Neutron Imaging of Al6061 Prepared by Solid-State Friction Stir Additive Manufacturing

Abstract

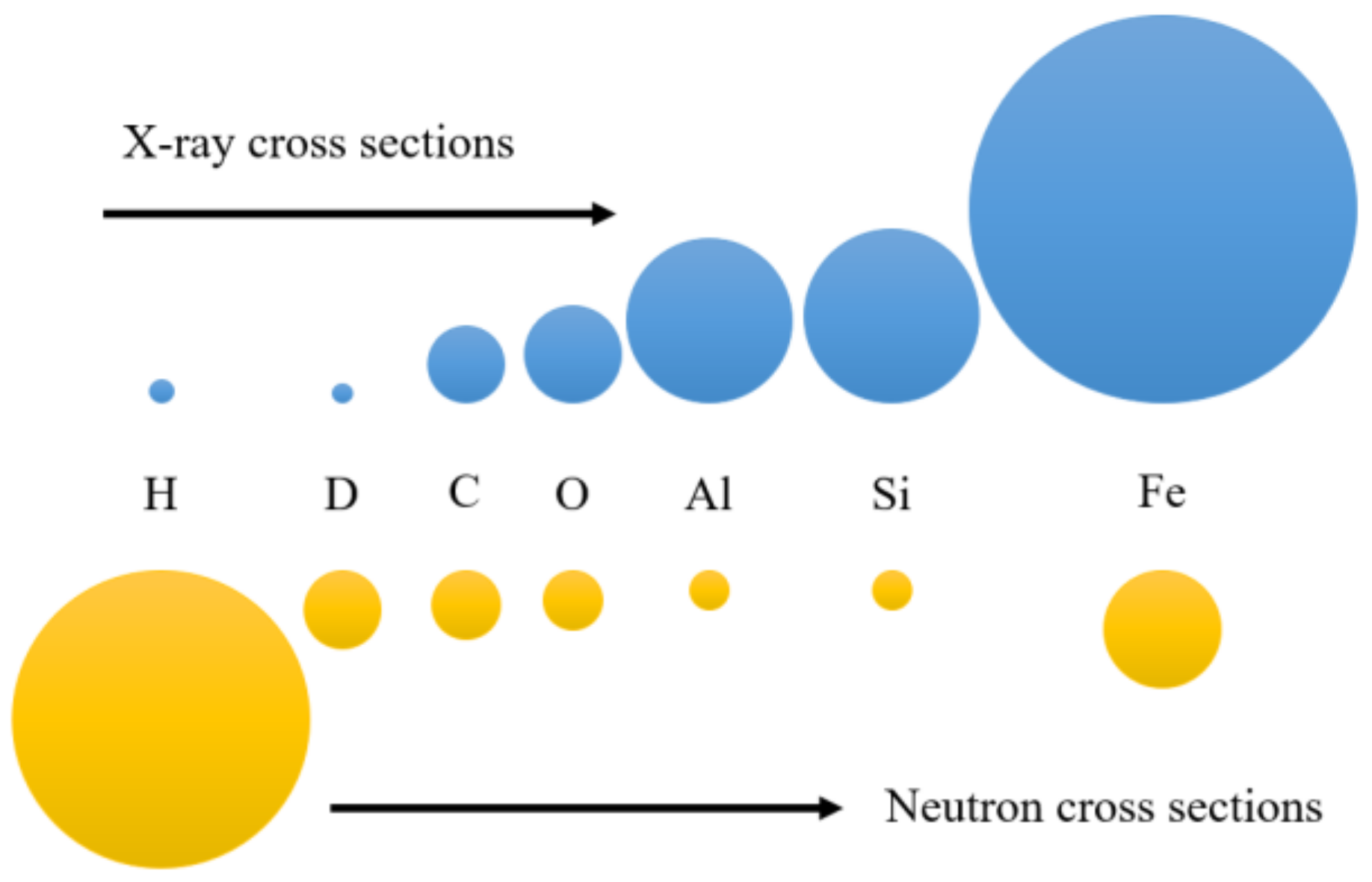

:1. Introduction

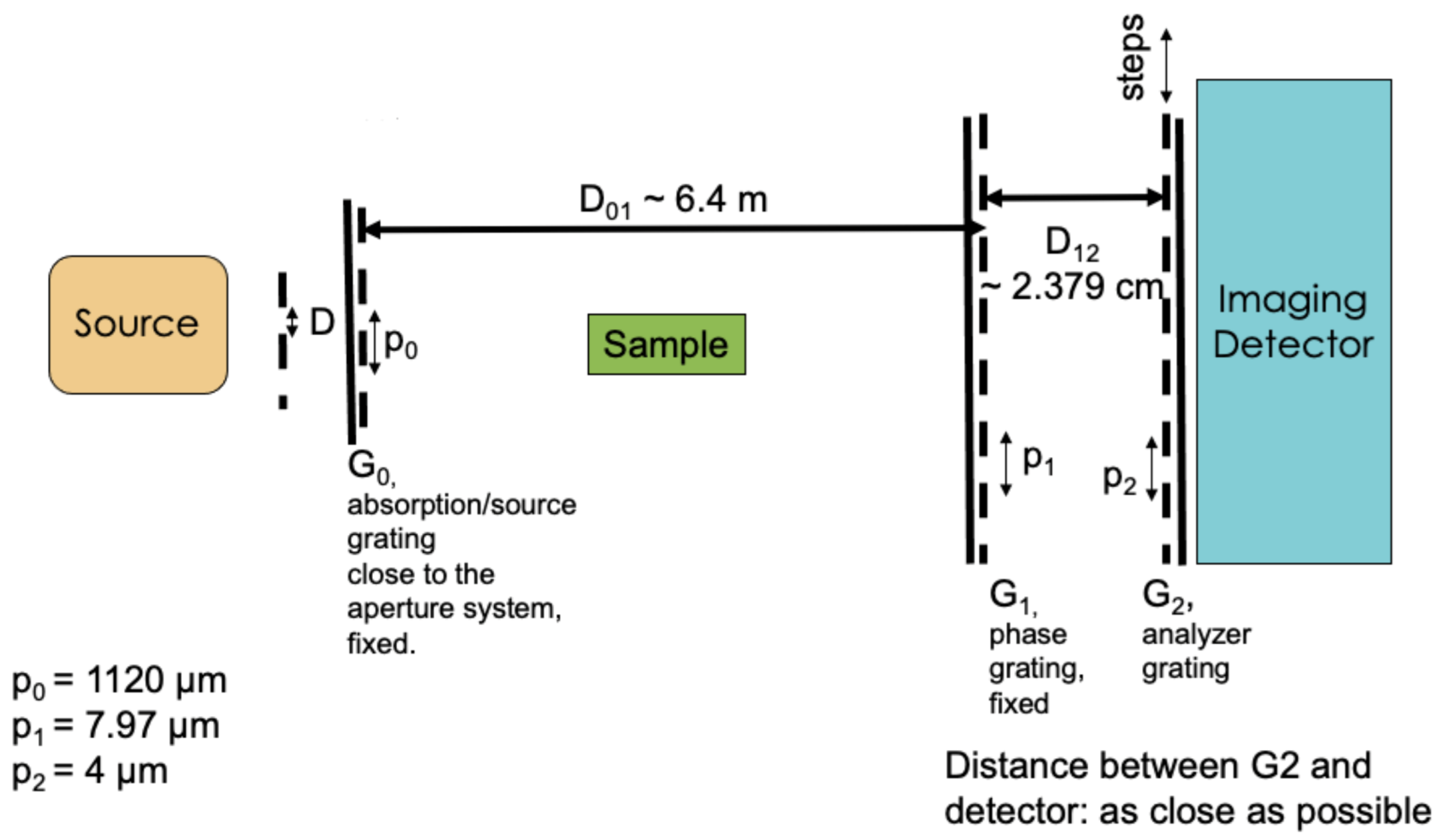

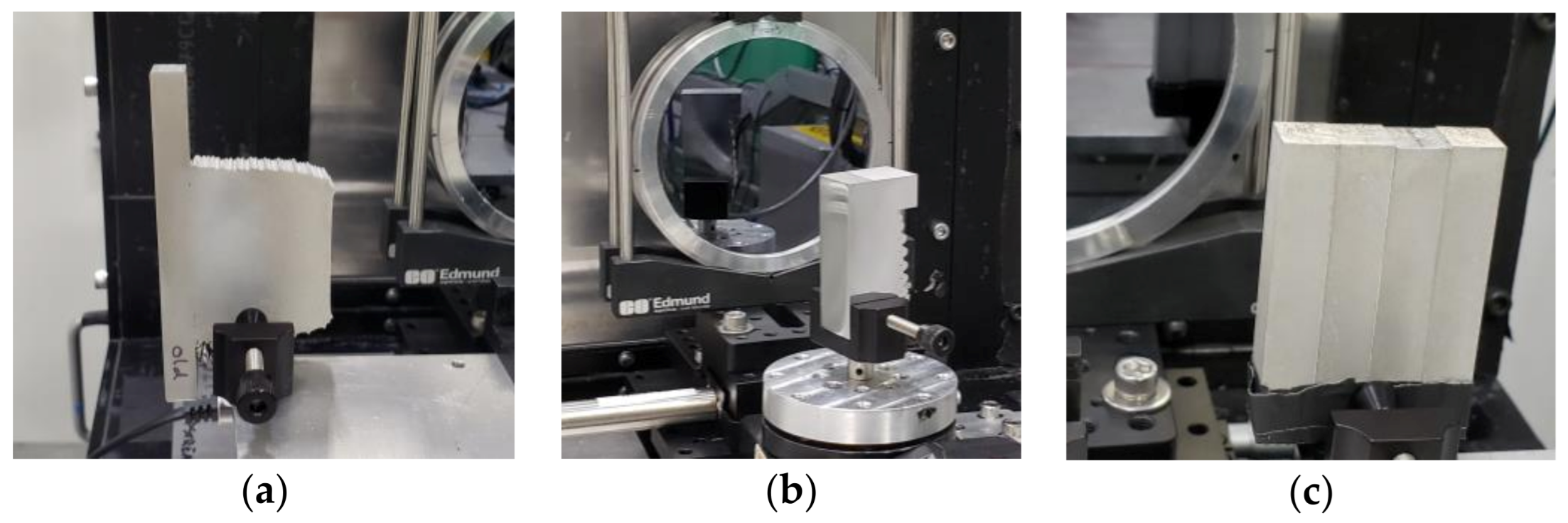

2. Materials and Methods

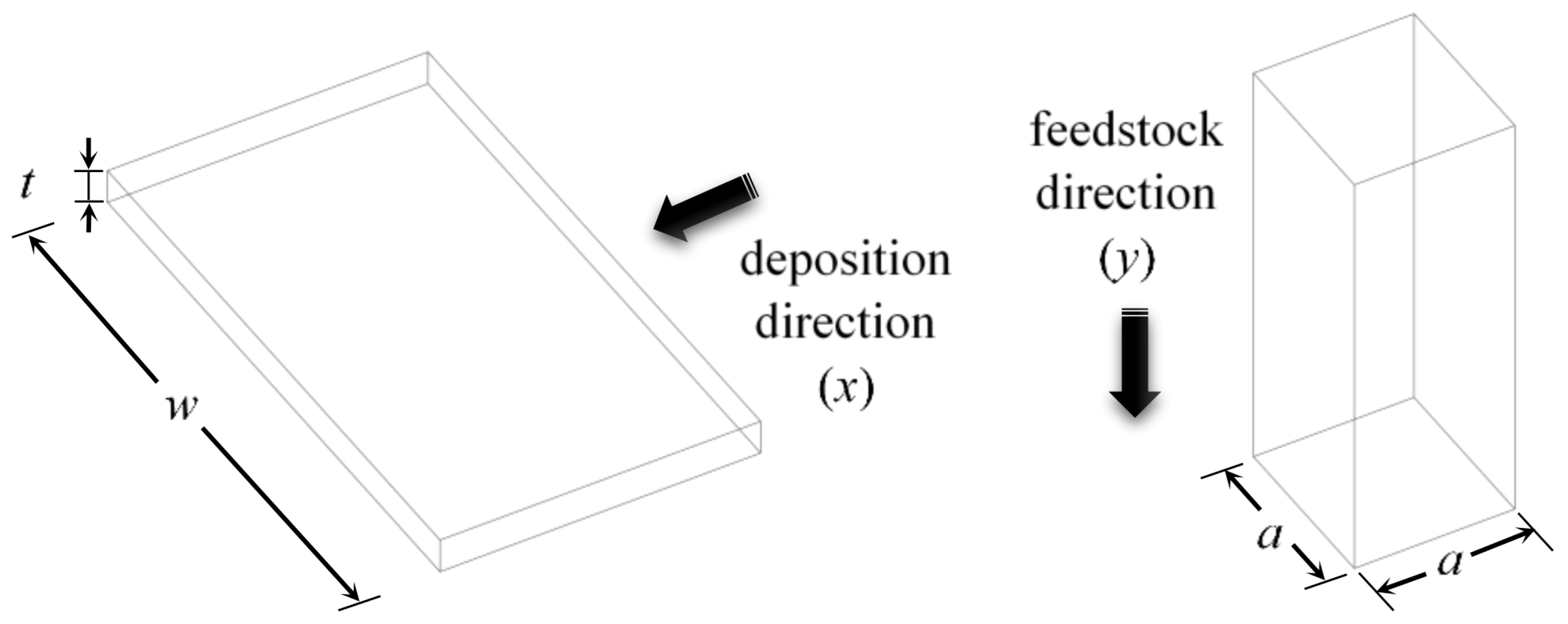

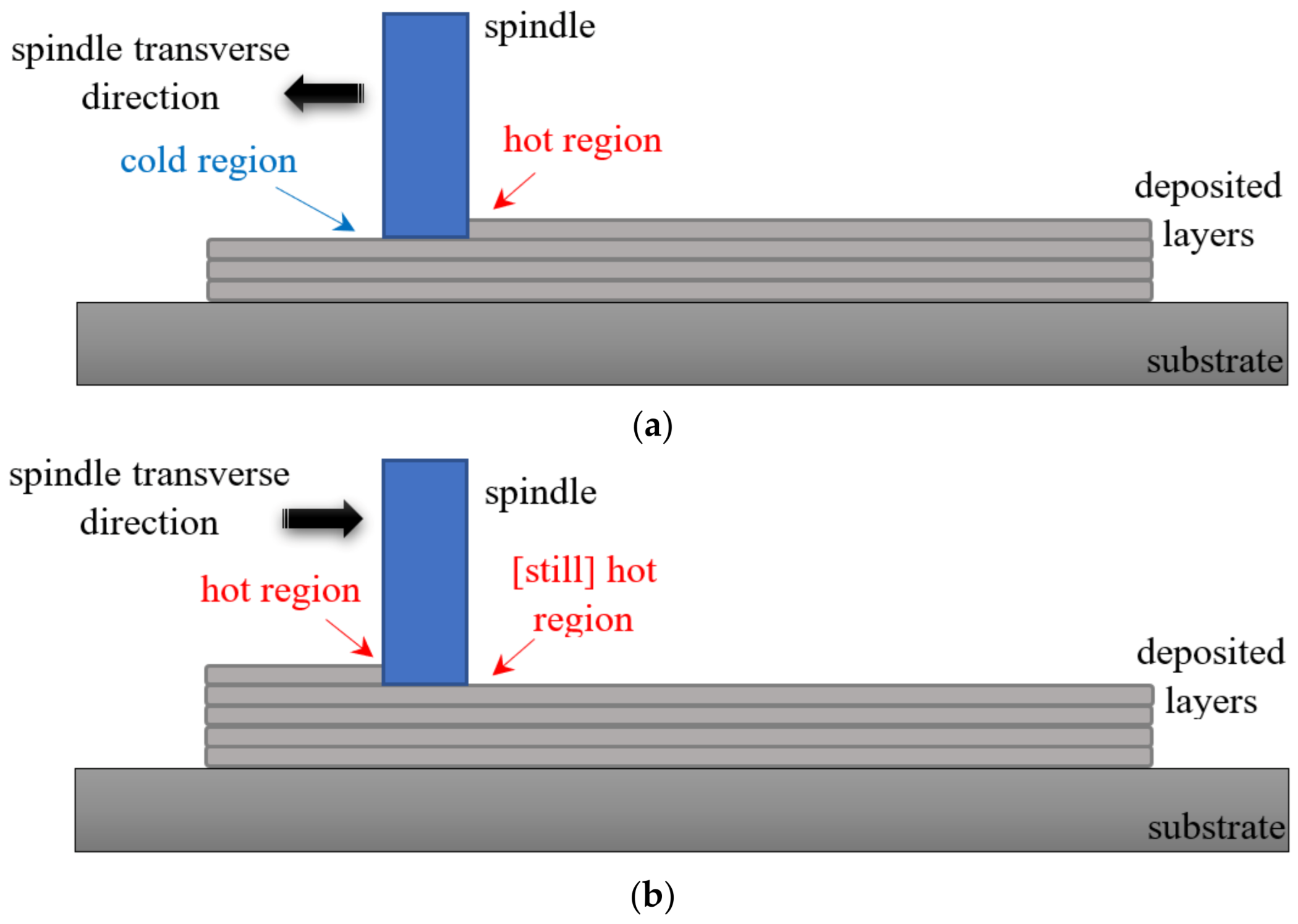

2.1. The AFS-D Process

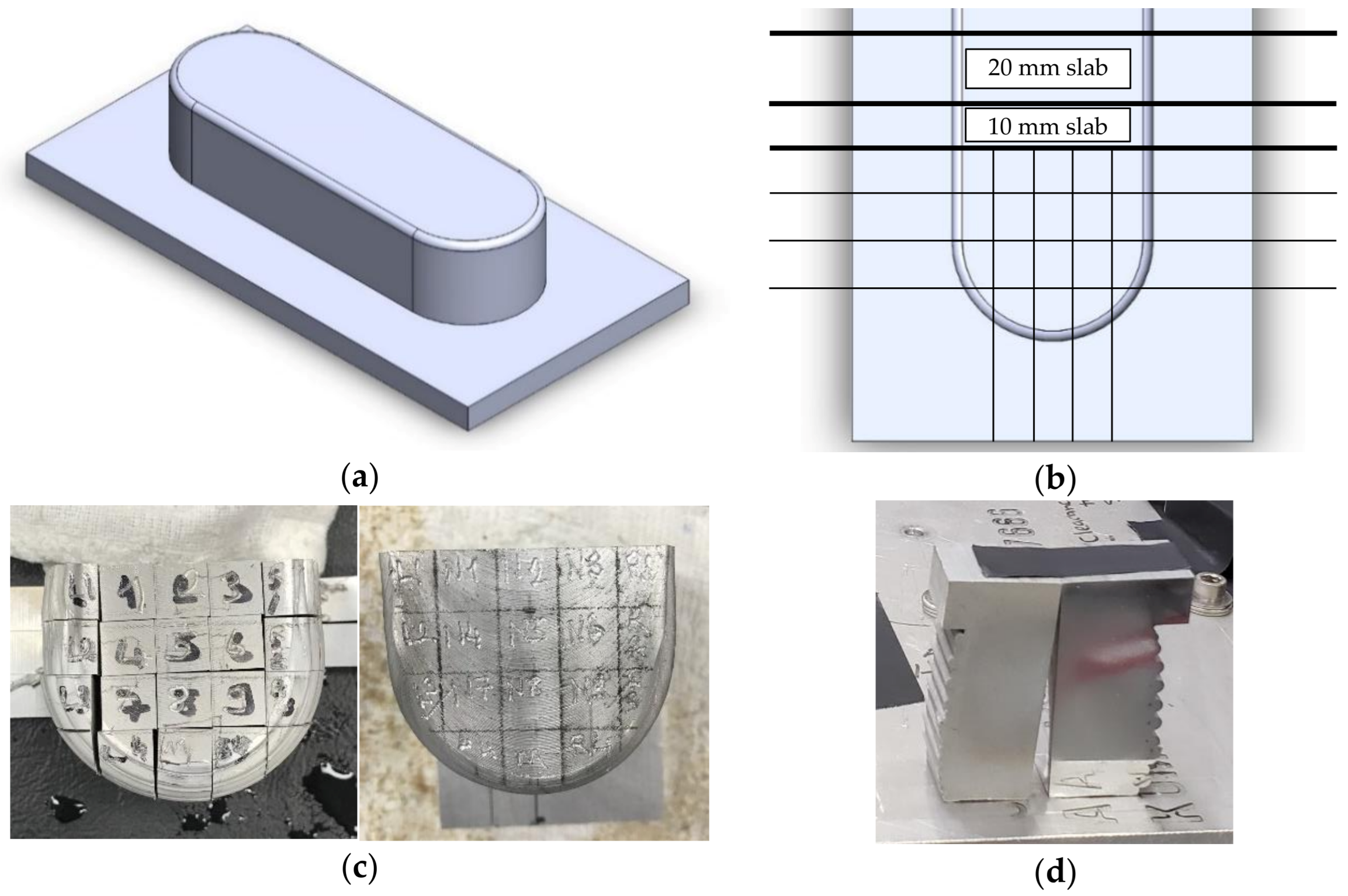

2.2. Sample Preparation

3. Results and Discussion

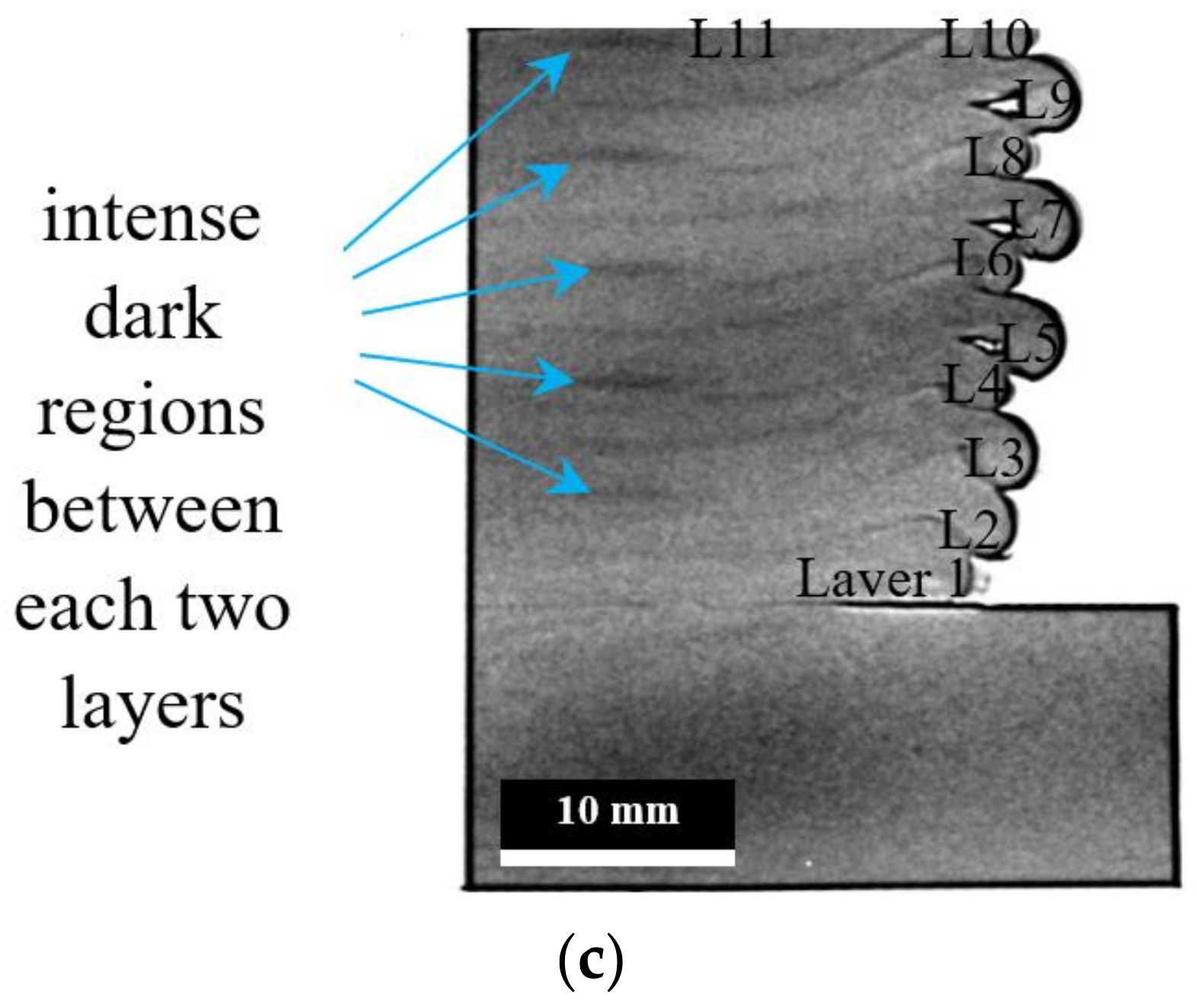

3.1. Ingot A: 10 mm Slab

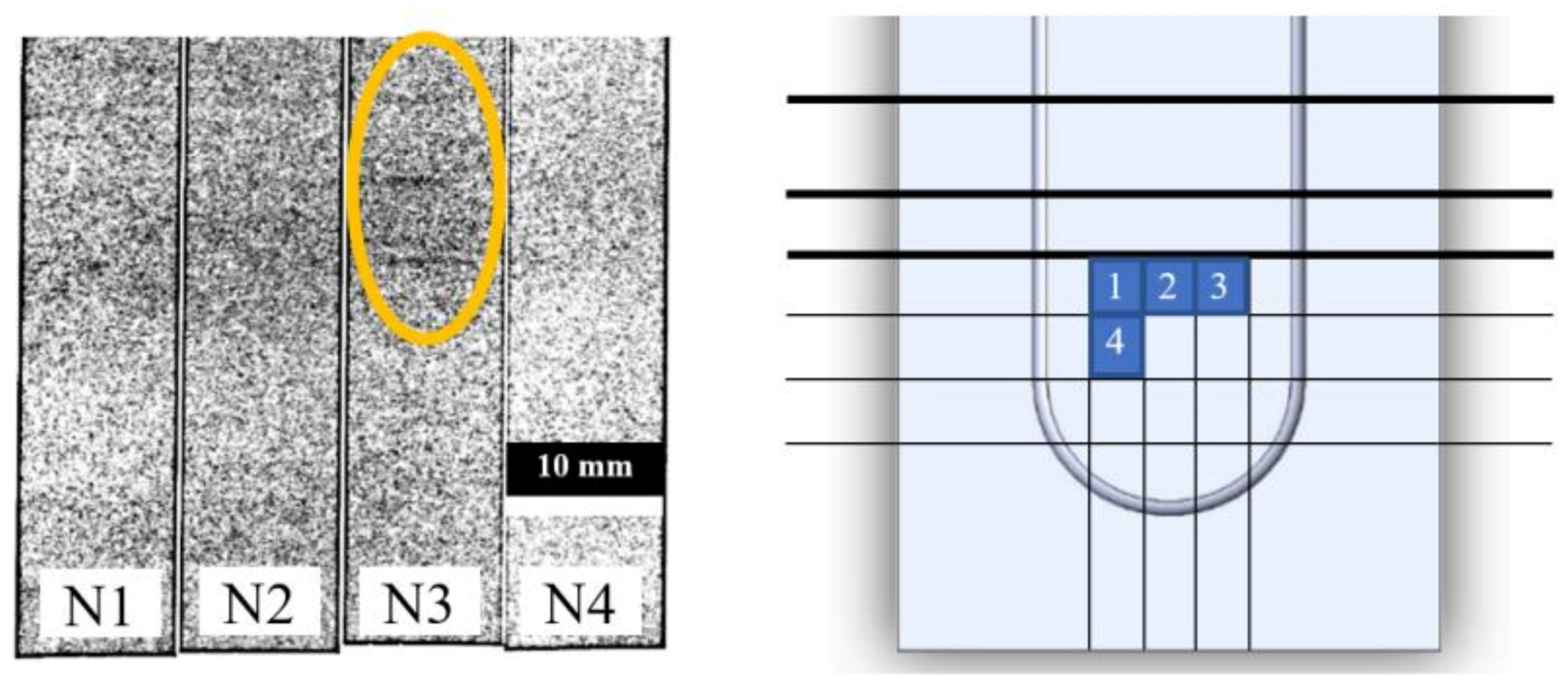

3.2. Ingot B: 10 mm Slab

3.3. Ingot B: 20 mm Slab

4. Conclusions

- The neutron beam proves to be effective in revealing the layering structure due to its high penetration range into aluminum, with 80% total transmission in a 20 mm slab.

- Signs of hydrogen contamination are observed in the fabricated part, which are most likely due to the hydrocarbon-based lubricant used during the deposition process.

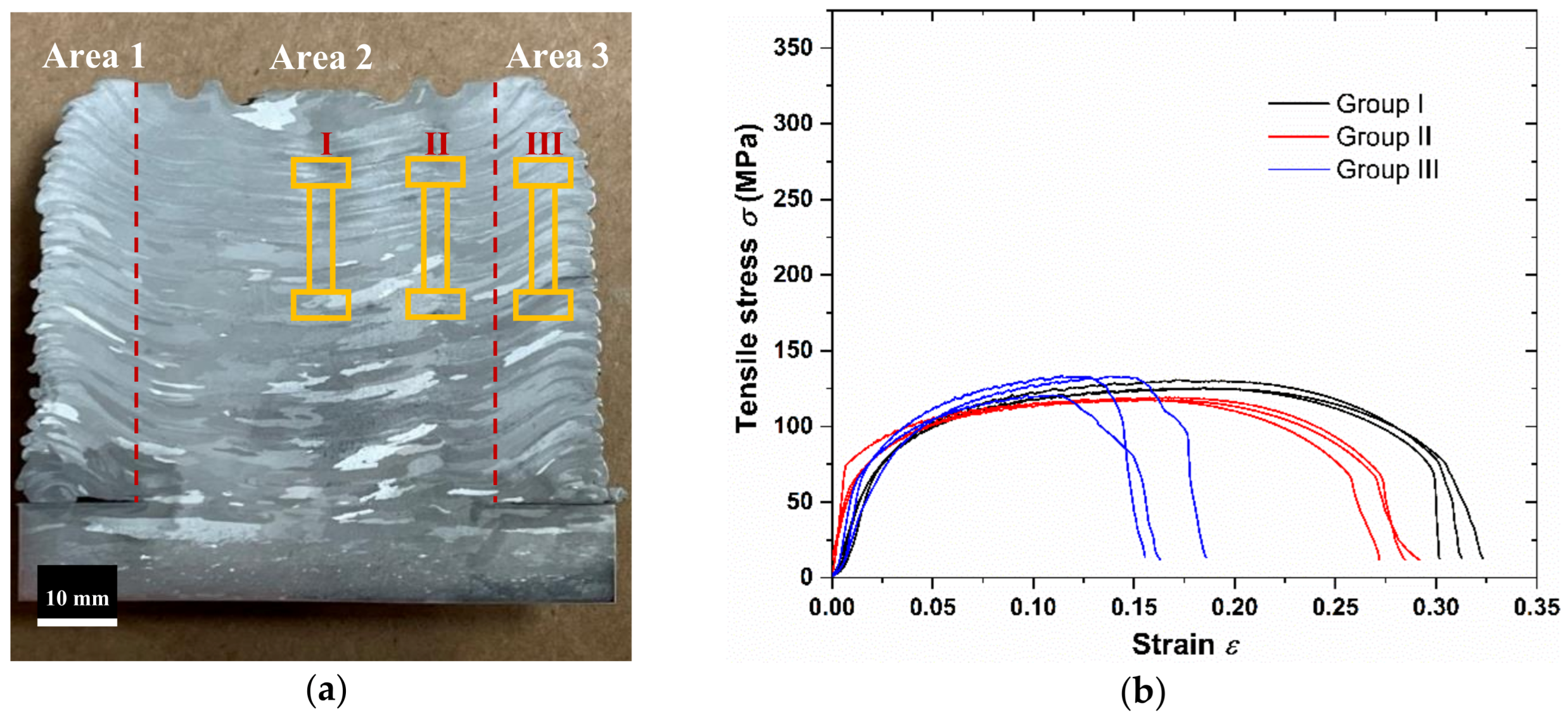

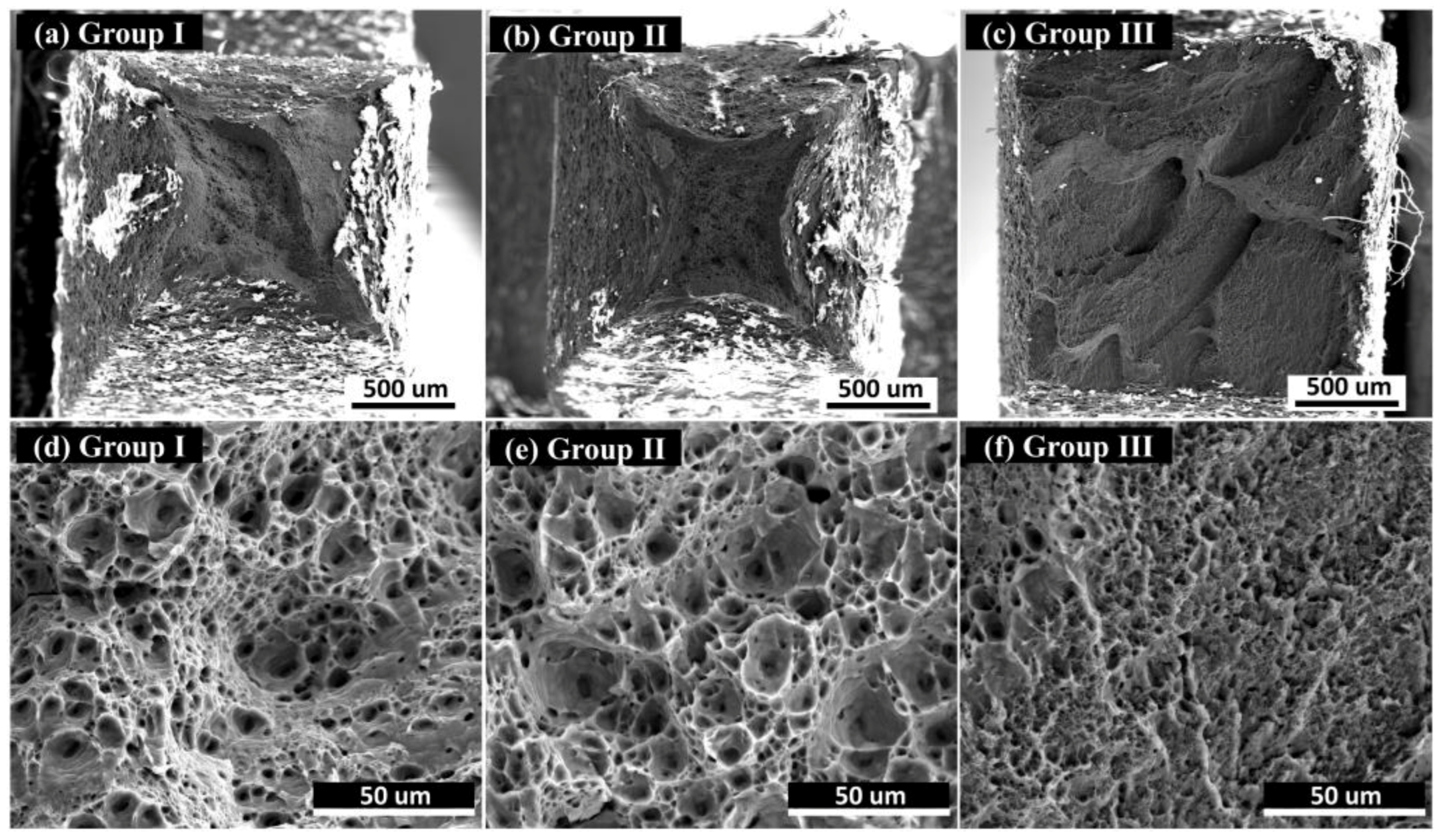

- These contaminations correlate with the mechanical properties of the as-fabricated part and the areas with higher contamination density show a 14% lower strain-to-failure value in tensile testing experiments.

- The nature of the contamination and its relationship to the feedstock preparation procedure, processing parameters, and mechanical properties need to be further studied in the future.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Temple-Smith, P.; Dawes, C.J. Friction Weldin. U.S. Patent 5,460,317, 24 October 1995. [Google Scholar]

- Griffiths, R.J.; Perry, M.E.J.; Sietins, J.M.; Zhu, Y.; Hardwick, N.; Cox, C.D.; Rauch, H.A.; Yu, H.Z. A Perspective on Solid-State Additive Manufacturing of Aluminum Matrix Composites Using MELD. J. Mater. Eng. Perform. 2019, 28, 648–656. [Google Scholar] [CrossRef]

- Rivera, O.G.; Allison, P.G.; Brewer, L.N.; Rodriguez, O.L.; Jordon, J.B.; Liu, T.; Whittington, W.R.; Martens, R.L.; McClelland, Z.; Mason, C.J.T.; et al. Influence of texture and grain refinement on the mechanical behavior of AA2219 fabricated by high shear solid state material deposition. Mater. Sci. Eng. A 2018, 724, 547–558. [Google Scholar] [CrossRef]

- Phillips, B.J.; Avery, D.Z.; Liu, T.; Rodriguez, O.L.; Mason, C.J.T.; Jordon, J.B.; Brewer, L.N.; Allison, P.G. Microstructure-deformation relationship of additive friction stir-deposition Al–Mg–Si. Materialia 2019, 7, 100387. [Google Scholar] [CrossRef]

- Griffiths, R.J.; Petersen, D.T.; Garcia, D.; Yu, H.Z. Additive Friction Stir-Enabled Solid-State Additive Manufacturing for the Repair of 7075 Aluminum Alloy. Appl. Sci. 2019, 9, 3486. [Google Scholar] [CrossRef] [Green Version]

- Zeng, C.; Ghadimi, H.; Ding, H.; Nemati, S.; Garbie, A.; Raush, J.; Guo, S. Microstructure Evolution of Al6061 Alloy Made by Additive Friction Stir Deposition. Materials 2022, 15, 3676. [Google Scholar] [CrossRef] [PubMed]

- Avery, D.Z.; Phillips, B.J.; Mason, C.J.T.; Palermo, M.; Williams, M.B.; Cleek, C.; Rodriguez, O.L.; Allison, P.G.; Jordon, J.B. Influence of Grain Refinement and Microstructure on Fatigue Behavior for Solid-State Additively Manufactured Al-Zn-Mg-Cu Alloy. Metall. Mater. Trans. A 2020, 51, 2778–2795. [Google Scholar] [CrossRef]

- Rutherford, B.A.; Avery, D.Z.; Phillips, B.J.; Rao, H.; Doherty, K.J.; Allison, P.G.; Brewer, L.N.; Jordon, J.B. Effect of Thermomechanical Processing on Fatigue Behavior in Solid-State Additive Manufacturing of Al-Mg-Si Alloy. Metals 2020, 10, 947. [Google Scholar] [CrossRef]

- Martin, L.P.; Luccitti, A.; Walluk, M.R. Repair of aluminum 6061 plate by additive friction stir deposition. Int. J. Adv. Manuf. Technol. 2021, 118, 759–773. [Google Scholar] [CrossRef]

- Rivera, O.G.; Allison, P.G.; Jordon, J.B.; Rodriguez, O.L.; Brewer, L.N.; McClelland, Z.; Whittington, W.R.; Francis, D.; Su, J.; Martens, R.L.; et al. Microstructures and mechanical behavior of Inconel 625 fabricated by solid-state additive manufacturing. Mater. Sci. Eng. A 2017, 694, 1–9. [Google Scholar] [CrossRef]

- Avery, D.Z.; Rivera, O.G.; Mason, C.J.T.; Phillips, B.J.; Jordon, J.B.; Su, J.; Hardwick, N.; Allison, P.G. Fatigue Behavior of Solid-State Additive Manufactured Inconel 625. JOM 2018, 70, 2475–2484. [Google Scholar] [CrossRef]

- Agrawal, P.; Haridas, R.S.; Yadav, S.; Thapliyal, S.; Gaddam, S.; Verma, R.; Mishra, R.S. Processing-structure-property correlation in additive friction stir deposited Ti-6Al-4V alloy from recycled metal chips. Addit. Manuf. 2021, 47, 102259. [Google Scholar] [CrossRef]

- Williams, M.B.; Robinson, T.W.; Williamson, C.; Kinser, R.P.; Ashmore, N.A.; Allison, P.G.; Jordon, J.B. Elucidating the Effect of Additive Friction Stir Deposition on the Resulting Microstructure and Mechanical Properties of Magnesium Alloy WE43. Metals 2021, 11, 1739. [Google Scholar] [CrossRef]

- Griffiths, R.J.; Garcia, D.; Song, J.; Vasudevan, V.K.; Steiner, M.A.; Cai, W.; Yu, H.Z. Solid-state additive manufacturing of aluminum and copper using additive friction stir deposition: Process-microstructure linkages. Materialia 2021, 15, 100967. [Google Scholar] [CrossRef]

- Priedeman, J.L.; Phillips, B.J.; Lopez, J.J.; Tucker Roper, B.E.; Hornbuckle, B.C.; Darling, K.A.; Jordon, J.B.; Allison, P.G.; Thompson, G.B. Microstructure Development in Additive Friction Stir-Deposited Cu. Metals 2020, 10, 1538. [Google Scholar] [CrossRef]

- Chou, K.; Eff, M.; Cox, C.; Saukas, C.; Carroll, J.W. Optical image and Vickers hardness dataset for repair of 1080 steel using additive friction stir deposition of Aermet 100. Data Brief 2022, 41, 107862. [Google Scholar] [CrossRef]

- Gotawala, N.; Mishra, N.K.; Shrivastava, A. Microstructure Evolution and Mechanical Properties of Friction Stir Metal Deposited SS304. In TMS 2022 151st Annual Meeting & Exhibition Supplemental Proceedings; The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2022; pp. 269–278. [Google Scholar] [CrossRef]

- Jordon, J.B.; Allison, P.G.; Phillips, B.J.; Avery, D.Z.; Kinser, R.P.; Brewer, L.N.; Cox, C.; Doherty, K.J. Direct recycling of machine chips through a novel solid-state additive manufacturing process. Mater. Des. 2020, 193, 108850. [Google Scholar] [CrossRef]

- Merritt, G.R.; Williams, M.B.; Allison, P.G.; Jordon, J.B.; Rushing, T.W.; Cousin, C.A. Closed-Loop Temperature and Force Control of Additive Friction Stir Deposition. J. Manuf. Mater. Process. 2022, 6, 92. [Google Scholar] [CrossRef]

- Garcia, D.; Hartley, W.D.; Rauch, H.A.; Griffiths, R.J.; Wang, R.; Kong, Z.J.; Zhu, Y.; Yu, H.Z. In situ investigation into temperature evolution and heat generation during additive friction stir deposition: A comparative study of Cu and Al-Mg-Si. Addit. Manuf. 2020, 34, 101386. [Google Scholar] [CrossRef]

- Stubblefield, G.G.; Fraser, K.; Phillips, B.J.; Jordon, J.B.; Allison, P.G. A meshfree computational framework for the numerical simulation of the solid-state additive manufacturing process, additive friction stir-deposition (AFS-D). Mater. Des. 2021, 202, 109514. [Google Scholar] [CrossRef]

- Mason, C.J.T.; Rodriguez, R.I.; Avery, D.Z.; Phillips, B.J.; Bernarding, B.P.; Williams, M.B.; Cobbs, S.D.; Jordon, J.B.; Allison, P.G. Process-structure-property relations for as-deposited solid-state additively manufactured high-strength aluminum alloy. Addit. Manuf. 2021, 40, 101879. [Google Scholar] [CrossRef]

- Perry, M.E.J.; Griffiths, R.J.; Garcia, D.; Sietins, J.M.; Zhu, Y.; Yu, H.Z. Morphological and microstructural investigation of the non-planar interface formed in solid-state metal additive manufacturing by additive friction stir deposition. Addit. Manuf. 2020, 35, 101293. [Google Scholar] [CrossRef]

- Perry, M.E.J.; Rauch, H.A.; Griffiths, R.J.; Garcia, D.; Sietins, J.M.; Zhu, Y.; Zhu, Y.; Yu, H.Z. Tracing plastic deformation path and concurrent grain refinement during additive friction stir deposition. Materialia 2021, 18, 101159. [Google Scholar] [CrossRef]

- Anderson, I.S.; Mcgreevy, R.L.; Bilheux, H.Z. Neutron Imaging and Applications: A Reference for the Imaging Community; Springer: New York, NY, USA, 2019. [Google Scholar]

- High Flux Isotope Reactor. Available online: https://neutrons.ornl.gov/hfir (accessed on 14 January 2023).

- Pfeiffer, F.; Bech, M.; Bunk, O.; Kraft, P.; Eikenberry, E.F.; Brönnimann, C.; Grünzweig, C.; David, C. Hard-X-ray dark-field imaging using a grating interferometer. Nature Materials 2008, 7, 134–137. [Google Scholar] [CrossRef] [PubMed]

- Dry Graphite Dry-Film Lubricant. Available online: https://zep.com/products/dry-graphite-lubricant-aerosol-16401 (accessed on 14 January 2023).

- Neutron Activation and Scattering Calculator. Available online: https://www.ncnr.nist.gov/resources/activation/ (accessed on 14 January 2023).

- NEUtron Imaging Toolbox (NEUIT). Available online: https://neuit.ornl.gov/transmission (accessed on 14 January 2023).

- Aervoe. Available online: https://www.aervoe.com/product/dry-graphite-lubricant/ (accessed on 14 January 2023).

| Parameter | Ingot A | Ingot B |

|---|---|---|

| Spindle speed (RPM) | 300 | 400 |

| Spindle transverse speed (mm/min) | 254 | 152.4 |

| Feedstock rate (mm/min) | 152.4 | 228.6 |

| Layer thickness (mm) | 1 | 2.5 |

| Ingot | Specimen | 2D Transmission Image | 2D Dark-Field Image | 2D Differential Phase Contrast | 3D Computed Tomography |

|---|---|---|---|---|---|

| A | 10 mm slab | ✓ | ✓ | ✓ | ✗ |

| B | 20 mm slab (polished half) | ✓ | ✓ | ✓ | ✓ |

| 20 mm slab (unpolished half) | ✓ | ✓ | ✓ | ✗ | |

| 10 mm slab | ✓ | ✓ | ✓ | ✗ | |

| N1, N2, N3, N4 | ✓ | ✓ | ✓ | ✗ |

| Interferometer | 2.6 Å, 12 to 18 grating steps |

| Effective pixel size at sample | 42 µm |

| L/D | 600 |

| Exposure time (2D) | 5 × 60 s (z-filter) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nemati, S.; Butler, L.G.; Ham, K.; Knapp, G.L.; Zeng, C.; Emanet, S.; Ghadimi, H.; Guo, S.; Zhang, Y.; Bilheux, H. Neutron Imaging of Al6061 Prepared by Solid-State Friction Stir Additive Manufacturing. Metals 2023, 13, 188. https://doi.org/10.3390/met13020188

Nemati S, Butler LG, Ham K, Knapp GL, Zeng C, Emanet S, Ghadimi H, Guo S, Zhang Y, Bilheux H. Neutron Imaging of Al6061 Prepared by Solid-State Friction Stir Additive Manufacturing. Metals. 2023; 13(2):188. https://doi.org/10.3390/met13020188

Chicago/Turabian StyleNemati, Saber, Leslie G. Butler, Kyungmin Ham, Gerald L. Knapp, Congyuan Zeng, Selami Emanet, Hamed Ghadimi, Shengmin Guo, Yuxuan Zhang, and Hassina Bilheux. 2023. "Neutron Imaging of Al6061 Prepared by Solid-State Friction Stir Additive Manufacturing" Metals 13, no. 2: 188. https://doi.org/10.3390/met13020188

APA StyleNemati, S., Butler, L. G., Ham, K., Knapp, G. L., Zeng, C., Emanet, S., Ghadimi, H., Guo, S., Zhang, Y., & Bilheux, H. (2023). Neutron Imaging of Al6061 Prepared by Solid-State Friction Stir Additive Manufacturing. Metals, 13(2), 188. https://doi.org/10.3390/met13020188