Finite Element Method in L-PBF of Ti-6Al-4V: Influence of Laser Power and Scan Speed on Residual Stress and Part Distortion

Abstract

:1. Introduction

2. Numerical Model

2.1. Governing Equations

2.1.1. Thermal Analysis

2.1.2. Mechanical Analysis

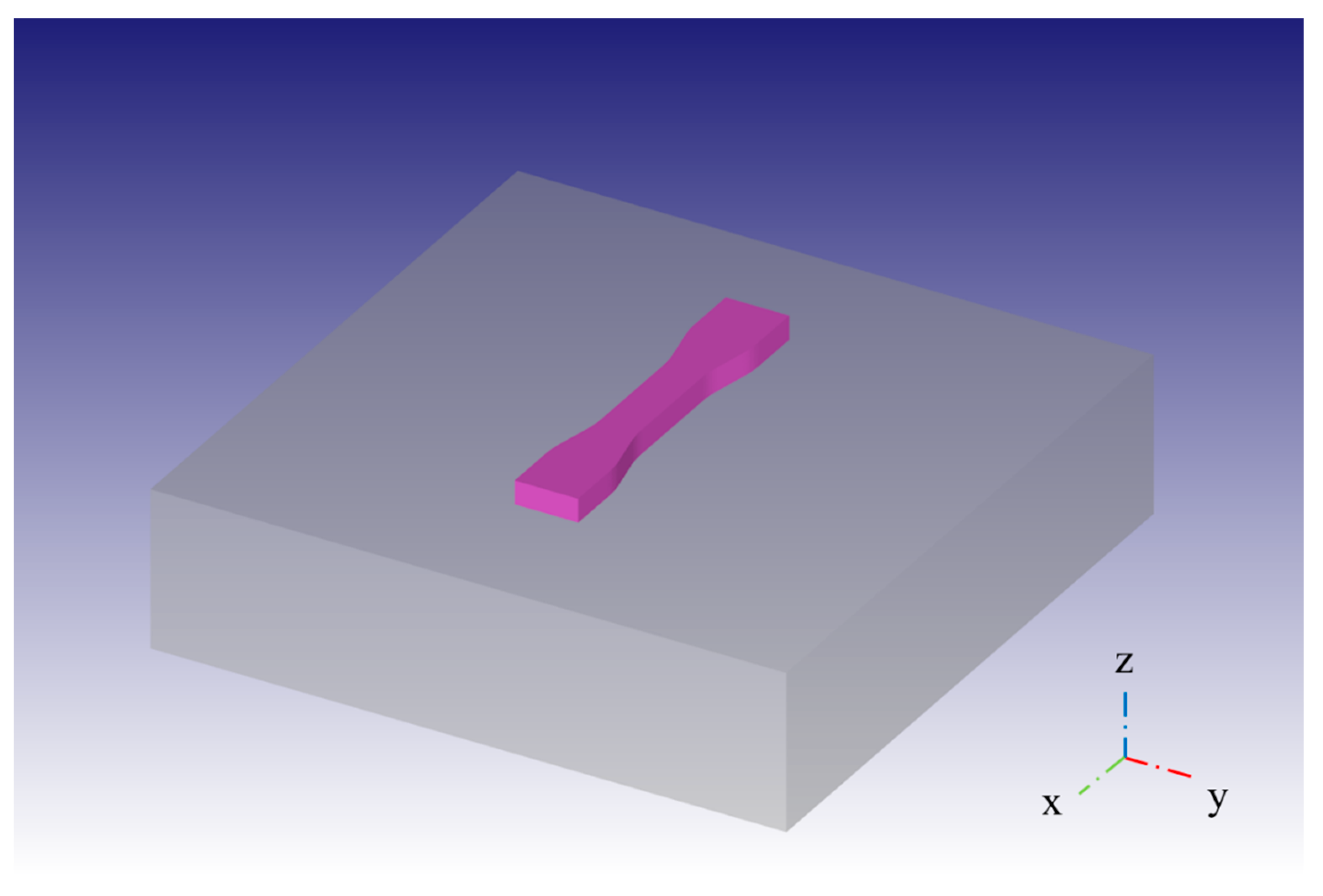

2.2. FEM Model for L-PBF

3. Experimental Details

4. Results

4.1. Accuracy of FEM Model to Predict the Part Distortion

4.2. FEM Simulation Results

5. Conclusions

- -

- The accuracy of the model is strictly dependent on the mesh used for the numerical analysis. In particular, a finer mesh allows for better activations of the elements according to the utilised voxel mesh.

- -

- The model accuracy varies when the laser power increases and the scan speed is kept constant. Instead, increasing scan speed does not have a significant influence on the model accuracy. When the laser power increases, while maintaining the scanning-speed constant, the volume of the material affected by remelting increases. In these conditions, the assumption made when not considering the presence of the surrounding powder can have a significant influence.

- -

- Laser power has a bigger impact on the residual stress and part distortion with respect to the scan speed. This is due to the small variation in the thermal gradients when the scan speed increases, which results in similar residual stress profiles and distortions. Instead, by increasing the laser power a significant variation in the thermal gradients and residual stress profiles is observed.

- -

- Simulation results, in agreement with the experimental ones, highlighted that the amount of distortions along the z-direction has a maximum when the laser power attains the value of 350 W and decreases for higher laser power values. For low laser power values, both temperature and temperature gradients along the building direction increase, with consequent increase for residual stress gradients and distortions; on the contrary, with higher laser power values, a decrease of the thermal gradient and consequent increase in the remelting zone of the material is found, resulting in decreasing residual stress gradients and distortions.

- -

- From the experimental analysis, the ID4 sample with laser power equal to 300 W and a scan speed of 1500 mm/s has shown better results in terms of distortion because of the smaller temperature gradients developed during the printing process, which led to a smaller amount of residual stress with respect to the other samples. Moreover, for ID4 the best results in terms of model accuracy were also obtained.

- -

- Even if it was possible to obtain the same trend between experimental and numerical analysis, the accuracy of the numerical model decreased with the increase of the laser power. This can be explained by a greater amount of the remelting area being involved in the numerical computation. In this case, using more computational layers and increasing the voxel mesh in the z-direction can help improve the model accuracy. This will be a topic of interest for future studies.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gao, S.; Tan, Z.; Lan, L.; Lu, G.; He, B. Experimental Investigation and Numerical Simulation of Residual Stress and Distortion of Ti6Al4V Components Manufactured Using Selective Laser Melting. J. Mater. Eng. Perform. 2022, 31, 8113–8123. [Google Scholar] [CrossRef]

- Ivanov, S.; Artinov, A.; Zemlyakov, E.; Karpov, I.; Rylov, S.; Em, V. Spatiotemporal Evolution of Stress Field during Direct Laser Deposition of Multilayer Thin Wall of Ti-6Al-4V. Materials 2022, 15, 263. [Google Scholar] [CrossRef] [PubMed]

- Gh Ghanbari, P.; Wrobel, R.; Rheingans, B.; Mayer, T.; Leinenbach, C.; Mazza, E.; Hosseini, E. Advancing Efficiency and Reliability in Thermal Analysis of Laser Powder-Bed Fusion. Int. J. Mech. Sci. 2023, 260, 108583. [Google Scholar] [CrossRef]

- Monu, M.C.C.; Afkham, Y.; Chekotu, J.C.; Ekoi, E.J.; Gu, H.; Teng, C.; Ginn, J.; Gaughran, J.; Brabazon, D. Bi-Directional Scan Pattern Effects on Residual Stresses and Distortion in As-Built Nitinol Parts: A Trend Analysis Simulation Study. Integr. Mater. Manuf. Innov. 2023, 12, 52–69. [Google Scholar] [CrossRef] [PubMed]

- Jażdżewska, M.; Kwidzińska, D.B.; Seyda, W.; Fydrych, D.; Zieliński, A. Mechanical Properties and Residual Stress Measurements of Grade IV Titanium and Ti-6Al-4V and Ti-13Nb-13Zr Titanium Alloys after Laser Treatment. Materials 2021, 14, 6316. [Google Scholar] [CrossRef]

- Buffa, G.; Costa, A.; Palmeri, D.; Pollara, G.; Barcellona, A.; Fratini, L. A New Control Parameter to Predict Micro-Warping-Induced Job Failure in LPBF of TI6AL4V Titanium Alloy. Int. J. Adv. Manuf. Technol. 2023, 126, 1143–1157. [Google Scholar] [CrossRef]

- Cook, P.S.; Ritchie, D.J. Determining the Laser Absorptivity of Ti-6Al-4V during Laser Powder Bed Fusion by Calibrated Melt Pool Simulation. Opt. Laser Technol. 2023, 162, 109247. [Google Scholar] [CrossRef]

- Dutta, J.; Bhanja, D.; Narendranath, S. Theoretical Evolution of Thermal Behaviour of Ti-6Al-4V Subjected to Selective Laser Melting: A Powder Free Approach. Optik 2023, 273, 170483. [Google Scholar] [CrossRef]

- Tan, P.; Shen, F.; Li, B.; Zhou, K. A Thermo-Metallurgical-Mechanical Model for Selective Laser Melting of Ti6Al4V. Mater. Des. 2019, 168, 107642. [Google Scholar] [CrossRef]

- Song, X.; Feih, S.; Zhai, W.; Sun, C.N.; Li, F.; Maiti, R.; Wei, J.; Yang, Y.; Oancea, V.; Romano Brandt, L.; et al. Advances in Additive Manufacturing Process Simulation: Residual Stresses and Distortion Predictions in Complex Metallic Components. Mater. Des. 2020, 193, 108779. [Google Scholar] [CrossRef]

- Ali, H.; Ghadbeigi, H.; Mumtaz, K. Effect of Scanning Strategies on Residual Stress and Mechanical Properties of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng. A 2018, 712, 175–187. [Google Scholar] [CrossRef]

- Jagatheeshkumar, S.; Raguraman, M.; Siva Prasad, A.V.S.; Nagesha, B.K.; Chandrasekhar, U. Study of Residual Stresses and Distortions from the Ti6Al4V Based Thin-Walled Geometries Built Using LPBF Process. Def. Technol. 2023, 28, 33–41. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, J.; Wang, Y. Evolution, Control, and Mitigation of Residual Stresses in Additively Manufactured Metallic Materials: A Review. Adv. Eng. Mater. 2023, 2300489. [Google Scholar] [CrossRef]

- Gan, M.; Wu, Q.; Long, L. Prediction of Residual Deformation and Stress of Laser Powder Bed Fusion Manufactured Ti-6Al-4V Lattice Structures Based on Inherent Strain Method. Mater. Res. 2023, 26, e20220516. [Google Scholar] [CrossRef]

- Li, X.; Zhang, M.; Qi, J.; Yang, Z.; Jiao, Z. A Simulation Study on the Effect of Residual Stress on the Multi-Layer Selective Laser Melting Processes Considering Solid-State Phase Transformation. Materials 2022, 15, 7175. [Google Scholar] [CrossRef]

- Kaess, M.; Werz, M.; Weihe, S. Residual Stress Formation Mechanisms in Laser Powder Bed Fusion—A Numerical Evaluation. Materials 2023, 16, 2321. [Google Scholar] [CrossRef]

- Bastola, N.; Jahan, M.P.; Rangasamy, N.; Rakurty, C.S. A Review of the Residual Stress Generation in Metal Additive Manufacturing: Analysis of Cause, Measurement, Effects, and Prevention. Micromachines 2023, 14, 1480. [Google Scholar] [CrossRef]

- Ahmed, N.; Barsoum, I.; Abu Al-Rub, R.K. Numerical Investigation of Residual Stresses in Thin-Walled Additively Manufactured Structures from Selective Laser Melting. Heliyon 2023, 9, e19385. [Google Scholar] [CrossRef]

- Olleak, A.; Xi, Z. A Study of Modeling Assumptions and Adaptive Remeshing for Thermomechanical Finite Element Modeling of the LPBF Process. Int. J. Adv. Manuf. Technol. 2021, 115, 3599–3615. [Google Scholar] [CrossRef]

- Promoppatum, P.; Yao, S.C. Influence of Scanning Length and Energy Input on Residual Stress Reduction in Metal Additive Manufacturing: Numerical and Experimental Studies. J. Manuf. Process. 2020, 49, 247–259. [Google Scholar] [CrossRef]

- Malmelöv, A.; Hassila, C.J.; Fisk, M.; Wiklund, U.; Lundbäck, A. Numerical Modeling and Synchrotron Diffraction Measurements of Residual Stresses in Laser Powder Bed Fusion Manufactured Alloy 625. Mater. Des. 2022, 216, 110548. [Google Scholar] [CrossRef]

- Xiao, Z.; Chen, C.; Zhu, H.; Hu, Z.; Nagarajan, B.; Guo, L.; Zeng, X. Study of Residual Stress in Selective Laser Melting of Ti6Al4V. Mater. Des. 2020, 193, 108846. [Google Scholar] [CrossRef]

- DEFORM 3D V12.0 User’s Manual; SFC: Columbus, OH, USA, 2020.

- Chiumenti, M.; Neiva, E.; Salsi, E.; Cervera, M.; Badia, S.; Moya, J.; Chen, Z.; Lee, C.; Davies, C. Numerical Modelling and Experimental Validation in Selective Laser Melting. Addit. Manuf. 2017, 18, 171–185. [Google Scholar] [CrossRef]

- Xu, R.; Wang, W.; Wang, K.; Dai, Q. Finite Element Simulation of Residual Stress Distribution during Selective Laser Melting of Mg-Y-Sm-Zn-Zr Alloy. Mater. Today Commun. 2023, 35, 105571. [Google Scholar] [CrossRef]

- Zeng, K.; Pal, D.; Stucker, B. A Review of Thermal Analysis Methods in Laser Sintering and Selective Laser Melting. In Proceedings of the 23rd Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, SFF 2012, Austin, TX, USA, 6–8 August 2012; pp. 796–814. [Google Scholar]

- Chen, C.; Xiao, Z.; Zhu, H.; Zeng, X. Deformation and Control Method of Thin-Walled Part during Laser Powder Bed Fusion of Ti–6Al–4V Alloy. Int. J. Adv. Manuf. Technol. 2020, 110, 3467–3478. [Google Scholar] [CrossRef]

- Chiumenti, M.; Lin, X.; Cervera, M.; Lei, W.; Zheng, Y.; Huang, W. Numerical Simulation and Experimental Calibration of Additive Manufacturing by Blown Powder Technology. Part I: Thermal Analysis. Rapid Prototyp. J. 2017, 23, 448–463. [Google Scholar] [CrossRef]

- Lu, X.; Chiumenti, M.; Cervera, M.; Slimani, M.; Gonzalez, I. Recoater-Induced Distortions and Build Failures in Selective Laser Melting of Thin-Walled Ti6Al4V Parts. J. Manuf. Mater. Process. 2023, 7, 64. [Google Scholar] [CrossRef]

- Bartsch, K.; Herzog, D.; Bossen, B.; Emmelmann, C. Material Modeling of Ti–6Al–4V Alloy Processed by Laser Powder Bed Fusion for Application in Macro-Scale Process Simulation. Mater. Sci. Eng. A 2021, 814, 141237. [Google Scholar] [CrossRef]

| Temperature [°C] | Density [kg/m3] | Specific Heat [J/(kg °C)] | Thermal Conductivity [W/(m°C)] | Poisson’s Ratio | Young’s Modulus [GPa] | Thermal Expansion [(µm/m)/°C] | Yield Stress [MPa] |

|---|---|---|---|---|---|---|---|

| 20 | 4420 | 546 | 7 | 0.345 | 110 | 8.78 | 850 |

| 205 | 4395 | 584 | 8.75 | 0.35 | 100 | 10 | 630 |

| 500 | 4350 | 651 | 12.6 | 0.37 | 76 | 11.2 | 470 |

| 995 | 4282 | 753 | 22.7 | 0.43 | 15 | 12.3 | 13 |

| 1100 | 4267 | 641 | 19.3 | 0.43 | 5 | 12.4 | 5 |

| 1200 | 4252 | 660 | 21 | 0.43 | 4 | 12.42 | 1 |

| 1600 | 4198 | 732 | 25.8 | 0.43 | 1 | 12.5 | 0.5 |

| 1650 | 3886 | 831 | 35 | 0.43 | 0.1 | 12.5 | 0.1 |

| 2000 | 3818 | 831 | 35 | 0.43 | 0.01 | 12.5 | 0.01 |

| P [W] | v [mm/s] | P/v [J/mm] | |

|---|---|---|---|

| ID1 | 350 | 1400 | 0.250 |

| ID2 | 350 | 1500 | 0.233 |

| ID3 | 350 | 1600 | 0.219 |

| ID4 | 300 | 1500 | 0.200 |

| ID5 | 400 | 1500 | 0.267 |

| Ti | Al | V | C | O | N | Fe | H |

|---|---|---|---|---|---|---|---|

| Balance | 5.50–6.50 | 3.50–4.50 | 0.08 | 0.13 | 0.03 | 0.25 | 0.0125 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palmeri, D.; Pollara, G.; Licari, R.; Micari, F. Finite Element Method in L-PBF of Ti-6Al-4V: Influence of Laser Power and Scan Speed on Residual Stress and Part Distortion. Metals 2023, 13, 1907. https://doi.org/10.3390/met13111907

Palmeri D, Pollara G, Licari R, Micari F. Finite Element Method in L-PBF of Ti-6Al-4V: Influence of Laser Power and Scan Speed on Residual Stress and Part Distortion. Metals. 2023; 13(11):1907. https://doi.org/10.3390/met13111907

Chicago/Turabian StylePalmeri, Dina, Gaetano Pollara, Roberto Licari, and Fabrizio Micari. 2023. "Finite Element Method in L-PBF of Ti-6Al-4V: Influence of Laser Power and Scan Speed on Residual Stress and Part Distortion" Metals 13, no. 11: 1907. https://doi.org/10.3390/met13111907

APA StylePalmeri, D., Pollara, G., Licari, R., & Micari, F. (2023). Finite Element Method in L-PBF of Ti-6Al-4V: Influence of Laser Power and Scan Speed on Residual Stress and Part Distortion. Metals, 13(11), 1907. https://doi.org/10.3390/met13111907