Characterization of Vapor Capillary Geometry in Laser Beam Welding of Copper with 515 nm and 1030 nm Laser Beam Sources by Means of In Situ Synchrotron X-ray Imaging

Abstract

:1. Introduction

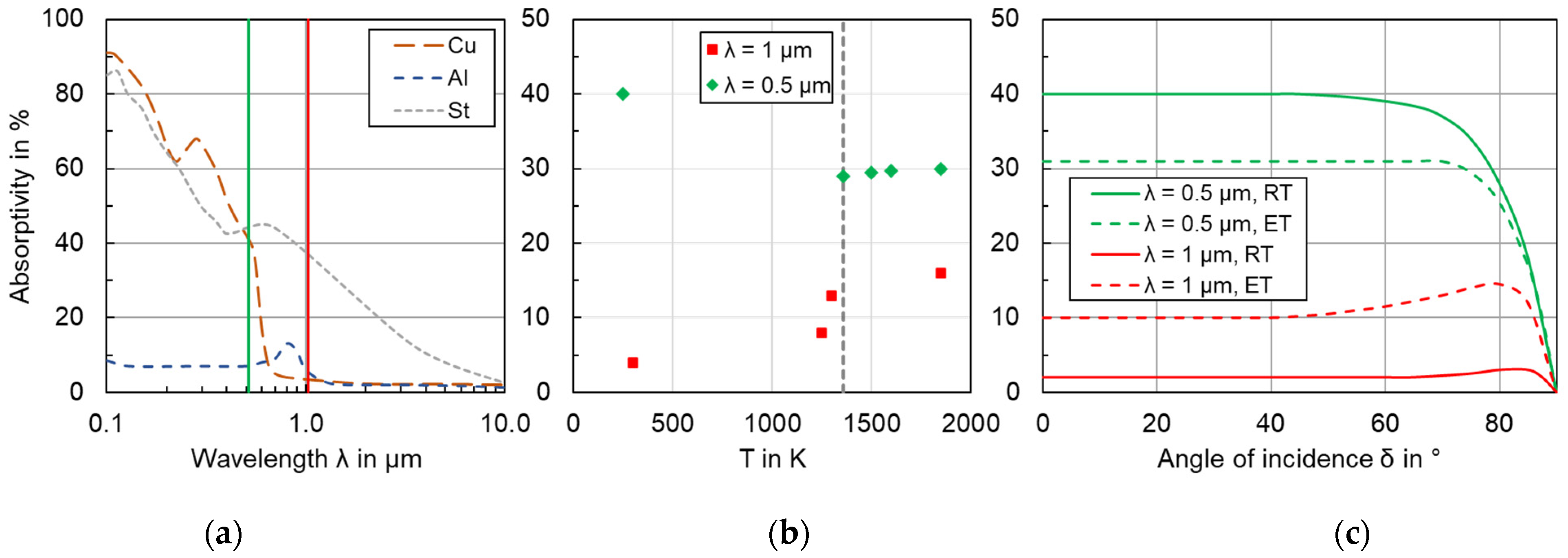

2. Theory and State of the Art

2.1. Fundamentals of Laser Beam Welding

2.2. Pressure Balance in the Keyhole

2.3. Copper Welding Using Visible Wavelength

2.4. Process Observation Using the X-ray Phase Contrast Method

3. Materials and Methods

3.1. Laser Beam Welding Setup

3.2. Image Processing and Data Evaluation

4. Results and Discussion

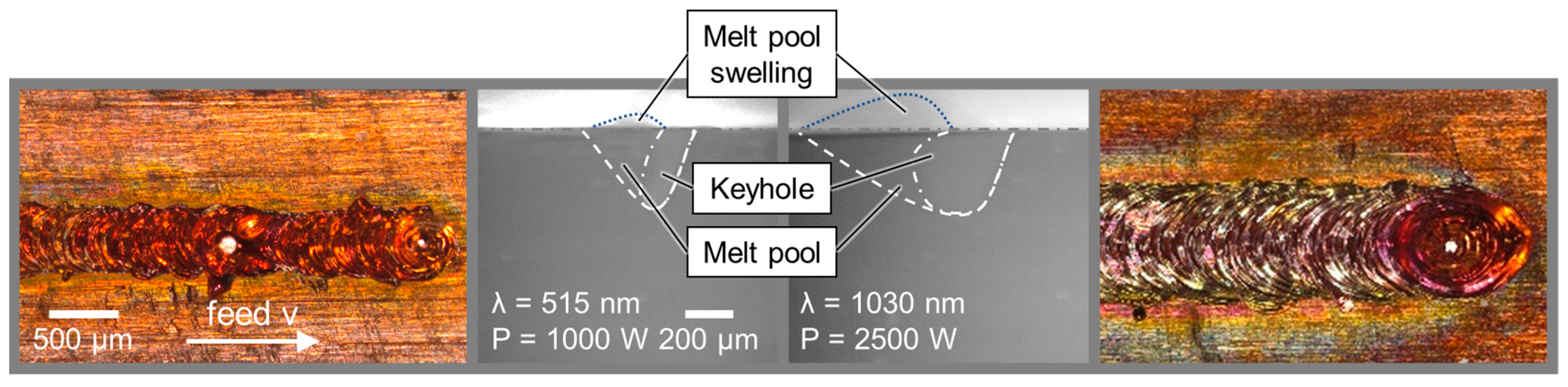

4.1. Observation of the Laser Welding Process of Copper with Visible and Infrared Laser Radiation

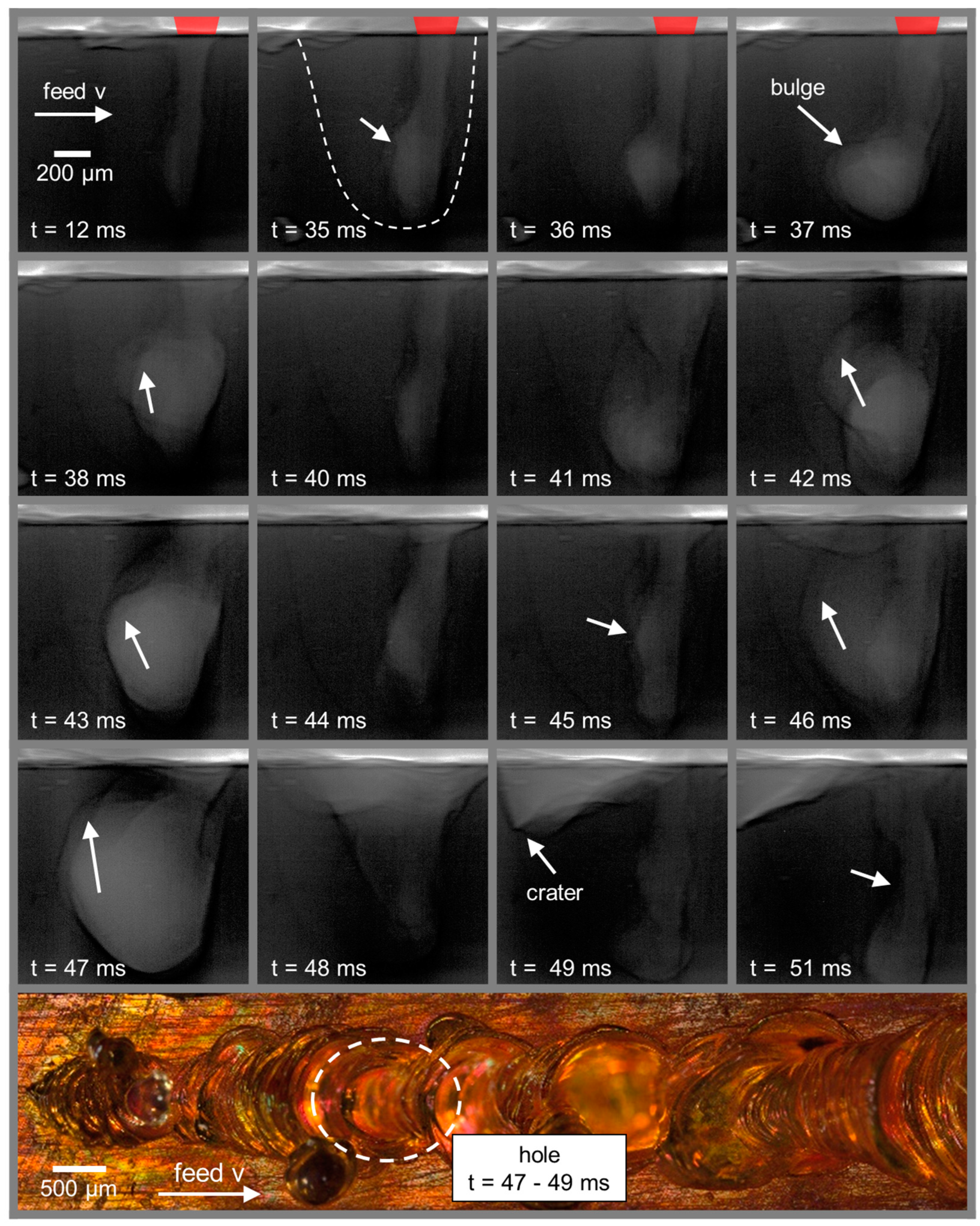

4.2. Investigation of the Formation of Weld Seam Imperfections

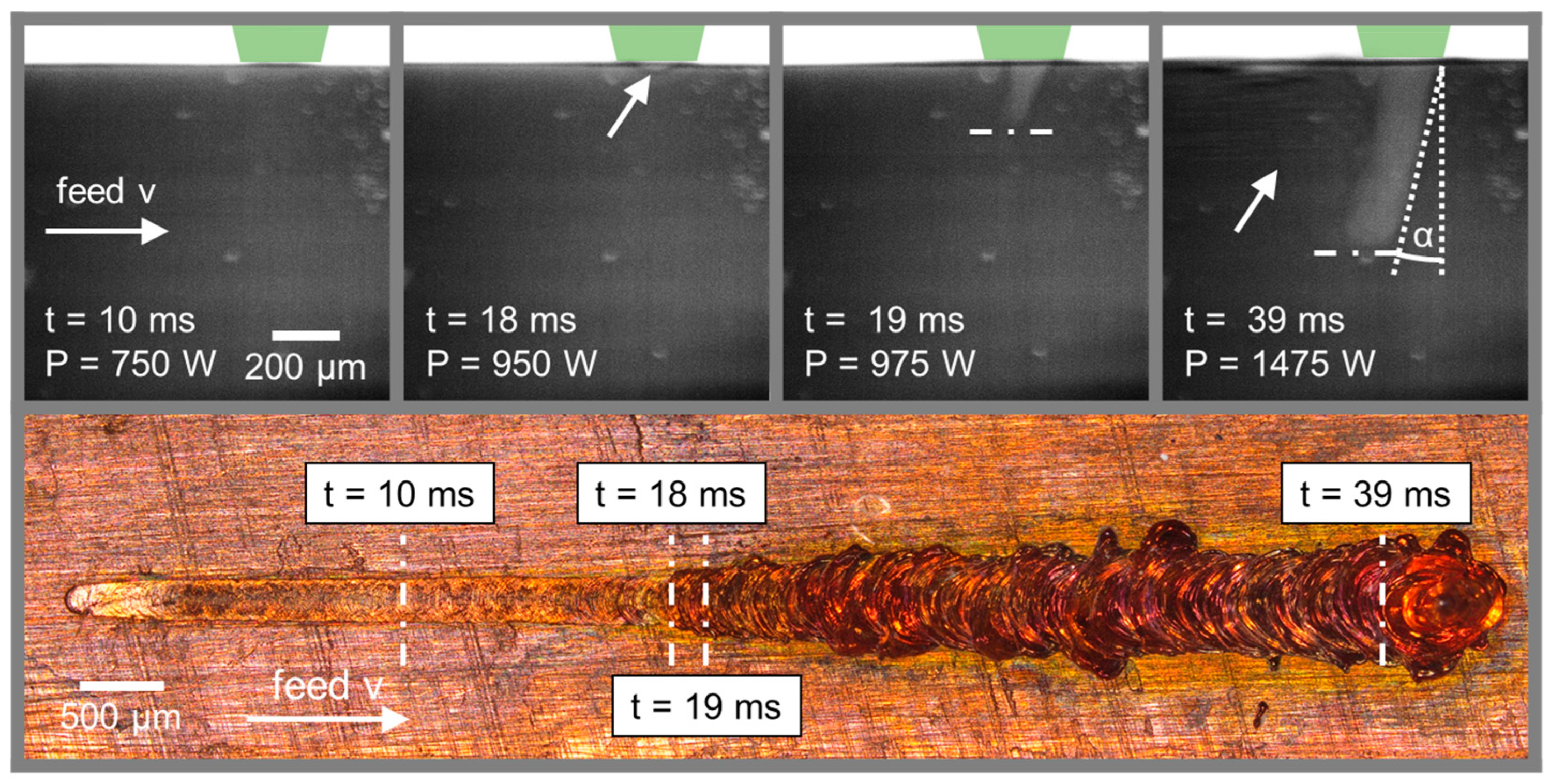

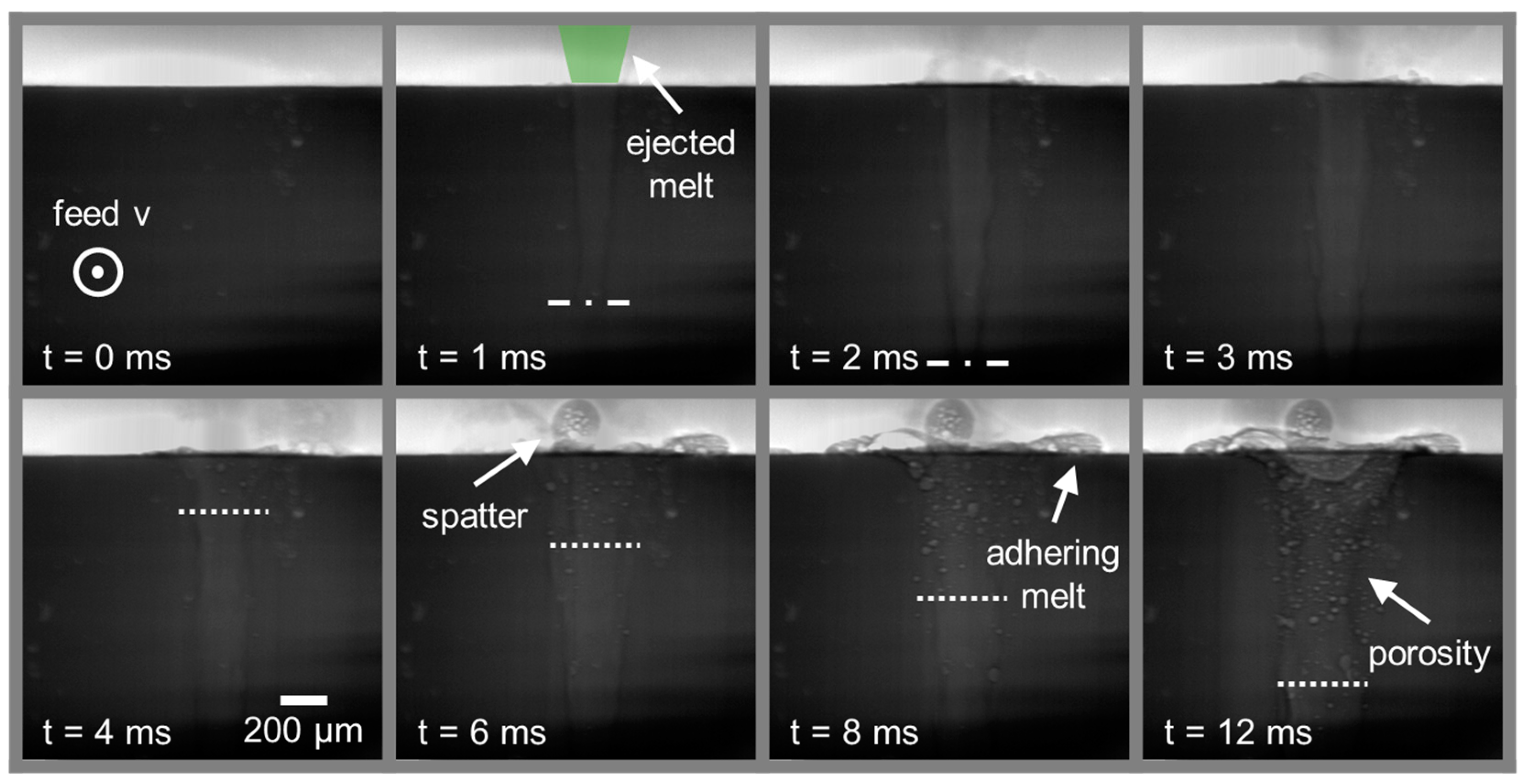

4.2.1. Melt Ejection/Spatter Formation

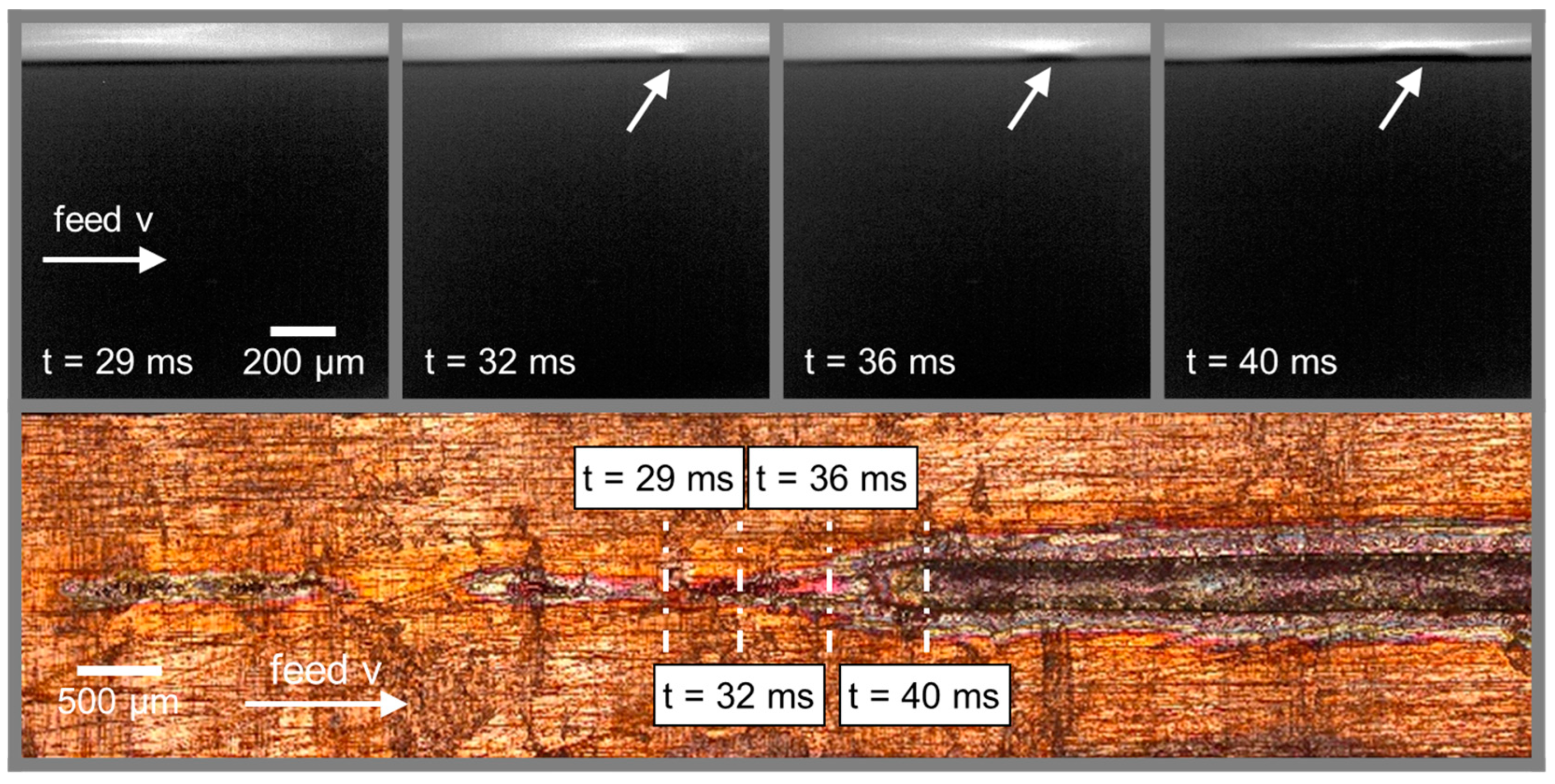

4.2.2. Pore Formation

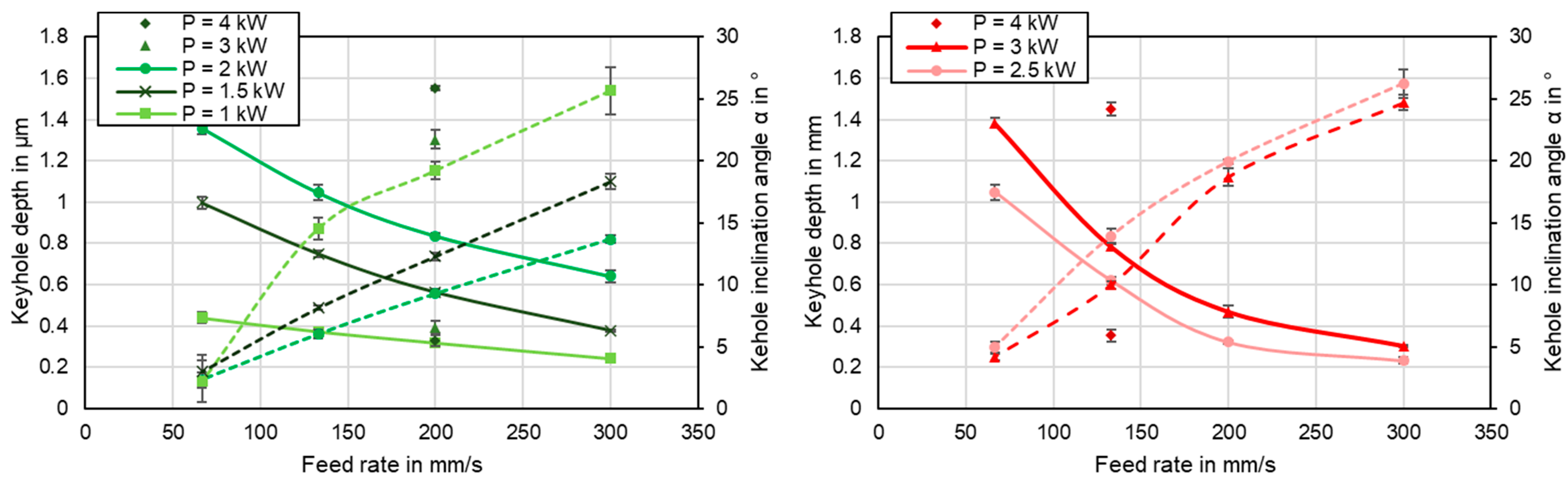

4.3. Influence of Process Parameters and Laser Wavelength on Keyhole Morphology

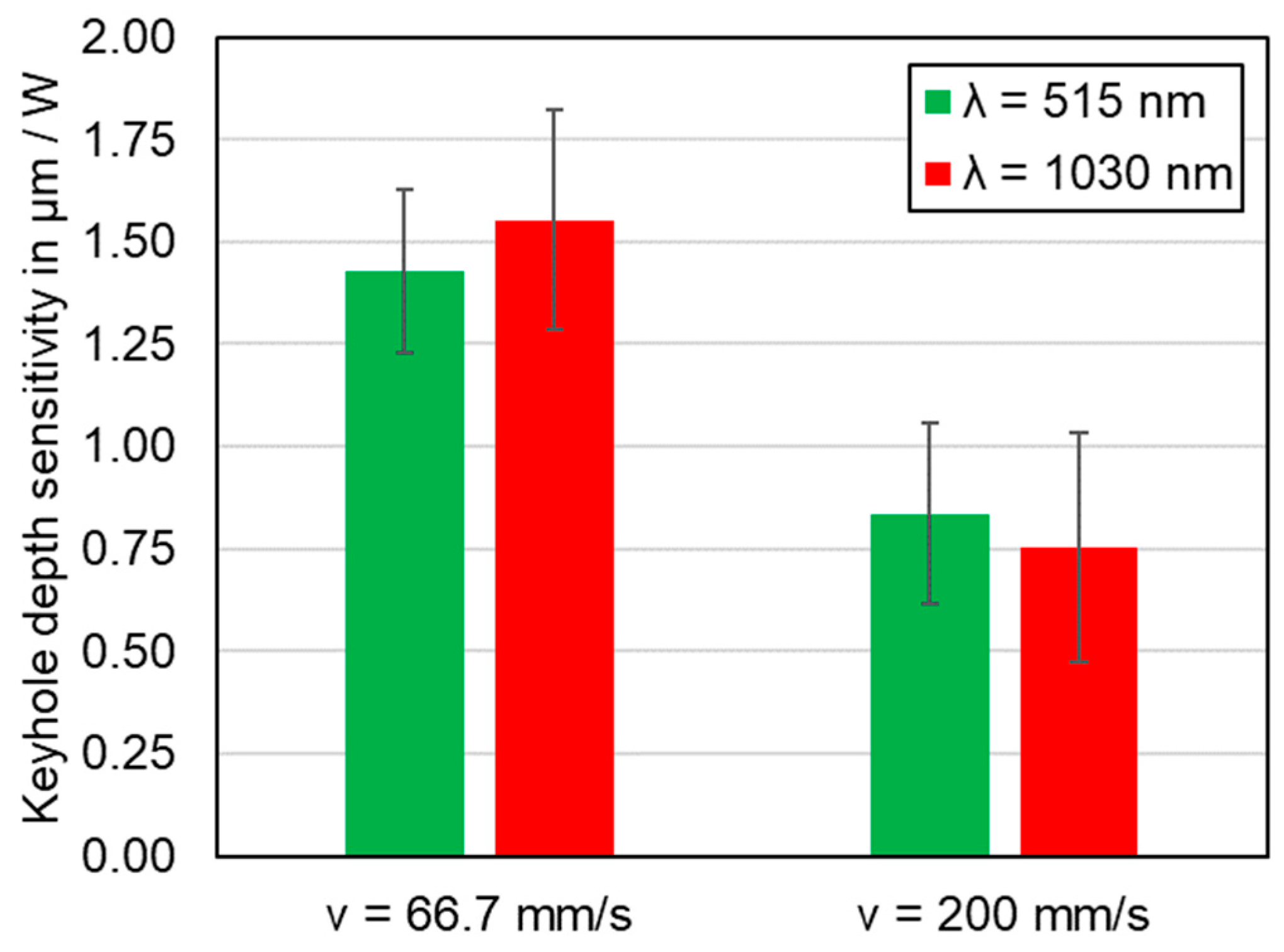

4.3.1. Evaluation of Keyhole Depth Sensitivity

4.3.2. Evaluation of Keyhole Width

5. Conclusions

- The high-speed phase contrast imaging of laser beam welding of copper enables the detailed observation of the dynamic processes inside the metal during the interaction between the laser beam, keyhole, and melt pool.

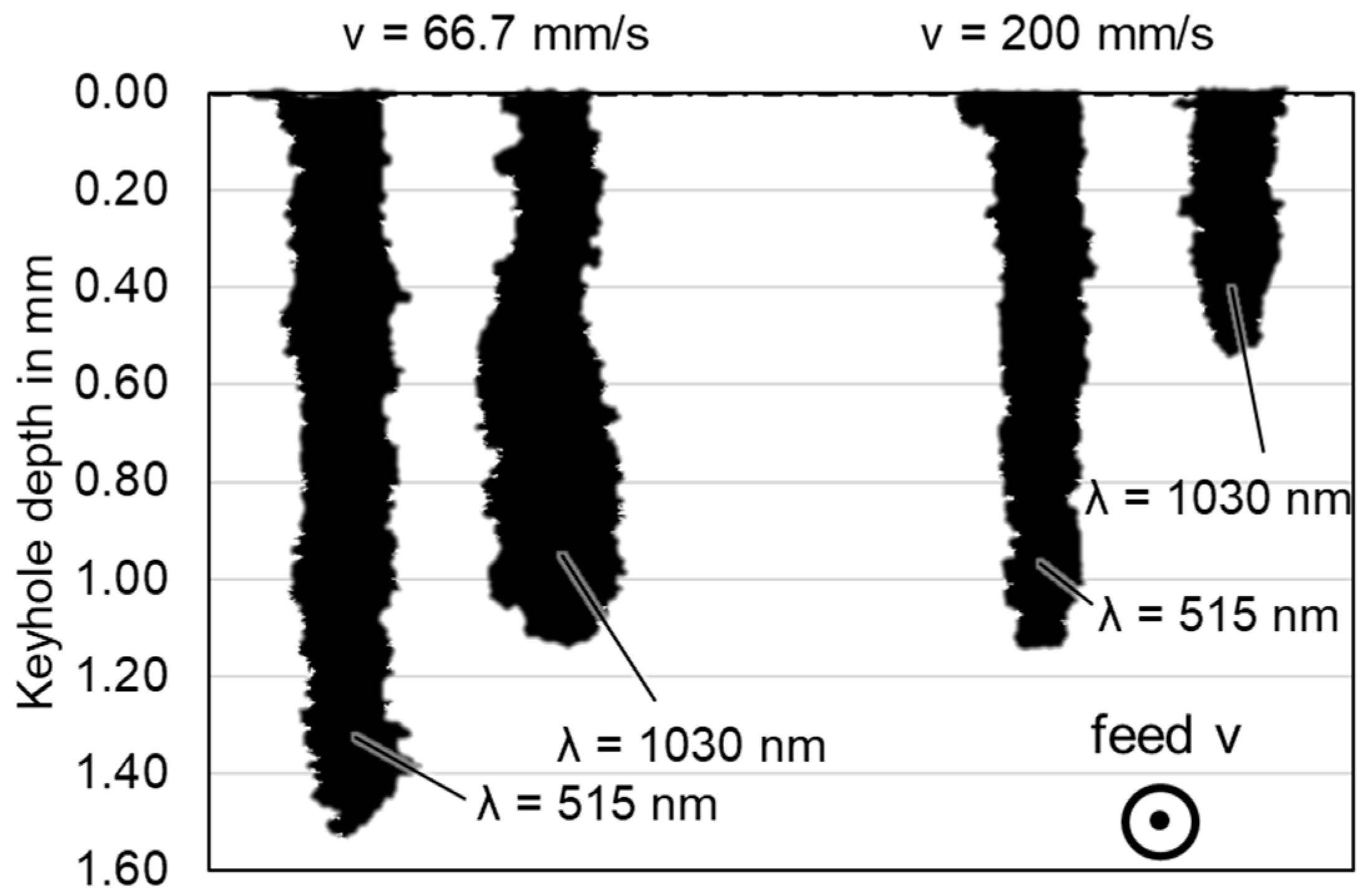

- The keyhole depth sensitivity for the 1030 nm laser is higher for the lower feed rate of v = 66.7 mm/s compared to the 515 nm laser, whereas the ratio is reversed for the feed rate of 200 mm/s when the laser power is continuously and linearly increased.

- The feed rate sensitivity decreases with increasing feed rate, which is attributed to the increasing inclination of the keyhole front wall in the case of both laser wavelengths.

- In general, the keyhole in the copper welding process using a 515 nm wavelength is observed to be less sensitive to changes in feed rate compared to the keyholes generated with an equal spot diameter and a 1030 nm laser wavelength.

- Multiple reflections have an increased effect in the case of infrared laser radiation, as the absorptivity for 1030 nm is lower compared to the 515 nm wavelength.

- This effect becomes particularly visible when looking at the keyhole in the width direction, where a decisive bulge is found in the lower keyhole area.

- The weld seam imperfections limit the usable parameter space, where especially key-hole bulging in the lower region at low feed rates (v ≤ 133 mm/s) is caused by the highly dynamic energy input for low keyhole inclination angles, which in consequence can result in spatter formation or complete ejection of the melt pool.

- The pore formation is observed as a time-progressive phenomenon in copper welding and is assumed to be caused by the chemical reaction of nitrogen and oxygen in the ambient gas.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schmidt, M.; Zäh, M.; Li, L.; Duflou, J.; Overmeyer, L.; Vollertsen, F. Advances in macro-scale laser processing. CIRP Ann. 2018, 67, 719–742. [Google Scholar] [CrossRef]

- Hügel, H.; Graf, T. Materialbearbeitung mit Laser: Grundlagen und Verfahren; 4., überarbeitete und erweiterte Auflage; Springer Vieweg: Wiesbaden, Germany, 2022; ISBN 9783658372521. [Google Scholar]

- Haubold, M.; Ganser, A.; Eder, T.; Zäh, M.F. Laser welding of copper using a high power disc laser at green wavelength. Procedia CIRP 2018, 74, 446–449. [Google Scholar] [CrossRef]

- Pavlicek, N.; Mohn, F. Laser bonding of copper ribbons and clips on SiC power MOSFETs with sintered copper bond buffers. In Proceedings of the 2020 IEEE 8th Electronics System-Integration Technology Conference (ESTC), Tønsberg, Vestfold, Norway, 15–18 September 2020; pp. 1–4, ISBN 978-1-7281-6293-5. [Google Scholar]

- Engler, S.; Ramsayer, R.; Poprawe, R. Process Studies on Laser Welding of Copper with Brilliant Green and Infrared Lasers. Phys. Procedia 2011, 12, 339–346. [Google Scholar] [CrossRef]

- Pricking, S.; Baumann, F.; Zaske, S.; Dold, E.; Kaiser, E.; Killi, A. Progress in green disk laser development for industrial high power applications. In Solid State Lasers XXX: Technology and Devices; Solid State Lasers XXX: Technology and Devices, Online Only, United States, 6–12 March 2021; Clarkson, W.A., Shori, R.K., Eds.; SPIE: Bellingham, WA, USA, 2021; p. 13. ISBN 9781510641631. [Google Scholar]

- Ramsayer, R.M.; Engler, S.; Schmitz, G. New approaches for highly productive laser welding of copper materials. In Proceedings of the 2011 1st International Electric Drives Production Conference, Nuremberg, Germany, 28–29 September 2011; pp. 69–73. [Google Scholar]

- Hummel, M.; Schöler, C.; Gillner, A. Metallographic Comparison for Laser Welding of Cu-ETP and CuSn6 with Laser Beam Sources of 515 nm and 1030 nm Wavelength. In Enhanced Material, Parts Optimization and Process Intensification: Proceedings; Reisgen, U., Drummer, D., Marschall, H., Eds.; Springer Nature: Cham, Switzerland, 2021; pp. 14–28. ISBN 978-3-030-70331-8. [Google Scholar]

- Schaaf, P. Laser Processing of Materials: Fundamentals, Applications and Developments; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2010; ISBN 9783642132810. [Google Scholar]

- Franco, D. Wobbling Laser Beam Welding of Copper. Ph.D. Thesis, Universidade Nova de Lisboa, Lisboa, Portugal, 2017. [Google Scholar]

- Kaufmann, F.; Maier, A.; Schrauder, J.; Roth, S.; Schmidt, M. Influence of superimposed intensity distributions on weld seam quality and spatter behavior during laser beam welding of copper with green laser radiation. J. Laser Appl. 2022, 34, 42008. [Google Scholar] [CrossRef]

- Beck, M. Modellierung des Lasertiefschweißens. Doctoral Thesis, Universität Stuttgart, Stuttgart, Germany, 1996. [Google Scholar]

- Kroos, J.; Gratzke, U.; Simon, G. Towards a self-consistent model of the keyhole in penetration laser beam welding. J. Phys. D Appl. Phys. 1993, 26, 474–480. [Google Scholar] [CrossRef]

- Berger, P.; Hügel, H. Fluid Dynamic Effects in Keyhole Welding—An Attempt to Characterize Different Regimes. Phys. Procedia 2013, 41, 216–224. [Google Scholar] [CrossRef] [Green Version]

- Kroos, J.; Gratzke, U.; Vicanek, M.; Simon, G. Dynamic behaviour of the keyhole in laser welding. J. Phys. D Appl. Phys. 1993, 26, 481–486. [Google Scholar] [CrossRef]

- Arata, Y.; Mario, I.; Miyamoto, T.; Takeuchi, S. Dynamic behavior of laser welding and cutting. In Proceedings of the 7th International Conference Electron and Ion Beam Science and Technology, Washington, WA, USA, 4–7 May 1976; pp. 111–128. [Google Scholar]

- Schricker, K.; Schmidt, L.; Friedmann, H.; Diegel, C.; Seibold, M.; Hellwig, P.; Fröhlich, F.; Bergmann, J.P.; Nagel, F.; Kallage, P.; et al. Characterization of keyhole dynamics in laser welding of copper by means of high-speed synchrotron X-ray imaging. Procedia CIRP 2022, 111, 501–506. [Google Scholar] [CrossRef]

- Klein, T.; Vicanek, M.; Kroos, J.; Decker, I.; Simon, G. Oscillations of the keyhole in penetration laser beam welding. J. Phys. D Appl. Phys. 1994, 27, 2023–2030. [Google Scholar] [CrossRef]

- Miyagi, M.; Zhang, X. Investigation of laser welding phenomena of pure copper by x-ray observation system. J. Laser Appl. 2015, 27, 42005. [Google Scholar] [CrossRef]

- Katayama, S. (Ed.) Handbook of Laser Welding Technologies: Woodhead Publishing Series in Electronic and Optical Materials; Woodhead Publishing: Sawston, UK, 2013; ISBN 978-0-85709-264-9. [Google Scholar]

- Heider, A. Erweitern der Prozessgrenzen Beim Laserstrahlschweißen von Kupfer mit Einschweißtiefen Zwischen 1 mm und 10 mm. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2018. [Google Scholar]

- DIN EN ISO 6520; Schweißen und Verwandte Prozesse—Einteilung von Geometrischen Unregelmäßigkeiten an Metallischen Werkstoffen—Teil 1: Schmelzschweißen. Beuth Verlag GmbH: Berlin, Germany, 2007.

- Heider, A.; Sollinger, J.; Abt, F.; Boley, M.; Weber, R.; Graf, T. High-Speed X-ray Analysis of Spatter Formation in Laser Welding of Copper. Phys. Procedia 2013, 41, 112–118. [Google Scholar] [CrossRef] [Green Version]

- Kaplan, A.F.H.; Powell, J. Spatter in laser welding. J. Laser Appl. 2011, 23, 32005. [Google Scholar] [CrossRef]

- Zhang, G.; Zhu, B.; Zou, J.; Wu, Q.; Xiao, R. Correlation between the spatters and evaporation vapor on the front keyhole wall during fiber laser keyhole welding. J. Mater. Res. Technol. 2020, 9, 15143–15152. [Google Scholar] [CrossRef]

- Weaver, J.H.; Krafka, C.; Lynch, D.W.; Koch, E.E. Optical properties of metals. Appl. Opt. 1981, 20, 1124_1–1125. [Google Scholar] [CrossRef]

- Pells, G.P.; Shiga, M. The optical properties of copper and gold as a function of temperature. J. Phys. C Solid State Phys. 1969, 2, 1835–1846. [Google Scholar] [CrossRef]

- Blom, A.; Dunias, P.; van Engen, P.; Hoving, W.; de Kramer, J. Process spread reduction of laser microspot welding of thin copper parts using real-time control. In Photon Processing in Microelectronics and Photonics II; International Society for Optics and Photonics: Bellingham, WA, USA, 2003; pp. 493–507. [Google Scholar]

- Krishnan, S.; Hansen, G.P.; Hauge, R.H.; Margrave, J.L. Emissivities and Optical Constants of Electromagnetically Levitated Liquid Metals as Functions of Temperature and Wavelength. In Materials Chemistry at High Temperatures; Hastie, J.W., Ed.; Humana Press: Clifton, NJ, USA, 1990; pp. 143–164. ISBN 978-1-4612-6781-2. [Google Scholar]

- Palik, E.D. (Ed.) Handbook of Optical Constants of Solids: Volume 2; Academic Press: San Diego, CA, USA; London, UK, 2012; ISBN 9780080556307. [Google Scholar]

- Punzel, E.; Hugger, F.; Dörringer, R.; Dinkelbach, T.L.; Bürger, A. Comparison of different system technologies for continuous-wave laser beam welding of copper. Procedia CIRP 2020, 94, 587–591. [Google Scholar] [CrossRef]

- Kaufmann, F.; Maier, A.; Ermer, J.; Roth, S.; Schmidt, M. Influence of defocusing in deep penetration welding of copper by using visible wavelength. In Proceedings of the 11th International WLT-Conference on Lasers in Manufacturing, Munich, Germany, 21–24 June 2021. [Google Scholar]

- Kohl, S.; Kaufmann, F.; Schmidt, M. Why Color Matters—Proposing a Quantitative Stability Criterion for Laser Beam Processing of Metals Based on Their Fundamental Optical Properties. Metals 2022, 12, 1118. [Google Scholar] [CrossRef]

- Fetzer, F.; Hagenlocher, C.; Weber, R.; Graf, T. Geometry and stability of the capillary during deep-penetration laser welding of AlMgSi at high feed rates. Opt. Laser Technol. 2021, 133, 106562. [Google Scholar] [CrossRef]

- Lind, J.; Fetzer, F.; Blazquez-Sanchez, D.; Weidensdörfer, J.; Weber, R.; Graf, T. Geometry and absorptance of the cutting fronts during laser beam cutting. J. Laser Appl. 2020, 32, 32015. [Google Scholar] [CrossRef]

- Kawahito, Y.; Wang, H. In-Situ Observation of Laser Manufacturing with X-ray Technique. Synchrotron Radiat. News 2019, 32, 14–19. [Google Scholar] [CrossRef]

- Chen, Y.; Clark, S.J.; Leung, C.L.A.; Sinclair, L.; Marussi, S.; Olbinado, M.P.; Boller, E.; Rack, A.; Todd, I.; Lee, P.D. In-situ Synchrotron imaging of keyhole mode multi-layer laser powder bed fusion additive manufacturing. Appl. Mater. Today 2020, 20, 100650. [Google Scholar] [CrossRef]

- Schell, N.; King, A.; Beckmann, F.; Fischer, T.; Müller, M.; Schreyer, A. The High Energy Materials Science Beamline (HEMS) at PETRA III. MSF 2013, 772, 57–61. [Google Scholar] [CrossRef] [Green Version]

- Hummel, M.; Külkens, M.; Schöler, C.; Schulz, W.; Gillner, A. In situ X-ray tomography investigations on laser welding of copper with 515 and 1030 nm laser beam sources. J. Manuf. Process. 2021, 67, 170–176. [Google Scholar] [CrossRef]

- Weckert, E.; Balewski, K.; Brefeld, W.; Decking, W.; Drube, W. PETRA III: A New High Brilliance Synchrotron Radiation Source at DESY. In AIP Conference Proceedings. Synchrotron Radiation Instrumentation: Eighth International Conference on Synchrotron Radiation Instrumentation, San Francisco, CA, USA, 25–29 August 2003; AIP: Woodbury, Long Island, NY, USA, 2003; pp. 73–76. [Google Scholar]

- Eriksson, I.; Powell, J.; Kaplan, A. Melt behavior on the keyhole front during high speed laser welding. Opt. Lasers Eng. 2013, 51, 735–740. [Google Scholar] [CrossRef] [Green Version]

- Kaufmann, F.; Ermer, J.; Maier, A.; Roth, S.; Schmidt, M. Influence of plume attenuation under high power laser welding of copper using visible wavelengths. J. Laser Appl. 2021, 33, 042006. [Google Scholar] [CrossRef]

- Harvey, A.C. Forecasting, Structural Time Series Model and Kalman Filter; Cambridge University Press: Cambridge, UK; New York, NY, USA, 1990; ISBN 9780521321969. [Google Scholar]

- Abt, F.; Boley, M.; Weber, R.; Graf, T. X-ray videography for investigation of capillary and melt pool dynamics in different materials. In Proceedings of the International Congress on Applications of Lasers & Electro-Optics. ICALEO® 2011: 30th International Congress on Laser Materials Processing, Laser Microprocessing and Nanomanufacturing, Orlando, FL, USA, 23–27 October 2011; Laser Institute of America: Woodbury, Long Island, NY, USA, 2011; pp. 179–186, ISBN 978-0-912035-94-9. [Google Scholar]

- Bergström, D.; Powell, J.; Kaplan, A.F.H. Absorptance of nonferrous alloys to Nd:YLF and Nd:YAG laser light at room temperature. Appl. Opt. 2007, 46, 1290–1301. [Google Scholar] [CrossRef] [Green Version]

- Alter, L.; Heider, A.; Bergmann, J.P. Influence of hydrogen, oxygen, nitrogen, and water vapor on the formation of pores at welding of copper using laser light at 515 nm wavelength. J. Laser Appl. 2020, 32, 022020. [Google Scholar] [CrossRef]

- Faure, F.; Weber, R.; Graf, T. Influence of beam parameters on the capillary formation and the depth progress in laser spot welding of copper. In Proceedings of the 11th International WLT-Conference on Lasers in Manufacturing, Munich, Germany, 21–24 June 2021. [Google Scholar]

| Dimension | Unit | Petra 3 Beamline P07 |

|---|---|---|

| Operation mode | [-] | Low Beta |

| Photon energy | [keV] | 89 |

| Beam area | [mm²] | 2 × 2 |

| Scintillator material | [-] | Ce:GAGG |

| Scintillator size | [mm²] | 11 × 11 |

| Scintillator thickness | [µm] | 600 |

| Distance scintillator—material sample | [mm] | 3500 |

| Dimension | Unit | Trumpf TruDisk Pulse 421 | Trumpf TruDisk 6001 |

|---|---|---|---|

| Wavelength (λ) | [nm] | 515 | 1030 |

| Laser power (Pmax) | [W] | 400 (cw)/4000 (pulsed) | 6000 |

| Fiber diameter (dLLK) | [µm] | 100 | 100 |

| Focal length collimator (fC) | [mm] | 80 | 80 |

| Focal length optics (fF) | [mm] | 163 | 163 |

| Focal diameter (dF, measured) | [µm] | 222.5 | 213.2 |

| Diffraction factor (M2) | [-] | 23.5 | 11.95 |

| Divergence angle (θ) | [mrad] | 71.5 | 75.9 |

| Beam parameter product (BPP) | [mm∙mrad] | 3.98 | 4.05 |

| Dimension | Unit | Choice of Parameters |

|---|---|---|

| Material of sample | [-] | Cu-ETP |

| Feed rate (v) | [mm/s] | 66.7; 133.3; 200; 300 |

| Power of laser (PL) | [kW] | 1; 1.5; 2; 2.5; 3; 4 |

| Energy of pulse (E) | [J] | 40 = const. @ λ = 515 nm/ var. @ λ = 1030 nm |

| Pulse length (tP) | [ms] | 40∙PL[kW]−1 @ λ = 515 nm/ 3∙v[m/min]−1 @ λ = 1030 nm |

| Frame rate X-ray (fX-ray) | [kHz] | 1 = const. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaufmann, F.; Forster, C.; Hummel, M.; Olowinsky, A.; Beckmann, F.; Moosmann, J.; Roth, S.; Schmidt, M. Characterization of Vapor Capillary Geometry in Laser Beam Welding of Copper with 515 nm and 1030 nm Laser Beam Sources by Means of In Situ Synchrotron X-ray Imaging. Metals 2023, 13, 135. https://doi.org/10.3390/met13010135

Kaufmann F, Forster C, Hummel M, Olowinsky A, Beckmann F, Moosmann J, Roth S, Schmidt M. Characterization of Vapor Capillary Geometry in Laser Beam Welding of Copper with 515 nm and 1030 nm Laser Beam Sources by Means of In Situ Synchrotron X-ray Imaging. Metals. 2023; 13(1):135. https://doi.org/10.3390/met13010135

Chicago/Turabian StyleKaufmann, Florian, Carola Forster, Marc Hummel, Alexander Olowinsky, Felix Beckmann, Julian Moosmann, Stephan Roth, and Michael Schmidt. 2023. "Characterization of Vapor Capillary Geometry in Laser Beam Welding of Copper with 515 nm and 1030 nm Laser Beam Sources by Means of In Situ Synchrotron X-ray Imaging" Metals 13, no. 1: 135. https://doi.org/10.3390/met13010135

APA StyleKaufmann, F., Forster, C., Hummel, M., Olowinsky, A., Beckmann, F., Moosmann, J., Roth, S., & Schmidt, M. (2023). Characterization of Vapor Capillary Geometry in Laser Beam Welding of Copper with 515 nm and 1030 nm Laser Beam Sources by Means of In Situ Synchrotron X-ray Imaging. Metals, 13(1), 135. https://doi.org/10.3390/met13010135