Correlation of Different Cemented Carbide Starting Powders with the Resulting Properties of Components Manufactured via Binder Jetting

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

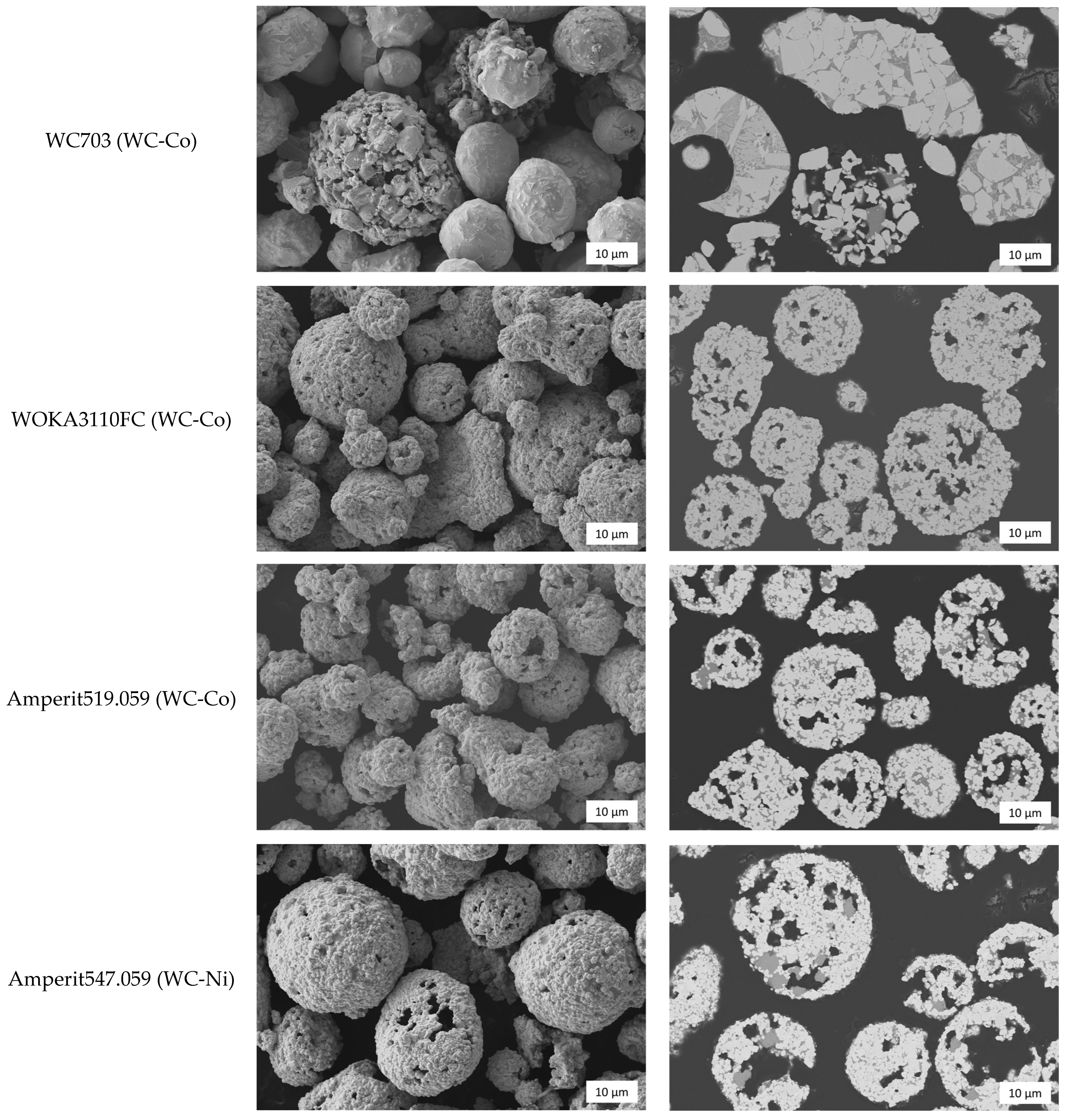

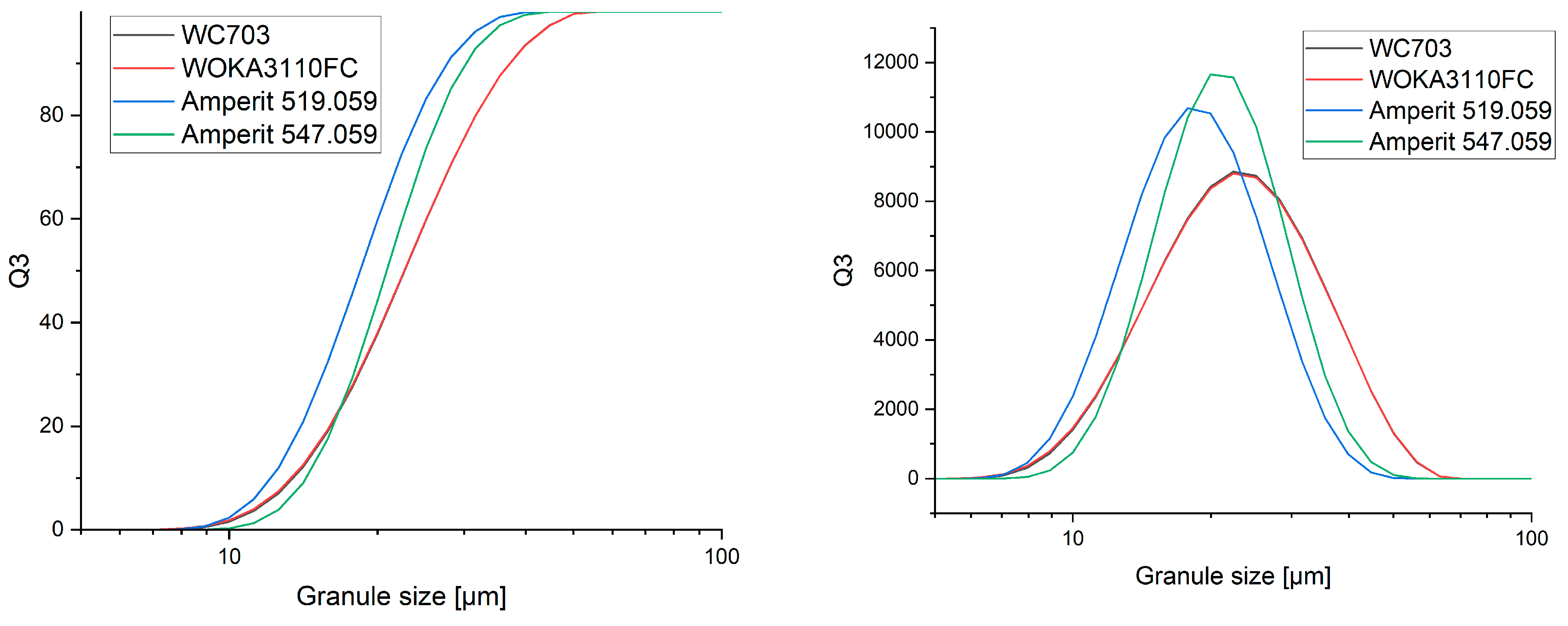

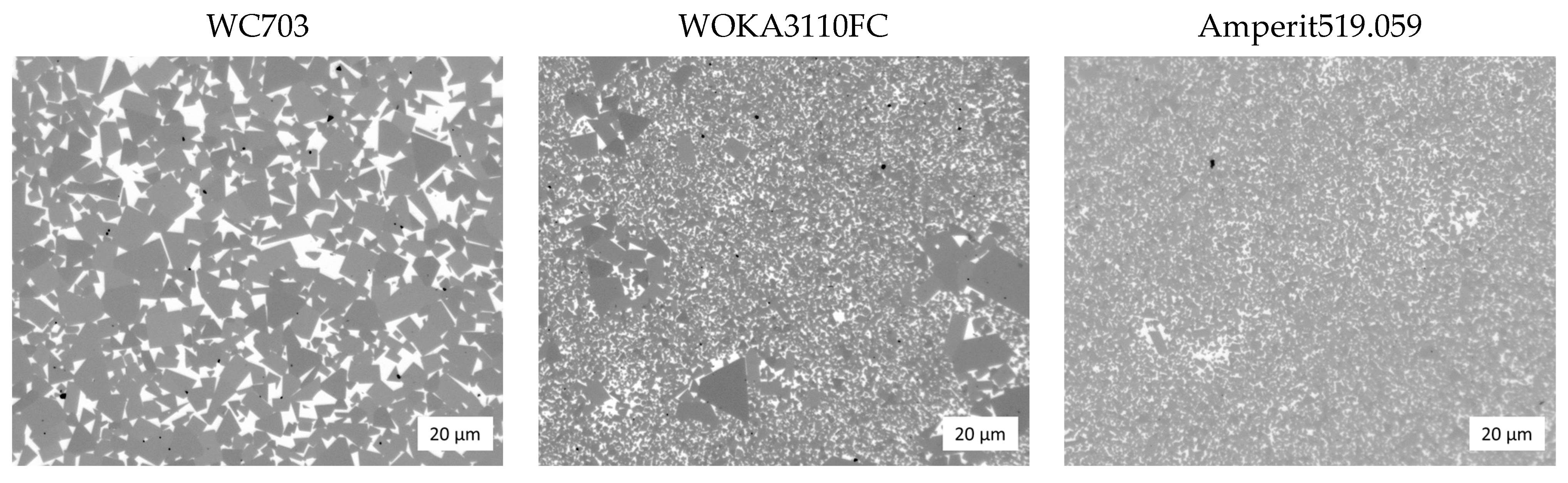

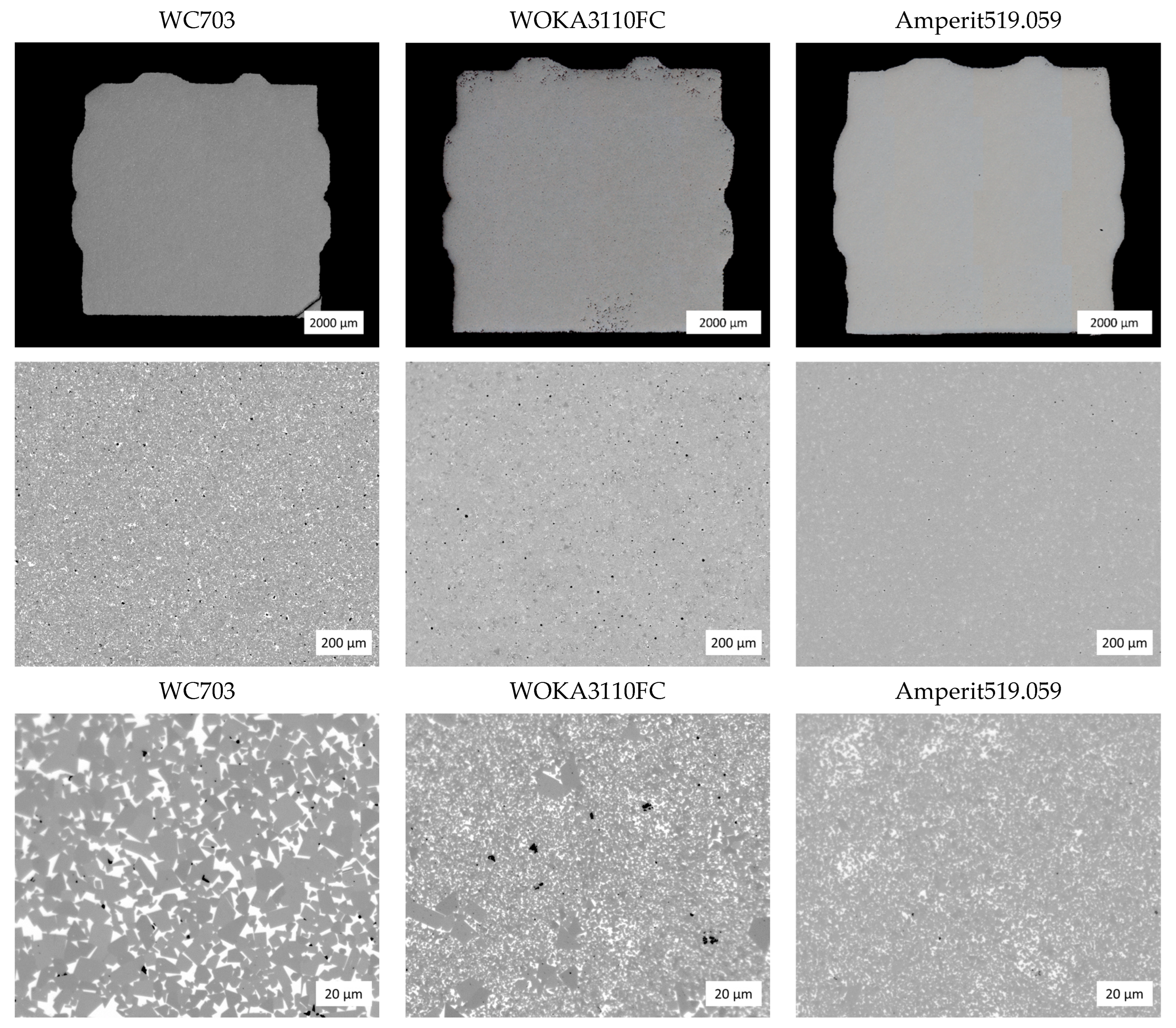

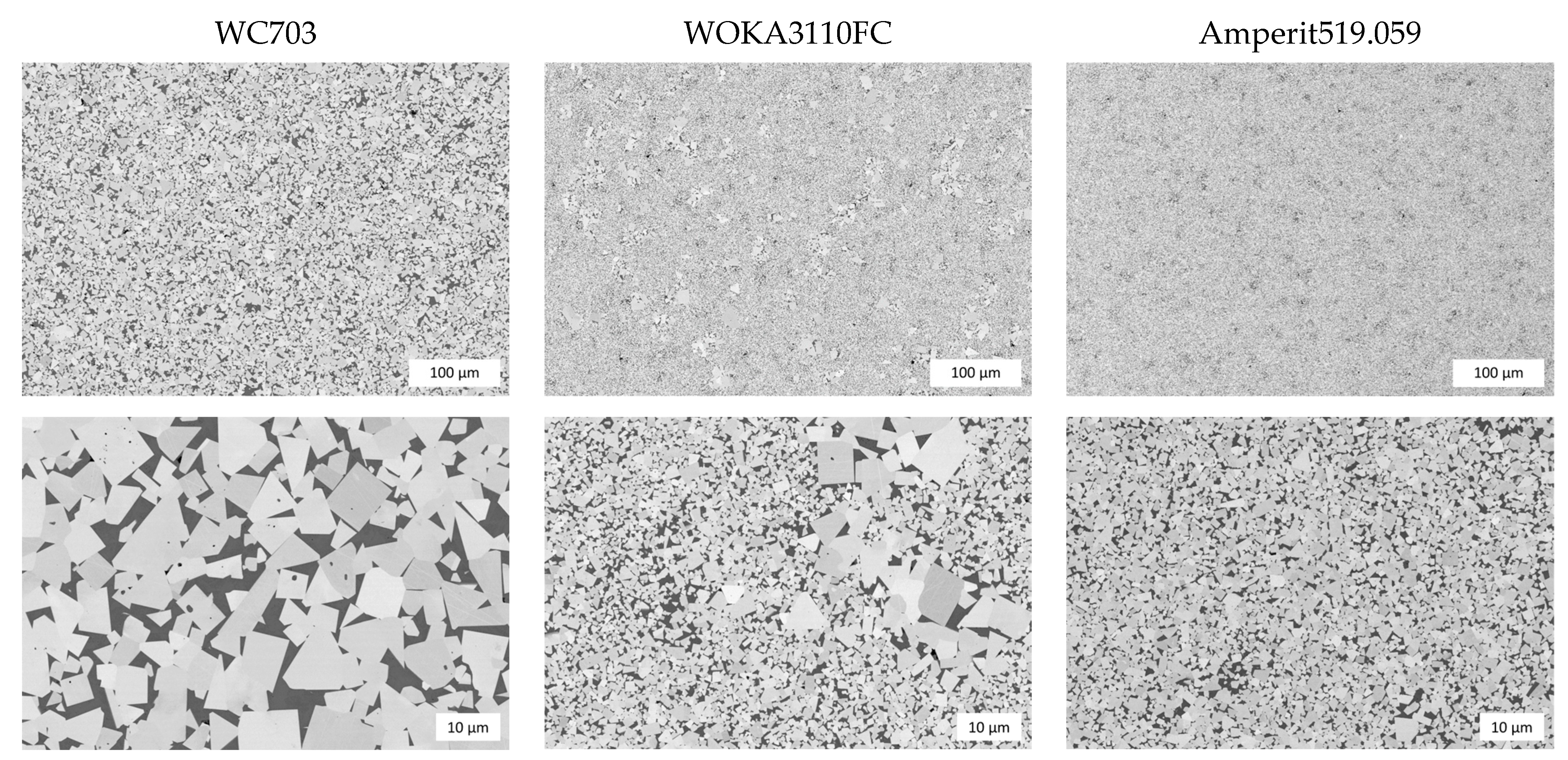

3.1. Characterisation of Starting Materials

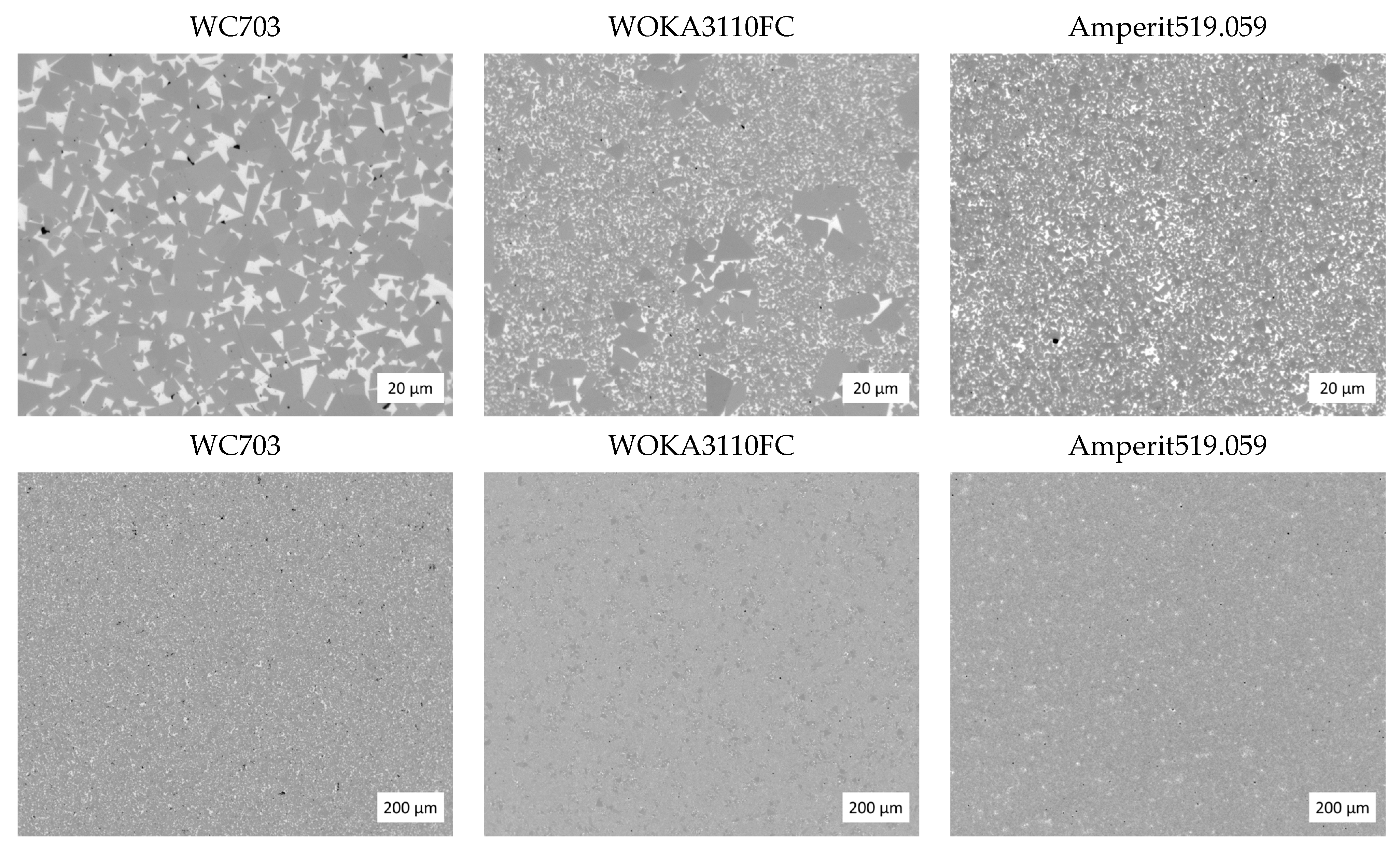

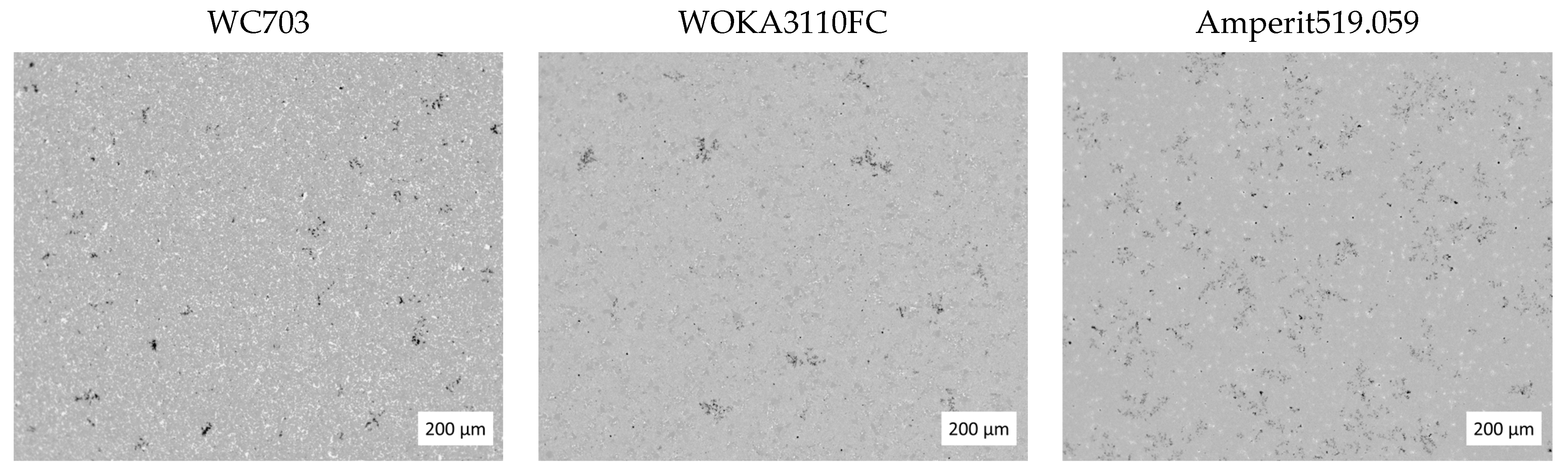

3.2. Shaping of WC-Co Components

3.3. Debinding and Sintering

3.4. WC-Ni as an Alternate Material System

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schwanekamp, T. Pulverbettbasiertes Laserstrahlschmelzen von Hartmetallen zur Additiven Herstellung von Zerspanwerkzeugen. Ph.D. Thesis, Ruhr-Universität Bochum, Universitätsbibliothek, Bochum, Germany, 2021. [Google Scholar]

- Schwanekamp, T.; Marginean, G.; Reuber, M. Laser beam melting of Cr3C2-NiCr. Int. J. Refract. Met. Hard Mater. 2019, 85, 105069. [Google Scholar] [CrossRef]

- Fries, S.; Vogelpoth, A.; Kaletsch, A.; Broeckmann, C. Laser-Based Additive Manufacturing of WC–Co with High-Temperature Powder Bed Preheating. Steel Res. Int. 2020, 91, 1900511. [Google Scholar] [CrossRef]

- Fries, S.; Vogelpoth, A.; Kaletsch, A.; Broeckmann, C. Influence of post heat treatment on microstructure and fracture strength of cemented carbides manufactured using laser-based additive manufacturing. Int. J. Refract. Met. Hard Mater. 2023, 111, 106085. [Google Scholar] [CrossRef]

- Schwanekamp, T.; Marginean, G.; Reuber, M.; Ostendorf, A. Impact of cobalt content and grain growth inhibitors in laser-based powder bed fusion of WC-Co. Int. J. Refract. Met. Hard Mater. 2022, 105, 105814. [Google Scholar] [CrossRef]

- Xing, M.; Wang, H.; Zhao, Z.; Lu, H.; Liu, C.; Lin, L. Additive manufacturing of cemented carbides inserts with high mechanical performance. Mater. Sci. Eng. A 2022, 861, 144350. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, C.; Yang, Y.; Misra, R.; Kondoh, K.; Lu, Y. Laser powder bed fusion of cemented carbides by developing a new type of Co coated WC composite powder. Addit. Manuf. 2022, 55, 102820. [Google Scholar] [CrossRef]

- Ibe, H.; Kato, Y.; Yamada, J.; Kato, M.; Suzuki, A.; Takata, N. Controlling WC/Co two-phase microstructure of cemented carbides additive-manufactured by laser powder bed fusion: Effect of powder composition and post heat-treatment. Mater. Des. 2021, 210, 110034. [Google Scholar] [CrossRef]

- Lengauer, W.; Duretek, I.; Schwarz, V.; Kukla, C.; Kitzmantel, M.; Neubauer, E.; Lieberwirth, C.; Morrison, V. Preparation and properties of extrusion-based 3D-printed hardmetal and cermet parts. In Proceedings of the Euro PM2018 Congress & Exhibition Euro PM2018 Proceedings, Bilbao Exhibition Centre (BEC), Bilbao, Spain, 14–18 October 2018; European Powder Metallurgy Association (EPMA): Shrewsbury, UK, 2018. [Google Scholar]

- Berger, C.; Abel, J.; Pötschke, J.; Moritz, T. Properties of Additive Manufactured Hardmetal Components Produced by Fused Filament Fabrication (FFF). In Proceedings of the Euro PM2018 Congress & Exhibition Euro PM2018 Proceedings, Bilbao Exhibition Centre (BEC), Bilbao, Spain, 14–18 October 2018; European Powder Metallurgy Association (EPMA): Shrewsbury, UK, 2018. [Google Scholar]

- Lengauer, W.; Duretek, I.; Fürst, M.; Schwarz, V.; Gonzalez-Gutierrez, J.; Schuschnigg, S.; Kukla, C.; Kitzmantel, M.; Neubauer, E.; Lieberwirth, C. Fabrication and properties of extrusion-based 3D-printed hardmetal and cermet components. Int. J. Refract. Met. Hard Mater. 2019, 82, 141–149. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, R.; Chen, J.; Xiong, X. Additive manufacturing of cemented carbide using analogous powder injection molding feedstock. Int. J. Refract. Met. Hard Mater. 2023, 111, 106095. [Google Scholar] [CrossRef]

- Lee, S.W.; Kim, Y.W.; Jang, K.M.; Lee, J.W.; Park, M.-S.; Koo, H.Y.; Ha, G.-H.; Kang, Y.C. Phase control of WC–Co hardmetal using additive manufacturing technologies. Powder Metall. 2021, 65, 13–21. [Google Scholar] [CrossRef]

- Rieger, T.; Schubert, T.; Schurr, J.; Butschle, M.; Schwenkel, M.; Bernthaler, T. Slurry development for lithography-based additive manufacturing of cemented carbide components. Powder Technol. 2021, 383, 498–508. [Google Scholar] [CrossRef]

- Rieger, T.; Schubert, T.; Schurr, J.; Kolb, D.; Riegel, H.; Bernthaler, T.; Schneider, G. Manufacturing (AM). In Proceedings of the Euro PM2019 Congress & Exhibition Euro PM2019 Proceedings, Maastricht Exhibition & Congress Centre (MECC), Maastricht, The Netherlands, 13–16 October 2019; European Powder Metallurgy Association (EPMA): Shrewsbury, UK, 2019; pp. 1–6. [Google Scholar]

- Pötschke, J.; Weingarten, S.; Scheithauer, U.; Mayer, M.; Moritz, T. Thermoplastic 3D Printing of Hardmetals. In Proceedings of the Euro PM2019 Congress & Exhibition Euro PM2019 Proceedings, Maastricht Exhibition & Congress Centre (MECC), Maastricht, The Netherlands, 13–16 October 2019; European Powder Metallurgy Association (EPMA): Shrewsbury, UK, 2019; pp. 1–6. [Google Scholar]

- ASTM 52900:2021; Additive Manufacturing–General Principles–Fundamentals and Vocabulary. Beuth Verlag GmbH: Berlin, Germany, 2022.

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar]

- Dini, F.; Ghaffari, S.A.; Jafar, J.; Hamidreza, R.; Marjan, S. A review of binder jet process parameters; powder, binder, printing and sintering condition. Met. Powder Rep. 2020, 75, 95–100. [Google Scholar] [CrossRef]

- Carreño-Morelli, E.; Alveen, P.; Moseley, S.; Rodriguez-Arbaizar, M.; Cardoso, K. A comparative study of cemented carbide parts produced by solvent on granules 3D-printing (SG-3DP) versus press and sinter. Int. J. Refract. Met. Hard Mater. 2021, 97, 105515. [Google Scholar] [CrossRef]

- Wolfe, T.; Shah, R.; Prough, K.; Trasorras, J.L. Coarse cemented carbide produced via binder jetting 3D printing. Int. J. Refract. Met. Hard Mater. 2023, 110, 106016. [Google Scholar] [CrossRef]

- Lehmann, M.; Kolb, C.G.; Gschloessl, J.; Zaeh, M.F. Using particle-loaded inks to selectively change the material properties in binder-jetted WC–Co parts. J. Mater. Sci. 2023. [Google Scholar] [CrossRef]

- Enneti, R.K.; Prough, K.C. Wear properties of sintered WC-12%Co processed via Binder Jet 3D Printing (BJ3DP). Int. J. Refract. Met. Hard Mater. 2019, 78, 228–232. [Google Scholar] [CrossRef]

- Carreño-Morelli, E.; Alveen, P.; Moseley, S.; Rodriguez-Arbaizar, M.; Cardoso, K. Three-dimensional printing of hard materials. Int. J. Refract. Met. Hard Mater. 2020, 87, 105–110. [Google Scholar] [CrossRef]

- Tang, J.-Y.; Luo, L.-M.; Liu, Z.; Zan, X.; Wu, Y.-C. Shape retention of cemented carbide prepared by Co melt infiltration into un-sintered WC green parts made via BJ3DP. Int. J. Refract. Met. Hard Mater. 2022, 107, 105904. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Wang, D.; Nie, L.; Wellmann, D.; Tian, Y. Additive manufacturing of WC-Co hardmetals: A review. Int. J. Adv. Manuf. Technol. 2020, 64, 219. [Google Scholar] [CrossRef]

- Aramian, A.; Razavi, S.M.J.; Sadeghian, Z.; Berto, F. A review of additive manufacturing of cermets. Addit. Manuf. 2020, 33, 101130. [Google Scholar] [CrossRef]

- Padmakumar, M. Additive Manufacturing of Tungsten Carbide Hardmetal Parts by Selective Laser Melting (SLM), Selective Laser Sintering (SLS) and Binder Jet 3D Printing (BJ3DP) Techniques. Lasers Manuf. Mater. Process. 2020, 7, 338–371. [Google Scholar]

- Azurmendi, N.; Agote, I.; Lores, A.; Fernandes, C.M.; Figuereido, D. Binder jetting of hardmetals: A comparative study of microstructure and properties of different commercial powders. In Proceedings of the World PM2022 Congress & Exhibition World PM2018 Proceedings, Lyon Convention Centre, Lyon, France, 9–13 October 2022; European Powder Metallurgy Association (EPMA): Chantilly, France, 2022. [Google Scholar]

- Mariani, M.; Goncharov, I.; Mariani, D.; De Gaudenzi, G.P.; Popovich, A.; Lecis, N.; Vedani, M. Mechanical and microstructural characterization of WC-Co consolidated by binder jetting additive manufacturing. Int. J. Refract. Met. Hard Mater. 2021, 100, 105639. [Google Scholar] [CrossRef]

- Berger, C.; Pötschke, J.; Fries, M.; Moritz, T.; Michaelis, A. Binder-jetting of TiCN-based cermets. Powder Metall. 2022, 65, 382–389. [Google Scholar] [CrossRef]

- ISO 39231:2018; Metallic Powders–Determination of Apparent Density–Part 1: Funnel Method. Beuth Verlag GmbH: Berlin, Germany, 2018.

- ISO 3953:2011; Metallic Powders–Determination of Tap Density. Beuth Verlag GmbH: Berlin, Germany, 2011.

- ISO 3369:2006; Impermeable Sintered Metal Materials and Hardmetals–Determination of Density. Beuth Verlag GmbH: Berlin, Germany, 2010.

- ISO 44994:2016; Hardmetals–Metallographic Determination of Microstructure–Part 4: Characterisation of Porosity, Carbon Defects and EtaPhase Content. Beuth Verlag GmbH: Berlin, Germany, 2016.

- ISO 44992:2020; Hardmetals–Metallographic Determination of Microstructure–Part 2: Measurement of WC Grain Size. Beuth Verlag GmbH: Berlin, Germany, 2020.

- Rocha, A.F.; Bastos, A.C.; Cardoso, J.P.; Rodrigues, F.; Fernandes, C.M.; Soares, E.; Sacramento, J.; Senos, A.M.R.; Ferreira, M.G.S. Corrosion behaviour of WC hardmetals with nickel-based binders. Corros. Sci. 2019, 147, 384–393. [Google Scholar]

| Company | Global Tungsten Powders | Oerlikon Metco | Höganäs | Höganäs |

|---|---|---|---|---|

| Type | WC703 | WOKA3110FC | Amperit519.059 | Amperit547.059 |

| Material | WC-12Co | WC-12Co | WC-12Co | WC-11Ni |

| WC Grain Size | Coarse (2.5–6.0 µm) | Fine (0.8–1.3 µm) | Fine (0.8–1.3 µm) | Fine (0.8–1.3 µm) |

| Application | Additive Manufacturing | High velocity oxygen fuel spraying (HVOF) | High velocity oxygen fuel spraying (HVOF) | High velocity oxygen fuel spraying (HVOF) |

| Properties | WC703 | WOKA3110FC | Amperit519.059 | Amperit547.059 |

|---|---|---|---|---|

| Apparent density [g/cm3/%TD] | 6.7/46.3 | 5.4/37.9 | 5.1/35.8 | 4.9/34.2 |

| Tap density [g/cm3/%TD] | 7.7/53.6 | 6.8/47.0 | 6.0/41.8 | 5.7/39.3 |

| Compressibility index | 15.6 | 24.1 | 16.7 | 15.0 |

| Granule size ditribution | ||||

| d10 [µm} | 13.5 | 13.4 | 12.2 | 14.3 |

| d50 [µm] | 22.7 | 22.7 | 18.4 | 20.9 |

| d90 [µm] | 37.0 | 37.0 | 27.6 | 30.1 |

| Properties | WC703 | WOKA3110FC | Amperit519.059 |

|---|---|---|---|

| Density [g/cm3/%TD] | 14.2/98.5 | 14.2/99.2 | 14.3/99.2 |

| Mag. Saturation [µTm3/kg/%TmS] | 23.9/99.0 | 23.7/98.2 | 23.6/97.8 |

| Hc [kA/m] | 3.9 | 8.6 | 9.7 |

| Lin. shrinkage X/Y/Z [%] | 20.1/20.8/22.2 | 27.2/27.6/29.5 | 27.7/28.1/29.4 |

| Porosity (ISO 4499-4) | A06B04C00 | A04B00C00 | A04B00C00 |

| Properties | Sintering Temperature [°C] | WC703 | WOKA3110FC | Amperit519.059 |

|---|---|---|---|---|

| Density [g/cm3/%TD] | 1350 | 14.2/98.7 | 14.3/99.4 | 14.2/99.0 |

| 1400 | 14.2/98.8 | 14.3/99.4 | 14.3/99.5 | |

| Mag. Saturation [µTm3/kg/%TmS] | 1350 | 24.0/99.5 | 24.0/99.5 | 23.9/99.0 |

| 1400 | 23.5/97.4 | 23.5/97.4 | 23.4/97.0 | |

| Hc [kA/m] | 1350 | 4.1 | 9.9 | 10.3 |

| 1400 | 4.1 | 8.9 | 10.0 | |

| Hardness [HV10] | 1400 | 910 ± 10 | 1211 ± 8 | 1300 ± 14 |

| Lin. Shrinkage X/Y/Z [%] | 1350 | 20.5/21.1/22.8 | 26.2/26.5/29.2 | 26.8/27.5/29.1 |

| 1400 | 18.7/19.6/21.6 | 27.3/27.5/29.5 | 27.0/27.9/28.4 | |

| Porosity (ISO 4499-4) | 1350 | A06B00C00 | A08B00C00 (inner structure) | A04B00C00 |

| 1400 | A06B00C00 | A06B00C00 | A04B00C00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berger, C.; Pötschke, J.; Scheithauer, U.; Michaelis, A. Correlation of Different Cemented Carbide Starting Powders with the Resulting Properties of Components Manufactured via Binder Jetting. Metals 2023, 13, 1848. https://doi.org/10.3390/met13111848

Berger C, Pötschke J, Scheithauer U, Michaelis A. Correlation of Different Cemented Carbide Starting Powders with the Resulting Properties of Components Manufactured via Binder Jetting. Metals. 2023; 13(11):1848. https://doi.org/10.3390/met13111848

Chicago/Turabian StyleBerger, Christian, Johannes Pötschke, Uwe Scheithauer, and Alexander Michaelis. 2023. "Correlation of Different Cemented Carbide Starting Powders with the Resulting Properties of Components Manufactured via Binder Jetting" Metals 13, no. 11: 1848. https://doi.org/10.3390/met13111848