Numerical Simulation and Temperature Modeling of Magnesium Alloy Strip Rolled by Heated Roll

Abstract

:1. Introduction

2. Materials and Methods

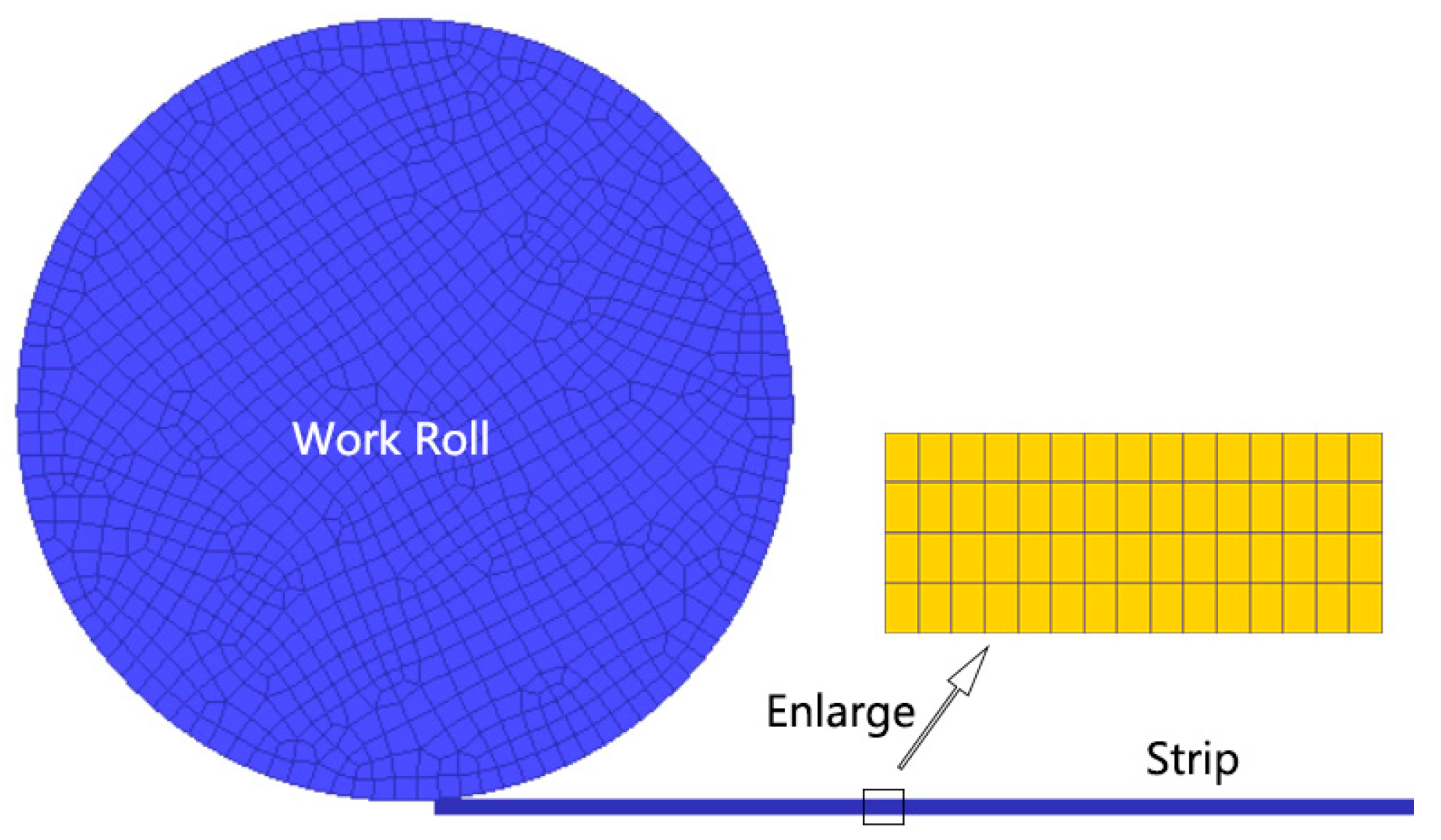

2.1. Finite Element Model

2.2. Test Methods for Hot Rolling

3. Results and Discussion

3.1. Temperature Analysis

3.2. Mechanical Analysis

3.3. Temperature

3.4. Experimental Validation and Application of the Model

4. Conclusions

- (1)

- When the metal particles transfer heat directly from the surface of the rolls, the temperature of the strip surface and core enters the rapid rise stage, at which time the maximum rate of temperature rise in the core is about 50 °C/s or more. When the strip approaches the outlet end, the surface temperature decreases slightly, but the core part continues to be heated until it reaches thermal equilibrium, and the cross-section temperature tends to be constant. Magnesium alloy has good thermal conductivity, and reasonable control of rolling parameters can realize dynamic recrystallization grain refinement of magnesium alloy strips through HSR-HR continuous large plastic deformation.

- (2)

- In the process of NSR-HR, the direct heat transfer from the roll to the rolled part makes the softening play a dominant role, and the stress value gradually decreases from the middle of the deformation zone to the inlet and outlet ends. The strain value of the strip surface is larger than that of the center at the front slip area, and the strain value of the strip surface is slightly smaller than that of the center at the back slip area. The constant velocity variation increases first and then decreases from the inlet end to the outlet end, and the strain rate of each particle in the deformation zone is different during the rolling process, resulting in uneven deformation.

- (3)

- The average temperature at the strip outlet rises linearly with the increase in rolling temperature and reduction. The average temperature at the strip outlet decreases exponentially with the increase in rolling speed and initial thickness. The outlet temperature is the most sensitive to the rolling speed, followed by the initial thickness. A prediction model of strip temperature for the hot rolling process including the rolling temperature, reduction rate, rolling speed, and initial thickness was constructed according to the variation rule of outlet temperature. The predicted temperature of the model is in good agreement with the experimental results, with relative errors of less than 10% accounting for 90% of the total data. The constructed temperature prediction model is reliable and capable of accurately predicting the strip outlet temperature during the hot rolling process. It can also realize the adjustment and optimization of hot rolling process parameters under known ideal temperature conditions. In addition, the fitting methods provide references of theoretical significance for modeling parametric equations and nonlinear relationships among variables in other plastic processing processes.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Xu, T.; Yang, Y.; Peng, X.; Song, J.; Pan, F. Overview of advancement and development trend on magnesium alloy. J. Magnes. Alloys 2019, 7, 536–544. [Google Scholar] [CrossRef]

- Singh, N.; Batra, U.; Kumar, K.; Ahuja, N.; Mahapatro, A. Progress in bioactive surface coatings on biodegradable Mg alloys: A critical review towards clinical translation. Bioact. Mater. 2023, 19, 717–757. [Google Scholar] [CrossRef]

- Miyano, H.; Takemoto, K.; Tsushida, M.; Kitahara, H.; Ando, S. Evaluation of Non-Basal Slip Activity in Rolled Mg-Li Alloys. Mater. Trans. 2021, 62, 1097–1101. [Google Scholar] [CrossRef]

- Han, S.; Li, Z.; Wang, Z.; Li, Y. Review on joining processes of magnesium alloy sheets. Int. J. Adv. Manuf. Technol. 2022, 118, 2787–2803. [Google Scholar] [CrossRef]

- Pan, F.; Jiang, B. Development and Application of Plastic Processing Technologies of Magnesium Alloys. Acta Metall. Sin. 2021, 57, 1362–1379. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Prangnell, P.B.; Priestner, R. Fine-grained alloys by thermomechanical processing. Curr. Opin. Solid State Mater. Sci. 2001, 5, 15–21. [Google Scholar] [CrossRef]

- Bi, X.; Hu, Y.; Li, R.; Zhao, H.; Li, T. A novel method for preparing Al/Mg/Al laminated composite material, processing maps and interface diffusion analysis. J. Alloys Compd. 2022, 900, 163417. [Google Scholar] [CrossRef]

- Gao, H.-T.; Kong, C.; Yu, H.-L. Lightweight metal laminated plates produced via (hot, cold and cryogenic) roll bonding: A review. Trans. Nonferrous Met. Soc. China 2023, 33, 337–356. [Google Scholar] [CrossRef]

- Pan, F.; Zeng, B.; Jiang, B.; Zhang, M.; Dong, H. Enhanced mechanical properties of AZ31B magnesium alloy thin sheets processed by on-line heating rolling. J. Alloys Compd. 2017, 693, 414–420. [Google Scholar] [CrossRef]

- Chen, W.Z.; Zhang, W.C.; Zhang, L.X.; Wang, E.D. Property improvements in fine-grained Mg-Zn-Zr alloy sheets produced by temperature-step-down multi-pass rolling. J. Alloys Compd. 2015, 646, 195–203. [Google Scholar] [CrossRef]

- Guo, J.; Sun, W.; Xiang, N.; Chen, F. Interfacial Bonding and Fracture Behaviors of AZ63 Magnesium Alloy Sheet Processed by Accumulative Roll Bonding. Materials 2023, 16, 4981. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, H.; Wang, M.; Jia, H.; Han, H.; Ma, P. Microstructure and Mechanical Properties of Al-Mg-Si Similar Alloy Laminates Produced by Accumulative Roll Bonding. Materials 2021, 14, 4200. [Google Scholar] [CrossRef]

- Mehr, V.Y.; Toroghinejad, M.R. On the texture evolution of aluminum-based composites manufactured by ARB process: A review. J. Mater. Res. Technol.-JmrT 2022, 21, 1095–1109. [Google Scholar] [CrossRef]

- Lee, S.-E.; Kim, M.-S.; Chae, Y.-W.; Guim, H.; Singh, J.; Choi, S.-H. Effect of intermediate heat treatment during hot rolling on the texture and formability of annealed AZ31 Mg alloy sheets. J. Alloys Compd. 2022, 897, 163238. [Google Scholar] [CrossRef]

- Wang, R.; Xu, Z.; Jiang, Y.; Tang, G.; Wan, J.; Li, Q. Design high-performance AZ31 ultrathin strip through multi-pass electroplastic rolling without off-line annealing. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2023, 862, 144510. [Google Scholar] [CrossRef]

- Fisher, R.B. A rolling mill with heated roll device. Heavy Mach. 1964, 13, 30–32. [Google Scholar] [CrossRef]

- Mei, R.-B.; Bao, L.; Huang, F.; Zhang, X.; Qi, X.-W.; Liu, X.-H. Simulation of the flow behavior of AZ91 magnesium alloys at high deformation temperatures using a piecewise function of constitutive equations. Mech. Mater. 2018, 125, 110–120. [Google Scholar] [CrossRef]

- Fukuoka, H.; Huang, X.; Suzuki, K.; Tsukada, Y.; Koyama, T.; Chino, Y. Effect of Rolling Temperature on Room Temperature Formability and Texture Formation of Mg-3 mass%Al-1 mass%Sn Alloy Sheet. J. Jpn. Inst. Met. Mater. 2021, 85, 120–127. [Google Scholar] [CrossRef]

- Li, R.; Xiao, Z.; Li, Z.; Meng, X.; Wang, X. Work Hardening Behavior and Microstructure Evolution of a Cu-Ti-Cr-Mg Alloy during Room Temperature and Cryogenic Rolling. Materials 2023, 16, 424. [Google Scholar] [CrossRef]

- Vignesh, P.; Abraham, A.; Kumaran, S. Microstructural correlation of cross rolling temperature of AT55 magnesium alloy in mechanical and formability behaviour. Micron 2022, 160, 103305. [Google Scholar] [CrossRef]

- Wang, J.; Guo, L.; Wang, C.; Zhao, Y.; Qi, W.; Yun, X. Prediction of Dynamically Recrystallized Microstructure of AZ31 Magnesium Alloys in Hot Rolling Using an Expanded Dislocation Density Model. J. Mater. Eng. Perform. 2023, 32, 2607–2615. [Google Scholar] [CrossRef]

- Yu, C.; He, Z.; Lv, Q.; Yu, J.; Xiao, H. Preparation of Ti/Al composite plates by differential temperature rolling with induction heating. Int. J. Adv. Manuf. Technol. 2021, 117, 383–394. [Google Scholar] [CrossRef]

- Zhou, L.; Wu, Z.; Li, Y.; Yao, H.; Liu, Y.; Yuan, Y.; Meng, W.; Han, L.; Cao, X. Temperature characteristics of indentation rolling resistance of belt conveyor. J. Mech. Sci. Technol. 2023, 37, 4125–4135. [Google Scholar] [CrossRef]

- Cai, L.; Feng, Y.; Lu, Y.-T.; Lin, Y.-F.; Hung, T.-P.; Hsu, F.-C.; Liang, S.Y. Analytical Model for Temperature Prediction in Milling AISI D2 with Minimum Quantity Lubrication. Metals 2022, 12, 697. [Google Scholar] [CrossRef]

- Yu, H.-L.; Yu, Q.-B.; Kang, J.-W.; Liu, X.-H. Investigation on Temperature Change of Cold Magnesium Alloy Strips Rolling Process with Heated Roll. J. Mater. Eng. Perform. 2012, 21, 1841–1848. [Google Scholar] [CrossRef]

- Sun, T.; Li, J.-P. Method for Outlet Temperature Control during Warm Rolling of AZ31 Sheets with Heated Rolls. Isij Int. 2017, 57, 1577–1585. [Google Scholar] [CrossRef]

- Zou, J.-F.; Ma, L.-F.; Zhang, G.-H.; Huang, Z.-Q.; Lin, J.-B.; Liu, P.-T. Controlling Roll Temperature by Fluid-Solid Coupled Heat Transfer. Chin. J. Mech. Eng. 2018, 31, 93. [Google Scholar] [CrossRef]

- Lee, H.-W.; Yoo, J.-H.; Kwon, Y.-C.; Kang, J.-H. Calculation Method for Cold Flow Stress of Al6082 Based on Tensile Test and Compression Test Results. Int. J. Precis. Eng. Manuf. 2021, 22, 1337–1344. [Google Scholar] [CrossRef]

- Romanova, T.P.; Yankovskii, A.P. Structural model for spatially and flatly reinforced medium of rigid-plastic materials considering three-dimensional stress state in all components. Mech. Adv. Mater. Struct. 2022, 29, 2668–2679. [Google Scholar] [CrossRef]

- Yu, Z.; Zhu, C.; Chen, M.; Luo, S.; Ma, C. 3D FE modeling simulation of the double-roll hot rotary forging of large diameter thin-walled metal disk. Int. J. Adv. Manuf. Technol. 2022, 123, 2123–2137. [Google Scholar] [CrossRef]

- Ding, Y.; Zhu, Q.; Le, Q.; Zhang, Z.; Bao, L.; Cui, J. Analysis of temperature distribution in the hot plate rolling of Mg alloy by experiment and finite element method. J. Mater. Process. Technol. 2015, 225, 286–294. [Google Scholar] [CrossRef]

- Raghunath, B.K.; Raghukandan, K.; Karthikeyan, R.; Palanikumar, K.; Pillai, U.T.S.; Gandhi, R.A. Flow stress modeling of AZ91 magnesium alloys at elevated temperature. J. Alloys Compd. 2011, 509, 4992–4998. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mei, R.; Chen, L.; Bao, L.; Li, C.; Liu, X. Numerical Simulation and Temperature Modeling of Magnesium Alloy Strip Rolled by Heated Roll. Metals 2023, 13, 1785. https://doi.org/10.3390/met13101785

Mei R, Chen L, Bao L, Li C, Liu X. Numerical Simulation and Temperature Modeling of Magnesium Alloy Strip Rolled by Heated Roll. Metals. 2023; 13(10):1785. https://doi.org/10.3390/met13101785

Chicago/Turabian StyleMei, Ruibin, Lihao Chen, Li Bao, Changsheng Li, and Xianghua Liu. 2023. "Numerical Simulation and Temperature Modeling of Magnesium Alloy Strip Rolled by Heated Roll" Metals 13, no. 10: 1785. https://doi.org/10.3390/met13101785