Determination of the Effect of Heat Input during Laser Welding on the Magnitude of Residual Stresses in the Refurbishment of Al Alloy Casting

Abstract

:1. Introduction

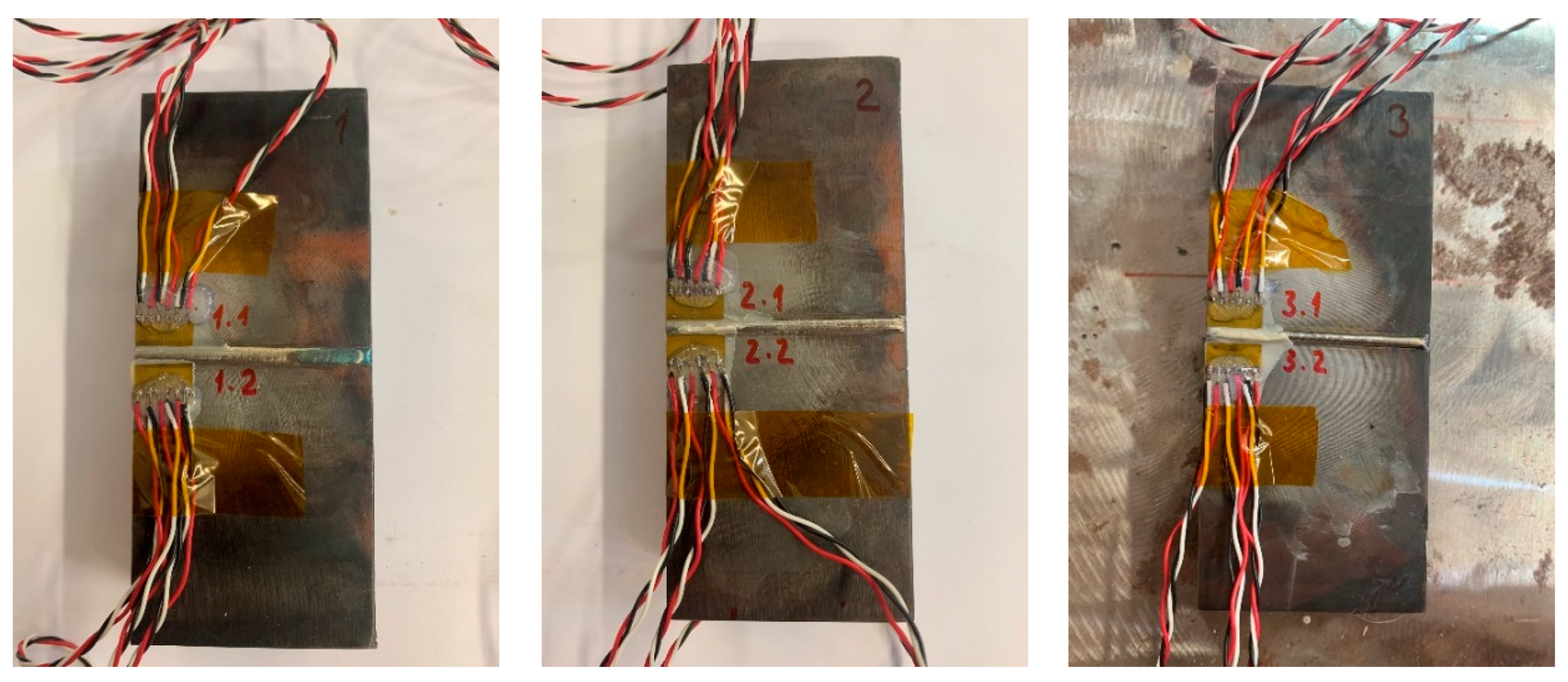

2. Materials and Methods

- -

- residual stresses by the drilling method;

- -

- light microscopy, (etchant used-3% HNO3 solution);

- -

- microstructure in the area of drilled holes (for the drilling method);

- -

- EDX analysis;

- -

- Clad hardness (in cross section in the plane of the drilled holes).

3. Results

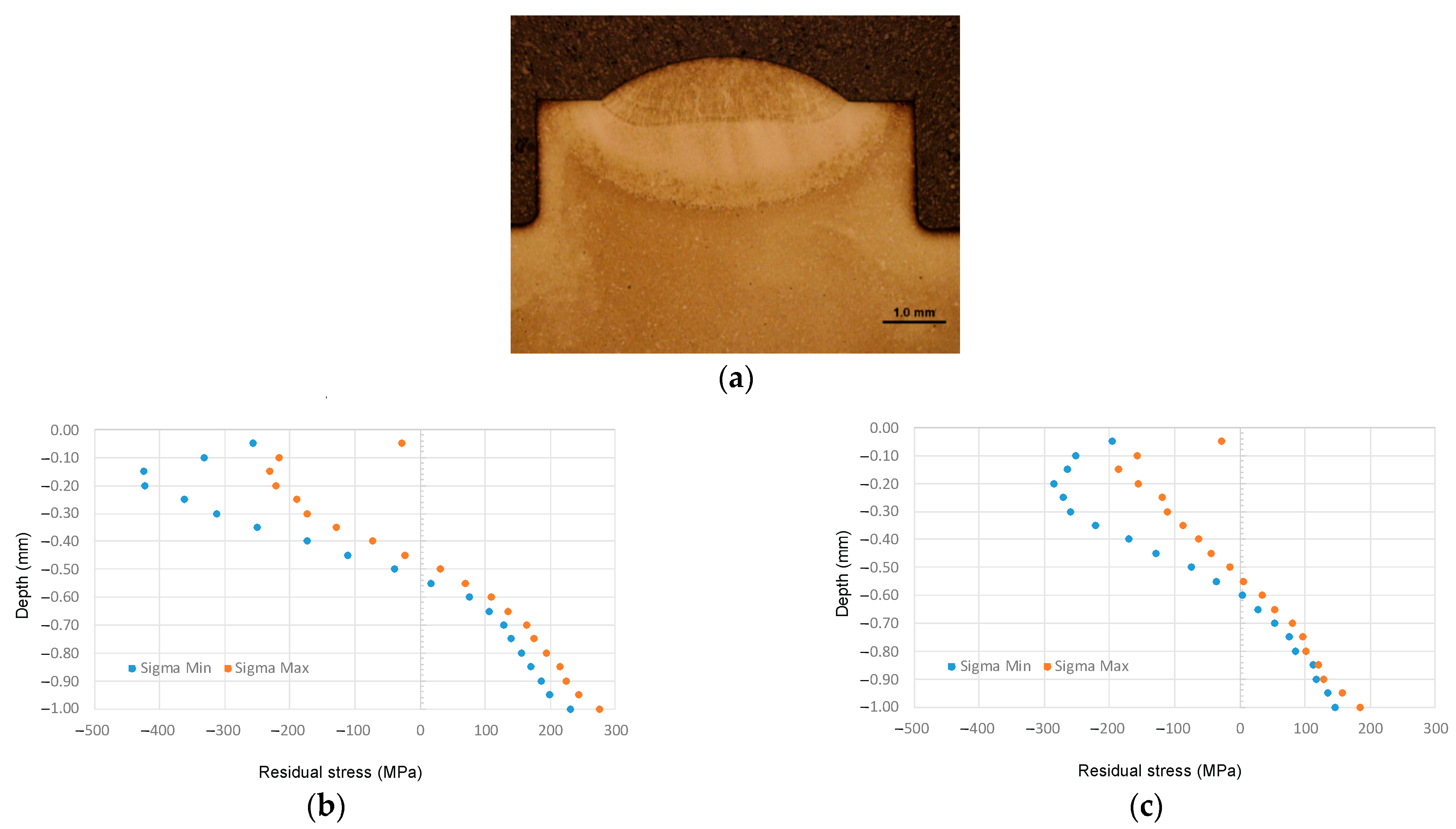

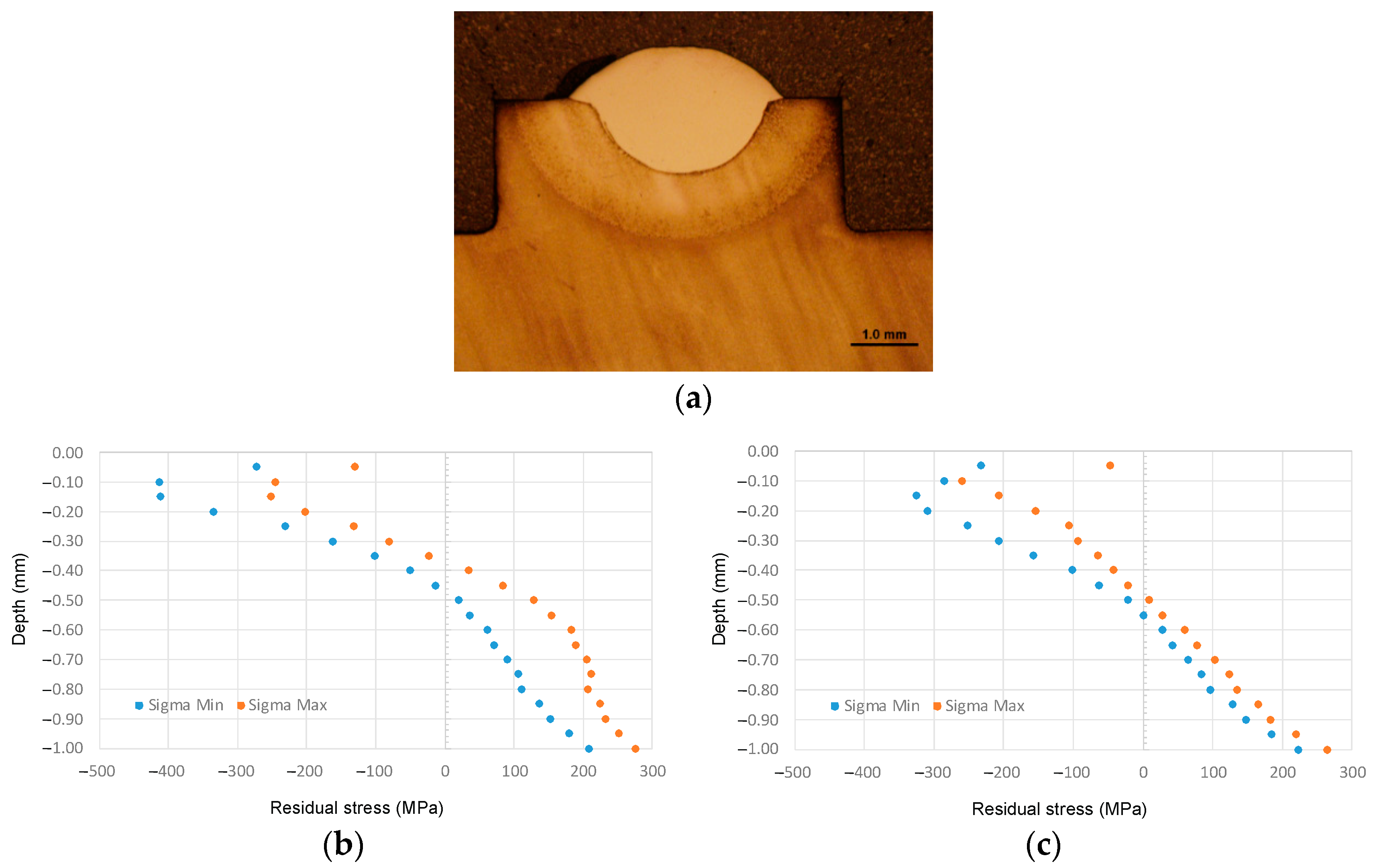

3.1. Residual Stresses

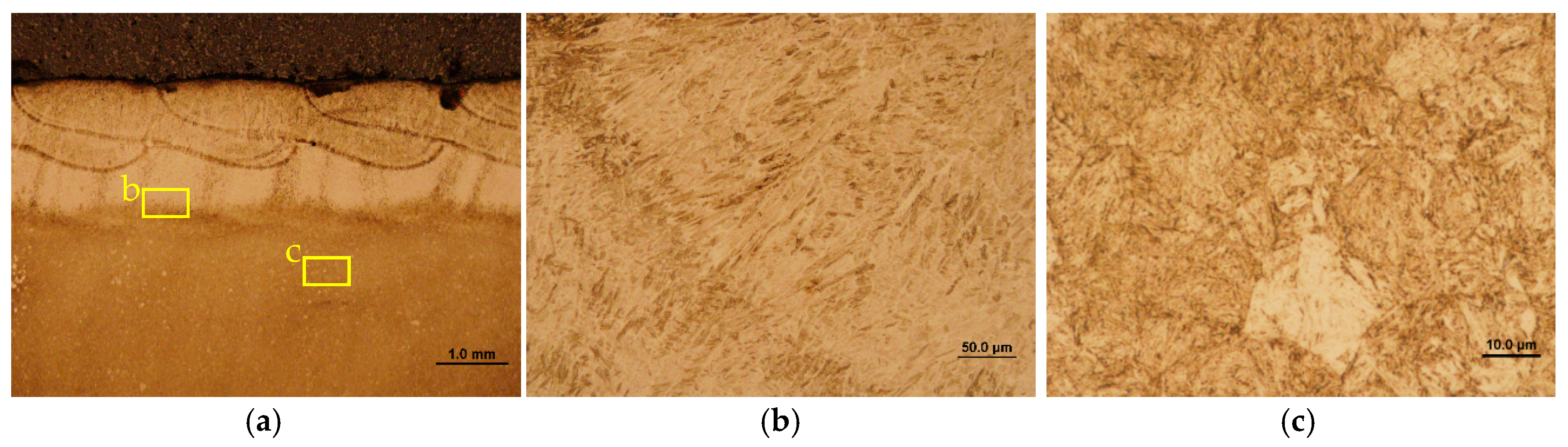

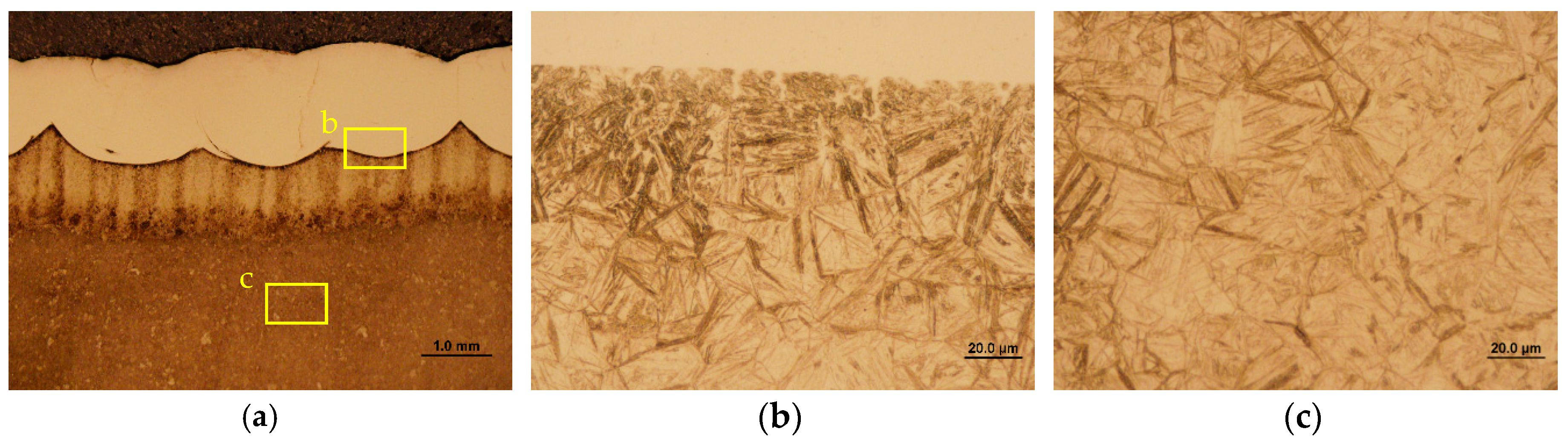

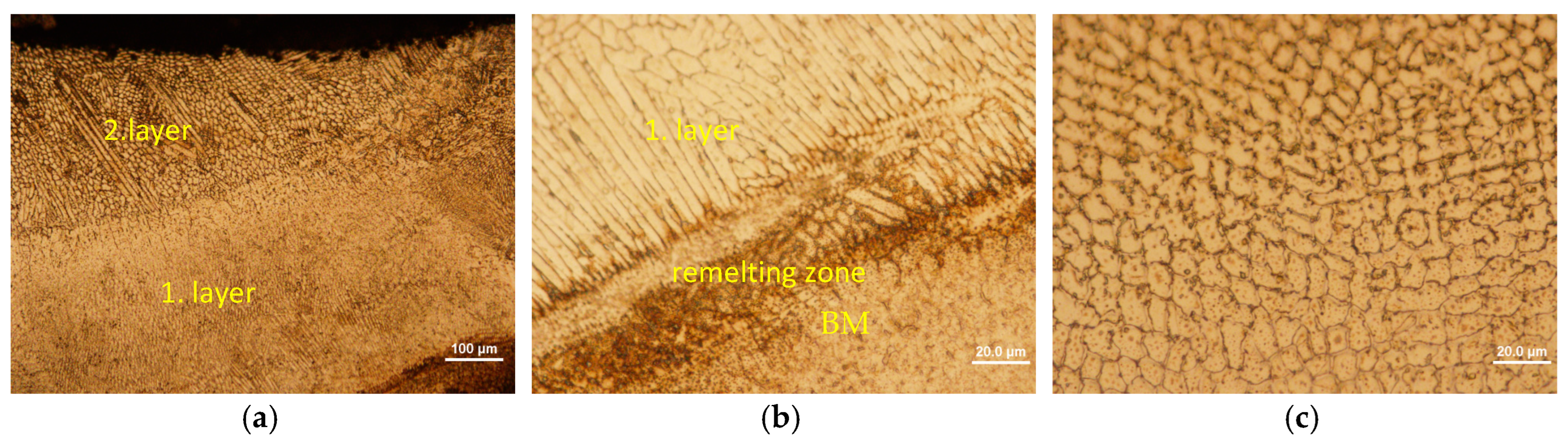

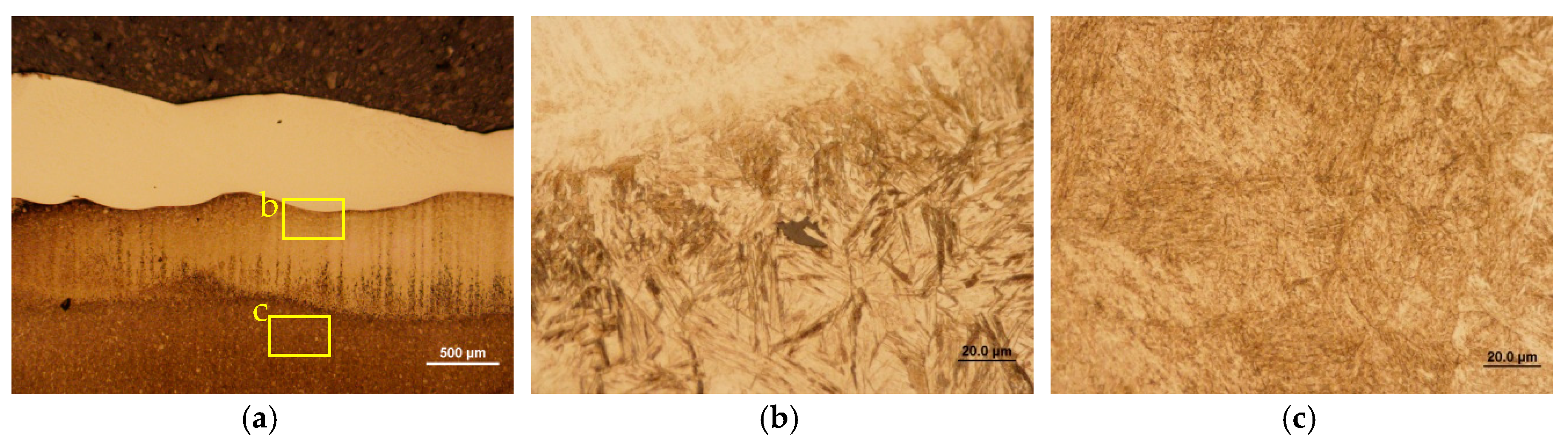

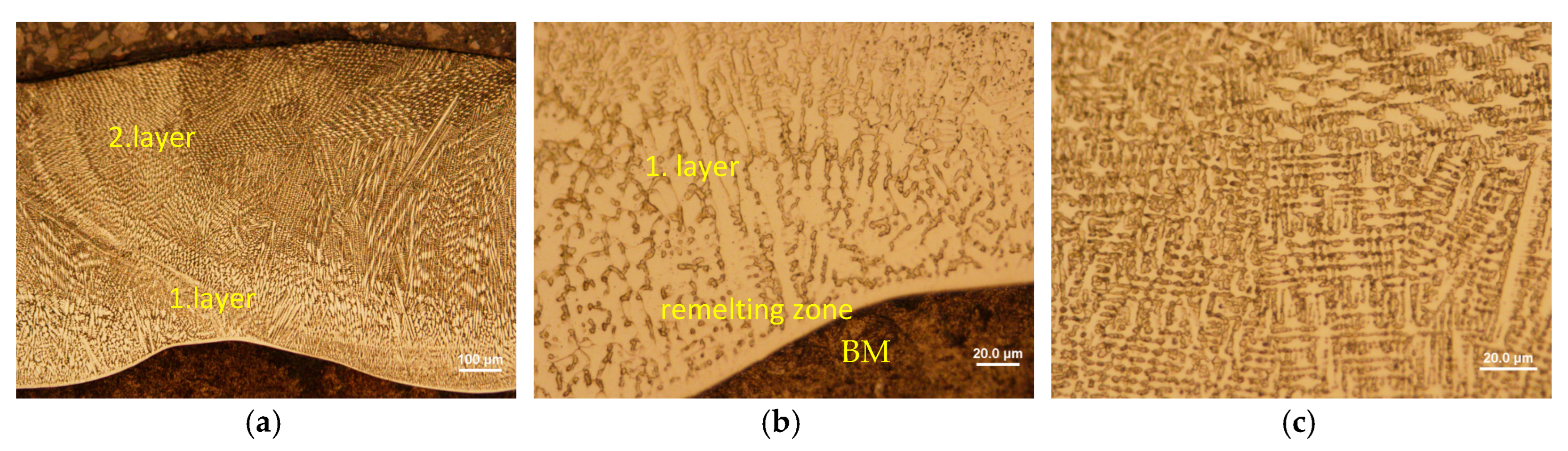

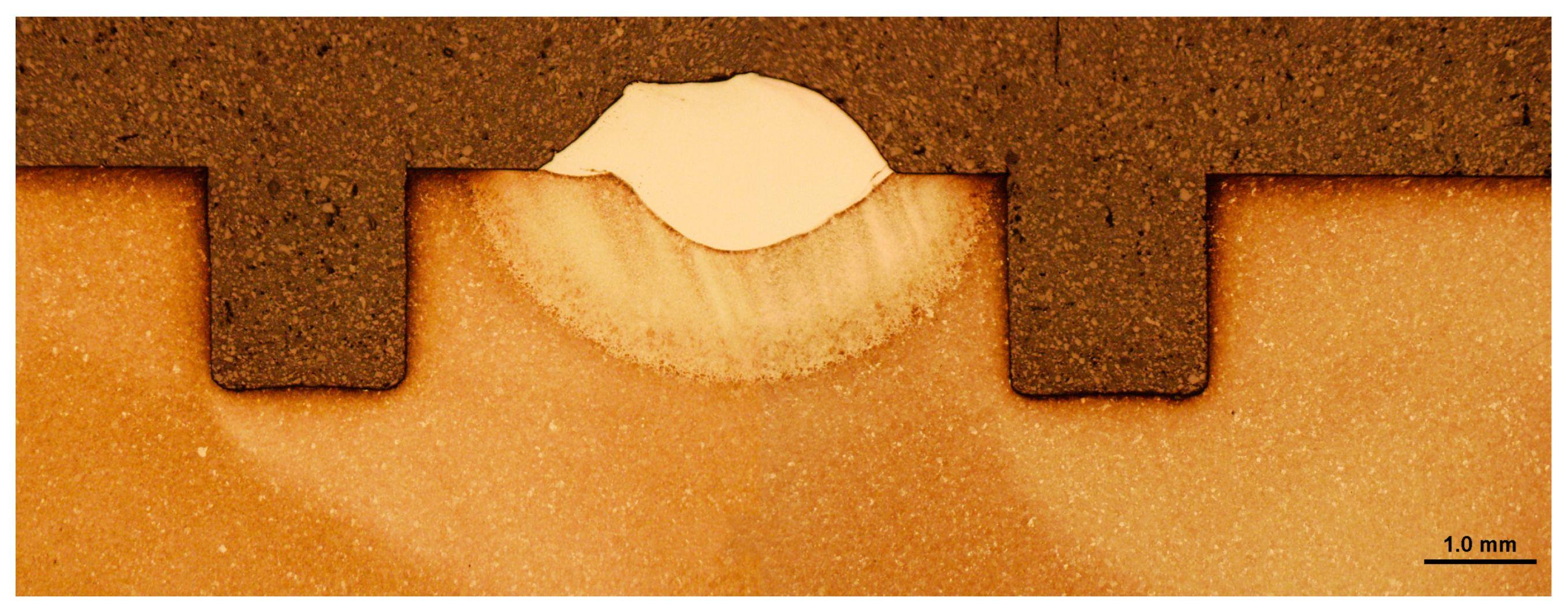

3.2. Light Microscopy

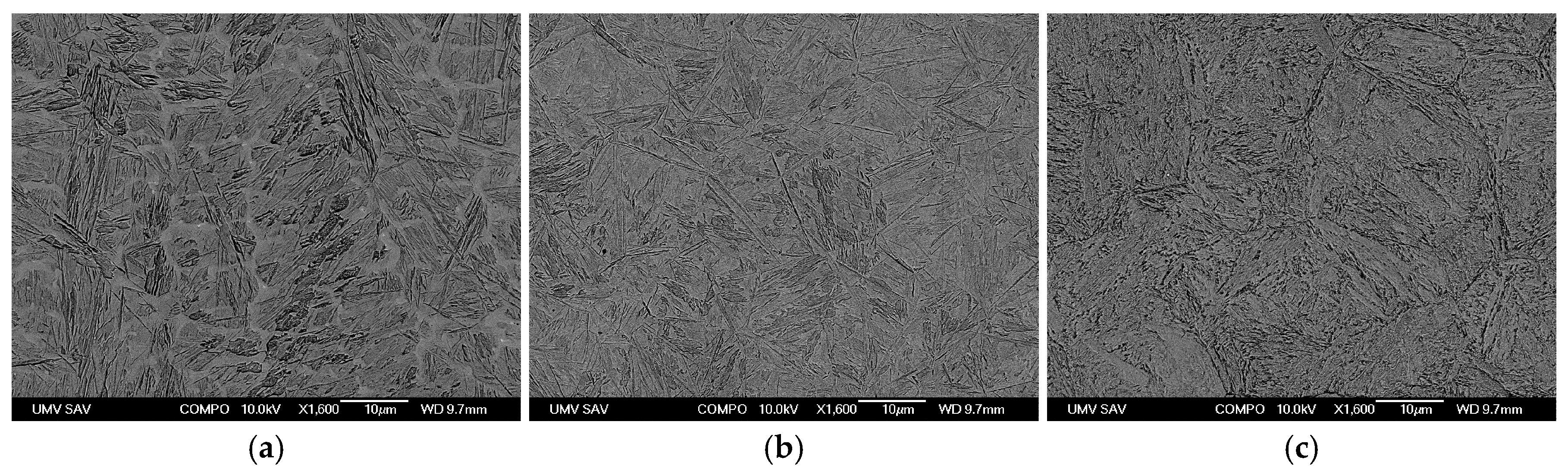

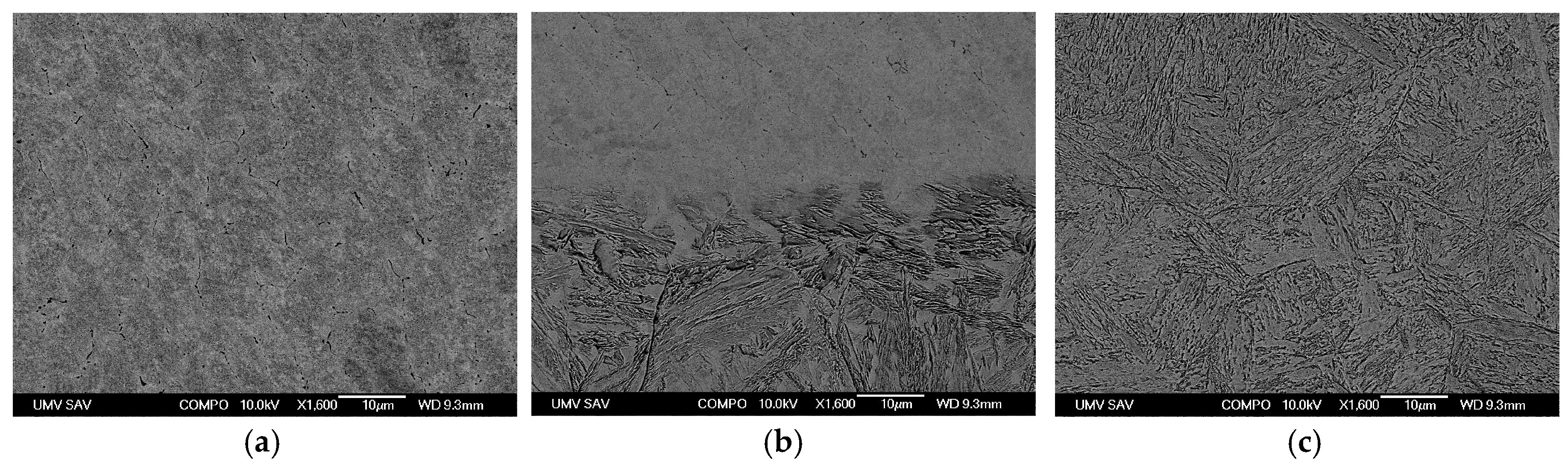

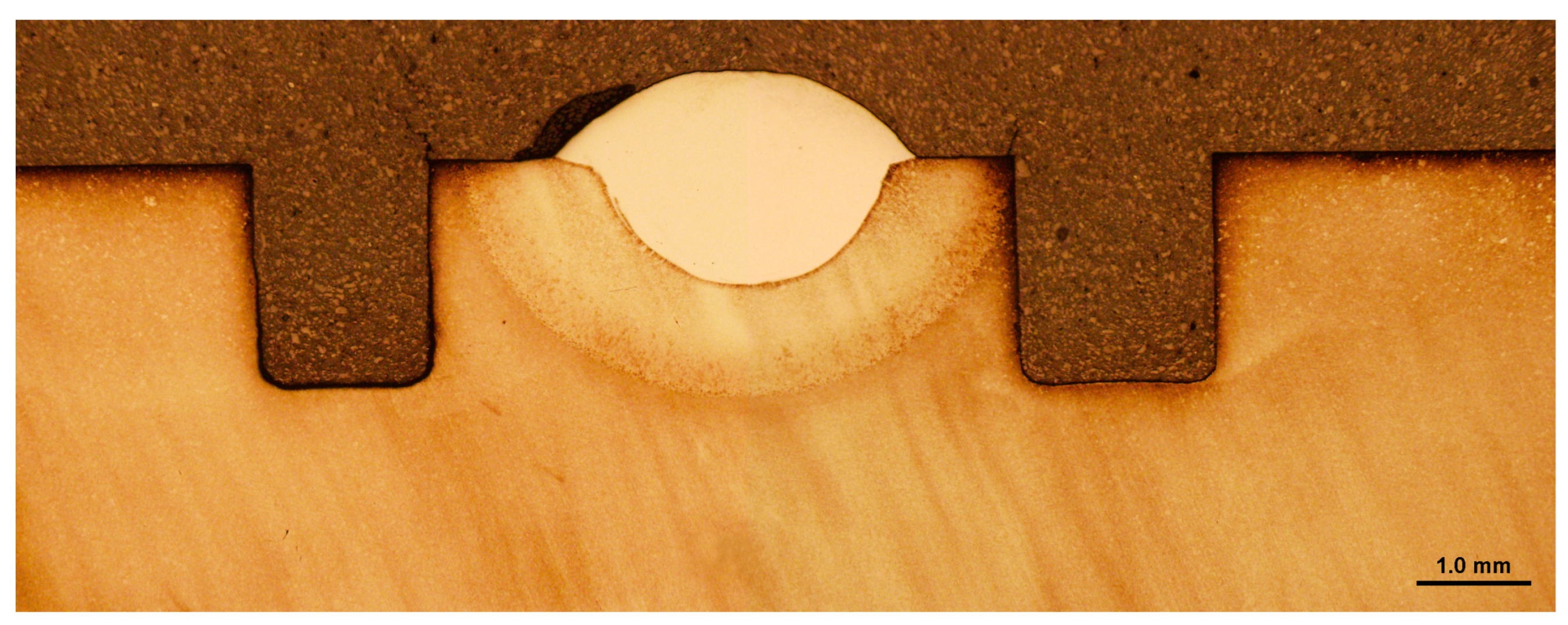

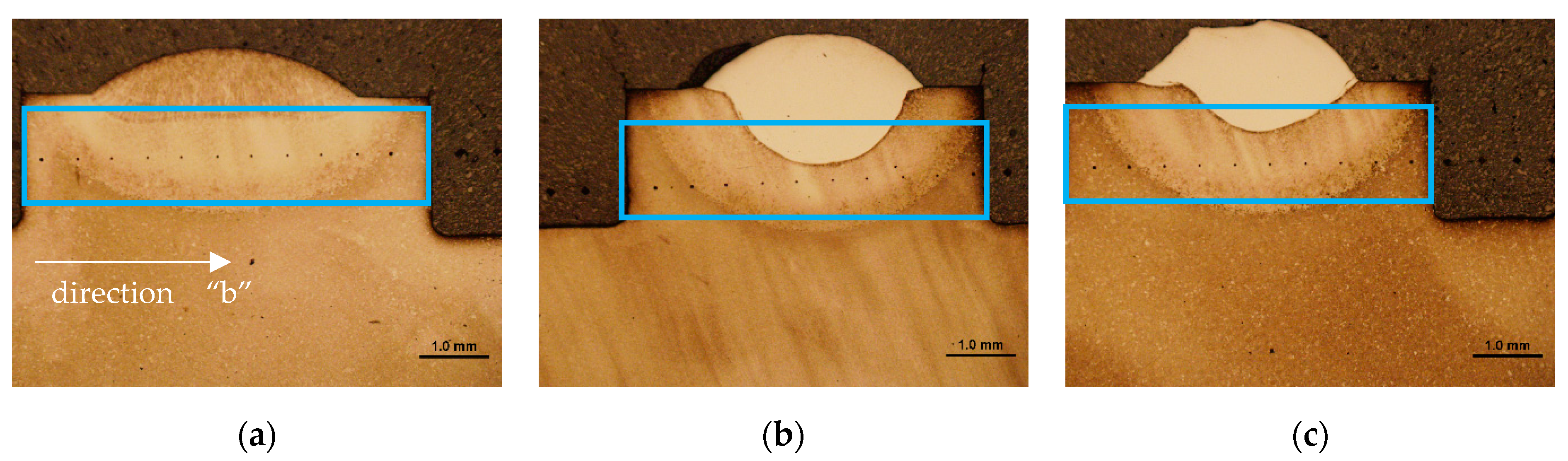

3.3. Microstructure in the Area of Drilled Holes

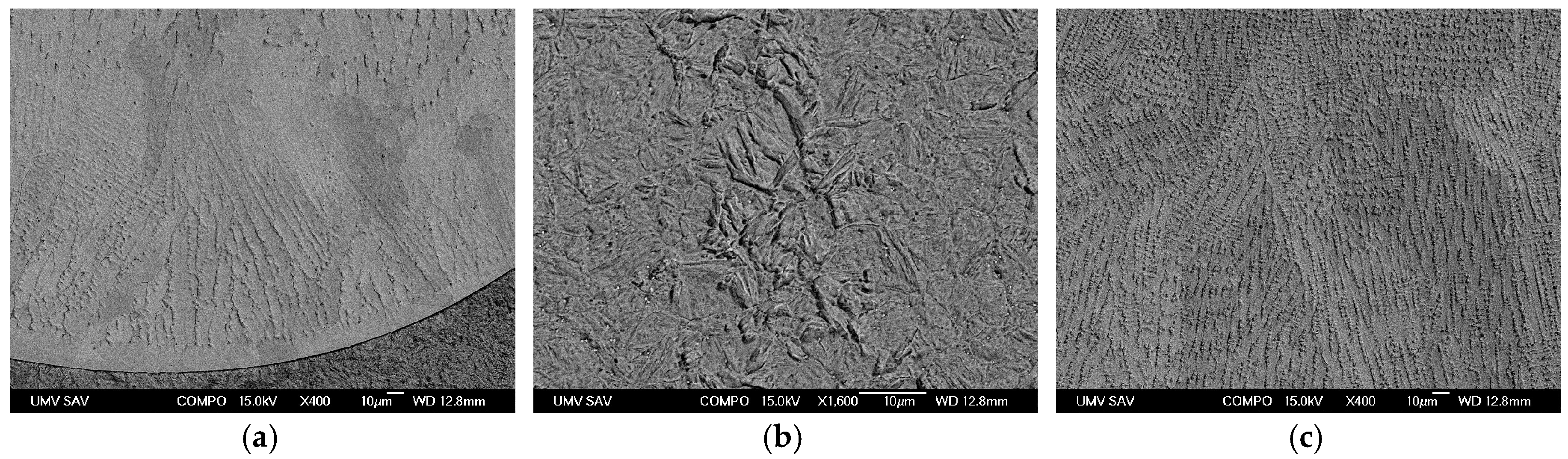

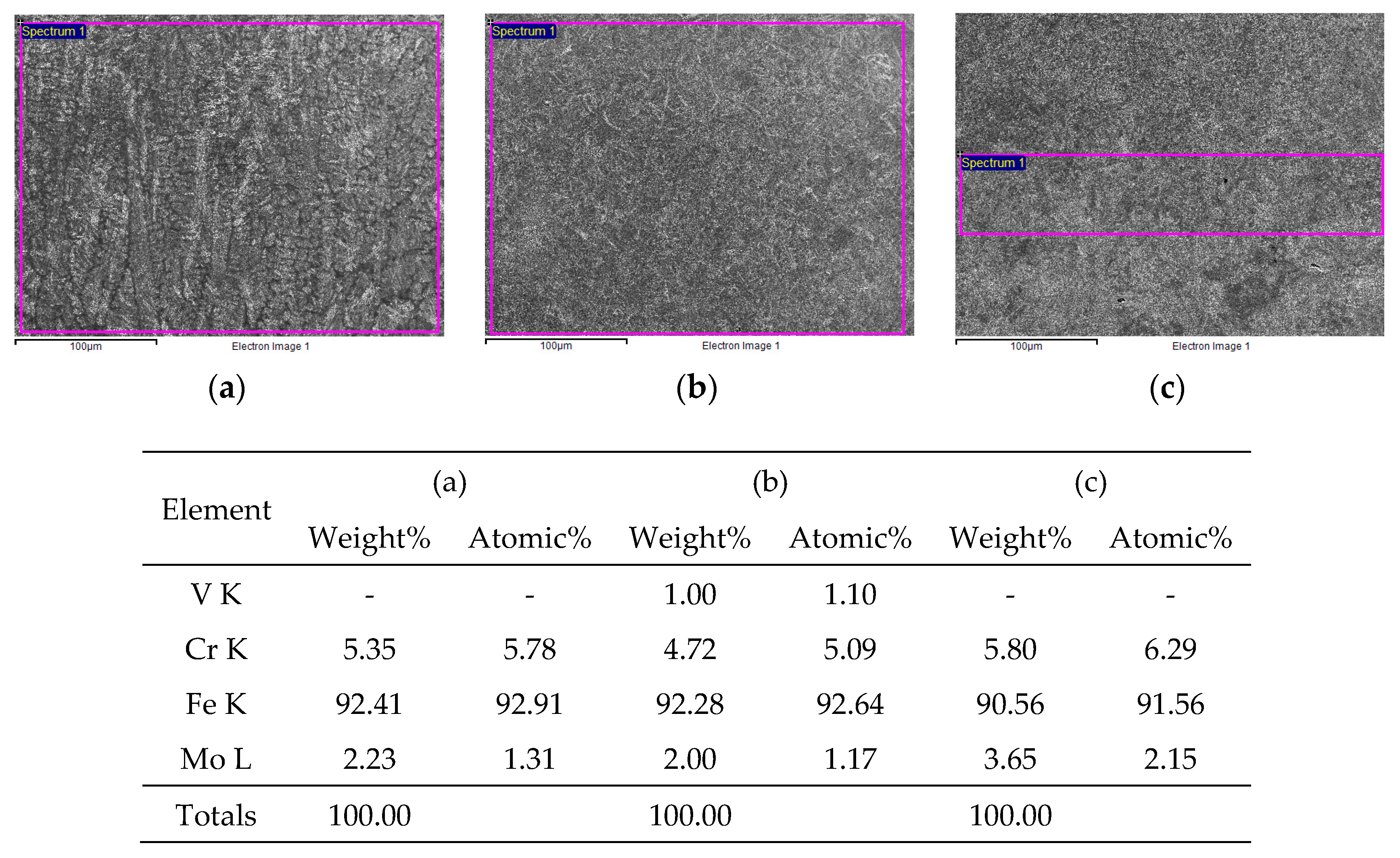

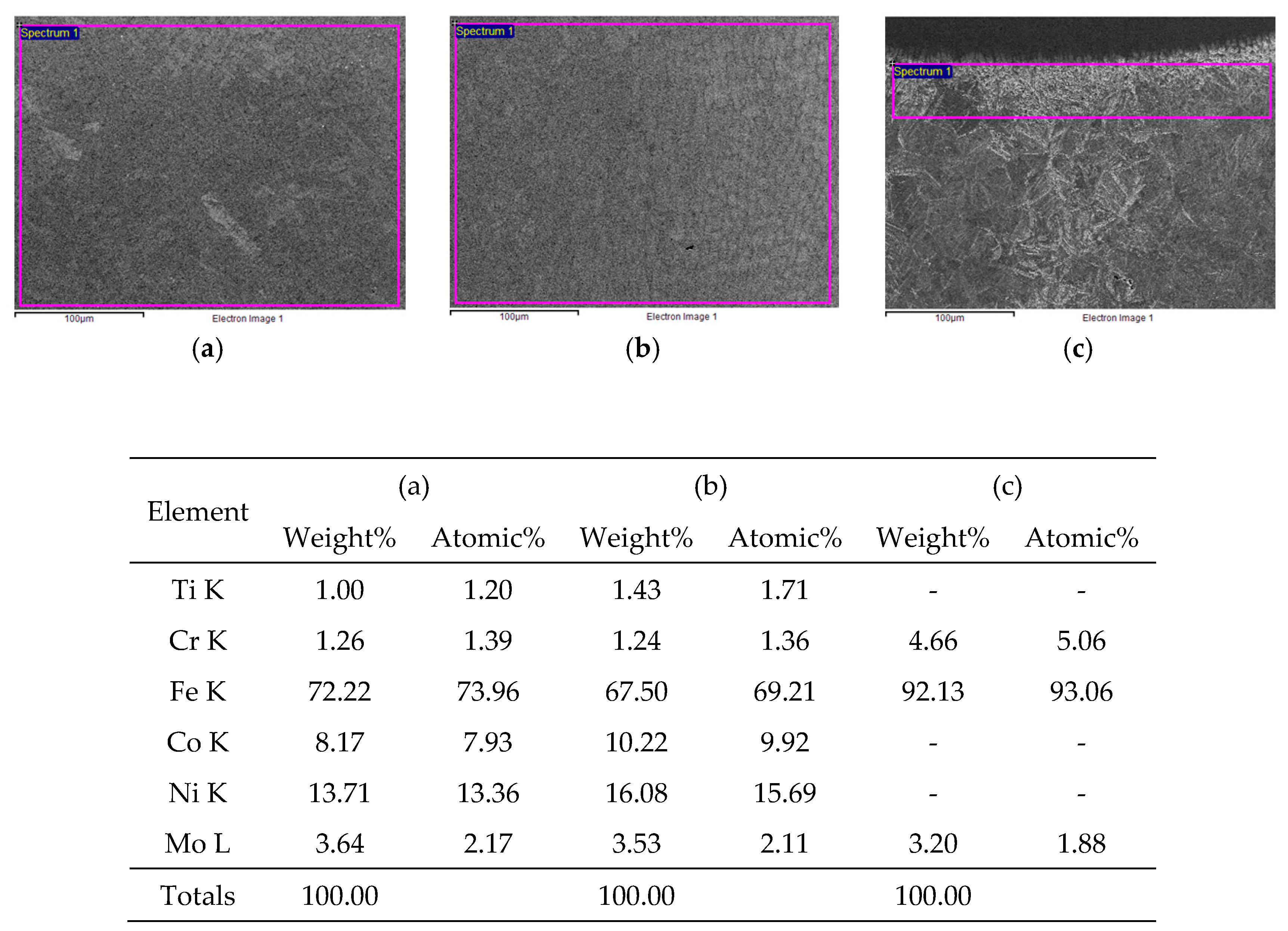

3.4. Scanning Electron Microscopy and EDX Microanalysis

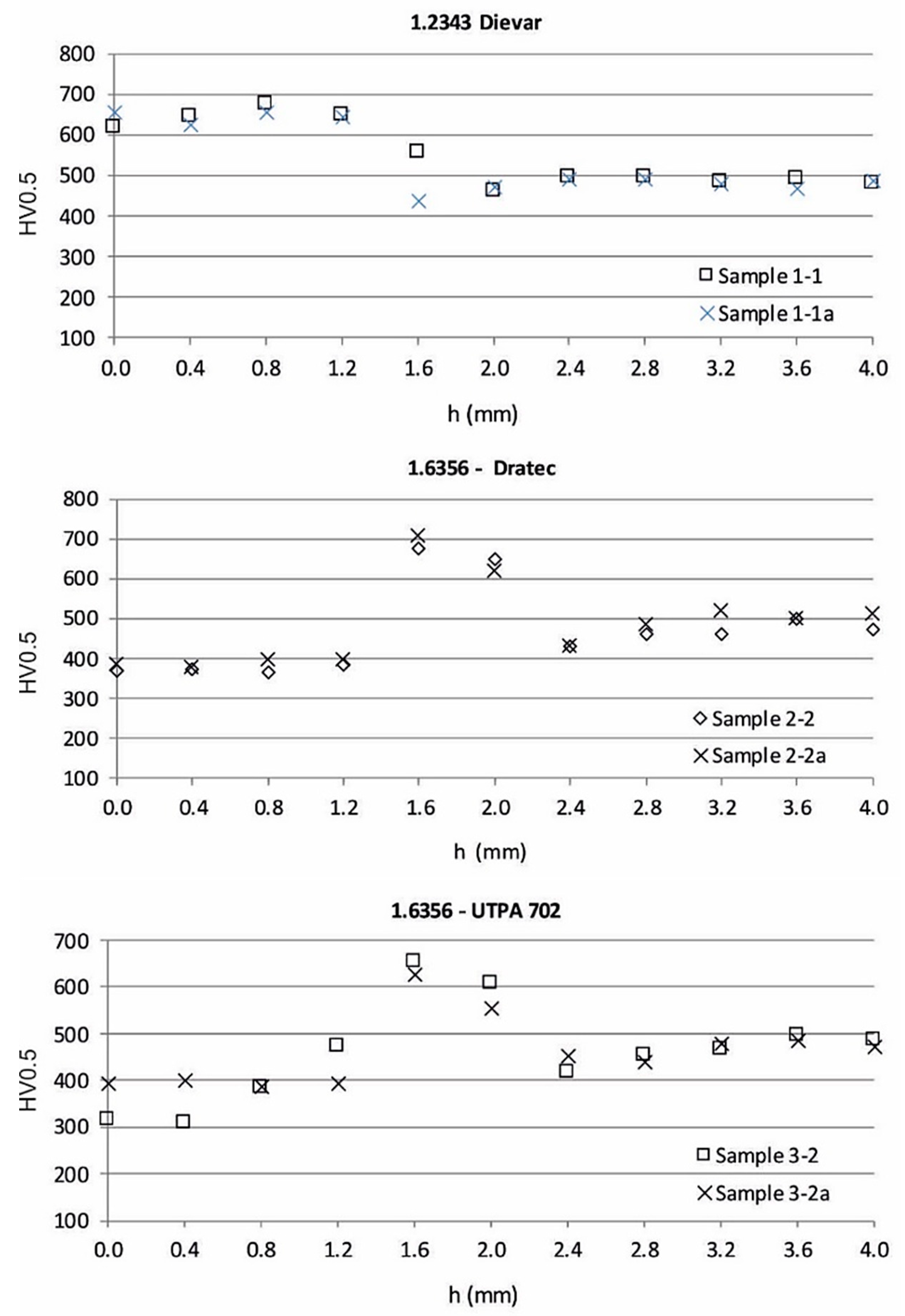

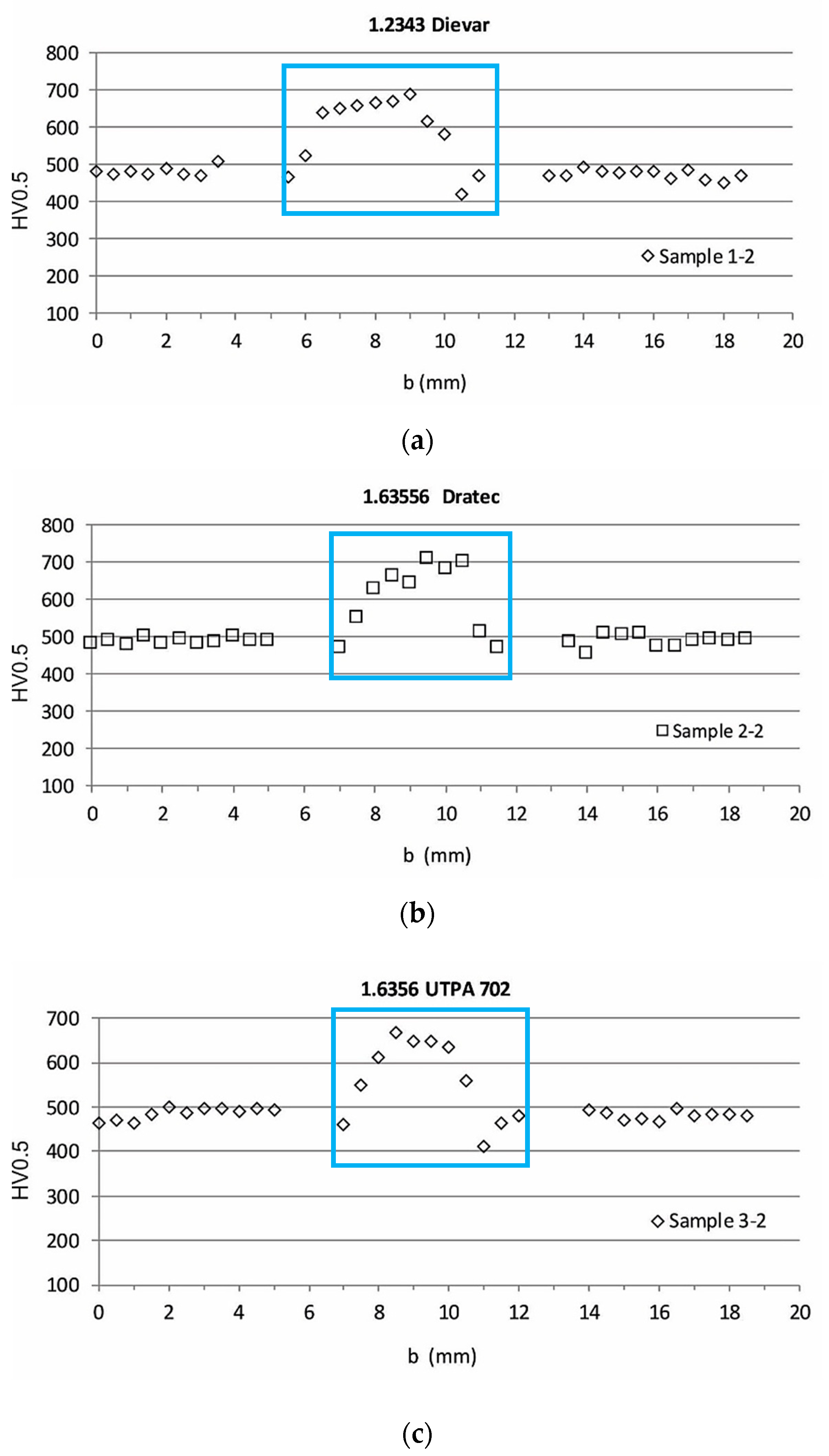

3.5. Results of Hardness Measurement of Clads

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Muigai, M.N.; Mwema, F.M.; Akinlabi, E.T.; Jen, T.C.; Fatoba, O.S.; Leso, T.P.; Obiko, J.O.; Mphasha, P. TIG Welding Methods of Repairing Steel Components with Stainless Steel Coatings. Tribol. Ind. 2022, 44, 434–448. [Google Scholar] [CrossRef]

- Ashokkumar, M.; Thirumalaikumarasamy, D.; Sonar, T.; Deepak, S.; Vignesh, P.; Anbarasu, M. An Overview of Cold Spray Coating in Additive Manufacturing, Component Repairing and Other Engineering Applications. J. Mech. Behav. Mater. 2022, 31, 514–534. [Google Scholar] [CrossRef]

- Brezinová, J.; Viňáš, J.; Guzanová, A.; Živčák, J.; Brezina, J.; Sailer, H.; Vojtko, M.; Džupon, M.; Volkov, A.; Kolařík, L.; et al. Selected Properties of Hardfacing Layers Created by Pta Technology. Metals 2021, 11, 134. [Google Scholar] [CrossRef]

- Lu, T.; Cheng, W.; Dong, S.; Ge, H.; Li, W.; He, J.; Hu, Z. Laser Additive Remanufacturing Cladding Thickness Detection System. J. Phys. Conf. Ser. 2022, 2395, 012061. [Google Scholar] [CrossRef]

- Trojan, K.; Ocelík, V.; Čapek, J.; Čech, J.; Canelo-yubero, D.; Ganev, N.; Kolařík, K.; De Hosson, J.T.M. Microstructure and Mechanical Properties of Laser Additive Manufactured H13 Tool Steel. Metals 2022, 12, 243. [Google Scholar] [CrossRef]

- Trembach, B.; Grin, A.; Makarenko, N.; Zharikov, S.; Trembach, I.; Markov, O. Influence of the Core Filler Composition on the Recovery of Alloying Elements during the Self-Shielded Flux-Cored Arc Welding. J. Mater. Res. Technol. 2020, 9, 10520–10528. [Google Scholar] [CrossRef]

- Viňáš, J.; Brezinová, J.; Guzanová, A. Analysis of the Quality Renovated Continuous Steel Casting Roller. Sadhana-Acad. Proc. Eng. Sci. 2013, 38, 477–490. [Google Scholar] [CrossRef]

- Wu, H.; Wu, R. The Role of Educational Action Research of Recycling Process to the Green Technologies, Environment Engineering, and Circular Economies. Int. J. Recent Technol. Eng. 2019, 8, 1639–1645. [Google Scholar] [CrossRef]

- Orečný, M.; Buršák, M.; Viňáš, J. The Influence of Heat Treatnemnt on the Abrasive Wear Resistnace of a Construction and a Tool Steel. Metalurgija 2015, 54, 5–24. [Google Scholar]

- Kónya, J.; Hargitai, H.; Jaber, H.; Pinke, P.; Kovács, T.A. Effect of Surface Modifications on Surface Roughness of Ti6Al4V Alloy Manufactured by 3D Printing, Casting, and Wrought. Materials 2023, 16, 3989. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, C.; Bai, L.; Han, C.; Chen, X.; Wang, C. Advances and Prospects in Lake Environment Science and Engineering: A Review. Hupo Kexue/J. Lake Sci. 2020, 32, 1. [Google Scholar]

- Inagaki, M.; Nakamura, H.; Okada, A. Studies of Cooling Processes in the Cases of Welding with Coated Electrode and Submerged Arc Welding. J. Jpn. Weld. Soc. 1965, 34, 1064–1075. [Google Scholar] [CrossRef]

- De Paula, M.P.M.; Modenesi, P.J.; Trindade, V.B. Analysis of the Influence of Welding Parameters on Microstructures and Mechanical Properties of Welding Joints of an API X70Q Steel Tube for the Sour Service Application. Soldag. Insp. 2018, 23, 180–190. [Google Scholar] [CrossRef]

- Lu, X.; Cervera, M.; Chiumenti, M.; Lin, X. Residual Stresses Control in Additive Manufacturing. J. Manuf. Mater. Process. 2021, 5, 138. [Google Scholar] [CrossRef]

- Fang, Z.C.; Wu, Z.L.; Huang, C.G.; Wu, C.W. Review on Residual Stress in Selective Laser Melting Additive Manufacturing of Alloy Parts. Opt. Laser Technol. 2020, 129, 106283. [Google Scholar] [CrossRef]

- Ahmad, B.; Zhang, X.; Guo, H.; Fitzpatrick, M.E.; Neto, L.M.S.C.; Williams, S. Influence of Deposition Strategies on Residual Stress in Wire + Arc Additive Manufactured Titanium Ti-6Al-4V. Metals 2022, 12, 253. [Google Scholar] [CrossRef]

- De, A.; DebRoy, T. A Perspective on Residual Stresses in Welding. Sci. Technol. Weld. Join. 2011, 16, 204–208. [Google Scholar] [CrossRef]

- Trembach, B.; Grin, A.; Turchanin, M.; Makarenko, N.; Markov, O.; Trembach, I. Application of Taguchi Method and ANOVA Analysis for Optimization of Process Parameters and Exothermic Addition (CuO-Al) Introduction in the Core Filler during Self-Shielded Flux-Cored Arc Welding. Int. J. Adv. Manuf. Technol. 2021, 114, 1099–1118. [Google Scholar] [CrossRef]

- Viňáš, J.; Brezinová, J.; Guzanová, A.; Balog, P. Evaluation of the Quality of Cladding Deposited on Continuous Steel Casting Rolls. Int. J. Mater. Res. 2013, 104, 183–191. [Google Scholar] [CrossRef]

- Viňáš, J.; Brezinová, J.; Brezina, J.; Maruschak, P.O. Structural and Mechanical Features of Laser-Welded Joints of Zinc-Coated Advanced Steel Sheets. Mater. Sci. 2019, 55, 46–51. [Google Scholar] [CrossRef]

- Schubnell, J.; Carl, E.; Farajian, M.; Gkatzogiannis, S.; Knödel, P.; Ummenhofer, T.; Wimpory, R.; Eslami, H. Residual Stress Relaxation in HFMI-Treated Fillet Welds after Single Overload Peaks. Weld. World 2020, 64, 1107–1117. [Google Scholar] [CrossRef]

- Kovács, T.A.; Pinke, P.; Bitay, E. Experimental Study of the Technology Parameters Affect in the Laser Welded Joints. IOP Conf. Ser. Mater. Sci. Eng. 2019, 613, 012038. [Google Scholar] [CrossRef]

- Dománková, M.; Adamech, M.; Petzová, J.; Bártová, K.; Pinke, P. Microstructure Characteristics of Borated Austenitic Stainless Steel Welds. Res. Pap. Fac. Mater. Sci. Technol. Slovak Univ. Technol. 2018, 26, 45–52. [Google Scholar] [CrossRef]

- Xin, H.; Veljkovic, M. Residual Stress Effects on Fatigue Crack Growth Rate of Mild Steel S355 Exposed to Air and Seawater Environments. Mater. Des. 2020, 193, 108732. [Google Scholar] [CrossRef]

- Sun, Y.L.; Vasileiou, A.N.; Pickering, E.J.; Collins, J.; Obasi, G.; Akrivos, V.; Smith, M.C. Impact of Weld Restraint on the Development of Distortion and Stress during the Electron Beam Welding of a Low-Alloy Steel Subject to Solid State Phase Transformation. Int. J. Mech. Sci. 2021, 196, 106244. [Google Scholar] [CrossRef]

- Trembach, B.; Grin, A.; Subbotina, V.; Vynar, V.; Knyazev, S.; Zakiev, V.; Trembach, I.; Kabatskyi, O. Effect of Exothermic Addition (Cuo-Al) on the Structure, Mechanical Properties and Abrasive Wear Resistance of the Deposited Metal during Self-Shielded Flux-Cored Arc Welding. Tribol. Ind. 2021, 43, 452–464. [Google Scholar] [CrossRef]

- Dománková, M.; Kocsisová, E.; Slatkovský, I.; Pinke, P. The Microstructure Evolution and Its Effect on Corrosion Properties of 18Cr-12Ni-2,5Mo Steel Annealed at 500–900 °C. Acta Polytech. Hung. 2014, 11, 125–137. [Google Scholar] [CrossRef]

- Rong, Y.; Huang, Y.; Wang, L. Evolution Mechanism of Transient Strain and Residual Stress Distribution in Al 6061 Laser Welding. Crystals 2021, 11, 205. [Google Scholar] [CrossRef]

- Thibault, D.; Bocher, P.; Thomas, M. Residual Stress and Microstructure in Welds of 13%Cr-4%Ni Martensitic Stainless Steel. J. Mater. Process. Technol. 2009, 209, 2195–2202. [Google Scholar] [CrossRef]

- Sarafan, S.; Wanjara, P.; Lévesque, J.B.; Gholipour, J.; Champliaud, H.; Mathieu, L. Through-Thickness Residual Stresses, Microstructure, and Mechanical Properties of Electron Beam-Welded CA6NM Martensitic Stainless Steel after Postweld Heat Treatment. Adv. Mater. Sci. Eng. 2020, 2020, 7194214. [Google Scholar] [CrossRef]

- Aung, M.P.; Katsuda, H.; Hirohata, M. Fatigue-Performance Improvement of Patch-Plate Welding via PWHT with Induction Heating. J. Constr. Steel Res. 2019, 160, 280–288. [Google Scholar] [CrossRef]

- Nagai, T.; Kawai, S.; Shindo, M.; Okano, S.; Mochizuki, M.; Suga, T. Comparative Study on Internal Residual Stresses in Electron Beam Welds. ISIJ Int. 2017, 57, 1072–1079. [Google Scholar] [CrossRef]

- Kovács-Coskun, T.; Pinke, P. The Effect of Microstructure on the Local Wear Behavior of Dual Phase Steels. IOP Conf. Ser. Mater. Sci. Eng. 2013, 47, 012032. [Google Scholar] [CrossRef]

- Cattivelli, A.; Roy, M.J.; Burke, M.G.; Dhers, J.; Lee, T.L.; Francis, J.A. Internal Stresses in a Clad Pressure Vessel Steel during Post Weld Heat Treatment and Their Relevance to Underclad Cracking. Int. J. Press. Vessels Pip. 2021, 193, 104448. [Google Scholar] [CrossRef]

- Vrancken, B. Study of Residual Stresses in Selective Laser Melting. Ph.D. Thesis, KU Leuven, Leuven, Belgium, 2016. [Google Scholar]

- Monin, V.I.; Lopes, R.T.; Turibus, S.N.; Payão Filho, J.C.; De Assis, J.T. X-ray Diffraction Technique Applied to Study of Residual Stresses after Welding of Duplex Stainless Steel Plates. Mater. Res. 2014, 17, 64–69. [Google Scholar] [CrossRef]

- Ahmed, I.I.; Adebisi, J.A.; Abdulkareem, S.; Sherry, A.H. Investigation of Surface Residual Stress Profile on Martensitic Stainless Steel Weldment with X-ray Diffraction. J. King Saud Univ.-Eng. Sci. 2018, 30, 183–187. [Google Scholar] [CrossRef]

- Trebuňa, F.; Šimčák, F.; Bocko, J.; Šarga, P.; Trebuňa, P.; Pástor, M.; Mihok, J. Quantification of Residual Stresses in the Weld by the Hole-Drilling Method. Metalurgija 2008, 47, 133–137. [Google Scholar]

- Van Puymbroeck, E.; Nagy, W.; Schotte, K.; Ul-Abdin, Z.; De Backer, H. Determination of Residual Welding Stresses in a Steel Bridge Component by Finite Element Modeling of the Incremental Hole-Drilling Method. Appl. Sci. 2019, 9, 536. [Google Scholar] [CrossRef]

- Zhang, H.; Li, L.; Ma, W.; Luo, Y.; Li, Z.; Kuai, H. Effects of Welding Residual Stresses on Fatigue Reliability Assessment of a PC Beam Bridge with Corrugated Steel Webs under Dynamic Vehicle Loading. Structures 2022, 45, 1561–1572. [Google Scholar] [CrossRef]

- Chiocca, A.; Frendo, F.; Aiello, F.; Bertini, L. Influence of Residual Stresses on the Fatigue Life of Welded Joints. Numerical Simulation and Experimental Tests. Int. J. Fatigue 2022, 162, 106901. [Google Scholar] [CrossRef]

- Xiong, Q.; Smith, M.C.; Muransky, O.; Mathew, J. Validated Prediction of Weld Residual Stresses in Austenitic Steel Pipe Girth Welds before and after Thermal Ageing, Part 2: Modelling and Validation. Int. J. Press. Vessels Pip. 2019, 172, 430–448. [Google Scholar] [CrossRef]

- Smith, M.C.; Muránsky, O.; Xiong, Q.; Bouchard, P.J.; Mathew, J.; Austin, C. Validated Prediction of Weld Residual Stresses in Austenitic Steel Pipe Girth Welds before and after Thermal Ageing, Part 1: Mock-up Manufacture, Residual Stress Measurements, and Materials Characterisation. Int. J. Press. Vessels Pip. 2019, 172, 233–250. [Google Scholar] [CrossRef]

- Trebuňa, F.; Šimčák, F.; Bocko, J.; Trebuňa, P.; Pástor, M.; Šarga, P. Analysis of Crack Initiation in the Press Frame and Innovation of the Frame to Ensure Its Further Operation. Eng. Fail. Anal. 2011, 18, 244–255. [Google Scholar] [CrossRef]

- Pástor, M.; Lengvarský, P.; Trebuňa, F.; Čarák, P. Prediction of Failures in Steam Boiler Using Quantification of Residual Stresses. Eng. Fail. Anal. 2020, 118, 104808. [Google Scholar] [CrossRef]

- Chen, Y.; Shang, X. Investigation on Large Elastoplastic Deformation in Expansion and Springback for a Composited Bioresorbable Stent. J. Mech. Behav. Biomed. Mater. 2021, 119, 104500. [Google Scholar] [CrossRef] [PubMed]

- Kovacs-Coskun, T.; Pinke, P. Surface Hardening of Austenitic Stainless Steel by Explosive Treatment. Mater. Sci. Forum 2015, 812, 107–111. [Google Scholar] [CrossRef]

- Chen, L.; Mi, G.; Zhang, X.; Wang, C. Numerical and Experimental Investigation on Microstructure and Residual Stress of Multi-Pass Hybrid Laser-Arc Welded 316L Steel. Mater. Des. 2019, 168, 107653. [Google Scholar] [CrossRef]

- Neugebauer, F.; Keller, N.; Xu, H.; Kober, C.; Ploshikhin, V. Simulation of Selective Laser Melting Using Process Specific Layer Based Meshing. In Proceedings of the Fraunhofer Direct Digital Manufacturing Conference 2014, Berlin, Germany, 12–13 March 2014. [Google Scholar]

- Yaping, L.; Weixin, G. Research on X-ray Welding Image Defect Detection Based on Convolution Neural Network. J. Phys. Conf. Ser. 2019, 1237, 032005. [Google Scholar] [CrossRef]

- Derakhshan, E.D.; Yazdian, N.; Craft, B.; Smith, S.; Kovacevic, R. Numerical Simulation and Experimental Validation of Residual Stress and Welding Distortion Induced by Laser-Based Welding Processes of Thin Structural Steel Plates in Butt Joint Configuration. Opt. Laser Technol. 2018, 104, 170–182. [Google Scholar] [CrossRef]

- Kovacs, T.; Pinke, P. BWRA and Séférian Model for Preheating Temperature Calculation in Case of Low Alloyed and Unalloyed Steel. Mater. Sci. Forum 2017, 885, 239–244. [Google Scholar] [CrossRef]

- Chen, B.Q.; Hashemzadeh, M.; Guedes Soares, C. Validation of Numerical Simulations with X-ray Diffraction Measurements of Residual Stress in Butt-Welded Steel Plates. Ships Offshore Struct. 2018, 13, 273–282. [Google Scholar] [CrossRef]

- Song, G.S.; Liu, X.H.; Wang, G.D.; Xu, X.Q. Numeric Simulation on the Effect of Phase Transformation on Quenching Stress of 22CrMo Steel. Suxing Gongcheng Xuebao/J. Plast. Eng. 2006, 56, 75–79. [Google Scholar]

- Engelhard, G.; Habip, L.M.; Pellkofer, D.; Schmidt, J.; Weber, J. Optimization of Residual Welding Stresses in Austenitic Steel Piping Welds: Proof-Testing and Numeric Simulation of Welding and Post-Welding Processes. Nucl. Eng. Des. 2000, 198, 141–151. [Google Scholar] [CrossRef]

- Ji, D.; Zhang, J.; Yi, K.; Huang, Y.; Lu, Q.; Zhang, H. Surface Crack Growth Simulation and Residual Life Assessment of High-Speed Train Axles Based on Extended Finite Element Method. Eng. Fail. Anal. 2022, 134, 106043. [Google Scholar] [CrossRef]

| Additive Material | Laser Power (W) | Cladding Speed (mm/s) | Feed Speed (mm/s) | Focus (mm) | Atmosphere Ar (4.6) (L/min) |

|---|---|---|---|---|---|

| Dievar | 1500 | 6 | 10 | 20 | 7 |

| Dratec | 1600 | 6 | 10 | 20 | 10 |

| UTPA 702 | 1500 | 6 | 5 | 0 | 12 |

| C | Mn | Si | P | S | Cr | Ni | Mo | V | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.382 | 0.377 | 0.914 | 0.002 | 0.002 | 4.893 | 0.199 | 1.277 | 0.499 | 0.077 | Bal. |

| Yield Strength (MPa) | Tensile Strength (MPa) | Elongation A5 (%) | Hardness HRC |

|---|---|---|---|

| 1420 | 1680 | 12 | 50 |

| Filler Mat. | C | Si | Mn | Cr | Mo | Ni | Co | Ti | Al | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.2343 (Dievar) | 0.4430 | 0.147 | 0.423 | 5.13 | 2.27 | 0.067 | 0.01 | 0.002 | 0.008 | - | Bal. |

| 1.6356 (Dratec) | 0.0005 | 0.200 | 0.50 | 0.15 | 4.0 | 18.0 | 12.0 | 1.60 | - | - | Bal. |

| 1.6356 (UTPA 702) | 0.0200 | - | - | - | 4.0 | 18.0 | 12.0 | 1.60 | 0.10 | - | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Viňáš, J.; Brezinová, J.; Pástor, M.; Šarga, P.; Džupon, M.; Brezina, J. Determination of the Effect of Heat Input during Laser Welding on the Magnitude of Residual Stresses in the Refurbishment of Al Alloy Casting. Metals 2023, 13, 2003. https://doi.org/10.3390/met13122003

Viňáš J, Brezinová J, Pástor M, Šarga P, Džupon M, Brezina J. Determination of the Effect of Heat Input during Laser Welding on the Magnitude of Residual Stresses in the Refurbishment of Al Alloy Casting. Metals. 2023; 13(12):2003. https://doi.org/10.3390/met13122003

Chicago/Turabian StyleViňáš, Ján, Janette Brezinová, Miroslav Pástor, Patrik Šarga, Miroslav Džupon, and Jakub Brezina. 2023. "Determination of the Effect of Heat Input during Laser Welding on the Magnitude of Residual Stresses in the Refurbishment of Al Alloy Casting" Metals 13, no. 12: 2003. https://doi.org/10.3390/met13122003

APA StyleViňáš, J., Brezinová, J., Pástor, M., Šarga, P., Džupon, M., & Brezina, J. (2023). Determination of the Effect of Heat Input during Laser Welding on the Magnitude of Residual Stresses in the Refurbishment of Al Alloy Casting. Metals, 13(12), 2003. https://doi.org/10.3390/met13122003