Failure of Elliptical Tubes with Different Long–Short Axis Ratios under Cyclic Bending in Different Directions

Abstract

:1. Introduction

2. Experiment

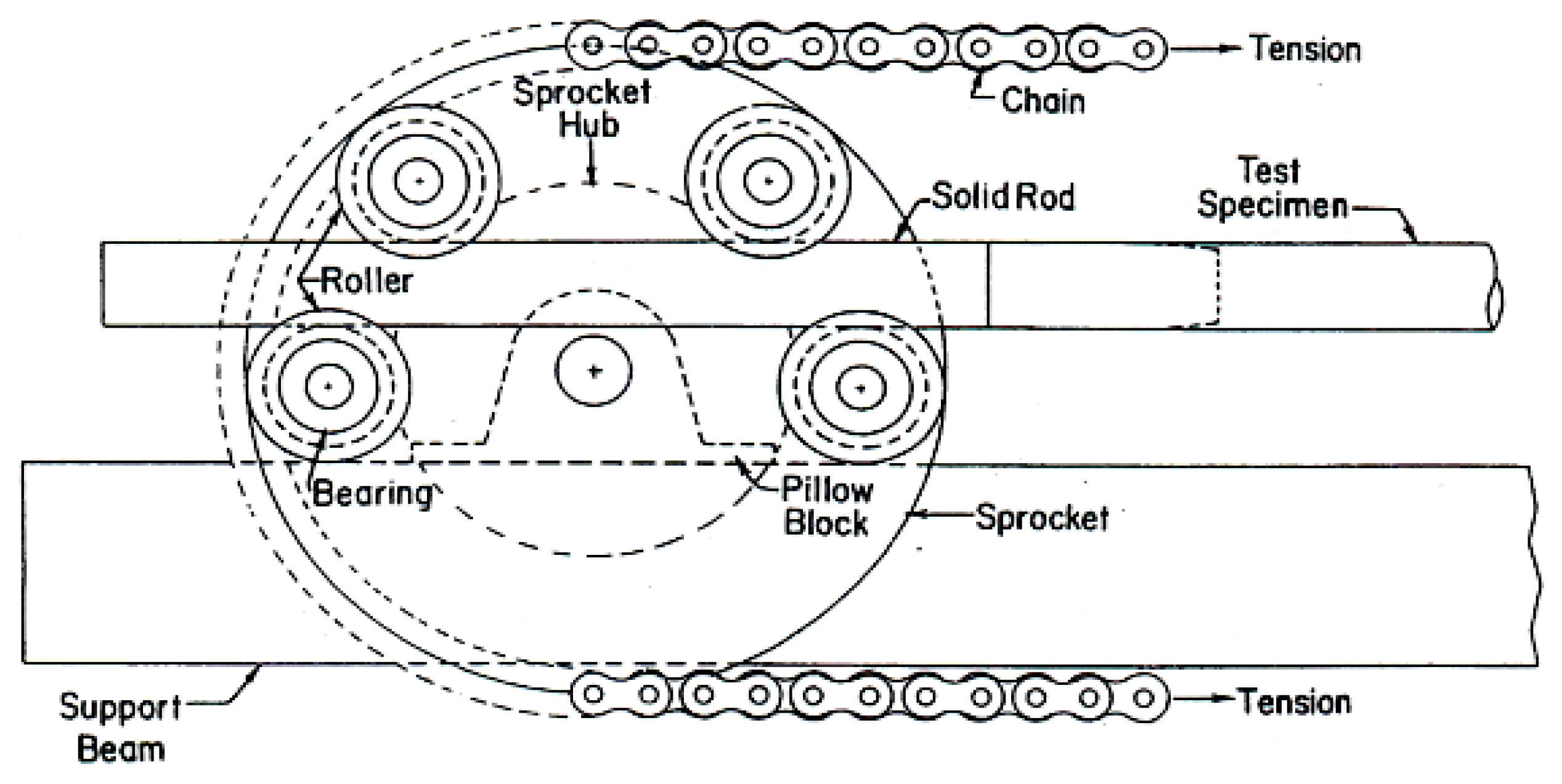

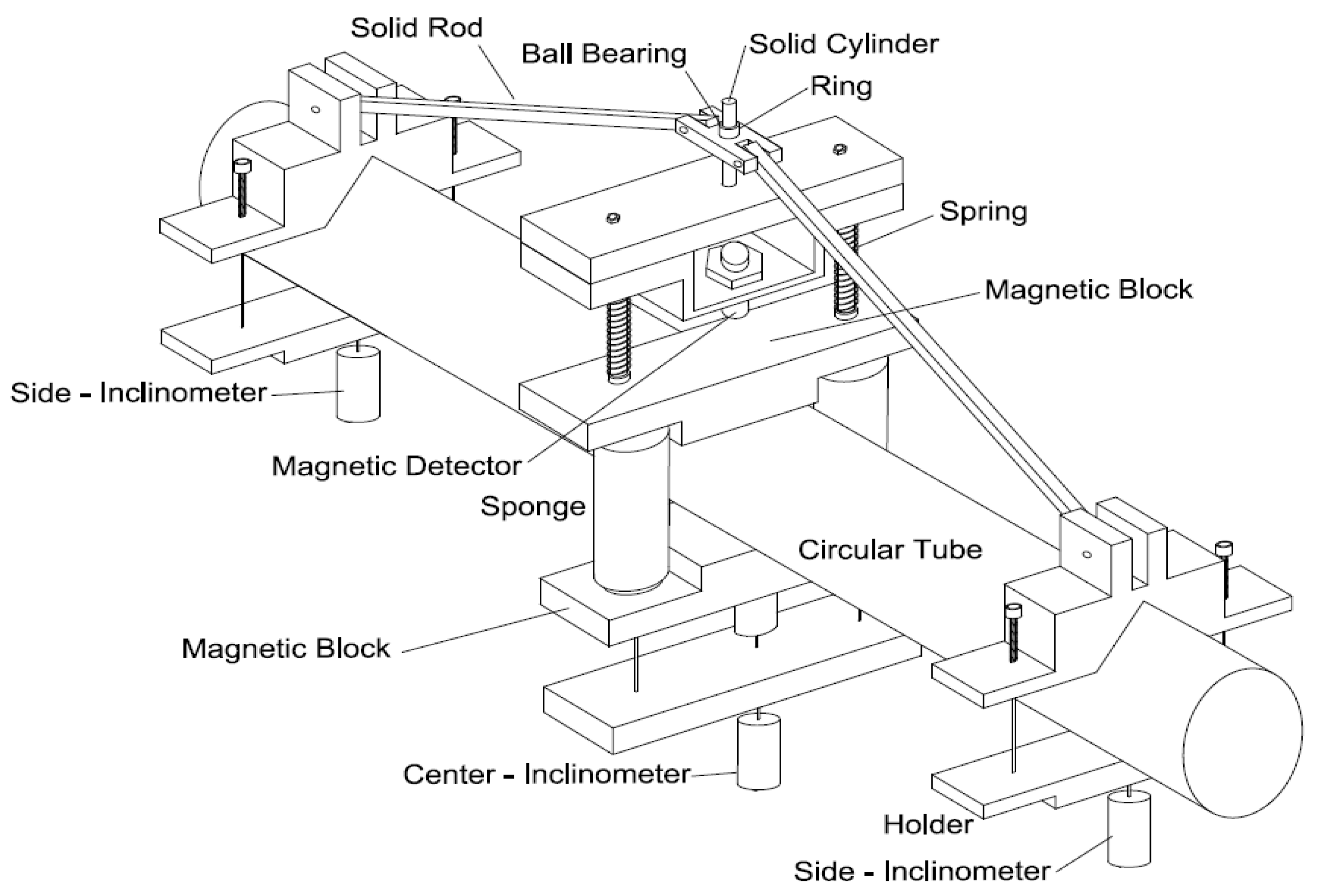

2.1. Bending Device

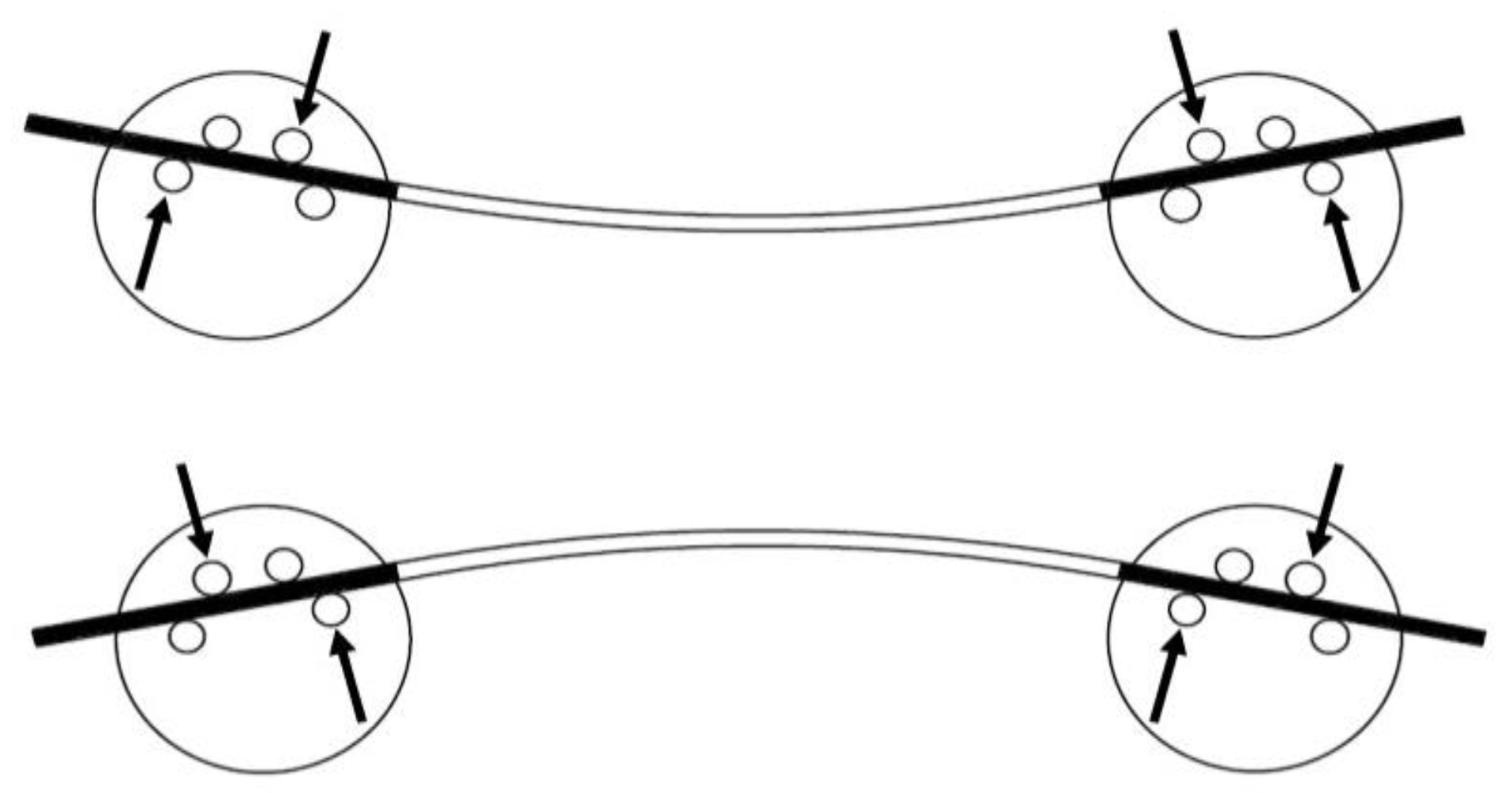

2.2. Curvature-Ovalization Measurement Apparatus (COMA)

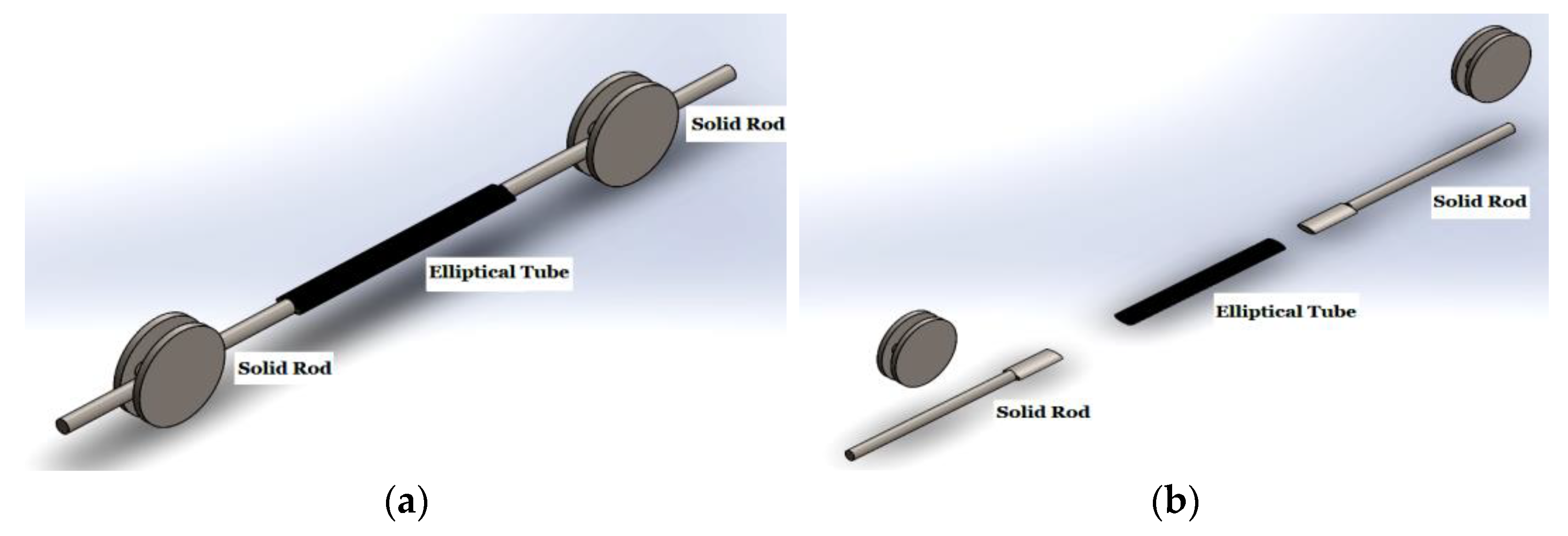

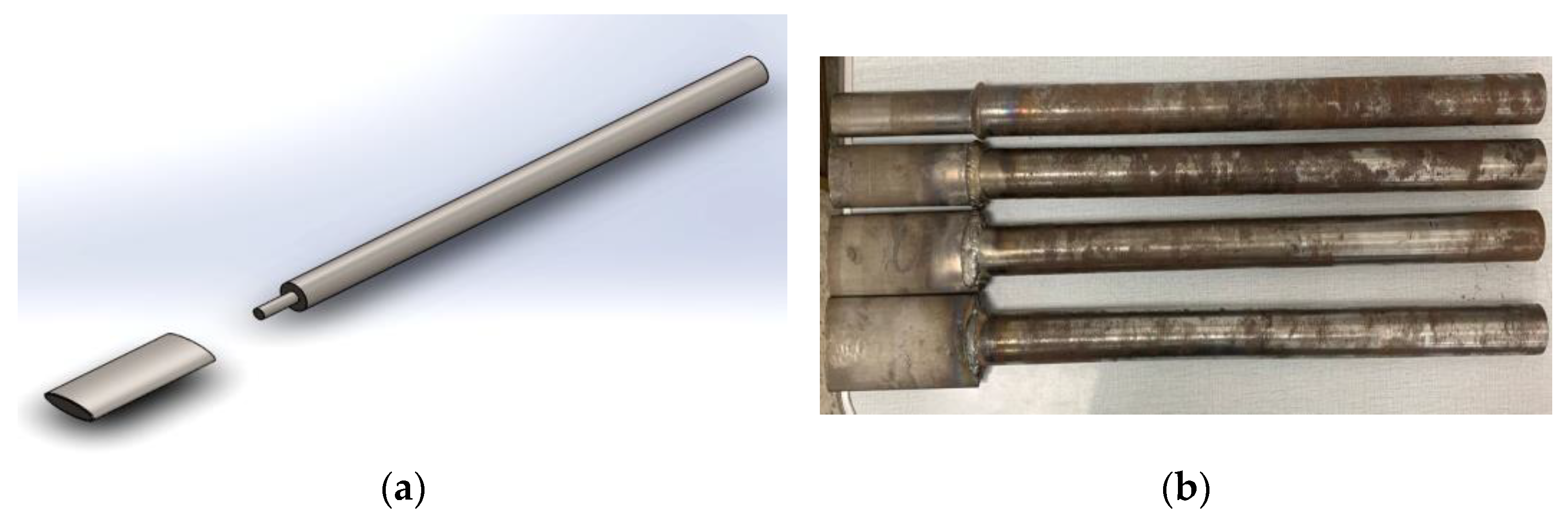

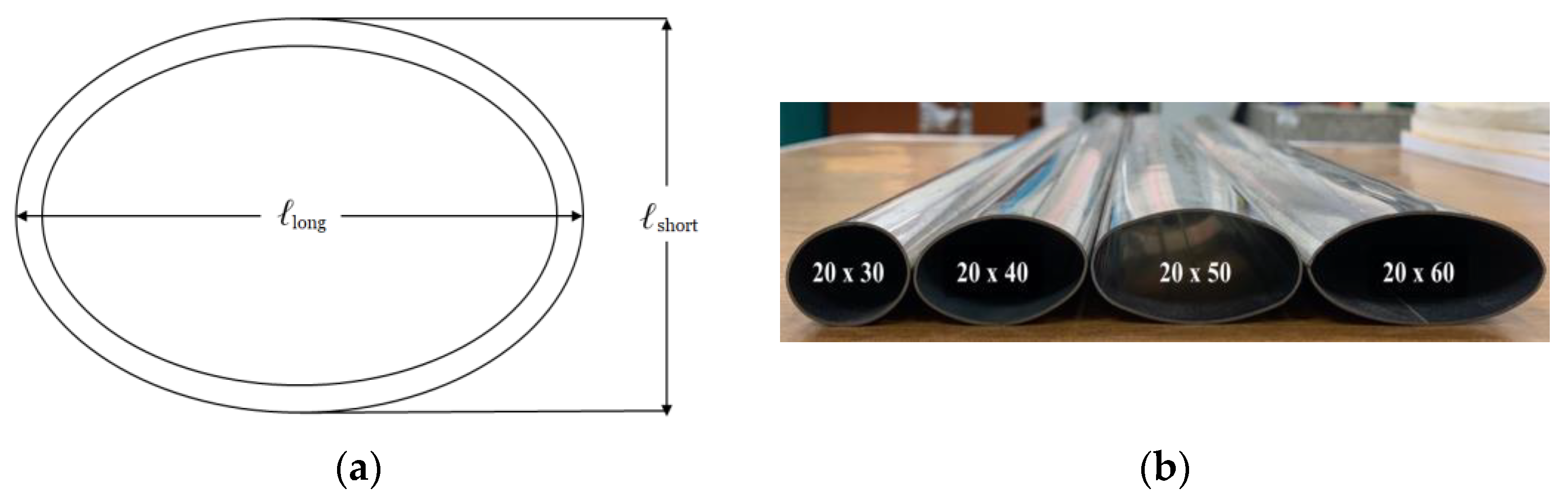

2.3. Elliptical Tubes

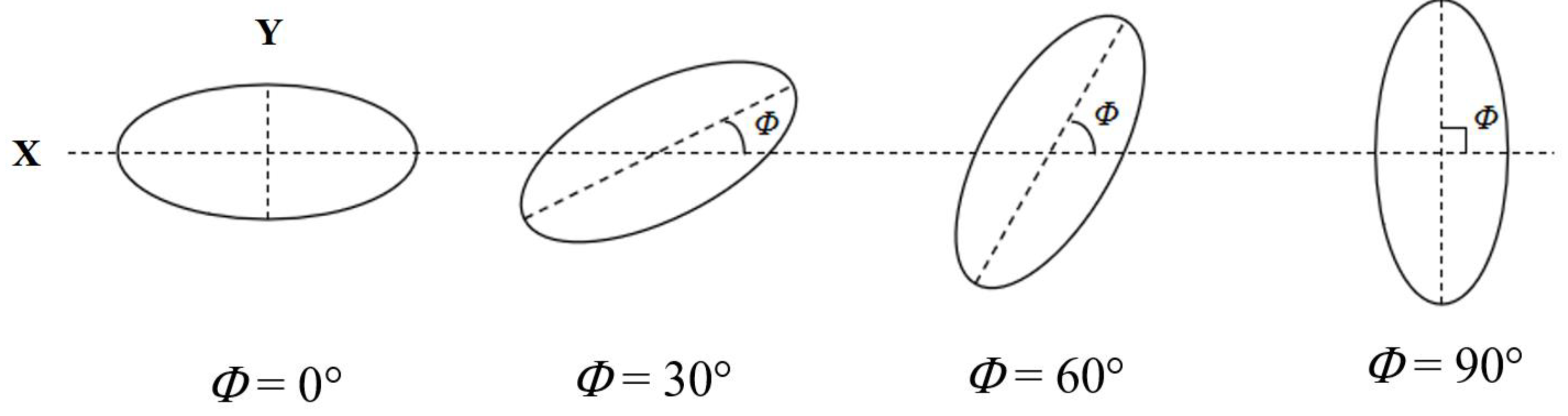

2.4. Test Procedures

3. Results and Discussion

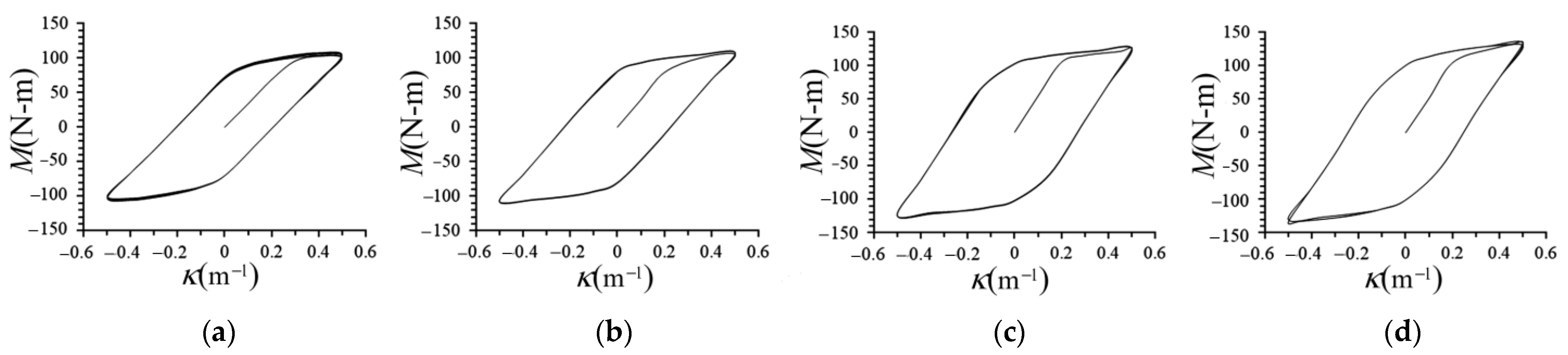

3.1. Relationship between the Moment and Curvature

3.2. Relationship between the Short-Axis Variation and Curvature

3.3. Relationship between the Curvature and Number of Cycles Required to Initiate Buckling

4. Conclusions

- (1)

- During the initial loading stage, the elliptical tubes were in the elastic range, so M increased linearly with increasing κ. As κ increased further, the elliptical tubes started to deform plastically, which caused a gradual flattening of the M–κ curves and resulted in permanent deformation. All M–κ curves exhibited cyclic hardening and became stable after a few cycles. For a fixed Φ, increasing ℓlong/ℓshort gradually decreased the peak M value. For a fixed ℓlong/ℓshort, increasing Φ gradually increased the peak M value.

- (2)

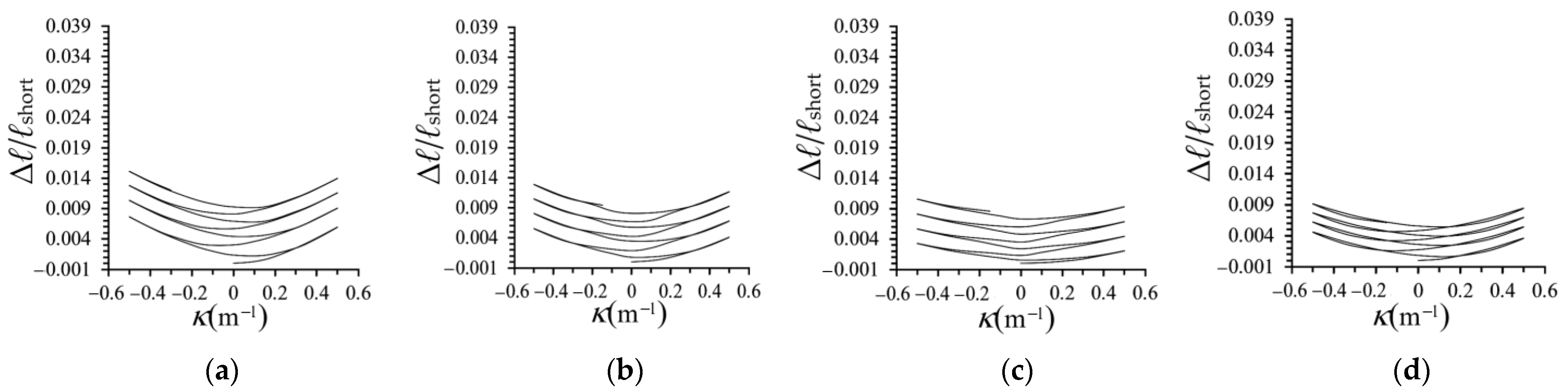

- The ∆ℓ/ℓshort–κ curves exhibited a nonlinear pattern regardless of whether the elliptical tube was subjected to elastic or plastic bending deformation. As the number of cyclic bending loads increased, ∆ℓ/ℓshort continued to increase. For a fixed Φ and ℓlong/ℓshort of 1.5, the ∆ℓ/ℓshort–κ curves showed symmetry, serrations, and a growth pattern as the number of cycles increased. This similarity to the behavior of circular tubes can be attributed to ℓlong/ℓshort being close to that of a circular cross-section. When ℓlong/ℓshort exceeded 2.0, the ∆ℓ/ℓshort–κ curves displayed a symmetric, serrated, growing, and even butterfly-like pattern. A larger ℓlong/ℓshort corresponded to a larger ∆ℓ/ℓshort. For a fixed ℓlong/ℓshort, increasing Φ decreased ∆ℓ/ℓshort.

- (3)

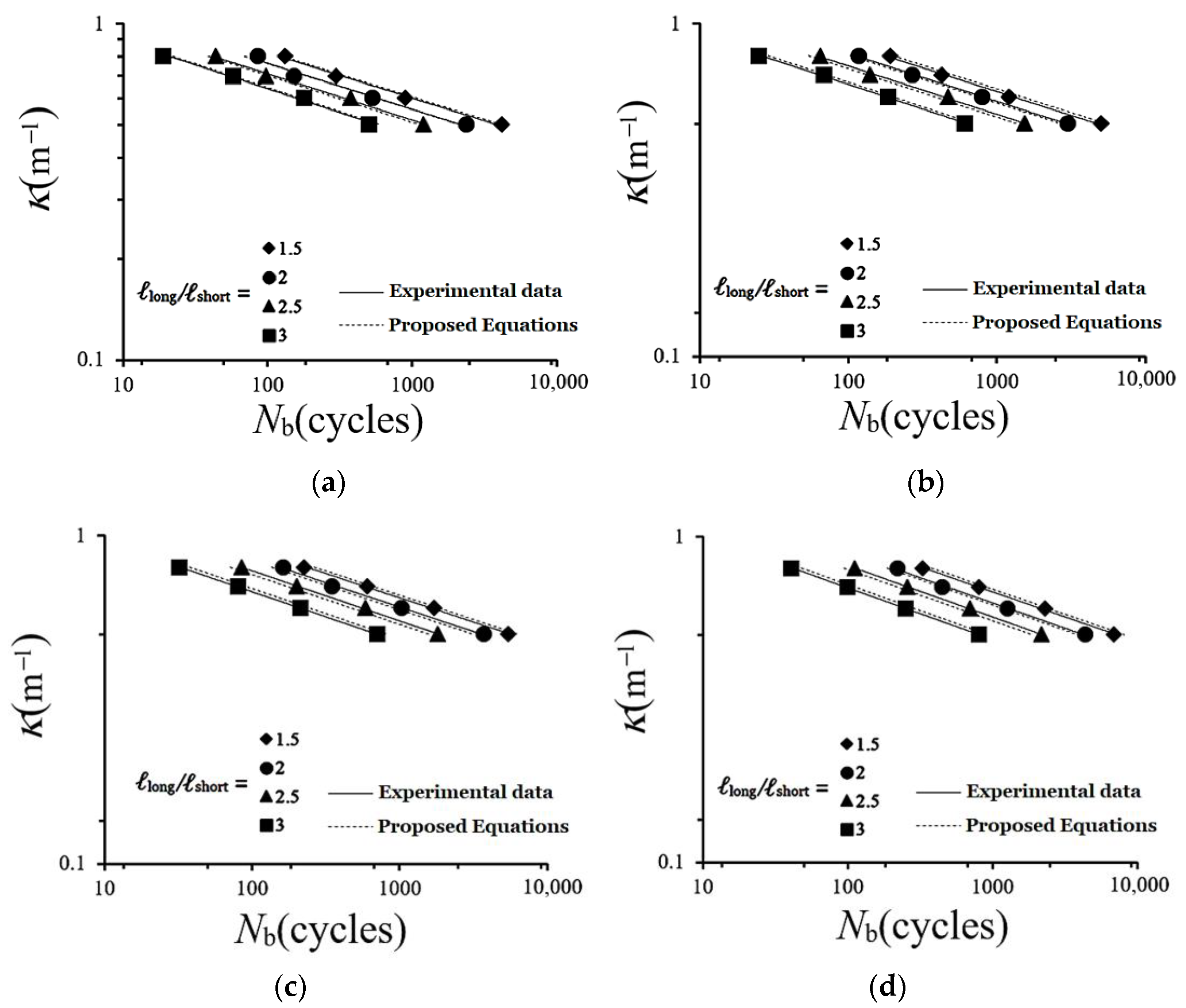

- For a fixed Φ and ℓlong/ℓshort, Nb decreased with increasing κ. For a fixed κ, Nb decreased with increasing ℓlong/ℓshort. For a fixed ℓlong/ℓshort, Nb decreased with increasing Φ. When these relationships were plotted on double logarithmic co-ordinates, it became apparent that the four distinct ℓlong/ℓshort corresponded to four straight lines for each Φ. Moreover, the four straight lines had distinct slopes and intercepts.

- (4)

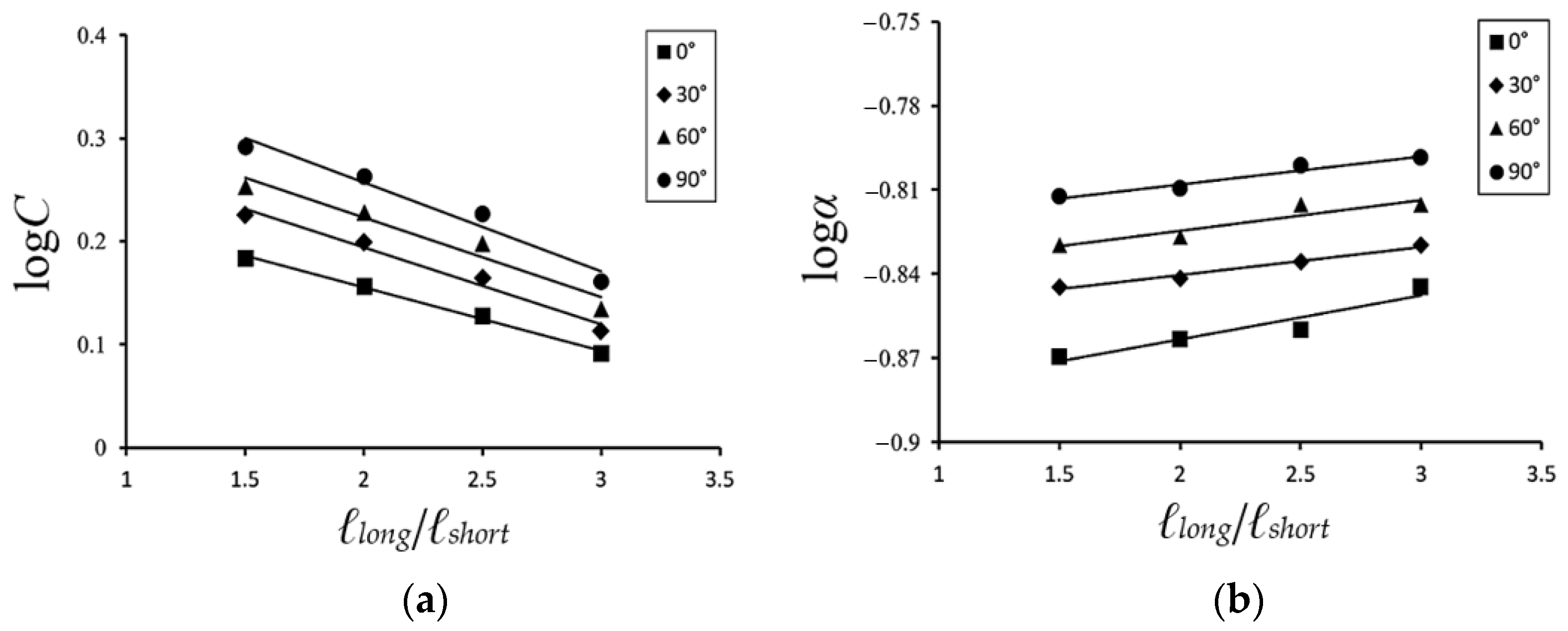

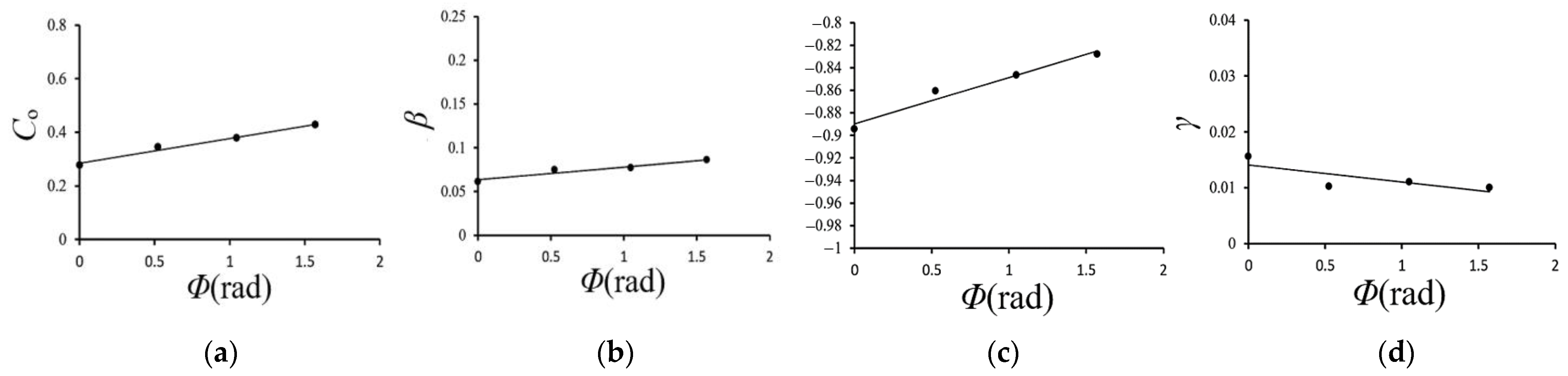

- Equation (3) or (4) can be used to describe the κ2013Nb curves. The experimental data were utilized to identify linear logC − ℓlong/ℓshort relationships (Figure 14a) and logα − ℓlong/ℓshort relationships (Figure 14b), which allowed Equations (5) and (6) to be derived. The data in Figure 14a,b were used to establish a linear Co − Φ relationship (Figure 15a), β − Φ relationship (Figure 15b), αo − Φ relationship (Figure 15c), and γ − Φ relationship (Figure 15d), which allowed Equations (7)–(10) to be derived. Equations (4)–(10) were then employed to describe the κ–Nb relationships for SUS304 stainless steel elliptical tubes under cyclic bending with different ℓlong/ℓshort and different Φ. They showed good agreement with the experimental data, as shown in Figure 16a–d. This indicates that the proposed equations reasonably describe the experimental results.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kyriakides, S.; Shaw, P.K. Inelastic buckling of tubes under cyclic bending. J. Pres. Ves. Technol. 1987, 109, 169–178. [Google Scholar] [CrossRef]

- Corona, E.; Kyriakides, S. An experimental investigation of the degradation and buckling of circular tubes under cyclic bending and external pressure. Thin-Walled Struct. 1991, 12, 229–263. [Google Scholar] [CrossRef]

- Corona, E.; Kyriakides, S. Asymmetric collapse modes of pipes under combined bending and pressure. Int. J. Solids Struct. 2000, 24, 505–535. [Google Scholar] [CrossRef]

- Corona, E.; Lee, L.H.; Kyriakides, S. Yield anisotropic effects on buckling of circular tubes under bending. Int. J. Solids Struct. 2006, 43, 7099–7118. [Google Scholar] [CrossRef]

- Limam, A.; Lee, L.H.; Corana, E. Inelastic wrinkling and collapse of tubes under combined bending and internal pressure. Int. J. Mech. Sci. 2010, 52, 37–47. [Google Scholar] [CrossRef]

- Limam, A.; Lee, L.H.; Corona, E.; Kyriakides, S. On the collapse of dented tubes under combined bending and internal pressure. Int. J. Solids Struct. 2012, 55, 1–12. [Google Scholar] [CrossRef]

- Bechle, N.J.; Kyriakides, S. Localization of NiTi tubes under bending. Int. J. Solids Struct. 2014, 51, 967–980. [Google Scholar] [CrossRef]

- Jiang, D.; Kyriakides, S.; Bechle, N.J.; Landis, C.M. Bending of pseudoelastic NiTi tubes. Int. J. Solids Struct. 2017, 124, 192–214. [Google Scholar] [CrossRef]

- Kazinakis, K.; Kyriakides, S.; Jiang, D.; Bechle, N.J.; Landis, C.M. Buckling and collapse of pseudoelastic NiTi tubes under bending. Int. J. Solids Struct. 2021, 221, 2–17. [Google Scholar] [CrossRef]

- Yuan, W.; Mirmiran, A. Buckling analysis of concrete-filled FRP tubes. Int. J. Struct. Stab. Dyn. 2001, 1, 367–383. [Google Scholar] [CrossRef]

- Elchalakani, M.; Zhao, X.L.; Grzebieta, R.H. Plastic mechanism analysis of circular tubes under pure bending. Int. J. Mech. Sci. 2002, 44, 1117–1143. [Google Scholar] [CrossRef]

- Houliara, S.; Karamanos, S.A. Buckling and post-buckling of long pressurized elastic thin-walled tubes under in-plane bending. Int. J. Nonlinear Mech. 2006, 44, 491–511. [Google Scholar] [CrossRef]

- Elchalakani, M.; Zhao, X.L.; Grzebieta, R.H. Variable amplitude cyclic pure bending tests to determine fully ductile section slenderness limits for cold-formed CHS. Eng. Struct. 2006, 28, 1223–1235. [Google Scholar] [CrossRef]

- Zhi, X.D.; Fan, F.; Shen, S.Z. Failure mechanism of single-layer cylindrical reticulated shells under earthquake motion. Int. J. Struct. Stab. Dyn. 2012, 12, 233–249. [Google Scholar] [CrossRef]

- Yazdani, H.; Nayebi, A. Continuum damage mechanics analysis of thin-walled tube under cyclic bending and internal constant pressure. Int. J. Appl. Mech. 2013, 5, 1350038. [Google Scholar] [CrossRef]

- Guo, L.; Yang, S.; Jiao, H. Behavior of thin-walled circular hollow section tubes subjected to bending. Thin-Walled Struct. 2013, 73, 281–289. [Google Scholar] [CrossRef]

- Shariati, M.; Kolasangiani, K.; Norouzi, G.; Shahnavaz, A. Experimental study of SS316L cantilevered cylindrical shells under cyclic bending load. Thin-Walled Struct. 2014, 82, 124–131. [Google Scholar] [CrossRef]

- Elchalakani, M.; Karrech, A.; Hassanein, M.F.; Yang, B. Plastic and yield slenderness limits for circular concrete filled tubes subjected to static pure bending. Thin-Walled Struct. 2016, 109, 50–64. [Google Scholar] [CrossRef]

- Shamass, R.; Alfano, G.; Guarracino, F. On elastoplastic buckling analysis of cylinders under nonproportional loading by differential quadrature method. Int. J. Struct. Stab. Dyn. 2017, 17, 1750072. [Google Scholar] [CrossRef]

- Li, P.; Wang, L. Nonlinear stability behavior of cable-stiffened single-layer latticed shells under earthquakes. Int. J. Struct. Stab. Dyn. 2018, 18, 1850117. [Google Scholar] [CrossRef]

- Chegeni, B.; Jayasuriya, S.; Das, S. Effect of corrosion on thin-walled pipes under combined internal pressure and bending. Thin-Walled Struct. 2019, 143, 106218. [Google Scholar] [CrossRef]

- Jin, S.; Cheng, P.; Saneian, M.; Yong, B. Mechanical behavior of thin tubes under combined axial compression and bending. Thin-Walled Struct. 2021, 159, 107255. [Google Scholar] [CrossRef]

- Da Silveira, T.; Pinto, V.T.; Neufeld, J.P.; Pavlovic, A.; Rocha, L.A.; Dos Santos, E.D.; Isoldi, L.A. Applicability evidence of constructal design in structural engineering: Case study of biaxial elasto-plastic buckling of square steel plates with elliptical cutout. J. Appl. Comput. Mech. 2021, 7, 922–934. [Google Scholar]

- He, Z.R.; Li, G.J.; Yang, J.C.; Guo, X.Z.; Duan, X.Y.; Guo, W.; Liu, X.; Deng, Y.Y.; Cheng, C. Insight into the deformation transition effect in free bending of tubes. Thin-Walled Struct. 2023, 348, 134673. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.R.; Li, H.; Lv, L.Y. Behaviour of square concrete-filled steel tubes reinforced with internal latticed steel angles under bending. Structures 2023, 48, 1436–1454. [Google Scholar] [CrossRef]

- Lee, K.L.; Tsai, Y.C.; Pan, W.F. Mean curvature effect on the response and failure of round-hole tubes submitted to cyclic bending. Adv. Mech. Eng. 2021, 13, 1–14. [Google Scholar] [CrossRef]

- Pan, W.F.; Wang, T.R.; Hsu, C.M. A curvature-ovalization measurement apparatus for circular tubes under cyclic bending. Exp. Mech. 1998, 38, 99–102. [Google Scholar] [CrossRef]

| Element | Fe | Cr | Ni | Mn | Si | C | P |

|---|---|---|---|---|---|---|---|

| Proportion (%) | 72.36 | 18.01 | 8.01 | 1.01 | 0.51 | 0.08 | 0.011 |

| Density | Elastic Modulus | Poisson’s Ratio | Yield Strength | Ultimate Strength |

|---|---|---|---|---|

| 7930 | 195 GPa | 0.33 | 296 MPa | 626 MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, M.-C.; Pan, W.-F. Failure of Elliptical Tubes with Different Long–Short Axis Ratios under Cyclic Bending in Different Directions. Metals 2023, 13, 1891. https://doi.org/10.3390/met13111891

Yu M-C, Pan W-F. Failure of Elliptical Tubes with Different Long–Short Axis Ratios under Cyclic Bending in Different Directions. Metals. 2023; 13(11):1891. https://doi.org/10.3390/met13111891

Chicago/Turabian StyleYu, Min-Cheng, and Wen-Fung Pan. 2023. "Failure of Elliptical Tubes with Different Long–Short Axis Ratios under Cyclic Bending in Different Directions" Metals 13, no. 11: 1891. https://doi.org/10.3390/met13111891

APA StyleYu, M.-C., & Pan, W.-F. (2023). Failure of Elliptical Tubes with Different Long–Short Axis Ratios under Cyclic Bending in Different Directions. Metals, 13(11), 1891. https://doi.org/10.3390/met13111891