1. Introduction

Obtaining information about the cementite behavior in steels under long-term deformation action is relevant and is determined by both the fundamental nature of the problem and its practical significance. In recent years, the attention of researchers in the field of physical materials science has been focused on the traditional study of rail steels. The development of special-purpose rails is conditioned by the intensive use of long-distance transport and an increase in the speed of movement.

In 2013, the production of 100 m differentially hardened rails of general purpose, made of DT350 hypoeutectoid steel, was started in Russia to solve this problem. In 2018, rails of special purpose with increased wear resistance and contact endurance, made of DT400IK hypereutectoid steel, were produced. DT400IK rails are used for tangent railway tracks with speeds up to 200 km/h and curves without tonnage restrictions.

During long-term deformation, complex processes occur in rails that deteriorate their mechanical properties. In this area, obtaining information is determined both by the fundamental character of the problems as well as their practical significance. The development of patterns of evolution of structural phase state parameters and dislocation substructure during long-term rail operation can only be studied through the use of highly informative methods of physical materials science, particularly transmission electron microscopy (TEM). By using TEM methods, we are able to quantify the contribution of structural components and defective substructures to rail hardening [

1,

2].

Cementite (or Θ—Fe

3C iron carbide) is the strengthening phase of carbon steels [

1,

2]. At temperatures below 727 °C, the structure of these steels contains only ferrite and cementite. The solubility of carbon in ferrite is very low. At 727 °C it is 0.0218%, but at 650 °C it drops to 0.010%, and at 400 °C it is less than 0.001%. If we neglect the carbon atoms that can be located in the defects of ferrite crystal lattice, then in steels at room temperature, almost all carbon will be concentrated in cementite [

1,

2]. It is known from statistical data that from 1.3 to 1.5 billion tons of iron alloys are smelted nowadays in the world. In Russia alone, more than 50 million tons of steel are smelted annually. Of course, a significant part is made up of low-carbon, mild steels in which the cementite content is low. For rails, rail fastenings, reinforcing bars and many other products, such as steels containing a noticeable amount of cementite, are used. It can be roughly estimated that in Russia alone, more than one million tons of cementite are produced per year. Since steel products can serve for decades, the amount of cementite in Russia exceeds ten million tons. So, it is reasonable to study the features of the cementite structure. At the same time, its various aspects can be studied: the morphology of precipitated or already existing crystals, the chemical composition of carbide, the exact type of cementite crystal lattice and defects in it. All these aspects are important and require discussion [

1,

2].

As a rule, cementite increases the wear resistance of steel, acting as an obstacle to the movement of dislocations. In rail steels subjected to cyclic rolling/sliding loads, the microstructure is initially responsible for the deformation hardening and increased wear resistance of the material. The transformation of rails is observed during operation, even with a relatively small tonnage passed [

3]. The strength and plastic properties of cementite crystallites are determined by the state of its defective substructure. Therefore, it is important to know about the evolution of the structure of cementite during operation to predict the behavior of rail steel in rolling–sliding conditions and to ensure the reliable operation of railways. There are a number of factors that determine the evolution of cementite. Contact fatigue, for example, depletes carbon in cementite plates by 20%, causing the formation of nonstoichiometric iron carbide [

4], which may be related to the removal of carbon from cementite lattices and plate cutting mechanisms. Pearlite steel’s deformability is correlated with its morphology. It has been found that the length of cementite plates is the principle factor affecting deformability [

5]. According to [

6], dissolved cementite particles are found around crushed ferrite boundaries in pearlitic steel surfaces under dry sliding wear.

In the works of Russian [

7] and foreign researchers in recent years [

8,

9,

10,

11,

12,

13], the evolution of structural-phase states, mechanical properties, and defective substructure in the rail head under various operating conditions has been analyzed and the mechanisms of cementite fracture have been revealed in model experiments. This has made it possible to analyze the mechanisms of wear, the degradation of rail properties and the reasons for their failure. The formed data bank, as well as the results of recent studies [

14,

15,

16,

17,

18,

19] of the patterns of structure formation, phase composition and dislocation substructure can be considered as achievements in the physics of hypoeutectoid pearlite steels. New steel grades have been sought for several years in order to limit contact fatigue and wear. In recent years, improved rail materials with good mechanical properties have been developed through increasing the carbon content to the hypereutectoid level [

20]. It was found that the hypereutectoid rail has better wear resistance and significantly lower wear losses compared with the eutectoid rail [

20]. In addition, the hypereutectoid rail has a smaller interlamellar distance, and the outer layer has a subgrain structure with a higher content of low-angle grain boundaries in the steel matrix and almost no cementite along the boundaries. For rails made of hypereutectoid steel, which include DT400IK rails, such information is practically absent in the literature [

20]. They are of undoubted interest for the formation of high operational properties of such rails and the improvement of differentiated hardening modes.

The purpose of this work is to analyze the cementite substructure of hypereutectoid steel formed during the differentiated hardening of rails and their subsequent long-term operation.

3. Results

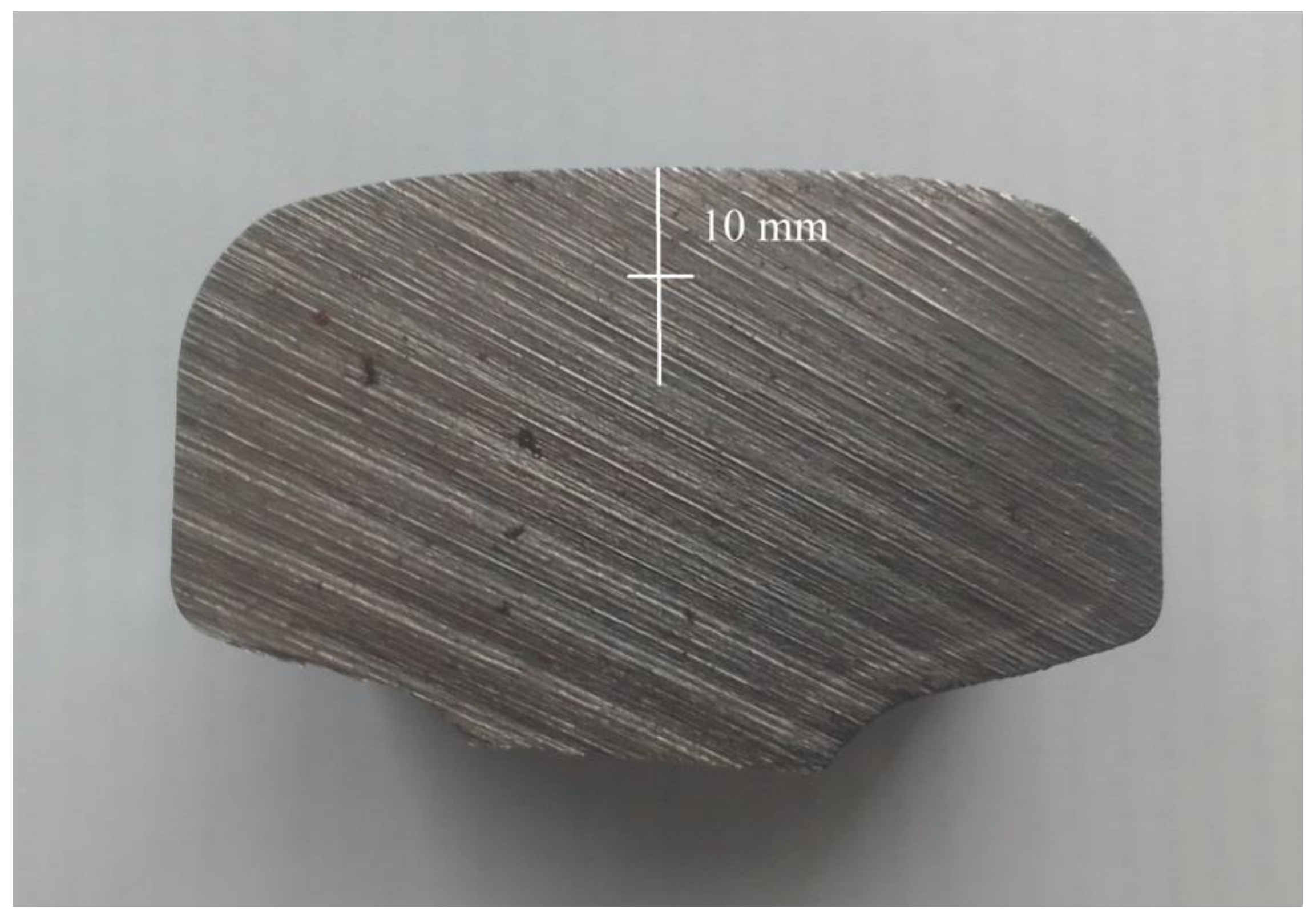

The conducted studies showed that the steel structure is represented by three morphological components at a distance of 10 mm from the sample surface. The first morphological component is lamellar perlite, which is a group (colony) of alternating parallel plates of ferrite (α-phase) and cementite (Fe

3C). The TEM image of lamellar perlite is shown in

Figure 2. It can be seen from the figure that the cementite particles have a lamellar shape and are located almost parallel to each other. The width of the α-phase plates (the distance between the cementite plates) is on average 125 nm. The average thickness of the cementite plates is 25 nm; that is, the steel under study is thin-lamellar pearlite. The volume fraction of lamellar perlite in the material is 65%.

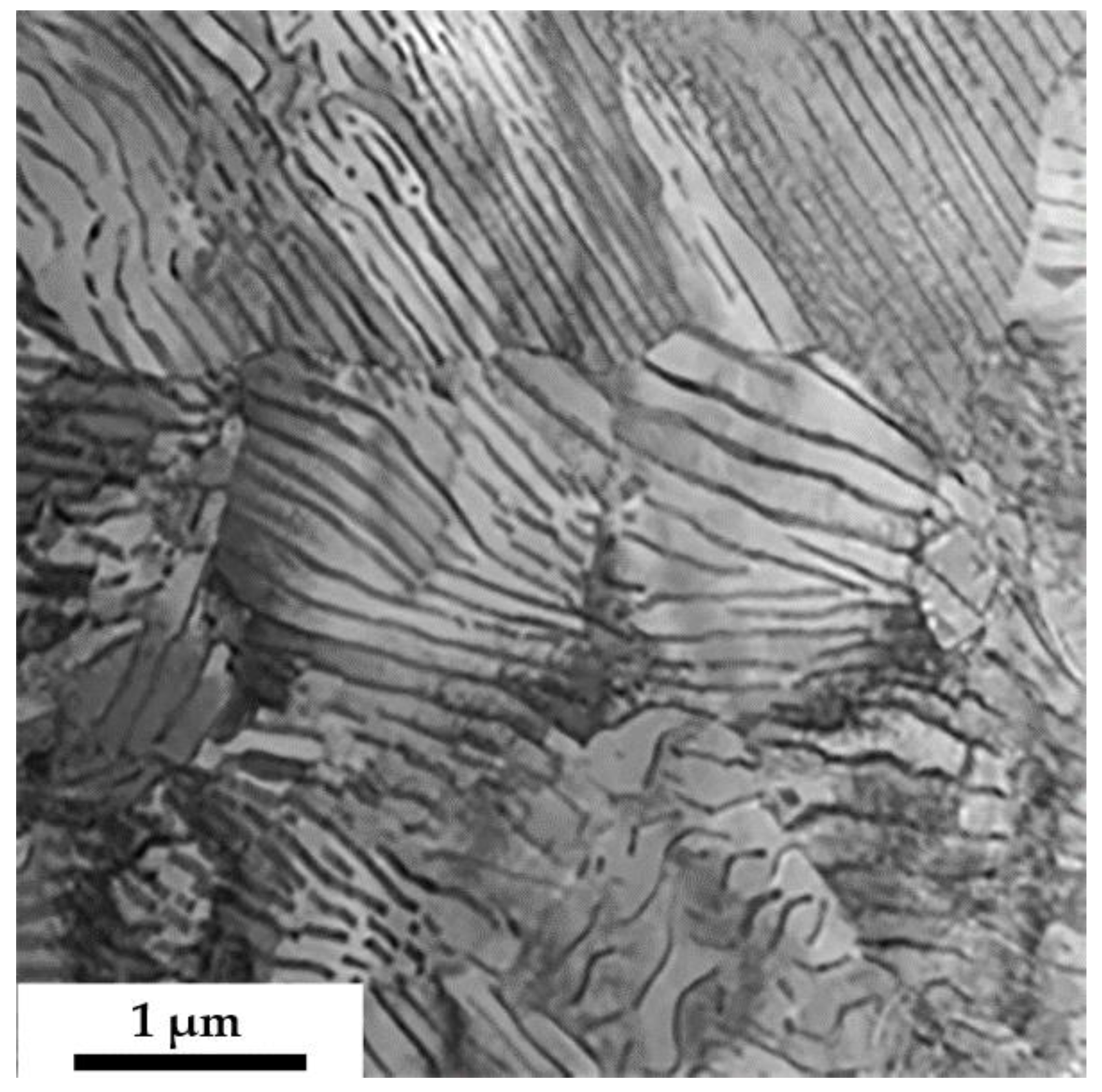

Quite often, the plates of cementite in perlite are curved and separated by ferritic bridges (

Figure 3). Thus, it is believed that ferrite is solid in perlite, and cementite is an intermittent phase consisting of separate plates [

24,

25]. The contrast along the cementite plate is heterogeneous, which indicates the disorientation of one part of the plate relative to the other.

The methods of bright-field, dark-field and micro-electron diffraction analysis were used to study the defective substructure of cementite plates. It is established that the long-term operation of rails leads to the plastic deformation of steel, accompanied by the formation of a dislocation substructure both in ferrite plates (

Figure 4a) and in cementite plates (

Figure 4b,d).

Dislocations in ferrite plates are distributed randomly or form a dislocation substructure of a mesh type. In the cementite plates, dislocations are arranged in a more orderly manner, forming parallel rows oriented both across (

Figure 4b,d) and along the cementite plates. It can be assumed that the dislocation substructure in cementite plates is formed along the interface, thereby minimizing the elastic stresses arising in the material due to the difference in the mechanical and thermal characteristics of ferrite and cementite.

The value of the average scalar density of dislocations is ρ = 4.8·1010 cm−2. The dislocation structure in pearlite is polarized, as evidenced by the presence of bend extinction contours in it, the sources of which are the boundaries of pearlite grains, as well as cementite plates in pearlite colonies.

The second morphological component of the material is fractured lamellar perlite; this includes areas or colonies of lamellar perlite with curved, cut and refined cementite plates. The volume fraction of this morphological component is 25% of the total volume of the material. The average particle size of cementite is 60–230 nm, and the particle’s volume fraction is ~9%. The dislocation structure in destroyed pearlite is also mainly represented by dense dislocation networks. The average scalar density of dislocations is 3.9·1010 cm−2. The dislocation structure is also polarized.

The third morphological component is fragmented lamellar perlite. All fragments formed in lamellar perlite have a non-equiaxed shape; they are elongated along the cementite plates. From the sides, the fragments are limited by lamellar cementite precipitations, the average size of which is 25–355 nm. The width of the fragments corresponds to the distance between the cementite plates: that is, it is equal to the width of the α-phase plate in lamellar pearlite. The length of the fragments is limited by the formed, fairly clear, dislocation walls, mainly oriented across the direction of the α-phase plates. The average fragment size is 125–550 nm. The volume fraction of fragmented pearlite is 10% of the material volume.

At the ferrite–cementite interface, the dislocation density is higher than in ferrite plates. The analysis of TEM images shows that dislocations, by the nature of their distribution, can be conditionally divided into two systems. As in [

24], it is noted that the dislocations of the first system are elongated within the ferrite layer in the direction from one interphase boundary to another, and for the second system, the dislocation sliding plane is perpendicular to the plane of the interphase boundary. Traces of the sliding plane of these dislocations can pass through the cement plate and penetrate into the adjacent ferritic.

As for rails made of hypoeutectoid steel [

3,

7], long-term operation is accompanied by the deformative transformation of plate perlite grains, namely, the fracture of the cementite plate. One of the main fracture mechanisms in cementite is its cutting because of sliding dislocations. This mechanism for carbon steels was studied in detail in works from the Ukrainian School of Metallophysics [

26,

27,

28,

29]. In pearlite columns, the distribution of deformations is heterogeneous: the lamellar character of the structure is preserved in the areas where the local deformation is small.

The second mechanism of destruction of cementite plates consists of pulling carbon atoms out of the carbide phase lattice by dislocations during plastic deformation, with the formation of Cottrell atmospheres due to a noticeable difference in the average binding energy of carbon atoms with dislocations (0.6 eV) and with iron atoms in the cementite lattice (0.4 eV). Carbon diffusion takes place in the stress field created by the dislocation substructure that forms around the cementite plate. In this case, the degree of decomposition of cementite should be determined by the magnitude of the dislocation density and the type of dislocation substructure.

At the initial stage of transformation, the cementite plates are enveloped by sliding dislocations, which is accompanied by splitting the plates into separated poorly oriented fragments. Then, a change in the structure of the carbide can occur because of the pulling of the carbon atoms from the cementite lattice. This is due to the penetration of sliding dislocations from the ferrite crystal lattice into the cementite crystal lattice. At this stage of dissolution of cementite plates, the interfacial boundaries “α-phase—cementite” play a special role. A coherent or semicoherent boundary [

26,

27,

28,

29] facilitates the penetration of dislocations from the α-phase into cementite and vice versa, and thereby contributes to the fracture and dissolution of cementite. An incoherent high-angle interphase boundary stabilizes the carbide structure and leaves only diffusion mass transfer possible. This is why the cementite plates in the pearlite colony are fractured, while the spherical particles of cementite at the boundaries of grains and subgrains are preserved. At the next stage of cementite dissolution, the entire volume previously occupied by the cementite plate is filled with nanoscale particles. The process of mass transfer of carbon atoms can be carried out via several mechanisms. First, there is interstitial diffusion [

26,

27,

28,

29]. This is a directed movement of a large number of vacancies between regions with different signs of internal stresses. The diffusion of carbon atoms over deformation vacancies is the second transfer mechanism. Under the long-term operation of rails, the dislocation density goes up, fragmented structure develops intensively, and the misorientation of fragments and density of crystal lattice defects increase in the near-boundary regions and at grain boundaries [

3]. The diffusion of carbon atoms can be accelerated over dislocation tubes, grain boundaries, and fragments. This will be the third transfer mechanism. It is known that the activation energy of diffusion over cores of dislocations is much less than that over the bulk of the material [

26,

27,

28,

29]. Of course, the specific gravity of all mechanisms in the process of cementite dissolution will depend on its structure, deformation conditions, and the degree of steel alloying. Dislocations can “lose” carbon atoms, most likely in the areas of solid solution with significant curvature torsion of the crystal lattice. These areas are fixed after carbon gets there. Otherwise, the process should happen in the opposite direction: carbon should go from the solid solution to dislocations. In addition, nanosized particles of the carbide phase are also observed in the ferrite matrix, which occupies the interlamellar space of pearlite colonies. These particles can be introduced there in the process of dislocation slip, or, less likely, they may have been formed as a result of the deformational decomposition of carbon solid solution in the iron crystal lattice.

Under severe plastic deformation of pearlitic steel at the last stage of cementite plate evolution, the formation of a misoriented quasi-strip structure based on α-Fe is possible [

3]. At a high dislocation density in the α-matrix, Fe

4C carbide particles turn out to be the most stable. Aspects related to the movement of carbon atoms under conditions of intense deformation action during the long-term operation of rails are of particular interest and require special mechanisms to explain them. These include the idea of the mechanism of plastic distortion, when due to the formation of the curvature of the crystal lattice, the material is able to experience significant shape changes without discontinuity [

30].

Within the framework of physical mesomechanics, such a mechanism is interpreted as a nanoscale mesoscopic structural state. This is a new approach in the mechanics of strength and the plasticity of solids [

30,

31,

32]. Since the rotational modes of plastic deformation are associated with the formation of local curvature of the lattice [

6], it can be assumed that the development of this effect facilitates the movement of carbon atoms. Due to the cyclic nature of the load application, such a mechanism can develop back, which allows the elements of the internal structure to be rebuilt without the formation of discontinuities. It should be specially noted that this process does not have a diffusion character, since it develops at low temperatures, and the load is applied cyclically. On the other hand, a critical defect density accumulates in the surface layer of rails, which hinders the development of reversible elastic deformation and the involvement (development) of the plastic distortion mechanism. The formation of such a “critical” structure will end with the initiation of microcracks through the fatigue mechanism and failure of rails. For this reason, an increase in the service life of rails can be achieved by preserving the structure for as long as possible, capable of developing reversible deformation processes that exclude the cementite plates’ fracture.

The phenomenon of cementite dissociation during the plastic deformation of high-carbon steels was observed in [

33]. Carbon removal from cementite plates occurs most intensively near defects in ferrite and cementite. For ferrite, these are dislocation subboundaries. It can be assumed that the carbon concentration in ferrite increases insignificantly compared to the equilibrium one (as in hypoeutectoid steels [

3]); the main proportion of carbon is not in solid solution, but in the form of small carbide precipitations and lattice defects.

Dislocations inside the cementite plate belong to planes, the trace of which in the cementite plate is a projection of the slip planes of dislocations in the ferrite plate. An accelerated dissolution of cementite was found near planar defects, which were present in the structure of cement plates of undeformed lamellar perlite. According to [

24], such defects could appear during the eutectoid decomposition of austenite. Such dissolution leads to the formation of characteristic layering in the structure of a partially dissolved cementite plate.

According to [

24], one of the mechanisms of carbide particle shape change is the formation of clusters or walls of dislocations crossing the carbide particle, which leads to an accelerated outflow of carbon near these defects into the ferrite matrix. The activation energy of carbon diffusion near dislocations is 2.5 times lower than in the volume of cementite. The formation of coil pile-ups of dislocations near ferrite/cementite interphase boundaries is another possible mechanism. In this case, the removal of carbon from the region with an increased density of dislocations leads to an effective displacement of the interphase boundary inside the carbide particle.

In different ferritic plates, the presence of dislocations of opposite signs in the sub-boundaries may be the cause of the alternation in diffraction contrast (contours of the excision) observed in TEM images during the transition from one ferritic plate to another. Similar places of formation of extinction contours and the causes of their occurrence for hypoeutectoid steels are analyzed in [

3]. The presence of bend extinction contours in the TEM images indicates the bending torsion of the crystal lattice of the foil (formation of internal stress fields).

Plates of ferrite (

Figure 5) and cementite (

Figure 6) of pearlite colonies are fragmented, i.e., they are divided into regions with a low-angle disorientation. Fragmentation did not fracture the pearlite colonies and did not create chaos in the structure; the initial structure of the pearlite colonies was preserved. Inside the fragments, a well-developed network or cellular dislocation substructure is observed. The average scalar density of dislocations inside the fragments is 2.9·10

10 cm

−2, which is even less than in unfragmented pearlite. This is in good agreement with the literature data, namely, the fragmentation of the material leads to a decrease in the scalar density of dislocations in the body of the formed fragments [

34]. It is explained by the energy decrease in the dislocation subsystem during the formation of a fragmented substructure [

35]. At the nodes of dislocation networks or cells, there are fine (~5–15 nm) cementite particles. Their volume fraction is small and amounts only to 0.16%. The analysis of microelectron diffraction patterns makes it possible to estimate the azimuthal component of the angle of complete disorientation of fragments of cementite and ferrite plates by the blurring of reflections. It was found that the fragments of cementite are disoriented at angles of 3.0–3.5 degrees. The disorientation of ferrite plate fragments is at 2.5–3 degrees. It can be assumed that the fragmentation of ferrite plates and cementite plates is another mechanism for the relaxation of elastic stresses that occur during differentiated welding and subsequent long-term operation. For hypoeutectoid rails of the Paris metro with comparable values of the passed tonnage, the formation of a fragmented structure was observed at a depth of ~4 mm from the rolling surface [

36,

37]. The resulting three-dimensional gradient of the microstructure may be the cause of microcracks.

As already noted, the thermomechanical processing of hypereutectoid steel and subsequent long-term operation lead to the release of nanoscale cementite particles (5–10 nm) in the volume of ferrite plates of the pearlite colony (

Figure 7). It can be assumed that this is tertiary cementite formed as a result of the decomposition of a supersaturated ferrite-based solid solution during the cooling of steel from the temperature of the pearlite transformation and subsequent long-term operation.

It was suggested in [

24] that facilitating the outflow of carbon through defects can lead to the formation of such ferritic interlayers in cementite near such defective planes. The new interfacial surfaces, in turn, can be places of separation of nanoscale carbides. Nanoscale cementite particles are distributed unequally in ferritic plates; their density is greater in the locations of ferritic subgrains, near interfacial boundaries and other defects. In the dark field images, the diffraction contrast is heterogeneous in the thickness of the cementite plates due to the decoration of the interfacial boundaries with carbides.