Comparative Study on the Friction Behaviour and the Particle Formation Process between a Laser Cladded Brake Disc and a Conventional Grey Cast Iron Disc

Abstract

1. Introduction

2. Experimental

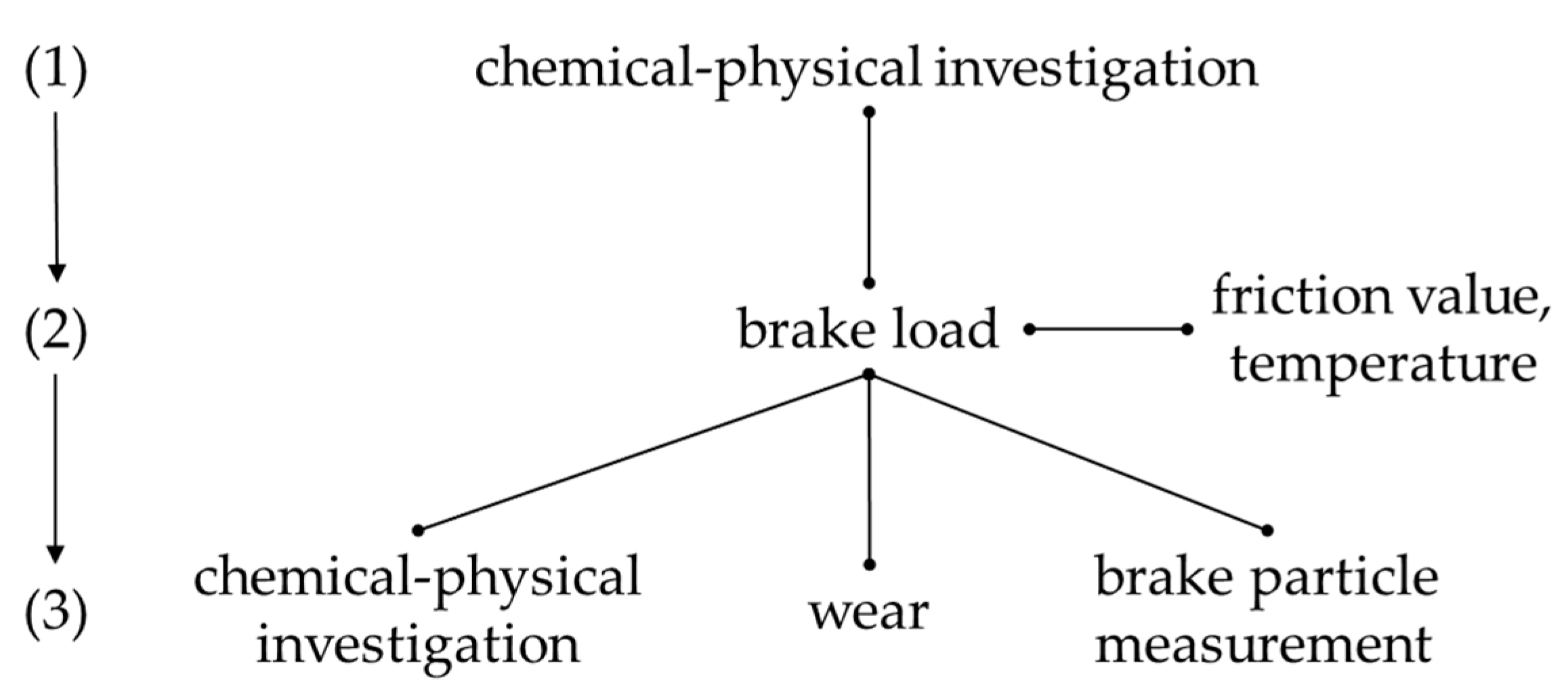

2.1. Method

2.2. Brake System and Friction Materials

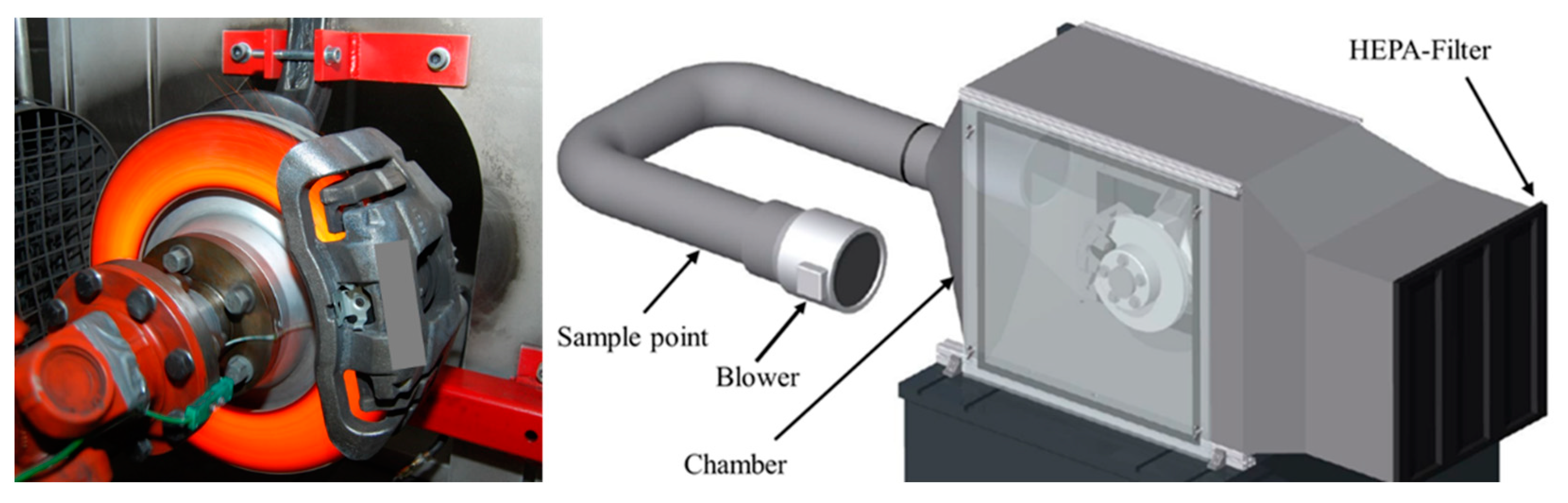

2.3. Brake Dyno and Dilution Tunnel

2.4. Microscope Technology

2.5. Test Protocol

3. Results

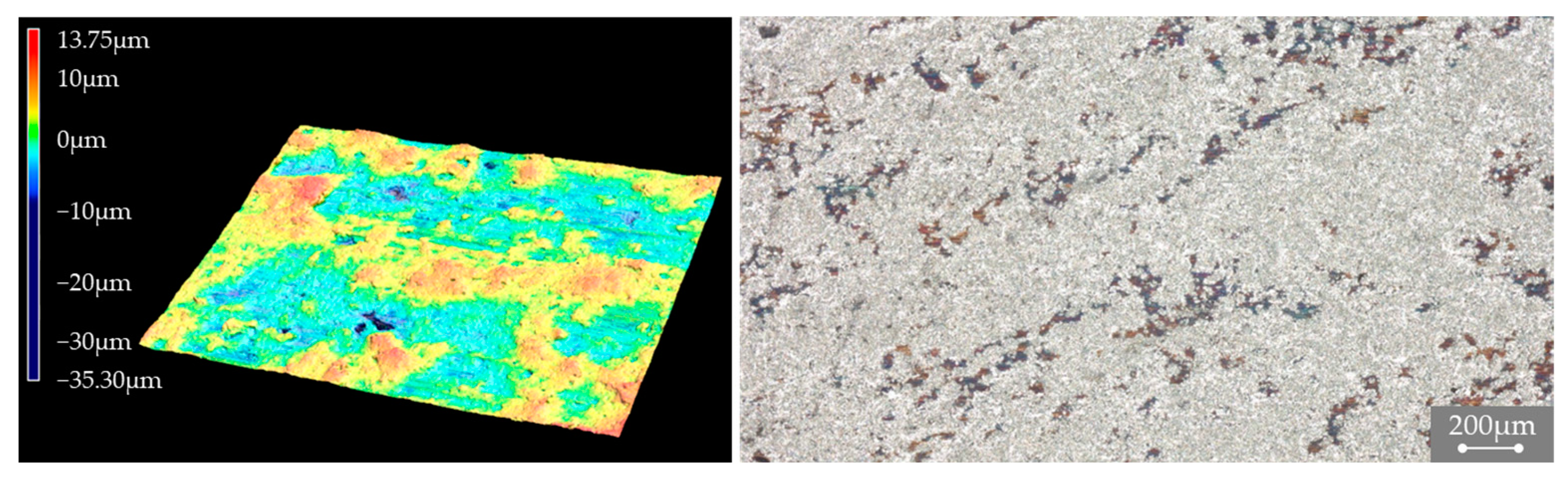

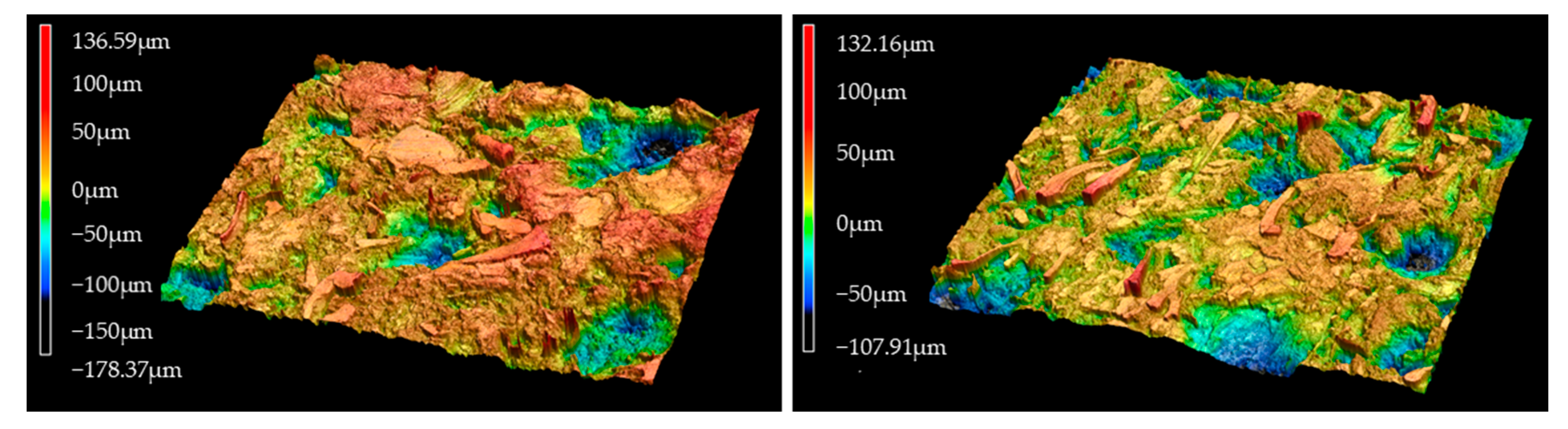

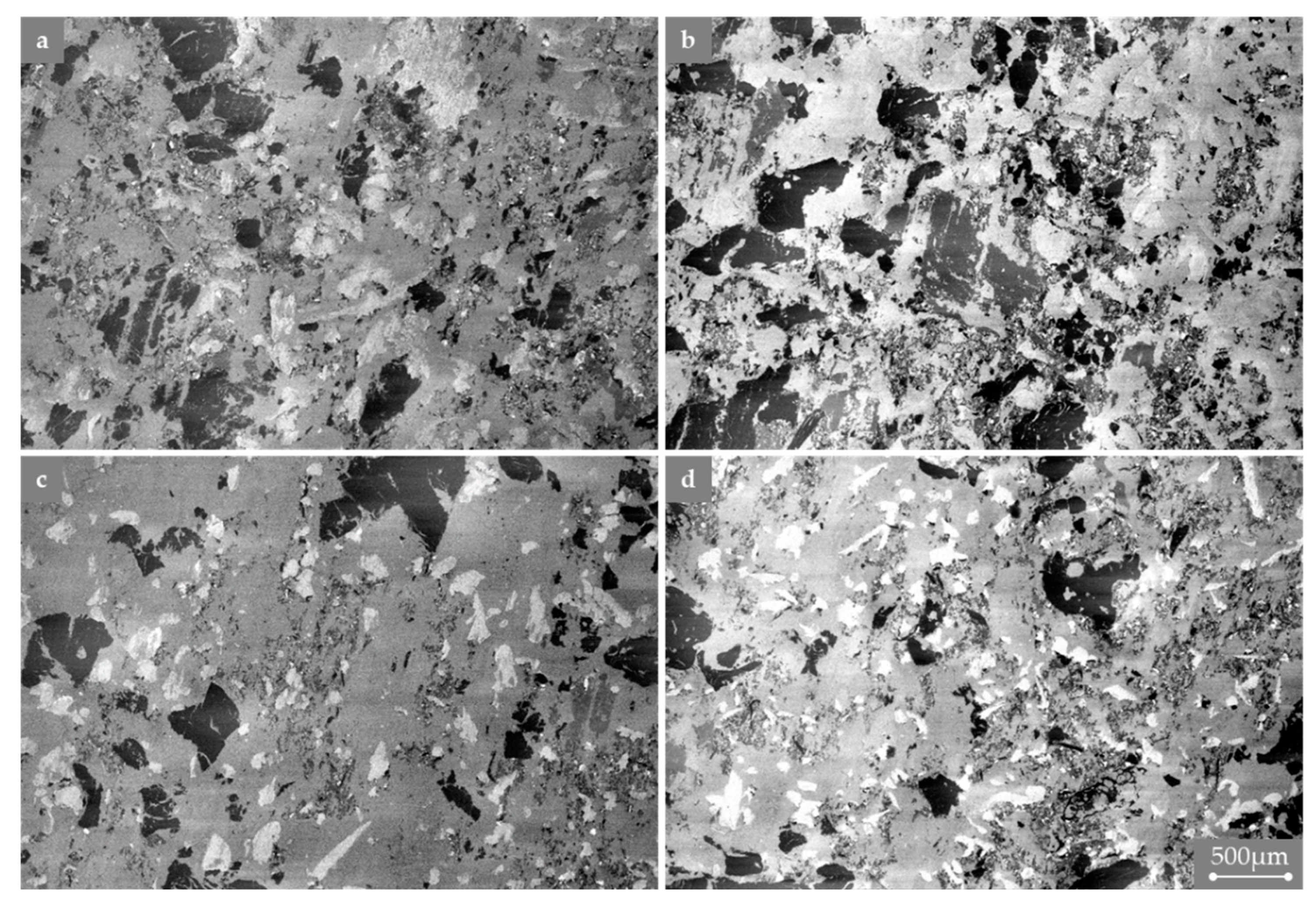

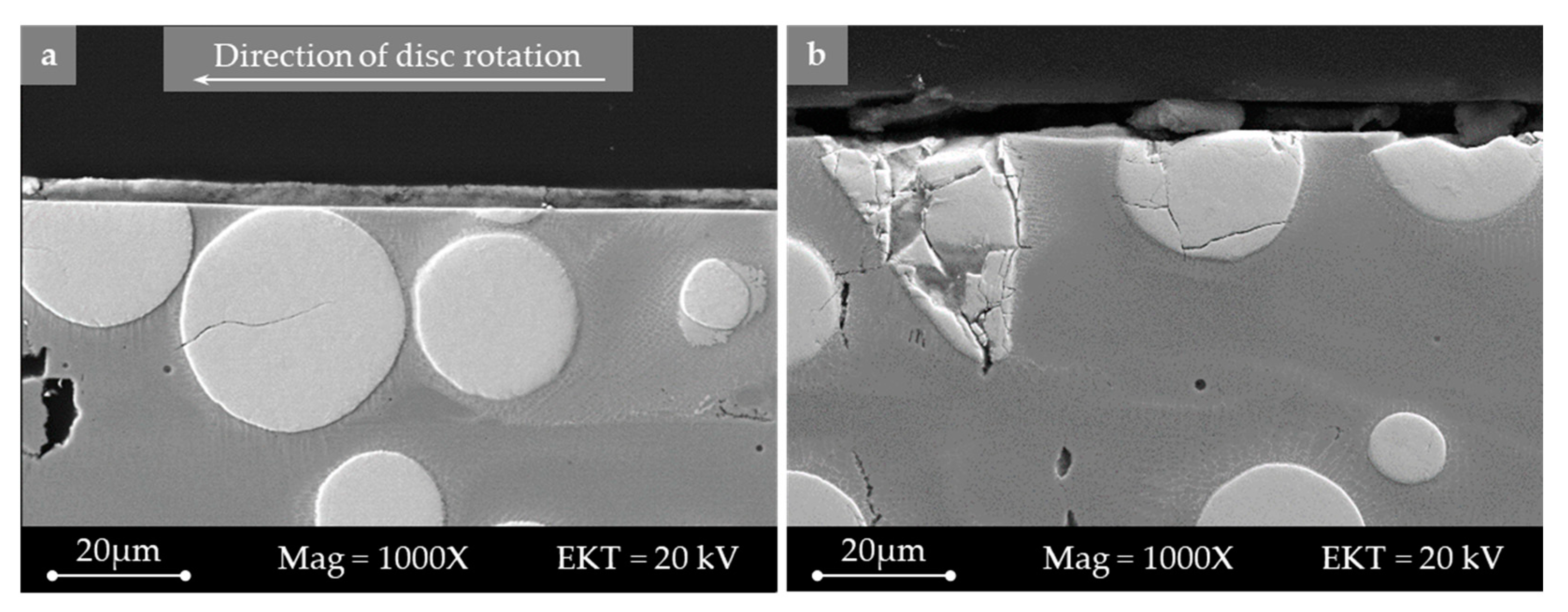

3.1. Initial Condition of the Components

3.2. Bedding Process

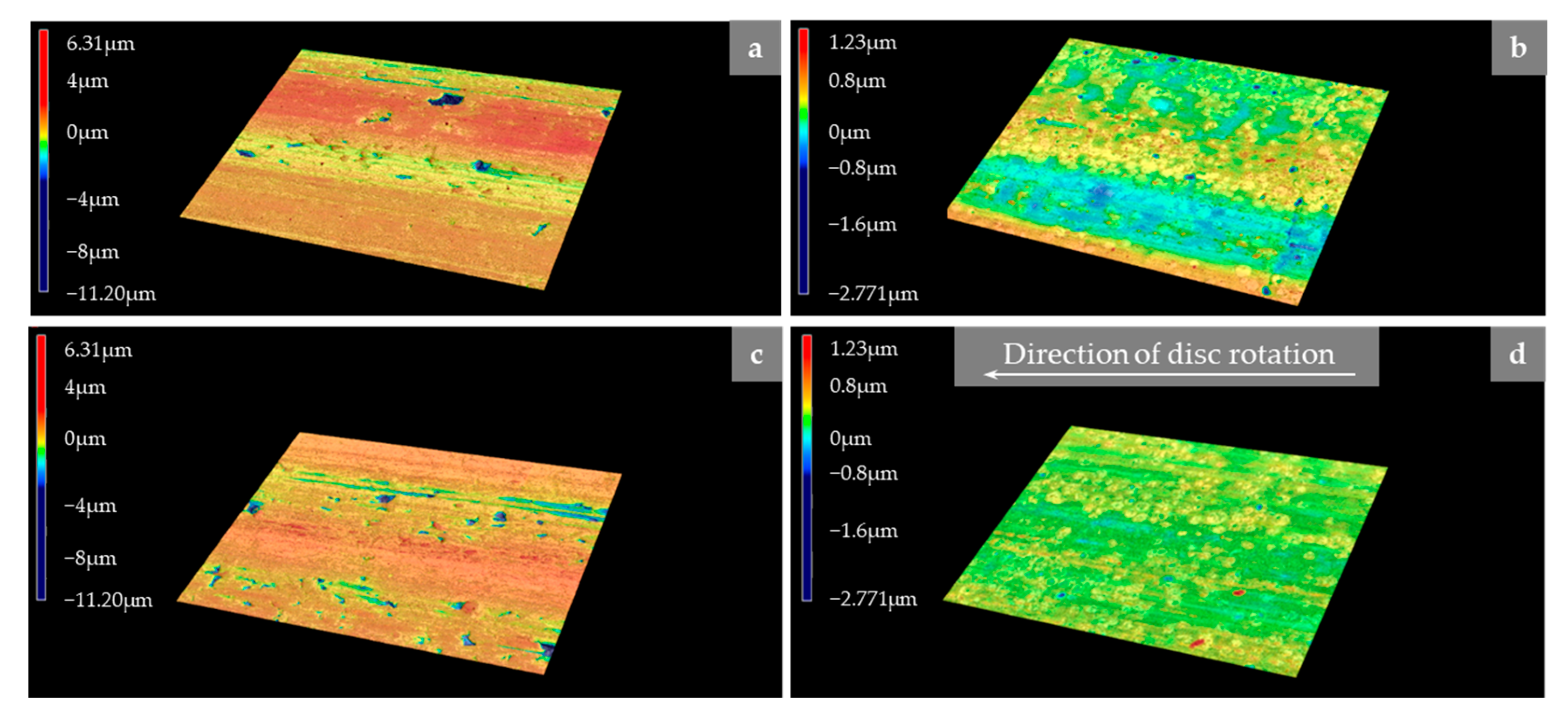

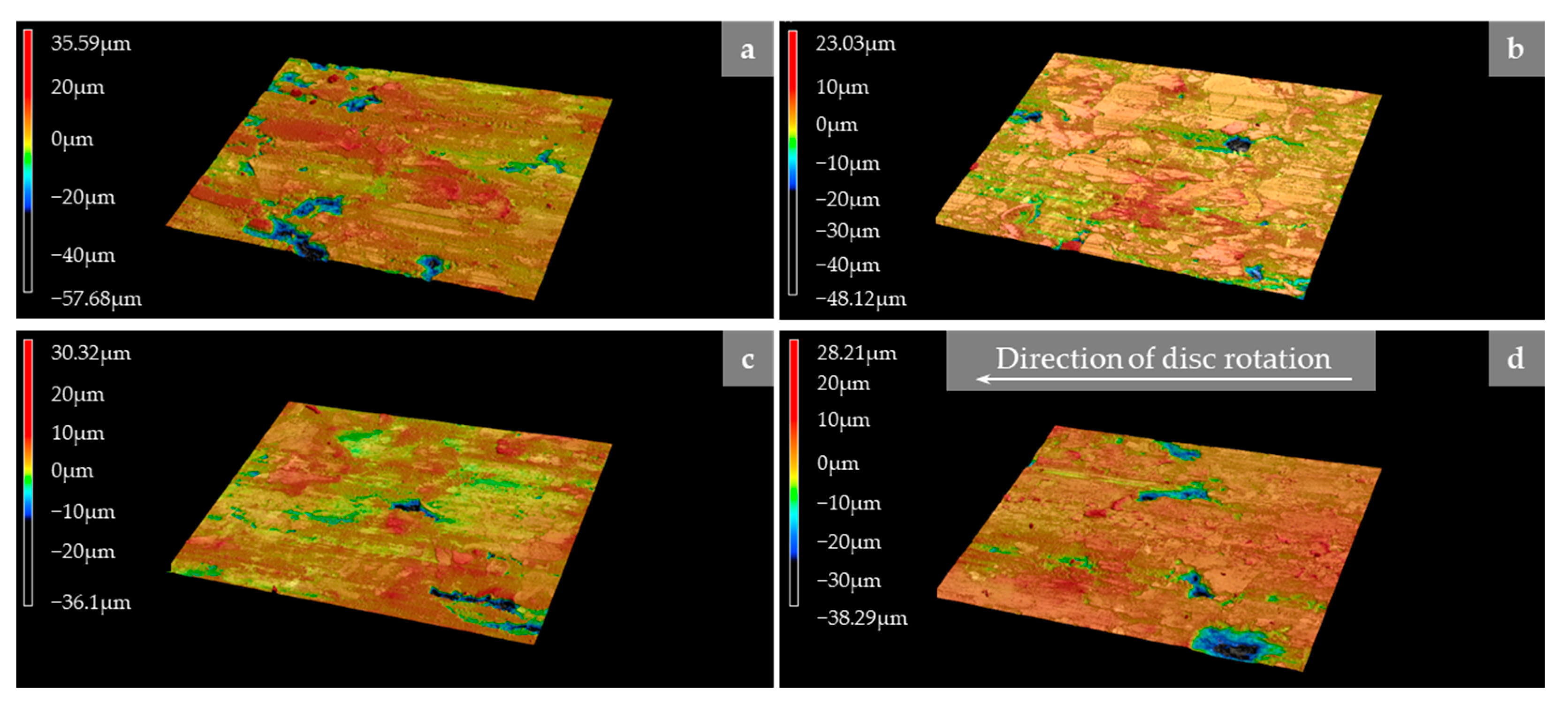

3.3. Surface Roughness

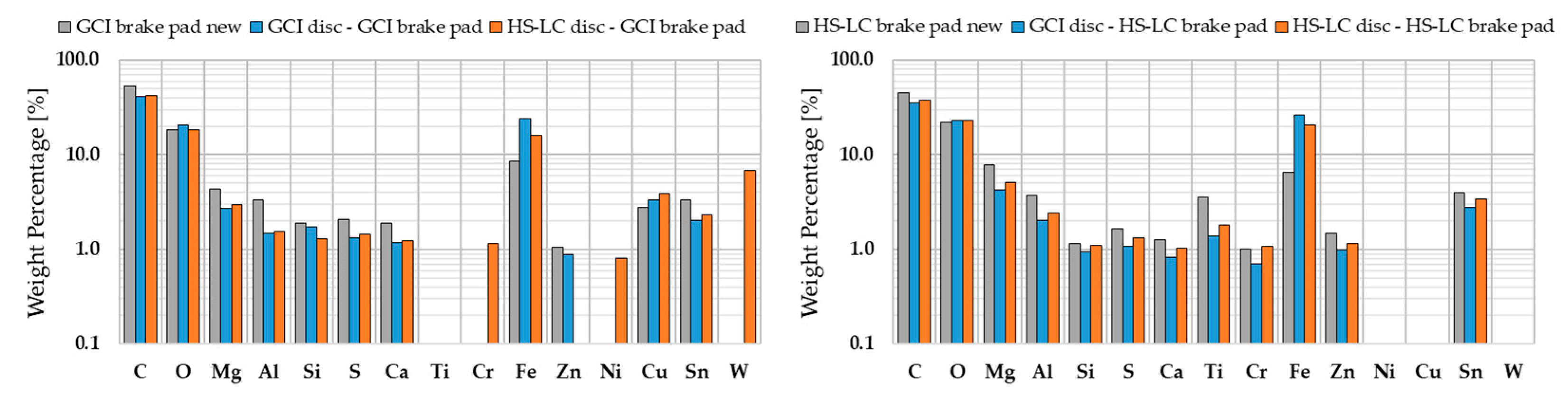

3.4. Chemical Composition

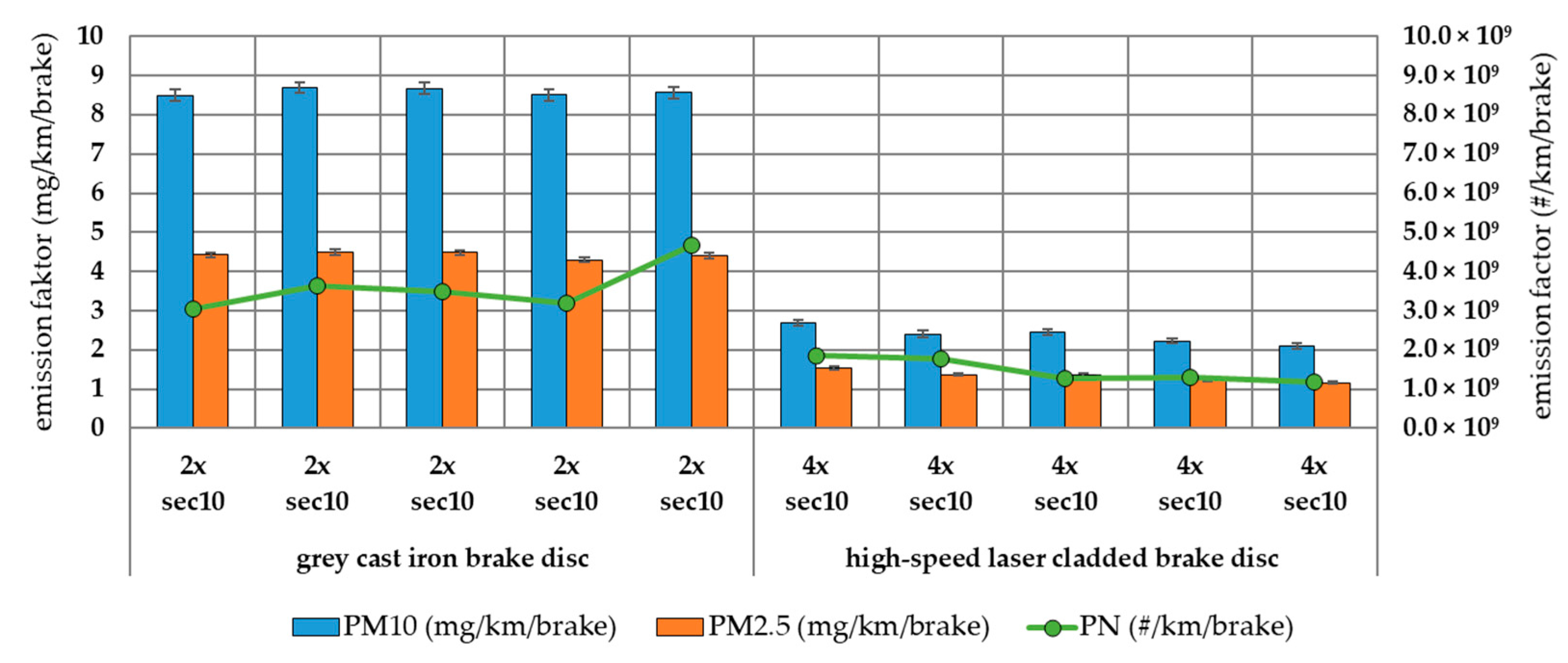

3.5. Brake Wear Particle

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CMD | Count median diameter |

| CVS | Constant volume sampler |

| DM | Digital microscope |

| ECE | Low-steel brake pad |

| EDXS | Energy-dispersive X-ray spectroscopy |

| ELPI | Electrical low pressure impactor |

| GCI | Grey cast iron |

| HS-LC | High-speed laser cladding |

| LM | Laser scanning microscope |

| Sa | Arithmetical mean height |

| SEM | Scanning electron microscope |

| Spk | Reduced peak height |

| Svk | Reduced dale height |

| Vvv | Dale void volume |

| Vmp | Peak material volume |

| WLTP | Worldwide harmonized Light-Duty vehicles Test Procedure |

| WSC | Spherical tungsten carbide particles |

References

- Pant, P.; Harrison, R.M. Estimation of the contribution of road traffic emissions to particulate matter concentrations from fieldmeasurements: A review. Atmos. Environ. 2013, 77, 78–97. [Google Scholar] [CrossRef]

- Thorpe, A.; Harrison, R.M. Sources and properties of non-exhaust particulate matter from road traffic: A review. Sci. Total Environ. 2008, 400, 270–282. [Google Scholar] [CrossRef] [PubMed]

- Hascoet, M.; Adamczak, L. At source brake dust collection system. Results Eng. 2020, 5, 100083. [Google Scholar] [CrossRef]

- Hesse, D. Beitrag Zur Experimentellen und Analytischen Beschreibung Partikelförmiger Bremsenemissionen. Ph.D. Thesis, Technische Universität Ilmenau, Ilmenau, Germany, 2020. [Google Scholar]

- Hesse, D.; Hamatschek, C.; Augsburg, K.; Weigelt, T.; Prahst, A.; Gramstat, S. Testing of Alternative Disc Brakes and Friction Materials Regarding Brake Wear Particle Emissions and Temperature Behavior. Atmosphere 2021, 12, 436. [Google Scholar] [CrossRef]

- Gramstat, S.; Mertens, T.; Waninger, R.; Augsburg, K.; Hamatschek, C.; Hesse, D. Functional Coatings of Gray-Cast Iron Brake Discs—Impact on the Tribology. In Berichte aus dem μ-Club 2020, Proceedings, S; Springer: Berlin/Heidelberg, Germany, 2021; pp. 162–170. [Google Scholar]

- Hart Wie Diamant Rostet Nicht und Produziert Kaum BREMSSTAUB. Im Neuen Cayenne Turbo ist Die Porsche Surface Coated Brake (PSCB) Erstmals Serienmäßig Im Einsatz. Available online: https://christophorus.porsche.com/de/2017/384/porsche-surface-coated-brake-cayenne-turbo-development-center-weissach-diamond-14479.html (accessed on 4 August 2022).

- Wirth, M. Hard-Metal-Coated brake discs—Impact of chemical and physical characteristics on fine dust emission behavior. In Proceedings of the Eurobrake 2022 Conference, Online, 17–19 May 2022. [Google Scholar]

- Utsch, P. Application development and industrialization of laser based hard coated brake discs. In Proceedings of the Eurobrake 2022 Conference, Online, 17–19 May 2022. [Google Scholar]

- Mathissen, M.; Grochowicz, J.; Schmidt, C.; Vogt, R.; Hagen, F.H.F.Z.; Grabiec, T.; Steven, H.; Grigoratos, T. A novel real-world braking cycle for studying brake wear particle emissions. Wear 2018, 414–415, 219–226. [Google Scholar] [CrossRef]

- Poeste, T. Untersuchungen zu reibungsinduzierten Veränderungen der Mikrostruktur und Eigenspannungen im System Bremse. Ph.D. Thesis, Technische Universität Darmstadt, Darmstadt, Germany, 2005. [Google Scholar]

- Eriksson, M. Friction and Contact Phenomena of Disc Brakes Related to Squeal. Ph.D. Thesis, Uppsala University, Uppsala, Sweden, 2000. [Google Scholar]

- J2522 SEP2014; Dynamometer Global Brake Effectiveness Stabilized J2522 SEP2014. SAE International: Warrendale, PA, USA, 2014.

- Kolbeck, K.; Bernhard, M.; Schröder, T.; Hesse, D.; Augsburg, K. Influence of the Run-in Methodology on the Particle Number Emission of Brakes. In Proceedings of the Eurobrake 2021 Conference, Online, 17–21 May 2021. [Google Scholar]

- Limmer, F.; Paulus, A.; Barton, D.; Brooks, P.; Neville, A.; Kosarieh, S. A comparison of methods for characterizing brake pad surfaces. In Proceedings of the Eurobrake 2020 Conference, Barcelona, Spain, 2–4 June 2020. [Google Scholar]

- Wahlström, J.; Lyua, Y.; Matjeka, V.; Söderberg, A. A pin-on-disc tribometer study of disc brake contact pairs with respect to wear and airborne particle emissions. Wear 2017, 384–385, 124–130. [Google Scholar] [CrossRef]

- Lyu, Y.; Leonardi, M.; Mancini, A.; Wahlström, J.; Olofsson, U. Tribology and Airborne Particle Emission of Laser-Cladded Fe-Based Coatings versus Non-Asbestos Organic and Low-Metallic Brake Materials. Metals 2021, 11, 1703. [Google Scholar] [CrossRef]

- Dizdar, S.; Lyu, Y.; Lampa, C.; Olofsson, U. Grey, Cast Iron Brake Discs Laser Cladded with Nickel-Tungsten Carbide—Friction, Wear and Airborne Wear Particle Emission. Atmosphere 2020, 11, 621. [Google Scholar] [CrossRef]

- Bildstein, M.; Mann, K.; Richter, B. Regenerative braking system. In Fundamentals of Automotive and Engine Technology; Reif, K., Ed.; Springer Fachmedien: Wiesbaden, Germany, 2014; pp. 240–243. ISBN 978-3-658-03971-4. [Google Scholar]

- Leyssens, L.; Vinck, B.; Van Der Straeten, C.; Wuyts, F.; Maes, L. Cobalt toxicity in humans—A review of the potential sources and systemic health effects. Toxicology 2017, 387, 43–56. [Google Scholar] [CrossRef] [PubMed]

- Ostermeyer, G.; Müller, M. New insights into the tribology of brake systems. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2008, 222, 1167–1200. [Google Scholar] [CrossRef]

- Denkhaus, E.; Salnikow, K. Nickel essentiality, toxicity, and carcinogenicity. Crit. Rev. Oncol. Hematol. 2002, 42, 35–56. [Google Scholar] [CrossRef] [PubMed]

- Bastian, S.; Busch, W.; Kühnel, D.; Springer, A.; Meißner, T.; Holke, R.; Scholz, S.; Iwe, M.; Pompe, W.; Gelinsky, M.; et al. Toxicity of Tungsten Carbide and Cobalt-Doped Tungsten Carbide Nanoparticles in Mammalian Cells In Vitro. Environ. Health Perspect. 2009, 117, 530–536. [Google Scholar] [CrossRef] [PubMed]

| Weight Percentage (%) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Friction Couple | C | O | Mg | Al | Si | S | Ca | Ti | Cr | Fe | Zn | Cu | Sn |

| GCI brake pad | 52.5 | 18.2 | 4.4 | 3.3 | 1.9 | 2.1 | 1.9 | - | - | 8.5 | 1.1 | 2.8 | 3.4 |

| HS-LC brake pad | 45.2 | 22.1 | 7.9 | 3.7 | 1.1 | 1.7 | 1.3 | 3.6 | 1 | 6.6 | 1.5 | - | 4.0 |

| Friction Couple | Sa (µm) | Spk (µm) | Svk (µm) | Vvv (mL/m2) | Vmp (mL/m2) |

|---|---|---|---|---|---|

| GCI disc | 2.552 | 3.556 | 3.024 | 0.303 | 0.161 |

| HS-LC disc | 0.278 | 0.219 | 0.869 | 0.080 | 0.011 |

| Friction Couple | Sa (µm) | Spk (µm) | Svk (µm) | Vvv (mL/m2) | Vmp (mL/m2) |

|---|---|---|---|---|---|

| GCI brake pad | 25.090 | 20.784 | 60.508 | 5.978 | 1.049 |

| HS-LC brake pad | 20.233 | 15.797 | 52.188 | 5.168 | 0.778 |

| Friction Couple | Disc (g) | Inner Pad (g) | Outer Pad (g) | Total (g) |

|---|---|---|---|---|

| GCI disc–GCI brake pad | 9.43 | 4.37 | 4.11 | 17.91 |

| HS-LC disc–GCI brake pad | 1.57 | 1.72 | 1.22 | 4.51 |

| GCI disc–HS-LC brake pad | 4.91 | 6.17 | 6.94 | 18.02 |

| HS-LC disc–HS-LC brake pad | 0.7 | 2.95 | 3.34 | 6.99 |

| Friction Couple | Sa (µm) | Spk (µm) | Svk (µm) | Vvv (mL/m2) | Vmp (mL/m2) |

|---|---|---|---|---|---|

| GCI disc–GCI brake pad | 0.637 | 0.474 | 0.523 | 0.054 | 0.021 |

| HS-LC disc–GCI brake pad | 0.148 | 0.310 | 0.248 | 0.023 | 0.015 |

| GCI disc–HS-LC brake pad | 0.600 | 1.017 | 0.553 | 0.065 | 0.038 |

| HS-LC disc–HS-LC brake pad | 0.145 | 0.407 | 0.319 | 0.028 | 0.021 |

| Friction Couple | Sa (µm) | Spk (µm) | Svk (µm) | Vvv (mL/m2) | Vmp (mL/m2) |

|---|---|---|---|---|---|

| GCI disc–GCI brake pad | 3.156 | 4.354 | 9.319 | 0.839 | 0.214 |

| HS-LC disc–GCI brake pad | 2.422 | 2.938 | 6.949 | 0.627 | 0.139 |

| GCI disc–HS-LC brake pad | 2.914 | 5.093 | 10.105 | 0.727 | 0.248 |

| HS-LC disc–HS-LC brake pad | 2.513 | 3.832 | 8.946 | 0.777 | 0.198 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hamatschek, C.; Augsburg, K.; Schobel, D.; Gramstat, S.; Stich, A.; Gulden, F.; Hesse, D. Comparative Study on the Friction Behaviour and the Particle Formation Process between a Laser Cladded Brake Disc and a Conventional Grey Cast Iron Disc. Metals 2023, 13, 300. https://doi.org/10.3390/met13020300

Hamatschek C, Augsburg K, Schobel D, Gramstat S, Stich A, Gulden F, Hesse D. Comparative Study on the Friction Behaviour and the Particle Formation Process between a Laser Cladded Brake Disc and a Conventional Grey Cast Iron Disc. Metals. 2023; 13(2):300. https://doi.org/10.3390/met13020300

Chicago/Turabian StyleHamatschek, Christopher, Klaus Augsburg, David Schobel, Sebastian Gramstat, Anton Stich, Florian Gulden, and David Hesse. 2023. "Comparative Study on the Friction Behaviour and the Particle Formation Process between a Laser Cladded Brake Disc and a Conventional Grey Cast Iron Disc" Metals 13, no. 2: 300. https://doi.org/10.3390/met13020300

APA StyleHamatschek, C., Augsburg, K., Schobel, D., Gramstat, S., Stich, A., Gulden, F., & Hesse, D. (2023). Comparative Study on the Friction Behaviour and the Particle Formation Process between a Laser Cladded Brake Disc and a Conventional Grey Cast Iron Disc. Metals, 13(2), 300. https://doi.org/10.3390/met13020300