Evolution of Poisson’s Ratio in the Tension Process of Low-Carbon Hot-Rolled Steel with Discontinuous Yielding

Abstract

1. Introduction

- (1)

- In Figure 1a, the onset point of specimen necking is a key point. On a macroscopic scale, the specimen is in a uniaxial stress state before the point, while the necked part is in a multiaxial stress state after the point. The longitudinal and transversal strains in the necked part were produced by the longitudinal and transversal stresses. According to the definition of the ν, the coefficient of the transverse strain to the longitudinal strain is not the ν. This point was not mentioned in their study.

- (2)

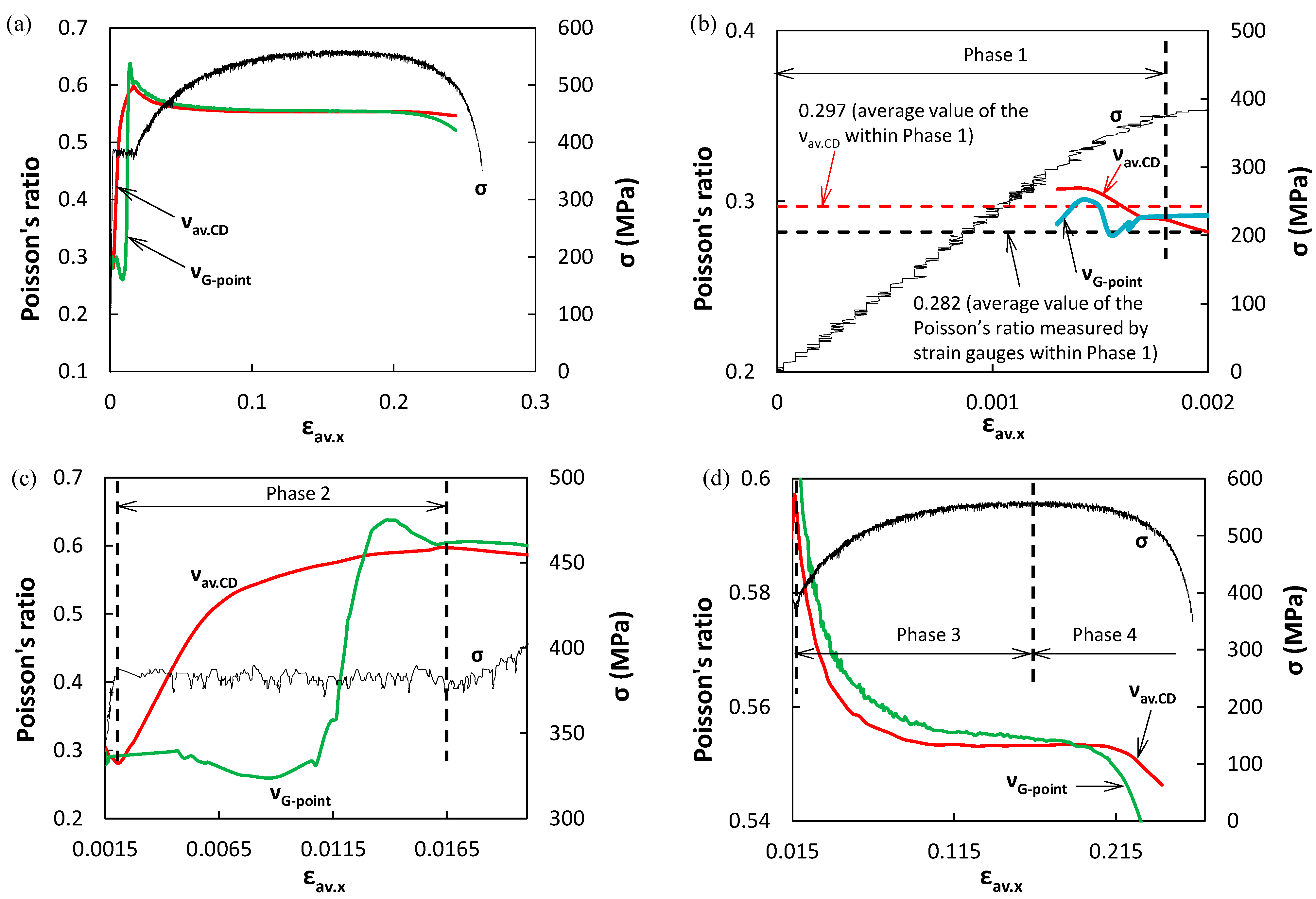

- In Phase 2, deformation is non-uniform, and thus the average ν cannot accurately represent the local value in some regions. The valid range of the average ν and the error between the average ν and the local ν need to be investigated.

- (3)

- A plastic band is a highly localized plastic-strain region, and it is a feature of discontinuous yielding. Its correlation with the ν was unknown.

- (4)

- The factors affecting the ν should be revealed.

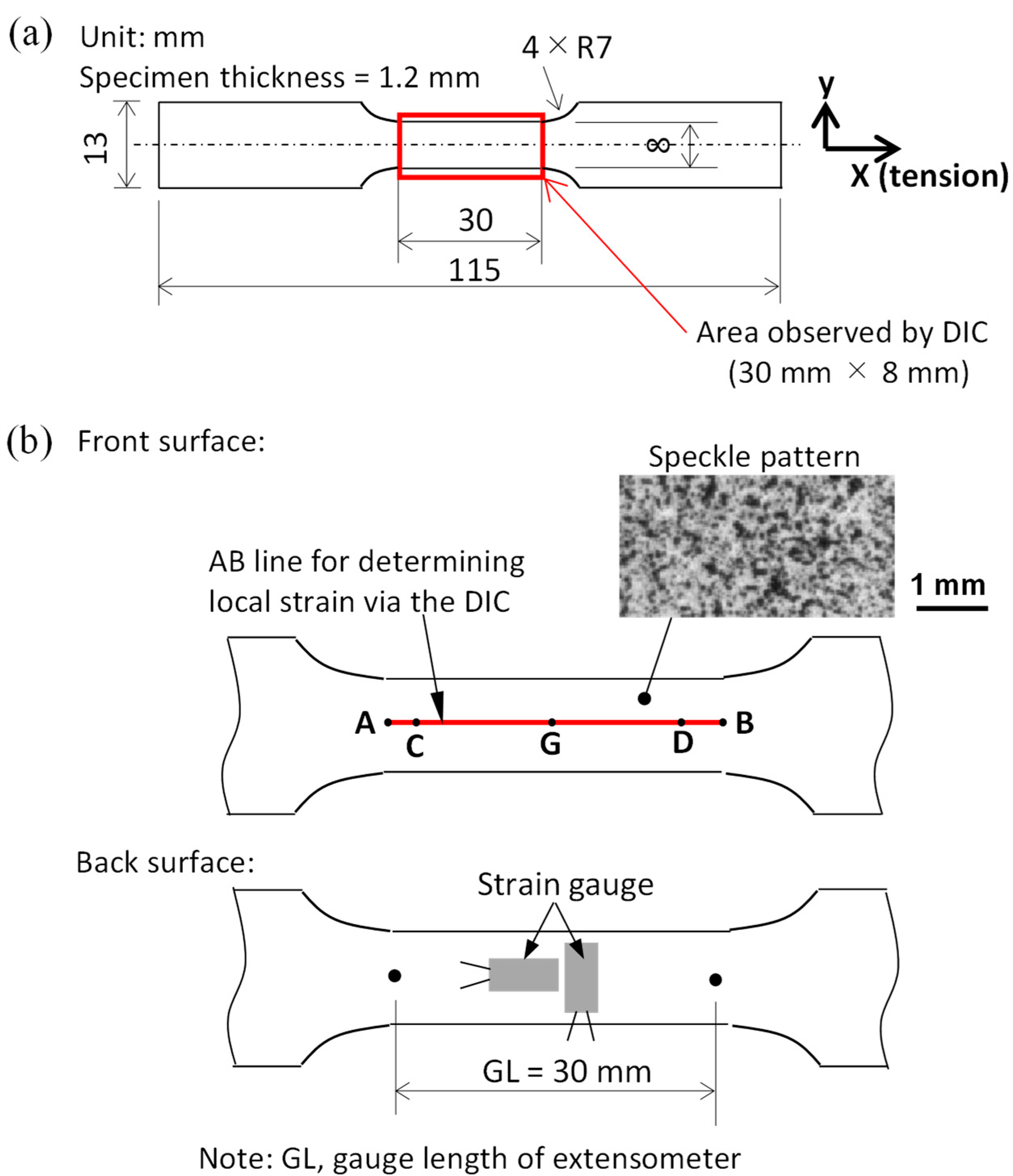

2. Materials and Methods

3. Results and Discussion

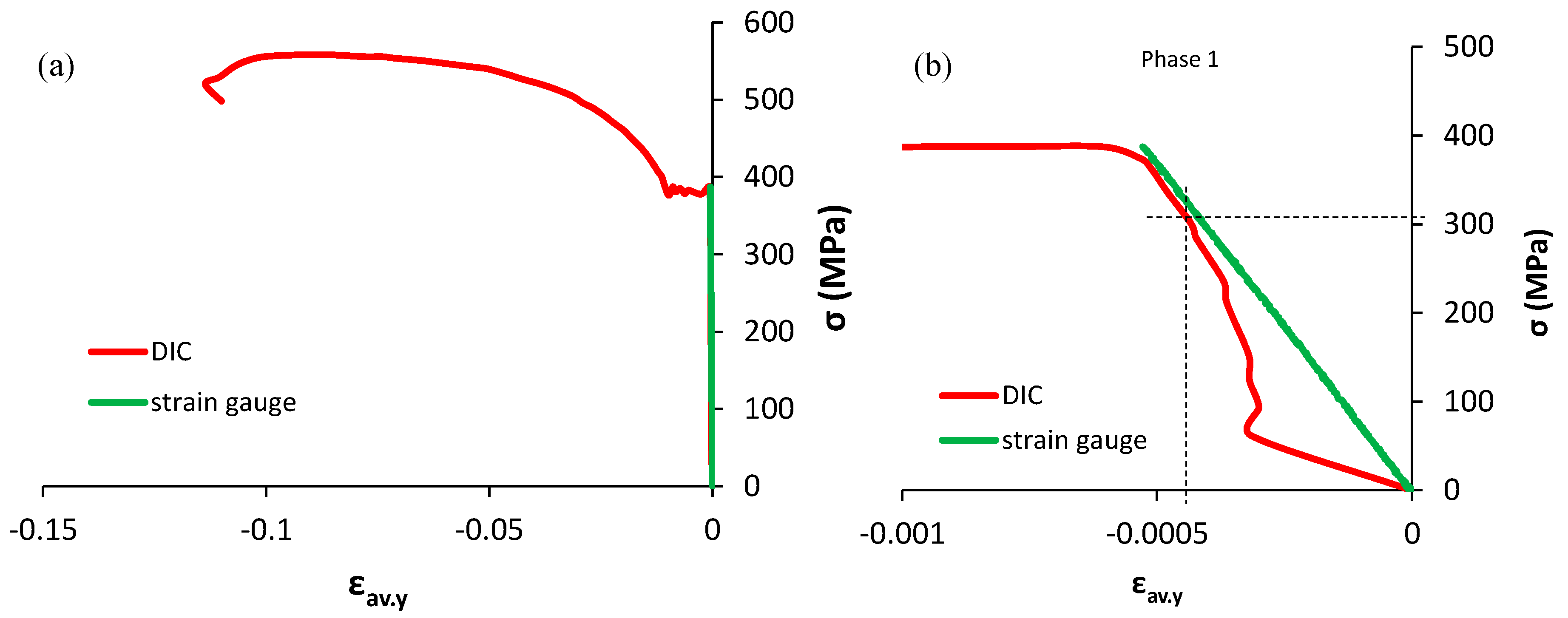

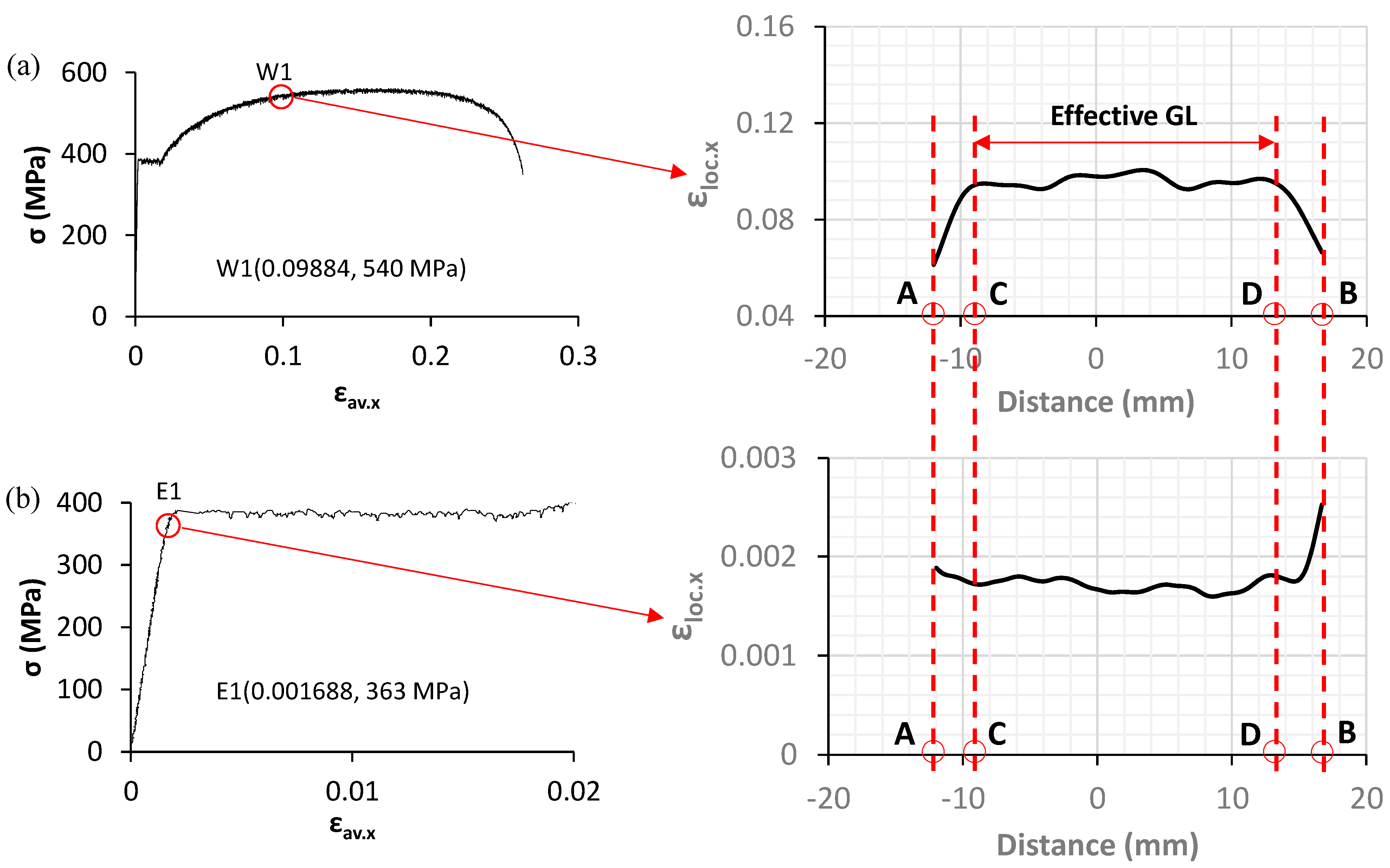

3.1. Longitudinal and Transversal Stress–Strain Curves

3.2. Poisson’s Ratio

- (1)

- The evolution of the ν in the tension process

- (2)

- Interpretation of the characteristic of the ν

3.2.1. The Evolution of the Average ν in the Tension Process

3.2.2. The Evolution of the Local Poisson’s Ratio in the Tension Process

3.2.3. Correlation of the Poisson’s Ratio with the Strain Rate

4. Conclusions

- (1)

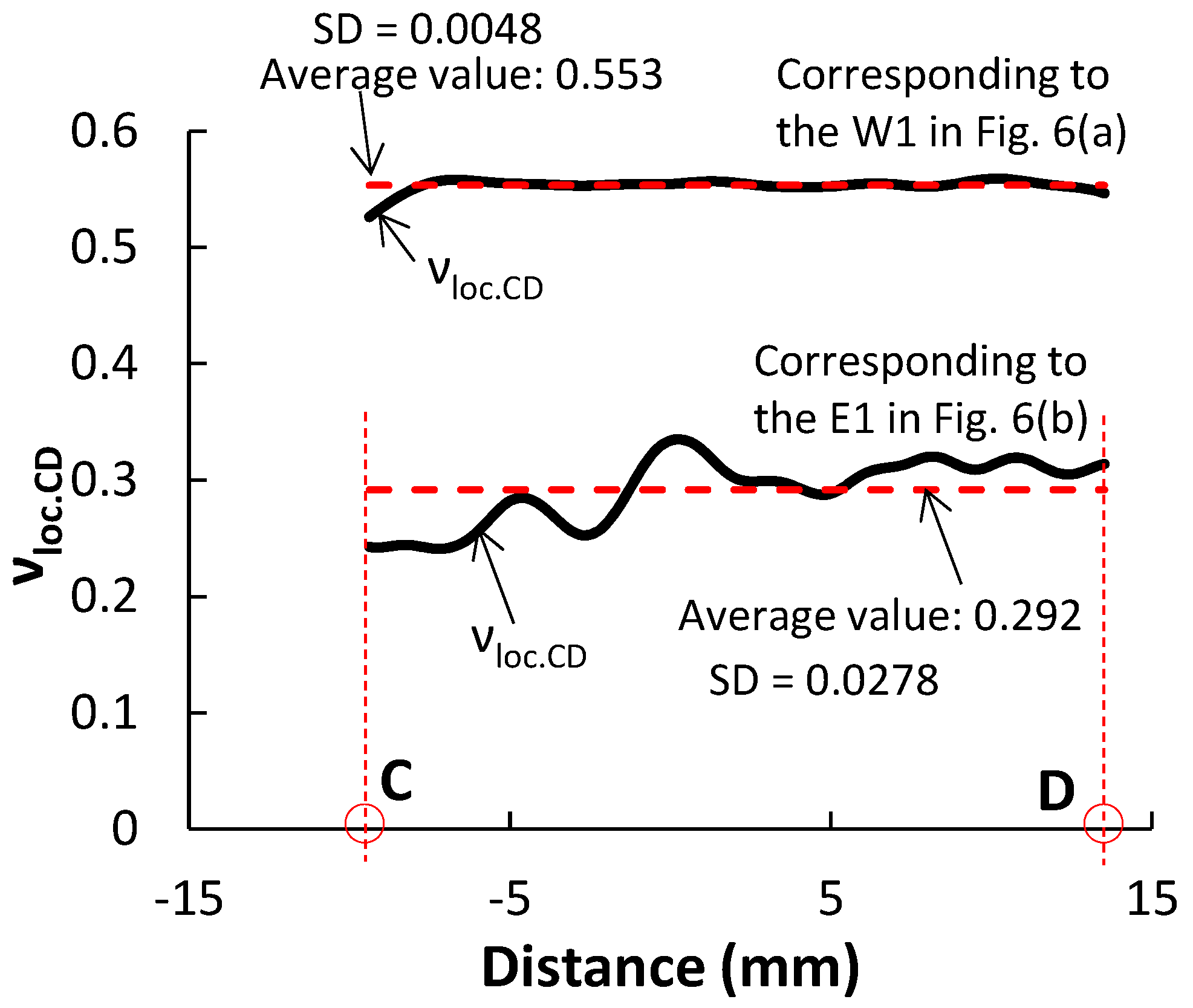

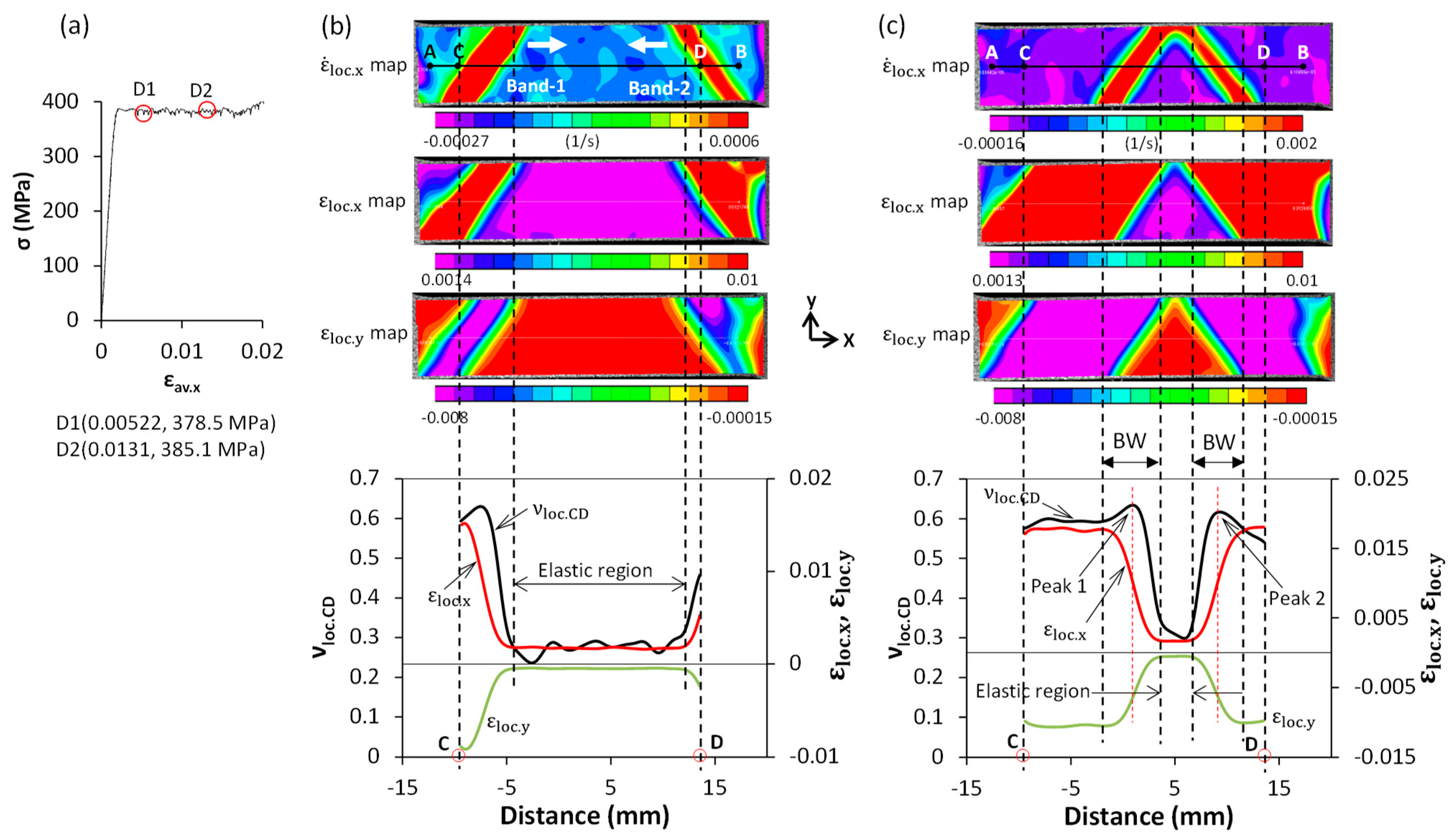

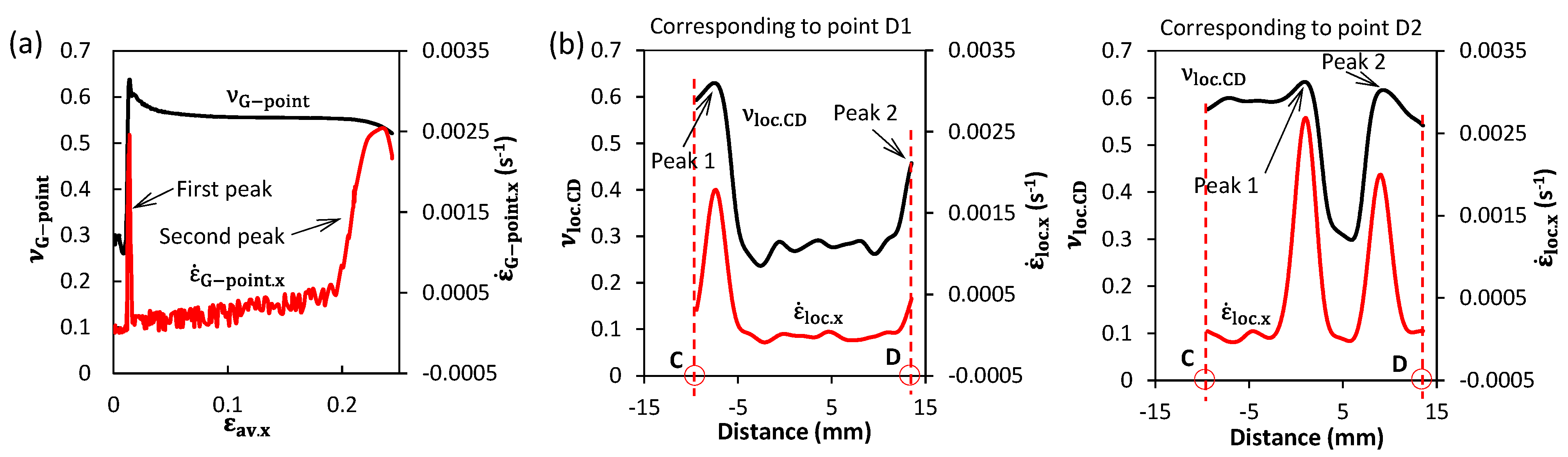

- The distribution of the Poisson’s ratio was generally uniform in the elastic deformation regime and the hard-working regime, but it was non-uniform in the discontinuous-yielding regime. The average Poisson’s ratio was almost identical to the local Poisson’s ratio in the elastic deformation regime and the hard-working regime. In the discontinuous-yielding regime, the average Poisson’s ratio cannot accurately express the local Poisson’s ratio.

- (2)

- The values of the Poisson’s ratio were obtained as follows: 0.28 in the elastic regime; 0.28 to 0.64 in the discontinuous-yielding regime; and 0.55 to 0.59 in the completely plastic deformation regime.

- (3)

- The Poisson’s ratio changed significantly within a moving plastic band in the discontinuous-yielding phase. A high strain rate within the plastic band enhanced the Poisson’s ratio. The maximum local strain rate within the band induced the maximum local Poisson’s ratio.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ashby, M.F.; Jones, D.R.H. Engineering Materials 1, An Introduction to Properties, Applications and Design, 3rd ed.; Elsevier Ltd: London, UK, 2005; p. 35. [Google Scholar]

- Gere, J.M.; Timoshenko, S.P. Mechanics of Materials, 3rd ed.; Chapman & Hall: London, UK, 1991. [Google Scholar]

- Eiriksson, H.J.; Bessason, B.; Unnthorsson, R. Uniaxial and lateral strain behavior of ribbed reinforcement bars inspected with digital image correlation. Struct. Concr. 2018, 19, 1992–2003. [Google Scholar] [CrossRef]

- JIMM (The Japan Institute of Materials and Metals), ISIJ (The Iron and Steel Institute of Japan). Handbook of Steels; Maruzen: Tokyo, Japan, 1967. [Google Scholar]

- Dmitriev, S.V.; Shigenari, T.; Abe, K. Poisson ratio beyond the limits of the elasticity theory. J. Phys. Soc. Jpn. 2001, 70, 1431–1432. [Google Scholar] [CrossRef]

- Zimin, B.A.; Smirnov, I.V.; Sudenkov, Y.V. Behavior of lateral-deformation coefficients during elastoplastic deformation of metals. Mechanics 2017, 62, 306–309. [Google Scholar] [CrossRef]

- Wang, B.R.; Sun, T.; Fezzaa, K.; Huang, J.Y.; Luo, S.N. Rate-dependent deformation and Poisson’s effect in porous titanium. Mater. Letters 2019, 245, 134–137. [Google Scholar] [CrossRef]

- Bhagavathula, K.B.; Meredith, C.S.; Ouellet, S.; Romanyk, D.L.; Hogan, J.D. Density, strain rate and strain effects on mechanical property evolution in polymeric foams. Int. J. Impact Eng. 2022, 161, 104100. [Google Scholar] [CrossRef]

- Filanova, Y.; Hauptmann, J.; Längler, F.; Naumenko, K. Inelastic behavior of polyoxymethylene for wide strain rate and temperature ranges: Constitutive modeling and identification. Materials 2021, 14, 3667. [Google Scholar] [CrossRef]

- Wei, Y.L.; Zao, L.Y.; Yuan, T.; Liu, W. Study on mechanical properties of shale under different loading rates. Front. Earth Sci. 2022, 9, 815616. [Google Scholar] [CrossRef]

- ISIJ (The Iron and Steel Institute of Japan). Handbook of Steels, I. Fundamentals, 3rd ed.; Maruzen: Tokyo, Japan, 1981. [Google Scholar]

- Anderson, T.L. Fracture Mechanics, Fundamentals and Applications, 3rd ed.; Taylor & Francis: London, UK, 2005. [Google Scholar]

- Peters, W.H.; Ranson, W.F. Digital imaging techniques in experimental stress analysis. Opt. Eng. 1982, 21, 427–431. [Google Scholar] [CrossRef]

- Sutton, M.A.; Wolters, W.J.; Peters, W.H.; Ranson, W.F.; McNeill, S.R. Determination of displacements using and improved digital correlation method. Image Vis. Comput. 1983, 1, 133–139. [Google Scholar] [CrossRef]

- Bai, R.X.; Jiang, H.; Lei, Z.K.; Liu, D.; Chen, Y.; Yan, C.; Wang, T.; Chu, Q.L. Virtual field method for identifying elastic-plastic constitutive parameters of aluminum alloy laser welding considering kinematic hardening. Opt. Lasers Eng. 2018, 110, 122–131. [Google Scholar] [CrossRef]

- Qiu, H.; Inoue, T.; Ueji, R. Experimental measurement of the variables of Lüders deformation in hot-rolled steel via digital image correlation. Mater. Sci. Eng. A 2020, 790, 139756. [Google Scholar] [CrossRef]

- Qiu, H.; Inoue, T.; Ueji, R. In-situ observation of Lüders band formation in hot-rolled steel via digital image correlation. Metals 2020, 10, 530. [Google Scholar] [CrossRef]

- Wojciechowski, K.W. Remarks on “Poisson ratio beyond the limits of the elasticity theory”. J. Phys. Soc. Jpn. 2003, 72, 1819–1820. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, H.; Inoue, T. Evolution of Poisson’s Ratio in the Tension Process of Low-Carbon Hot-Rolled Steel with Discontinuous Yielding. Metals 2023, 13, 562. https://doi.org/10.3390/met13030562

Qiu H, Inoue T. Evolution of Poisson’s Ratio in the Tension Process of Low-Carbon Hot-Rolled Steel with Discontinuous Yielding. Metals. 2023; 13(3):562. https://doi.org/10.3390/met13030562

Chicago/Turabian StyleQiu, Hai, and Tadanobu Inoue. 2023. "Evolution of Poisson’s Ratio in the Tension Process of Low-Carbon Hot-Rolled Steel with Discontinuous Yielding" Metals 13, no. 3: 562. https://doi.org/10.3390/met13030562

APA StyleQiu, H., & Inoue, T. (2023). Evolution of Poisson’s Ratio in the Tension Process of Low-Carbon Hot-Rolled Steel with Discontinuous Yielding. Metals, 13(3), 562. https://doi.org/10.3390/met13030562