Predictive Modeling of the Hot Metal Sulfur Content in a Blast Furnace Based on Machine Learning

Abstract

1. Introduction

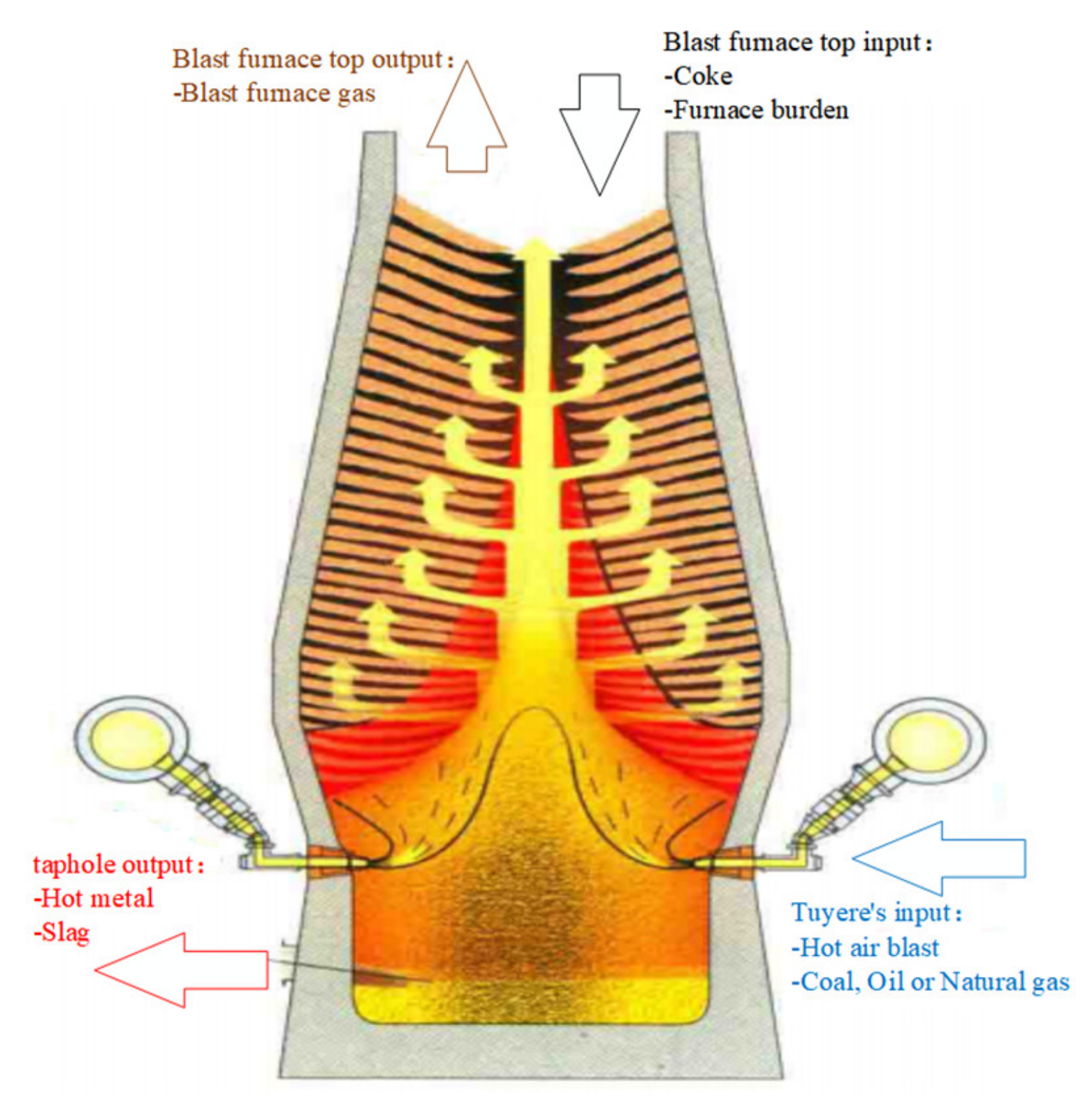

2. Blast Furnace Production Process

- The iron-containing raw materials (sinter, pellet, or lump ore), fuel (coke), and slag-making flux (limestone, dolomite, and manganese ore) are loaded into the blast furnace from the furnace top in specific proportions;

- Hot air (oxygen enrichment) is blown into the blast furnace tuyere from the hot air stove (some blast furnaces also inject auxiliary fuels such as coal powder, heavy oil, and natural gas); carbon monoxide and hydrogen are then generated by coke burning with oxygen (from hot air) at high temperature;

- Raw materials and fuels descend during the process of smelting in the furnace; the hot metal is then produced by heat transfer reaction, reduction reaction, melting reaction, and deoxidation with the rising gas, successively; slag is produced by gangue material in iron-containing raw materials and flux;

- The gas produced is discharged from the furnace top; after being dedusted, this gas is used as fuel for the hot stoves, heating furnace, coke oven, boiler, etc. Finally, it enables the recycling of resources and improves the comprehensive utilization efficiency of C resources;

- Hot metal is obtained through iron–slag separation and is used as the raw material for steelmaking. Blast furnace slag can be used as raw material for the production of cement and building materials.

3. Brief Review of XGBoost and MLP

3.1. Extreme Gradient Boosting (XGBoost)

3.2. Multilayer Perceptron Algorithm (MLP)

3.3. The Process of Modeling

4. Preprocessing of Data and Feature Selection

4.1. Collection of Data

4.2. Preprocessing of Data

4.2.1. Significance

4.2.2. Processing of Extreme Outliers

4.2.3. Handling of Missing Value

4.3. Feature Selection

4.3.1. Correlation Analysis

4.3.2. Feature Determination

5. Model Comparison

5.1. Comparison of the Predictions of the Two Models

5.2. Model Evaluation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Wu, S.; Kou, M.; Liu, X.; Wang, Y.; Zhuang, W. Influence of Operation Parameters on Mass Fraction of Sulfur in the Hot Metal in Corex Process. In Proceedings of the 7th International Symposium on High-Temperature Metallurgical Processing; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; pp. 327–334. [Google Scholar]

- Bhattacharya, T. Prediction of Silicon Content in Blast Furnace Hot Metal Using Partial Least Squares (PLS). ISIJ Int. 2005, 45, 1943–1945. [Google Scholar] [CrossRef]

- Jiao, K.-X.; Zhang, J.-L.; Liu, Z.-J.; Liu, F.; Liang, L.-S. Formation mechanism of the graphite-rich protective layer in blast furnace hearths. Int. J. Miner. Met. Mater. 2016, 23, 16–24. [Google Scholar] [CrossRef]

- Wang, Y.K.; Zhang, Y. Final Sulfur Content Prediction Model in Hot Metal Desulphurization Process Based on IEA-SVM. In Proceedings of the 2011 Chinese Control and Decision Conference (CCDC), Mianyang, China, 23–25 May 2011; pp. 1684–1687. [Google Scholar]

- Zhenyang, W.; Jianliang, Z.; Gang, A.; Zhengjian, L.; Zhengming, C.; Junjie, H.; Jingwei, Z. Analysis on the Oversize Blast Furnace Desulfurization and a Sulfide Capacity Prediction Model Based on Congregated Electron Phase. Met. Mater. Trans. B 2015, 47, 127–134. [Google Scholar] [CrossRef]

- Zhang, H.S.; Zhan, D.P.; Jiang, Z.H. Application of Improved BP Neural Network to Final Sulfur Content Prediction of Hot Metal Pre-desulfurization. J. Northeast. Univ. (Nat. Sci.) 2007, 28, 1140–1142. [Google Scholar]

- Shi, L.; Li, Z.-L.; Yu, T.; Li, J.-P. Model of Hot Metal Silicon Content in Blast Furnace Based on Principal Component Analysis Application and Partial Least Square. J. Iron Steel Res. Int. 2011, 18, 13–16. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, J.; Zhang, Y.; Fu, L.; Luo, Y.; Liu, Y.; Li, L. Research on Hyperparameter Optimization of Concrete Slump Prediction Model Based on Response Surface Method. Materials 2022, 15, 4721. [Google Scholar] [CrossRef]

- Li, J.; Hua, C.; Yang, Y.; Guan, X. A Novel MIMO T–S Fuzzy Modeling for Prediction of Blast Furnace Molten Iron Quality With Missing Outputs. IEEE Trans. Fuzzy Syst. 2020, 29, 1654–1666. [Google Scholar] [CrossRef]

- Gao, C.; Zhou, Z.; Chen, J. Assessing the Predictability for Blast Furnace System through Nonlinear Time Series Analysis. Ind. Eng. Chem. Res. 2008, 47, 3037–3045. [Google Scholar] [CrossRef]

- Jian, L.; Gao, C.; Xia, Z. A Sliding-window Smooth Support Vector Regression Model for Nonlinear Blast Furnace System. Steel Res. Int. 2010, 82, 169–179. [Google Scholar] [CrossRef]

- Xu, X.; Hua, C.; Tang, Y.; Guan, X. Modeling of the hot metal silicon content in blast furnace using support vector machine optimized by an improved particle swarm optimizer. Neural Comput. Appl. 2015, 27, 1451–1461. [Google Scholar] [CrossRef]

- Yan, C.; Qi, J.; Ma, J.; Tang, H.; Zhang, T.; Li, H. Determination of carbon and sulfur content in coal by laser induced breakdown spectroscopy combined with kernel-based extreme learning machine. Chemom. Intell. Lab. Syst. 2017, 167, 226–231. [Google Scholar] [CrossRef]

- Zhang, J.H.; Xie, G.A.; Shen, F.M. Optimization and Analysis of Sulfur Content in Hot Metal Based on Neural Network. J. Mater. Metall. 2006, 5, 86–89. [Google Scholar]

- Wang, W.; Chen, W.; Ye, Y.; Xu, Z.; Jia, F. Application of neural network in prediction of sulfur content in molten iron of blast furnace. Iron Steel 2006, 10, 19–22. [Google Scholar] [CrossRef]

- Zhou, H.; Tang, Z.; Wen, B.; Wang, S.; Yang, J.; Kou, M.; Wu, S.; Dianyu, E. Application of statistical analysis, Deng’s relevancy and BP neural network for predicting molten iron sulfur in COREX process. Int. J. Chem. React. Eng. 2020, 18, 20200122. [Google Scholar] [CrossRef]

- Jiang, D.; Zhou, X.; Wang, Z.; Li, K.; Zhang, J. Predictive modeling of the hot metal silicon content in blast furnace based on ensemble method. Met. Res. Technol. 2022, 119, 515. [Google Scholar] [CrossRef]

- Manojlović, V.; Kamberović, Z.; Korać, M.; Dotlić, M. Machine learning analysis of electric arc furnace process for the evaluation of energy efficiency parameters. Appl. Energy 2022, 307. [Google Scholar] [CrossRef]

- He, T.; Dong, Z.; Meng, K.; Wang, H.; Oh, Y.T. Accelerating multi-layer perceptron based short term demand forecasting using graphics processing units. In Proceedings of the 2009 Transmission & Distribution Conference & Exposition: Asia and Pacific, Seoul, Republic of Korea, 26–30 October 2009. [Google Scholar]

- Jiang, D.; Wang, Z.; Zhang, J.; Jiang, D.; Li, K.; Liu, F. Machine Learning Modeling of Gas Utilization Rate in Blast Furnace. Jom 2022, 74, 1633–1640. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, S.; Yin, Y.; Chen, X. Prediction of the hot metal silicon content in blast furnace based on extreme learning machine. Int. J. Mach. Learn. Cybern. 2017, 9, 1697–1706. [Google Scholar] [CrossRef]

- Zhou, P.; Song, H.; Wang, H.; Chai, T. Data-Driven Nonlinear Subspace Modeling for Prediction and Control of Molten Iron Quality Indices in Blast Furnace Ironmaking. IEEE Trans. Control Syst. Technol. 2016, 25, 1761–1774. [Google Scholar] [CrossRef]

- Wang, X. Iron and Steel Metallurgy (Iron-Making Part); Metallurgical Industry Press: Beijing, China, 2000. [Google Scholar]

- Geerdes, M.; Chaigneau, R.; Kurunov, I.; Lingiardi, O.; Rieketts, J. Modern Blast Furnace lronmaking, 3rd ed.; IOS Press under the Imprint Delft University Press: Amsterdam, The Netherlands, 2015. [Google Scholar]

- An, X.-W.; Wang, J.-S.; Lan, R.-Z.; Han, Y.-H.; Xue, Q.-G. Softening and Melting Behavior of Mixed Burden for Oxygen Blast Furnace. J. Iron Steel Res. Int. 2013, 20, 11–16. [Google Scholar] [CrossRef]

- Liu, S.; Lyu, Q.; Liu, X.; Sun, Y.; Zhang, X. A Prediction System of Burn through Point Based on Gradient Boosting Decision Tree and Decision Rules. ISIJ Int. 2019, 59, 2156–2164. [Google Scholar] [CrossRef]

| Daily output (DO) | Utilization coefficient (UC) | Dry coke consumption (DCC) | Moisture content (MC) | Coke ratio (CKR) |

| Coal consumption (CC) | Coal ratio (CLR) | Breeze ratio (BR) | Fuel ratio (FR) | Sinter consumption (SC) |

| Ore consumption (OC) | Ore ratio (OR) | Number of batches (NB) | Blast volume (BV) | Blast temperature (BT) |

| Wind pressure (WP) | Top pressure (TP) | Differential pressure (DP) | Top temperature (TT) | Air permeability index (API) |

| Wind velocity (WV) | Blast kinetic energy (BKE) | Oxygen enrichment rate (OER) | Temperatures in the northwest (TNW) | Temperatures in the southeast (TSE) |

| Temperature in the center (TC) | Temperatures in the southwest (TSW) | Temperature in the Northeast (TNE) | CO content (CO) | CO2 content (CO2) |

| H2 content (H2) | N2 content (N2) | Sulfur content in coke (SCC) | M40 | M10 |

| CRI | CSR | Silicon content in metal (Si) | Manganese content in metal (Mn) | Phosphorus content in metal (P) |

| Titanium content in metal (Ti) | Carbon content in metal (C) | Ferrum content in metal (Fe) | Hot metal temperature (HMT) | Sulfur content in metal (S) |

| Parameters | S | DP | SCC | CLR | WP | OC | P | TSE | CO2 |

| CKR | DCC | NB | WV | C | OR | Ti | TT | OER | |

| MC | H2 | UC | CRI | TNW | Mn | SC | API | HMT | |

| TNE |

| Evaluation Indicators | Dataset | MAPE | RMSE | HR |

|---|---|---|---|---|

| XGBoost model | Training set | 4.1050 | 0.0059 | 0.9430 |

| Testing set | 3.9857 | 0.0056 | 0.9507 | |

| MLP model | Training set | 4.6780 | 0.0086 | 0.9214 |

| Testing set | 4.5536 | 0.0060 | 0.9413 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Jiang, D.; Wang, Z.; Wang, F.; Zhang, J.; Zong, Y.; Zeng, S. Predictive Modeling of the Hot Metal Sulfur Content in a Blast Furnace Based on Machine Learning. Metals 2023, 13, 288. https://doi.org/10.3390/met13020288

Zhang S, Jiang D, Wang Z, Wang F, Zhang J, Zong Y, Zeng S. Predictive Modeling of the Hot Metal Sulfur Content in a Blast Furnace Based on Machine Learning. Metals. 2023; 13(2):288. https://doi.org/10.3390/met13020288

Chicago/Turabian StyleZhang, Song, Dewen Jiang, Zhenyang Wang, Feiwang Wang, Jianliang Zhang, Yanbing Zong, and Shuigen Zeng. 2023. "Predictive Modeling of the Hot Metal Sulfur Content in a Blast Furnace Based on Machine Learning" Metals 13, no. 2: 288. https://doi.org/10.3390/met13020288

APA StyleZhang, S., Jiang, D., Wang, Z., Wang, F., Zhang, J., Zong, Y., & Zeng, S. (2023). Predictive Modeling of the Hot Metal Sulfur Content in a Blast Furnace Based on Machine Learning. Metals, 13(2), 288. https://doi.org/10.3390/met13020288