Influence of Stress Relief Annealing Parameters on Mechanical Properties and Decomposition of Eutectic Si Network of L-PBF Additive Manufactured Alloy AlSi10Mg

Abstract

:1. Introduction

- Supersaturated solid solutions and residual stresses are formed and occur in the alloy during the printing, primarily because of the high cooling rate.

- Heat treatment of previously solidified material subsequently causes local phase transformations and precipitation.

2. Materials and Methods

3. Results and Discussion

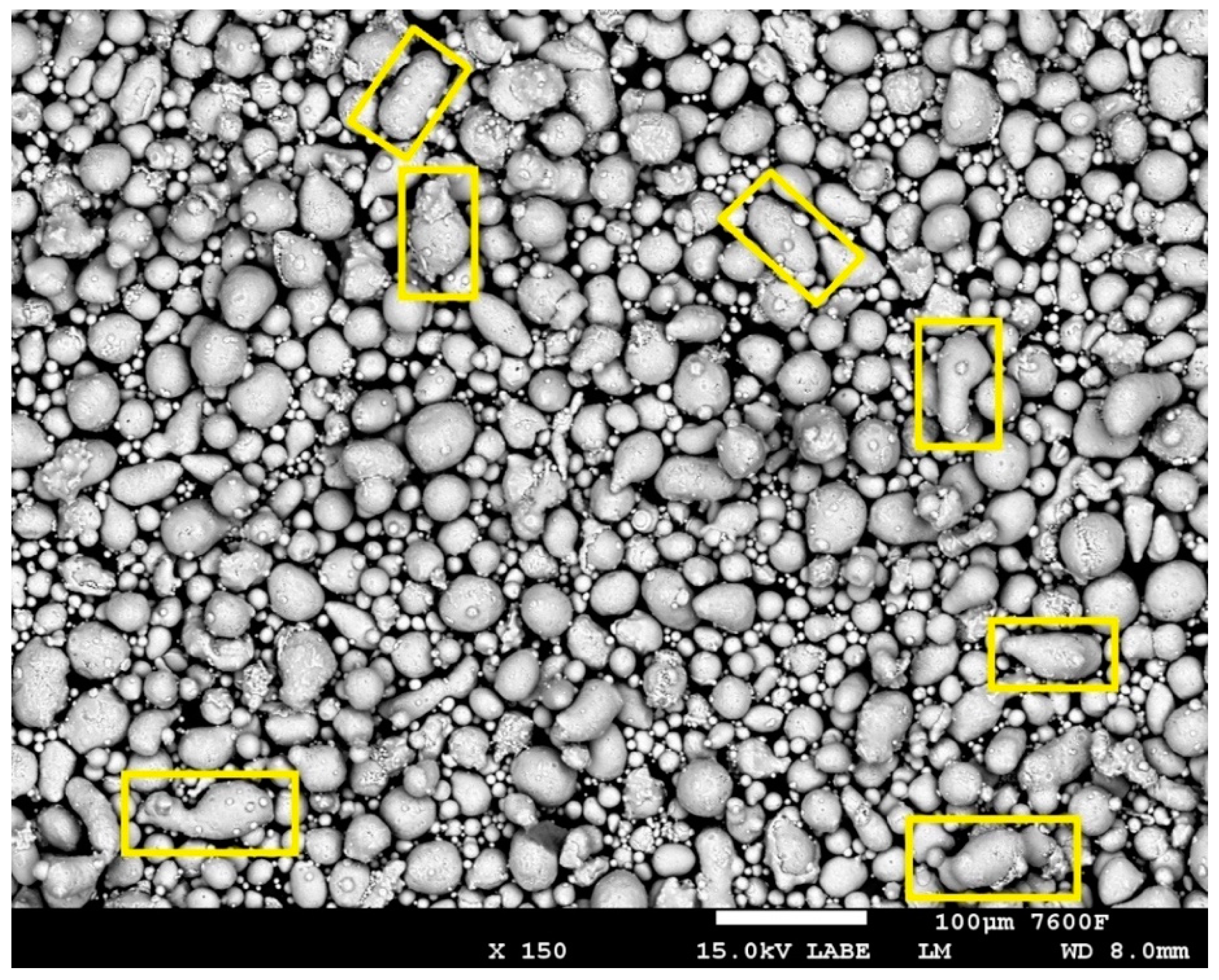

3.1. Mechanical Properties and Microstructure of the As-Built State

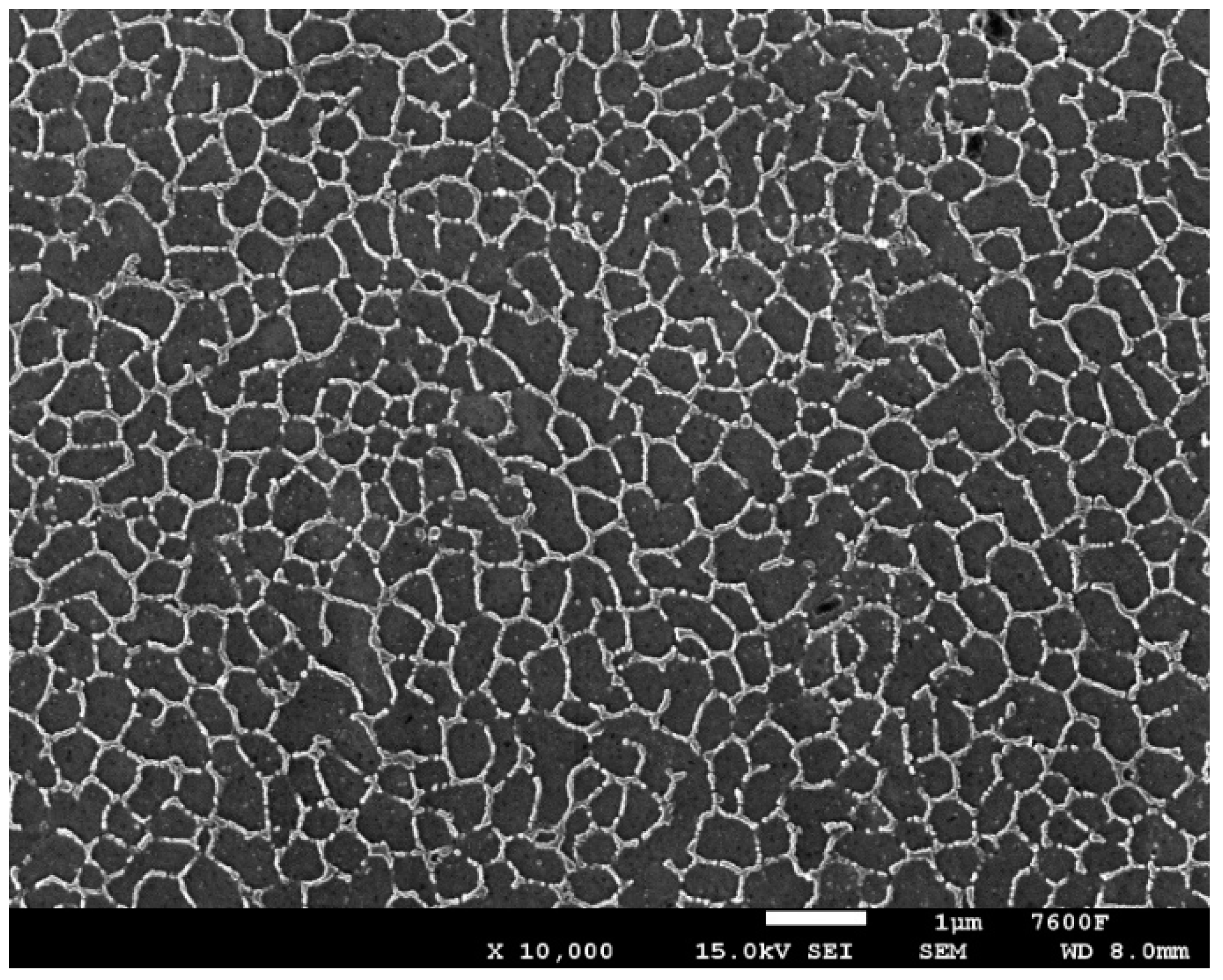

- Orowan strengthening in the as-built condition upon the dislocations is pinned by the eutectic Si phase at cell boundaries, the bend around eutectic Al phases, and the Orowan looping mode is activated. Dislocations glide through the cell boundary, thus highly strengthening the alloy. A large number of new dislocations are initiated by this mechanism, which increases the alloy’s strain hardening ability [8,23].

- Strengthening induced by localized shear stress: nano-sized Si particles and Si precipitates in the matrix [24].

- Dislocation strengthening hardening by dislocation interactions (pre-existing dislocation network) [25].

- Solid solution strengthening: supersaturated solid solution of Si in an aluminum matrix. Due to the fast cooling rate, the equilibrium solubility is higher; for the L-PBF AlSi10Mg the solubility of Si was measured [26] to be approximately in the range of 1–3%. Authors [22] calculated the solubility of Si atoms in the Al matrix to be 8.89 at. %.

3.2. Mechanical Properties and Microstructure of Intermediate-Temperature Annealing Treatments of L-PBF AlSi10Mg

4. Summary and Conclusions

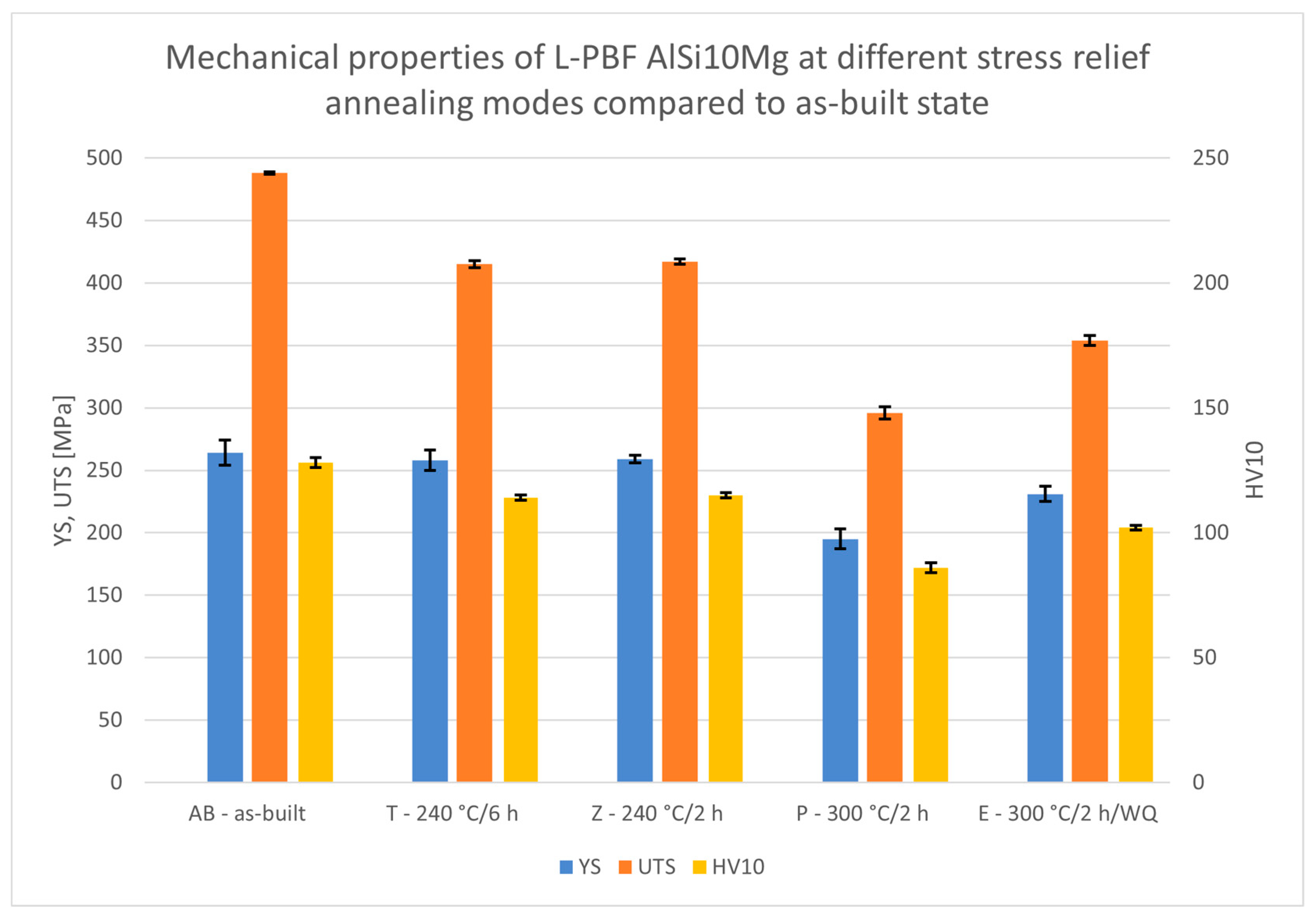

- The as-built state has the highest mechanical properties compared to the applied heat treatment: stress relief at temperatures of 240 and 300 °C with different cooling methods.

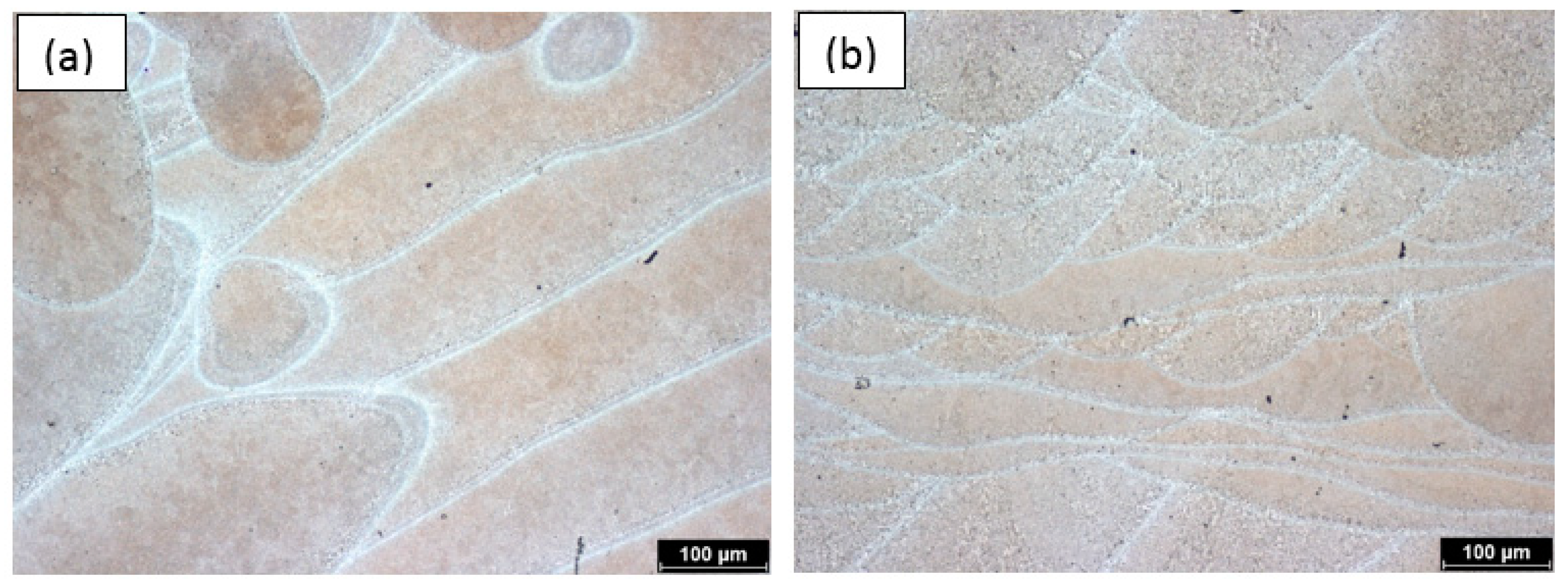

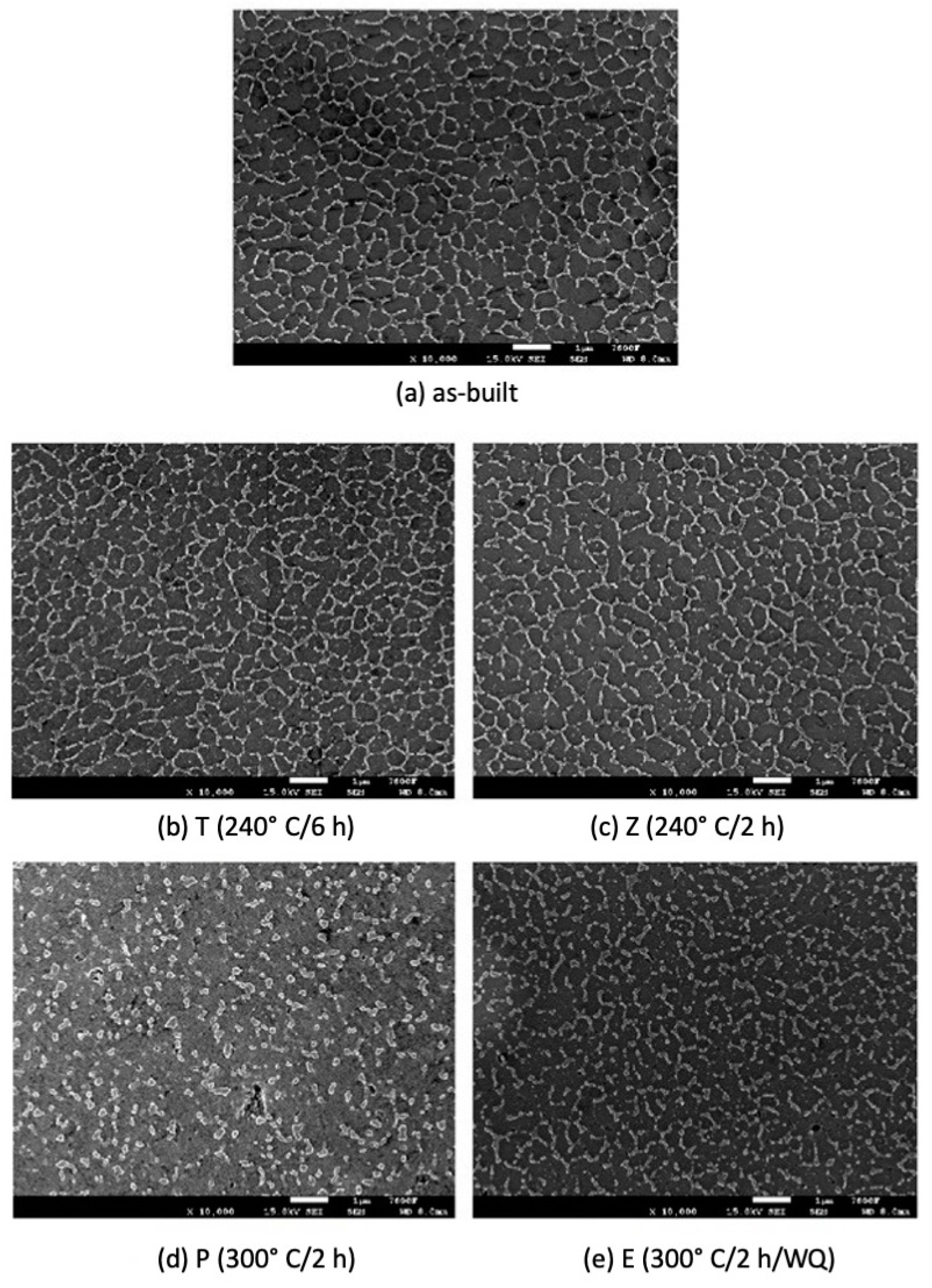

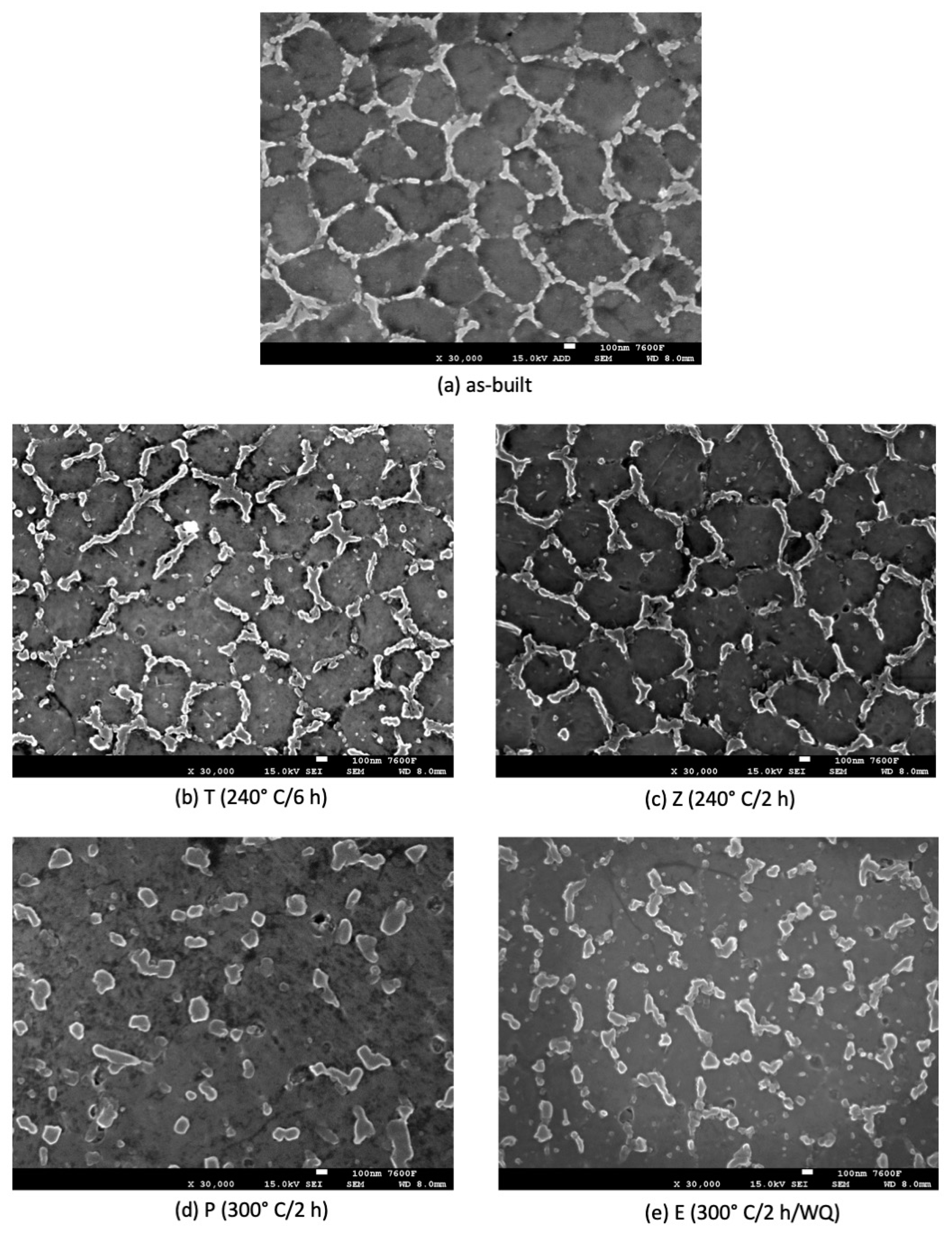

- The structure of the AlSi10Mg alloy in the as-built state consists of an aluminum matrix with finely dispersed magnesium and a continuous Si network deposited along the cell boundaries.

- After annealing, the following changes occurred in the structure of the AlSi10Mg alloy:

- o

- When annealing at 240 °C, the continuity of the Si network was slightly disrupted, which was more pronounced by a dwell time of 6 hours compared to 2 h. However, this phenomenon did not manifest itself in the expected decrease in strength, probably due to the parallel precipitation of the Mg2Si phase.

- o

- When annealing at 300 °C, the Si network decomposed, and the Si particles were spheroidized and coarse. These effects were more pronounced when the cooling rate from 300 °C was lower. Mechanical properties of the AlSi10Mg alloy annealed at 300 °C were in good agreement with the changes in structure.

- Stress relief annealing mode T (240 °C/2 h) and mode Z (240 °C/6 h) achieved the same mechanical properties, within the standard deviations.

- Stress relief annealing mode E (300 °C/2 h/WQ) achieved 15% higher strength values than mode P (300 °C/2 h/FC to 100 °C then AC).

- When comparing the same cooling rate but variable temperature, the annealing at 240 °C (modes T—6 h, Z—2 h) showed a 15% strength decrease compared to the as-built state when annealing at 300 °C, where there was a 39% decrease. The change in the mechanical properties of L-PBF AlSi10Mg during the intermediate temperature annealing treatments was more temperature- than dwell-time-dependent.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ponnusamy, P.; Rahman Rashid, R.A.; Masood, S.H.; Ruan, D.; Palanisamy, S. Mechanical Properties of SLM-Printed Aluminium Alloys: A Review. Materials 2020, 13, 4301. [Google Scholar] [CrossRef] [PubMed]

- Leon, A.; Shirizly, A.; Aghion, E. Corrosion Behavior of AlSi10Mg Alloy Produced by Additive Manufacturing (AM) vs. Its Counterpart Gravity Cast Alloy. Metals 2016, 6, 148. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Wang, J.; Ni, D.; Wang, D.; Xiao, B.; Ma, Z. Achieving superior mechanical properties of selective laser melted AlSi10Mg via direct aging treatment. J. Mater. Sci. Technol. 2022, 108, 226–235. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef]

- Girelli, L.; Tocci, M.; Gelfi, M.; Pola, A. Study of heat treatment parameters for additively manufactured AlSi10Mg in comparison with corresponding cast alloy. Mater. Sci. Eng. A 2019, 739, 317–328. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Van Humbeeck, J.; Kruth, J.-P. Mechanical Properties of AlSi10Mg Produced by Selective Laser Melting. Phys. Procedia 2012, 39, 439–446. [Google Scholar] [CrossRef]

- Fousová, M.; Dvorský, D.; Michalcová, A.; Vojtěch, D. Changes in the microstructure and mechanical properties of additively manufactured AlSi10Mg alloy after exposure to elevated temperatures. Mater. Charact. 2018, 137, 119–126. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. The microstructure and mechanical properties of selectively laser melted AlSi10Mg: The effect of a conventional T6-like heat treatment. Mater. Sci. Eng. A 2016, 667, 139–146. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Tuck, C.; Ashcroft, I.; Maskery, I.; Everitt, N. On the Precipitation Hardening of Selective Laser Melted AlSi10Mg. Met. Mater. Trans. A 2015, 46, 3337–3341. [Google Scholar] [CrossRef]

- Tang, M.; Pistorius, P.C. Oxides, porosity and fatigue performance of AlSi10Mg parts produced by selective laser melting. Int. J. Fatigue 2017, 94, 192–201. [Google Scholar] [CrossRef]

- Fiocchi, J.; Tuissi, A.; Biffi, C. Heat treatment of aluminium alloys produced by laser powder bed fusion: A review. Mater. Des. 2021, 204, 109651. [Google Scholar] [CrossRef]

- Jung, H.Y.; Choi, S.J.; Prashanth, K.G.; Stoica, M.; Scudino, S.; Yi, S.; Kühn, U.; Kim, D.H.; Kim, K.B.; Eckert, J. Fabrication of Fe-based bulk metallic glass by selective laser melting: A parameter study. Mater. Des. 2015, 86, 703–708. [Google Scholar] [CrossRef]

- Concept Laser a ge Additive Company. Aluminium Alloy (Powder), Chemical Composition CL 30AL/CL 31AL: Material Sheet [online]. 2018. 2 s. Available online: https://www.ge.com/additive/sites/default/files/2018-12/CLMAT_30_31AL_DS_EN_US_2_v1.pdf (accessed on 7 February 2022).

- Rosenthal, I.; Shneck, R.; Stern, A. Heat treatment effect on the mechanical properties and fracture mechanism in AlSi10Mg fabricated by additive manufacturing selective laser melting process. Mater. Sci. Eng. A 2018, 729, 310–322. [Google Scholar] [CrossRef]

- Uzan, N.E.; Shneck, R.; Yeheskel, O.; Frage, N. Fatigue of AlSi10Mg specimens fabricated by additive manufacturing selective laser melting (AM-SLM). Mater. Sci. Eng. A 2017, 704, 229–237. [Google Scholar] [CrossRef]

- Takata, N.; Kodaira, H.; Sekizawa, K.; Suzuki, A.; Kobashi, M. Change in microstructure of selectively laser melted AlSi10Mg alloy with heat treatments. Mater. Sci. Eng. A 2017, 704, 218–228. [Google Scholar] [CrossRef]

- Zhuo, L.; Wang, Z.; Zhang, H.; Yin, E.; Wang, Y.; Xu, T.; Li, C. Effect of post-process heat treatment on microstructure and properties of selective laser melted AlSi10Mg alloy. Mater. Lett. 2019, 234, 196–200. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, J.; Wang, G.; Qin, Y.; Sun, M.; Yang, J.; Shen, X.; Huang, S. Effect of building orientation and heat treatment on the anisotropic tensile properties of AlSi10Mg fabricated by selective laser melting. J. Alloys Compd. 2021, 895, 162665. [Google Scholar] [CrossRef]

- Rosenthal, I.; Stern, A.; Frage, N. Strain rate sensitivity and fracture mechanism of AlSi10Mg parts produced by Selective Laser Melting. Mater. Sci. Eng. A 2017, 682, 509–517. [Google Scholar] [CrossRef]

- Patakham, U.; Palasay, A.; Wila, P.; Tongsri, R. MPB characteristics and Si morphologies on mechanical properties and fracture behavior of SLM AlSi10Mg. Mater. Sci. Eng. A 2021, 821, 141602. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.Q.; Wang, W.; Attallah, M.M.; Loretto, M.H. Microstructure and strength of selectively laser melted AlSi10Mg. Acta Mater. 2016, 117, 311–320. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.; Yan, C.; Shi, Y. Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture mechanism. Mater. Sci. Eng. A 2016, 663, 116–125. [Google Scholar] [CrossRef]

- Chen, B.; Moon, S.; Yao, X.; Bi, G.; Shen, J.; Umeda, J.; Kondoh, K. Strength and strain hardening of a selective laser melted AlSi10Mg alloy. Scr. Mater. 2017, 141, 45–49. [Google Scholar] [CrossRef]

- Alghamdi, F.; Song, X.; Hadadzadeh, A.; Shalchi-Amirkhiz, B.; Mohammadi, M.; Haghshenas, M. Post heat treatment of additive manufactured AlSi10Mg: On silicon morphology, texture and small-scale properties. Mater. Sci. Eng. A 2020, 783, 139296. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Baxter, C.; Amirkhiz, B.S.; Mohammadi, M. Strengthening mechanisms in direct metal laser sintered AlSi10Mg: Comparison between virgin and recycled powders. Addit. Manuf. 2018, 23, 108–120. [Google Scholar] [CrossRef]

- Zhou, L.; Mehta, A.; Schulz, E.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure, precipitates and hardness of selectively laser melted AlSi10Mg alloy before and after heat treatment. Mater. Charact. 2018, 143, 5–17. [Google Scholar] [CrossRef]

- Takata, N.; Liu, M.; Kodaira, H.; Suzuki, A.; Kobashi, M. Anomalous strengthening by supersaturated solid solutions of selectively laser melted Al–Si-based alloys. Addit. Manuf. 2020, 33, 101152. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, J. Effect of hot isostatic pressing on nanoparticles reinforced AlSi10Mg produced by selective laser melting. Mater. Sci. Eng. A 2020, 788, 139570. [Google Scholar] [CrossRef]

- Park, T.-H.; Baek, M.-S.; Hyer, H.; Sohn, Y.; Lee, K.-A. Effect of direct aging on the microstructure and tensile properties of AlSi10Mg alloy manufactured by selective laser melting process. Mater. Charact. 2021, 176, 111113. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Amirkhiz, B.S.; Mohammadi, M. Contribution of Mg2Si precipitates to the strength of direct metal laser sintered AlSi10Mg. Mater. Sci. Eng. A 2019, 739, 295–300. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Xue, Y.F.; Elbestawi, M.A.; Veldhuis, S.C. The Effect of Selective Laser Melting Process Parameters on the Microstructure and Mechanical Properties of Al6061 and AlSi10Mg Alloys. Materials 2019, 12, 12. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Lei, H.; Zhu, X.; Chen, H.; Fang, D. Influence of manufacturing geometric defects on the mechanical properties of AlSi10Mg alloy fabricated by selective laser melting. J. Alloys Compd. 2019, 789, 852–859. [Google Scholar] [CrossRef]

- Dong, Z.; Zhang, X.; Shi, W.; Zhou, H.; Lei, H.; Liang, J. Study of Size Effect on Microstructure and Mechanical Properties of AlSi10Mg Samples Made by Selective Laser Melting. Materials 2018, 11, 2463. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, H.; Liao, H.; Cheng, Y.; Hu, Z.; Zeng, X. Effect of heat treatments on fatigue property of selective laser melting AlSi10Mg. Int. J. Fatigue 2018, 116, 513–522. [Google Scholar] [CrossRef]

- Fiocchi, J.; Biffi, C.A.; Colombo, C.; Vergani, L.M.; Tuissi, A. Ad Hoc Heat Treatments for Selective Laser Melted Alsi10mg Alloy Aimed at Stress-Relieving and Enhancing Mechanical Performances. JOM 2020, 72, 1118–1127. [Google Scholar] [CrossRef]

| Si | Mg | Fe | Mn | Ti | Cu | Zn | C | Ni | Pb | Sn | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 9.0–11.0 | 0.20–0.45 | 0–0.55 | 0–0.45 | 0–0.15 | 0–0.10 | 0–0.10 | 0–0.05 | 0–0.05 | 0–0.05 | 0–0.05 | Bal. |

| Power (W) | Speed (mm/s) | Layer Thickness (µm) | Spot Size (µm) | |

|---|---|---|---|---|

| Skin | 200 | 800 | 25 | 190 |

| Core | 370 | 1400 | 50 | 190 |

| Support | 200 | 1600 | 50 | 50 |

| Identification of the Sample Group | Description of the Heat Treatment |

|---|---|

| AB (as-built) | With no further heat treatment after printing |

| T | 240 °C/6 h; FC to 100 °C then AC |

| Z | 240 °C/2 h; FC to 100 °C then AC |

| E | 300 °C/2 h; WQ |

| P | 300 °C/2 h; FC to 100 °C then AC |

| Ref. | UTS (MPa) | HV10 | |

|---|---|---|---|

| As-built | This paper | 486 ± 1 | 128 ± 2 |

| Conventional cast and aged | [6] | 300–317 | 86 |

| High-pressure die casting, as-cast | [6] | 300–350 | 95–105 |

| High-pressure die casting, T6 | [6] | 330–365 | 130–133 |

| UTS (MPa) | YS (MPa) | Printing Parameters | L-PBF Machine | Ref. |

|---|---|---|---|---|

| 488 ± 1 | 264 ± 10 | Power 370 W, speed 1400 mm/s, layer thickness 50 µm, spot size 190 µm | Concept Laser M2 | This paper |

| 386 ± 10 | 235 ± 5 | Power 370 W, speed 1300 mm/s, layer thickness 30 µm, spot size 100 µm | EOS M290 | [30] |

| 396 | 196 | Power 370 W, speed 1300 mm/s, layer thickness 30 µm | - | [31] |

| 404 ± 4 | 268 ± 12 | Power 370 W, speed 1300 mm/s, layer thickness 30 µm | EOS M290 | [32] |

| 476 | 220 | Power 380 W, layer thickness 30 µm | EOSINT M 280 | [16] |

| 349 ± 6 | 224 ± 6 | Power 370 W, speed 1500 mm/s, layer thickness 30 µm, spot size 100 µm | Concept X-line 1000R | [33] |

| 384 ± 16 | 241 ± 10 | Power 400 W, speed 1000 mm/s, layer thickness 30 µm, spot size 100–150 µm | EOSINT M 280 | [15] |

| Group | Description of the Heat Treatment | YS (MPa) | UTS (MPa) | HV 10 |

|---|---|---|---|---|

| AB | As-built | 264 ± 10 | 488 ± 1 | 128 ± 2 |

| T | 240 °C/6 h; FC to 100 °C then AC | 258 ± 8 | 415 ± 3 | 114 ± 1 |

| Z | 240 °C/2 h; FC to 100 °C then AC | 259 ± 3 | 417 ± 2 | 115 ± 1 |

| P | 300 °C/2 h; FC to 100 °C then AC | 195 ± 8 | 296 ± 5 | 86 ± 2 |

| E | 300 °C/2 h; WQ | 231 ± 6 | 354 ± 4 | 102 ± 1 |

| Heat Treatment | YS (MPa) | UTS (MPa) | Ref. |

|---|---|---|---|

| Mode T | |||

| As-built | 264 ± 10 | 488 ± 1 | This paper |

| 240 °C/6 h/ FC | 258 ± 8 | 415 ± 3 | |

| Mode Z | |||

| As-built | 264 ± 10 | 488 ± 1 | This paper |

| 240 °C/2 h/ FC | 259 ± 3 | 417 ± 2 | |

| Comparison of mode E | |||

| As-built | 264 ± 10 | 488 ± 1 | This paper |

| 300 °C/2 h/WQ | 231 ± 6 | 354 ± 4 | |

| As-built | 220 | 476 | [16] |

| 300 °C/2 h/WQ | 175 | 290 | |

| As-built | 270 | 446 | [17] |

| 300 °C/2 h/WQ | 169 | 273 | |

| Comparison of mode P | |||

| As-built | 264 ± 10 | 488 ± 1 | This paper |

| 300 °C/2 h/ FC | 195 ± 8 | 296 ± 5 | |

| As-built | 241 ± 10 | 384 ± 16 | [15] |

| 300 °C/2 h/ FC | 205 ± 8 | 253 ± 18 | |

| As-built | 319 ± 3 | 477 ± 5 | [34] |

| 300 °C/2 h/ FC | 266 ± 4 | 369 ± 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Růžičková, L.; Sobotová, J.; Beránek, L.; Pelikán, L.; Šimota, J. Influence of Stress Relief Annealing Parameters on Mechanical Properties and Decomposition of Eutectic Si Network of L-PBF Additive Manufactured Alloy AlSi10Mg. Metals 2022, 12, 1497. https://doi.org/10.3390/met12091497

Růžičková L, Sobotová J, Beránek L, Pelikán L, Šimota J. Influence of Stress Relief Annealing Parameters on Mechanical Properties and Decomposition of Eutectic Si Network of L-PBF Additive Manufactured Alloy AlSi10Mg. Metals. 2022; 12(9):1497. https://doi.org/10.3390/met12091497

Chicago/Turabian StyleRůžičková, Ludmila, Jana Sobotová, Libor Beránek, Lukáš Pelikán, and Jan Šimota. 2022. "Influence of Stress Relief Annealing Parameters on Mechanical Properties and Decomposition of Eutectic Si Network of L-PBF Additive Manufactured Alloy AlSi10Mg" Metals 12, no. 9: 1497. https://doi.org/10.3390/met12091497

APA StyleRůžičková, L., Sobotová, J., Beránek, L., Pelikán, L., & Šimota, J. (2022). Influence of Stress Relief Annealing Parameters on Mechanical Properties and Decomposition of Eutectic Si Network of L-PBF Additive Manufactured Alloy AlSi10Mg. Metals, 12(9), 1497. https://doi.org/10.3390/met12091497