Wire-Feed Electron Beam Additive Manufacturing: A Review

Abstract

1. Introduction

2. Titanium Alloys

3. Nickel-Based Alloys

4. Steels

5. Copper

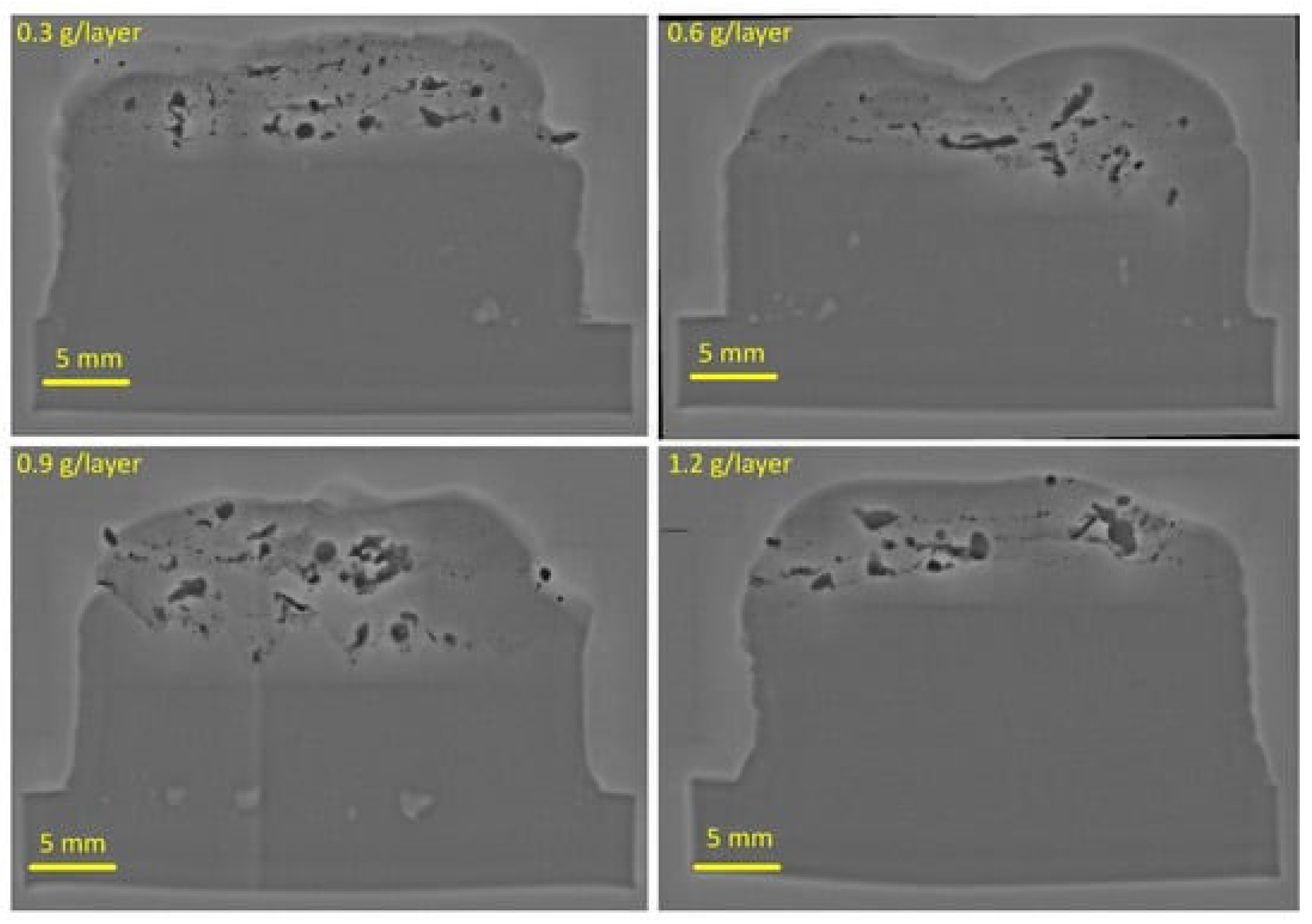

6. Aluminum Alloys

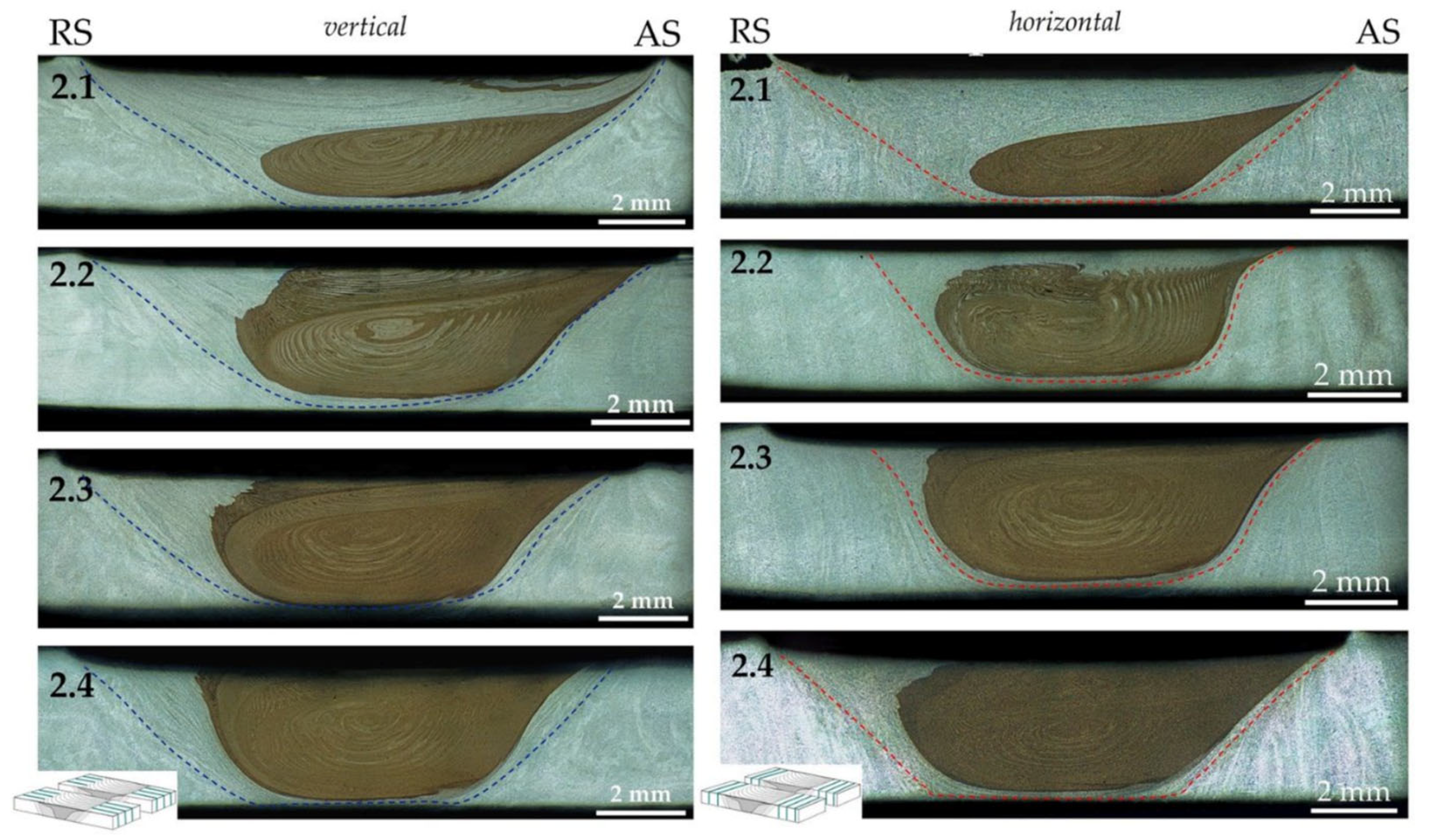

7. Polymetallic Composites and Bimetallic Elements

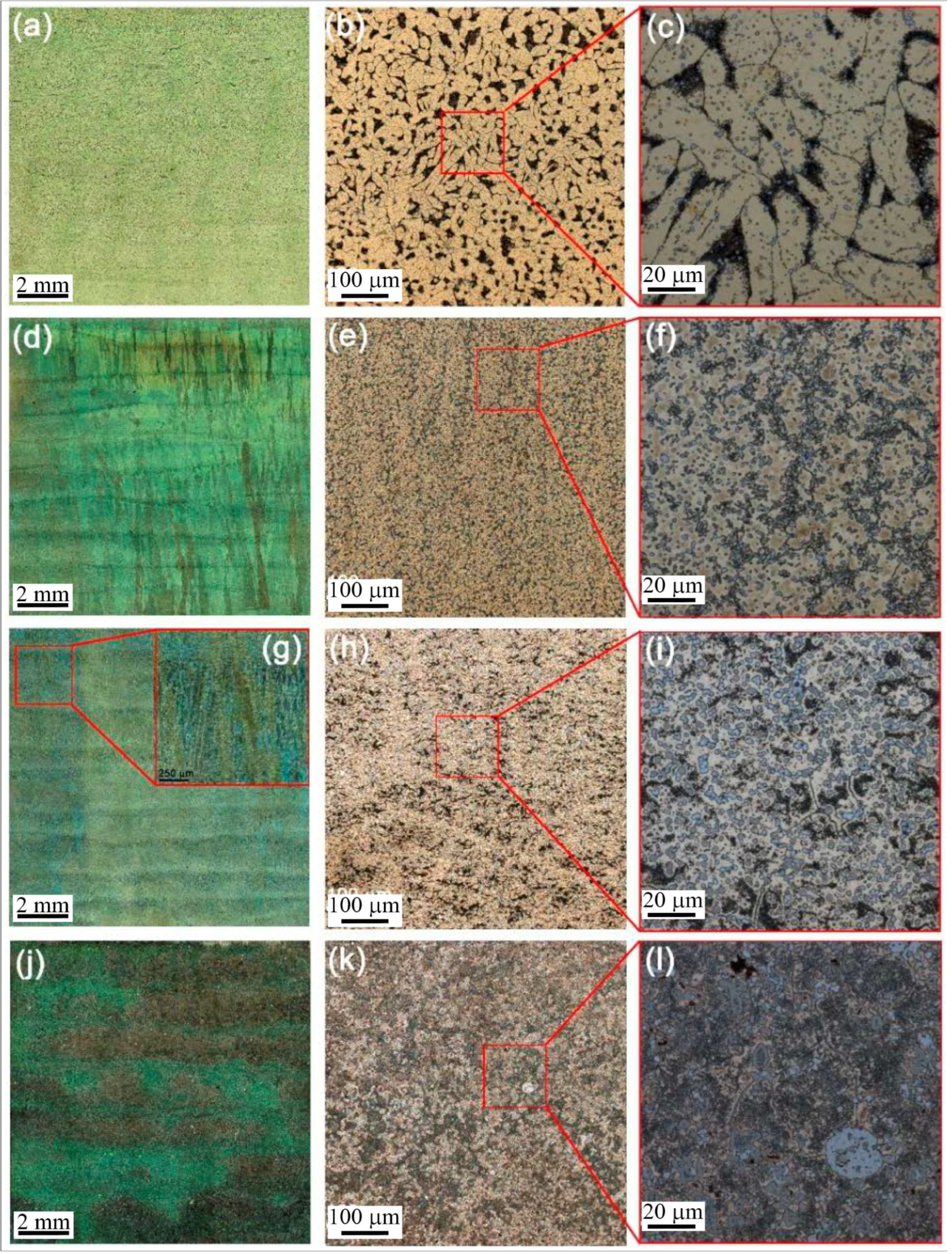

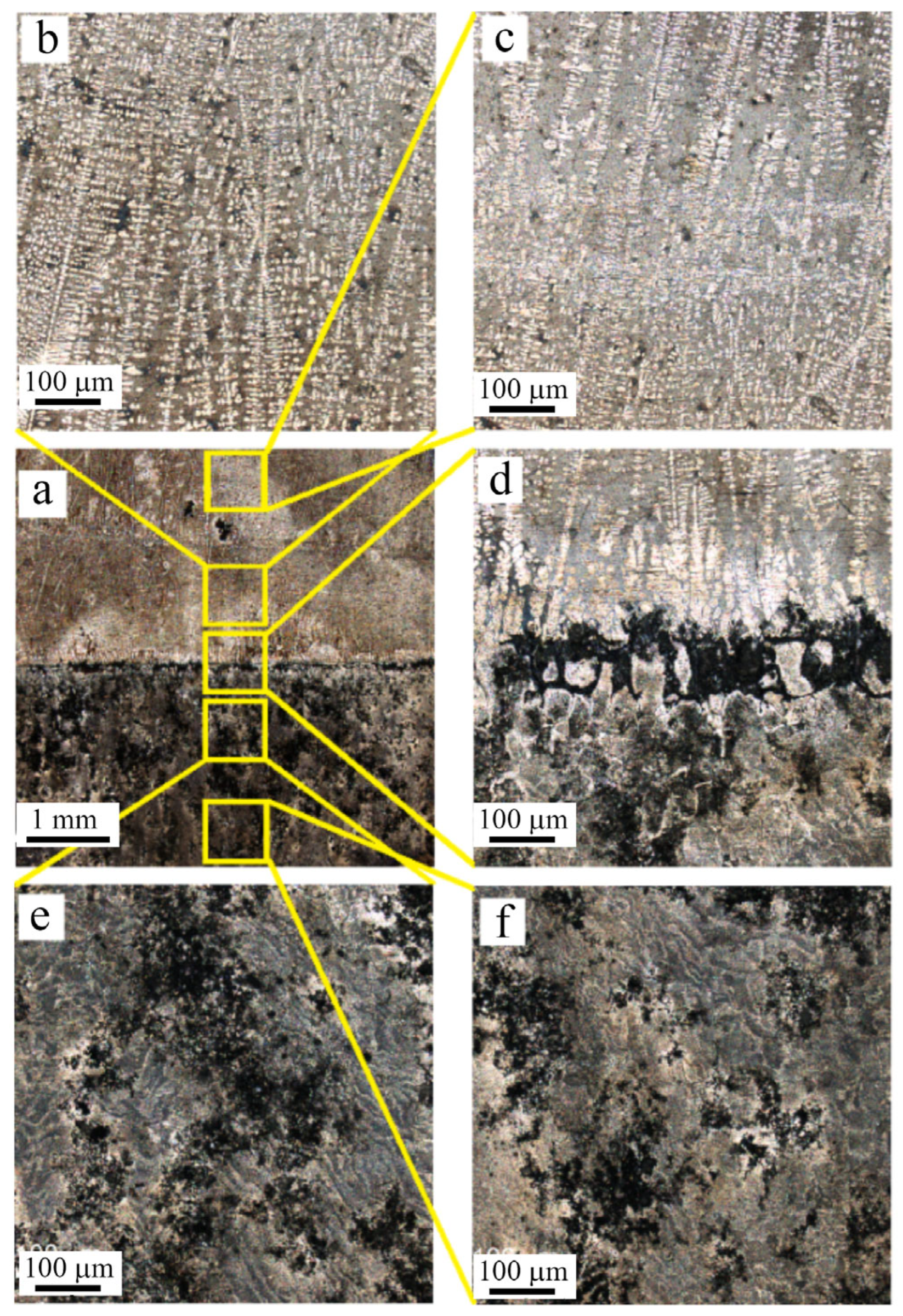

7.1. Polymetallic Composite Materials and Bimetallic Elements of the Copper–Steel System

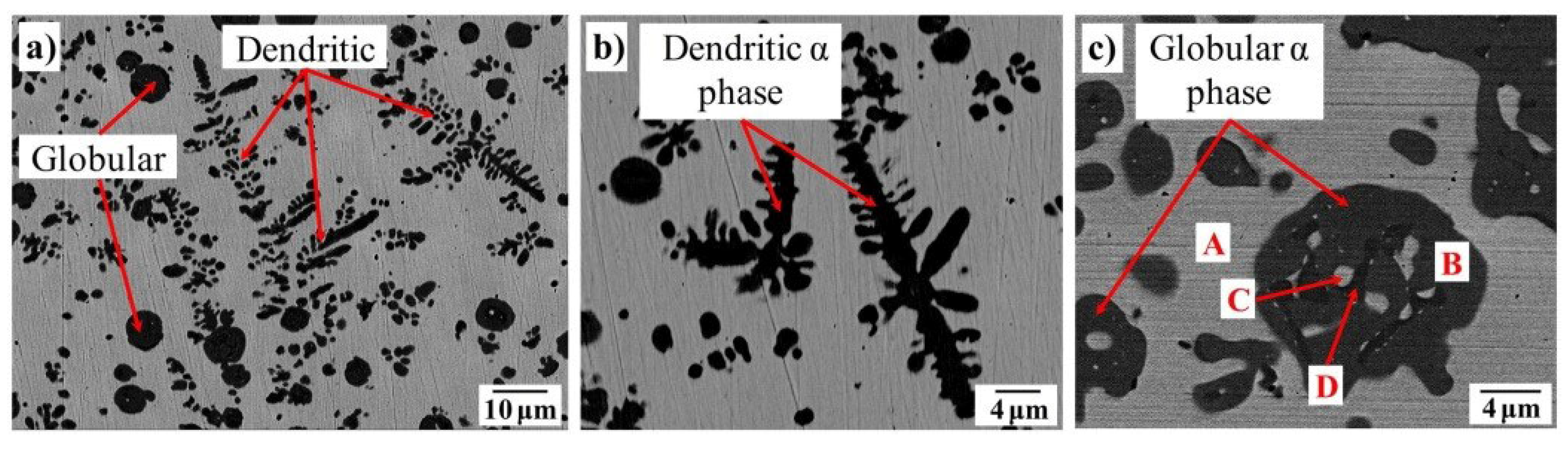

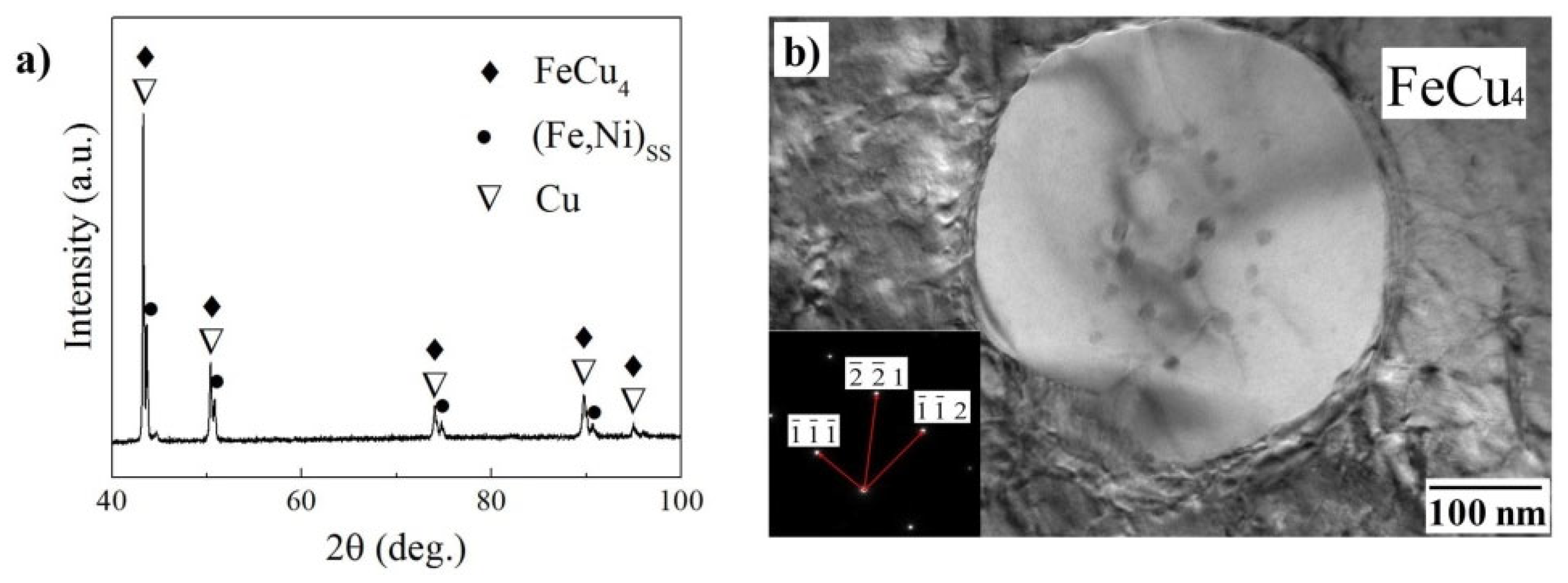

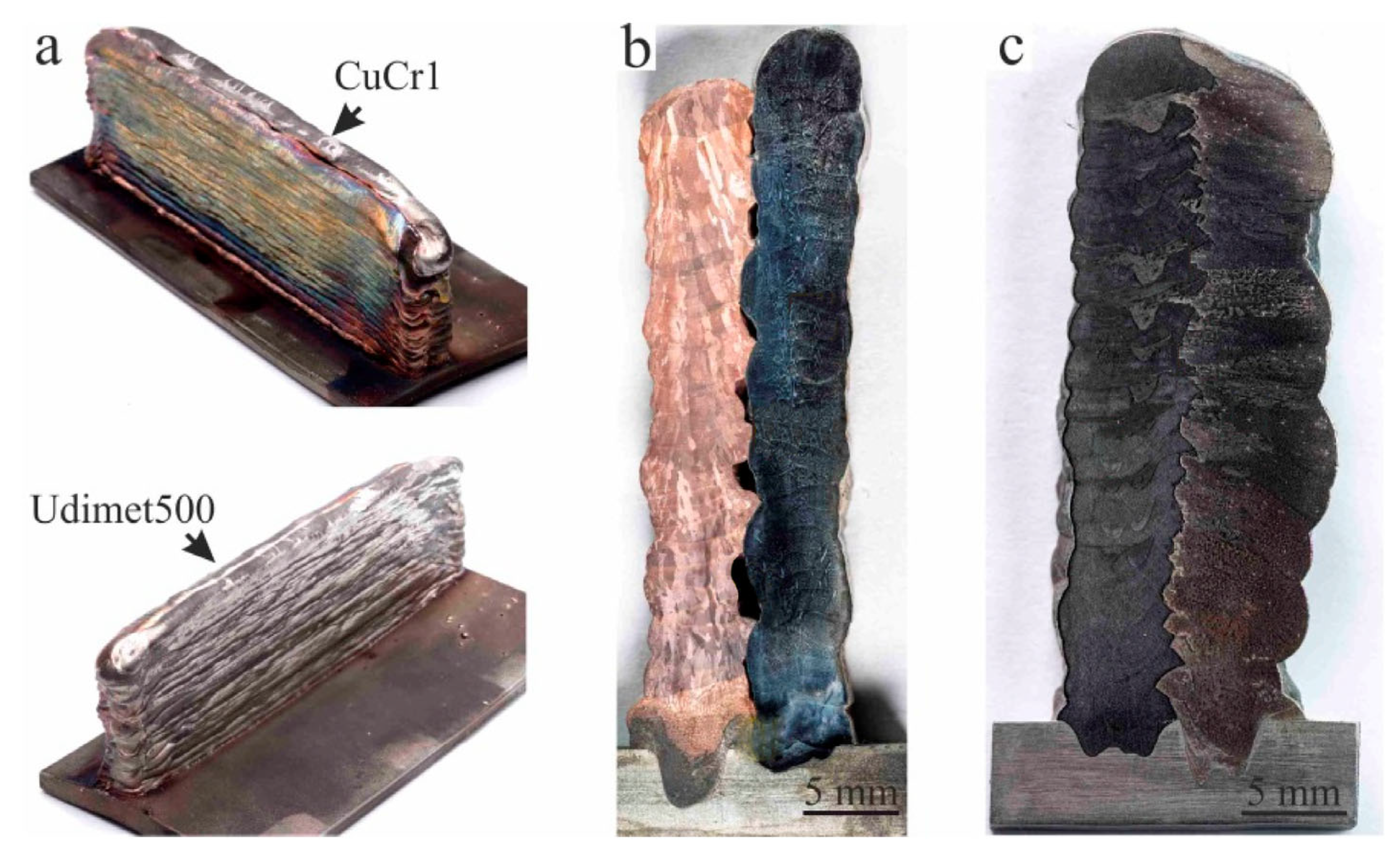

7.2. Composite Materials Based on Copper Alloys

7.3. Polymetallic and Composite Products Based on Aluminum and Titanium Alloys

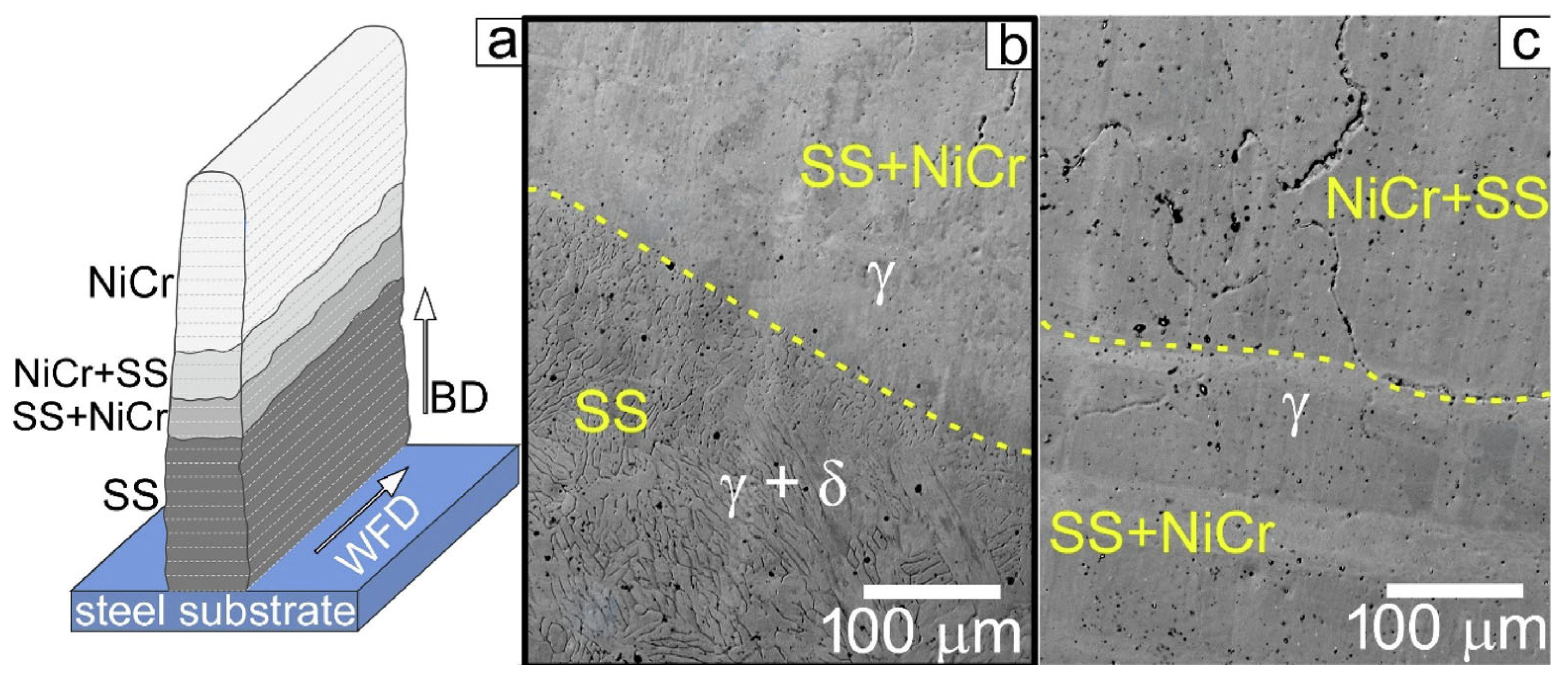

7.4. Bimetallic Products on “Steel–Nickel Alloy” and “Copper Alloy–Nickel Alloy” Systems

8. Modification of Structure and Hardening of Additive-Formed Materials by Friction Stirring Treatment

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kodama, H. Automatic Method for Fabricating a Three-dimensional Plastic Model with Photo-hardening Polymer. Rev. Sci. Instrum. 1981, 52, 1770–1773. [Google Scholar] [CrossRef]

- Melchels, F.P.W. Celebrating Three Decades of Stereolithography. Virtual Phys. Prototyp. 2012, 7, 173–175. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A Review on Selective Laser Sintering/Melting (SLS/SLM) of Aluminium Alloy Powders: Processing, Microstructure, and Properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Sefene, E.M. State-of-the-art of selective laser melting process: A comprehensive review. J. Manuf. Syst. 2022, 63, 250–274. [Google Scholar] [CrossRef]

- Lekurwale, S.; Karanwad, T.; Banerjee, S. Selective laser sintering (SLS) of 3D printlets using a 3D printer comprised of IR/red-diode laser. Ann. 3D Print. Med. 2022, 6, 100054. [Google Scholar] [CrossRef]

- Lulu-Bitton, N.; Sabatani, E.; Rosen, B.A.; Kostirya, N.; Agronov, G.; Tiferet, E.; Eliaz, N.; Navi, N.U. Mechanical behavior of electrochemically hydrogenated electron beam melting (EBM) and wrought Ti–6Al–4V using small punch test. Int. J. Hydrog. Energy 2022, 47, 6388–6403. [Google Scholar] [CrossRef]

- Onuike, B.; Bandyopadhyay, A. Bond strength measurement for additively manufactured Inconel 718- GRCop84 copper alloy bimetallic joints. Addit. Manuf. 2019, 27, 576–585. [Google Scholar] [CrossRef]

- Bouaziz, M.A.; Djouda, J.M.; Chemkhi, M.; Rambaudon, M.; Kauffmann, J.; Hild, F. Heat treatment effect on 17-4PH stainless steel manufactured by Atomic Diffusion Additive Manufacturing (ADAM). Procedia CIRP 2021, 104, 935–938. [Google Scholar] [CrossRef]

- Papyrin, A.; Kosarev, V.; Klinkov, S.; Alkhimov, A.; Fomin, V.M. Cold Spray Technology; Elsevier: Amsterdam, The Netherlands, 2007; pp. 1–32. [Google Scholar] [CrossRef]

- Singh, R.; Kondás, J.; Bauer, C.; Cizek, J.; Medricky, J.; Csaki, S.; Čupera, J.; Procházka, R.; Melzer, D.; Konopík, P. Bulk-like ductility of cold spray additively manufactured copper in the as-sprayed state. Addit. Manuf. Lett. 2022, 3, 100052. [Google Scholar] [CrossRef]

- Liu, J.; Xu, Y.; Ge, Y.; Hou, Z.; Chen, S. Wire and Arc Additive Manufacturing of Metal Components: A Review of Recent Research Developments. Int. J. Adv. Manuf. Technol. 2020, 111, 149–198. [Google Scholar] [CrossRef]

- Recent Studies of Laser Metal 3D Deposition with Wire Feeding. J. Weld. Join. 2016, 34, 35–40. [CrossRef]

- Tarasov, S.Y.; Filippov, A.V.; Shamarin, N.N.; Fortuna, S.V.; Maier, G.G.; Kolubaev, E.A. Microstructural Evolution and Chemical Corrosion of Electron Beam Wire-Feed Additively Manufactured AISI 304 Stainless Steel. J. Alloys Compd. 2019, 803, 364–370. [Google Scholar] [CrossRef]

- Evans, S.I.; Wang, J.; Qin, J.; He, Y.; Shepherd, P.; Ding, J. A review of WAAM for steel construction–Manufacturing, material and geometric properties, design, and future directions. Structures 2022, 44, 1506–1522. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-Feed Additive Manufacturing of Metal Components: Technologies, Developments and Future Interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Negi, S.; Nambolan, A.A.; Kapil, S.; Joshi, P.S.R.M.; Karunakaran, K.P.; Bhargava, P. Review on Electron Beam Based Additive Manufacturing. Rapid Prototyp. J. 2020, 26, 485–498. [Google Scholar] [CrossRef]

- Węglowski, M.S.; Błacha, S.; Pilarczyk, J.; Dutkiewicz, J.; Rogal, Ł. Electron Beam Additive Manufacturing with Wire–Analysis of the Process. AIP Conf. Proc. 2018, 1960, 140015. [Google Scholar] [CrossRef]

- Kolubaev, E.A.; Rubtsov, V.E.; Chumaevsky, A.V.; Astafurova, E.G. Micro-, Meso- and Macrostructural Design of Bulk Metallic and Polymetallic Materials by Wire-Feed Electron-Beam Additive Manufacturing. Phys. Mesomech. 2022, 25, 479–491. [Google Scholar] [CrossRef]

- Tshephe, T.S.; Akinwamide, S.O.; Olevsky, E.; Olubambi, P.A. Additive manufacturing of titanium-based alloys- A review of methods, properties, challenges, and prospects. Heliyon 2022, 8, e09041. [Google Scholar] [CrossRef]

- Shahwaz, M.; Nath, P.; Sen, I. A critical review on the microstructure and mechanical properties correlation of additively manufactured nickel-based superalloys. J. Alloys Compd. 2022, 907, 164530. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, L.; Andersson, J.; Ojo, O. Additive manufacturing of 18% nickel maraging steels: Defect, structure and mechanical properties: A review. J. Mater. Sci. Technol. 2022, 120, 227–252. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, A.; Yin, B.; Wen, P. Additive manufacturing of duplex stainless steels—A critical review. J. Manuf. Process. 2022, 73, 496–517. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Wei, S.; Ni, X.; Zhang, L.; Li, R.; Wang, L.; Man, C.; Li, X. About metastable cellular structure in additively manufactured austenitic stainless steels. Addit. Manuf. 2021, 38, 101804. [Google Scholar] [CrossRef]

- Roccetti Campagnoli, M.; Galati, M.; Saboori, A. On the processability of copper components via powder-based additive manufacturing processes: Potentials, challenges and feasible solutions. J. Manuf. Process. 2021, 72, 320–337. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Yardley, V.A.; Shi, Z.; Lin, J. Challenges in additive manufacturing of high-strength aluminium alloys and current developments in hybrid additive manufacturing. Int. J. Light. Mater. Manuf. 2021, 4, 246–261. [Google Scholar] [CrossRef]

- Kumar Sinha, A.; Pramanik, S.; Yagati, K.P. Research progress in arc based additive manufacturing of aluminium alloys—A review. Measurement 2022, 200, 111672. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Heer, B. Additive manufacturing of multi-material structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Shakil, S.I.; Smith, N.R.; Yoder, S.P.; Ross, B.E.; Alvarado, D.J.; Hadadzadeh, A.; Haghshenas, M. Post fabrication thermomechanical processing of additive manufactured metals: A review. J. Manuf. Process. 2022, 73, 757–790. [Google Scholar] [CrossRef]

- He, P.; Bai, X.; Zhang, H. Microstructure refinement and mechanical properties enhancement of wire and arc additively manufactured 6061 aluminum alloy using friction stir processing post-treatment. Mater. Lett. 2023, 330, 133365. [Google Scholar] [CrossRef]

- Sibum, H.; Güther, V.; Roidl, O.; Habashi, F.; Wolf, H.; Siemers, C. Titanium, Titanium Alloys and Titanium Compounds. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley: Weinheim, Germany, 2017; pp. 1–35. [Google Scholar]

- Boyer, R.R. An Overview on the Use of Titanium in the Aerospace Industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Boyer, R.R. Attributes, Characteristics, and Applications of Titanium and Its Alloys. JOM 2010, 62, 21–24. [Google Scholar] [CrossRef]

- FUJII, H.; TAKAHASHI, K.; YAMASHITA, Y. Application of Titanium and Its Alloys for Automobile Parts. Nippon Steel Tech. Rep. 2003, 88, 70–75. [Google Scholar]

- Lee, H.S.; Yoon, J.H.; Yoo, J.T. Manufacturing Titanium and Al-Li Alloy Cryogenic Tanks. Key Eng. Mater. 2020, 837, 64–68. [Google Scholar] [CrossRef]

- Cotton, J.D.; Briggs, R.D.; Boyer, R.R.; Tamirisakandala, S.; Russo, P.; Shchetnikov, N.; Fanning, J.C. State of the Art in Beta Titanium Alloys for Airframe Applications. JOM 2015, 67, 1281–1303. [Google Scholar] [CrossRef]

- Singh, P.; Pungotra, H.; Kalsi, N.S. On the Characteristics of Titanium Alloys for the Aircraft Applications. Mater. Today Proc. 2017, 4, 8971–8982. [Google Scholar] [CrossRef]

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium Alloys for Aerospace Applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Veiga, C.; Davim, J.; Loureiro, A. Review on Machinability of Titanium Alloys: The Process Perspective. Rev. Adv. Mater. Sci. 2013, 34, 148–164. [Google Scholar]

- Pramanik, A. Problems and Solutions in Machining of Titanium Alloys. Int. J. Adv. Manuf. Technol. 2014, 70, 919–928. [Google Scholar] [CrossRef]

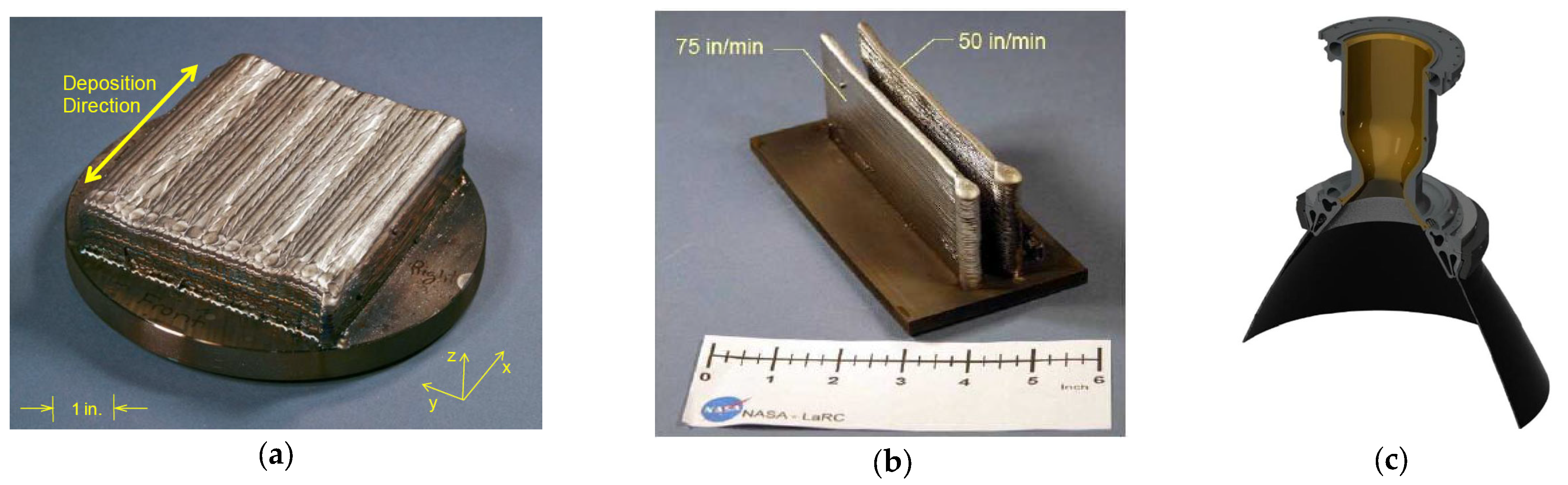

- Taminger, K.M.; Hafley, R.A. Electron Beam Freeform Fabrication for Cost Effective Near-Net Shape Manufacturing. NATO/RTO AVT 2006, 139, 11–16. [Google Scholar]

- Wanjara, P.; Watanabe, K.; de Formanoir, C.; Yang, Q.; Bescond, C.; Godet, S.; Brochu, M.; Nezaki, K.; Gholipour, J.; Patnaik, P. Titanium Alloy Repair with Wire-Feed Electron Beam Additive Manufacturing Technology. Adv. Mater. Sci. Eng. 2019, 2019, 3979471. [Google Scholar] [CrossRef]

- Electron Beam Additive Manufacturing (EBAM®). Available online: https://www.sciaky.com/additive-manufacturing/electron-beam-additive-manufacturing-technology (accessed on 27 December 2022).

- Pixner, F.; Warchomicka, F.; Peter, P.; Steuwer, A.; Colliander, M.H.; Pederson, R.; Enzinger, N. Wire-Based Additive Manufacturing of Ti-6Al-4V Using Electron Beam Technique. Materials 2020, 13, 3310. [Google Scholar] [CrossRef]

- Zhang, G.; Xiong, H.; Yu, H.; Qin, R.; Liu, W.; Yuan, H. Microstructure Evolution and Mechanical Properties of Wire-Feed Electron Beam Additive Manufactured Ti-5Al-2Sn-2Zr-4Mo-4Cr Alloy with Different Subtransus Heat Treatments. Mater. Des. 2020, 195, 109063. [Google Scholar] [CrossRef]

- Kalashnikov, K.N.; Chumaevskii, A.V.; Kalashnikova, T.A.; Kolubaev, E.A. A Substrate Material and Thickness Influence on the 3D-Printing of Ti–6Al–4V Components via Wire-Feed Electron Beam Additive Manufacturing. J. Mater. Res. Technol. 2022, 16, 840–852. [Google Scholar] [CrossRef]

- Panin, A.; Martynov, S.; Kazachenok, M.; Kazantseva, L.; Bakulin, A.; Kulkova, S.; Perevalova, O.; Sklyarova, E. Effects of Water Cooling on the Microstructure of Electron Beam Additive-Manufactured Ti-6Al-4V. Metals 2021, 11, 1742. [Google Scholar] [CrossRef]

- Kalashnikov, K.N.; Rubtsov, V.E.; Savchenko, N.L.; Kalashnikova, T.A.; Osipovich, K.S.; Eliseev, A.A.; Chumaevskii, A.V. The Effect of Wire Feed Geometry on Electron Beam Freeform 3D Printing of Complex-Shaped Samples from Ti-6Al-4V Alloy. Int. J. Adv. Manuf. Technol. 2019, 105, 3147–3156. [Google Scholar] [CrossRef]

- Kalashnikov, K.; Chumaevskii, A.; Kalashnikova, T.; Cheremnov, A.; Moskvichev, E.; Amirov, A.; Krasnoveikin, V.; Kolubaev, E. Friction Stir Processing of Additively Manufactured Ti-6Al-4V Alloy: Structure Modification and Mechanical Properties. Metals 2021, 12, 55. [Google Scholar] [CrossRef]

- Carroll, B.E.; Palmer, T.A.; Beese, A.M. Anisotropic Tensile Behavior of Ti–6Al–4V Components Fabricated with Directed Energy Deposition Additive Manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Kalashnikova, T.; Cheremnov, A.; Eliseev, A.; Gurianov, D.; Knyazhev, E.; Moskvichev, E.; Beloborodov, V.; Chumaevskii, A.; Zykova, A.; Kalashnikov, K. Structural Changes in Block-Shaped WEBAM’ed Ti6Al4V Samples after Friction Stir Processing. Lubricants 2022, 10, 349. [Google Scholar] [CrossRef]

- Matz, J.E.; Eagar, T.W. Carbide formation in alloy 718 during electron-beam solid freeform fabrication. Met. Mater. Trans. A 2020, 33, 2559–2567. [Google Scholar] [CrossRef]

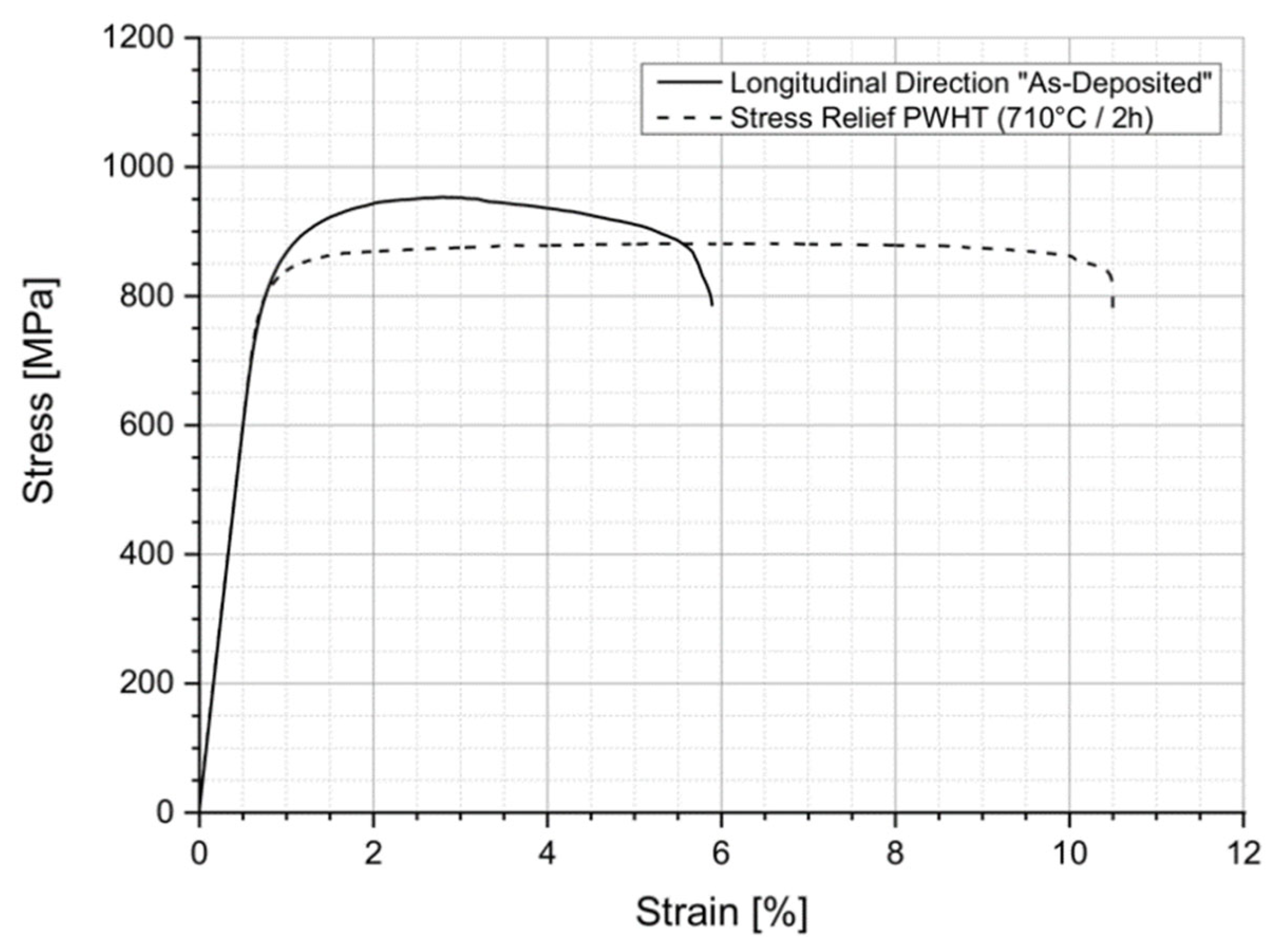

- Waters, B.R. Mechanical Properties of Inconel 718 Processed Using Electron Beam Free Form Fabrication (EBAM). Master’s Thesis, Brigham Young University, Provo, UT, USA, 2018. [Google Scholar]

- Tayon, W.A.; Shenoy, R.N.; Redding, M.R.; Keith Bird, R.; Hafley, R.A. Correlation Between Microstructure and Mechanical Properties in an Inconel 718 Deposit Produced Via Electron Beam Freeform Fabrication. Manuf. Sci. Eng. 2014, 136, 061005. [Google Scholar] [CrossRef]

- Tayon, W.; Shenoy, R.; Bird, T.; Hafley, R.; Redding, M. Texture-induced anisotropy in an inconel 718 alloy deposited using electron beam freeform fabrication. In Proceedings of the International Conference on Texture of Materials, Dresden, Germany, 24–29 August 2014. [Google Scholar]

- Bird, R.K.; Atherton, T.S. Effect of Orientation on Tensile Properties of Inconel 718 Block Fabricated with Electron Beam Freeform Fabrication (EBAM). Technical Memorandum. NASA/TM-2010-216719. In Proceedings of the Langley Research Center, Hampton, VA, USA, 13–15 April 2010. [Google Scholar]

- Bird, R.K.; Hibberd, J. Tensile Properties and Microstructure of Inconel 718 Fabricated with Electron Beam Freeform Fabrication (EBAM); Technical Memorandum. NASA/TM-2009-215929; Langley Research Center: Hampton, VA, USA, 2009; pp. 1–19. [Google Scholar]

- Hales, S.J.; Domack, C.S.; Brown, T.; Karen, M. Electron Beam Freeform Fabrication of Dissimilar Materials: Cracking in Inconel 625 on GRCop-84; Technical Publication NASA-TP-2020-5005040; Langley Research Center: Hampton, VA, USA, 2020; pp. 1–83. [Google Scholar]

- Wahlmann, B.; Korner, C.; Nunn, M. Electron beam wire cladding of nickel alloys and stainless steel on a reactor pressure vessel steel. Mater. Sci. Eng. A 2021, 811, 141082. [Google Scholar] [CrossRef]

- Xu, D.; Wang, H.; Tao, X.; Yao, Z.; Zhang, S.; Oleksander, M. Investigation on Microstructure, Hardness and Wear Resistance of Electron Beam Wire-Feeding Deposited Inconel 718 Alloy Coatings. Met. Mater. Int. 2021, 27, 1263–1272. [Google Scholar] [CrossRef]

- Sun, W.; Xin, J.; Wang, S.; Chen, Y.; Huang, Y. Effect of deposited layer thickness on the microstructure and mechanical properties of IC10 single-crystal Ni3Al-based alloy electron beam welded joint. J. Mater. Res. Technol. 2021, 11, 1206–1219. [Google Scholar] [CrossRef]

- Moskvina, V.A.; Melnikov, E.V.; Panchenko, M.Y.; Maier, G.G.; Reunova, K.A.; Astafurov, S.V.; Kolubaev, E.A.; Astafurova, E.G. Stabilization of austenitic structure in transition zone of “austenitic stainless steel/NiCr alloy” joint fabricated by wire-feed electron beam melting. Mater. Lett. 2020, 277, 128321. [Google Scholar] [CrossRef]

- Small, K.A.; Taheri, M.L. Role of Processing in Microstructural Evolution in Inconel 625: A Comparison of Three Additive Manufacturing Techniques. Metall. Mater. Trans. A 2021, 52, 2811–2820. [Google Scholar] [CrossRef]

- Fortuna, S.V.; Gurianov, D.A.; Kalashnikov, K.N.; Chumaevskii, A.V.; Mironov, Y.P.; Kolubaev, E.A. Directional Solidification of a Nickel-Based Superalloy Product Structure Fabricated on Stainless Steel Substrate by Electron Beam Additive Manufacturing. Met. Mater. Trans. A 2021, 52, 857–870. [Google Scholar] [CrossRef]

- Fortuna, S.V.; Gurianov, D.A.; Kalashnikov, K.N. Directional solidification features of nickel-based superalloy in the electron beam additive manufacturing process. AIP Conf. Proc. 2019, 2167, 020107. [Google Scholar] [CrossRef]

- Safarzade, A.; Sharifitabar, M.; Afarani, M.S. Effects of heat treatment on microstructure and mechanical properties of Inconel 625 alloy fabricated by wire arc additive manufacturing process. Trans. Nonferrous Met. Soc. China 2020, 30, 3016–3030. [Google Scholar] [CrossRef]

- Asala, G.; Andersson, J.; Ojo, O.A. Improved dynamic impact behaviour of wire-arc additive manufactured ATI 718Plus®. Mater. Sci. Eng. A 2018, 738, 111–124. [Google Scholar] [CrossRef]

- Seow, C.E.; Zhang, J.; Coules, H.E. Effect of crack-like defects on the fracture behaviour of Wire + Arc Additively Manufactured nickel-base Alloy 718. Addit. Manuf. 2020, 36, 101578. [Google Scholar] [CrossRef]

- Baufeld, B. Mechanical Properties of INCONEL 718 Parts Manufactured by Shaped Metal Deposition (SMD). J. Mater. Eng. Perform. 2012, 21, 1416–1421. [Google Scholar] [CrossRef]

- Qiu, Z.; Wu, B.; Zhu, H.; Wang, Z.; Hellier, A.; Ma, Y.; Li, H.; Muransky, O.; Wexel, D. Microstructure and mechanical properties of wire arc additively manufactured Hastelloy C276 alloy. Mater. Des. 2020, 195, 109007. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.M.; Santos, T.G.; Oliveira, J.P. Current Status and Perspectives on Wire and Arc Additive Manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef] [PubMed]

- Cormier, D.; Harrysson, O.; West, H. Characterization of H13 steel produced via electron beam melting. Rapid Prototyp. J. 2004, 10, 35–41. [Google Scholar] [CrossRef]

- Gardner, L. Stability and design of stainless steel structures–Review and outlook. Thin Walled Struct. 2019, 141, 208–216. [Google Scholar] [CrossRef]

- Grigorescu, A.C.; Hilgendorff, P.M.; Zimmermann, M.; Fritzen, C.P.; Christ, H.J. Cyclic deformation behavior of austenitic Cr–Ni-steels in the VHCF regime: Part I–Experimental study. Int. J. Fatigue 2016, 93, 250–260. [Google Scholar] [CrossRef]

- Kalinin, G.; Barabash, V.; Cardella, A.; Dietz, J.; Ioki, K.; Matera, R.; Santoro, R.T.; Tivey, R. Assessment and selection of materials for ITER in-vessel components. J. Nucl. Mater. 2000, 283–287, 10–19. [Google Scholar] [CrossRef]

- Hsiao, C.N.; Chiou, C.S.; Yang, J.R. Aging reactions in a 17-4 PH stainless steel. Mater. Chem. Phys. 2002, 74, 134–142. [Google Scholar] [CrossRef]

- Fayazfar, H.; Salarian, M.; Rogalsky, A.; Sarker, D.; Russo, P.; Paserin, V.; Toyserkani, E. A critical review of powder-based additive manufacturing of ferrous alloys: Process parameters, microstructure and mechanical properties. Mater. Des. 2018, 144, 98–128. [Google Scholar] [CrossRef]

- Kumar, S.; Pityana, S. Laser-Based Additive Manufacturing of Metals. Adv. Mater. Res. 2011, 227, 92–95. [Google Scholar] [CrossRef]

- Rannar, L.E.; Glad, A.; Gustafson, C.G. Efficient cooling with tool inserts manufactured by electron beam melting. Rapid Prototyp. J. 2007, 13, 128–135. [Google Scholar] [CrossRef]

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in additive manufacturing: A review of their microstructure and properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- Astafurov, S.; Astafurova, E. Phase Composition of Austenitic Stainless Steels in Additive Manufacturing: A Review. Metals 2021, 11, 1052. [Google Scholar] [CrossRef]

- Panchenko, M.Y.; Astafurova, E.G.; Moskvina, V.A.; Maier, G.G.; Astafurov, S.V.; Melnikov, E.V.; Reunova, K.A.; Rubtsov, V.E.; Kolubaev, E.A. The effect of niobium on microstructure and mechanical properties of austenitic crni steel produced by wire-feed electron beam additive manufacturing. Nanosci. Technol. Int. J. 2020, 11, 109–118. [Google Scholar] [CrossRef]

- Astafurova, E.G.; Panchenko, M.Y.; Moskvina, V.A.; Maier, G.G.; Astafurov, S.V.; Melnikov, E.V.; Fortuna, A.S.; Reunova, K.A.; Rubtsov, V.E.; Kolubaev, E.A. Microstructure and grain growth inhomogeneity in austenitic steel produced by wire-feed electron beam melting: The effect of post-building solid-solution treatment. J. Mater. Sci. 2020, 55, 9211–9224. [Google Scholar] [CrossRef]

- Feng, Y.; Zhan, B.; He, J.; Wang, K. The double-wire feed and plasma arc additive manufacturing process for deposition in Cr-Ni stainless steel. J. Mater. Process. Technol. 2018, 259, 206–215. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Tarasov, S.Y.; Filippov, A.V.; Savchenko, N.L.; Fortuna, S.V.; Rubtsov, V.E.; Kolubaev, E.A.; Psakhie, S.G. Effect of heat input on phase content, crystalline lattice parameter, and residual strain in wire-feed electron beam additive manufactured 304 stainless steel. Int. J. Adv. Manuf. Technol. 2018, 99, 2353–2363. [Google Scholar] [CrossRef]

- Lin, X.; Yue, T.M. Phase formation and microstructure evolution in laser rapid forming of graded SS316L/Rene88DT alloy. Mater. Sci. Eng. A 2005, 402, 294–306. [Google Scholar] [CrossRef]

- Huang, Y.; Ansari, M.; Asgari, H.; Farshidianfar, M.H.; Sarker, D.; Khamesee, M.B.; Toyserkani, E. Rapid prediction of real-time thermal characteristics, solidification parameters and microstructure in laser directed energy deposition (powder-fed additive manufacturing). J. Mater. Process. Technol. 2019, 274, 116286. [Google Scholar] [CrossRef]

- Abd-Elghany, K.; Bourell, D.L. Property evaluation of 304L stainless steel fabricated by selective laser melting. Rapid Prototyp. J. 2012, 18, 420–428. [Google Scholar] [CrossRef]

- Niendorf, T.; Leuders, S.; Riemer, A.; Richard, H.A.; Tröster, T.; Schwarze, D. Highly anisotropic steel processed by selective laser melting. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2013, 44, 794–796. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Z.; Wang, D.; Zeng, X. Control of shape and performance for direct laser fabrication of precision large-scale metal parts with 316L Stainless Steel. Opt. Laser Technol. 2013, 45, 209–216. [Google Scholar] [CrossRef]

- Luecke, W.E.; Slotwinski, J.A. Mechanical Properties of Austenitic Stainless Steel Made by Additive Manufacturing. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 15. [Google Scholar] [CrossRef] [PubMed]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Wanjara, P.; Brochu, M.; Jahazi, M. Electron beam freeforming of stainless steel using solid wire feed. Mater. Des. 2007, 28, 2278–2286. [Google Scholar] [CrossRef]

- Nassour, A.; Bose, W.W.; Spinelli, D. Creep properties of austenitic stainless-steel weld metals. J. Mater. Eng. Perform. 2001, 10, 693–698. [Google Scholar] [CrossRef]

- Sun, G.F.; Yao, S.; Wang, Z.D.; Shen, X.T.; Yan, Y.; Zhou, R.; Ni, Z.H. Microstructure and mechanical properties of HSLA-100 steel repaired by laser metal deposition. Surf. Coat. Technol. 2018, 351, 198–211. [Google Scholar] [CrossRef]

- Abramov, O.V. High-Intensity Ultrasonics: Theory and Industrial Applications. High-Intensity Ultrason. 2019, 21, 1954. [Google Scholar] [CrossRef]

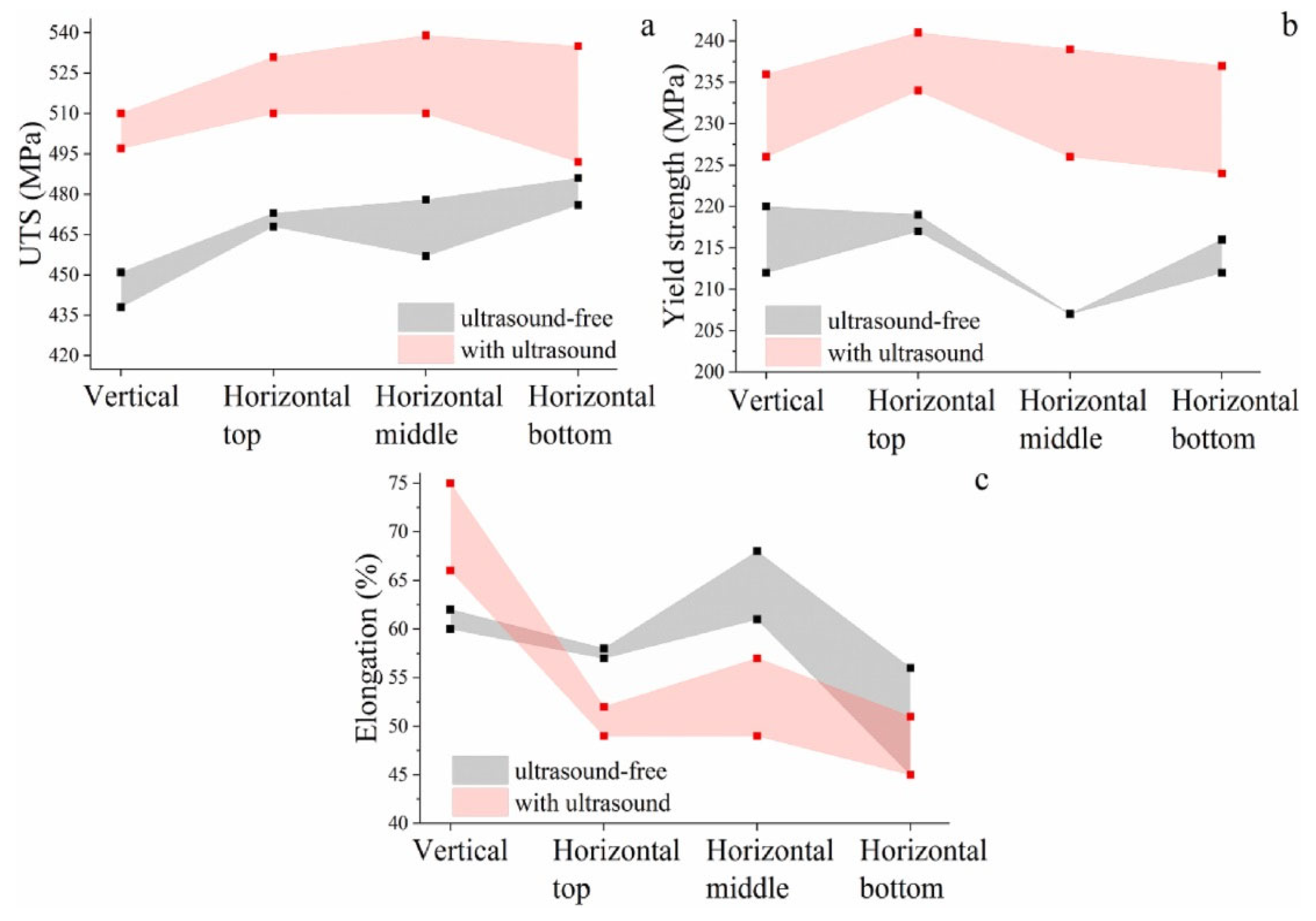

- Vorontsov, A.; Astafurov, S.; Melnikov, E.; Moskvina, V.; Kolubaev, E.; Astafurova, E. The microstructure, phase composition and tensile properties of austenitic stainless steel in a wire-feed electron beam melting combined with ultrasonic vibration. Mater. Sci. Eng. A 2021, 820, 141519. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Dadbakhsh, S.; Goossens, L.; Kruth, J.-P.; Van Humbeeck, J.; Vanmeensel, K. Influence of selective laser melting process parameters on texture evolution in pure copper. J. Mater. Process. Technol. 2019, 270, 47–58. [Google Scholar] [CrossRef]

- Singer, F.; Deisenroth, D.C.; Hymas, D.M.; Ohadi, M.M. Additively manufactured copper components and composite structures for thermal management applications. In Proceedings of the 2017 16th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Orlando, FL, USA, 30 May–2 June 2017; pp. 174–183. [Google Scholar] [CrossRef]

- El-Wardany, T.I.; She, Y.; Jagdale, V.N.; Garofano, J.K.; Liou, J.J.; Schmidt, W.R. Challenges in Three-Dimensional Printing of High-Conductivity Copper. J. Electron. Packag. Trans. ASME 2018, 140, 39974. [Google Scholar] [CrossRef]

- Li, J.; Cai, Y.; Yan, F.; Wang, C.; Zhu, Z.; Hu, C. Porosity and liquation cracking of dissimilar Nd:YAG laser welding of SUS304 stainless steel to T2 copper. Opt. Laser Technol. 2020, 122, 105881. [Google Scholar] [CrossRef]

- Wolf, T.; Fu, Z.; Körner, C. Selective electron beam melting of an aluminum bronze: Microstructure and mechanical properties. Mater. Lett. 2019, 238, 241–244. [Google Scholar] [CrossRef]

- Osipovich, K.S.; Chumaevskii, A.V.; Eliseev, A.A.; Kalashnikov, K.N.; Kolubaev, E.A.; Rubtsov, V.E.; Astafurova, E.G. Peculiarities of Structure Formation in Copper/Steel Bimetal Fabricated by Electron-Beam Additive Technology. Russ. Phys. J. 2019, 62, 1867. [Google Scholar] [CrossRef]

- Moriya, S.; Inoue, T.; Sasaki, M.; Nakamoto, T.; Kimura, T.; Nomura, N.; Kikuchi, K.; Kawasaki, A.; Kato, T.; Masuda, I. Feasibility Study on Additive Manufacturing of Liquid Rocket Combustion Chamber. Trans. JAPAN Soc. Aeronaut. Sp. Sci. Aerosp. Technol. JAPAN 2018, 16, 261–266. [Google Scholar] [CrossRef]

- Ledford, C.; Rock, C.; Carriere, P.; Frigola, P.; Gamzina, D.; Horn, T. Characteristics and Processing of Hydrogen-Treated Copper Powders for EB-PBF Additive Manufacturing. Appl. Sci. 2019, 9, 3993. [Google Scholar] [CrossRef]

- King, W.E.; Anderson, A.T.; Ferencz, R.M.; Hodge, N.E.; Kamath, C.; Khairallah, S.A.; Rubenchik, A.M. Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. Appl. Phys. Rev. 2015, 2, 041304. [Google Scholar] [CrossRef]

- Dehoff, R.R.; Kirka, M.M.; Sames, W.J.; Bilheux, H.; Tremsin, A.S.; Lowe, L.E.; Babu, S.S. Site specific control of crystallographic grain orientation through electron beam additive manufacturing. Mater. Sci. Technol. 2014, 31, 931–938. [Google Scholar] [CrossRef]

- Chen, N.; Khan, H.A.; Wan, Z.; Lippert, J.; Sun, H.; Shang, S.L.; Liu, Z.K.; Li, J. Microstructural characteristics and crack formation in additively manufactured bimetal material of 316L stainless steel and Inconel 625. Addit. Manuf. 2020, 32, 101037. [Google Scholar] [CrossRef]

- Zhang, X.; Pan, T.; Chen, Y.; Li, L.; Zhang, Y.; Liou, F. Additive manufacturing of copper-stainless steel hybrid components using laser-aided directed energy deposition. J. Mater. Sci. Technol. 2021, 80, 100–116. [Google Scholar] [CrossRef]

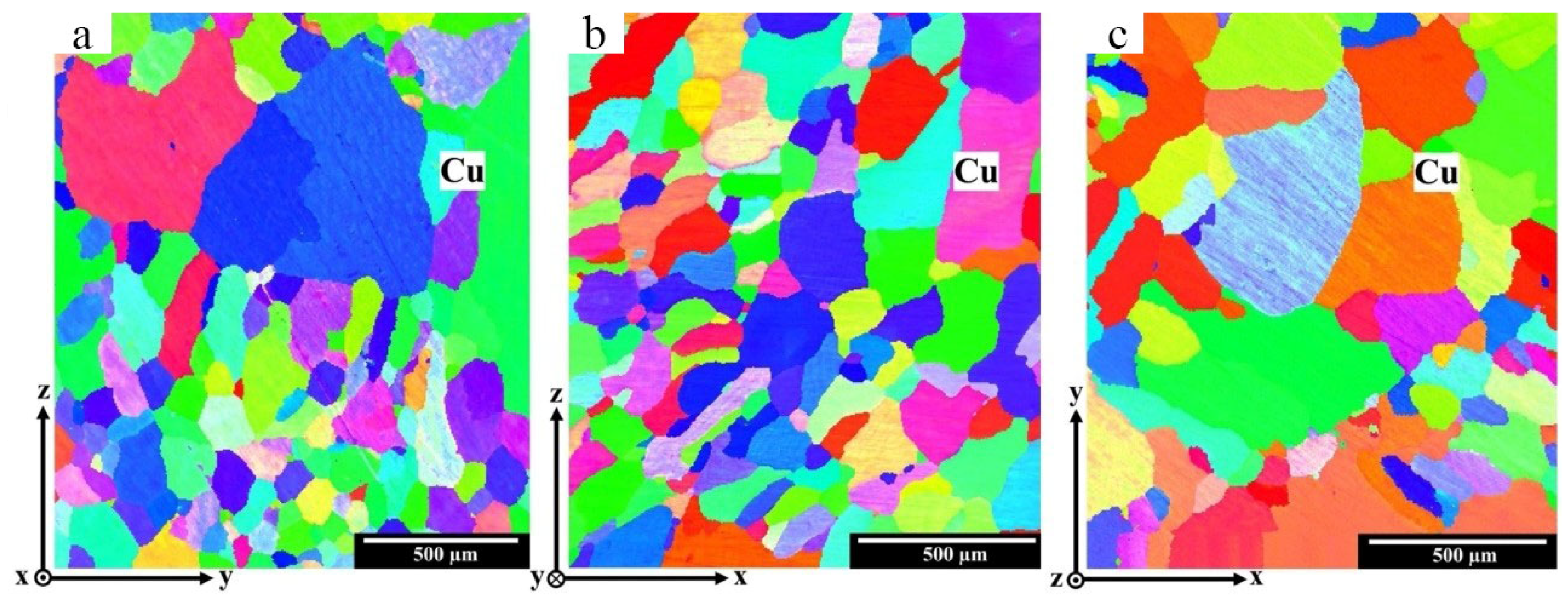

- Osipovich, K.; Vorontsov, A.; Chumaevskii, A.; Moskvichev, E.; Zakharevich, I.; Dobrovolsky, A.; Sudarikov, A.; Zykova, A.; Rubtsov, V.; Kolubaev, E. Features of Microstructure and Texture Formation of Large-Sized Blocks of C11000 Copper Produced by Electron Beam Wire-Feed Additive Technology. Materials 2022, 15, 814. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Li, Y.; Tian, W.; Hu, J.; Li, B.; Li, P.; Liao, W. Influence of Ultrasonic Impact Treatment and Working Current on Microstructure and Mechanical Properties of 2219 Aluminium Alloy Wire Arc Additive Manufacturing Parts. J. Mater. Res. Technol. 2022, 21, 781–797. [Google Scholar] [CrossRef]

- Zhou, Y.; Lin, X.; Kang, N.; Huang, W.; Wang, Z. Mechanical Properties and Precipitation Behavior of the Heat-Treated Wire + Arc Additively Manufactured 2219 Aluminum Alloy. Mater. Charact. 2021, 171, 110735. [Google Scholar] [CrossRef]

- Guo, N.; Wu, D.; Wang, G.; Cheng, Q.; Fu, Y.; Yu, M. Investigation on Underwater Wire-Feed Laser Deposition of 5052 Aluminum Alloy. J. Manuf. Process. 2022, 76, 687–694. [Google Scholar] [CrossRef]

- Brice, C.A.; Tayon, W.A.; Newman, J.A.; Kral, M.V.; Bishop, C.; Sokolova, A. Effect of Compositional Changes on Microstructure in Additively Manufactured Aluminum Alloy 2139. Mater. Charact. 2018, 143, 50–58. [Google Scholar] [CrossRef]

- Utyaganova, V.R.; Filippov, A.V.; Shamarin, N.N.; Vorontsov, A.V.; Savchenko, N.L.; Fortuna, S.V.; Gurianov, D.A.; Chumaevskii, A.V.; Rubtsov, V.E.; Tarasov, S.Y. Controlling the Porosity Using Exponential Decay Heat Input Regimes during Electron Beam Wire-Feed Additive Manufacturing of Al-Mg Alloy. Int. J. Adv. Manuf. Technol. 2020, 108, 2823–2838. [Google Scholar] [CrossRef]

- Knyazhev, E.O.; Panfilov, A.O.; Kalashnikova, T.A.; Kalashnikov, K.N.; Gusarova, A.V.; Chumaevskii, A.V. Structure Formation Features of Large Block-Shaped Samples from AA5356 Alloy at the Electron-Beam Wire-Feed Additive Manufacturing; AIP Publishing LLC: Melville, NY, USA, 2020; p. 020151. [Google Scholar]

- Chumaevskii, A.V.; Nikonov, S.Y.; Gusarova, A.V.; Knyazhev, E.O.; Panfilov, A.O.; Zykova, A.P.; Gurianov, D.A. Anisotropy of the Aluminum-Silicon and Aluminum-Magnesium Alloys Properties Produced by Wire-Feed Electron Beam Additive Manufacturing; AIP Publishing LLC: Melville, NY, USA, 2022; p. 020047. [Google Scholar]

- Feenstra, D.R.; Banerjee, R.; Fraser, H.L.; Huang, A.; Molotnikov, A.; Birbilis, N. Critical Review of the State of the Art in Multi-Material Fabrication via Directed Energy Deposition. Curr. Opin. Solid State Mater. Sci. 2021, 25, 100924. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Hari, S.; Amirthalingam, M. Wire Arc Additive Manufacturing of Functionally Graded Material for Marine Risers. Mater. Sci. Eng. A 2020, 792, 139530. [Google Scholar] [CrossRef]

- Wu, B.; Qiu, Z.; Pan, Z.; Carpenter, K.; Wang, T.; Ding, D.; Duin, S.V.; Li, H. Enhanced Interface Strength in Steel-Nickel Bimetallic Component Fabricated Using Wire Arc Additive Manufacturing with Interweaving Deposition Strategy. J. Mater. Sci. Technol. 2020, 52, 226–234. [Google Scholar] [CrossRef]

- Shen, C.; Liss, K.-D.; Reid, M.; Pan, Z.; Hua, X.; Li, F.; Mou, G.; Huang, Y.; Zhu, Y.; Li, H. Fabrication of FeNi Intermetallic Using the Wire-Arc Additive Manufacturing Process: A Feasibility and Neutron Diffraction Phase Characterization Study. J. Manuf. Process. 2020, 57, 691–699. [Google Scholar] [CrossRef]

- Shen, C.; Liss, K.-D.; Reid, M.; Pan, Z.; Hua, X.; Li, F.; Mou, G.; Huang, Y.; Dong, B.; Luo, D.; et al. Effect of the Post-Production Heat Treatment on Phase Evolution in the Fe3Ni–FeNi Functionally Graded Material: An in-Situ Neutron Diffraction Study. Intermetallics 2021, 129, 107032. [Google Scholar] [CrossRef]

- Mohan Kumar, S.; Rajesh Kannan, A.; Pravin Kumar, N.; Pramod, R.; Siva Shanmugam, N.; Vishnu, A.S.; Channabasavanna, S.G. Microstructural Features and Mechanical Integrity of Wire Arc Additive Manufactured SS321/Inconel 625 Functionally Gradient Material. J. Mater. Eng. Perform. 2021, 30, 5692–5703. [Google Scholar] [CrossRef]

- Ahsan, M.R.U.; Fan, X.; Seo, G.-J.; Ji, C.; Noakes, M.; Nycz, A.; Liaw, P.K.; Kim, D.B. Microstructures and Mechanical Behavior of the Bimetallic Additively-Manufactured Structure (BAMS) of Austenitic Stainless Steel and Inconel 625. J. Mater. Sci. Technol. 2021, 74, 176–188. [Google Scholar] [CrossRef]

- Rajesh Kannan, A.; Mohan Kumar, S.; Pravin Kumar, N.; Siva Shanmugam, N.; Vishnu, A.S.; Palguna, Y. Process-Microstructural Features for Tailoring Fatigue Strength of Wire Arc Additive Manufactured Functionally Graded Material of SS904L and Hastelloy C-276. Mater. Lett. 2020, 274, 127968. [Google Scholar] [CrossRef]

- Shen, C.; Hua, X.; Reid, M.; Liss, K.-D.; Mou, G.; Pan, Z.; Huang, Y.; Li, H. Thermal Induced Phase Evolution of Fe–Fe3Ni Functionally Graded Material Fabricated Using the Wire-Arc Additive Manufacturing Process: An in-Situ Neutron Diffraction Study. J. Alloys Compd. 2020, 826, 154097. [Google Scholar] [CrossRef]

- Wang, J.; Pan, Z.; Ma, Y.; Lu, Y.; Shen, C.; Cuiuri, D.; Li, H. Characterization of Wire Arc Additively Manufactured Titanium Aluminide Functionally Graded Material: Microstructure, Mechanical Properties and Oxidation Behaviour. Mater. Sci. Eng. A 2018, 734, 110–119. [Google Scholar] [CrossRef]

- Dharmendra, C.; Shakerin, S.; Ram, G.D.J.; Mohammadi, M. Wire-Arc Additive Manufacturing of Nickel Aluminum Bronze/Stainless Steel Hybrid Parts—Interfacial Characterization, Prospects, and Problems. Materialia 2020, 13, 100834. [Google Scholar] [CrossRef]

- Chen, G.; Shu, X.; Liu, J.; Zhang, B.; Feng, J. Crystallographic Texture and Mechanical Properties by Electron Beam Freeform Fabrication of Copper/Steel Gradient Composite Materials. Vacuum 2020, 171, 109009. [Google Scholar] [CrossRef]

- Filippov, A.; Utyaganova, V.; Shamarin, N.; Vorontsov, A.; Savchenko, N.; Gurianov, D.; Chumaevskii, A.; Rubtsov, V.; Kolubaev, E.; Tarasov, S. Microstructure and Corrosion Resistance of AA4047/AA7075 Transition Zone Formed Using Electron Beam Wire-Feed Additive Manufacturing. Materials 2021, 14, 6931. [Google Scholar] [CrossRef]

- Utyaganova, V.; Filippov, A.; Tarasov, S.; Shamarin, N.; Gurianov, D.; Vorontsov, A.; Chumaevskii, A.; Fortuna, S.; Savchenko, N.; Rubtsov, V.; et al. Characterization of AA7075/AA5356 Gradient Transition Zone in an Electron Beam Wire-Feed Additive Manufactured Sample. Mater. Charact. 2021, 172, 110867. [Google Scholar] [CrossRef]

- Xu, J.; Peng, Y.; Zhou, Q.; Fan, J.; Kong, J.; Wang, K.; Guo, S.; Zhu, J. Microstructure and Mechanical Properties of Ti-52 At% Al Alloy Synthesized in-Situ via Dual-Wires Electron Beam Freeform Fabrication. Mater. Sci. Eng. A 2020, 798, 140232. [Google Scholar] [CrossRef]

- Zykova, A.; Chumaevskii, A.; Panfilov, A.; Vorontsov, A.; Nikolaeva, A.; Osipovich, K.; Gusarova, A.; Chebodaeva, V.; Nikonov, S.; Gurianov, D.; et al. Aluminum Bronze/Udimet 500 Composites Prepared by Electron-Beam Additive Double-Wire-Feed Manufacturing. Materials 2022, 15, 6270. [Google Scholar] [CrossRef] [PubMed]

- Zykova, A.; Vorontsov, A.; Nikolaeva, A.; Chumaevskii, A.; Kalashnikov, K.; Gurianov, D.; Savchenko, N.; Nikonov, S.; Kolubaev, E. Structural Design and Performance Evaluation of Ti6Al4V/5%Cu Produced by Electron-Beam Additive Technology with Simultaneous Double-Wire Feeding. Mater. Lett. 2022, 312, 131586. [Google Scholar] [CrossRef]

- Zykova, A.; Chumaevskii, A.; Vorontsov, A.; Kalashnikov, K.; Gurianov, D.; Gusarova, A.; Kolubaev, E. Evolution of Microstructure and Properties of Fe-Cu, Manufactured by Electron Beam Additive Manufacturing with Subsequent Friction Stir Processing. Mater. Lett. 2022, 307, 131023. [Google Scholar] [CrossRef]

- Filippov, A.; Shamarin, N.; Moskvichev, E.; Savchenko, N.; Kolubaev, E.; Khoroshko, E.; Tarasov, S. Heat Input Effect on Microstructure and Mechanical Properties of Electron Beam Additive Manufactured (EBAM) Cu-7.5wt.%Al Bronze. Materials 2021, 14, 6948. [Google Scholar] [CrossRef]

- Kalashnikov, K.; Kalashnikova, T.; Semenchuk, V.; Knyazhev, E.; Panfilov, A.; Cheremnov, A.; Chumaevskii, A.; Nikonov, S.; Vorontsov, A.; Rubtsov, V.; et al. Development of a Multimaterial Structure Based on CuAl9Mn2 Bronze and Inconel 625 Alloy by Double-Wire-Feed Additive Manufacturing. Metals 2022, 12, 2048. [Google Scholar] [CrossRef]

- Filippov, A.V.; Khoroshko, E.S.; Shamarin, N.N.; Savchenko, N.L.; Moskvichev, E.N.; Utyaganova, V.R.; Kolubaev, E.A.; Smolin, A.Y.; Tarasov, S.Y. Characterization of Gradient CuAl–B4C Composites Additively Manufactured Using a Combination of Wire-Feed and Powder-Bed Electron Beam Deposition Methods. J. Alloys Compd. 2021, 859, 157824. [Google Scholar] [CrossRef]

- Osipovich, K.; Gurianov, D.; Vorontsov, A.; Knyazhev, E.; Panfilov, A.; Chumaevskii, A.; Savchenko, N.; Nikonov, S.; Rubtsov, V.; Kolubaev, E. Phase Formation, Microstructure, and Mechanical Properties of Ni-Cu Bimetallic Materials Produced by Electron Beam Additive Manufacturing. Metals 2022, 12, 1931. [Google Scholar] [CrossRef]

- Kar, J.; Roy, S.K.; Roy, G.G. Effect of beam oscillation on electron beam welding of copper with AISI-304 stainless steel. J. Mater. Process. Technol. 2016, 233, 174–185. [Google Scholar] [CrossRef]

- Sen, I.; Amankwah, E.; Kumar, N.S.; Fleury, E.; Oh-ishi, K.; Hono, K.; Ramamurty, U. Microstructure and mechanical properties of annealed SUS 304H austenitic stainless steel with copper. Mater. Sci. Eng. A 2011, 528, 4491–4499. [Google Scholar] [CrossRef]

- Tran, T.Q.; Chinnappan, A.; Lee, J.K.Y.; Loc, N.H.; Tran, L.T.; Wang, G.; Kumar, V.V.; Jayathilaka, W.A.D.M.; Ji, D.; Doddamani, M.; et al. 3D Printing of Highly Pure Copper. Metals 2019, 9, 756. [Google Scholar] [CrossRef]

- Silbernagel, C.; Gargalis, L.; Ashcroft, I.R.H.-A. Electrical Resistivity of Pure Copper Processed by Medium-Powered Laser Powder Bed Fusion Additive Manufacturing for Use In Electromagnetic Applications; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Gladkovsky, S.V.; Kuteneva, S.V.; Sergeev, S.N. Microstructure and mechanical properties of sandwich copper/steel composites produced by explosive welding. Mater. Charact. 2019, 154, 294–303. [Google Scholar] [CrossRef]

- Chen, S.; Huang, J.; Xia, J.; Zhao, X.; Lin, S. Influence of processing parameters on the characteristics of stainless steel/copper laser welding. J. Mater. Process. Technol. 2015, 222, 43–51. [Google Scholar] [CrossRef]

- Magnabosco, I.; Ferro, P.; Bonollo, F.; Arnberg, L. An investigation of fusion zone microstructures in electron beam welding of copper–stainless steel. Mater. Sci. Eng. A 2006, 424, 163–173. [Google Scholar] [CrossRef]

- Sabetghadam, H.; Hanzaki, A.Z.; Araee, A. Diffusion bonding of 410 stainless steel to copper using a nickel interlayer. Mater. Charact. 2010, 61, 626–634. [Google Scholar] [CrossRef]

- Martinsen, K.; Hu, S.J.; Carlson, B.E. Joining of dissimilar materials. CIRP Ann. Manuf. Technol. 2015, 64, 679–699. [Google Scholar] [CrossRef]

- Imran, M.K.; Masood, S.H.; Brandt, M.; Bhattacharya, S.; Mazumder, J. Direct metal deposition (DMD) of H13 tool steel on copper alloy substrate: Evaluation of mechanical properties. Mater. Sci. Eng. A 2011, 528, 3342–3349. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Ma, W.; Min, L. Interfacial characteristic and mechanical performance of maraging steel-copper functional bimetal produced by selective laser melting based hybrid manufacture. Mater. Des. 2018, 155, 77–85. [Google Scholar] [CrossRef]

- Liu, Z.H.; Zhang, D.Q.; Sing, S.L.; Chua, C.K.; Loh, L.E. Interfacial characterization of SLM parts in multi-material processing: Metallurgical diffusion between 316L stainless steel and C18400 copper alloy. Mater. Charact. 2014, 94, 116–125. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, Y.; Wang, D.; Song, C.; Chen, J. Microstructure and mechanical properties of CuSn/18Ni300 bimetallic porous structures manufactured by selective laser melting. Mater. Des. 2019, 165, 107583. [Google Scholar] [CrossRef]

- Nguyen, Q.; Azadkhou, A.; Akbari, M.; Panjehpour, A.; Karimipour, A. Experimental investigation of temperature field and fusion zone microstructure in dissimilar pulsed laser welding of austenitic stainless steel and copper. J. Manuf. Process. 2020, 56, 206–215. [Google Scholar] [CrossRef]

- Kuryntsev, S.V.; Morushkin, A.E.; Gilmutdinov, A.K. Fiber laser welding of austenitic steel and commercially pure copper butt joint. Opt. Lasers Eng. 2017, 90, 101–109. [Google Scholar] [CrossRef]

- Mannucci, A.; Tomashchuk, I.; Vignal, V.; Sallamand, P.; Duband, M. Parametric study of laser welding of copper to austenitic stainless steel. Procedia CIRP 2018, 74, 450–455. [Google Scholar] [CrossRef]

- Osipovich, K.; Vorontsov, A.; Chumaevskii, A.; Gurianov, D.; Shamarin, N.; Savchenko, N.; Kolubaev, E. Characterization of a Bimetallic Multilayered Composite “Stainless Steel/Copper” Fabricated with Wire-Feed Electron Beam Additive Manufacturing. Metals 2021, 11, 1151. [Google Scholar] [CrossRef]

- Shu, X.; Chen, G.; Liu, J.; Zhang, B.; Feng, J. Microstructure evolution of copper/steel gradient deposition prepared using electron beam freeform fabrication. Mater. Lett. 2018, 213, 374–377. [Google Scholar] [CrossRef]

- Osipovich, K.S.; Astafurova, E.G.; Chumaevskii, A.V.; Kalashnikov, K.N.; Astafurov, S.V.; Maier, G.G.; Melnikov, E.V.; Moskvina, V.A.; Panchenko, M.Y.; Tarasov, S.Y.; et al. Gradient transition zone structure in “steel–copper” sample produced by double wire-feed electron beam additive manufacturing. J. Mater. Sci. 2020, 55, 9258–9272. [Google Scholar] [CrossRef]

- Tosto, S.; Nenci, F.; Jiandong, H.; Corniani, G.; Pierdominici, F. Microstructure of copper-AISI type 304L electron beam welded alloy. Mater. Sci. Technol. 2003, 19, 519–522. [Google Scholar] [CrossRef]

- Munitz, A.; Abbaschian, R. Liquid separation in Cu-Co and Cu-Co-Fe alloys solidified at high cooling rates. J. Mater. Sci. 1998, 33, 3639–3649. [Google Scholar] [CrossRef]

- Zhou, Z.M.; Gao, J.; Li, F.; Zhang, Y.K.; Wang, Y.P.; Kolbe, M. On the metastable miscibility gap in liquid Cu–Cr alloys. J. Mater. Sci. 2009, 44, 3793–3799. [Google Scholar] [CrossRef]

- Chbihi, A.; Sauvage, X.; Blavette, D. Atomic scale investigation of Cr precipitation in copper. Acta Mater. 2012, 60, 4575–4585. [Google Scholar] [CrossRef]

- Kibitkin, V.; Vorontsov, A.; Osipovich, K.; Shamarin, N.; Chumaevskii, A.; Rubtsov, V.; Moskvichev, E.; Savchenko, N.; Kolubaev, E. Characterizing the Tensile Behavior of Double Wire-Feed Electron Beam Additive Manufactured “Copper–Steel” Using Digital Image Correlation. Metals 2022, 12, 1797. [Google Scholar] [CrossRef]

- Kalashnikov, K.N.; Chumaevskii, A.V.; Kalashnikova, T.A.; Osipovich, K.S.; Kolubaev, E.A. Defect Formation in Titanium Alloy during Non-Stationary Process of Local Metallurgy. Russ. Phys. J. 2020, 63, 962–967. [Google Scholar] [CrossRef]

- Yao, M.; Yao, Z.; Tao, X.; Huang, C.; Zhang, S. Alleviating Plastic Anisotropy of Boron Modified Titanium Alloy by Constructing Layered Structure via Electron Beam Directed Energy Deposition. Addit. Manuf. 2022, 50, 102561. [Google Scholar] [CrossRef]

- Lei, S.; Li, X.; Deng, Y.; Xiao, Y.; Chen, Y.; Wang, H. Microstructure and Mechanical Properties of Electron Beam Freeform Fabricated TiB2/Al-Cu Composite. Mater. Lett. 2020, 277, 128273. [Google Scholar] [CrossRef]

- Chen, G.; Shu, X.; Liu, J.; Zhang, B.; Feng, J. A New Coating Method with Potential for Additive Manufacturing: Premelting Electron Beam-Assisted Freeform Fabrication. Addit. Manuf. 2020, 33, 101118. [Google Scholar] [CrossRef]

- Zykova, A.; Chumaevskii, A.; Vorontsov, A.; Shamarin, N.; Panfilov, A.; Knyazhev, E.; Moskvichev, E.; Gurianov, D.; Savchenko, N.; Kolubaev, E.; et al. Microstructural Evolution of AA5154 Layers Intermixed with Mo Powder during Electron Beam Wire-Feed Additive Manufacturing (EBAM). Metals 2022, 12, 109. [Google Scholar] [CrossRef]

- Chumaevskii, A.V.; Kolubaev, E.A.; Osipovich, K.S.; GurIanov, D.A.; Rubtsov, V.E.; Nikonov, S.Y.; Boltrushevich, A.E. Obtaining of Bimetallic Product from Nickel Superalloy and Heat-Resistant Bronze by Wire-Feed Electron Beam Additive Manufacturing. Russ. Phys. J. 2022, 65, 1231–1238. [Google Scholar] [CrossRef]

- Ma, Z.Y. Friction Stir Processing Technology: A Review. Metall. Mater. Trans. A 2008, 39, 642–658. [Google Scholar] [CrossRef]

- Zykova, A.P.; Tarasov, S.Y.; Chumaevskiy, A.V.; Kolubaev, E.A. A Review of Friction Stir Processing of Structural Metallic Materials: Process, Properties, and Methods. Metals 2020, 10, 772. [Google Scholar] [CrossRef]

- Tongne, A.; Desrayaud, C.; Jahazi, M.; Feulvarch, E. On Material Flow in Friction Stir Welded Al Alloys. J. Mater. Process. Technol. 2017, 239, 284–296. [Google Scholar] [CrossRef]

- Moustafa, E.B.; Alazwari, M.A.; Abushanab, W.S.; Ghandourah, E.I.; Mosleh, A.O.; Ahmed, H.M.; Taha, M.A. Influence of Friction Stir Process on the Physical, Microstructural, Corrosive, and Electrical Properties of an Al–Mg Alloy Modified with Ti–B Additives. Materials 2022, 15, 835. [Google Scholar] [CrossRef] [PubMed]

- Ralls, A.M.; Daroonparvar, M.; Kasar, A.K.; Misra, M.; Menezes, P.L. Influence of Friction Stir Processing on the Friction, Wear and Corrosion Mechanisms of Solid-State Additively Manufactured 316L Duplex Stainless Steel. Tribol. Int. 2023, 178, 108033. [Google Scholar] [CrossRef]

- He, C.; Wei, J.; Li, Y.; Zhang, Z.; Tian, N.; Qin, G.; Zuo, L. Improvement of Microstructure and Fatigue Performance of Wire-Arc Additive Manufactured 4043 Aluminum Alloy Assisted by Interlayer Friction Stir Processing. J. Mater. Sci. Technol. 2023, 133, 183–194. [Google Scholar] [CrossRef]

- Kalashnikova, T.A.; Chumaevskii, A.V.; Rubtsov, V.E.; Kalashnikov, K.N.; Kolubaev, E.A.; Eliseev, A.A. Structural Heredity of the Aluminum Alloy Obtained by the Additive Method and Modified Under Severe Thermomechanical Action on Its Final Structure and Properties. Russ. Phys. J. 2020, 62, 1565–1572. [Google Scholar] [CrossRef]

- Kalashnikova, T.; Chumaevskii, A.; Kalashnikov, K.; Knyazhev, E.; Gurianov, D.; Panfilov, A.; Nikonov, S.; Rubtsov, V.; Kolubaev, E. Regularities of Friction Stir Processing Hardening of Aluminum Alloy Products Made by Wire-Feed Electron Beam Additive Manufacturing. Metals 2022, 12, 183. [Google Scholar] [CrossRef]

- Mironov, S.; Sato, Y.S.; Kokawa, H. Friction-stir welding and processing of Ti-6Al-4V titanium alloy: A review. J. Mater. Sci. Technol. 2018, 34, 58–72. [Google Scholar] [CrossRef]

- Lippold, J.C.; Livingston, J.J. Microstructure evolution during friction stir processing and hot torsion simulation of Ti—6Al—4V. Metall. Mater. Trans. A. 2013, 44, 3815–3825. [Google Scholar] [CrossRef]

- Xie, X.; Chen, C.; Chen, Z.; Wang, W.; Yin, S.; Ji, G.; Liao, H. Achieving simultaneously improved tensile strength and ductility of a nano-TiB2/AlSi10Mg composite produced by cold spray additive manufacturing. Compos. Part B Eng. 2020, 202, 108404. [Google Scholar] [CrossRef]

- Gusarova, A.V.; Chumaevskii, A.V.; Osipovich, K.S.; Kalashnikov, K.N.; Kalashnikova, T.A. Regularities of structural changes after friction stir processing in materials obtained by the additive method. Nanosci. Technol. Int. J. 2020, 11, 195–205. [Google Scholar] [CrossRef]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Technol. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Moshtaghi, M.; Loder, B.; Safyari, M.; Willidal, T.; Hojo, T.; Mori, G. Hydrogen trapping and desorption affected by ferrite grain boundary types in shielded metal and flux-cored arc weldments with Ni addition. Int. J. Hydrog. Energy 2022, 47, 20676–20683. [Google Scholar] [CrossRef]

| Alloy | Ni | Cr | Fe | Mo | Nb | Co | Al | Ti | Mn | W | Ta |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Alloy 82 | 67.0 | 18.0–22.0 | 3.0 | - | 2.7 | - | - | 0.75 | 2.5–3.5 | - | - |

| In 600 | 72.0 | 14.0–17.0 | 6.0–10.0 | - | - | - | - | - | - | - | - |

| In 625 | 58.0 | 20.0–23.0 | 5.0 | 8.0–10.0 | 3.15–4.15 | 1.0 | 0.4 | 0.4 | - | - | - |

| In 718 | 50.0–55.0 | 17.0–21.0 | Bal | 2.8–3.3 | 4.75–5.5 | 1.0 | 0.65–1.15 | 0.3 | <0.35 | - | - |

| IC10 | Bal | 7.5 | - | 2.0 | 12.1 | 12.1 | 6.2 | - | - | 5.2 | 7.5 |

| K465 | 54.3–62.7 | 8.0–9.5 | 1.0 | 1.2–2.4 | 0.8–1.2 | 9.0–10.5 | 5.1–6.0 | 2.0–2.9 | - | 9.5–11.0 | - |

| Hastelloy C276 | Bal | 16.0 | 5.8 | 16.5 | - | 0.20 | - | - | 0.19 | 4.0 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osipovich, K.; Kalashnikov, K.; Chumaevskii, A.; Gurianov, D.; Kalashnikova, T.; Vorontsov, A.; Zykova, A.; Utyaganova, V.; Panfilov, A.; Nikolaeva, A.; et al. Wire-Feed Electron Beam Additive Manufacturing: A Review. Metals 2023, 13, 279. https://doi.org/10.3390/met13020279

Osipovich K, Kalashnikov K, Chumaevskii A, Gurianov D, Kalashnikova T, Vorontsov A, Zykova A, Utyaganova V, Panfilov A, Nikolaeva A, et al. Wire-Feed Electron Beam Additive Manufacturing: A Review. Metals. 2023; 13(2):279. https://doi.org/10.3390/met13020279

Chicago/Turabian StyleOsipovich, Ksenia, Kirill Kalashnikov, Andrey Chumaevskii, Denis Gurianov, Tatiana Kalashnikova, Andrey Vorontsov, Anna Zykova, Veronika Utyaganova, Aleksandr Panfilov, Aleksandra Nikolaeva, and et al. 2023. "Wire-Feed Electron Beam Additive Manufacturing: A Review" Metals 13, no. 2: 279. https://doi.org/10.3390/met13020279

APA StyleOsipovich, K., Kalashnikov, K., Chumaevskii, A., Gurianov, D., Kalashnikova, T., Vorontsov, A., Zykova, A., Utyaganova, V., Panfilov, A., Nikolaeva, A., Dobrovolskii, A., Rubtsov, V., & Kolubaev, E. (2023). Wire-Feed Electron Beam Additive Manufacturing: A Review. Metals, 13(2), 279. https://doi.org/10.3390/met13020279