Fatigue Strength Estimation of Ductile Cast Irons Containing Solidification Defects

Abstract

1. Introduction

- -

- approach (a): the defects are treated as notches and the fatigue limit is calculated on the basis of the elastic stress concentration factor [19,20]. Note that, since the actual value of such a factor is difficult to be determined in presence of defects with an irregular shape, Mitchell [19] proposed to consider the defect equivalent to a hemispherical pit;

- -

- approach (b): the defects are considered as pre-existent cracks and the fatigue limit is determined by using the stress intensity factor concept [18,21]. The main drawback of this approach is related to the computation of the threshold stress intensity factor range, especially in presence of defects with a complex shape;

- -

2. Fundamentals of the Procedure for Fatigue Strength Estimation of Defective Metals

2.1. The -Parameter Model

2.2. The Carpinteri et al. Multiaxial Fatigue Criterion

- determination of the averaged directions of the principal stress axes by means of the averaged values of the principal Euler angles, obtained through an appropriate weight function;

- definition of the critical plane orientation, which is linked to the above averaged principal stress directions through an off-angle , defined as follows:

- computation of the normal, , and shear, , components of the stress vector related to the critical plane orientation;

- estimation of the fatigue endurance condition by equating an equivalent uniaxial stress amplitude, , to the normal fatigue limit, , that is

3. Experimental Fatigue Data Examined

- -

- a ferritic DCI with 14% graphite nodules in a white ferrite matrix, identified as EN-GJS-400-18, according to the European designation;

- -

- a ferritic/pearlitic DCI with a typical bulls-eye structure of 14% graphite nodules in a matrix of 46% ferrite and 40% dark pearlite, identified as EN-GJS-600-3 DCI;

- -

- a pearlitic DCI with 13% graphite nodules in a matrix of 62% pearlite and 25% ferrite, identified as EN-GJS-700-2 DCI.

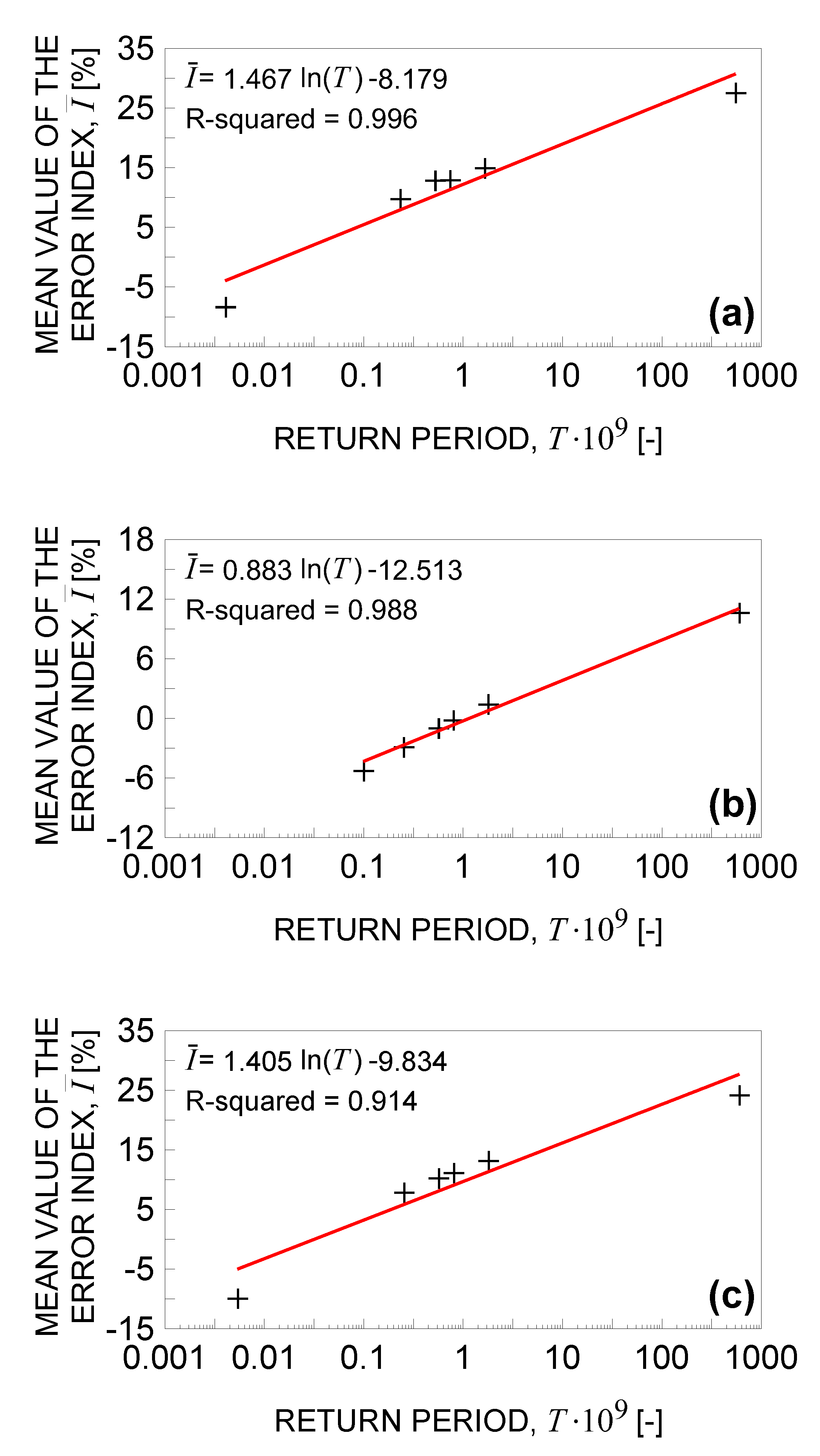

4. Defect Content Analysis and Return Period Optimisation

- -

- mm3 is the volume of the specimen gauge section for which the return period is ;

- -

- mm3 is five times the volume of the specimen gauge section (i.e., ) for which the return period is ;

- -

- mm3 is ten times the volume of the specimen gauge section (i.e., ) for which the return period is ;

- -

- mm3 is fifty times the volume of the specimen gauge section (i.e., ) for which the return period is .

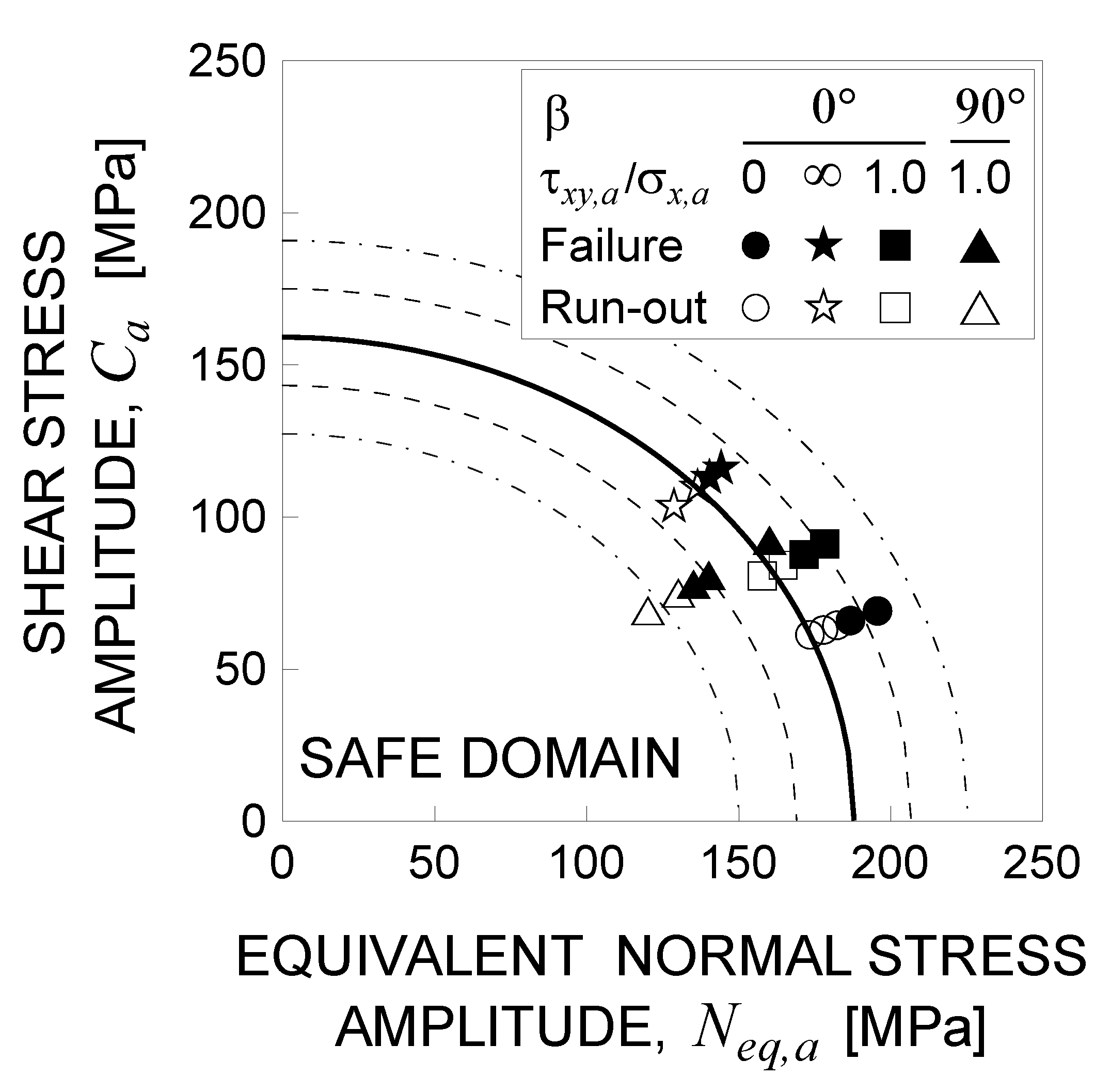

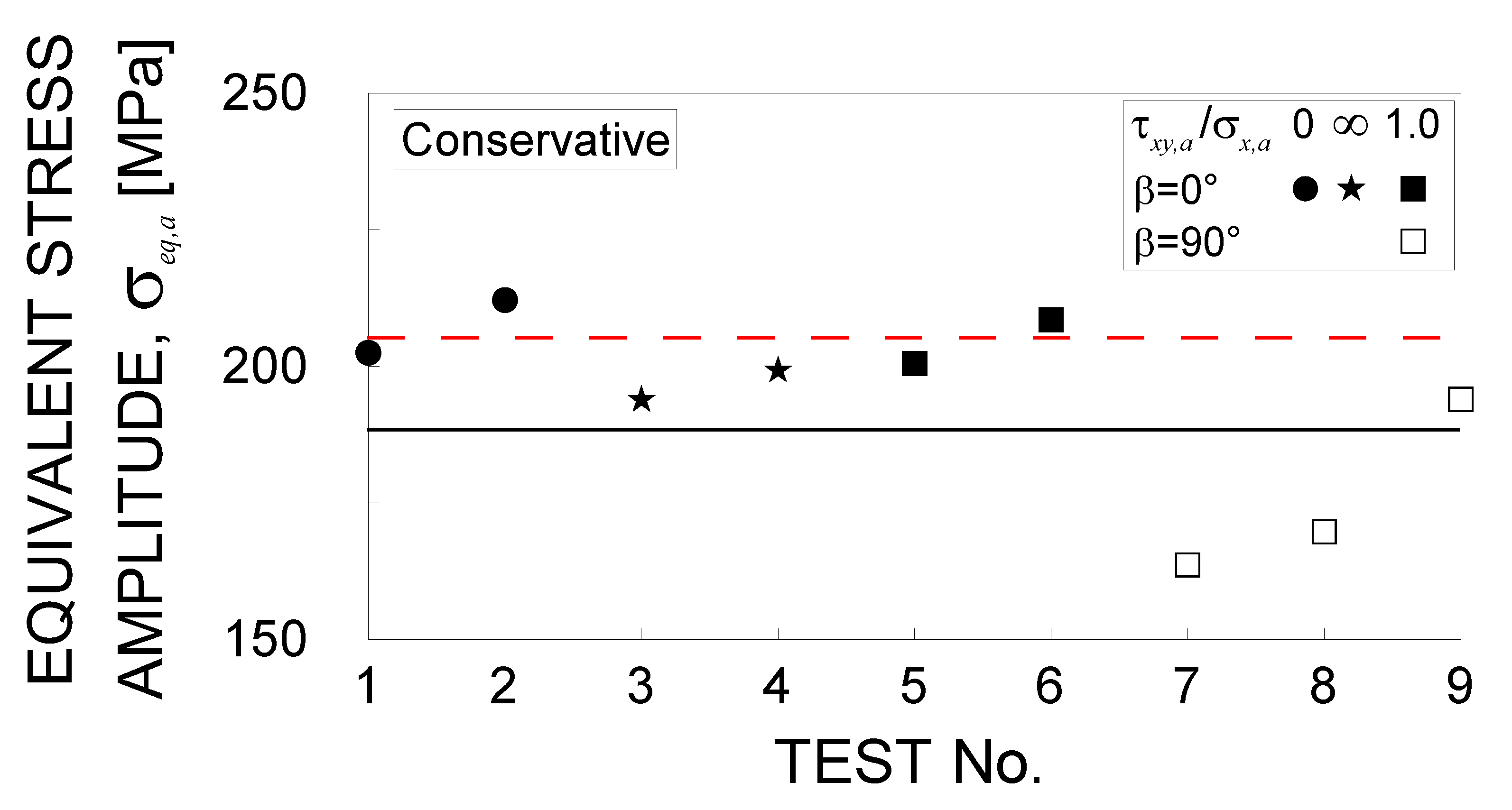

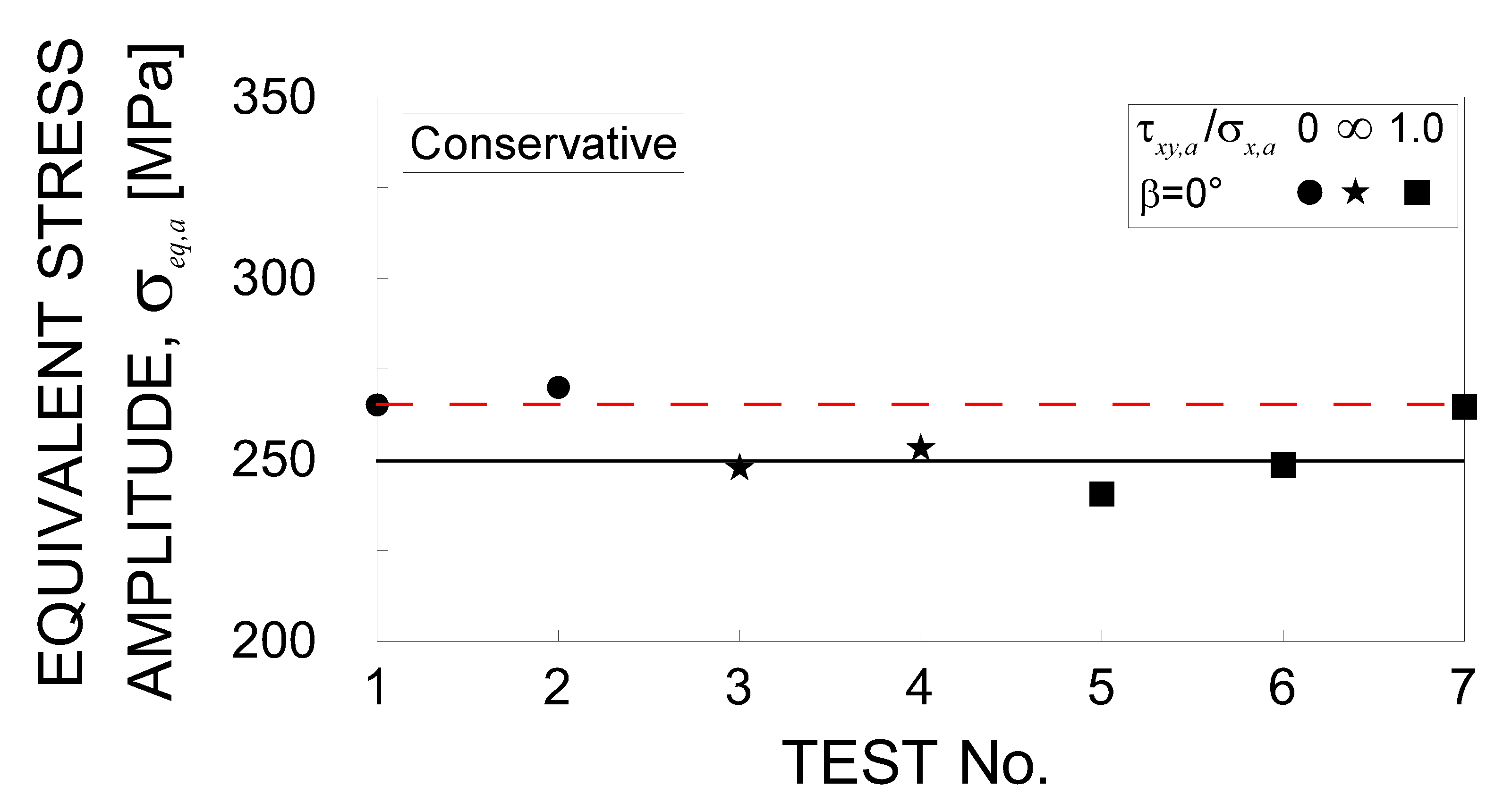

5. Discussion of the Results

- -

- for uniaxial fatigue tests (i.e., and ), the above procedure is able to correctly estimate the fatigue failures (being all the full symbols outside the ellipse), whereas the experimental run-out conditions are not capture, with the exception of one data relating to torsion. However, the empty symbols lie on or very close to the failure curve (within the error band equal to ), thus representing a condition of incipient failure;

- -

- for proportional biaxial fatigue tests (i.e., with ), all the experimental failures and one of the two run-outs are perfectly predicted by means of the present procedure;

- -

- for non-proportional biaxial fatigue tests (i.e., with ), all the empty symbols are inside the elliptical domain, in agreement with the experimental observations. On the other hand, two of the three experimental failures are not capture by means of the present procedure, falling the results into the error band equal to .

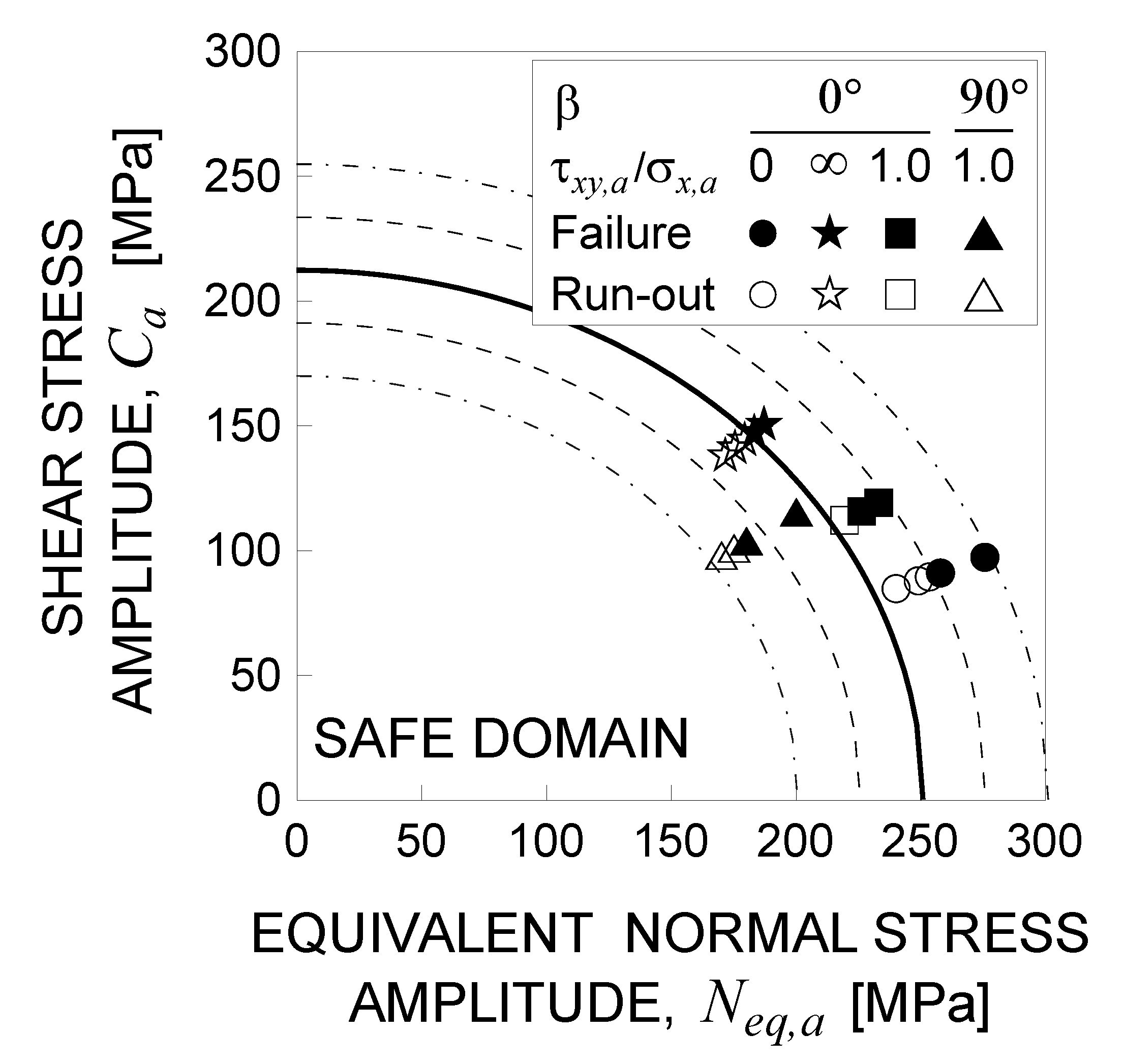

- -

- for rotating bending fatigue tests (i.e., ), the fatigue failure conditions are perfectly estimated, whereas incipient failure conditions (i.e., the corresponding points lie very close to the failure curve) are obtained, even if run-outs were observed;

- -

- for torsion fatigue tests (i.e., ), the present procedure allows to correctly estimate the experimental run-out and one of the two experimental fatigue failure, while for the other it is possible to predict an incipient failure condition;

- -

- for proportional biaxial fatigue tests (i.e., with ), experimental run-outs are correctly represent by the empty symbols falling inside the elliptical domain; regarding fatigue failures, only one is perfectly predicted by means of the present procedure, whereas incipient failure conditions are achieved for the other two.

- -

- for rotating bending fatigue tests (i.e., ), the full symbols falling outside the elliptical domain correctly represent experimental failures, whereas the empty symbols should be located inside the ellipse, since run-outs were experimentally observed. However, such points lie very close to the failure curve (inside the error band equal to ), and, consequently, the procedure allows to estimate conditions of incipient failure;

- -

- for torsion fatigue tests (i.e., ), the experimental failure and run-out conditions are perfectly predicted by means of the present procedure;

- -

- for proportional biaxial fatigue tests (i.e., with ), all the full symbols are outside the elliptical domain, in agreement with the experimental outcomes. An incipient failure instead of a run-out is predicted, since the empty symbol is outside the ellipse, but very close to it;

- -

- for non-proportional biaxial fatigue tests (i.e., with ), the present procedure allows to correctly capture the run-outs but not the fatigue failures, even if the full symbols lie inside the error band equal to .

6. Conclusions

Funding

Informed Consent Statement

Conflicts of Interest

Nomenclature

| square root of the expected maximum size of the defect under normal cyclic loading | |

| square root of the expected maximum size of the defect under shear cyclic loading | |

| amplitude of the shear stress component on the critical plane | |

| gauge section diameter | |

| thickness associated to the inspection area under normal cyclic loading | |

| Vickers hardness | |

| error index | |

| gauge length | |

| amplitude of the normal stress component perpendicular to the critical plane | |

| equivalent normal stress amplitude | |

| mean value of the normal stress component perpendicular to the critical plane | |

| loading ratio | |

| inspection area | |

| stress vector on the critical plane | |

| return period related to normal cyclic loading | |

| return period related to shear cyclic loading | |

| optimised return period | |

| prediction volume (i.e., useful cross-section volume) | |

| standard inspection volume related to normal cyclic loading | |

| standard inspection volume related to shear cyclic loading | |

| phase shift between normal stress and shear stress | |

| off-angle defining the normal to the critical plane | |

| applied normal stress amplitude | |

| experimental material fatigue strength under fully reversed normal stress | |

| equivalent stress amplitude | |

| material ultimate tensile strength | |

| fatigue limit under normal loading | |

| applied shear stress amplitude | |

| experimental material fatigue strength under fully reversed shear stress | |

| fatigue limit under torsion | |

| Subscripts | |

| amplitude | |

| mean value | |

References

- Machado, P.V.S.; Araújo, L.C.; Venicius, S.M.; Reis, L.; Araújo, J.A. Multiaxial fatigue assessment of steels with non-metallic inclusions by means of adapted critical plane criteria. Theor. Appl. Fract. Mech. 2020, 108, 102585. [Google Scholar] [CrossRef]

- Ishii, T.; Takahashi, K. Prediction of fatigue limit of spring steel considering surface defect size and stress ratio. Metals 2021, 11, 483. [Google Scholar] [CrossRef]

- Karr, U.; Schönbauer, B.M.; Sandaiji, Y.; Mayer, H. Effects of non-metallic inclusions and mean stress on axial and torsion very high cycle fatigue of SWOSC-V spring steel. Metals 2022, 12, 1113. [Google Scholar] [CrossRef]

- Khan, M.A.A.; Sheikh, A.K.; Gasem, Z.M.; Asad, M. Fatigue life and reliability of steel castings through integrated simulations and experiments. Metals 2022, 12, 339. [Google Scholar] [CrossRef]

- Randić, M.; Pavletić, D.; Potkonjak, Ž. The influence of heat input on the formation of fatigue cracks for high-strength steels resistant to low temperatures. Metals 2022, 12, 929. [Google Scholar] [CrossRef]

- Endo, M.; Yanase, K. Effects of small defects, matrix structures and loading conditions on the fatigue strength of ductile cast irons. Theor. Appl. Fract. Mech. 2014, 69, 34–43. [Google Scholar] [CrossRef]

- Benedetti, M.; Torresani, E.; Fontanari, V.; Lusuardi, D. Fatigue and fracture resistance of heavy-section ferritic ductile cast iron. Metals 2017, 7, 88. [Google Scholar] [CrossRef]

- Bellini, C.; Di Cocco, V.; Favaro, G.; Iacoviello, F.; Sorrentino, L. Ductile cast irons: Microstructure influence on the fatigue initiation mechanisms. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 2172–2182. [Google Scholar] [CrossRef]

- Borsato, T.; Ferro, P.; Berto, F. Novel method for the fatigue strength assessment of heavy sections made by ductile cast iron in presence of solidification defects. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 1746–1757. [Google Scholar] [CrossRef]

- Borsato, T.; Ferro, P.; Fabrizi, A.; Berto, F.; Carollo, C. Long solidification time effect on solution strengthened ferritic ductile iron fatigue properties. Int. J. Fatigue 2021, 145, 106137. [Google Scholar] [CrossRef]

- Gebhardt, C.; Nellessen, J.; Bührig-polaczek, A.; Broeckmann, C. Influence of aluminum on fatigue strength of solution- strengthened nodular cast iron. Metals 2021, 11, 311. [Google Scholar] [CrossRef]

- Tenkamp, J.; Awd, M.; Siddique, S.; Starke, P.; Walther, F. Fracture–mechanical assessment of the effect of defects on the fatigue lifetime and limit in cast and additively manufactured aluminum–silicon alloys from HCF to VHCF regime. Metals 2020, 10, 943. [Google Scholar] [CrossRef]

- Nourian-Avval, A.; Fatemi, A. Fatigue performance and life prediction of cast aluminum under axial, torsion, and multiaxial loadings. Theor. Appl. Fract. Mech. 2021, 111, 102842. [Google Scholar] [CrossRef]

- Nadot, Y.; Billaudeau, T. Multiaxial fatigue limit criterion for defective materials. Eng. Fract. Mech. 2006, 73, 112–133. [Google Scholar] [CrossRef]

- Murakami, Y.; Beretta, S. Small defects and inhomogeneities in fatigue strength: Experiments, models and statistical implications. Extremes 1999, 2, 123–147. [Google Scholar] [CrossRef]

- Alonso, G.; Stefanescu, D.M.; Aguado, E.; Suarez, R. The role of selenium on the formation of spheroidal graphite in cast iron. Metals 2021, 11, 1600. [Google Scholar] [CrossRef]

- Tenaglia, N.E.; Fernandino, D.O.; Basso, A.D. Effect of Ti addition and cast part size on solidification structure and mechanical properties of medium carbon, low alloy cast steel. Frattura ed Integrità Strutturale 2022, 16, 212–224. [Google Scholar] [CrossRef]

- Karolczuk, A.; Nadot, Y.; Dragon, A. Non-local stress gradient approach for multiaxial fatigue of defective material. Comput. Mater. Sci. 2008, 44, 464–475. [Google Scholar] [CrossRef]

- Mitchell, M.R. Review of the mechanical properties of cast steels with emphasis on fatigue behavior and the influence of microdiscontinuities. J. Eng. Mater. Technol. Trans. ASME 1977, 99, 329–343. [Google Scholar] [CrossRef]

- Lukas, O.; Kunz, L.; Weisse, B.; Stickler, R. Non-damaging notches in fatigue. Fatigue Fract. Eng. Mater. Struct. 1986, 9, 195–204. [Google Scholar] [CrossRef]

- Nadot, Y.; Mendez, J.; Ranganathan, N. Influence of casting defects on the fatigue limit of nodular cast iron. Int. J. Fatigue 2004, 26, 311–319. [Google Scholar] [CrossRef]

- Murakami, Y. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Yanase, K.; Endo, M. Multiaxial high cycle fatigue threshold with small defects and cracks. Eng. Fract. Mech. 2014, 123, 182–196. [Google Scholar] [CrossRef]

- Castro, F.C.; Mamiya, E.N.; Bemfica, C. A critical plane criterion to multiaxial fatigue of metals containing small defects. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 517. [Google Scholar] [CrossRef]

- Queiroz, H.S.; Araújo, J.A.; Silva, C.R.M.; Ferreira, J.L.A. A coupled critical plane-area methodology to estimate fatigue life for an AISI 1045 steel with small artificial defects. Theor. Appl. Fract. Mech. 2022, 121, 103426. [Google Scholar] [CrossRef]

- Billaudeau, T.; Nadot, Y.; Bezine, G. Multiaxial fatigue limit for defective materials: Mechanisms and experiments. Acta Mater. 2004, 52, 3911–3920. [Google Scholar] [CrossRef]

- Gadouini, H.; Nadot, Y.; Rebours, C. Influence of mean stress on the multiaxial fatigue behaviour of defective materials. Int. J. Fatigue 2008, 30, 1623–1633. [Google Scholar] [CrossRef]

- Endo, M.; Ishimoto, I. The fatigue strength of steels containing small holes under out-of-phase combined loading. Int. J. Fatigue 2006, 28, 592–597. [Google Scholar] [CrossRef]

- Scorza, D.; Carpinteri, A.; Ronchei, C.; Vantadori, S.; Zanichelli, A. Effect of non-metallic inclusions on AISI 4140 fatigue strength. Int. J. Fatigue 2022, 163, 107031. [Google Scholar] [CrossRef]

- Vantadori, S.; Ronchei, C.; Scorza, D.; Zanichelli, A.; Luciano, R. Effect of the porosity on the fatigue strength of metals. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 2734–2747. [Google Scholar] [CrossRef]

- Carpinteri, A.; Ronchei, C.; Scorza, D.; Vantadori, S. Critical plane orientation influence on multiaxial high-cycle fatigue assessment. Phys. Mesomech. 2015, 18, 348–354. [Google Scholar] [CrossRef]

- Vantadori, S.; Ronchei, C.; Carpinteri, A. Multiaxial fatigue life evaluation of notched structural components: An analytical approach. Mater. Des. Process. Commun. 2019, 1, e74. [Google Scholar] [CrossRef]

- Vantadori, S.; Carpinteri, A.; Luciano, R.; Ronchei, C.; Scorza, D.; Zanichelli, A.; Okamoto, Y.; Saito, S.; Itoh, T. Crack initiation and life estimation for 316 and 430 stainless steel specimens by means of a critical plane approach. Int. J. Fatigue 2020, 138, 105677. [Google Scholar] [CrossRef]

- Ronchei, C.; Vantadori, S. Notch fatigue life estimation of Ti-6Al-4V. Eng. Fail. Anal. 2021, 120, 105098. [Google Scholar] [CrossRef]

- Vantadori, S.; Ronchei, C.; Scorza, D.; Zanichelli, A.; Carpinteri, A. Fatigue behaviour assessment of ductile cast iron smooth specimens. Int. J. Fatigue 2021, 152, 106459. [Google Scholar] [CrossRef]

- Vantadori, S.; Carpinteri, A.; Ronchei, C.; Scorza, D.; Zanichelli, A. Fatigue strength evaluation and lifetime estimation for ductile cast irons under multiaxial loading. Procedia Struct. Integr. 2021, 33, 773–780. [Google Scholar] [CrossRef]

- Murakami, Y. Inclusion rating by statistics of extreme values and its application to fatigue strength prediction and quality control of materials. J. Res. Natl. Inst. Stand. Technol. 1994, 99, 345. [Google Scholar] [CrossRef]

- Murakami, Y.; Toriyama, T.; Coudert, E.M. Instructions for a new method of inclusion rating and correlations with the fatigue limit. J. Test. Eval. 1994, 22, 318–326. [Google Scholar]

- Zhan, Z.; Hu, W.; Meng, Q. Data-driven fatigue life prediction in additive manufactured titanium alloy: A damage mechanics based machine learning framework. Eng. Fract. Mech. 2021, 252, 107850. [Google Scholar] [CrossRef]

- Zhan, Z.; Ao, N.; Hu, Y.; Liu, C. Defect-induced fatigue scattering and assessment of additively manufactured 300M-AerMet100 steel: An investigation based on experiments and machine learning. Eng. Fract. Mech. 2022, 264, 108352. [Google Scholar] [CrossRef]

- Endo, M. Fatigue Strength Prediction of Ductile Irons Subjected to Combined Loading. In Proceedings of the European Conference on Fracture (ECF13), San Sebastian, Spain, 8 February 2013. [Google Scholar]

- Endo, M. Effects of graphite, shape, size and distribution on the fatigue strength of spheroidal graphite cast irons. J. Soc. Mater. Sci. Jpn. 1989, 38, 1139–1144. [Google Scholar] [CrossRef]

- Endo, M.; Wang, X. Effects of graphite and artificial small defect on the fatigue strength of current ductile cast irons. J. Soc. Mater. Sci. Jpn. 1994, 43, 1245–1250. [Google Scholar] [CrossRef]

| MATERIAL | C | Si | Mn | P | S | Mg | Cu |

|---|---|---|---|---|---|---|---|

| EN-GJS-400-18 DCI | 3.72 | 2.14 | 0.32 | 0.01 | 0.02 | 0.04 | 0.04 |

| EN-GJS-600-3 DCI | 3.76 | 2.98 | 0.14 | 0.23 | 0.02 | 0.05 | 0.30 |

| EN-GJS-700-2 DCI | 3.77 | 2.99 | 0.44 | 0.02 | 0.11 | 0.06 | 0.47 |

| MATERIAL | [MPa] | Elongation [%] | [-] | [MPa] |

|---|---|---|---|---|

| EN-GJS-400-18 DCI | 418.0 | 25.0 | 186 | 205.0 |

| EN-GJS-600-3 DCI | 641.0 | 14.1 | 318 | 265.0 |

| EN-GJS-700-2 DCI | 734.0 | 8.0 | 318 | 280.0 |

| [-] | [mm3] | [MPa] | [MPa] | |

|---|---|---|---|---|

| Symbol | Value | |||

| 5.54·104 | 1.41·103 | 171.14 | 144.44 | |

| 2.77·105 | 7.07·103 | 167.67 | 141.51 | |

| 5.54·105 | 1.41·104 | 166.31 | 140.36 | |

| 2.77·106 | 7.07·104 | 163.44 | 137.94 | |

| 3.09·1011 | 7.90·109 | 149.36 | 126.05 | |

| 1.67·10 | 4.27·10−1 | 205.00 | 173.01 | |

| 2.64·102 | 6.75 | 188.21 | 158.84 | |

| [-] | [mm3] | [MPa] | [MPa] | |

|---|---|---|---|---|

| Symbol | Value | |||

| 6.50·104 | 1.41·103 | 258.32 | 218.02 | |

| 3.25·105 | 7.07·103 | 253.40 | 213.86 | |

| 6.50·105 | 1.41·104 | 251.47 | 212.23 | |

| 3.25·106 | 7.07·104 | 247.35 | 208.75 | |

| 3.63·1011 | 7.90·109 | 226.82 | 191.43 | |

| 1.01·104 | 2.29·102 | 265.00 | 223.65 | |

| 1.43·106 | 3.11·104 | 249.39 | 210.48 | |

| [-] | [mm3] | [MPa] | [MPa] | |

|---|---|---|---|---|

| Symbol | Value | |||

| 6.54·104 | 1.41·103 | 233.86 | 197.37 | |

| 3.27·105 | 7.07·103 | 228.88 | 193.17 | |

| 6.54·105 | 1.41·104 | 226.96 | 191.54 | |

| 3.27·106 | 7.07·104 | 222.88 | 188.10 | |

| 3.65·1011 | 7.90·109 | 203.13 | 171.44 | |

| 2.94·10 | 6.35·10−1 | 280.00 | 236.31 | |

| 1.10·103 | 2.37·10 | 251.24 | 212.04 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ronchei, C. Fatigue Strength Estimation of Ductile Cast Irons Containing Solidification Defects. Metals 2023, 13, 83. https://doi.org/10.3390/met13010083

Ronchei C. Fatigue Strength Estimation of Ductile Cast Irons Containing Solidification Defects. Metals. 2023; 13(1):83. https://doi.org/10.3390/met13010083

Chicago/Turabian StyleRonchei, Camilla. 2023. "Fatigue Strength Estimation of Ductile Cast Irons Containing Solidification Defects" Metals 13, no. 1: 83. https://doi.org/10.3390/met13010083

APA StyleRonchei, C. (2023). Fatigue Strength Estimation of Ductile Cast Irons Containing Solidification Defects. Metals, 13(1), 83. https://doi.org/10.3390/met13010083