Abstract

In the automobile industry, high-strength plates are increasingly used to reduce vehicle weight due to strict regulations on fuel efficiency and safety, and these plates achieve a tensile strength of 1500 MPa due to the hot-stamping process. Recently, research has been conducted to examine the flow behavior of materials according to the relationship between hot stamping time-temperature characteristics, coil shape, cooling method, and thermodynamic flow characteristics of quenching materials. In this study, a basic experiment in the form of a plate was conducted using an eddy current generated during high-frequency induction heating. It presents the surface temperature change, mechanical characteristics, and microstructure of boron steel that has undergone a high-frequency induction heating process. Surface temperature data were analyzed at different high-frequency induction heating forces (15, 18, 21, 24, 27, and 30 kW) and distances from specimens (6, 9, 12, and 15 mm). Two phases, austenite and ferrite, were formed in the low-temperature region, and martensite was formed in the high-temperature region. Mechanical properties and microstructures were also analyzed under different high-frequency induction heating coil conditions. The correlation between the high-frequency induction heating force and the specimen with the maximum tensile strength was investigated. Due to high-frequency induction heating, scale generation and surface decarbonization can be avoided. As a result of this experiment, 1500 MPa of the same tensile strength as the mechanical characteristics obtained in the existing heat treatment could be obtained.

1. Introduction

Policies to regulate the automotive industry for fuel economy as well as greenhouse gas and exhaust gas emissions have been implemented and will be continuously reinforced until the early or mid-2020s [1]. Various types of steel, from general to ultra-high strength, are currently used in automotive bodies; thus, the research and development of new types of steel with high formability and strength are also being accelerated to reduce the weight of automotive bodies [2,3].

Currently, the auto parts industry is undergoing research on the development of lightweight and rigid technologies using high strength, and as a way of doing so, research on improving existing structures and developing auto parts for materials with lightweight characteristics are actively underway [4,5,6,7]. In particular, it will be a more positive opportunity due to the growth of the eco-friendly vehicle market, including hydrogen vehicles, hybrid electric vehicles, and electric vehicles. The global market size of hybrid electric vehicles is expected to grow to more than 800,000 in 2010 but to 9 million in 2025, and the demand for lightweight parts will continue to increase to improve energy efficiency and performance, especially after 2020 when fuel efficiency regulations in Europe and North America are implemented [8].

Ultra-high-strength steel sheets of up to 1.5 to 2.0 GPa are applied to automobile body parts, and replacing general steel with ultra-high-strength steel sheets reduces the thickness of the product and removes the reinforcement, enabling significant weight reduction in the body [9,10]. With the expansion of the application of GIGA-class ultra-high-strength steel sheets, processes such as hot stamping and roll forming are being used along with existing press molding processes to manufacture parts for vehicle bodies. Among them, the hot stamping method is a technology that can manufacture steel sheets with a maximum tensile strength of 1.5 GPa and is actively introduced and applied by domestic and foreign automakers [11].

Currently, a lot of high-strength steel is applied. However, due to the limitation of press formability, thickness is increased or reinforcement is added to areas that require high strength. This method has a problem of increasing weight and cost. Therefore, in order to solve this problem, we are studying a high-frequency heat treatment technology that strengthens the product locally using high-frequency induction heating after press molding the plate.

In high-frequency induction heating, a high-frequency current flow and a magnetic field are generated when an alternating current (AC) is applied to a high-frequency coil. Heat is generated due to the resistance of the metal by inducing a secondary current [12]. Heat is transferred from the surface to the inside of the coil, whereas the current is concentrated on the surface of the object to be heated. The physical characteristics of steel materials are affected by the coil shape, high-frequency induction power, and cooling conditions [13]. Under high-frequency induction heating, the mechanical characteristics of the steel change due to the conduction of heat from the surface inside of the material [14,15].

Recently, such studies have expanded to automotive parts. Hyun et al. [16] studied the mechanical properties of general steel plates subjected to high-frequency induction heating and analyzed the changes in the mechanical properties. They also tested the tensile strength, impact, and hardness under various cooling conditions. Kolleck et al. [17] designed a coil shape for applying high-frequency induction heating in the hot-stamping process and reported that the material strength was improved depending on the cooling method. Local heat treatment of boron steel was studied via high-frequency induction heating, but no parts with characteristics were obtained. It has attracted the attention of many researchers as a key part of the induction heating process. Although the hot-stamping process has been developed for the production of 1500 MPa-grade ultra-high-strength steel for automobiles, the process suffers from high manufacturing costs, a low production rate, and requires local heat treatments for areas where greater strength is required.

As a rule of thumb, studies have shown that the elongation of steel increases when the strength decreases, and vice versa [18]. As the strength of the steel increases, the spring-back phenomenon (in which the steel returns to its original state due to the lack of elastic restoration during press forming) occurs, making the processing of complicated shapes challenging [19]. To address this formability problem, the hot-stamping process was recently developed [20,21], in which boron steel with excellent hardenability [22,23] is heated and formed at above 900 °C (equal to or higher than that of AC3). Moreover, few studies have analyzed the changes in physical characteristics due to the high-frequency induction heating method; however, high-frequency induction heat is rapidly increasing in popularity, thereby reducing time and avoiding scale generation.

In this study, the process standards of longitudinal heating (LH), which is a high-frequency induction heating method, were investigated to locally change boron steel into 1500-MPa grade ultra-high-strength steel. Experiments on various temperature-related variables, such as the coil power and the distance from the boron steel specimen, were conducted, and optimal conditions were evaluated. The physical characteristics of the boron steel material were examined after heat treatment using high-frequency induction heating. Based on these experimental results, changes in the metal structure of the boron steel material by the main variables were investigated to determine the optimization direction and causes of strength reduction.

2. Eddy Current of High-Frequency Induction

Induction heating has been widely used in casting, molding, welding and heat treatment, and annealing metal materials as a complex electromagnetic temperature–stress multi-field coupling heating process. The main variables of high-frequency induction heating include the coil shape, power, and frequency, but the actual penetration depth of heat may also vary depending on the material type. The power absorbed by the workpiece during induction heating is determined by the shape of the workpiece (flat or cylindrical) in a constant magnetic field. Moreover, the penetration depth of heat by high-frequency power is determined by the coil shape and length. To obtain the desired properties of the material, an understanding of the high-frequency induction heating system is essential [13]. The heating coil and coil power are very important for high-frequency induction heating and for maintaining product quality in the case of heat treatment or the joining of metals.

To power high-frequency induction heating, high-frequency power sources are selected. In addition, the thermal power transferred to the heated part varies with the power density, heating temperature, cooling rate, and material preprocessing conditions. Therefore, the frequency and power are determined by the power capacity, heating temperature, and time required for high-frequency induction heating.

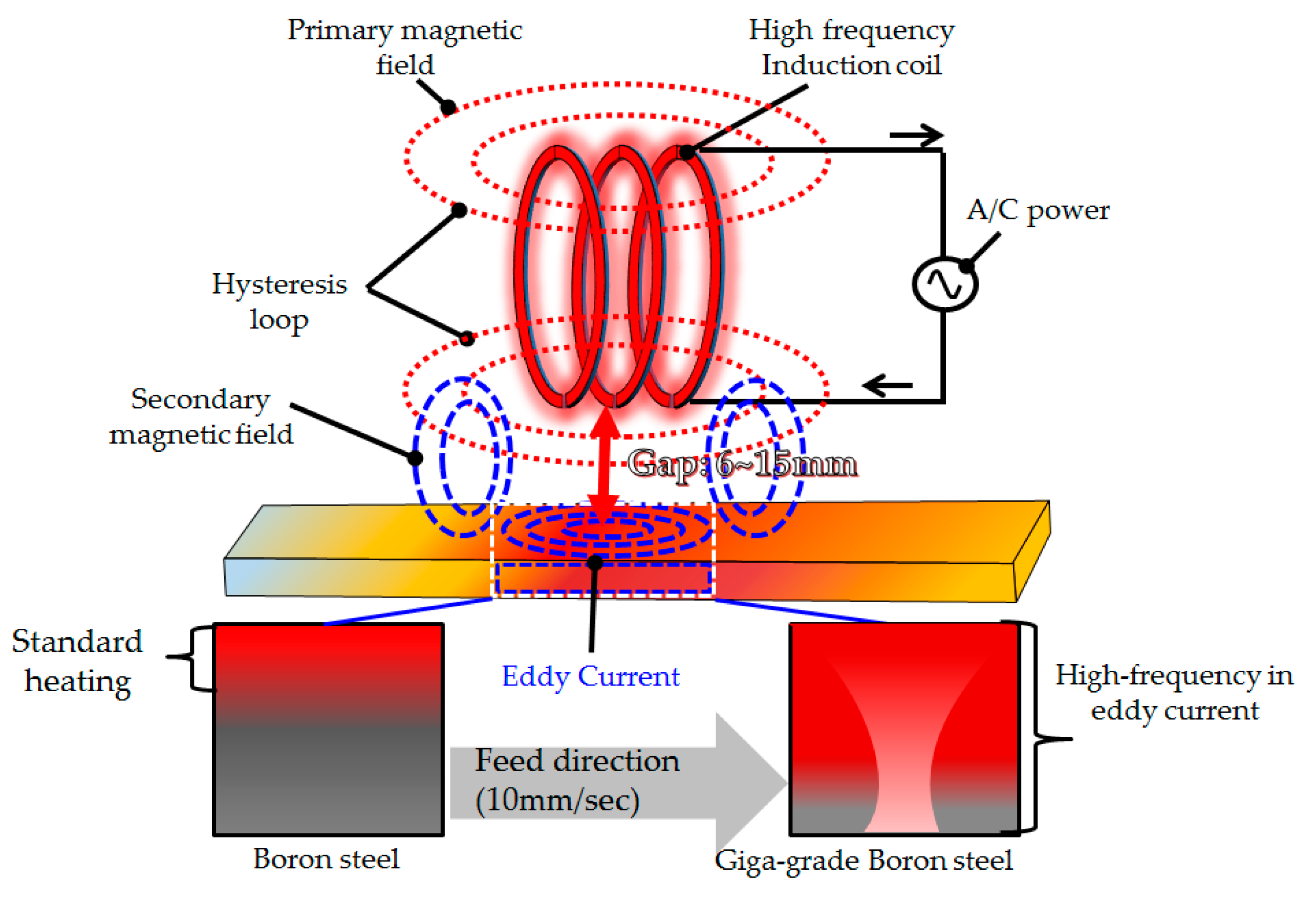

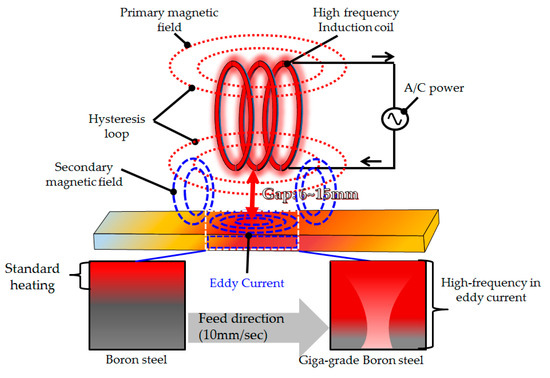

Figure 1 shows the structure of high-frequency induction heating by eddy currents. An eddy current heating method by high-frequency induction heating was used. When the high-frequency induction coil was moved to the specimen to be heated and the high-frequency AC flowed into the coil, a high-frequency primary magnetic field was generated. The direction of the high-frequency magnetic flux drew a hysteresis loop and penetrated the specimen through the secondary magnetic field. The current, which is referred to as an eddy current, was generated in the specimen by the magnetic field, and the temperature of the specimen increased due to heating. The boron steel material formed an austenite structure on ferrite and pearlite phases when heated at temperatures higher than 900 °C [14]. Due to the phase transformation of martensite after the high-frequency induction heating process, the tensile strength increased to 1500 MPa, and the elongation decreased to 5% [13].

Figure 1.

Schematic process drawings of the eddy current method, which is a high-frequency induction heating method.

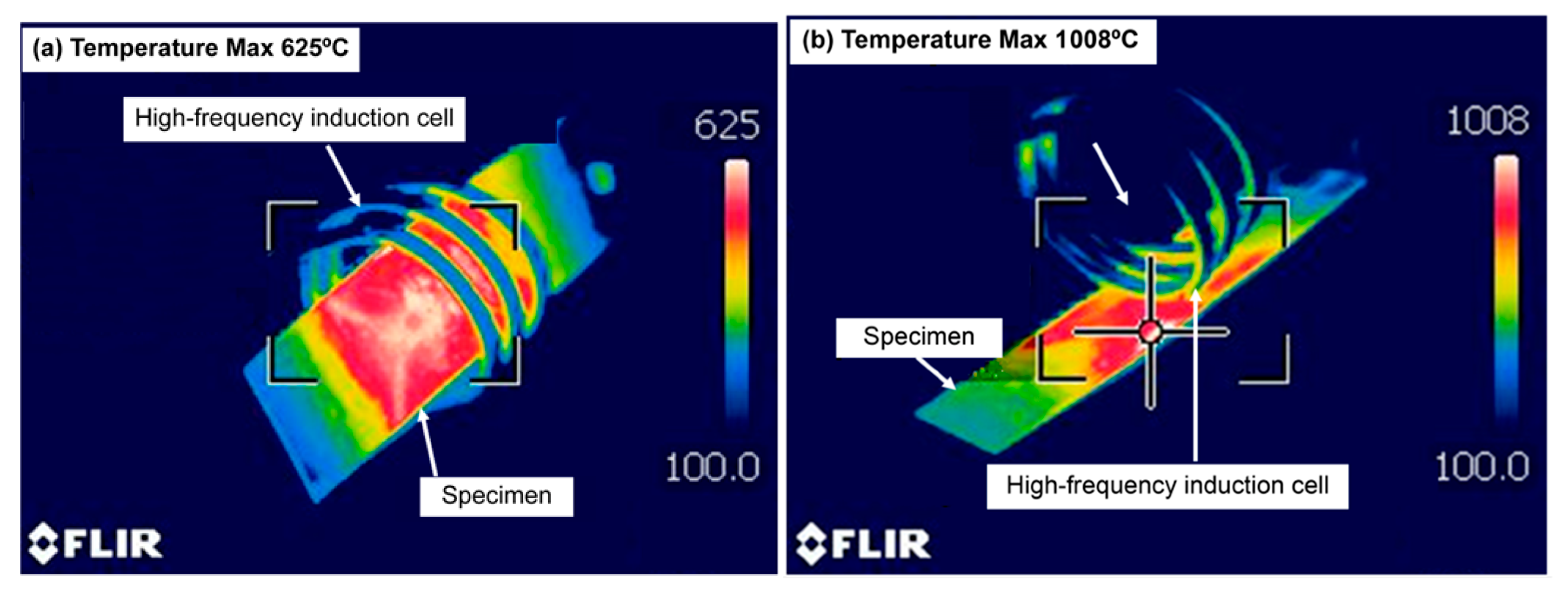

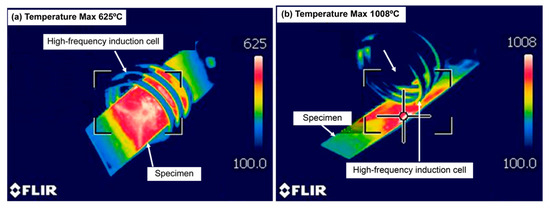

Figure 2 shows the heat treatment results of the transverse heating (TH) and LH methods, which were applied using the maximum high-frequency induction heating power of 30 kW. In Figure 2a, the heated object is located inside the high-frequency induction coil. This method is mostly applied to pipe-shaped specimens. In Figure 2b, the high-frequency induction heating coil is located outside the specimen. Depending on the high-frequency induction heating coil method, the heating temperature applied from the outside reached a minimum of 625 °C and a maximum of 1008 °C. This confirmed that heating outside the coil produced a higher maximum temperature than heating inside the coil under the same coil power conditions. The LH method exhibited higher heat treatment efficiency because the secondary magnetic field of the high-frequency AC was affected locally. Therefore, the role of the high-frequency induction heating coil was very important depending on the penetration depth (δ), specimen thickness (t), and length (d). The maximum strength is achieved after quenching above Ac3, which was not necessarily higher than 900 °C [24]. This indicates that the LH method can achieve excellent local heat treatment during the high-frequency induction heating process.

Figure 2.

Photo of high-frequency induction heating coil methods: (a) transverse heating method; (b) longitudinal heating method.

3. Experimental Procedure

In this study, boron steel coated with Al–Si, which is typically applied to commercial automobiles, was used. The test specimen size of the plate was 100 mm in length, 200 mm in width, and 1.2 mm in thickness. The experimental material was boron steel plates. The chemical composition of the steel plate is listed in Table 1. Boron effectively improves the hardenability of steel, even when a trace of several tens of ppm is added; thus, studies have long been conducted to replace costly hardenability elements, such as Ni, Cr, and Mo, with boron [17]. Although various mechanisms for hardenability improvement by boron addition have been proposed, boron is segregated in the austenite grain boundary and reduces the energy of the grain boundary [18]. However, it would not actually be a hardenability loose effect, but rather a reduction in the effectiveness of boron because its solid solubility in steel is low, and it easily forms precipitates (e.g., AlN, BN, and M23(C,B)6) in the grain boundary depending on the alloying elements or the heat treatment conditions [19].

Table 1.

Chemical composition of boron steel.

Table 2 shows the mechanical properties of boron steel before and after heat treatment. As the hardenability of steel is significantly improved when boron is added (0.020–0.030 wt%), the alloying elements and heat treatment conditions are very important to obtain the maximum hardenability [25]. In general, boron steel is adopted in press-hardening (PH) techniques due to its low formation. The PH process is a thermo-mechanical sheet-metal molding process in which the blank is first heated to a full austenite temperature and then molded and quenched in a mold

Table 2.

Mechanical properties of boron steel.

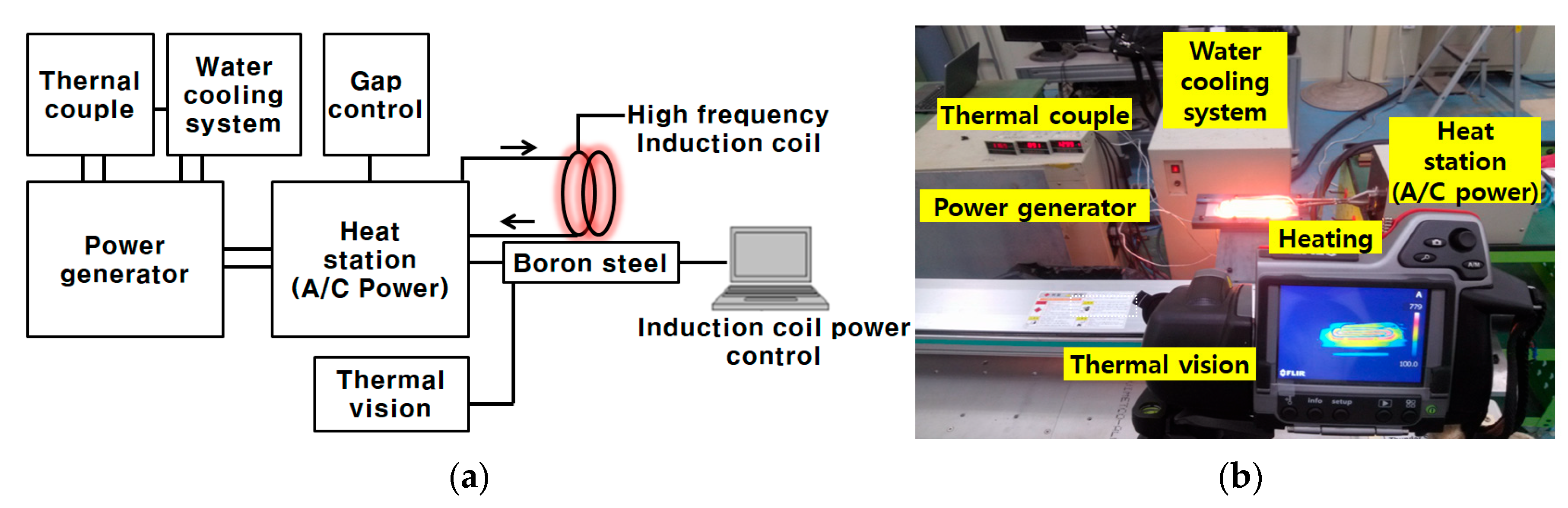

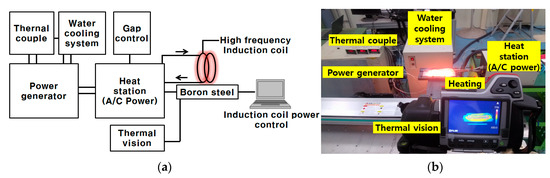

Figure 3 shows the experimental setup for the high-frequency induction heating LH method, which uses eddy currents. The coil diameter is 120mm and the number of coils is applied. The high-frequency induction heater (PSIH series, PSTEK Corp., Gunpo-Gyeonggi, Republic of Korea) used the 380-V 3Φ power supply; the coil power was from 15 to 30 kW, and the maximum travel speed was 30 mm per minute. The temperature field was checked using Thermal vision (T540, Flir Corp., Wilsonville, OR, USA). System integration was performed using a jig, an induction coil, a specimen temperature measurement device (thermal imaging cameras and thermocouples were measured in the central area of the specimen), and a cooling device. The system was heated to the target temperature in the fixed state; then, transport and continuous water quenching were applied.

Figure 3.

High-frequency induction heating system: (a) schematic diagram of high-frequency induction heating equipment; (b) experimental setup of high-frequency induction heating.

Table 3 shows the experimental conditions for high-frequency induction heating, which affects the maximum heat transfer depending on the coil power. The output of the high-frequency induction heating coil was fine at 15–30 kW through a dial gauge at 3 kW intervals, and the interval between the heating coil and the boron steel specimen was set between 6 and 15 mm.

Table 3.

Conditions of high-frequency induction heating.

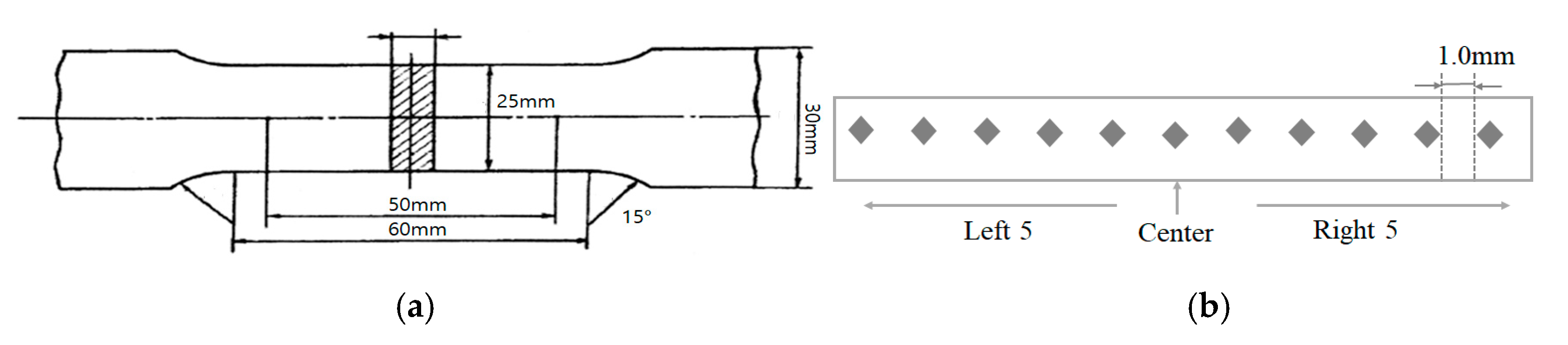

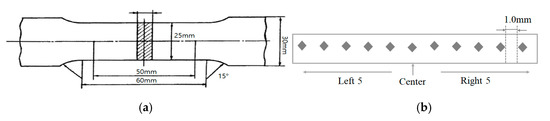

Figure 4a shows the specimen for the tensile test, which was performed by processing a specimen subjected to high-frequency induction heating using a waterjet (SJA-1224, Tops Corp., Siheung-Gyeonggi, Republic of Korea) for standard specimen production. The tensile strength was measured using a tensile tester (ESM 1500, Exstec Corp., Bucheon-Gyeonggi, Republic of Korea) in accordance with ASTM E8. In the test method, a fixing jig was installed so that the RAM mounted on the universal material tester (UTM) was located, and then the RAM was set to have a moving speed of 50 mm/min, and a static load was applied vertically to the specimen. Figure 4b shows the measurement positions in the hardness test. The hardness was measured using a micro-Vickers hardness tester (Tukon 2100 series, Powertech Corp., Gwangju, Republic of Korea). A 98-N load was applied to the specimen. The hardness was measured at 10 points located on the left and right sides of the center at 1 mm intervals.

Figure 4.

Specimen configuration of tensile strength test and micro-Vickers hardness. (a) Schematic diagram of specimen for the tensile test; (b) schematic diagram of specimen for micro-Vickers hardness.

To analyze the microstructures of the parts fabricated by each high-frequency induction heating power, a scanning electron microscope (S-4800, Hitachi Corp., Tokyo, Japan) was used. Specimens were prepared by processing the plates subjected to high-frequency induction heating into the size of 10 mm × 10 mm. The specimens were observed after polishing with 1 μm diamond paste.

4. Results and Discussion

4.1. Temperature Characteristics of the LH Method

The main variables that can be adjusted in the high-frequency induction heater are the coil power, the distance between the coil, and the mean values of three specimens (r). The tensile strength obtained depends on the heat treatment of boron steel; temperatures of 900 °C or higher are required to reach the maximum strength after quenching from above Ac3, which is not necessarily higher than 900 °C [26].

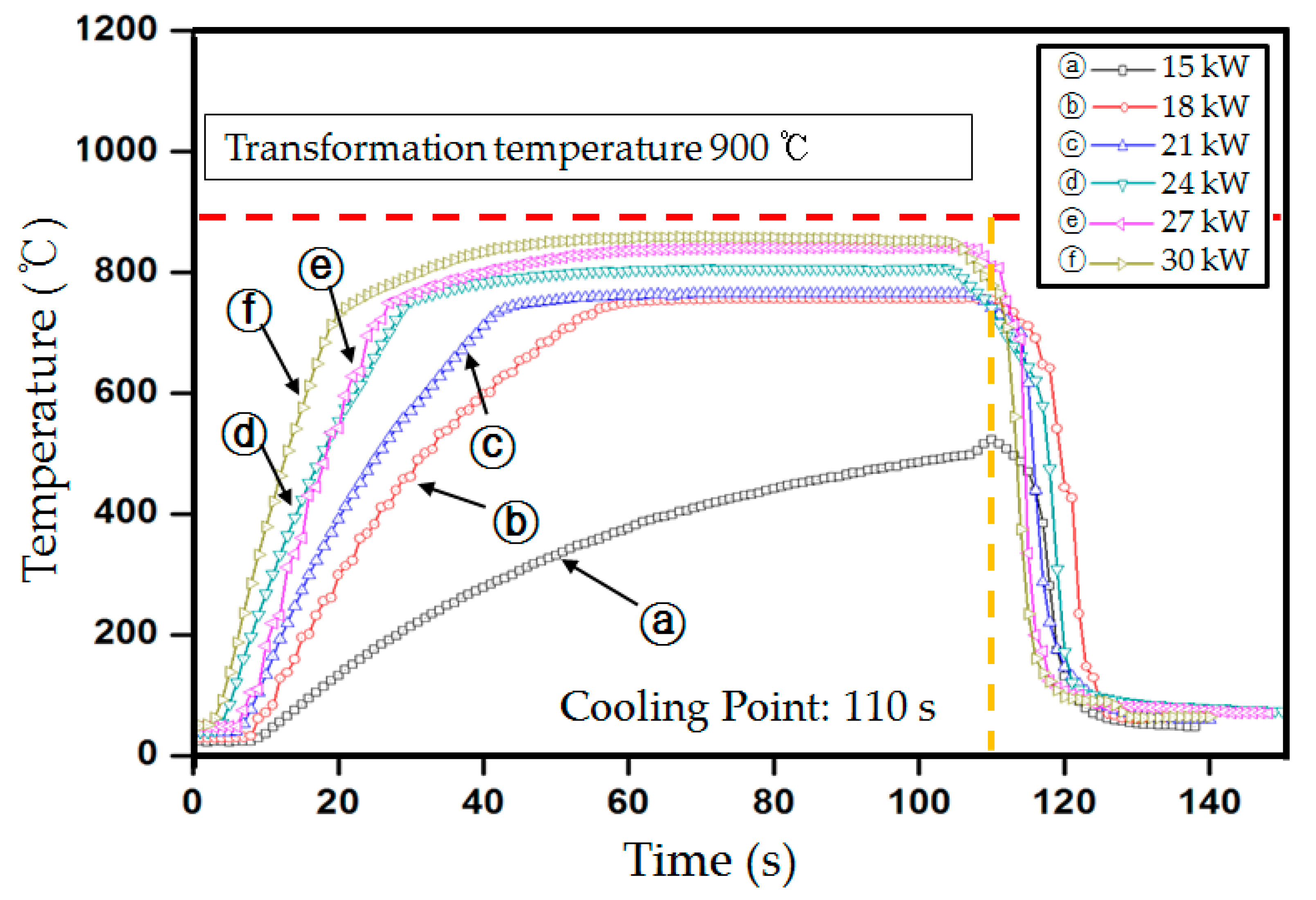

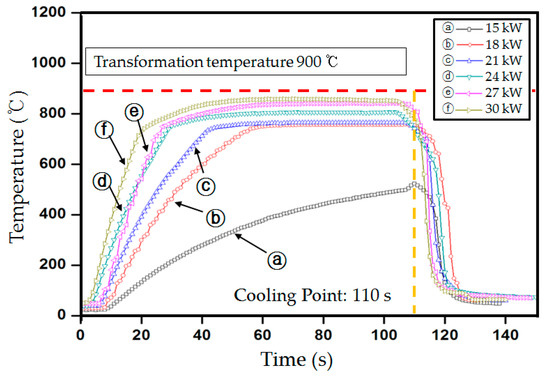

Figure 5 shows the results obtained when the coil power increased from 15 kW to the maximum output of 30 kW in 3-kW intervals, whereas the distance between the boron steel specimen and the fixed position of the coil stopped at 15 mm. The temperature increased after 20 s, except for at a coil power of 15 kW, and converged to a certain value before 50 s in all the cases. However, the target temperature of 900 °C could not be reached.

Figure 5.

Temperature variations with the high-frequency coil power.

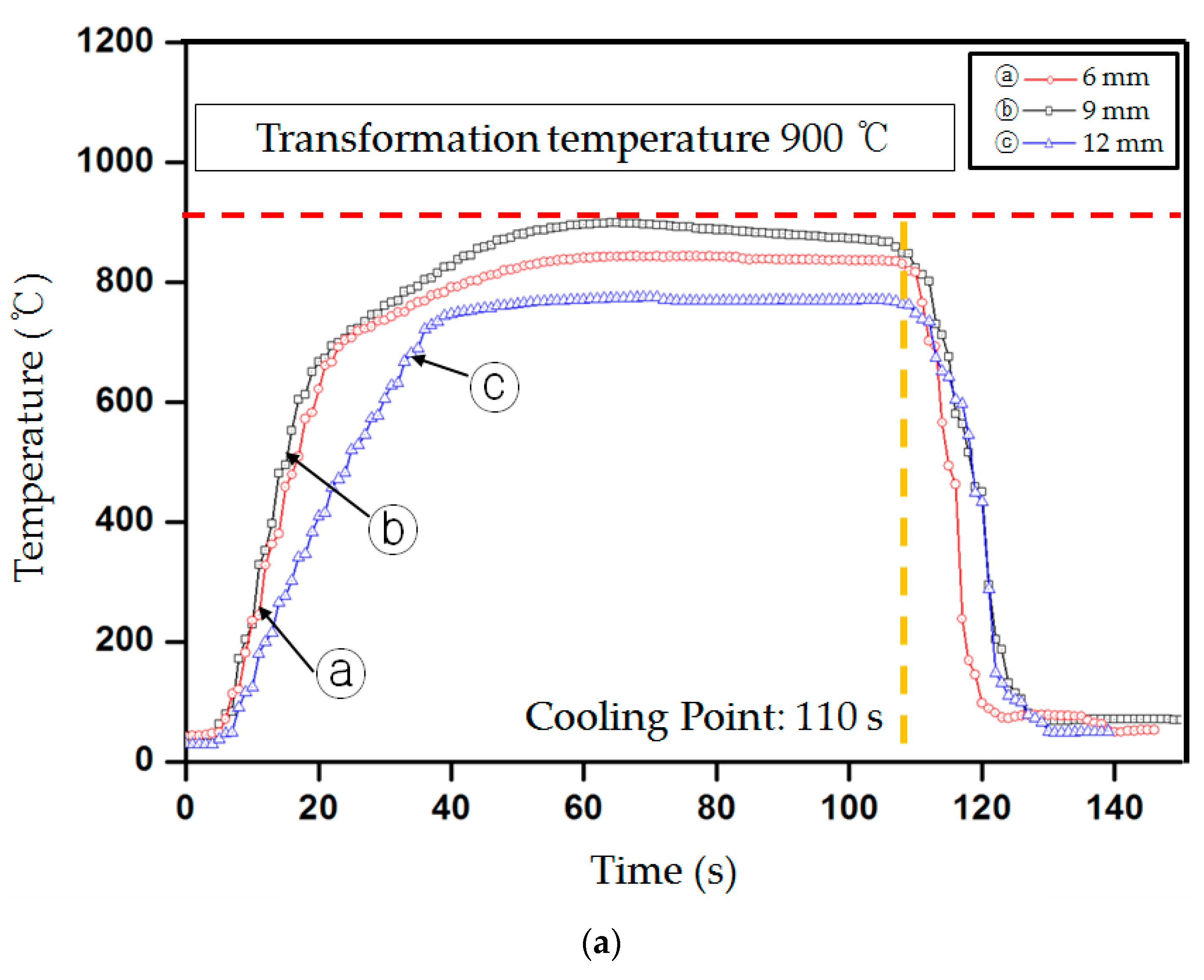

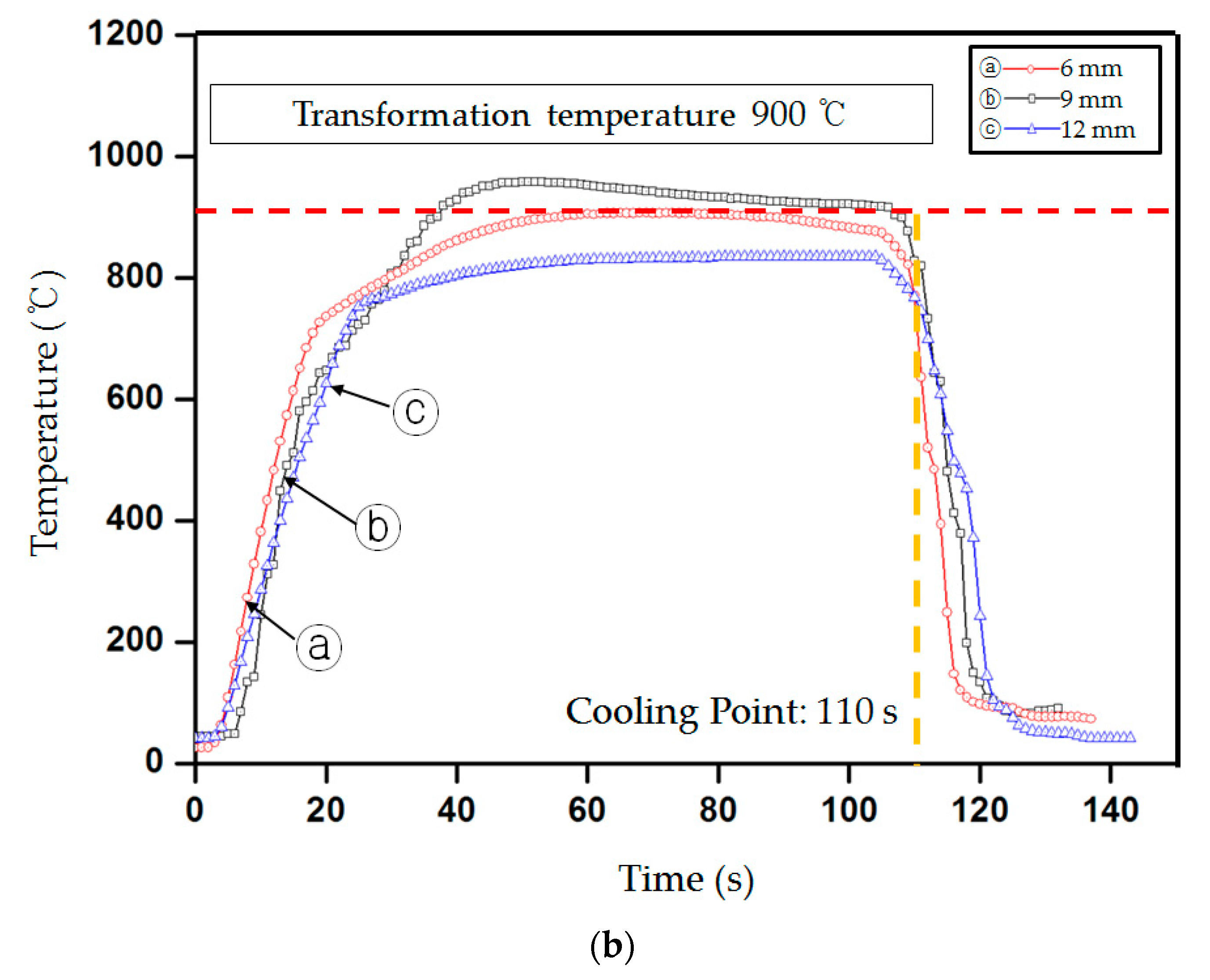

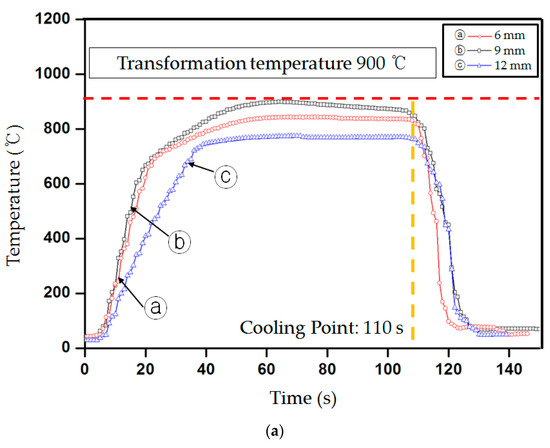

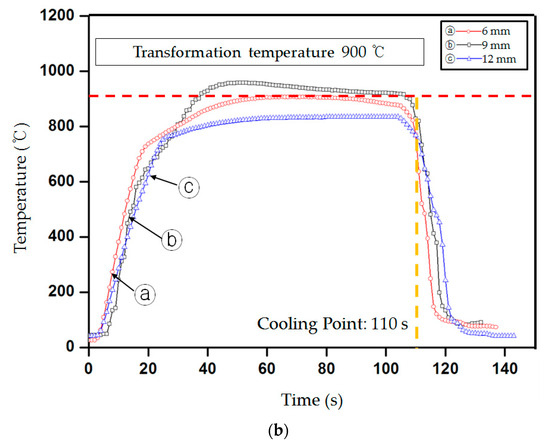

Figure 6 shows the results of the temperature measurements at coil powers of 21 and 24 kW and distances of 6, 9, and 12 mm. As the distance decreased, the temperature became closer to the target value. As displayed in Figure 6a, the surface temperatures were 898, 843, and 775 °C at the distances of 6, 9, and 12 mm, respectively, under a coil power of 21 kW. In Figure 6b, the surface temperatures are 952, 907, and 835 °C at the distances of 6, 9, and 12 mm, respectively, under a coil power of 24 kW. The target temperature of 900 °C was maintained at a coil power of 24 kW and a distance of 6 or 9 mm. As a result, as the distance decreased, the temperature became closer to the target value.

Figure 6.

Temperature variations with the distance from the specimen at the coil power of 21 and 24 kW: (a) coil power: 21 kW, distance: 6, 9, and 12 mm; (b) coil power: 24 kW, distance: 6, 9, and 12 mm.

4.2. Evaluation of Mechanical Properties

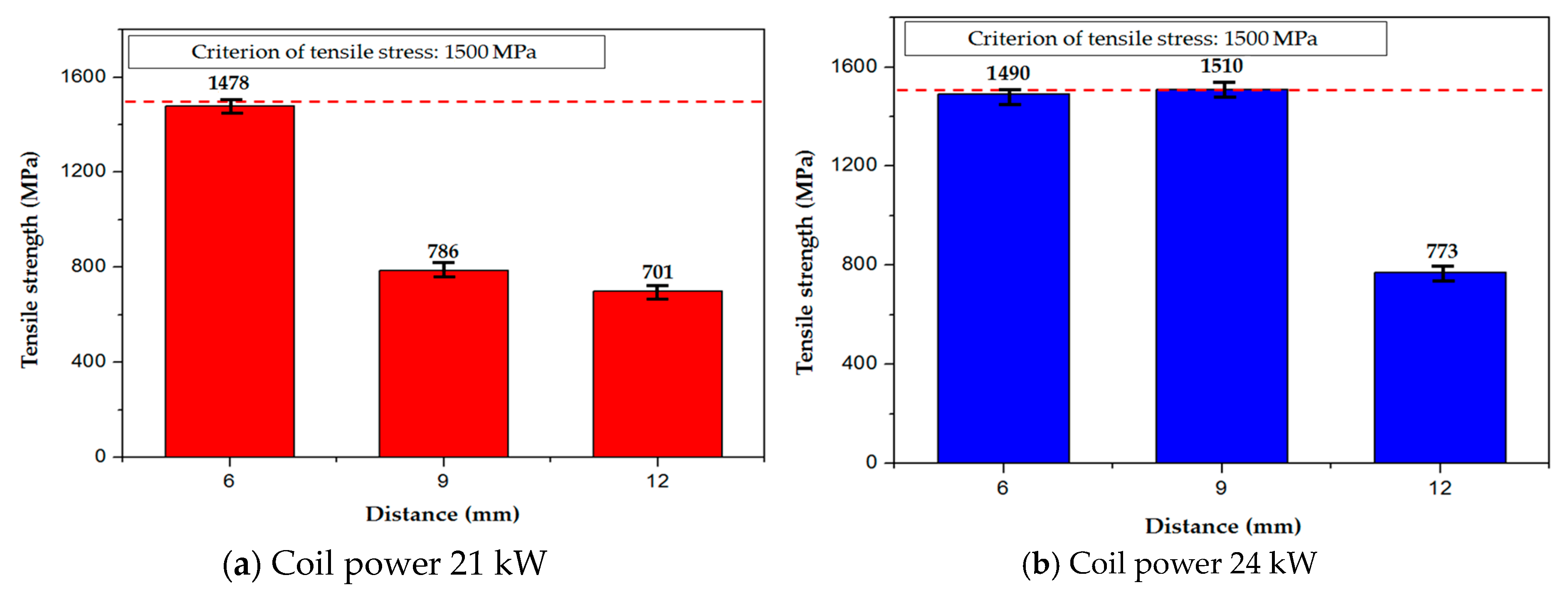

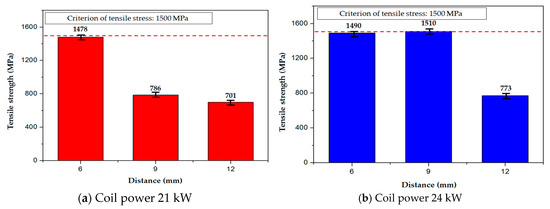

To evaluate the mechanical properties of boron steel hardened by the LH method, the tensile strength and hardness were analyzed at different values of coil power. Figure 7 shows the change in tensile strength with the high-frequency induction heating condition and the distance from the mean values of three specimens. As shown in Figure 7a, an average tensile strength of 1478 MPa was measured when the coil power was 21 kW and the distance from the specimen was 6 mm. In Figure 7b, the average tensile strength values of 1490 and 1510 MPa were measured at distances of 6 and 9 mm, respectively, under a coil power of 24 kW. The tensile strength increased as the coil power increased and the distance from the specimen decreased. However, as the distance from the specimen decreases further, burnout may occur on the surface or inside the boron steel, which can affect its strength. Therefore, it is necessary to maintain appropriate values of coil power and distance from the boron steel specimen.

Figure 7.

The change in tensile strength with the distance from the specimen at the coil powers of 21 and 24 kW; (a) coil power: 21 kW, distance: 6, 9, and 12 mm; (b) coil power: 24 kW, distance: 6, 9, and 12 mm.

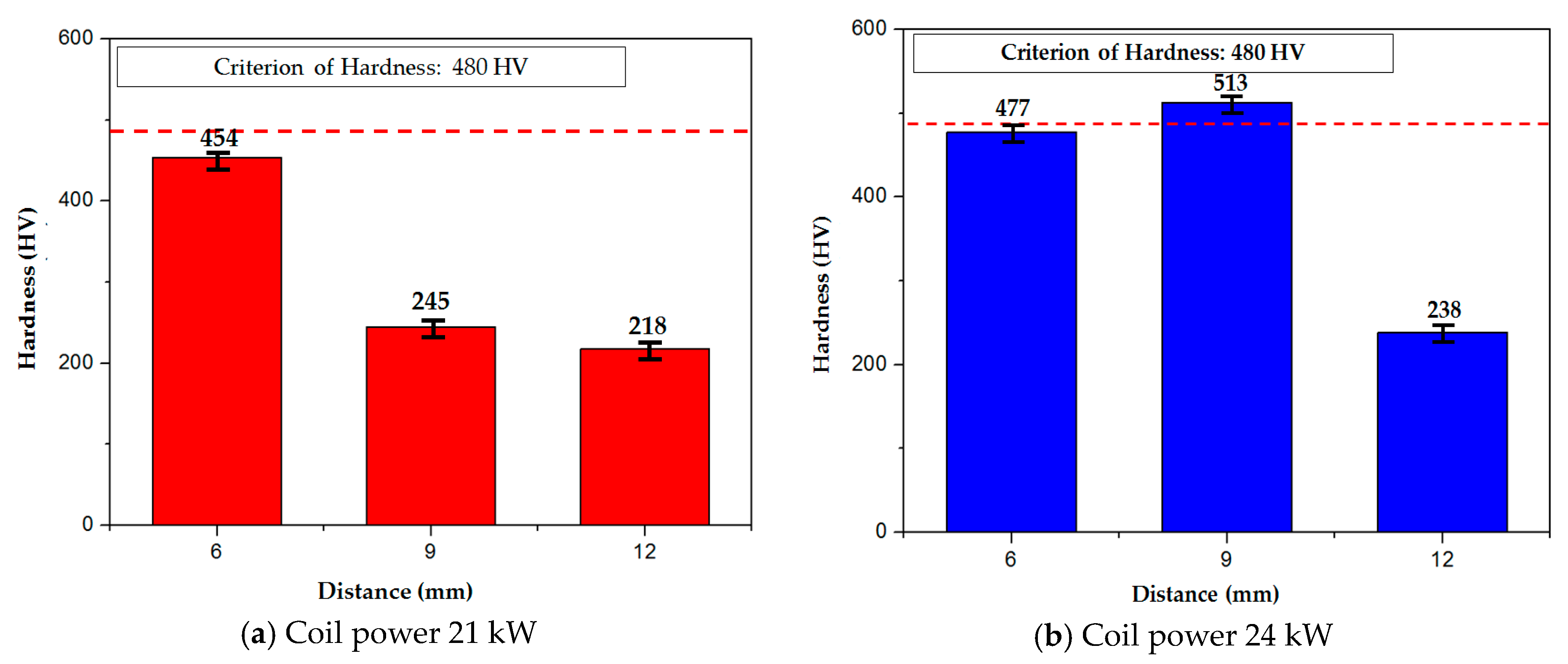

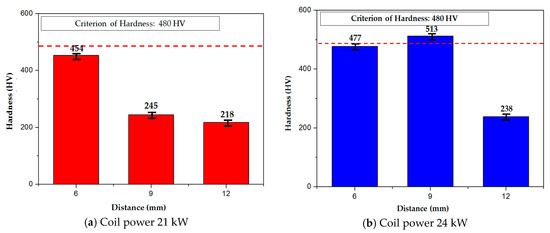

Figure 8 shows how the hardness values varied with the coil power and distance from the specimen. To examine the hardness of the mean values of three specimens, the hardness value at the thermocouple installation position was measured using a Vickers hardness tester after setting it to 1 Hv (1 kg). The hardness increased as the tensile strength increased. A tensile strength of 1500 MPa or higher and a hardness of 500 Hv or higher could be secured when the coil power was 24 kW and the distance from the specimen was 9 mm.

Figure 8.

The change in hardness with the distance from the specimen at the coil power of 21 and 24 kW; (a) coil power: 21 kW, distance: 6, 9, and 12 mm; (b) coil power: 24 kW, distance: 6, 9, and 12 mm.

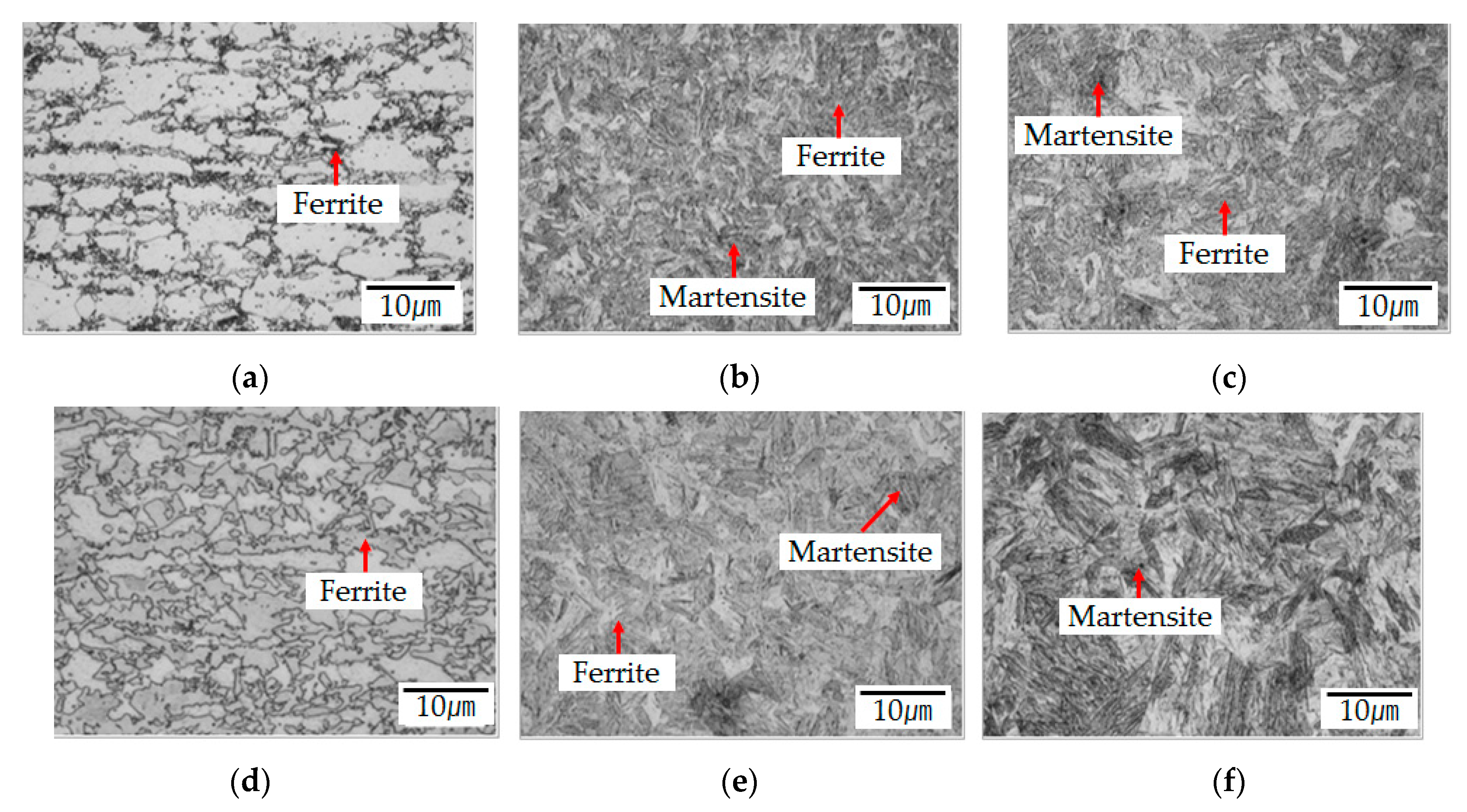

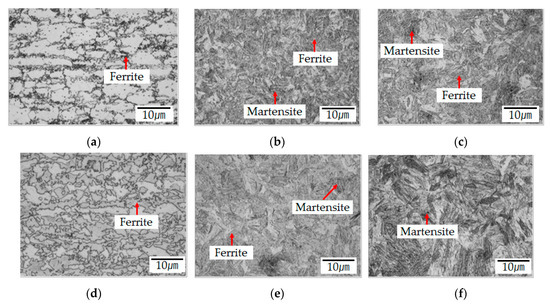

4.3. Microstructural Analysis

Boron steel changes from austenite to martensite at a high-temperature stage in the heating process, including the degree of homogenization, particle shape, and particle size. In particular, the austenite particle properties affect the mechanical properties of the final quenching blank. After the formation of the austenite crystal core, the particle size depends primarily on the heat treatment process such as heating rate, heating temperature, and holding time. It also depends on the original structure and chemical composition of the blank. Austenite is fully realized in the high-temperature region, and the microstructure after quenching is a fine lat martensite; the microstructure in the low-temperature region is a mixed microstructure of ferrite and pearlite, indicating that austenite deformation has not yet occurred [26]. Figure 9 shows the phase composition of the structures after high-frequency induction heating in the specimen center. The formation of austenite and a small amount of ferrite was confirmed when the high-frequency induction heating coil power was 21 kW and the distance from the boron steel specimen was 12 mm in Figure 9a. As the coil power increased, the grain size decreased in austenite and ferrite structures. When the coil power was 21 kW and the distance from the specimen was 6 mm, a martensite structure was formed in Figure 9b,c. Figure 9d–f shows that martensite could also be observed when the distance from the specimen was 6 or 9 mm at a coil power of 24 kW. The structural analysis results revealed that austenite and ferrite structures appeared as the coil power increased and transformed into the martensite structure at the highest temperature. The maximum tensile strength could be obtained depending on the coil power and the distance between the coil and the specimen, which were the control variables of high-frequency induction heat treatment. The coil power of 24 kW or higher and the distance from the boron steel specimen of 9 mm would be appropriate to meet the tensile strength of 1500 MPa or higher and hardness of Hv 500 or higher, which were the target values determined from the experimental conditions.

Figure 9.

Temperature increases at different high-frequency coil power values. (a) 21 kW, 12 mm; (b) 1 kW, 9 mm; (c) 21 kW, 6 mm; (d) 24 kW, 12 mm; (e) 24 kW, 9 mm; (f) 24 kW, 6 mm.

5. Conclusions

High-frequency induction heating means that the heating time due to high heat conduction of the boron steel material will be shortened. If the heating time is short, energy can be saved and production efficiency can be improved, and it helps to maintain the heat shield of the steel sheet and prevent temperature homogenization. It is important to transform from an austenite structure to a martensite structure via appropriate temperature control in a short time, which can be manufactured into a variety of automotive parts according to various strength requirements and local heat treatment.

In this study, the surface temperature variations of boron steel specimens were investigated at different values of coil power and distance from the specimen during longitudinal heating (LH), which is a high-frequency induction heating method that uses eddy currents. The following results were obtained by evaluating the mechanical properties and the microstructural evolution. The conclusions are as follows:

- When the high-frequency induction heating coil power was between 15 and 30 kW and the distance from the specimen was 15 mm, the boron steel material could not reach the target temperature of 900 °C.

- When the high-frequency induction coil power was 21 kW and the distance from the boron steel specimen was 6 mm, a tensile strength of 1478 MPa was obtained when the surface temperature was 898 °C. When the coil power was 24 kW or higher and the distance from the specimen was 9 mm, a tensile strength of 1510 MPa could be obtained.

- The hardness of the boron steel ranged from 218 to 513 Hv depending on the coil power and the distance from the specimen. The hardness increased as the coil power increased. However, it decreased to 477 Hv when the coil power was 24 kW and the distance from the specimen was 6 mm. Low hardness was a result of the local melting of the boron steel, causing burnout.

- The microstructure was transformed into the martensite structure when the coil power was 21 kW and the distance from the specimen was 6 mm. The transformation into the martensite structure was also confirmed when the distance from the specimen was 6 or 9 mm at a coil power of 24 kW. Using the heat treatment for the coil power and the distance from the specimen, their correlations with the maximum tensile strength were determined.

Author Contributions

Conceptualization, K.K.; methodology, K.K.; software, K.K.; formal analysis, K.K.; data curation, K.K.; writing—original draft preparation, K.K.; writing—review and editing, M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yang, Z.; Mehdi, N.; Omer, T. Vehicle to grid regulation services of electric delivery trucks: Economic and environmental benefit analysis. Appl. Energy 2016, 15, 161–175. [Google Scholar]

- Lin, W.; Li, F.; Hua, X.; Zhang, Z. Laser welding Al–Si coated hot stamping steel in conduction mode: Weld formation and Al-rich microstructure. J. Mater. Res. Technol. 2022, 19, 4282–4295. [Google Scholar] [CrossRef]

- Xu, W.; Yang, S.; Tao, W.; Zhang, J.; Luo, H. Effect of Al-Si Coating Removal State on Microstructure and Mechanical Properties of Laser Welded 22MnB5 Steel. J. Mater. Eng. Perform. 2022, 32, 4205–4215. [Google Scholar] [CrossRef]

- Xue, Y. Design and Multi-Objective Optimization of Vehicle Bumper Beams Prepared in LFT-PP. Master’s Thesis, Shandong University, Jinan, China, 2021. [Google Scholar]

- Jiang, R.C.; Zhang, T.; Sun, H.X.; Liu, D.W.; Chen, H.M.; Wang, D.F. Study on Lightweighting of CFRP Bumper Beam Using Entropy-based Approach. Automot. Eng. 2021, 43, 421–428. [Google Scholar]

- Du, Y. Research on the Forming Process and Performance of Carbon Fiber Composite Car Inner Plate and Anti-Collision Beam. Master’s Thesis, Donghua University, Shanghai, China, 2019. [Google Scholar]

- Davoodi, M.M.; Sapuan, S.M.; Ahmad, D.; Aidy, A.; Khalina, A.; Jonoobi, M. Concept selection of car bumper beam with developed hybrid bio-composite material. Mater. Des. 2011, 32, 4857–4865. [Google Scholar] [CrossRef]

- Trends in Electric Light-Duty Vehicles—Global EV Outlook 2023—Analysis. IEA. Available online: https://www.iea.org/reports/global-ev-outlook-2023/trends-in-electric-light-duty-vehicles (accessed on 10 October 2023).

- Wróbel, I.; Skowronek, A.; Grajcar, A. A Review on Hot Stamping of Advanced High-Strength Steels: Technological-Metallurgical Aspects and Numerical Simulation. Symmetry 2022, 14, 969. [Google Scholar] [CrossRef]

- Senuma, T. Hot Stamping Steel. In Encyclopedia of Materials: Metals and Alloys; Francisca, G.C., Ed.; Elsevier: Oxford, UK, 2022; pp. 26–36. [Google Scholar]

- Zhang, W.; Jun, X. Advanced Lightweight Materials for Automobiles: A Review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Matsuoka, S.; Hasegawa, K.; Tanaka, Y. Newly-developed ultra-high tensile strength steels with excellent formability and weldability. JFE Tech. Rep. 2007, 10, 13–18. [Google Scholar]

- Kim, K.Y.; Choy, L.J.; Shin, H.I.; Cho, J.H.; Lee, C.H.; Kang, M.C. Characteristics of mechanical procerties and micro structure according to high-frequency induction heating conditions in rol forming process of a sill side part. J. Korean Soc. Manuf. Process Eng. 2017, 16, 87–94. [Google Scholar]

- Zhu, L.J.; Gu, Z.W.; Xu, H.; Lü, Y.; Chao, J. Modeling of microstructure evolution in 22MnB5 steel during hot stamping. J. Iron Steel Res. Int. 2014, 21, 197–201. [Google Scholar] [CrossRef]

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Hyun, C.M.; Yi, M.S.; Cho, S.H.; Jang, T.W. A study on the mechanical properties of heated plates by induction heating system. Korean Weld. Join. Soc. 2014, 32, 47–51. [Google Scholar]

- Kolleck, R.; Veit, R.; Merklein, M.; Lechler, J.; Geiger, M. Investigation on induction heating for hot stamping of boron alloyed steels. CIRP Annals 2009, 58, 275–278. [Google Scholar] [CrossRef]

- Jisung, Y.; Selim, K.; Min, C.J. Effects of Al-Si coating structures on bendability and resistance to hydrogen embrittlement in 1.5-GPa-grade hot-press-forming steel. Acta Mater. 2022, 225, 117561. [Google Scholar]

- Merklein, M.; Wieland, M.; Lechner, M.; Bruschi, S.; Ghiotti, A. Hot stamping of boron steel sheets with tailored properties: A review. J. Mater. Process. Technol. 2016, 228, 11–24. [Google Scholar] [CrossRef]

- Sul, Y.T.; Lee, E.Y.; Kwon, H.M. Development of induction heating superheater system using new heat exchanging method. J. Korea Acad.-Ind. Coop. Soc. 2009, 10, 740–746. [Google Scholar]

- Yanhong, M.; Baoyu, W.; Jing, Z.; Xu, H.; Xuetao, L. Hot stamping of boron steel using partition heating for tailored properties: Experimental trials and numerical analysis. Metall. Mater. Trans. A 2017, 48, 5467–5479. [Google Scholar]

- Kucera, V.; Cabibbo, M.; Prusa, F.; Fojt, J.; Petr-Soini, J.; Pilvousek, T.; Kolarikova, M.; Vojtech, D. Phase Composition of Al-Si Coating from the Initial State to the Hot-Stamped Condition. Materials 2021, 14, 1125. [Google Scholar] [CrossRef]

- Gui, Z.; Liang, W.; Liu, Y.; Zhang, Y. Thermo-mechanical behavior of the Al–Si alloy coated hot stamping boron steel. Mater. Des. 2014, 60, 26–33. [Google Scholar] [CrossRef]

- Somunkiran, I.; Buytoz, S.; Dagdelen, F. Determination of curie temperatures and thermal oxidation behavior of Fe-Cr matrix composites produced by hot pressing. J. Alloys Compd. 2019, 777, 302–308. [Google Scholar] [CrossRef]

- Billur, E. Hot Stamping of Ultra High-Strength Steels; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Bao, L.; Liu, W.J.; Wang, B.; Li, H.; You, X.; Zhou, Q.; Liu, M.; Gao, S. Laser Experimental investigation on partition controllable induction heating-hot stamping process of high- strength boron alloyed steel plates with designable temperature patterns. J. Mater. Res. Technol. 2020, 9, 13963–13976. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).