Effects of Natural Aging and Discontinuous Cyclic Loading on High Cycle Fatigue Behavior of Steels

Abstract

:1. Introduction

2. Materials and Experiments

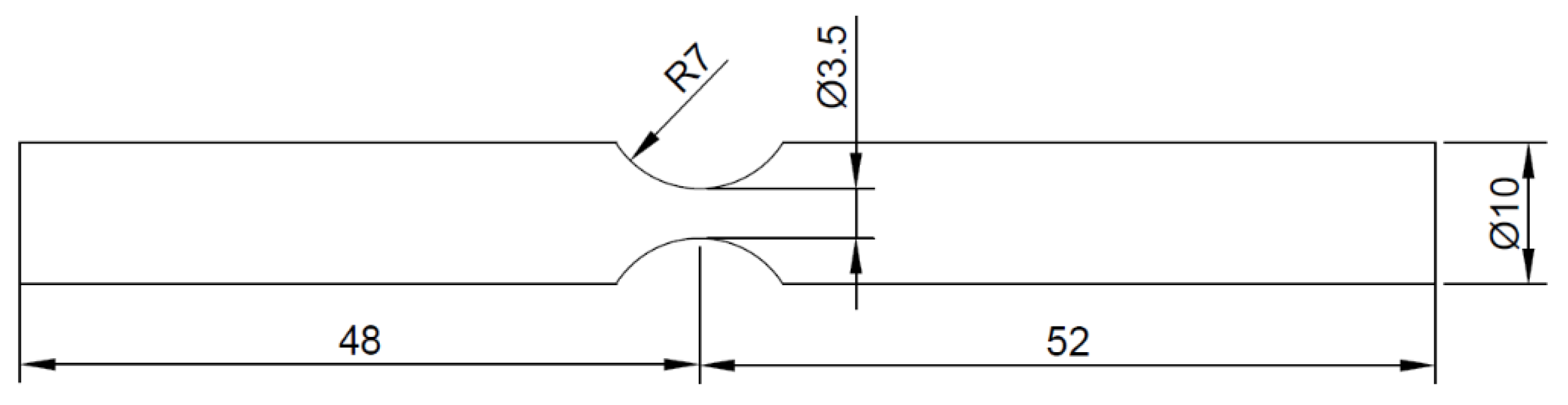

2.1. Materials and Specimens

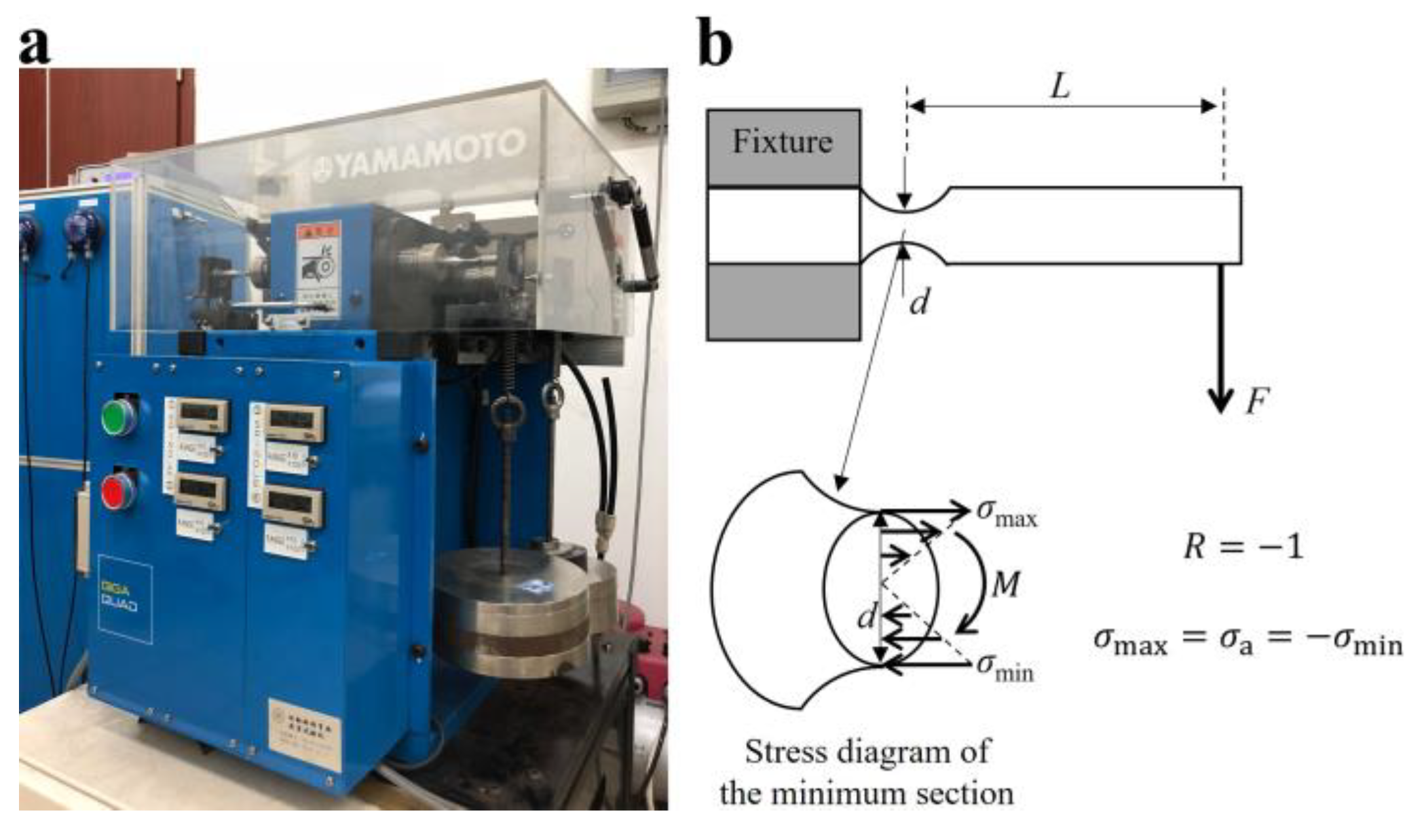

2.2. Experimental Methods

3. Results and Discussion

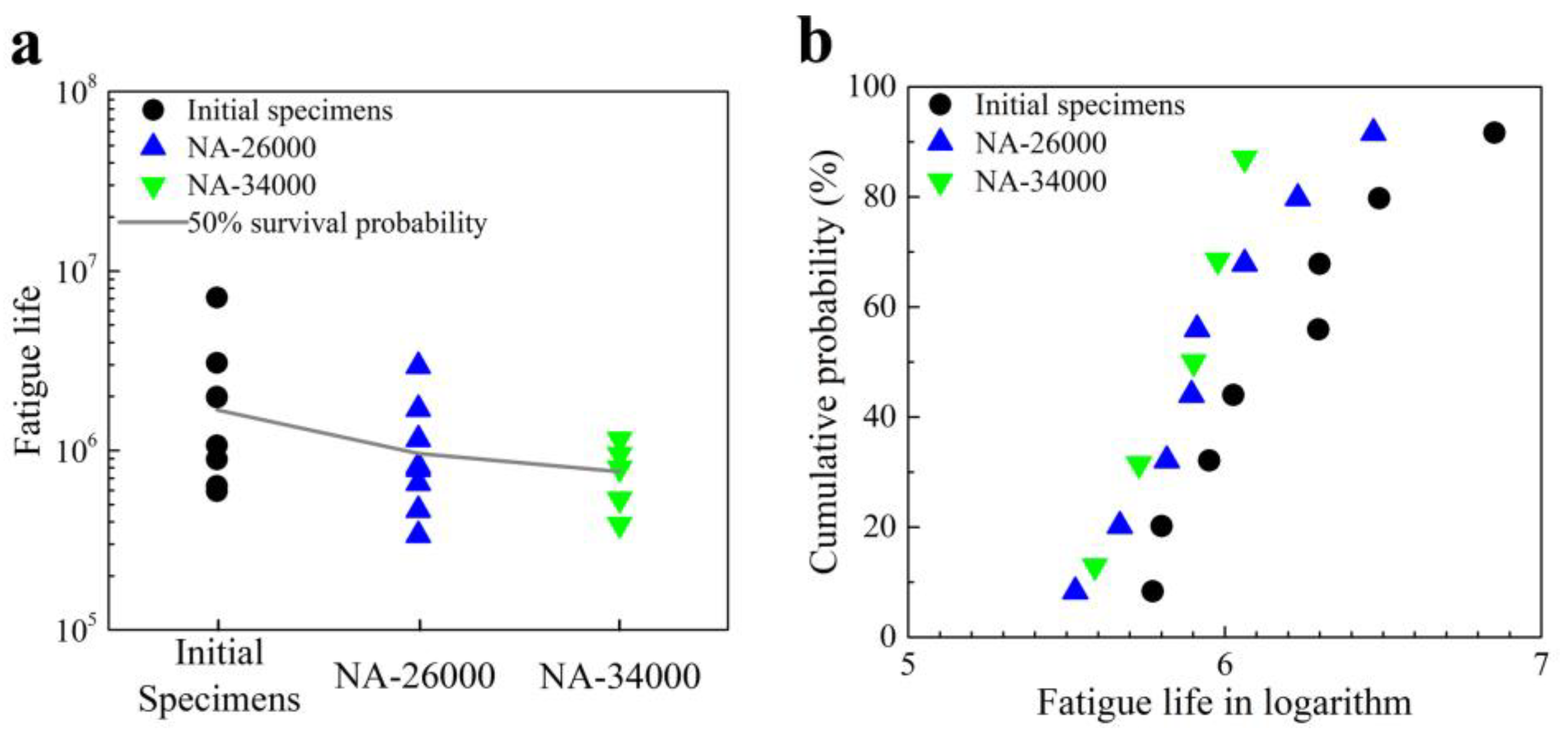

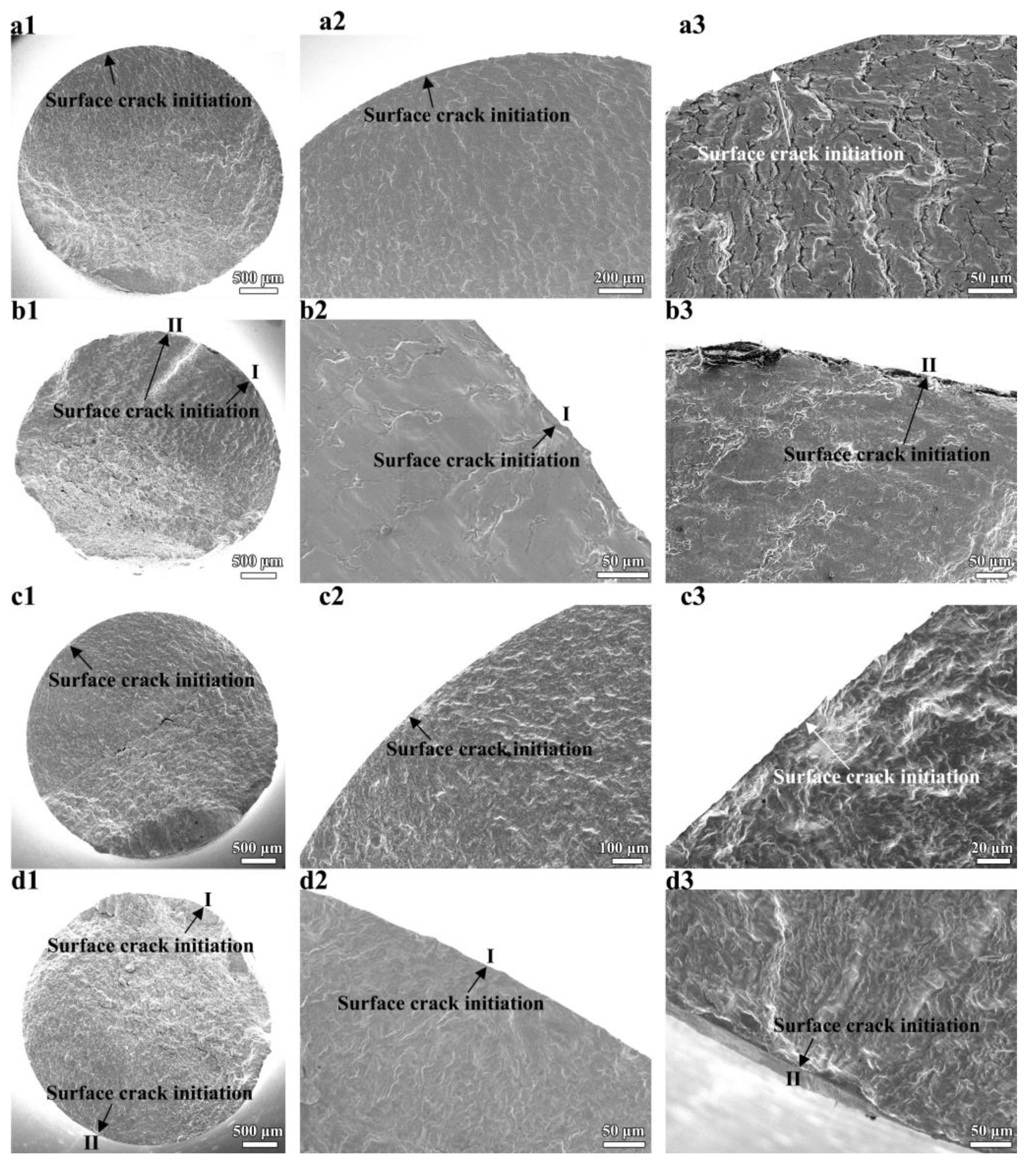

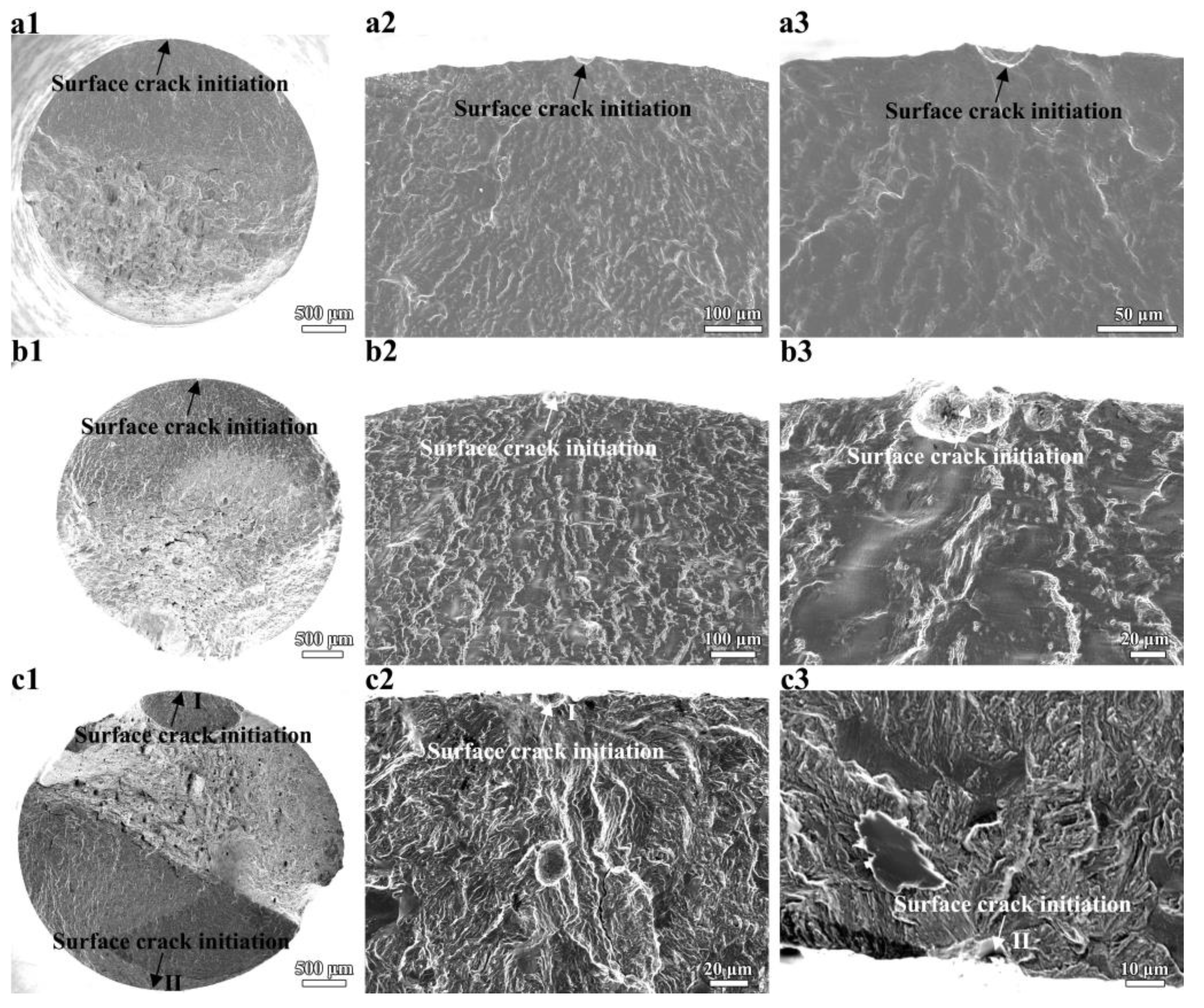

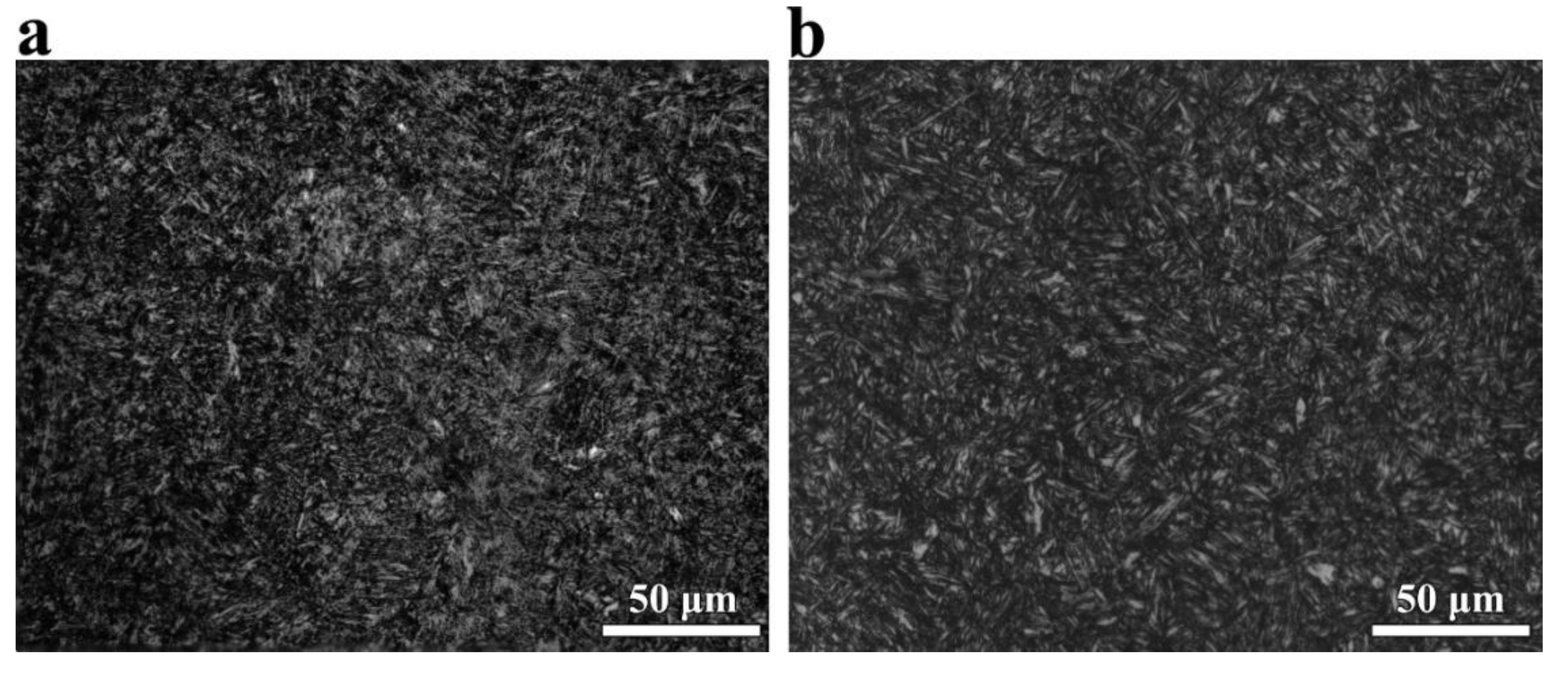

3.1. Effect of Natural Aging on HCF of 25CrMo4 Steel

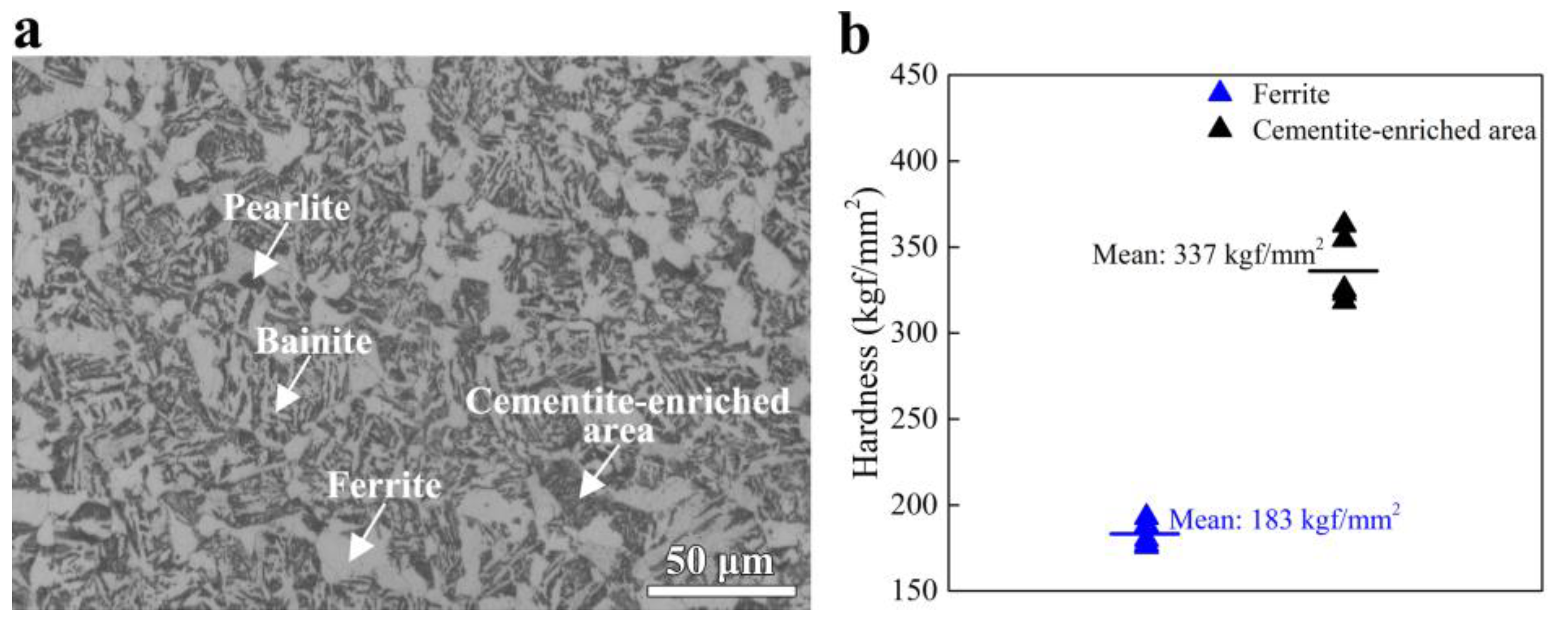

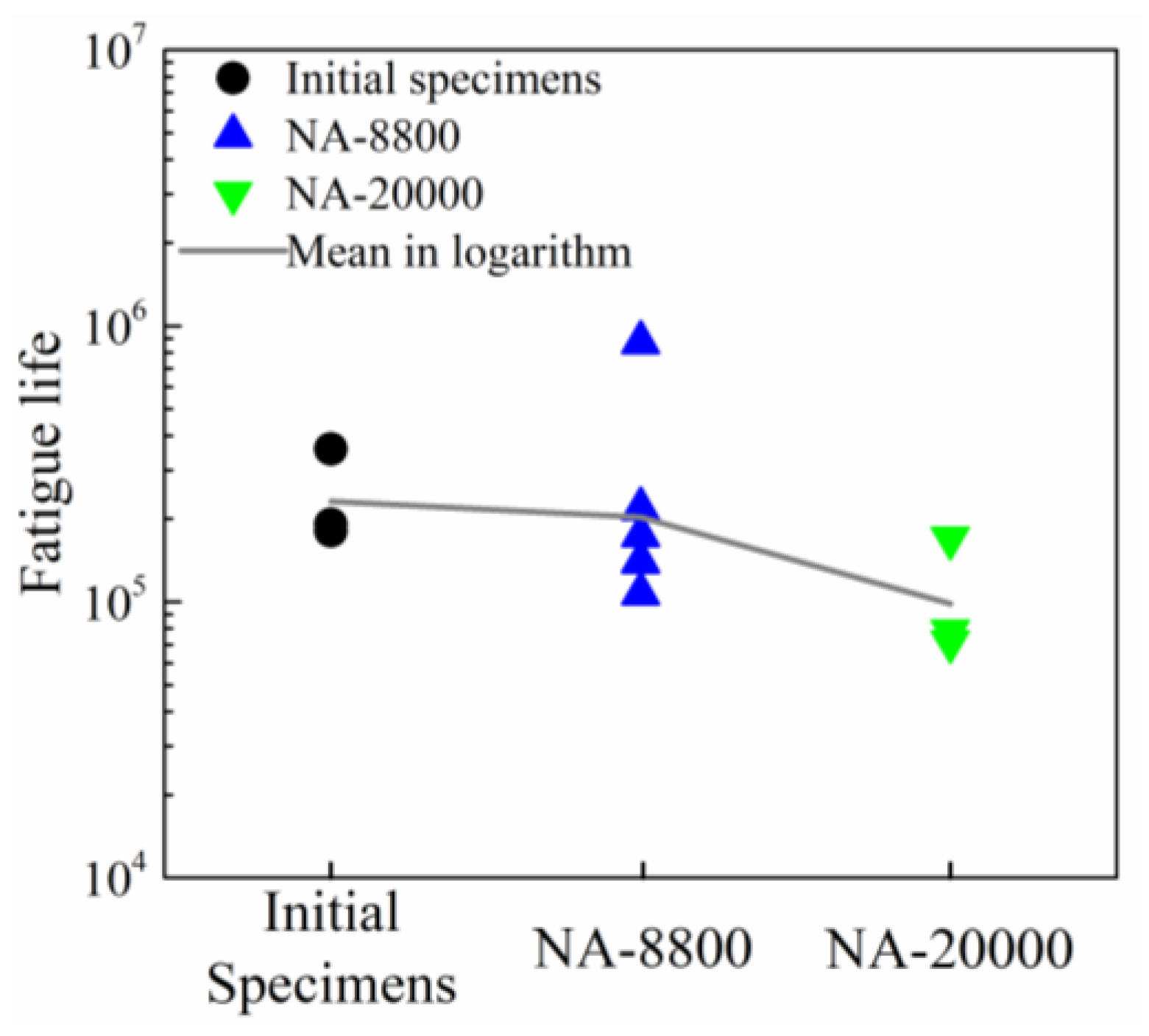

3.2. Effect of Natural Aging on HCF of 30CrMnSiA Steel

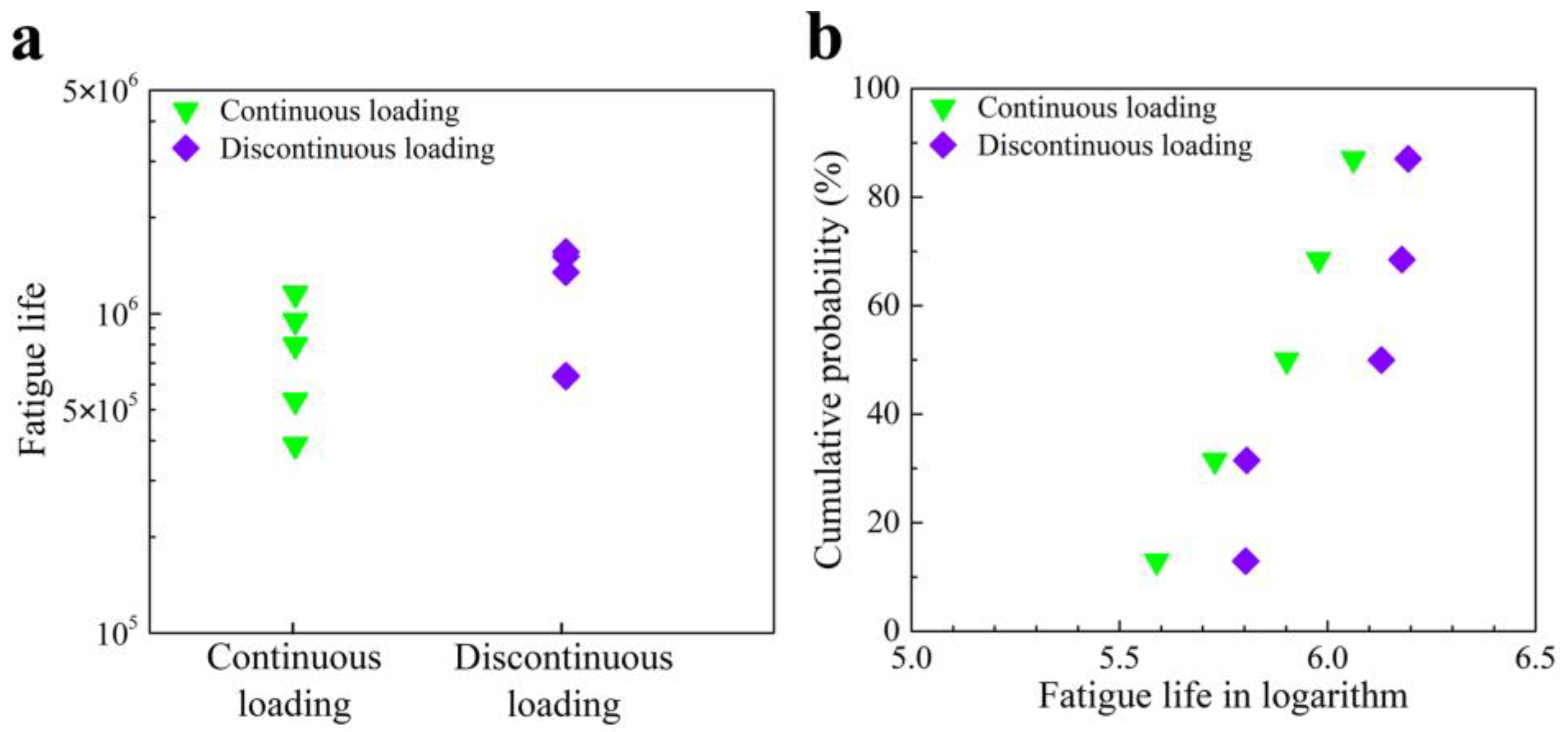

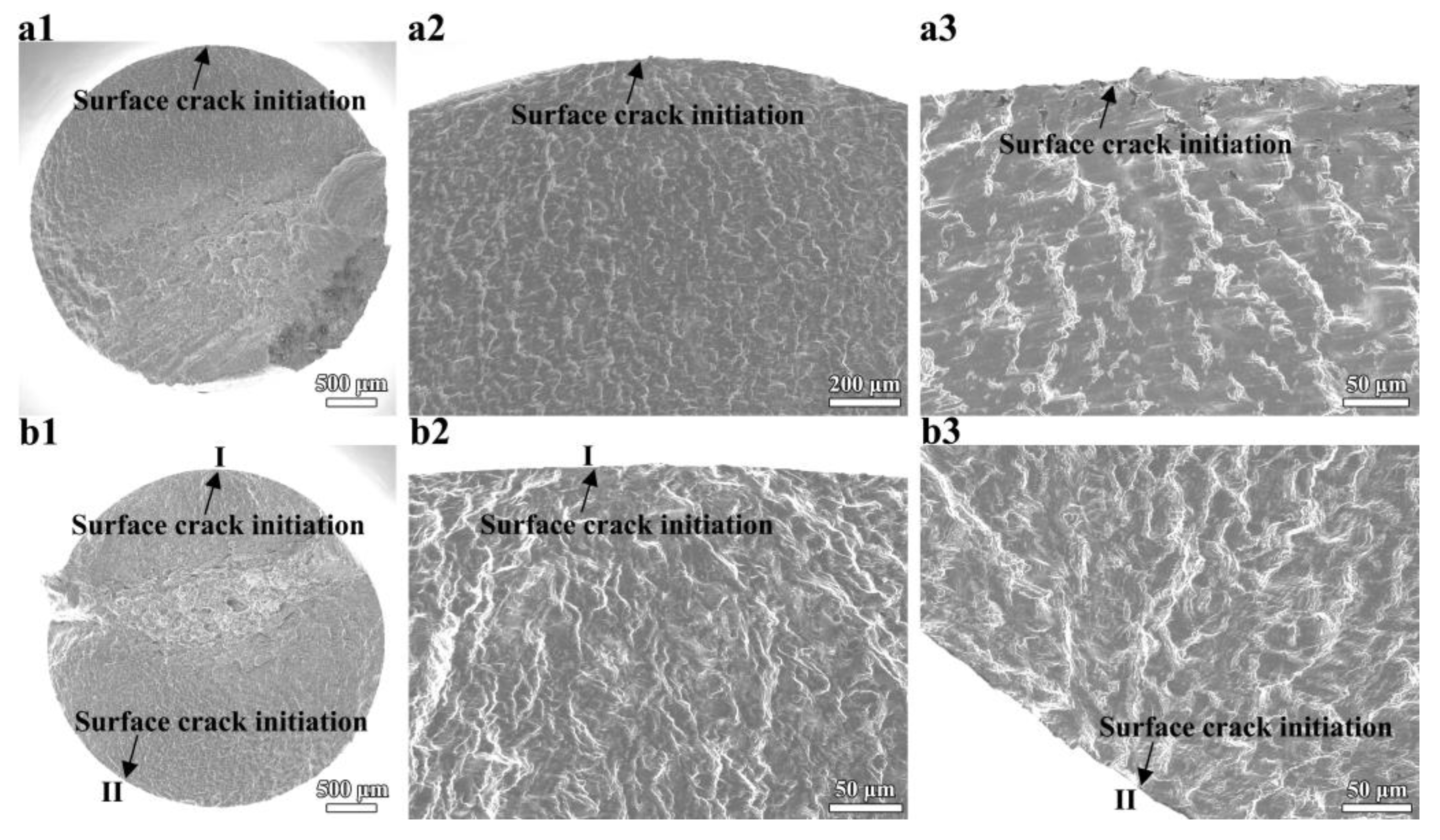

3.3. Effect of Discontinuous Loading on HCF of 25CrMo4 Steel

4. Conclusions

- (1)

- The natural aging in a moderate period (e.g., less than 10,000 h) has no or negligible harmful influence on the fatigue life, while the long-term natural aging (e.g., more than 20,000 h) reduces the fatigue life of the 25CrMo4 steel and 30CrMnSiA steel. The reduction of the fatigue life should be due to the corrosion and the action of hydrogen at the specimen surface during the long-term natural aging.

- (2)

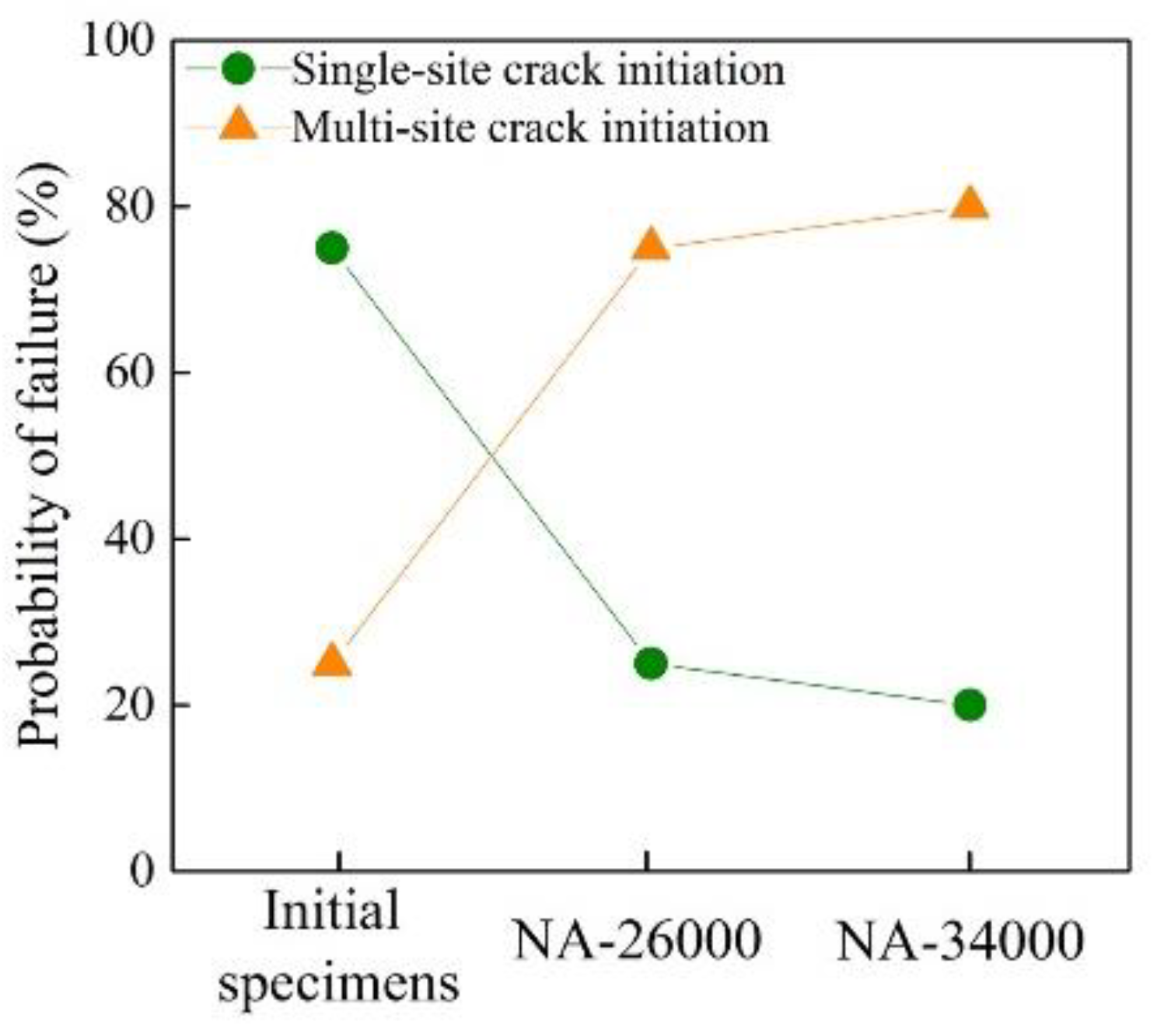

- The effect of natural aging on the failure mechanism is related to the microstructure of materials. The dominant failure mode of 25CrMo4 specimens is switched from single-site crack initiation in the initial state to multi-site crack initiation after natural aging. While the dominant failure mode of 30CrMnSiA specimens after natural aging remains the single-site crack initiation.

- (3)

- The discontinuous cyclic loading has no harmful influence on the fatigue life of the 25CrMo4 steel. It does not change the fatigue crack initiation mode. The specimens under continuous and discontinuous loadings both fail from single-site crack initiation or multi-site crack initiation at the specimen surface.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Heinz, A.; Neumann, P. Crack initiation during high cycle fatigue of an austenitic steel. Acta Metall. Mater. 1990, 38, 1933–1940. [Google Scholar] [CrossRef]

- Sonsino, C. Course of SN-curves especially in the high-cycle fatigue regime with regard to component design and safety. Int. J. Fatigue 2007, 29, 2246–2258. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Wu, S.; Yang, H.; Zhang, Z. High-cycle microscopic severe corrosion fatigue behavior and life prediction of 25crmo steel used in railway axles. Metals 2017, 7, 134. [Google Scholar] [CrossRef]

- Giorgetti, A.; Millefanti, U.; La Battagllia, V.; Citti, P. Investigations of fatigue damage in a nitriding low-carbon bainitic steel for high-performance crankshaft. Metals 2022, 12, 2052. [Google Scholar] [CrossRef]

- Krupp, U.; Giertler, A. Surface or internal fatigue crack initiation during VHCF of tempered martensitic and bainitic steels: Microstructure and frequency/strain rate dependency. Metals 2022, 12, 1815. [Google Scholar] [CrossRef]

- Zhao, A.; Xie, J.; Sun, C.; Lei, Z.; Hong, Y. Effects of strength level and loading frequency on very-high-cycle fatigue behavior for a bearing steel. Int. J. Fatigue 2012, 38, 46–56. [Google Scholar] [CrossRef] [Green Version]

- Sun, C.; Lei, Z.; Hong, Y. Effects of stress ratio on crack growth rate and fatigue strength for high cycle and very-high-cycle fatigue of metallic materials. Mech. Mater. 2014, 69, 227–236. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Yeh, J.; Jeng, S.; Chen, C.; Kuo, R. High-cycle fatigue behavior of type 316L stainless steel. Mater. Trans. 2006, 47, 409–417. [Google Scholar] [CrossRef] [Green Version]

- Kwon, J.; Woo, S.; Lee, Y.; Park, J.; Park, Y. Effects of thermal aging on the low cycle fatigue behavior of austenitic–ferritic duplex cast stainless steel. Nucl. Eng. Des. 2001, 206, 35–44. [Google Scholar] [CrossRef]

- Llanes, L.; Mateo, A.; Violan, P.; Mendez, J.; Anglada, M. On the high cycle fatigue behavior of duplex stainless steels: Influence of thermal aging. Mater. Sci. Eng. A 1997, 234, 850–852. [Google Scholar] [CrossRef]

- Pérez-Mora, R.; Palin-Luc, T.; Bathias, C.; Paris, P. Very high cycle fatigue of a high strength steel under sea water corrosion: A strong corrosion and mechanical damage coupling. Int. J. Fatigue 2015, 74, 156–165. [Google Scholar] [CrossRef] [Green Version]

- El May, M.; Palin-Luc, T.; Saintier, N.; Devos, O. Effect of corrosion on the high cycle fatigue strength of martensitic stainless steel X12CrNiMoV12-3. Int. J. Fatigue 2013, 47, 330–339. [Google Scholar] [CrossRef] [Green Version]

- Gao, J.; Pan, X.; Han, J.; Zhu, S.; Liao, D.; Li, Y.; Dai, G. Influence of artificial defects on fatigue strength of induction hardened S38C axles. Int. J. Fatigue 2020, 139, 105746. [Google Scholar] [CrossRef]

- Murakami, Y.; Endo, M. Effects of defects, inclusions and inhomogeneities on fatigue strength. Int. J. Fatigue 1994, 16, 163–182. [Google Scholar] [CrossRef]

- Li, G.; Ke, L.; Peng, W.; Ren, X.; Sun, C. Effects of natural aging and variable loading on very high cycle fatigue behavior of a bearing steel GCr15. Theor. Appl. Fract. Mech. 2022, 119, 103360. [Google Scholar] [CrossRef]

- Botvina, L.; Petrova, I.; Gadolina, I.; Levin, V.; Demina, Y.; Soldatenkov, A.; T’utin, M. High-cycle fatigue failure of low-carbon steel after long-term aging. Inorg. Mater. 2010, 46, 1570–1577. [Google Scholar] [CrossRef]

- Chang, P. Temper-aging of continuously annealed low carbon dual phase steel. Metall. Trans. A 1984, 15, 73–86. [Google Scholar] [CrossRef]

- Zamani, M.; Mirzadeh, H.; Maleki, M. Enhancement of mechanical properties of low carbon dual phase steel via natural aging. Mater. Sci. Eng. A 2018, 734, 178–183. [Google Scholar] [CrossRef]

- Tai, C.; Tai, P.; Hsiao, T.; Chiu, P.; Tseng, C.; Tsao, T.; Chung, T.; Yang, Y.; Chen, C.; Wang, S.; et al. Effect of natural ageing on subsequent artificial ageing of aa7075 aluminum alloy. Metals 2022, 12, 1766. [Google Scholar] [CrossRef]

- Fritsch, S.; Wagner, M. On the effect of natural aging prior to low temperature ECAP of a high-strength aluminum alloy. Metals 2018, 8, 63. [Google Scholar] [CrossRef] [Green Version]

- Cui, Z.; Jiang, H.; Zhang, D.; Song, Y.; Yan, D.; Rong, L. Effect of natural aging on precipitation strengthening behaviors in al-mg-si alloy. Metals 2022, 12, 470. [Google Scholar] [CrossRef]

- Park, M.; So, H.; Kim, K.; Byeon, J.; Kang, L. Natural Aging Effect of Al-20Zn-3Cu alloy on mechanical properties and its relation to microstructural change. Metals 2021, 11, 1485. [Google Scholar] [CrossRef]

- Sun, C.; Li, Y.; Xu, K.; Xu, B. Effects of intermittent loading time and stress ratio on dwell fatigue behavior of titanium alloy Ti-6Al-4V ELI used in deep-sea submersibles. J. Mater. Sci. Technol. 2021, 77, 223–236. [Google Scholar] [CrossRef]

- Peng, W.; Zhang, Y.; Qiu, B.; Xue, H. A brief review of the application and problems in ultrasonic fatigue testing. AASRI Procedia 2012, 2, 127–133. [Google Scholar] [CrossRef]

- Sun, C.; Song, Q.; Hu, Y.; Wei, Y. Effects of intermittent loading on fatigue life of a high strength steel in very high cycle fatigue regime. Int. J. Fatigue 2018, 117, 9–12. [Google Scholar] [CrossRef]

- Murtaza, G.; Akid, R. Corrosion fatigue short crack growth behaviour in a high strength steel. Int. J. Fatigue 1996, 18, 557–566. [Google Scholar] [CrossRef]

- GB/T4337-2015; Metallic Materials-Fatigue Testing-Rotating Bar Bending Method. Standardization Administration of China: Beijing, China, 2015.

- Goodno, B.; Gere, J. Mechanics of Materials; Cengage Learning: Stamford, CT, USA, 2020. [Google Scholar]

- Sun, C.; Song, Q. A method for predicting the effects of specimen geometry and loading condition on fatigue strength. Metals 2018, 8, 811. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.; Wu, S.; Withers, P.; Cao, H.; Chen, P.; Zhang, Y.; Shen, Z.; Vojtek, T.; Hutar, P. Corrosion fatigue lifetime assessment of high-speed railway axle EA4T steel with artificial scratch. Eng. Fract. Mech. 2021, 245, 107588. [Google Scholar] [CrossRef]

- Xu, Z.; Wu, S.; Wang, X. Fatigue evaluation for high-speed railway axles with surface scratch. Int. J. Fatigue 2019, 123, 79–86. [Google Scholar] [CrossRef]

- Polák, J.; Mazánová, V.; Heczko, M.; Petráš, R.; Kuběna, I.; Casalena, L.; Man, J. The role of extrusions and intrusions in fatigue crack initiation. Eng. Fract. Mech. 2017, 185, 46–60. [Google Scholar] [CrossRef]

- Dugstad, A.; Hemmer, H.; Seiersten, M. Effect of steel microstructure on corrosion rate and protective iron carbonate film formation. Corrosion 2001, 57, 369–378. [Google Scholar] [CrossRef]

- Kamimura, T.; Stratmann, M. The influence of chromium on the atmospheric corrosion of steel. Corros. Sci. 2001, 43, 429–447. [Google Scholar] [CrossRef]

- Murakami, Y.; Nomoto, T.; Ueda, T. Factors influencing the mechanism of superlong fatigue failure in steels. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 581–590. [Google Scholar] [CrossRef]

- Hijazi, F.; Kar, J.; Pavan, A.; Singh, K.; Kumar, P.; Jayaram, V. Application of bending creep for examining effect of service conditions on creep response of steel. Mater. Sci. Eng. A 2019, 766, 138398. [Google Scholar] [CrossRef]

- Miller, K.; O’ donnell, W. The fatigue limit and its elimination. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 545–557. [Google Scholar] [CrossRef]

| Materials | Chemical Compositions (wt%) | |||||||

|---|---|---|---|---|---|---|---|---|

| 25CrMo4 | C | Cr | Si | Mn | Mo | S | P | Fe |

| 0.22 | 0.54 | 0.26 | 0.85 | 0.17 | 0.027 | 0.016 | balanced | |

| 30CrMnSiA | C | Cr | Mn | Si | Fe | |||

| 0.34 | 1.20 | 1.10 | 1.10 | balanced | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Liu, J.; Sun, J.; Sun, C. Effects of Natural Aging and Discontinuous Cyclic Loading on High Cycle Fatigue Behavior of Steels. Metals 2023, 13, 511. https://doi.org/10.3390/met13030511

Li G, Liu J, Sun J, Sun C. Effects of Natural Aging and Discontinuous Cyclic Loading on High Cycle Fatigue Behavior of Steels. Metals. 2023; 13(3):511. https://doi.org/10.3390/met13030511

Chicago/Turabian StyleLi, Gen, Jiajun Liu, Jian Sun, and Chengqi Sun. 2023. "Effects of Natural Aging and Discontinuous Cyclic Loading on High Cycle Fatigue Behavior of Steels" Metals 13, no. 3: 511. https://doi.org/10.3390/met13030511