Activation Energy of Alumina Dissolution in FeO-Bearing Slags

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

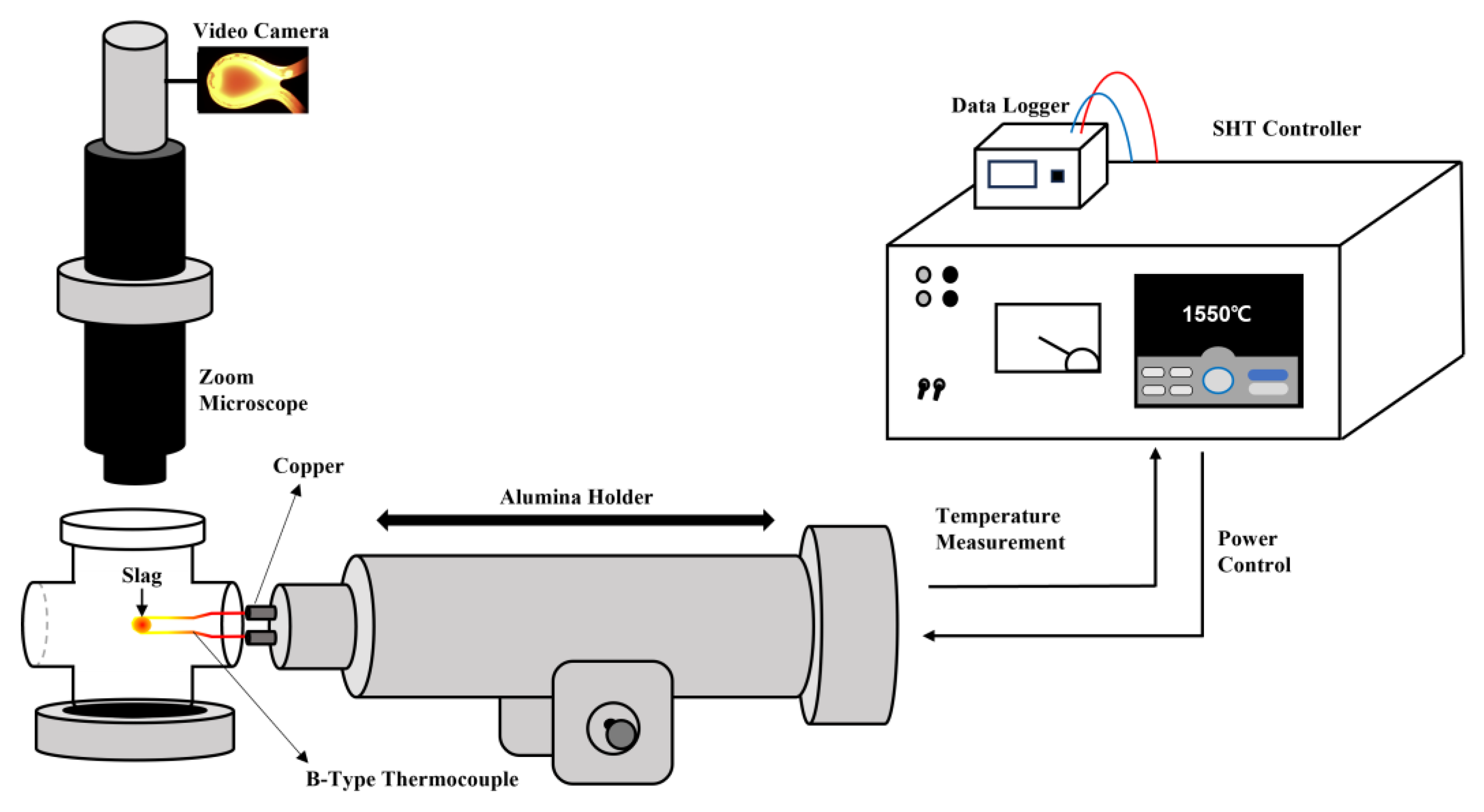

2.2. Single Hot Thermocouple Apparatus (SHT Apparatus)

2.3. Experimental Conditions

3. Results and Discussion

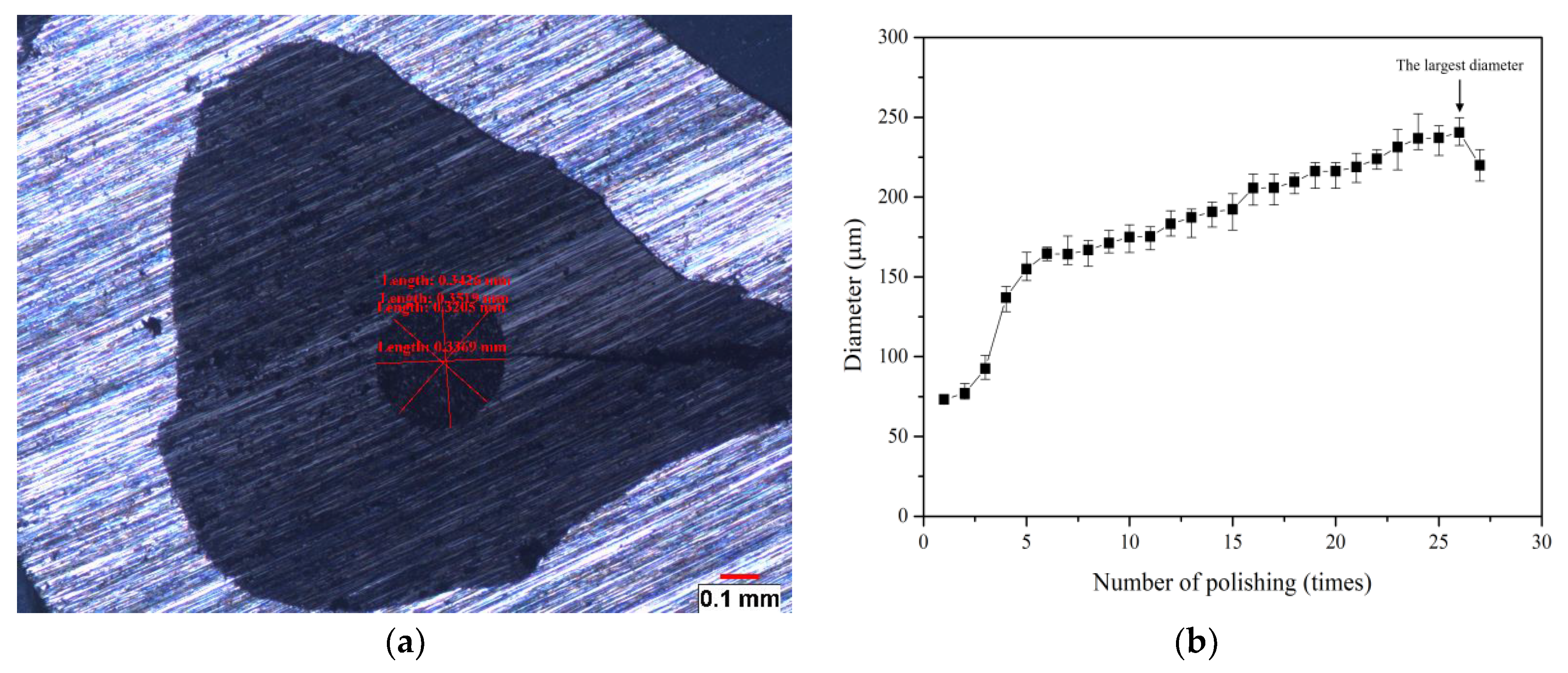

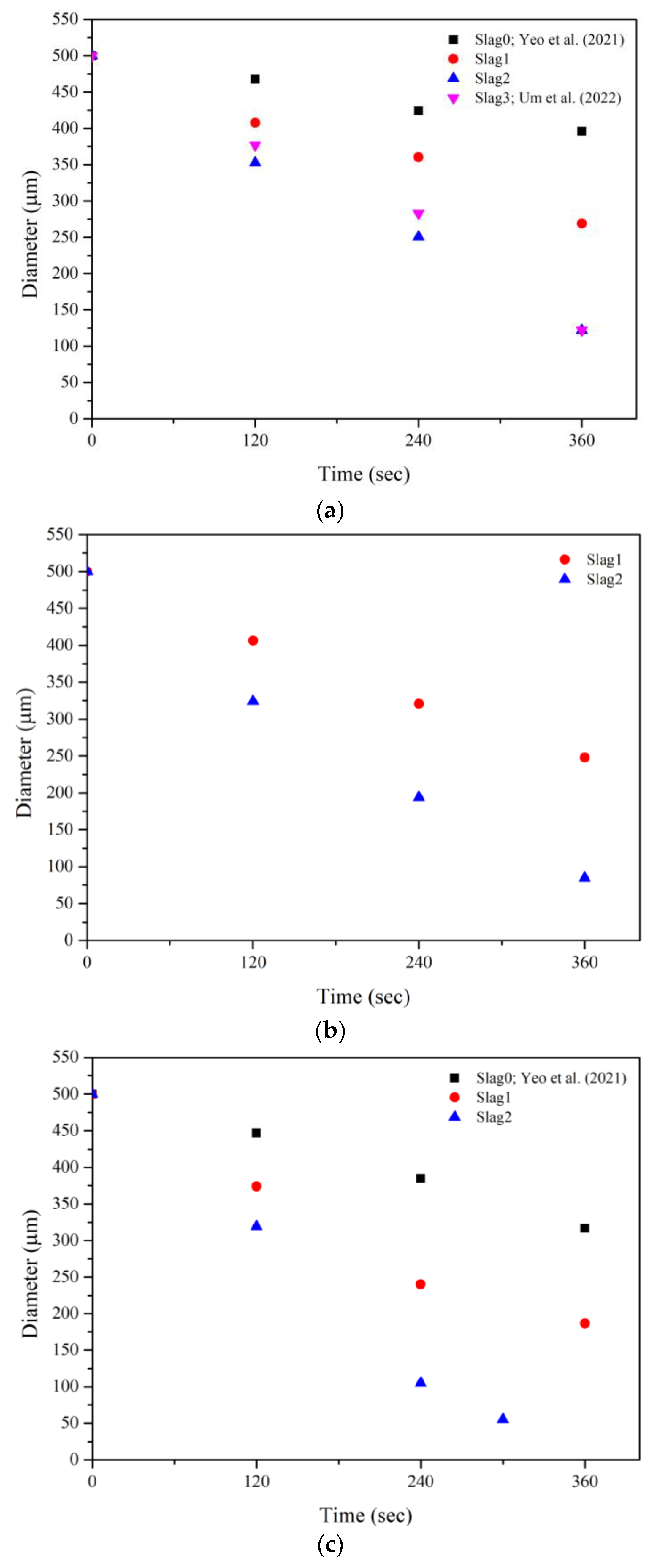

3.1. Dissolution Behavior of Al2O3 Particles according to Temperature and FeO Content in Slag

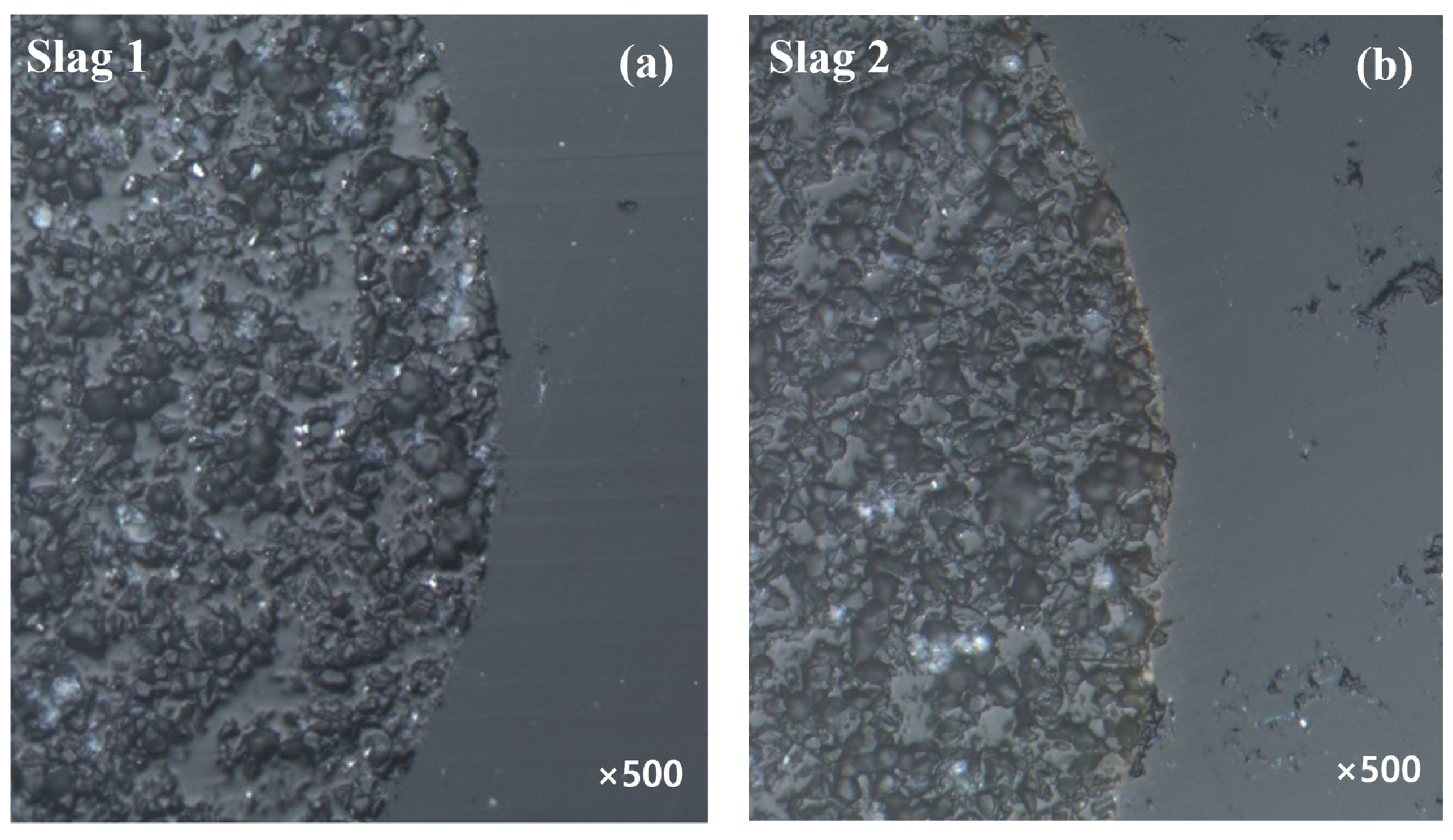

3.2. Analysis of Slag/Al2O3 Particle Interface through SEM

3.3. Dissolution Mechanism of Al2O3

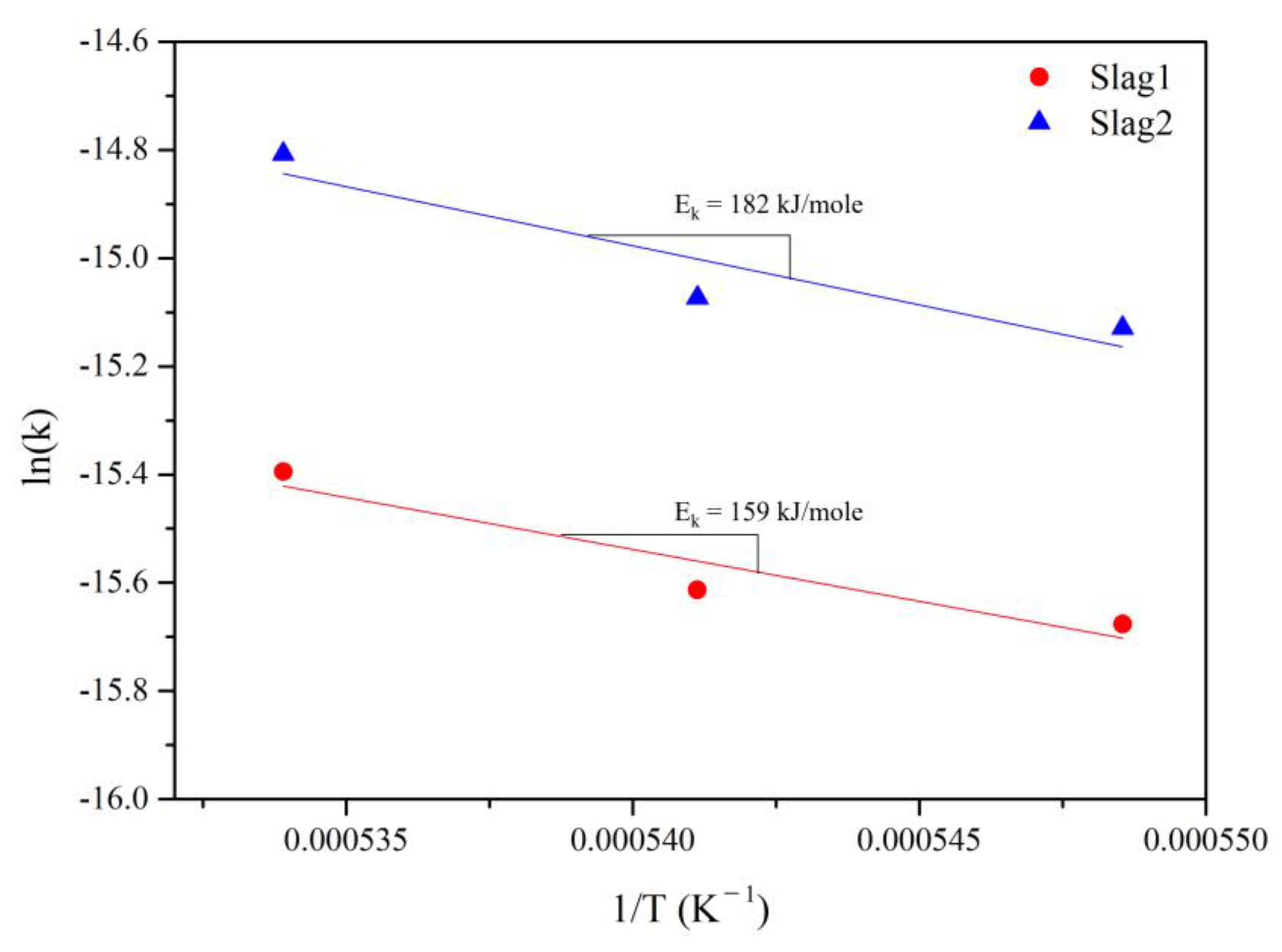

3.4. Activation Energy

3.5. Increased Dissolution Rate of Al2O3 by Increasing FeO Content

4. Conclusions

- (1)

- The dissolution rate increased linearly as the FeO content of the slag increased from 0 to 20 wt% and the dissolution temperature increased from 1550 to 1600 °C.

- (2)

- Through an SEM and EDS analysis, it was observed that no compound was formed at the interface of Al2O3 particles and slag. In addition, it was observed that the concentration of Al in the boundary layer decreased linearly as it moved from Al2O3 particles to slag. Therefore, the rate step of Al2O3 particle dissolution is interpreted as liquid-phase mass transfer.

- (3)

- The mass transfer coefficient was obtained using the dissolution rate equation. The mass transfer coefficient increased with increasing FeO content in the slag and increasing dissolution temperature.

- (4)

- The mass transfer coefficient was plotted in a graph as a function of temperature, and the Ek values of slag1 and slag2 (159 and 182 kJ/mole, respectively) were found using the Arrhenius equation.

- (5)

- The Ek of Al2O3 mass transfer in slag containing FeO in this study was lower than the Ek of slag without FeO.

- (6)

- As the FeO content in the slag increased, the viscosity decreased and Al2O3 dissolution driving force increased, resulting in an increase in the dissolution rate. Additionally, as viscosity decreased, liquid-mass transfer occurred more easily and the mass transfer coefficient increased.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fan, Z.; Friedmann, S.J. Low-carbon production of iron and steel: Technology options, economic assessment, and policy. Joule 2021, 5, 829–862. [Google Scholar] [CrossRef]

- Lee, B.; Sohn, I. Review of Innovative Energy Savings Technology for the Electric Arc Furnace. JOM 2014, 66, 1581–1594. [Google Scholar] [CrossRef]

- Park, J.H.; Todoroki, H. Control of MgO·Al2O3 spinel inclusions in stainless steels. ISIJ Int. 2010, 50, 1333–1346. [Google Scholar] [CrossRef]

- Dimitrov, S.; Weyl, A.; Janke, D. Control of the aluminium-oxygen reaction in pure iron melts. Steel Res. 1995, 66, 3–7. [Google Scholar] [CrossRef]

- Um, H.; Yeo, S.; Kang, Y.-B.; Chung, Y. The effect of FexO content on dissolution behavior of an alumina inclusion in CaO–Al2O3–SiO2–FexO slag by a single hot thermocouple technique. Ceram. Int. 2022, 48, 35301–35309. [Google Scholar] [CrossRef]

- Jung, I.-H.; Decterov, S.A.; Pelton, A.D. Computer applications of thermodynamic databases to inclusion engineering. ISIJ Int. 2004, 44, 527–536. [Google Scholar] [CrossRef]

- Holappa, L.; Hämäläinen, M.; Liukkonen, M.; Lind, M. Thermodynamic examination of inclusion modification and precipitation from calcium treatment to solidified steel. Ironmak. Steelmak. 2003, 30, 111–115. [Google Scholar] [CrossRef]

- Park, J.-H.; Jung, I.-H.; Hae-Geon, L.E.E. Dissolution behavior of Al2O3 and MgO inclusions in the CaO-Al2O3-SiO2 slags: Formation of ring-like structure of MgAl2O4 and Ca2SiO4 around MgO inclusions. ISIJ Int. 2006, 46, 1626–1634. [Google Scholar] [CrossRef]

- Sridhar, S.; Cramb, A.W. Kinetics of Al2O3 dissolution in CaO-MgO-SiO2-Al2O3 slags: In situ observations and analysis. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2000, 31, 406–410. [Google Scholar] [CrossRef]

- Shu, Q.; Zhang, X.; Wang, Y.; Li, J.; Chou, K. Effect of Na2O on dissolution rate of alumina in CaO-Al2O3-MgO-SiO2 slag. In Proceedings of the 6th International Congress on the Science and Technology of Steelmaking, ICS, Beijing, China, 12–14 May 2015; pp. 606–609. [Google Scholar]

- Yi, K.W.; Tse, C.; Park, J.-H.; Valdez, M.; Cramb, A.W.; Sridhar, S. Determination of dissolution time of Al2O3 and MgO inclusions in synthetic Al2O3-CaO-MgO slags. Scand. J. Metall. 2003, 32, 177–184. [Google Scholar] [CrossRef]

- Ren, C.; Zhang, L.; Zhang, J.; Wu, S.; Zhu, P.; Ren, Y. In Situ Observation of the Dissolution of Al2O3 Particles in CaO-Al2O3-SiO2 Slags. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2021, 52, 3288–3301. [Google Scholar] [CrossRef]

- Holappa, L.; Kekkonen, M.; Louhenkilpi, S.; Hagemann, R.; Schröder, C.; Scheller, P. Active tundish slag. Steel Res. Int. 2013, 84, 638–648. [Google Scholar] [CrossRef]

- Park, Y.-J.; Cho, Y.-M.; Cha, W.-Y.; Kang, Y.-B. Dissolution kinetics of alumina in molten CaO–Al2O3–FetO–MgO–SiO2 oxide representing the RH slag in steelmaking process. J. Am. Ceram. Soc. 2020, 103, 2210–2224. [Google Scholar] [CrossRef]

- Yeo, S.; Um, H.; Chung, Y. The Effect of Alumina Activity on Dissolution Behavior of Alumina Particles in CaO–Al2O3–SiO2 Slags. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2021, 52, 3938–3945. [Google Scholar] [CrossRef]

- Zhang, S.; Rezaie, H.R.; Sarpoolaky, H.; Lee, W.E. Alumina dissolution into silicate slag. J. Am. Ceram. Soc. 2000, 83, 897–903. [Google Scholar] [CrossRef]

- Valdez, M.; Prapakorn, K.; Cramb, A.W.; Seetharaman, S. A study of the dissolution of Al2O3, MgO and MgAl2O4 particles in a CaO-Al2O3-SiO2 slag. Steel Res. 2001, 72, 291–297. [Google Scholar] [CrossRef]

- Monaghan, B.J.; Chen, L.; Sorbe, J. Comparative study of oxide inclusion dissolution in CaO-SiO2-Al2O3 slag. Ironmak. Steelmak. 2005, 32, 258–264. [Google Scholar] [CrossRef]

- Chen, G.; He, S.; Wang, Q. Dissolution behavior of Al2O3 into tundish slag for high-al steel. J. Mater. Res. Technol. 2020, 9, 11311–11318. [Google Scholar] [CrossRef]

- Shi, G.-Y.; Zhang, T.-A.; Dou, Z.-H.; Niu, L.-P. Dissolution behavior of Al2O3 inclusions in CaO-Al2O3 based slag representing aluminothermic reduction slag. Crystals 2020, 10, 1061. [Google Scholar] [CrossRef]

- Odenthal, H.-J.; Kemminger, A.; Krause, F.; Sankowski, L.; Uebber, N.; Vogl, N. Review on Modeling and Simulation of the Electric Arc Furnace (EAF). Steel Res. Int. 2018, 89, 1700098. [Google Scholar] [CrossRef]

- Lee, S.; Chung, Y. The effect of C content in MgO–C on dissolution behavior in CaO–SiO2–Al2O3 slag. Ceram. Int. 2022, 48, 26984–26991. [Google Scholar] [CrossRef]

- Kim, Y.; Kashiwaya, Y.; Chung, Y. Effect of varying Al2O3 contents of CaO–Al2O3–SiO2 slags on lumped MgO dissolution. Ceram. Int. 2020, 46, 6205–6211. [Google Scholar] [CrossRef]

- Taira, S.; Nakashima, K.; Mori, K. Kinetic Behavior of Dissolution of Sintered Alumina Into CaO-SiO2&Al2O3 Slags. ISIJ Int. 1993, 33, 116–123. [Google Scholar] [CrossRef]

- Choi, J.-Y.; Lee, H.-G.; Kim, J.-S. Dissolution rate of Al2O3 into molten CaO-SiO2-Al2O3 slags. ISIJ Int. 2002, 42, 852–860. [Google Scholar] [CrossRef]

- Samaddar, B.N.; Kingery, W.D.; Cooper, A.R. Dissolution in Ceramic Systems: 11, Dissolution of Aluminu, Mullite, Anorthite, and Silica in a Calcium-Aluminum-Silicate Slag. J. Am. Ceram. Soc. 1964, 47, 249–254. [Google Scholar] [CrossRef]

- Oishi, Y.; Cooper, A.R.; Kingery, W.D. Dissolution in Ceramic Systems: III, Boundary Layer Concentration Gradients. J. Am. Ceram. Soc. 1965, 48, 88–95. [Google Scholar] [CrossRef]

- Bui, A.-H.; Ha, H.-M.; Kang, Y.-B.; Chung, I.-S.; Lee, H.-G. Dissolution behavior of alumina in mold fluxes for steel continuous casting. Met. Mater. Int. 2005, 11, 183–190. [Google Scholar] [CrossRef]

- Yan, P.; Webler, B.A.; Pistorius, P.C.; Fruehan, R.J. Nature of MgO and Al2O3 Dissolution in Metallurgical Slags. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2015, 46, 2414–2418. [Google Scholar] [CrossRef]

- Sharma, M.; Mu, W.; Dogan, N. In Situ Observation of Dissolution of Oxide Inclusions in Steelmaking Slags. JOM 2018, 70, 1220–1224. [Google Scholar] [CrossRef]

- Cho, W.D.; Fan, P. Diffusional Dissolution of Alumina in Various Steelmaking Slags. ISIJ Int. 2004, 44, 229–234. [Google Scholar] [CrossRef]

- Petrucci, R.H.; Harwood, W.S. General Chemistry, 6th ed.; Macmillan: New York, NY, USA, 1993; p. 535. [Google Scholar]

- Liu, Y.Q.; Wang, L.J.; Chou, K.C. Dissolution behavior of Al2O3 in refining slags containing Ce2O3. ISIJ Int. 2014, 54, 728–733. [Google Scholar] [CrossRef]

- Park, J.S.; Park, J.H. Effect of Physicochemical Properties of Slag and Flux on the Removal Rate of Oxide Inclusion from Molten Steel. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2016, 47, 3225–3230. [Google Scholar] [CrossRef]

- Valdez, M.; Shannon, G.S.; Sridhar, S. The ability of slags to absorb solid oxide inclusions. ISIJ Int. 2006, 46, 450–457. [Google Scholar] [CrossRef]

| Type | Source | Diameter | Weight | Concentration | |

|---|---|---|---|---|---|

| Al2O3 (%) | Other (%) | ||||

| Alumina sphere | GoodFellow | 500 ± 2.5 μm | 0.25 ± 0.05 mg | 99.9 | 0.1 |

| Headings | CaO | SiO2 | Al2O3 | FeO | Basicity | References |

|---|---|---|---|---|---|---|

| Slag0 | 47.5 | 47.5 | 5 | 0 | 1 | [15] |

| Slag1 | 43.7 | 42.6 | 4.6 | 9.1 | 1 | |

| Slag2 | 37.7 | 38.4 | 4.4 | 19.5 | 1 | |

| Slag3 | 32.5 | 32.5 | 5 | 30 | 1 | [5] |

| Temperature (°C) | Slag | 120 s | 240 s | 360 s | References |

|---|---|---|---|---|---|

| 1550 | 0 | 465 | 420 | 393 | [15] |

| 1 | 408 | 360 | 269 | ||

| 2 | 353 | 251 | 122 | ||

| 3 | 377 | 283 | 122 | [5] | |

| 1575 | 1 | 407 | 321 | 248 | |

| 2 | 324 | 194 | 85 | ||

| 1600 | 0 | 447 | 385 | 317 | [15] |

| 1 | 374 | 240 | 187 | ||

| 2 | 319 | 105 | 55 (300 s) |

| Driving Force of Dissolution (mole/m3) *FactSage7.3TM | Slag Density (kg/m3) | Dissolution Rate (cm/s) | Mass Transfer Coefficient (cm/s) | References | |

|---|---|---|---|---|---|

| Slag0 1550 °C | 10,745 | 2660 | 2.96 × 10−5 | 7.19 × 10−8 | [15] |

| Slag0 1600 °C | 11,399 | 2647 | 5.10 × 10−5 | 1.16 × 10−7 | |

| Slag1 1550 °C | 10,885 | 2796 | 6.18 × 10−5 | 1.56 × 10−7 | Present study |

| Slag1 1575 °C | 11,581 | 2789 | 7.01 × 10−5 | 1.66 × 10−7 | |

| Slag1 1600 °C | 11,846 | 2782 | 8.95 × 10−5 | 2.06 × 10−7 | |

| Slag2 1550 °C | 11,050 | 2943 | 1.03 × 10−4 | 2.69 × 10−7 | Present study |

| Slag2 1575 °C | 11,600 | 2935 | 1.15 × 10−4 | 2.84 × 10−7 | |

| Slag2 1600 °C | 11,925 | 2928 | 1.54 × 10−4 | 3.71 × 10−7 |

| Slag | Chemical Composition (wt%) | Ek (kJ/mole) | References | |||||

|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | MgO | Ce2O3 | FeO | |||

| 0 | 47.5 | 47.5 | 5.0 | 0 | 0 | 0 | 304 | [15] |

| 1 | 42.5 | 42.5 | 5.0 | 0 | 0 | 10 | 159 | Present study |

| 2 | 37.5 | 37.5 | 5.0 | 0 | 0 | 20 | 182 | |

| 4 | 45.0 | 10.0 | 45.0 | 0 | 0 | 0 | 445 | [31] |

| 5 | 35.0 | 30.0 | 35.0 | 0 | 0 | 0 | 334 | |

| 6 | 45.0 | 4.5 | 37.5 | 10.0 | 3 | 0 | 292 | [33] 1 |

| 7 | 45.0 | 4.5 | 35.5 | 10.0 | 5 | 0 | 347 | |

| 8 | 45.0 | 4.5 | 32.5 | 10.0 | 8 | 0 | 249 | |

| Headings | Slag Viscosity (Pa·s) *FactSage7.3TM | Driving Force of Dissolution (mole/m3) *FactSage7.3TM | References |

|---|---|---|---|

| Slag0 1550 °C | 3.235 | 10,745 | [15] |

| Slag0 1600 °C | 2.202 | 11,399 | |

| Slag1 1550 °C | 0.159 | 10,885 | |

| Slag1 1575 °C | 0.140 | 11,581 | Present study |

| Slag1 1600 °C | 0.124 | 11,846 | |

| Slag2 1550 °C | 0.098 | 11,050 | |

| Slag2 1575 °C | 0.087 | 11,600 | Present study |

| Slag2 1600 °C | 0.078 | 11,925 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwack, T.; Um, H.; Chung, Y. Activation Energy of Alumina Dissolution in FeO-Bearing Slags. Metals 2023, 13, 1702. https://doi.org/10.3390/met13101702

Kwack T, Um H, Chung Y. Activation Energy of Alumina Dissolution in FeO-Bearing Slags. Metals. 2023; 13(10):1702. https://doi.org/10.3390/met13101702

Chicago/Turabian StyleKwack, Taejun, Hyungsic Um, and Yongsug Chung. 2023. "Activation Energy of Alumina Dissolution in FeO-Bearing Slags" Metals 13, no. 10: 1702. https://doi.org/10.3390/met13101702

APA StyleKwack, T., Um, H., & Chung, Y. (2023). Activation Energy of Alumina Dissolution in FeO-Bearing Slags. Metals, 13(10), 1702. https://doi.org/10.3390/met13101702