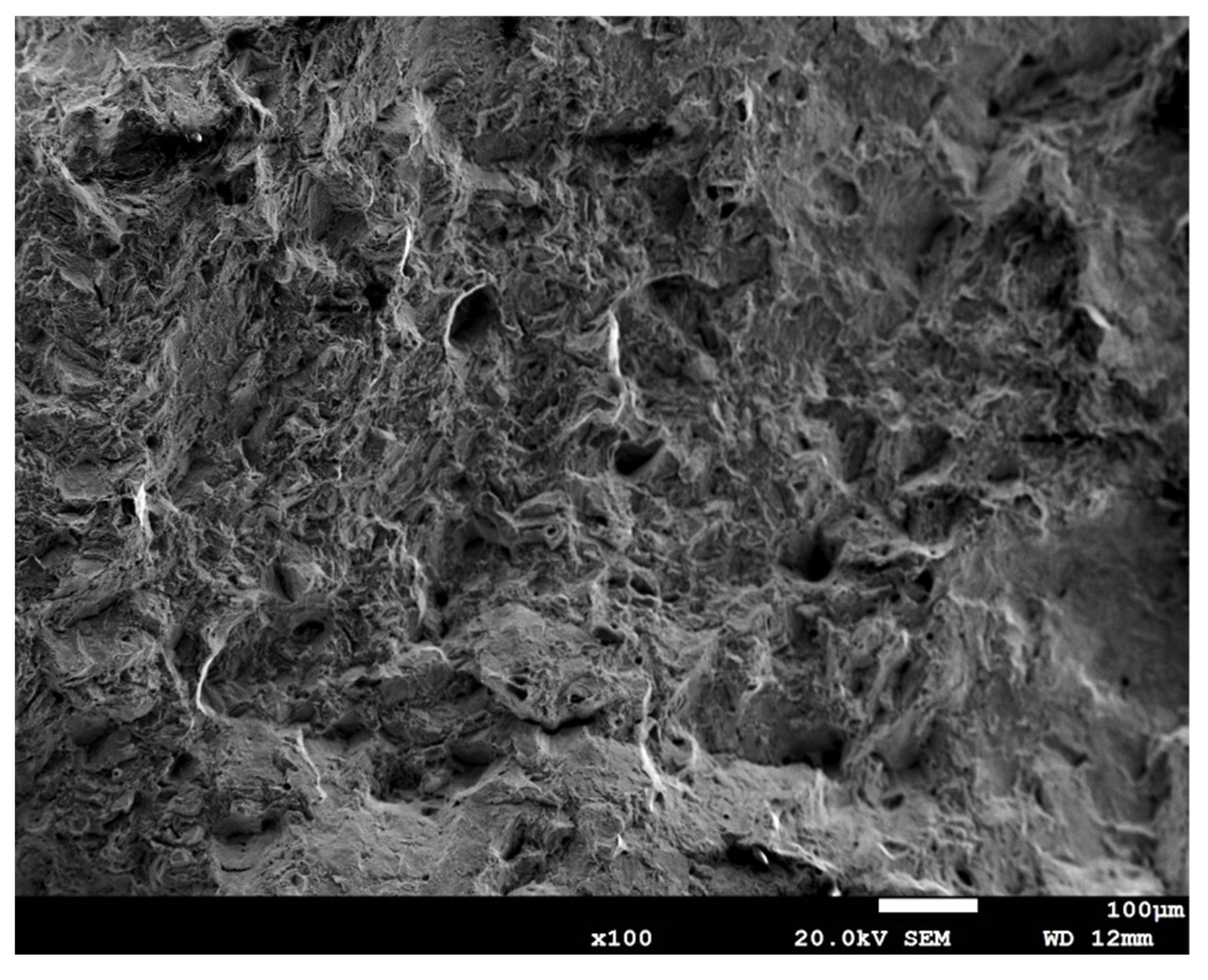

3.5. Fractograph

4. Conclusions

- (1)

- The combination of optimal process parameters for tensile strength is laser power of 140 W, scanning speed of 800 mm/s, hatching space of 70 μm, and interlayer angle of 45°, which results in a tensile strength of 1167 MPa. The difference between the predicted and experimental average tensile strength is 1.2%.

- (2)

- With tensile strength, elongation, impact energy, and hardness as targets in multiobjective optimization analysis, the combination of the optimal process is just the same as that of single-objective optimization with tensile strength as the target. The error of the predicted optimal strength index is 12.6%.

- (3)

- The most important control factor for tensile strength and multiple responses is the interlayer angle, with a contribution rate exceeding 90%.

- (4)

- For Laves phase precipitates in an as-built Inconel 718 alloy, when the volume energy density of the LPBF process is similar, the higher the power and scanning speed that overaccumulates energy, the larger the amount of cellular crystals and the lower the tensile strength.

- (5)

- Both the transgranular cleavage and fibrous and dimple fracture appear in the tensile specimen fractograph. Under the optimal process condition, the fractograph is mainly composed of fibrous and dimple fracture.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gu, D.; Meiners, W.; Hagedorn, Y.-C.; Wissenbach, K.; Poprawe, R. Bulk-form TiCx/Ti nanocomposites with controlled nanostructure prepared by a new method: Selective laser melting. J. Phys. D Appl. Phys. 2010, 43, 295402. [Google Scholar] [CrossRef]

- Kanazawa, M.; Iwaki, M.; Minakuchi, S.; Nomura, N. Fabrication of titanium alloy frameworks for complete dentures by selective laser melting. J. Prosthet. Dent. 2014, 112, 1441–1447. [Google Scholar] [CrossRef] [PubMed]

- Ford, S.L. Additive manufacturing technology: Potential implications for US manufacturing competitiveness. J. Int. Commer. Econ. 2014, 6, 40. [Google Scholar]

- Lopes, J.; Machado, C.M.; Duarte, V.R.; Rodrigues, T.A.; Santos, T.G.; Oliveira, J. Effect of milling parameters on HSLA steel parts produced by wire and arc additive manufacturing (WAAM). J. Manuf. Process 2020, 59, 739–749. [Google Scholar] [CrossRef]

- Mythreyi, O.V.; Raja, A.; Nagesha, B.K.; Jayaganthan, R. Corrosion study of selective laser melted IN718 alloy upon post heat treatment and shot peening. Metals 2020, 10, 1562. [Google Scholar] [CrossRef]

- Savinykh, A.S.; Garkushin, G.V.; Razorenov, S.V.; Atroshenko, S.A.; Klimova-Korsmik, O.G.; Kislov, N.G. Strength properties of the heat-resistant Inconel 718 superalloy additively manufactured by direct laser deposition method under shock compression. Metals 2022, 12, 967. [Google Scholar] [CrossRef]

- Chang, S.-H.; Hwang, J.-R.; Doong, J.-L. Manufacturing process optimization of short glass fiber reinforced polycarbonate composites in injection molding. J. Reinf. Plast. Compos. 2000, 19, 301–321. [Google Scholar] [CrossRef]

- Taguchi, G. Introduction to quality engineering, Tokyo. Asian Product. Organ. 1990, 4, 10–15. [Google Scholar]

- Tong, L.I.; Su, C.T. Optimizing multi-response problems in the Taguchi method by fuzzy multiple attribute decision making. Qual. Reliab. Eng. 1997, 13, 25–34. [Google Scholar] [CrossRef]

- Han, P. Additive design and manufacturing of jet engine parts. J. Eng. 2017, 3, 648–652. [Google Scholar] [CrossRef]

- Wang, F.; Del Bosque, H.; Hyder, J.; Corliss, M.; Hung, W.N. Experimental investigation of porosity distribution in selective laser melted Inconel 718. Procedia Manuf. 2020, 48, 807–813. [Google Scholar] [CrossRef]

- Yi, J.; Kang, J.; Wang, T.; Wang, X.; Hu, Y.; Feng, T.; Feng, Y.; Wu, P. Effect of laser energy density on the microstructure, mechanical properties, and deformation of Inconel 718 samples fabricated by selective laser melting. J. Alloys Compd. 2019, 786, 481–488. [Google Scholar] [CrossRef]

- Jia, Q.; Gu, D. Selective laser melting additive manufacturing of Inconel 718 superalloy parts: Densification, microstructure and properties. J. Alloys Compd. 2014, 585, 713–721. [Google Scholar] [CrossRef]

- Parida, R.P.; Senthilkumar, V. Experimental studies of defect generation in selective laser melted Inconel 718 alloy. Mater. Today Proc. 2021, 39, 1372–1377. [Google Scholar] [CrossRef]

- Borisov, E.; Popovich, V.; Popovich, A.; Sufiiarov, V.S.; Zhu, J.-N. Selective laser melting of Inconel 718 under high laser power. Mater. Today Proc. 2020, 30, 784–788. [Google Scholar] [CrossRef]

- Cao, Y.; Bai, P.; Liu, F.; Hou, X. Investigation on the precipitates of IN718 alloy fabricated by selective laser melting. Metals 2019, 9, 1128. [Google Scholar] [CrossRef]

- Wan, H.; Zhou, Z.; Li, C.; Chen, G.; Zhang, G. Effect of scanning strategy on mechanical properties of selective laser melted Inconel 718. Mater. Sci. Eng. A 2019, 753, 42–48. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, P.; Chew, Y.; Wen, Y.; Zhang, M.; Wang, P.; Bi, G.; Wei, J. Mechanical properties and microstructure evolution of selective laser melting Inconel 718 along building direction and sectional dimension. Mater. Sci. Eng. A 2020, 794, 139941. [Google Scholar] [CrossRef]

- Yong, C.K.; Gibbons, G.J.; Wong, C.C.; West, G. A critical review of the material characteristics of additive manufactured IN718 for high-temperature application. Metals 2020, 10, 1576. [Google Scholar] [CrossRef]

- Schmiedel, A.; Burkhardt, C.; Henkel, S.; Weidner, A.; Biermann, H. Very high cycle fatigue investigations on the fatigue strength of additive manufactured and conventionally wrought Inconel 718 at 873 K. Metals 2021, 11, 1682. [Google Scholar] [CrossRef]

- Cheng, B.; Shrestha, S.; Chou, K. Stress and deformation evaluations of scanning strategy effect in selective laser melting. Addit. Manuf. 2016, 12, 240–251. [Google Scholar]

- Zhang, Y.; Wu, L.; Guo, X.; Kane, S.; Deng, Y.; Jung, Y.-G.; Lee, J.-H.; Zhang, J. Additive manufacturing of metallic materials: A review. J. Mater. Eng. Perform. 2018, 27, 1–13. [Google Scholar] [CrossRef]

- Pérez-Ruiz, J.D.; de Lacalle, L.N.L.; Urbikain, G.; Pereira, O.; Martínez, S.; Bris, J. On the relationship between cutting forces and anisotropy features in the milling of LPBF Inconel 718 for near net shape parts. Int. J. Mach. Tools Manuf. 2021, 170, 103801. [Google Scholar] [CrossRef]

- Pérez-Ruiz, J.D.; Marin, F.; Martínez, S.; Lamikiz, A.; Urbikain, G.; López de Lacalle, L.N. Stiffening near-net-shape functional parts of Inconel 718 LPBF considering material anisotropy and subsequent machining issues. Mech. Syst. Sig. Process. 2022, 168, 108675. [Google Scholar] [CrossRef]

- Ji, H.; Gupta, M.K.; Song, Q.; Cai, W.; Zheng, T.; Zhao, Y.; Liu, Z.; Pimenov, D.Y. Microstructure and machinability evaluation in micro milling of selective laser melted Inconel 718 alloy. J. Mater. Res. Technol. 2021, 14, 348–362. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Robak, G.; Moj, K.; Krolczyk, G.M.; Kuntoğlu, M. Development of lattice structure with selective laser melting process: A state of the art on properties, future trends and challenges. J. Manuf. Processes 2022, 81, 1040–1063. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Waqar, S.; Kuntoğlu, M.; Krolczyk, G.M.; Maruda, R.W.; Pimenov, D.Y. A short review on thermal treatments of Titanium & Nickel based alloys processed by selective laser melting. J. Mater. Res. Technol. 2022, 16, 1090–1101. [Google Scholar]

- Fayed, E.M.; Saadati, M.; Shahriari, D.; Brailovski, V.; Jahazi, M.; Medraj, M. Optimization of the post-process heat treatment of Inconel 718 superalloy fabricated by laser powder bed fusion process. Metals 2021, 11, 144. [Google Scholar] [CrossRef]

- Bassini, E.; Marchese, G.; Aversa, A. Tailoring of the microstructure of laser powder bed fused Inconel 718 using solution annealing and aging treatments. Metals 2021, 11, 921. [Google Scholar] [CrossRef]

- Zheng, J.Y. Optimization of Additive Manufacturing Parameters in Inconel 718 Alloy. Master’s Thesis, National Central University, Taoyuan, Taiwan, 2020. [Google Scholar]

- Pearson, K. LIII. On lines and planes of closest fit to systems of points in space. J. Sci. 1901, 2, 559–572. [Google Scholar] [CrossRef]

- Hotelling, H. Analysis of a complex of statistical variables into principal components. J. Educ. Psychol. 1933, 24, 417. [Google Scholar] [CrossRef]

- Huang, C.; Fung, C.; Chang, S.; Hwang, J.; Doong, J. Optimization study in manufacturing process for PC/ABS blends. Chin. J. Mech. Eng. 2003, 16, 233–236. [Google Scholar] [CrossRef]

- Ni, M.; Chen, C.; Wang, X.; Wang, P.; Li, R.; Zhang, X.; Zhou, K. Anisotropic tensile behavior of in situ precipitation strengthened Inconel 718 fabricated by additive manufacturing. Mater. Sci. Eng. A 2017, 701, 344–351. [Google Scholar] [CrossRef]

- Jia, H.; Sun, H.; Wang, H.; Wu, Y.; Wang, H. Scanning strategy in selective laser melting (SLM): A review. Int. J. Adv. Manuf. Technol. 2021, 113, 2413–2435. [Google Scholar] [CrossRef]

- Zhang, W.; Tong, M.; Harrison, N.M. Scanning strategies effect on temperature, residual stress and deformation by multi-laser beam powder bed fusion manufacturing. Addit. Manuf. 2020, 36, 101507. [Google Scholar] [CrossRef]

- Mei, X.; Wang, X.; Peng, Y.; Gu, H.; Zhong, G.; Yang, S. Interfacial characterization and mechanical properties of 316L stainless steel/Inconel 718 manufactured by selective laser melting. Mater. Sci. Eng. A 2019, 758, 185–191. [Google Scholar] [CrossRef]

- Popovich, V.A.; Borisov, E.V.; Popovich, A.A.; Sufiiarov, V.S.; Masaylo, D.V.; Alzina, L. Impact of heat treatment on mechanical behaviour of Inconel 718 processed with tailored microstructure by selective laser melting. Mater. Des. 2017, 131, 12–22. [Google Scholar] [CrossRef]

- Liu, S.Y.; Li, H.Q.; Qin, C.X.; Zong, R.; Fang, X.Y. The effect of energy density on texture and mechanical anisotropy in selective laser melted Inconel 718. Mater. Des. 2020, 191, 108642. [Google Scholar] [CrossRef]

- Huang, X.; Chaturvedi, M.; Richards, N. Effect of homogenization heat treatment on the microstructure and heat-affected zone microfissuring in welded cast alloy 718. Metall. Mater. Trans. 1996, 27, 785–790. [Google Scholar] [CrossRef]

- Radavich, J.F. The physical metallurgy of cast and wrought alloy 718. Superalloy 1989, 718, 229–240. [Google Scholar]

- Konečná, R.; Kunz, L.; Nicoletto, G.; Bača, A. Long fatigue crack growth in Inconel 718 produced by selective laser melting. Int. J. Fatigue 2016, 92, 499–506. [Google Scholar] [CrossRef]

- Karabulut, Y.; Tascioglu, E.; Kaynak, Y. Heat treatment temperature-induced microstructure, microhardness and wear resistance of Inconel 718 produced by selective laser melting additive manufacturing. Optik 2021, 227, 163907. [Google Scholar] [CrossRef]

- Watring, D.S.; Carter, K.C.; Crouse, D.; Raeymaekers, B.; Spear, A. Mechanisms driving high-cycle fatigue life of as-built Inconel 718 processed by laser powder bed fusion. Mater. Sci. Eng. A 2019, 761, 137993. [Google Scholar] [CrossRef]

- Zhang, Q.; Ren, P.; Tu, X.; Dai, Y.; Wang, X.; Li, W. Effect of heat treatment on microstructure evolution and mechanical properties of selective laser melted Inconel 718 alloy. J. Mater. Eng. Perform. 2019, 28, 5376–5386. [Google Scholar] [CrossRef]

| Level | Control Factor | |||

|---|---|---|---|---|

| A | B | C | D | |

| Laser Power (W) | Scanning Speed (mm/s) | Hatching Space (µm) | Orientation (degree) | |

| 1 | 140 | 800 | 60 | 0° |

| 2 | 150 | 900 | 70 | 45° |

| 3 | 160 | 1000 | 80 | 90° |

| Specimen ID | Control Factor and Level | Mechanical Property | ||||||

|---|---|---|---|---|---|---|---|---|

| Tensile Strength (MPa) | Elongation (%) | Impact Energy (J) | Hardness (HRC) | |||||

| N1 | A1 | B1 | C1 | D1 | 1021.9 ± 2.8 | 28.2 ± 0.6 | 83.2 ± 2.2 | 32.2 ± 1.7 |

| N2 | A1 | B2 | C2 | D2 | 1128.5 ± 11.9 | 22.5 ± 0.9 | 73.8 ± 1.0 | 33.0 ± 0.1 |

| N3 | A1 | B3 | C3 | D3 | 1070.3 ± 2.5 | 23.8 ± 0.8 | 61.1 ± 3.4 | 33.4 ± 0.3 |

| N4 | A2 | B3 | C2 | D1 | 1006.4 ± 6.1 | 25.7 ± 1.5 | 68.7 ± 2.9 | 28.5 ± 0.8 |

| N5 | A2 | B1 | C3 | D2 | 1129.6 ± 15.0 | 23.1 ± 2.1 | 78.5 ± 1.6 | 30.8 ± 0.3 |

| N6 | A2 | B2 | C1 | D3 | 1042.1 ± 9.9 | 25.8 ± 1.2 | 71.5 ± 2.1 | 33.3 ± 0.5 |

| N7 | A3 | B2 | C3 | D1 | 979.9 ± 14.3 | 26.9 ± 0.1 | 78.9 ± 0.8 | 31.3 ± 0.3 |

| N8 | A3 | B3 | C1 | D2 | 1106.5 ± 9.4 | 22.3 ± 0.8 | 75.2 ± 1.4 | 30.0 ± 0.4 |

| N9 | A3 | B1 | C2 | D3 | 1064.3 ±12.6 | 25.6 ± 0.9 | 77.5 ± 3.5 | 27.5 ± 1.1 |

| Factor | S/N Ratio (dB) | F | Contribution (%) | ||

|---|---|---|---|---|---|

| Level 1 | Level 2 | Level 3 | |||

| A | 60.61 | 60.49 | 60.41 | 6.411 | 3.8 |

| B | 60.60 | 60.41 | 60.51 | 5.694 | 3.4 |

| C | 60.47 | 60.55 | 60.49 | 1.000 | 0.6 |

| D | 60.02 | 60.99 | 60.50 | 156.45 | 92.2 |

| Tensile Strength (MPa) | S/N Ratio (dB) | Error (%) | |||

|---|---|---|---|---|---|

| #1 | #2 | #3 | Predicted | Experimental | |

| 1140 | 1177 | 1184 | 61.23 | 61.33 | 0.1 |

| Eigenvector | Tensile Strength | Elongation | Impact Energy | Hardness |

|---|---|---|---|---|

| V1 | 0.635 | −0.674 | −0.312 | 0.212 |

| V2 | 0.329 | −0.193 | 0.618 | −0.688 |

| V3 | 0.213 | 0.101 | 0.685 | 0.689 |

| V4 | 0.666 | 0.706 | −0.227 | −0.083 |

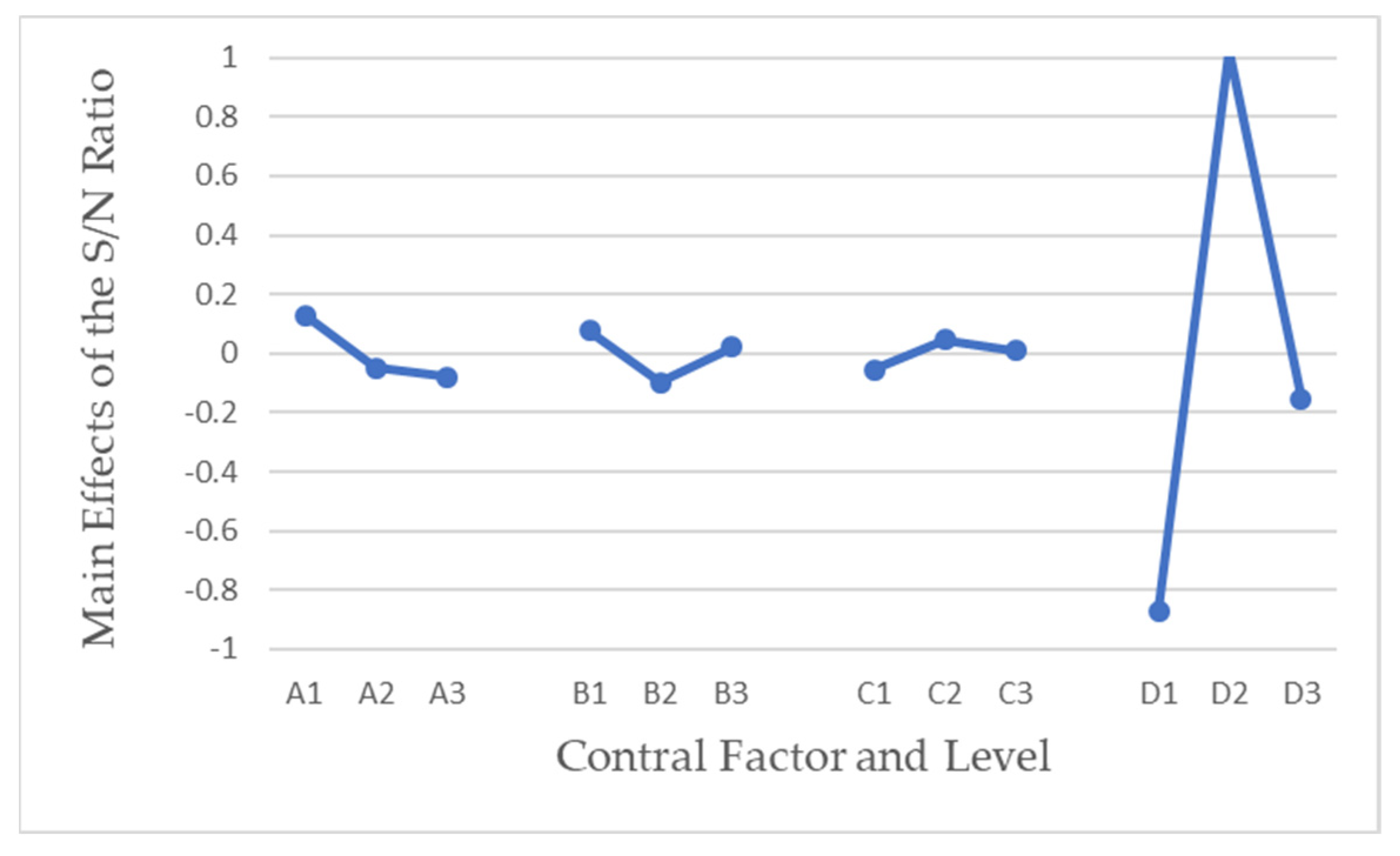

| Factor | S/N Ratio (dB) | F | Contribution (%) | |||

|---|---|---|---|---|---|---|

| Level 1 | Level 2 | Level 3 | Mean Square | |||

| A | 0.128 | −0.049 | −0.079 | 0.075 | 4.712 | 1.3 |

| B | 0.076 | −0.097 | 0.021 | 0.047 | 2.957 | 0.8 |

| C | −0.056 | 0.046 | 0.010 | 0.016 | 1.000 | 0.3 |

| D | −0.870 | 1.023 | −0.154 | 5.483 | 345.2 | 97.6 |

| Factor | Specimen | Average | ||

|---|---|---|---|---|

| #1 | #2 | #3 | ||

| Tensile Strength (MPa) | 1140 | 1177 | 1184 | 1167 |

| Elongation (%) | 27.4 | 21.2 | 24.5 | 24.4 |

| Impact Energy (J) | 82.2 | 79.4 | 82.2 | 81.3 |

| Hardness (HRC) | 32.5 | 31.9 | 31.6 | 32.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, J.-R.; Zheng, J.-Y.; Kuo, P.-C.; Huang, C.-D.; Fung, C.-P. Process Optimization of Inconel 718 Alloy Produced by Laser Powder Bed Fusion. Metals 2022, 12, 1494. https://doi.org/10.3390/met12091494

Hwang J-R, Zheng J-Y, Kuo P-C, Huang C-D, Fung C-P. Process Optimization of Inconel 718 Alloy Produced by Laser Powder Bed Fusion. Metals. 2022; 12(9):1494. https://doi.org/10.3390/met12091494

Chicago/Turabian StyleHwang, Jiun-Ren, Jing-Yuan Zheng, Po-Chen Kuo, Chou-Dian Huang, and Chin-Ping Fung. 2022. "Process Optimization of Inconel 718 Alloy Produced by Laser Powder Bed Fusion" Metals 12, no. 9: 1494. https://doi.org/10.3390/met12091494

APA StyleHwang, J.-R., Zheng, J.-Y., Kuo, P.-C., Huang, C.-D., & Fung, C.-P. (2022). Process Optimization of Inconel 718 Alloy Produced by Laser Powder Bed Fusion. Metals, 12(9), 1494. https://doi.org/10.3390/met12091494