Effect of Isochronous Annealings on the Microstructure and Mechanical Properties of the Ti49.8Ni50.2 (at.%) Alloy after abc Pressing at 573 K

Abstract

:1. Introduction

2. Materials and Methods

3. Results

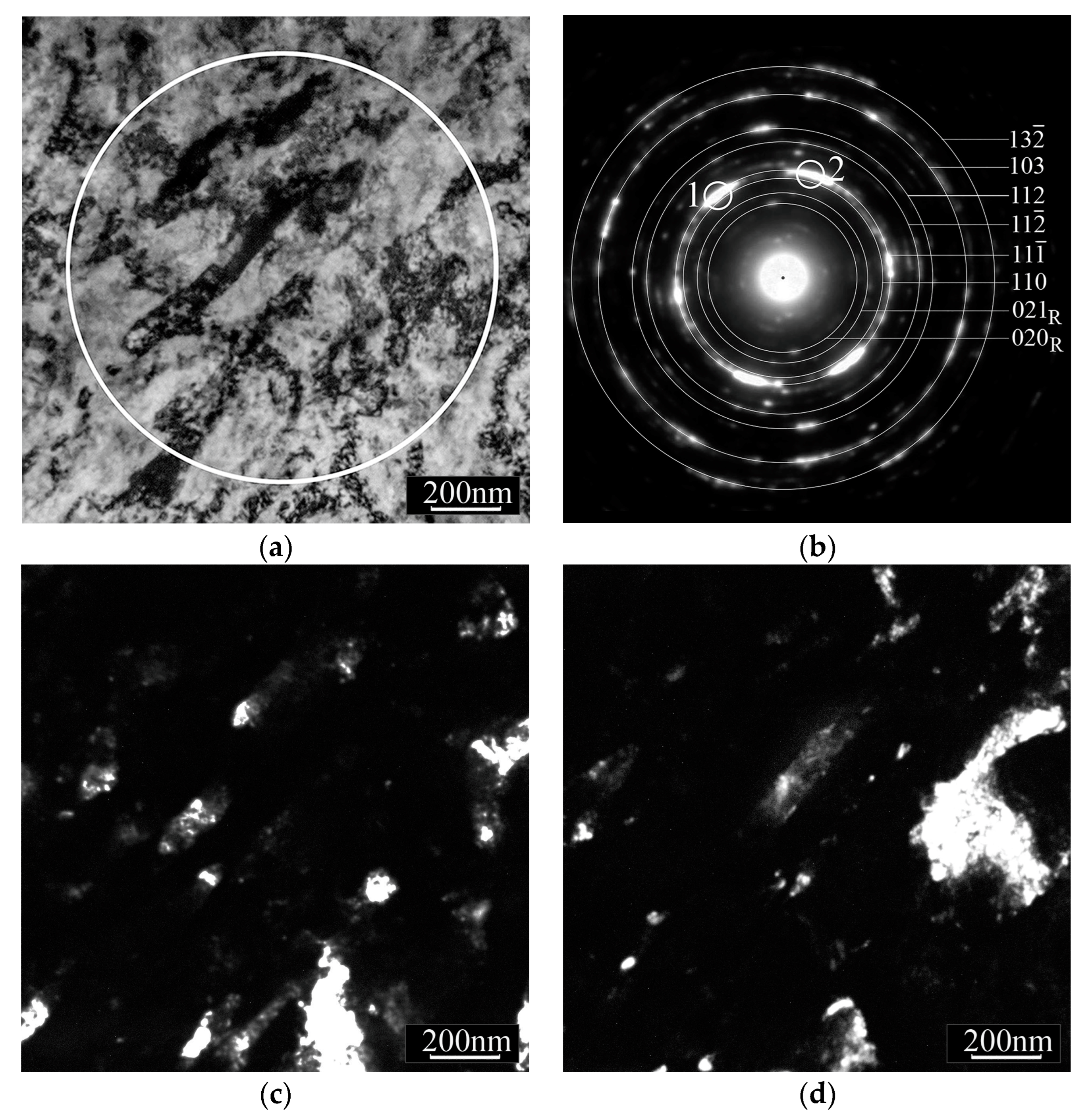

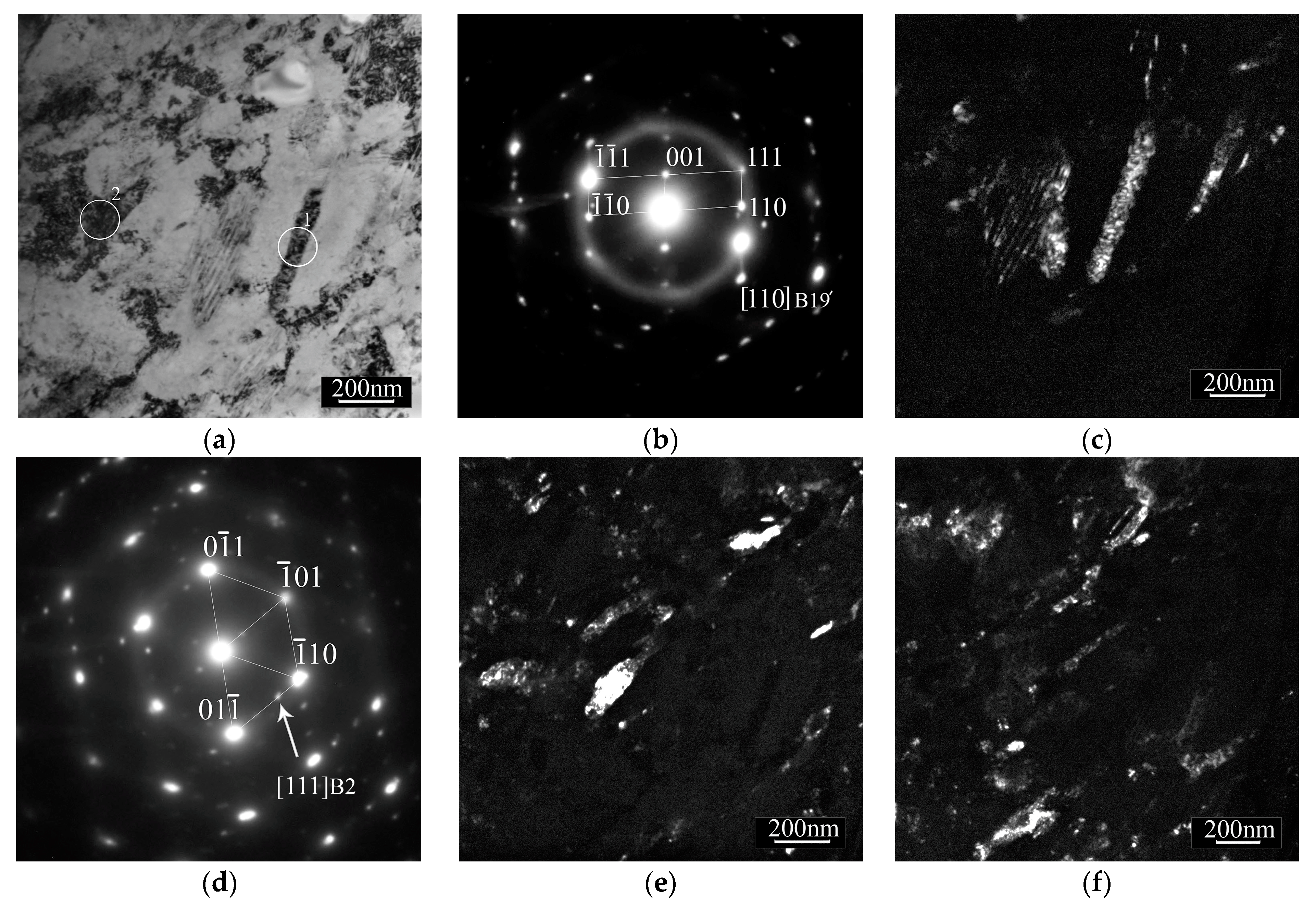

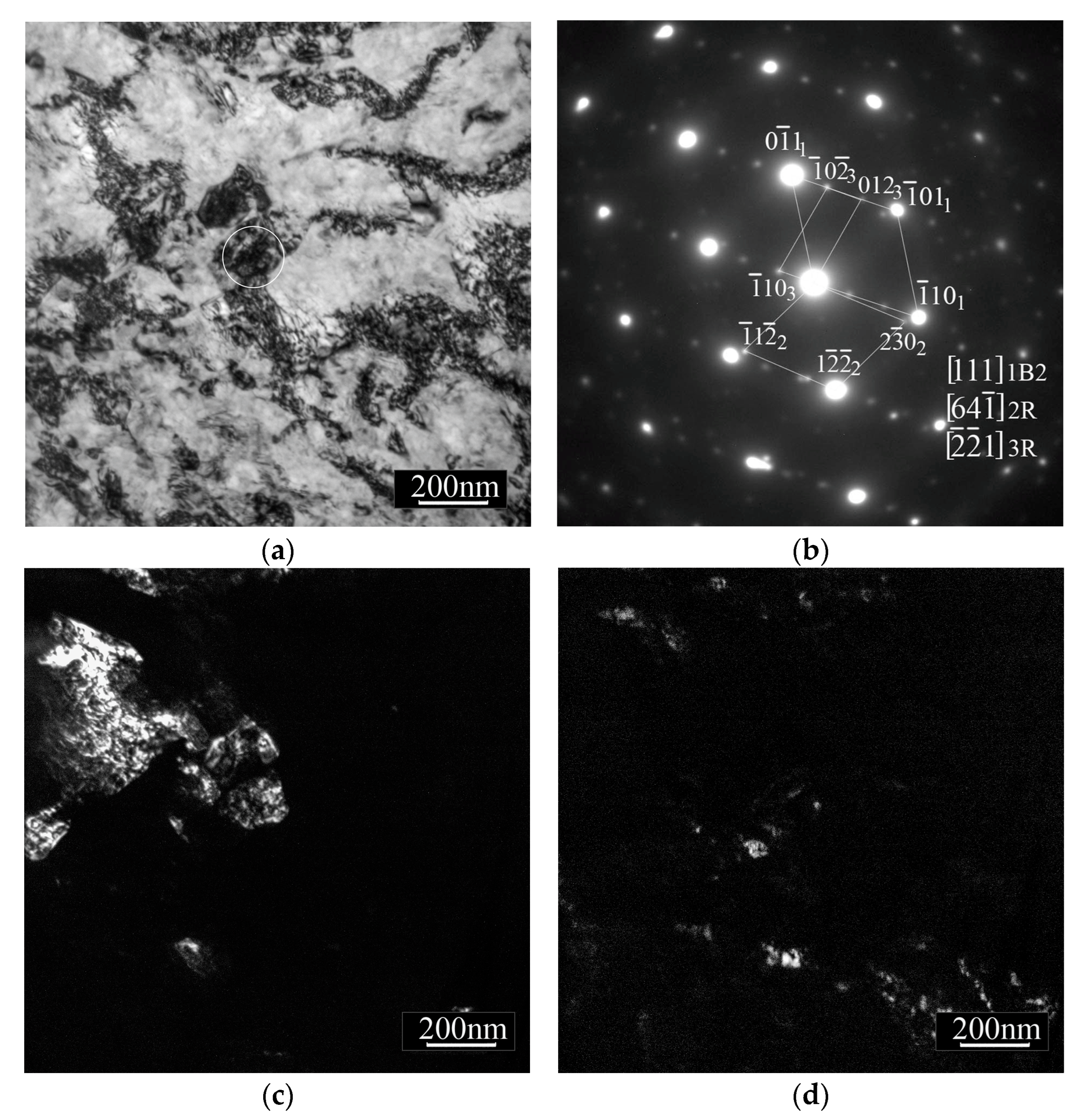

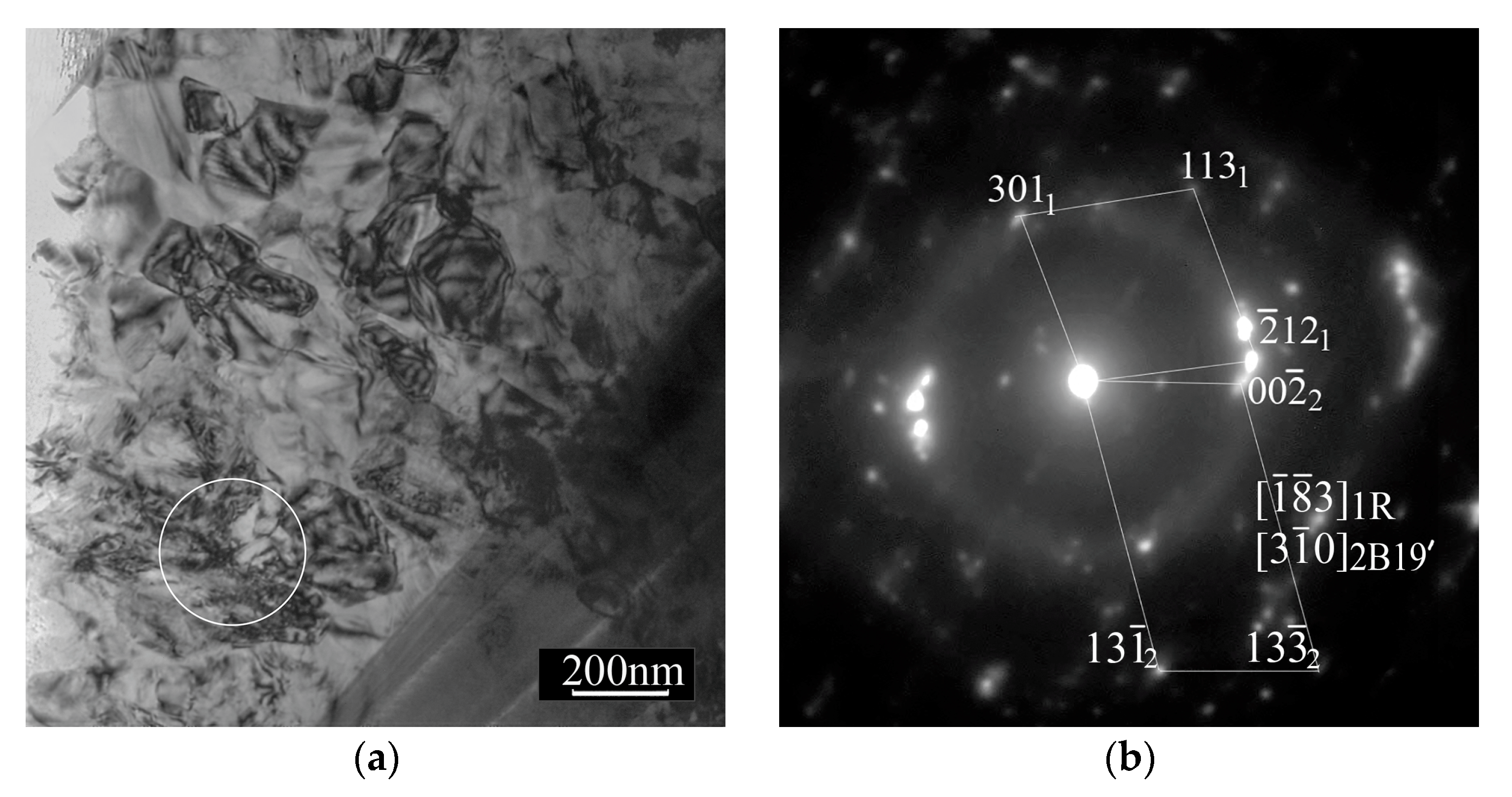

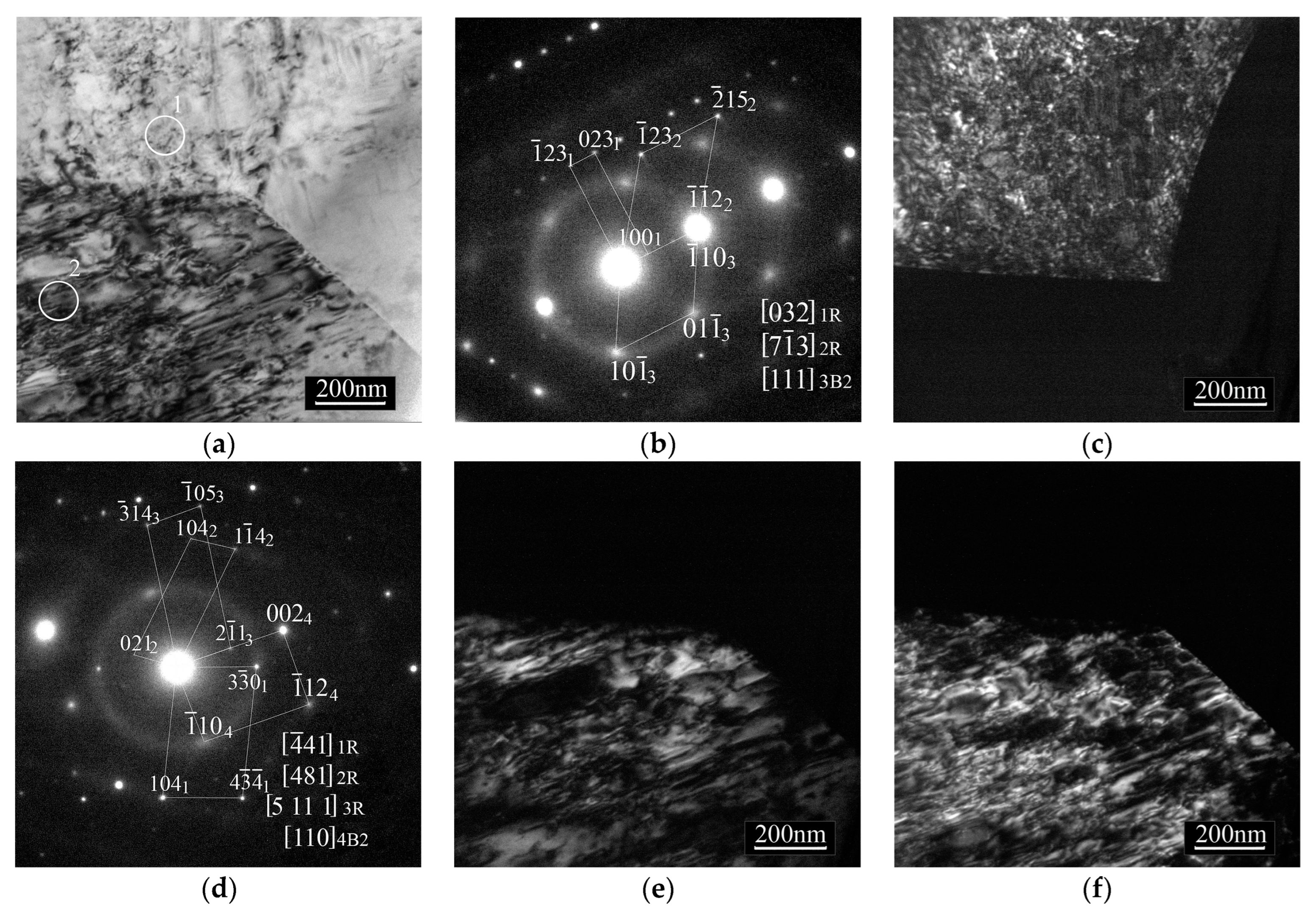

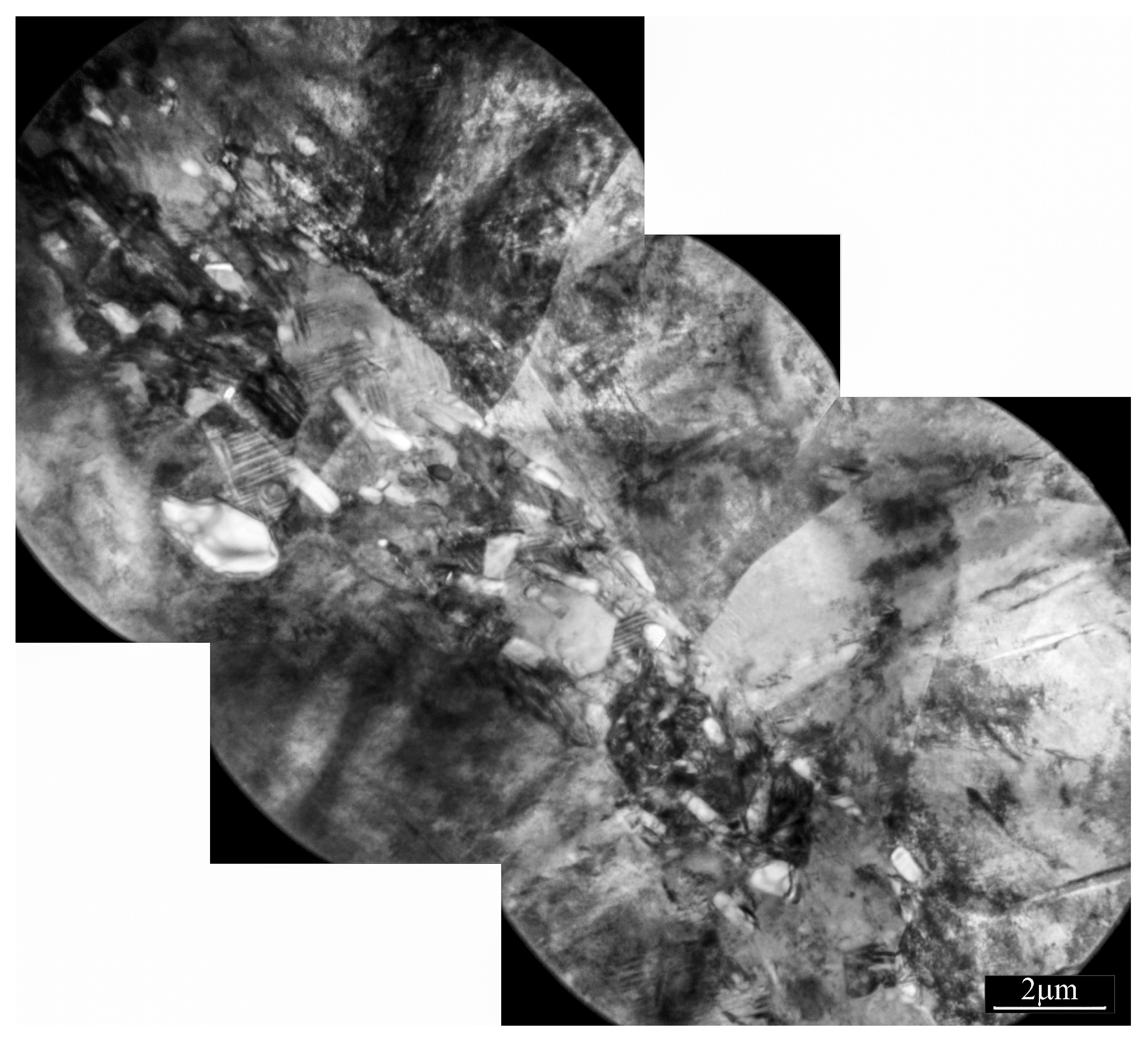

3.1. The Effect of Post-Deformation Annealing on Microstructure of Ti49.8Ni50.2 after abc Pressing with e = 9.55 at 573 K

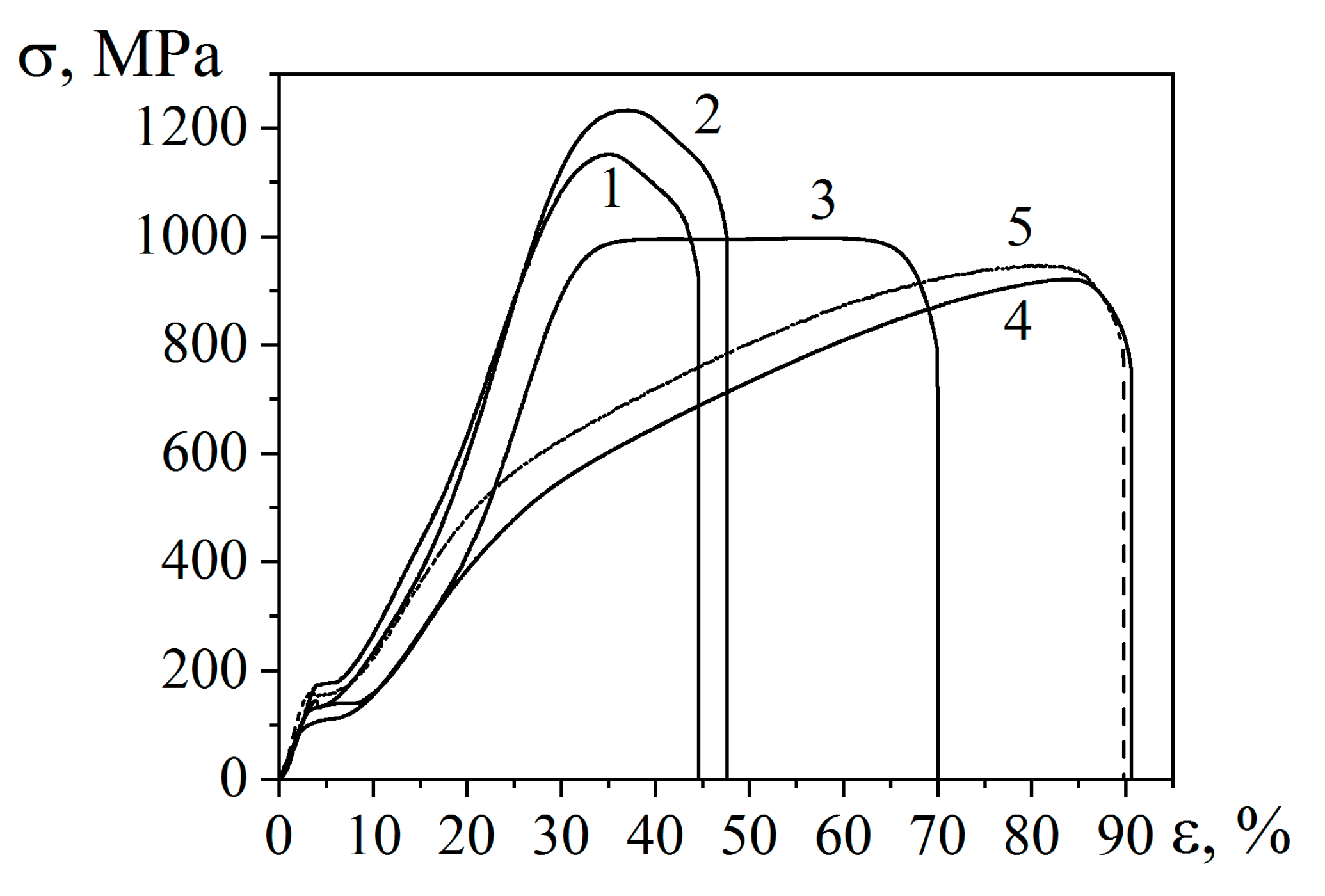

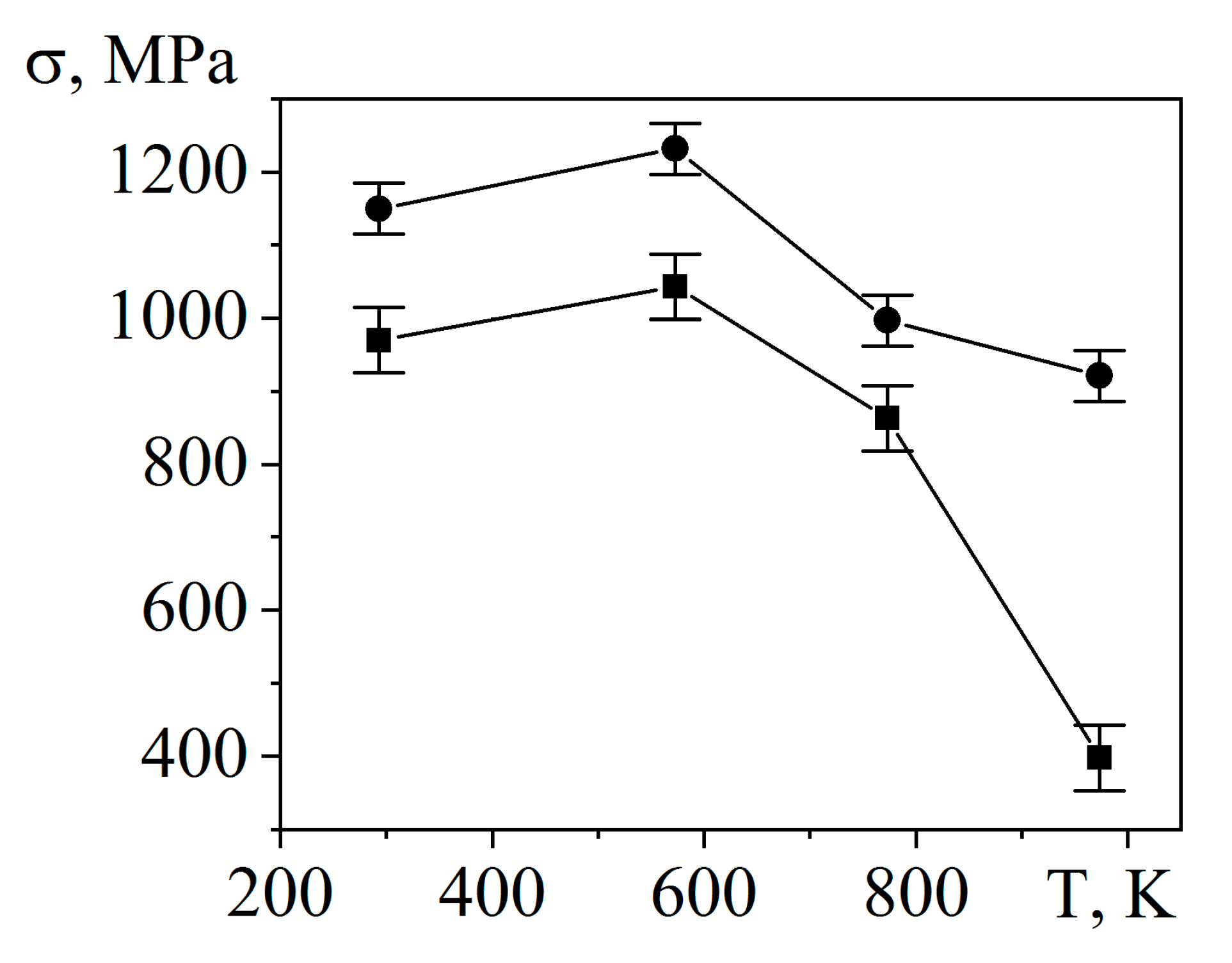

3.2. The Effect of Post-Deformation Isochronous Annealing on the Mechanical Properties of Ti49.8Ni50.2 after abc Pressing with e = 9.55 at 573 K

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Utyashev, F.Z.; Beygelzimer, Y.E.; Valiev, R.Z. Large and Severe Plastic Deformation of Metals: Similarities and Differences in Flow Mechanics and Structure Formation. Adv. Eng. Mater. 2021, 23, 2100110. [Google Scholar] [CrossRef]

- Valiyev, R.Z.; Aleksandrov, I.A. Bulk Nanostructure Metal Materials: Obtaining, Structure and Properties; Akademkniga: Moscow, Russia, 2007; p. 398. [Google Scholar]

- Semenova, I.P.; Polyakov, A.V.; Pesin, M.V.; Stotskiy, A.G.; Modina, Y.M.; Valiev, R.Z.; Langdon, T.G. Strength and FaligueLife at 625 K of the Ultrafine-Grained Ti-6Al-4V Alloy Produced by Equal-Channel Angular Pressing. Metals 2022, 12, 1345. [Google Scholar] [CrossRef]

- Cao, Y.; Ni, S.; Liao, X.; Song, M.; Zhu, Y. Structural evolutions of metallic materials processed by severe plastic deformation. Mater. Sci. Eng. R Reports 2018, 133, 1–59. [Google Scholar] [CrossRef]

- Edalati, K.; Bachmaier, A.; Beloshenko, V.A.; Beygelzimer, Y.; Blank, V.D. Nanomaterials by severe plastic deformation: Review of historical developments and recent advances. Mater. Res. Lett. 2022, 10, 163–256. [Google Scholar] [CrossRef]

- Bagherpour, E.; Pardis, N.; Reihanian, M.; Ebrahimi, R. An overview on severe plastic deformation: Research status, techniques classification, microstructure evolution, and applications. Int. J. Adv. Manuf. Technol. 2019, 100, 1647–1694. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Straumal, B.; Langdon, T.G. Using Severe Plastic Deformation to Produce Nanostructured Materials with Superior Properties. Annu. Rev. Mater. Res. 2022, 52, 357–382. [Google Scholar] [CrossRef]

- Yurchenko, L.I.; Dyupin, A.P.; Gunderov, D.V.; Valiev, R.Z.; Kuranova, N.N.; Pushin, V.G.; Uksusnikov, A.N. Mechanical Properties and Structure of High-Strength Nanostructured Nickel-Titanium Alloys Subjected to ECAP and Rolling. Faz. Perekh. Uporyad. Sost. Novye Mater. 2006, 10, 45–51. Available online: http://www.ptosnm.ru (accessed on 4 October 2006).

- Khmelevskaya, I.Y.; Karelin, R.D.; Prokoshkin, S.D.; Andreev, V.A.; Yusupov, V.S.; Perkas, M.M.; Prosvirnin, V.V.; Shelest, A.E.; Komarov, V.S. Effect of the quasi-continuous equal-channel angular pressing on the structure and functional properties of Ti–Ni-based shape-memory alloys. Phys. Met. Metallogr. 2017, 118, 279–287. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Prokoshkin, S.; Gunderov, D.; Khomutov, M.; Inaekyan, K. Effect of the grain/subgrain size on the strain-rate sensitivity and deformability of Ti–50 at%Ni alloy. Mater. Sci. Eng. A 2015, 622, 21–29. [Google Scholar] [CrossRef]

- Karelin, R.D.; Khmelevskaya, I.Y.; Komarov, V.S.; Andreev, V.A.; Perkas, M.M.; Yusupov, V.S.; Prokoshkin, S.D. Effect of Quasi-Continuous Equal-Channel Angular Pressing on Structure and Properties of Ti-Ni Shape Memory Alloys. J. Mater. Eng. Perform. 2021, 30, 3096–3106. [Google Scholar] [CrossRef]

- Kuranova, N.N.; Makarov, V.V.; Pushin, V.G.; Ustyugov, Y.M. Influence of Heat Treatment and Deformation on the Structure, Phase Transformation, and Mechanical Behavior of Bulk TiNi-Based Alloys. Metals 2022, 12, 2188. [Google Scholar] [CrossRef]

- Lotkov, A.I.; Grishkov, V.N.; Kashin, O.A.; Baturin, A.A.; Zhapova, D.Y.; Timkin, V.N. Mechanisms of microstructure evolution in TiNi-based alloys under warm deformation and its effect on martensite transformations. Mater. Sci. Found. 2015, 81, 245–259. [Google Scholar] [CrossRef]

- Komarov, V.; Karelin, R.; Cherkasov, V.; Yusupov, V.; Korpala, G.; Kawalla, R.; Prahl, U.; Prokoshkin, S. Effect of Severe Torsion Deformation on Structure and Properties of Titanium–Nickel Shape Memory Alloy. Metals 2023, 13, 1099. [Google Scholar] [CrossRef]

- Kashin, O.; Lotkov, A.I.; Grishkov, V.; Krukovskii, K.; Zhapova, D.; Mironov, Y.; Girsova, N.; Kashina, O.; Barmina, E. Effect of abc Pressing at 573 K on the Microstructure and Martensite Transformation Temperatures in Ti49.8Ni50.2 (at%). Metals 2021, 11, 1145. [Google Scholar] [CrossRef]

- Pushin, V.G. Nickel-Titanium Shape Memory Alloys. Part 1. Structure, Phase Transformations and Properties; UrB RAS: Yekaterinburg, Russia, 2006; p. 438. (In Russian) [Google Scholar]

- Mironov, Y.P.; Lotkov, A.I.; Grishkov, V.N.; Laptev, R.S.; Gusarenko, A.A.; Barmina, E.G. Changes in the structural-phase state and dislocation density in the Ti49.8Ni50.2 alloy depending on the temperature of isochronous annealing after severe plastic deformation by the abc pressing method at 573 K. Phys. Mesomech. 2023, unpublished. [Google Scholar]

- Polukhin, P.I.; Gorelik, S.S.; Vorontsov, V.K. Physical Bases of Plastic Deformation; Metallurgiya: Moscow, Russia, 1982; 584p. (In Russian) [Google Scholar]

- Shi, X.B.; Guo, F.M.; Zhang, J.S.; Ding, H.L.; Cui, L.S. Grain size effect on stress hysteresis of nanocrystalline NiTi alloys. J. Alloys Compd. 2016, 688, 62–68. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lotkov, A.; Grishkov, V.; Laptev, R.; Zhapova, D.; Girsova, N.; Gusarenko, A. Effect of Isochronous Annealings on the Microstructure and Mechanical Properties of the Ti49.8Ni50.2 (at.%) Alloy after abc Pressing at 573 K. Metals 2023, 13, 1632. https://doi.org/10.3390/met13101632

Lotkov A, Grishkov V, Laptev R, Zhapova D, Girsova N, Gusarenko A. Effect of Isochronous Annealings on the Microstructure and Mechanical Properties of the Ti49.8Ni50.2 (at.%) Alloy after abc Pressing at 573 K. Metals. 2023; 13(10):1632. https://doi.org/10.3390/met13101632

Chicago/Turabian StyleLotkov, Aleksandr, Victor Grishkov, Roman Laptev, Dorzhima Zhapova, Natalia Girsova, and Angelina Gusarenko. 2023. "Effect of Isochronous Annealings on the Microstructure and Mechanical Properties of the Ti49.8Ni50.2 (at.%) Alloy after abc Pressing at 573 K" Metals 13, no. 10: 1632. https://doi.org/10.3390/met13101632

APA StyleLotkov, A., Grishkov, V., Laptev, R., Zhapova, D., Girsova, N., & Gusarenko, A. (2023). Effect of Isochronous Annealings on the Microstructure and Mechanical Properties of the Ti49.8Ni50.2 (at.%) Alloy after abc Pressing at 573 K. Metals, 13(10), 1632. https://doi.org/10.3390/met13101632