Effect of N Content on the Microstructure and Impact Properties of Normalized Vanadium Micro-Alloyed P460NL1 Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Method

2.2.1. Heat Treatment

2.2.2. Mechanical Properties Test

2.2.3. Microstructure

3. Results and Discussion

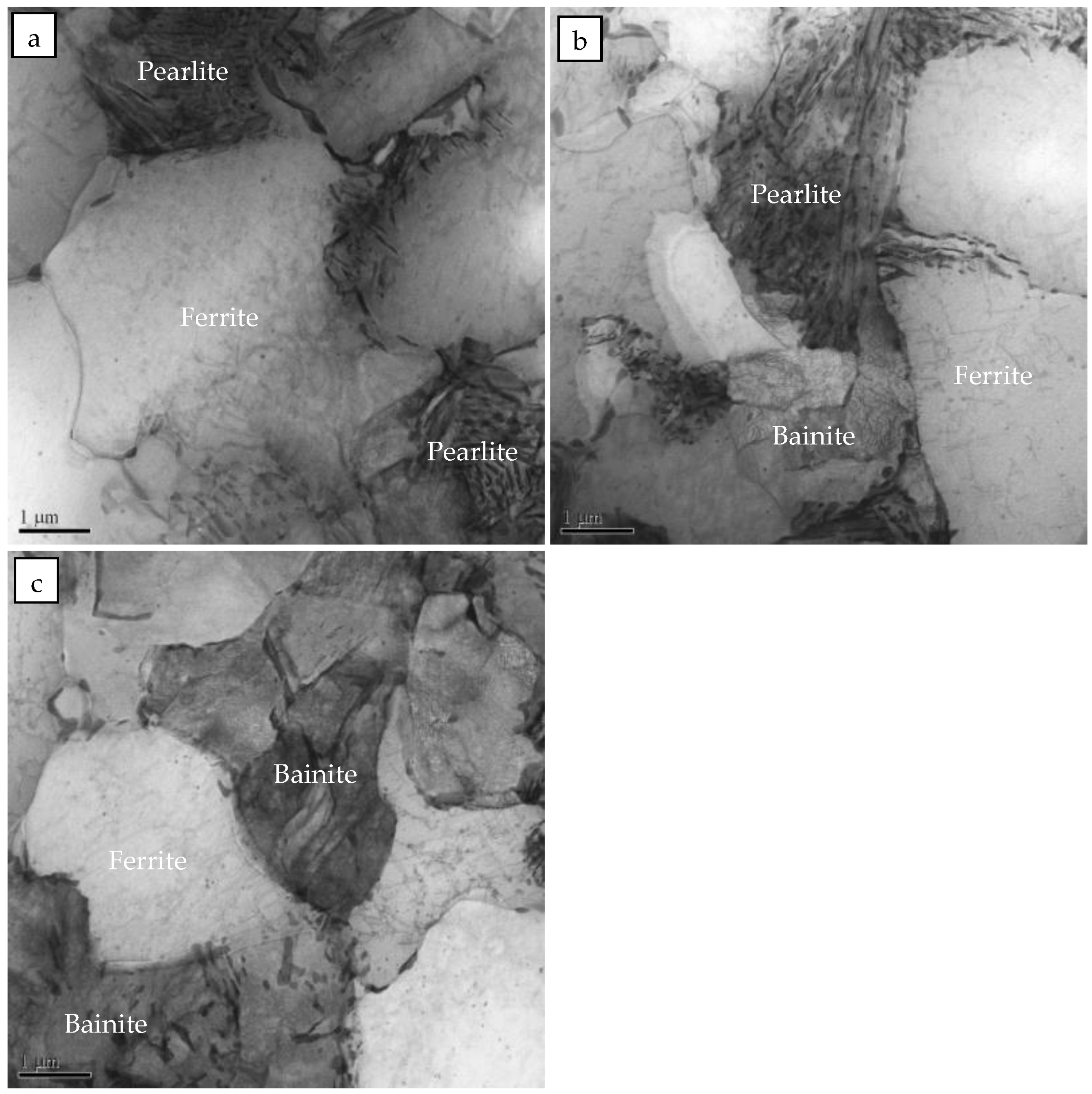

3.1. Effect of N Content on the Microstructures of Steel Samples

3.2. Effect of N Content on the Mechanical Properties of Steel Samples

4. Discussion

4.1. Analysis of the Microstructures of Steel Samples

4.2. Impact Toughness of Steel Samples

5. Conclusions

- (1)

- Doping of N in vanadium micro-alloyed P460NL1 steel can transform coarse ferrite and pearlite blocks into fine ferrite and bainitic ferrite blocks.

- (2)

- High N doping (165ppm) promoted the precipitation of V (C,N) particles in V micro-alloyed P460NL1 steel, leading to the formation of more fine V (C,N) particles and improving the stability of V (C,N) particles. The fine and stable V (C,N) particles in the normalizing process can effectively pin the prior austenite boundary and refine the prior austenite grains. During cooling, V (C,N) particles induced ferrite nucleation, resulting in fine ferrite.

- (3)

- As the N content increased from 36 ppm to 165 ppm in vanadium micro-alloyed P460NL1 steel, the impact toughness of the steel significantly increased from 34 J to 88 J, and the failure pattern changed from brittle failure to mixed failure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ouchi, C. Advances in Physical Metallurgy and Processing of Steels. Development of Steel Plates by Intensive Use of TMCP and Direct Quenching Processes. ISIJ Int. 2001, 41, 542–553. [Google Scholar] [CrossRef]

- Moss, D.R.; Basic, M.M. Pressure Vessel Design Manual; Elsevier: Amsterdam, The Netherlands, 1987. [Google Scholar]

- Tong, M.W.; Yuan, Z.X.; Zhang, K.G. Influence of Vanadium on Microstructures and Mechanical Properties of High Strength Normalized Steel. Adv. Mater. Res. 2012, 535, 628–632. [Google Scholar] [CrossRef]

- Pan, T.; Chai, X.; Wang, J.; Su, H.; Yang, C. Precipitation Behavior of V-N Microalloyed Steels during Normalizing. J. Iron Steel Res. Int. 2015, 22, 1037–1042. [Google Scholar] [CrossRef]

- Pindor, L.; Matějka, V.; Kozelsky, P.; Michalek, K.; Gigacher, G. Investigation into Secondary Phases in Steels Microalloyed with Vanadium and Nitrogen. Ironmak. Steelmak. 2013, 35, 124–128. [Google Scholar] [CrossRef]

- Medina, S.F.; Gómez, M.; Rancel, L. Grain Refinement by Intragranular Nucleation of Ferrite in a High Nitrogen Content Vanadium Microalloyed Steel. Scr. Mater. 2008, 58, 1110–1113. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Liu, Y.; Zhou, Y.N.; Dong, X.M.; Zhang, C.X.; Cao, G.H.; Schneider, R.; Gerthsen, D. Effect of Precipitation of (Ti,V)N and V(C,N) Secondary Phases on Mechanical Properties of V and N Microalloyed 1Cr Steels. Mater. Sci. Eng. A 2018, 738, 203–212. [Google Scholar] [CrossRef]

- Xie, Z.; Hui, W.; Bai, S.; Zhang, Y.; Zhao, X.; Li, B. Effects of Annealing Temperature and V Addition on Microstructure and Mechanical Properties of Fe-Mn-Al-C Austenitic Low-Density Steel. Mater. Today Commun. 2023, 35, 106328. [Google Scholar] [CrossRef]

- Zhao, X.; Zhao, K.; Liu, C.; Yang, Z.; Zhang, F. Effect of Ausforming on the Bainitic Transformation and Microstructure in Medium Carbon V–N Micro-Alloyed Steel. J. Mater. Res. Technol. 2023, 23, 637–647. [Google Scholar] [CrossRef]

- Li, L.; Song, B.; Cui, X.; Liu, Z.; Wang, L.; Cheng, W. Effects of Finish Rolling Deformation on Hydrogen-Induced Cracking and Hydrogen-Induced Ductility Loss of High-Vanadium TMCP X80 Pipeline Steel—ScienceDirect. Int. J. Hydrogen Energy 2020, 45, 30828–30844. [Google Scholar] [CrossRef]

- Liang, X.; Shen, J.; Jiao, S.; Wang, C. Precipitation Behavior of Vanadium in a High Nitrogen and Vanadium Bearing Steel Treated with TMCP. In Materials Science & Technology Conference and Exhibition: Product Manufacturing; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Xia, Z.X.; Zhang, C.; Yang, Z.G. Control of Precipitation Behavior in Reduced Activation Steels by Intermediate Heat Treatment. Mater. Sci. Eng. A 2011, 528, 6764–6768. [Google Scholar] [CrossRef]

- Tao, P.; Zhang, C.; Yang, Z.G.; Hiroyuki, T. Evolution and Coarsening of Carbides in 2. 25Cr1Mo Steel Weld Metal During High Temperature Tempering. J. Iron Steel Res. Int. 2010, 17, 74–78. [Google Scholar] [CrossRef]

- Hong, H.; Chunming, L.; Hanqian, Z. Effect of N Content on Microstructure and Properties of Normalized Steel for Mobile Containers. J. Chin. Core J. Criterion PKU Press. Vessel. 2019, 36, 1–7. [Google Scholar]

- Medina, S.F.; Rancel, L.; Gómez, M.; Ishak, R.; De Sanctis, M. Intragranular Nucleation of Ferrite on Precipitates and Grain Refinement in a Hot Deformed V-Microalloyed Steel. ISIJ Int. 2008, 48, 1603–1608. [Google Scholar] [CrossRef]

- Fan, H.; Shi, G.; Peng, T.; Wang, Q.; Wang, L.; Wang, Q.; Zhang, F. N-Induced Microstructure Refinement and Toughness Improvement in the Coarse Grain Heat-Affected Zone of a Low Carbon Mo–V–Ti–B Steel Subjected to a High Heat Input Welding Thermal Cycle. Mater. Sci. Eng. A 2021, 824, 141799. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Capdevila, C.; Caballero, F.G.; Andres, C.G.D. Influence of V Precipitates on Acicular Ferrite Transformation Part 1: The Role of Nitrogen. ISIJ Int. 2008, 48, 1270–1275. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, S.; Song, R.; Ren, S.; Zhang, Y.; Sun, X.; Dai, G.; Hao, Y.; Huo, W.; Zhao, S.; et al. Effect of V, Nb, and Ti Microalloying on Low–Temperature Impact Fracture Behavior of Non–Quenched and Tempered Forged Steel. Mater. Sci. Eng. A 2023, 879, 145299. [Google Scholar] [CrossRef]

- Pickering, F. High-Strength, Low Alloy Steels—A Decade of Progress; Union Carbide Corp: New York, NY, USA, 1975. [Google Scholar]

- Ricks, R.A.; Howell, P.R.; Barritte, G.S. The Nature of Acicular Ferrite in HSLA Steel Weld Metals. J. Mater. Sci. 1982, 17, 732–740. [Google Scholar] [CrossRef]

- Hu, J.; Du, L.X.; Wang, J.J.; Gao, C.R. Effect of Welding Heat Input on Microstructures and Toughness in Simulated CGHAZ of V–N High Strength Steel. Mater. Sci. Eng. A 2013, 577, 161–168. [Google Scholar] [CrossRef]

- Fang, F.; Qi-Long, Y.; Cai-Fu, Y.; Hang, S.U. Microstructure and Precipitation Behavior in Heat Affected Zone of Nitrogen-Enhanced Microalloyed Steel Containing V and Ti. J. Iron Steel Res. Int. 2007, 14, 249–253. [Google Scholar] [CrossRef]

- Hu, J.; Du, L.X.; Wang, J.J. Effect of V on Intragranular Ferrite Nucleation of High Ti Bearing Steel. Scr. Mater. 2013, 68, 953–956. [Google Scholar] [CrossRef]

- Contribution of Grain Size to Resistance against Cleavage Crack Propagation in Ferritic Steel—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/abs/pii/S1359645419304112?via%3Dihub (accessed on 21 June 2019).

- Mohseni, P.; Solberg, J.K.; Karlsen, M.; Akselsen, O.M.; Østby, E. Investigation of Mechanism of Cleavage Fracture Initiation in Intercritically Coarse Grained Heat Affected Zone of HSLA Steel. Mater. Sci. Technol. 2012, 28, 1261–1268. [Google Scholar] [CrossRef]

- Han, J.; Da Silva, A.K.; Ponge, D.; Raabe, D.; Lee, S.M.; Lee, Y.K.; Lee, S.I.; Hwang, B. The Effects of Prior Austenite Grain Boundaries and Microstructural Morphology on the Impact Toughness of Intercritically Annealed Medium Mn Steel. Acta Mater. 2017, 122, 199–206. [Google Scholar] [CrossRef]

- Zhang, S.; Romo, S.; Giorjao, R.A.; Leao, P.B.P.; Ramirez, A.J. EBSD Analysis of Strain Distribution and Evolution in Ferritic-Pearlitic Steel under Cyclic Deformation at Intermediate Temperature. Mater. Charact. 2022, 193, 112293. [Google Scholar] [CrossRef]

- Shi, G.; Luo, B.; Zhang, S.; Wang, Q.; Zhao, H. Microstructural Evolution and Mechanical Properties of a Low-Carbon V-N-Ti Steel Processed with Varied Isothermal Temperatures. Mater. Sci. Eng. A 2021, 801, 140396. [Google Scholar] [CrossRef]

- Rodriguez-Ibabe, J.M. The Role of Microstructure in Toughness Behaviour of Microalloyed Steels. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 1998; Volume 284, pp. 51–62. [Google Scholar] [CrossRef]

- Wang, K.; Hu, F.; Zhou, S.; Zhou, W.; Hu, C.; Yershov, S.; Wu, K. Microstructural Evolution and Ultra-High Impact Toughness of Austempered Lamellar Bainitic Steel Far below Ms Temperature. J. Mater. Res. Technol. 2023, 24, 5449–5462. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | P | S | Ni | V | N | Alt |

|---|---|---|---|---|---|---|---|---|---|

| 36N | 0.182 | 0.26 | 1.63 | 0.010 | 0.002 | 0.51 | 0.159 | 0.0036 | 0.002 |

| 103N | 0.180 | 0.27 | 1.65 | 0.010 | 0.002 | 0.50 | 0.155 | 0.0103 | 0.004 |

| 165N | 0.183 | 0.26 | 1.70 | 0.009 | 0.002 | 0.51 | 0.162 | 0.0165 | 0.008 |

| Steel | Impact Energy/J | Average Value/J | Yield Stress/MPa | Tensile Strength/MPa | Tensile Elongation | ||

|---|---|---|---|---|---|---|---|

| 36N | 31 | 36 | 35 | 34 | 479 | 636 | 28.5 |

| 103N | 45 | 49 | 50 | 48 | 495 | 653 | 26.3 |

| 165N | 83 | 89 | 92 | 88 | 513 | 670 | 21.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Fan, H.; Wang, Q.; Wang, Q. Effect of N Content on the Microstructure and Impact Properties of Normalized Vanadium Micro-Alloyed P460NL1 Steel. Metals 2023, 13, 1896. https://doi.org/10.3390/met13111896

Li X, Fan H, Wang Q, Wang Q. Effect of N Content on the Microstructure and Impact Properties of Normalized Vanadium Micro-Alloyed P460NL1 Steel. Metals. 2023; 13(11):1896. https://doi.org/10.3390/met13111896

Chicago/Turabian StyleLi, Xinliang, Huibing Fan, Qiuming Wang, and Qingfeng Wang. 2023. "Effect of N Content on the Microstructure and Impact Properties of Normalized Vanadium Micro-Alloyed P460NL1 Steel" Metals 13, no. 11: 1896. https://doi.org/10.3390/met13111896

APA StyleLi, X., Fan, H., Wang, Q., & Wang, Q. (2023). Effect of N Content on the Microstructure and Impact Properties of Normalized Vanadium Micro-Alloyed P460NL1 Steel. Metals, 13(11), 1896. https://doi.org/10.3390/met13111896