Improvement of Analytical Model for Oblique Cutting—Part I: Identification of Mechanical Characteristics of Machined Material

Abstract

:1. Introduction

2. Cutting Force Calculation Using Analytical Models

3. Materials and Methods

3.1. Materials

3.1.1. Compression Test

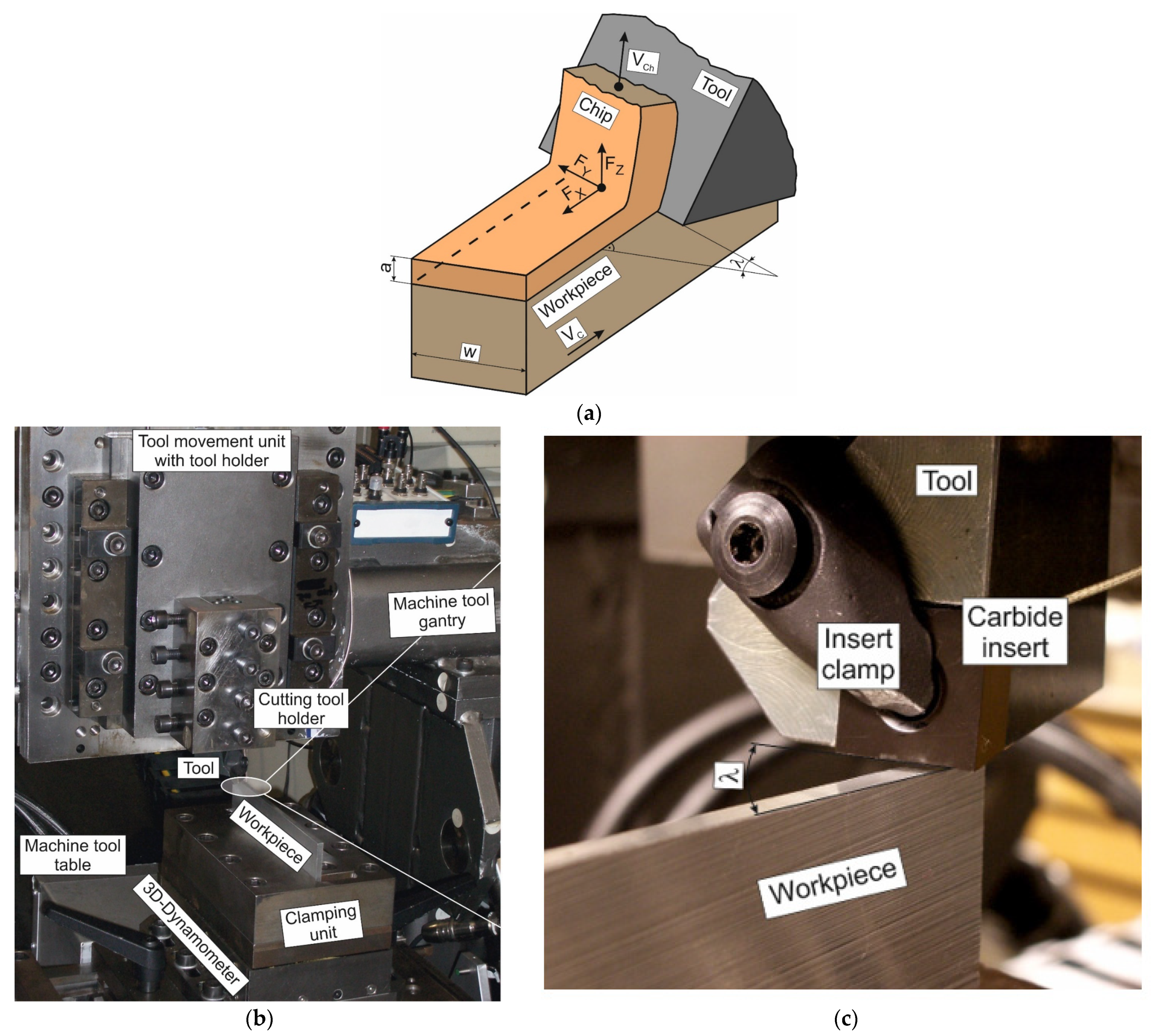

3.1.2. Oblique Cutting Test

3.2. Methods

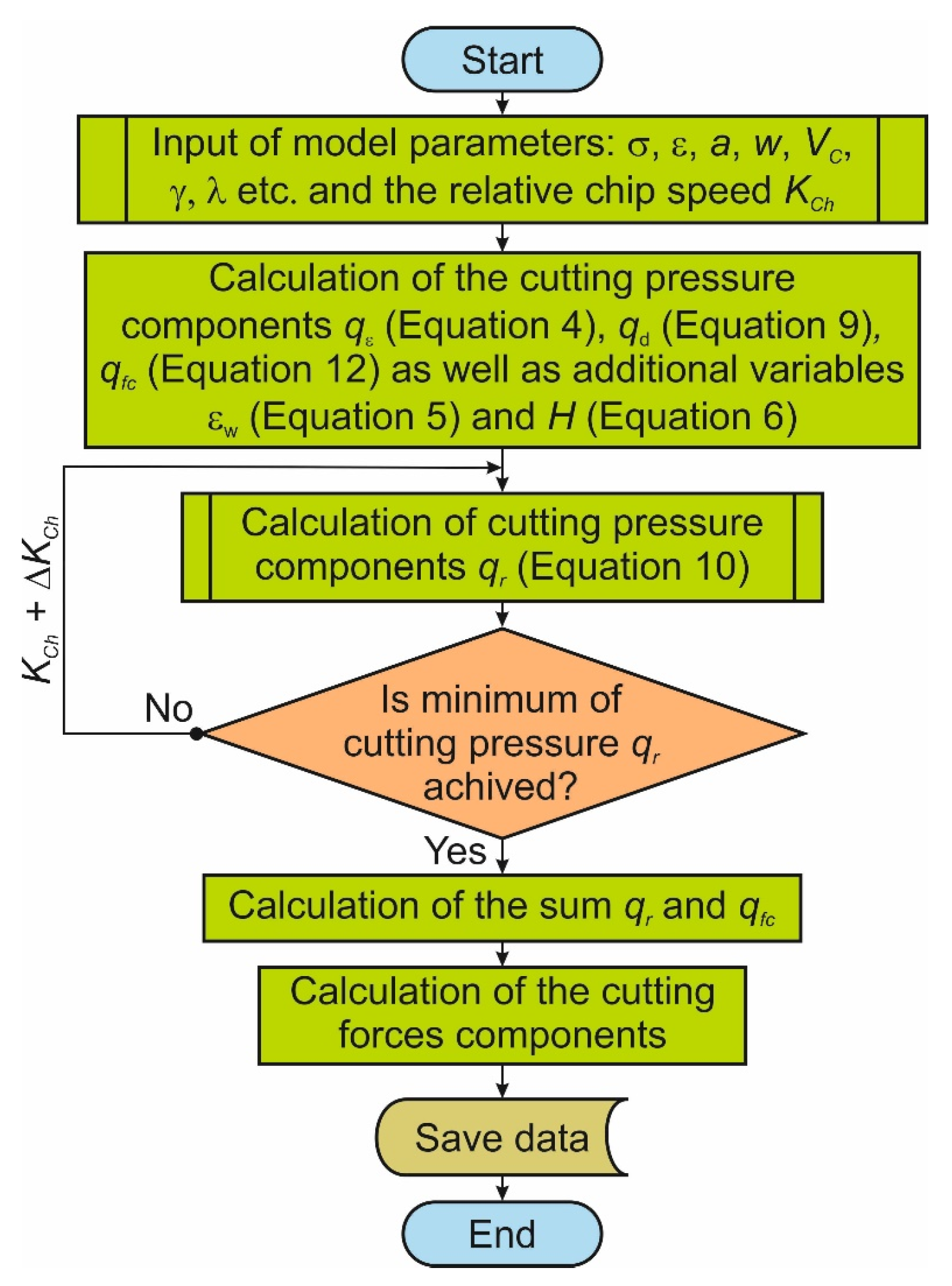

3.2.1. Analytical Cutting Model

- Analysis of chip formation is based on the cutting scheme with a single shear plane [10,23,24,82]. According to this scheme, the machined material is deformed in a thin layer in the vicinity of the shear plane. The speed field during chip formation is disruptive. The speed break boundary is the shear plane. In the shear plane, the tangential velocities suffer a break, while the normal speed retains its value;

- The machined material is rigidly plastic and subject to strain-hardening. This corresponds to the conditions of complete cold deformation;

- Power in the cutting process is consumed for plastic deformation in the shear plane, for overcoming the friction forces on the rake and clearance faces, and for crack propagation work associated with the formation of new surfaces;

- New surfaces for chip formation arise in front of the cutting wedge in the area of wedge rounding. They are formed due to crack propagation in the direction of the cutting speed vector;

- The analysis of the oblique cutting process is performed in cutting pressure terms;

- Friction on the rake and clearance faces is assumed to be proportional to the normal contact pressure, i.e., described by Coulomb–Amonton’s law;

- The friction coefficient does not reach its limit, which is defined by the Tresca–Saint-Venant criterion [105]. Contact on the clearance face of the cutting wedge is limited by the wear field.

3.2.2. FEM Cutting Model

3.2.3. Methodology for Determining the Mechanical Properties of Machined Material

4. Results and Discussion

4.1. Experimental Studies

4.2. Numerical Simulation

4.3. Calculation of Cutting Forces Using an Improved Analytical Model

5. Conclusions

- The cutting forces calculated using the analytical model of oblique cutting with the use of refined mechanical parameters of the machined material satisfactorily coincide with the corresponding measured values of these forces.

- The calculated value deviations of the cutting force components when the cutting depth a (undeformed chip thickness) changes from 0.1 mm to 0.2 mm from their measured values in the vast majority of cases do not exceed 15%. The difference between the calculated and measured values of the cutting force components when the cutting speed VC changes from 48 m/min to 144 m/min in the vast majority of cases does not exceed 20%.

- The developed algorithm for determining the mechanical properties of the machined material using the Johnson–Cook constitutive equation can be successfully used in analytical models of orthogonal and oblique cutting. This is evidenced by the satisfactory coincidence of the measured and analytically calculated kinetic characteristics of the cutting process.

- The proposed symbiosis of analytical and numerical cutting models is successfully realized by implementing the algorithm for determining the mechanical properties of the machined material into the analytical cutting model.

- The suggested technique of determining the initial parameters for the analytical cutting model can be extended to determine the parameters of the contact interaction between the tool and the machined material and the chip, as well as to determine the damage parameters of the machined material with chip formation.

- Thus, improved analytical models of orthogonal and oblique cutting can be successfully used for the optimization of existing machining processes and tool designs, as well as for the purposeful creation of new processes and tools for their implementation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Davim, J.P. Machining of Complex Sculptured Surfaces; Springer: London, UK, 2012; 258p. [Google Scholar] [CrossRef]

- Andrianto, M.; Wu, Y.R.; Arifin, A. Mathematical modeling on a novel manufacturing method for roller-gear cams using a whirl-machining process. Int. J. Adv. Manuf. Technol. 2023, 125, 5015–5029. [Google Scholar] [CrossRef]

- Babichev, D.; Storchak, M. Synthesis of cylindrical gears with optimum rolling fatigue strength. Prod. Eng. Res. Dev. 2015, 9, 87–97. [Google Scholar] [CrossRef]

- Finnie, I. Review of the metal-cutting analysis of the past hundred years. Mech. Eng. 1956, 78, 715–721. [Google Scholar]

- Arrazola, P.J.; Özel, T.; Umbrello, D.; Davies, M.; Jawahir, I.S. Recent advances in modelling of metal machining processes. Ann. CIRP 2013, 62, 695–718. [Google Scholar] [CrossRef]

- Melkote, S.; Liang, S.; Özel, T.; Jawahir, I.S.; Stephenson, D.A.; Wang, B.A. Review of Advances in Modeling of Conventional Machining Processes: From Merchant to the Present. ASME J. Manuf. Sci. Eng. 2022, 144, 110801. [Google Scholar] [CrossRef]

- Malishev, V. Essays on the History of the Science of Cutting Materials; TSU: Tolyatti, Russia, 2011; 216p, ISBN 978-5-8259-0624-9. (In Russian) [Google Scholar]

- Cocquilhat, C.M. Expériences sur la Resistance Utile Produites dans le Forage. Ann. des Trav. Publics en Belg. 1851, 10, 199–215. [Google Scholar]

- Hartig, E.; Teubner, B. Versuche über Leistung und Arbeitsverbrauch der Werkzeugmaschinen; Classic Reprint; Wentworth Press: Sydney, Australia, 2018; 266p, ISBN 10:0270499350. [Google Scholar]

- Time, I.A. Mémoire sur le Rabotage des Métaux; Classic Reprint, French Edition; Forgotten Books: London, UK, 2018; 48p, ISBN 13:978-0365617273. [Google Scholar]

- Mallock, A. The action of cutting tools. Proc. R. Soc. Lond. 1882, 33, 127–139. [Google Scholar] [CrossRef]

- Tresca, H.E. Mémoire sur l’écoulement des corps solides. In Mémoires de l’Académie des Sciences de l’Institut de France; Imprimerie Impériale: Paris, France, 1868; Volume 18, 111p. [Google Scholar]

- Zworykin, K.A. Work and Forces Required for Separation of Metal Chips; Russian Printing House: Moscow, Russia, 1893; 91p. (In Russian) [Google Scholar]

- Bricks, A.A. Cutting of Metalls (Planing); Stasiulevich Printing House: Sankt-Petersburg, Russia, 1896; 163p. (In Russian) [Google Scholar]

- Merchant, M.E. Twentieth century evolution of machining in the United States—An interpretative review. Sadhana 2003, 28, 867–874. [Google Scholar] [CrossRef]

- Soo, S.L.; Aspinwall, D.K. Developments in modeling of metal cutting processes. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2007, 221, 197–211. [Google Scholar] [CrossRef]

- Merchant, M.E. Basic mechanics of the metal cutting process. J. Appl. Mech. 1944, 11, A168–A175. [Google Scholar] [CrossRef]

- Merchant, M.E. Mechanics of the metal cutting process II. Plasticity conditions in orthogonal cutting. J. Appl. Phys. 1945, 16, 318–324. [Google Scholar] [CrossRef]

- Piispanen, V. Theory of formation of metal chips. J. Appl. Phys. 1948, 19, 876–881. [Google Scholar] [CrossRef]

- Lee, E.H.; Shaffer, B.W. The theory of plasticity applied to a problem of machining. J. Appl. Mech. 1951, 18, 405–413. [Google Scholar] [CrossRef]

- Shaw, M.C.; Cook, N.H.; Finnel, L. The Shear Angle Relationship in Metal Cutting. J. Fluid Eng. 1953, 75, 273–283. [Google Scholar] [CrossRef]

- Palmer, W.B.; Oxley, P.L.B. Mechanics of metal cutting. Proc. Inst. Mech. Eng. 1959, 173, 623–654. [Google Scholar] [CrossRef]

- Zorev, N.N. Metal Cutting Mechanics; Pergamon Press GmbH: Frankfurt am Main, Germany, 1966; 526p, ISBN 978-0080107233. [Google Scholar]

- Oxley, P.L.B. Mechanics of Machining. An Analytical Approach to Assessing Machinability; Ellis Horwood: Chichester, UK, 1989; 242p, ISBN 13:978-0470213827. [Google Scholar]

- Boothroyd, G. Temperatures in Orthogonal Metal Cutting. Proc. Inst. Mech. Eng. 1963, 177, 789–802. [Google Scholar] [CrossRef]

- Bao, H.; Stevenson, M.G. An investigation of built-up edge formation in the machining of aluminium. Int. J. Mach. Tool Des. Res. 1976, 16, 165–178. [Google Scholar] [CrossRef]

- Kristyanto, B.; Mathew, P.; Arsecularatne, J.A. Development of a variable flow stress machining theory for aluminium alloys. Mach. Sci. Technol. 2002, 6, 365–378. [Google Scholar] [CrossRef]

- Adibi-Sedeh, A.H.; Madhavan, V.; Bahr, B. Extension of Oxley’s Analysis of Machining to Use Different Material Models. J. Manuf. Sci. Eng. 2003, 125, 656–666. [Google Scholar] [CrossRef]

- Lalwani, D.I.; Mehta, N.K.; Jain, P.K. Extension of Oxley’s predictive machining theory for Johnson and Cook flow stress model. J. Mater. Process. Technol. 2009, 209, 5305–5312. [Google Scholar] [CrossRef]

- Tay, A.O.; Stevenson, M.G.; De Vahl Davis, G.; Oxley, P.L.B. A Numerical method for calculating temperature distributions in machining from force and shear angle measurement. Int. J. Mach. Tool Des. Res. 1976, 16, 335–349. [Google Scholar] [CrossRef]

- Komanduri, R.; Hou, Z.B. Thermal modeling of the metal cutting process—Part III: Temperature rise distribution due to the combined effects of shear plane heat source and the tool–chip interface frictional heat source. Int. J. Mech. Sci. 2001, 43, 89–107. [Google Scholar] [CrossRef]

- Karpat, Y.; Özel, T. Predictive Analytical and Thermal Modeling of Orthogonal Cutting Process—Part I: Predictions of Tool Forces, Stresses, and Temperature Distributions. J. Manuf. Sci. Eng. 2006, 128, 435–444. [Google Scholar] [CrossRef]

- Shan, C.; Zhang, X.; Shen, B.; Zhang, D. An improved analytical model of cutting temperature in orthogonal cutting of Ti6Al4V. Chin. J. Aeronaut. 2019, 32, 759–769. [Google Scholar] [CrossRef]

- Chen, Y.; Li, H.; Wang, J. Further Development of Oxley’s Predictive Force Model for Orthogonal Cutting. Mach. Sci. Technol. Int. J. 2015, 19, 86–111. [Google Scholar] [CrossRef]

- Tlusty, G. Manufacturing Equipment and Processes; Prentice-Hall: Upper Saddle River, NJ, USA, 2000; 928p, ISBN 978020149865. [Google Scholar]

- Dargnat, F.; Darnis, P.; Cahuc, O. On the adaptability of cutting model to drilling. In Proceedings of the 12th CIRP Conference on Modelling of Machining Operations, Donostia-San Sebastián, Spain, 7–8 May 2009; ISBN 978-84-608-0865-7. [Google Scholar]

- Marinov, V.R. Hybrid analytical-numerical solution for the shear angle in orthogonal metal cutting—Part I: Theoretical foundation. Int. J. Mech. Sci. 2001, 43, 399–414. [Google Scholar] [CrossRef]

- Qi, H.S.; Mills, B. Modelling of the dynamic tool-chip interface in metal cutting. J. Mater. Process. Technol. 2003, 138, 201–207. [Google Scholar] [CrossRef]

- Moufki, A.; Molinari, A.; Dudzinski, D. Modelling of orthogonal cutting with a temperature dependent friction law. J. Mech. Phys. Solids 1998, 46, 2103–2138. [Google Scholar] [CrossRef]

- Dubrovskiy, A.A. Towards the problem of plastic deformation of the sheared layer, Part 2. In Cutting without Adhesion of Contact Surfaces; Institute of Technical Acoustics of the National Academy of Sciences of Belarus: Vitebsk, Belarus, 2004; pp. 22–27. (In Russian) [Google Scholar]

- Ozlu, E.; Molinari, A.; Budak, E. Two-zone analytical contact model applied to orthogonal cutting. Mach. Sci. Technol. 2010, 14, 323–343. [Google Scholar] [CrossRef]

- Bahi, S.; List, G.; Sutter, G. Analysis of adhered contacts and boundary conditions of the secondary shear zone. Wear 2015, 330–331, 608–617. [Google Scholar] [CrossRef]

- Rosenberg, Y.A. Metal Cutting; Kurgan State University: Kurgan, Russia, 2007; 294p, ISBN 5-86328. (In Russian) [Google Scholar]

- Nodelman, M.O. Machining by cutting. In Fundamentals of Theory and Practice; Chelyabinsk House of Printing: Chelyabinsk, Russia, 2018; 176p, ISBN 978-5-87184-653-7. (In Russian) [Google Scholar]

- Pravednikov, I.S. Theoretical prediction of stresses and cutting forces based on the physical and mechanical properties of materials. Oil Gas Bus. 2006, 1–11. (In Russian) [Google Scholar]

- Vorontsov, A.L.; Syltan-Zade, N.M.; Albagachiev, A.U. Problems of theory and practice of material cutting. Development of a new cutting theory. Bull. Mech. Eng. 2008, 7, 56–61. (In Russian) [Google Scholar]

- Hucks, H. Plastizitätsmechanische Theorie der Spanbildung. Werkstatt Betr. Z. Maschinenbau Fert. 1952, 85, 1–6. [Google Scholar]

- Pugh, H.L.D. Mechanics of cutting process. In Proceedings of the Conference on Technology and Engineering Nanufacturing; The Institute of Mechanical Engineers: London, UK, 1958; Volume 53, pp. 237–254. [Google Scholar]

- Stabler, G.V. The Foundational Geometry of Cutting Tool. Proc. Inst. Mech. Eng. 1951, 165, 14–26. [Google Scholar] [CrossRef]

- Shaw, M.C.; Cook, N.H.; Smith, P.A. The mechanics of three-dimensional cutting operations. Trans. ASME 1952, 74, 1055–1064. [Google Scholar] [CrossRef]

- Colwell, L.V. Predicting the Angle of Chip Flow for Single-Point Cutting Tools. Trans. ASME 1954, 76, 199–203. [Google Scholar] [CrossRef]

- Armarego, E.J.A.; Wiriyacosol, S. Oblique machining with triangular form tools—I. Theoretical investigation. Int. J. Mach. Tool Des. Res. 1978, 18, 67–80. [Google Scholar] [CrossRef]

- Rubenstein, C. The mechanics of continuous chip formation in oblique cutting in the absence of chip distortion. Part 1—Theory. Int. J. Mach. Tool Des. Res. 1983, 23, 11–20. [Google Scholar] [CrossRef]

- Seethaler, R.J.; Yellowley, I. An upper-bound cutting model for oblique cutting tools with a nose radius. Int. J. Mach. Tools Manuf. 1997, 37, 119–134. [Google Scholar] [CrossRef]

- Lin, G.C.I.; Mathew, P.; Oxley, P.L.B.; Watson, R.A. Predicting Cutting Forces for Oblique Machining Conditions. Proc. Inst. Mech. Eng. 1982, 196, 141–148. [Google Scholar] [CrossRef]

- Arsecularatne, J.A.; Mathew, P.; Oxley, P.L.B. Predicting of chip flow direction and cutting forces in oblique machining with nose radius tools. Proc. Inst. Mech. Eng. 1995, 209, 305–315. [Google Scholar] [CrossRef]

- Moufki, A.; Devillez, A.; Dudzinski, D.; Molinari, A. Thermomechanical modelling of oblique cutting and experimental validation. Int. J. Mach. Tools Manuf. 2004, 44, 971–989. [Google Scholar] [CrossRef]

- Usui, E.; Hirota, A.; Masuko, M. Analytical Prediction of Three Dimensional Cutting Process—Part I: Basic Cutting Model and Energy Approach. J. Eng. Ind. 1978, 100, 222–228. [Google Scholar] [CrossRef]

- Moufki, A.; Molinari, A. A new thermomechanical model of cutting applied to turning operations. Part II: Parametric study. Int. J. Mach. Tools Manuf. 2005, 45, 181–193. [Google Scholar] [CrossRef]

- Fu, Z.; Chen, X.; Mao, J.; Xiong, T. An analytical force model applied to three-dimensional turning based on a predictive machining theory. Int. J. Mech. Sci. 2018, 136, 94–105. [Google Scholar] [CrossRef]

- Abdellaoui, L.; Khlifi, H.; Bouzid Sai, W. Prediction of turning performances using an equivalent oblique cutting model. Int. J. Adv. Manuf. Technol. 2022, 120, 7735–7753. [Google Scholar] [CrossRef]

- Orra, K.; Choudhury, S.K. Mechanistic modelling for predicting cutting forces in machining considering effect of tool nose radius on chip formation and tool wear land. Int. J. Mech. Sci. 2018, 142–143, 255–268. [Google Scholar] [CrossRef]

- Karpat, Y.; Özel, T. Analytical and Thermal Modeling of High-Speed Machining with Chamfered Tools. J. Manuf. Sci. Eng. 2008, 130, 011001. [Google Scholar] [CrossRef]

- Hu, C.; Zhang, W.; Zhuang, K.; Zhou, J.; Ding, H. On the Steady-State Workpiece Flow Mechanism and Force Prediction Considering Piled-Up Effect and Dead Metal Zone Formation. J. Manuf. Sci. Eng. 2021, 143, 041009. [Google Scholar] [CrossRef]

- Hu, C.; Zhuang, K.; Weng, J.; Zhang, X.; Ding, H. Cutting temperature prediction in negative-rake-angle machining with chamfered insert based on a modified slip-line field model. Int. J. Mech. Sci. 2020, 167, 105273. [Google Scholar] [CrossRef]

- Wan, M.; Wen, D.-Y.; Ma, Y.-C.; Zhang, W.-H. On material separation and cutting force prediction in micro milling through involving the effect of dead metal zone. Int. J. Mach. Tools Manuf. 2019, 146, 103452. [Google Scholar] [CrossRef]

- Babu, B.H.; Rao, K.V.; Ben, B.S. Modeling and optimization of dead metal zone to reduce cutting forces in micro-milling of hardened AISI D2 steel. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 142. [Google Scholar] [CrossRef]

- Albrecht, P. New Developments in the Theory of Metal Cutting Process. Part I: The Ploughing Process in Metal Cutting. J. Eng. Ind. 1960, 82, 348–357. [Google Scholar] [CrossRef]

- Waldorf, D.J.; DeVor, R.E.; Kapoor, S.G. A Slip-line Field for Ploughing during Orthogonal Cutting. J. Manuf. Sci. Eng. 1998, 120, 693–699. [Google Scholar] [CrossRef]

- Zhou, J.; Ren, J. Predicting cutting force with unequal division parallel-sided shear zone model for orthogonal cutting. Int. J. Adv. Manuf. Technol. 2020, 107, 4201–4211. [Google Scholar] [CrossRef]

- Huang, Y.; Liang, S.Y. Force Modeling in Shallow Cuts with Large Negative Rake Angle and Large Nose Radius Tools—Application to Hard Turning. Int. J. Adv. Manuf. Technol. 2003, 22, 626–632. [Google Scholar] [CrossRef]

- Aslantas, K.; Ülker, S.; Şahan, Ö.; Pimenov, D.Y.; Giasin, K. Mechanistic modeling of cutting forces in high-speed microturning of titanium alloy with consideration of nose radius. Int. J. Adv. Manuf. Technol. 2022, 119, 2393–2408. [Google Scholar] [CrossRef]

- Sahoo, P.; Patra, K.; Singh, V.K.; Gupta, M.K.; Song, Q.; Mia, M.; Pimenov, D.Y. Influences of TiAlN coating and limiting angles of flutes on prediction of cutting forces and dynamic stability in micro milling of die steel (P-20). J. Mater. Process. Technol. 2020, 278, 116500. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Matuszak, M.; Powałka, B.; Madajewski, M.; Maruda, R.W.; Królczyk, G.M. Prediction of cutting forces during micro end milling considering chip thickness accumulation. Int. J. Mach. Tools Manuf. 2019, 147, 103466. [Google Scholar] [CrossRef]

- Liu, T.; Liu, Y.; Zhang, K. An improved cutting force model in micro-milling considering the comprehensive effect of tool runout, size effect and tool wear. Int. J. Adv. Manuf. Technol 2022, 120, 659–668. [Google Scholar] [CrossRef]

- Gao, S.; Duan, X.; Zhu, K.; Zhang, Y. Generic Cutting Force Modeling with Comprehensively Considering Tool Edge Radius, Tool Flank Wear and Tool Runout in Micro-End Milling. Micromachine 2022, 13, 1805. [Google Scholar] [CrossRef]

- Ercetin, A.; Aslantas, K.; Özgün, Ö.; Perçin, M.; Patel, G.C.M. Optimization of Machining Parameters to Minimize Cutting Forces and Surface Roughness in Micro-Milling of Mg13Sn Alloy. Micromachines 2023, 14, 1590. [Google Scholar] [CrossRef]

- Cai, L.; Feng, Y.; Lu, Y.T.; Lin, Y.F.; Hung, T.P.; Hsu, F.C.; Liang, S.Y. Analytical Model for Temperature Prediction in Milling AISI D2 with Minimum Quantity Lubrication. Metals 2022, 12, 697. [Google Scholar] [CrossRef]

- Vereshchaka, A.S.; Kushner, V.S. Cutting of Metals; Moscow High School: Moscow, Russia, 2009; 535p, ISBN 978-5-06-004415-7. (In Russian) [Google Scholar]

- Atkins, A.G. Modelling metal cutting using modern ductile fracture mechanics: Quantitative explanations for some longstanding problems. Int. J. Mech. Sci. 2003, 45, 373–396. [Google Scholar] [CrossRef]

- Astakhov, V.; Xiao, X. A methodology for practical cutting force evaluation based on the energy spent in the cutting system. Mach. Sci. Technol. 2008, 12, 325–347. [Google Scholar] [CrossRef]

- Tsekhanov, J.; Storchak, M. Development of analytical model for orthogonal cutting. Production Engineering. Res. Dev. 2015, 9, 247–255. [Google Scholar] [CrossRef]

- Prandtl, L. Über die Härte Plastischer Körper; Nachrichten von der Gesellschaft der Wissenschaften zu Göttingen: Göttingen, Germany, 1920; pp. 74–85. [Google Scholar]

- Olenin, L.D.; Storchak, M.; Lekveishvili, M.A. Development of analytical model of bevel cutting. Izv. MGTU MAMI 2014, 8, 123–128. [Google Scholar] [CrossRef]

- Kudo, H. Some new slip-line solutions for two-dimensional steady-state machining. Int. J. Mech. Sci. 1965, 7, 43–55. [Google Scholar] [CrossRef]

- Fang, N. Slip-line modeling of machining with a rounded-edge tool – Part 1: New model and theory. J. Mech. Phys. Solids 2003, 51, 715–742. [Google Scholar] [CrossRef]

- Maity, K.P.; Das, N.S. A class of slipline field solutions for metal machining with sticking-slipping zone including elastic contact. Mater. Des. 2007, 28, 2310–2317. [Google Scholar] [CrossRef]

- Gonzalo, O.; Jauregi, H.; Uriarte, L.G.; López de Lacalle, L.N. Prediction of specific force coefficients from a FEM cutting model. Int. J. Adv. Manuf. Technol. 2009, 43, 348–356. [Google Scholar] [CrossRef]

- Wan, M.; Li, S.-E.; Yuan, H.; Zhang, W.-H. Cutting force modelling in machining of fiber-reinforced polymer matrix composites (PMCs): A review. Compos. Part A: Appl. Sci. Manuf. 2019, 117, 34–55. [Google Scholar] [CrossRef]

- Shan, C.; Zhang, M.; Yang, Y.; Zhang, S.; Luo, M. A dynamic cutting force model for transverse orthogonal cutting of unidirectional carbon/carbon composites considering fiber distribution. Compos. Struct. 2020, 251, 112668. [Google Scholar] [CrossRef]

- Liu, C.; Gao, L.; Jiang, X.; Xu, W.; Liu, S.; Yang, T. Analytical modeling of subsurface damage depth in machining of SiCp/ Al composites. Int. J. Mech. Sci. 2020, 185, 105874. [Google Scholar] [CrossRef]

- Wang, R.; Zhao, M.; Mao, J.; Liang, S.Y. Force Prediction and Material Removal Mechanism Analysis of Milling SiCp/2009Al. Micromachines 2022, 13, 1687. [Google Scholar] [CrossRef] [PubMed]

- Ning, H.; Zheng, H.; Wang, G. Establishment of Analytical Model for CFRP Cutting Force Considering the Radius of the Edge Circle. Materials 2022, 15, 2127. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Wang, S.; To, S.; Sun, Z.; Jiao, J.; Xu, S. High-efficient fabrication of infrared optics with uniform microstructures by a semi-ductile diamond milling approach. Int. J. Adv. Manuf. Technol. 2023, 126, 919–934. [Google Scholar] [CrossRef]

- Sun, Z.; To, S.; Li, P.; Wang, S.; Zhang, T. Analytical modelling of cutting forces in ultra-precision fly grooving considering effects of trans-scale chip thickness variation and material microstructure. Int. J. Adv. Manuf. Technol. 2022, 118, 3209–3227. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, S.; To, S.; Xu, S.; Guo, G. Modelling and analysis of the specific cutting energy for ultra-precision diamond cutting of Ti6Al4V alloy. J. Manuf. Process. 2023, 85, 844–857. [Google Scholar] [CrossRef]

- Chen, X.; Tang, J.; Shao, W.; Hu, B.; Ye, J. An Analytical and Experimental Study on Cutting Characteristics and Transient Cutting Force Modeling in Feed Directional Ultrasonic Vibration-Assisted Cutting of High Strength Alloys. Materials 2022, 15, 7388. [Google Scholar] [CrossRef] [PubMed]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Heisel, U.; Krivoruchko, D.V.; Zaloha, W.A.; Storchak, M.; Stehle, T. Thermomechanical material models in the modeling of cutting processes. Z. Wirtsch. Fabr. ZWF 2009, 104, 482–491. [Google Scholar] [CrossRef]

- Storchak, M.; Rupp, P.; Möhring, H.-C.; Stehle, T. Determination of Johnson–Cook Constitutive Parameters for Cutting Simulations. Metals 2019, 9, 473. [Google Scholar] [CrossRef]

- Kushner, V.; Storchak, M. Determining mechanical characteristics of material resistance to deformation in machining. Production Engineering. Res. Dev. 2014, 8, 679–688. [Google Scholar] [CrossRef]

- Heisel, U.; Kushner, V.; Storchak, M. Effect of machining conditions on specific tangential forces. Production Engineering. Res. Dev. 2012, 6, 621–629. [Google Scholar] [CrossRef]

- Kushner, V.; Storchak, M. Determination of Material Resistance Characteristics in Cutting. Procedia CIRP 2017, 58, 293–298. [Google Scholar] [CrossRef]

- Storchak, M.; Stehle, T.; Möhring, H.-C. Determination of thermal material properties for the numerical simulation of cutting processes. Int. J. Adv. Manuf. 2021, 118, 1941–1956. [Google Scholar] [CrossRef]

- Lubliner, J. Plasticity Theory; Dover Publications Inc.: Mineola, NY, USA, 2008; 528p, ISBN 978-0486462905. [Google Scholar]

- Chakrabarty, J. Theory of Plasticity, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2012; 896p, ISBN 978-0080481364. [Google Scholar]

- Heisel, U.; Krivoruchko, D.V.; Zaloha, W.A.; Storchak, M.; Stehle, T. Thermomechanical exchange effects in machining. Z. Fuer Wirtsch. Fabr. ZWF 2009, 104, 263–272. [Google Scholar] [CrossRef]

- Storchak, M.; Möhring, H.-C.; Stehle, T. Improving the friction model for the simulation of cutting processes. Tribol. Int. 2021, 167, 107376. [Google Scholar] [CrossRef]

- Heisel, U.; Krivoruchko, D.V.; Zaloha, W.A.; Storchak, M.; Stehle, T. Breakage models for the modeling of cutting processes. ZWF Z. Fuer Wirtsch. Fabr. 2009, 104, 330–339. [Google Scholar] [CrossRef]

- Storchak, M.; Jiang, L.; Xu, Y.; Li, X. Finite element modeling for the cutting process of the titanium alloy Ti10V2Fe3Al. Production Engineering. Res. Dev. 2016, 10, 509–517. [Google Scholar] [CrossRef]

- Storchak, M.; Stehle, T.; Möhring, H.-C. Determination of the Shear Angle in the Orthogonal Cutting Process. J. Manuf. Mater. Process. 2022, 6, 132. [Google Scholar] [CrossRef]

- Storchak, M.; Drewle, K.; Menze, C.; Stehle, T.; Möhring, H.C. Determination of the Tool–Chip Contact Length for the Cutting Processes. Materials 2022, 15, 3264. [Google Scholar] [CrossRef] [PubMed]

- Heisel, U.; Storchak, M.; Krivoruchko, D. Thermal effects in orthogonal cutting. Production Engineering. Res. Dev. 2013, 7, 203–211. [Google Scholar] [CrossRef]

- Storchak, M.; Kushner, V.; Möhring, H.-C.; Stehle, T. Refinement of temperature determination in cutting zones. J. Mech. Sci. Technol. 2021, 35, 3659–3673. [Google Scholar] [CrossRef]

| No. | Year | Author(s) | Study Results |

|---|---|---|---|

| 1. | 1851 | Cocquilhat, C.M. [8] | The first scientific studies of the cutting process. Study of process energy in the drilling process. |

| 2. | 1868 | Tresca, H.E. [12] | The main mechanism of chip formation is the plastic deformation of the machined material. Chips during metal cutting are formed as a result of compression in the tool front. |

| 3. | 1870 | Time, I.A. [10] | Chip formation model with a single shear plane. The work input to the cutting zone is consumed by plastic deformation in the shear plane. |

| 4. | 1893 | Zworykin, K.A. [13] | Cutting model based on the principle of minimum potential energy. The energy balance equation takes into account the friction forces on the tool rake face. |

| 5. | 1896 | Bricks, A.A. [14] | A chip formation model with a wedge fan-shaped shear zone. A force equilibrium system is developed. |

| 6. | 1945 | Merchant, M.E. [18] | Chip formation model with a single shear plane. The shear angle depends on the machined material properties. |

| 7. | 1948 | Piispanen, V. [19] | A chip formation model with sequential shear elements (volumes) of the cutting layer. |

| 8. | 1949 | Lee, E.H.; Shaffer, B.W. [20] | A model with a plastic zone located in the chip above the shear plane. The shear plane is considered to be the lower boundary of this zone. The slip line method is used for analysis. |

| 9. | 1951 | Stabler, G.V. [49] | Oblique cutting model. Geometric analysis of cutting tool edge. The chip flow law is established. |

| 10. | 1960 | Albrecht, P. [68] | Model with a single shear plane for tools with rounded tips. Ploughing forces are taken into account. |

| 11. | 1965 | Kudo, H. [85] | Orthogonal cutting model with slip line fields. The cutting forces, chip curl radius, chip thickening coefficient, and the tool chip contact length as a function of the main cutting edge inclination angle and friction stress are calculated. |

| 12. | 1966 | Zorev, N.N. [23] | Chip formation model with a straight line fan. Tangential stresses in cutting and compression tests are equal in the case of equal strains. |

| 13. | 1989 | Oxley, P.L.B. [24] | A model for orthogonal and oblique cutting with a single shear plane and a slip line field. This field consists of two parallel slip lines. The effects of strain, strain rate, and temperature are taken into account. |

| 14. | 1998 | Waldorf, D.J. et al. [69] | A slip line model for predicting ploughing forces in orthogonal cutting. |

| 15. | 2001 | Marinov, V.R. [37] | Oxley model improvement takes into account the effect of deformation and strain rate in the secondary cutting zone. |

| 16. | 2003 | Fang, N. [86] | A slip line model divided into 27 sub-areas. |

| 17. | 2003 | Adibi-Sedeh, A.H. et al. [28] | Oxley model improvement through the application of different rheological material models. |

| 18. | 2003 | Huang, Y.; Liang, S.Y. [71] | Model for turning operations with tool tip radius and negative rake angle. Ploughing forces are taken into account. |

| 19. | 2003 | Atkins, A.G. [80] | Chip formation model with a single shear plane. The damage work of chip formation is taken into account. The impact toughness of the machined material is used to determine the damage work. |

| 20. | 2004 | Moufki, A. et al. [57] | An oblique cutting model takes into account the properties of the tool and the machined material, as well as general principles of mechanics, heat transfer, and tribology. The value of the chip flow angle is determined. |

| 21. | 2005 | Moufki, A.; Molinari, A. [59] | A chip formation model for three-dimensional turning conditions that takes into account thermomechanical effects. |

| 22. | 2007 | Rosenberg, Y.A. [43] | Model with a single shear plane. The tangential stresses in the shear plane are determined using the mechanical properties of the machined material’s initial state. |

| 23. | 2008 | Vorontsov, A.L. et al. [46] | A model with a rectangular zone in the tool front, the lower boundary of which is a continuation of the cutting plane. Friction stresses on the contact faces are determined by Siebel’s law. |

| 24. | 2008 | Karpat, Y.; Özel, T. [63] | A chip formation model for a tool with a hardening chamfer. The presence of a stagnant zone at the tool tip is taken into account. |

| 25. | 2008 | Astakhov, V.; Xiao, X. [81] | A model based on the energy analysis method. The damage power of new surface formation in the shear plane is taken into account. |

| 26. | 2009 | Dargnat, F. et al. [36] | Improvement of the Oxley model. The equations for determining the strain and strain rate are developed for three cutting zones: the zone of chip formation, the zone of contact between the tool and the chip, and the zone at the tool tip. |

| 27. | 2009 | Kushner, V.S. [79] | A model of chip formation using a tool with a stabilizing chamfer. A material rheological model that takes into account the simultaneous effects of strain and strain rate hardening as well as temperature softening. |

| 28. | 2010 | Ozlu, E. et al. [41] | A model that takes into account the plastic contact area and the elastic–plastic contact area in the interaction zone between the tool rake face and the chip. |

| 29. | 2014 | Olenin, L.D. et al. [84] | An oblique cutting model based on the principle of potential energy minimum. The ductile damage power during the formation of new surfaces is taken into account. The specific work of crack propagation is used for this purpose. |

| 30. | 2015 | Tsekhanov, J.; Storchak, M. [82] | Orthogonal cutting model based on the principle of minimum potential energy. Friction power on the tool clearance face is considered using the slip line method. |

| 31. | 2018 | Orra, K.; Sounak, K. [62] | A model for predicting cutting forces taking into account tools with rounded tips and tool wear. |

| 32. | 2019 | Wan, M. et al. [66] | A material separation model for the front of the cutting edge for theoretical calculation of the stagnant zone shape in micro-milling. |

| 33. | 2020 | Hu, C. et al. [65] | Slip line field model for machining with a tool using an insert with a hardening chamfer and considering the thermal load’s effect on the tool rake face. |

| 34. | 2022 | Aslantas, K. et al. [72] | Mechanical model of micro-turning. Cutting forces are predicted by taking into account the tool geometry. |

| Material | Strength (MPa) | Elastic Modulus (GPa) | Elongation (%) | Hard-ness | Poisson′s Ratio | Specific Heat (J/kg·K) | Thermal Expansion (µm/m·°C) | Thermal Conductivity (W/m·K) | |

|---|---|---|---|---|---|---|---|---|---|

| Tensile | Yield | ||||||||

| AISI 1045 | 690 | 620 | 206 | 12 | HB 180 | 0.29 | 486 | 14 | 49.8 |

| SNMG-SM-1105 | - | - | 650 | - | HRC 76 | 0.25 | 251 | - | 59 |

| Constitutive Parameters | ||||

|---|---|---|---|---|

| Initial Yield Stress, A (MPa) | Stress Coefficient of Strain Hardening, B (MPa) | Power Coefficient of Strain Hardening, n (–) | Strain Rate Coefficient, C (–) | Power Coefficient of Thermal Softening, m (–) |

| 594.5 | 682.4 | 0.3215 | 0.02364 | 0.91 |

| Constitutive Parameters | ||||

|---|---|---|---|---|

| Initial Yield Stress, A (MPa) | Stress Coefficient of Strain Hardening, B (MPa) | Power Coefficient of Strain Hardening, n (–) | Strain Rate Coefficient, C (–) | Power Coefficient of Thermal Softening, m (–) |

| 631.2 | 742.1 | 0.29368 | 0.027065 | 0.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Storchak, M.; Lekveishvili, M.A. Improvement of Analytical Model for Oblique Cutting—Part I: Identification of Mechanical Characteristics of Machined Material. Metals 2023, 13, 1750. https://doi.org/10.3390/met13101750

Storchak M, Lekveishvili MA. Improvement of Analytical Model for Oblique Cutting—Part I: Identification of Mechanical Characteristics of Machined Material. Metals. 2023; 13(10):1750. https://doi.org/10.3390/met13101750

Chicago/Turabian StyleStorchak, Michael, and Maria A. Lekveishvili. 2023. "Improvement of Analytical Model for Oblique Cutting—Part I: Identification of Mechanical Characteristics of Machined Material" Metals 13, no. 10: 1750. https://doi.org/10.3390/met13101750

APA StyleStorchak, M., & Lekveishvili, M. A. (2023). Improvement of Analytical Model for Oblique Cutting—Part I: Identification of Mechanical Characteristics of Machined Material. Metals, 13(10), 1750. https://doi.org/10.3390/met13101750