Effect of Particle Size Distribution on the Printing Quality and Tensile Properties of Ti-6Al-4V Alloy Produced by LPBF Process

Abstract

:1. Introduction

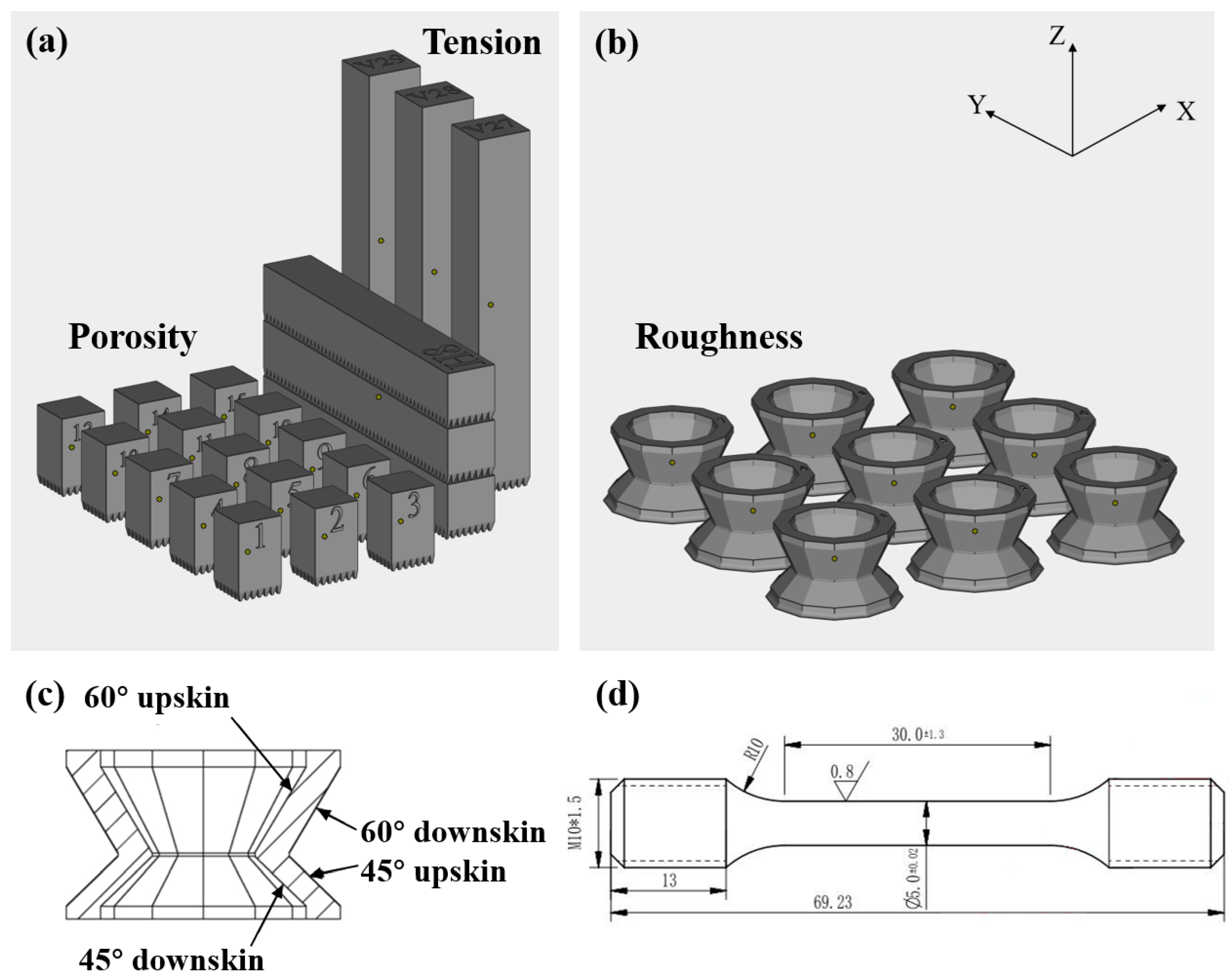

2. Materials and Methods

2.1. Feedstock Powder

2.2. LPBF Process

2.3. Material Characterization

2.4. Tensile Test

3. Results and Discussion

3.1. Flowability

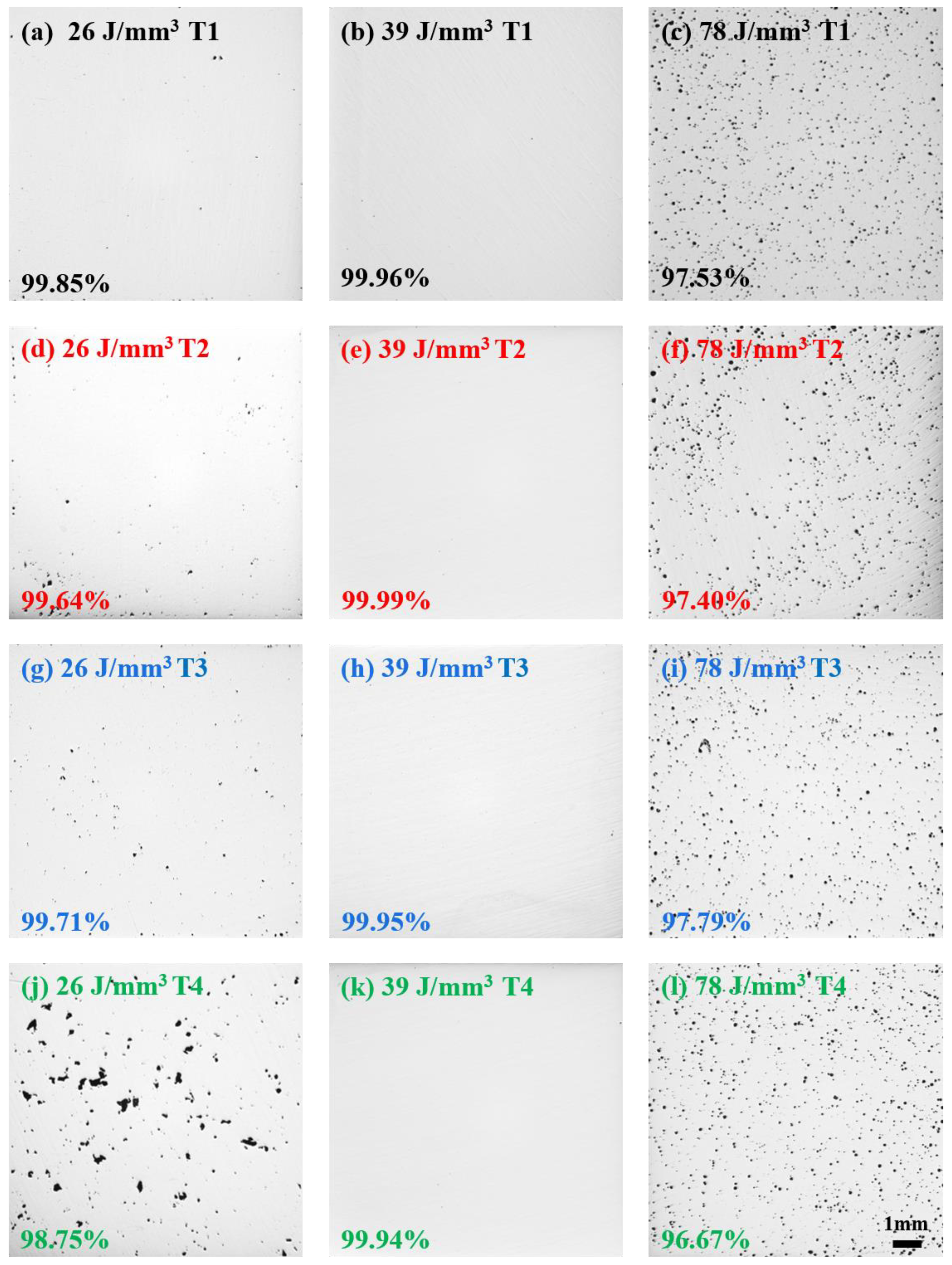

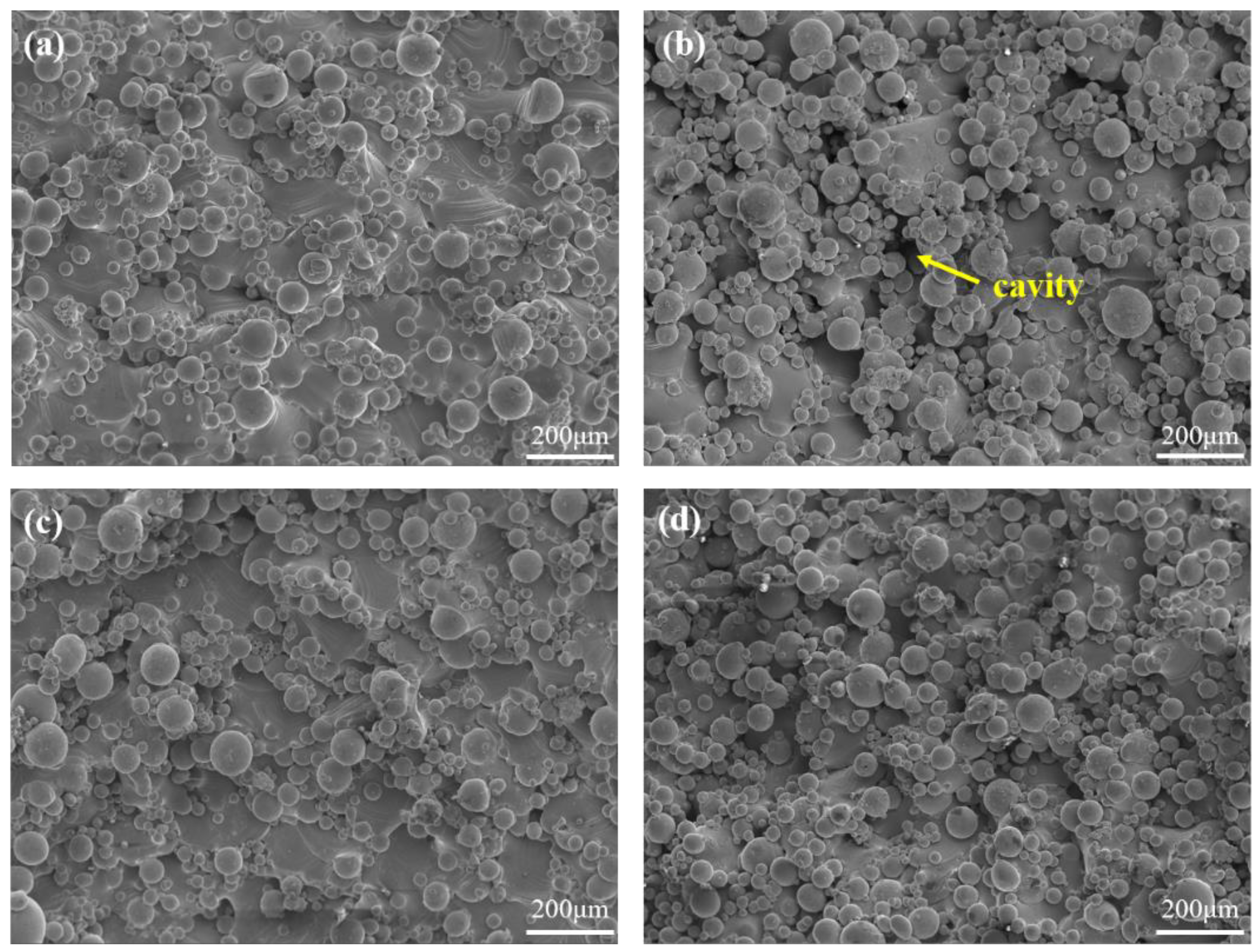

3.2. Relative Density

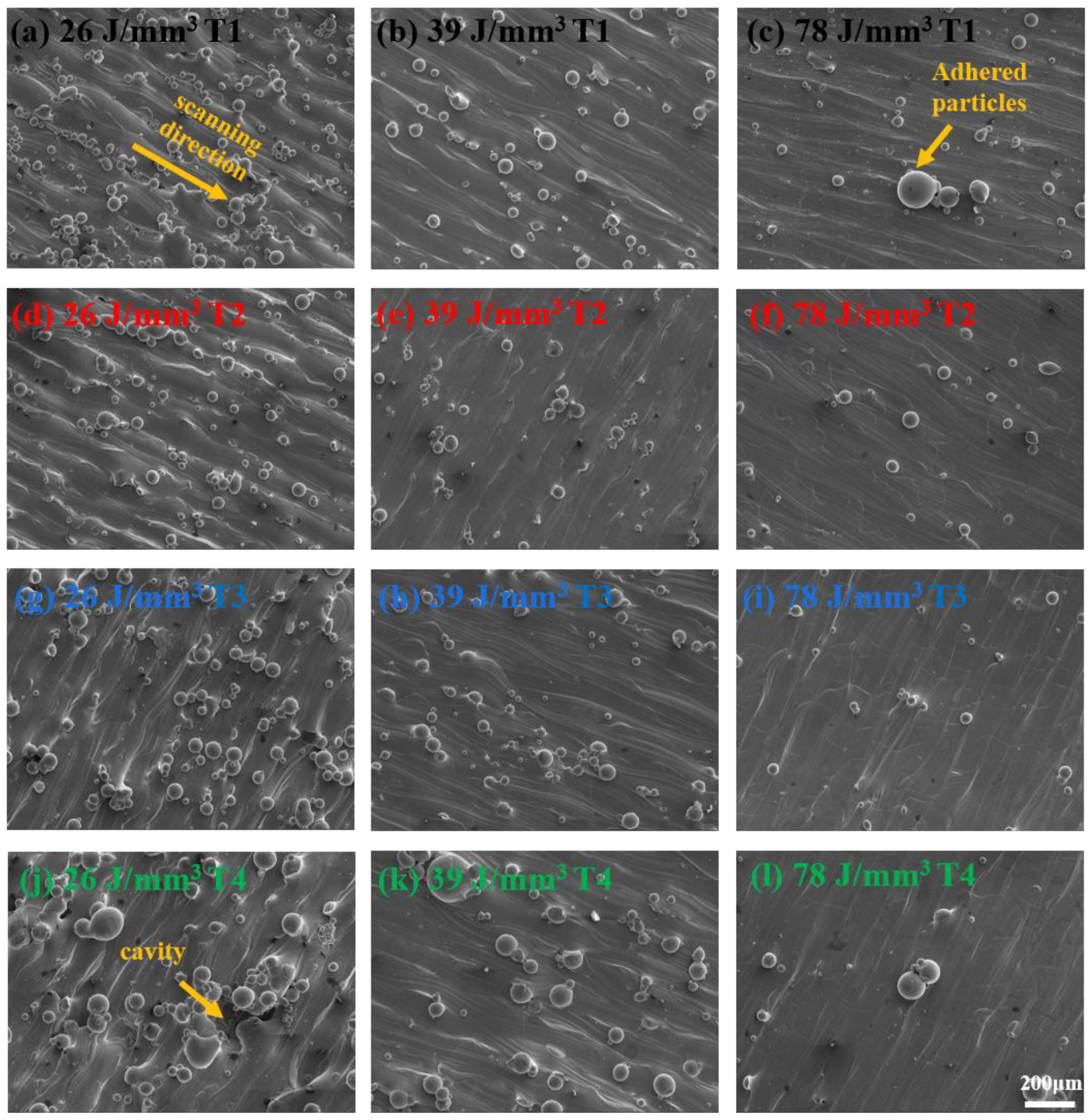

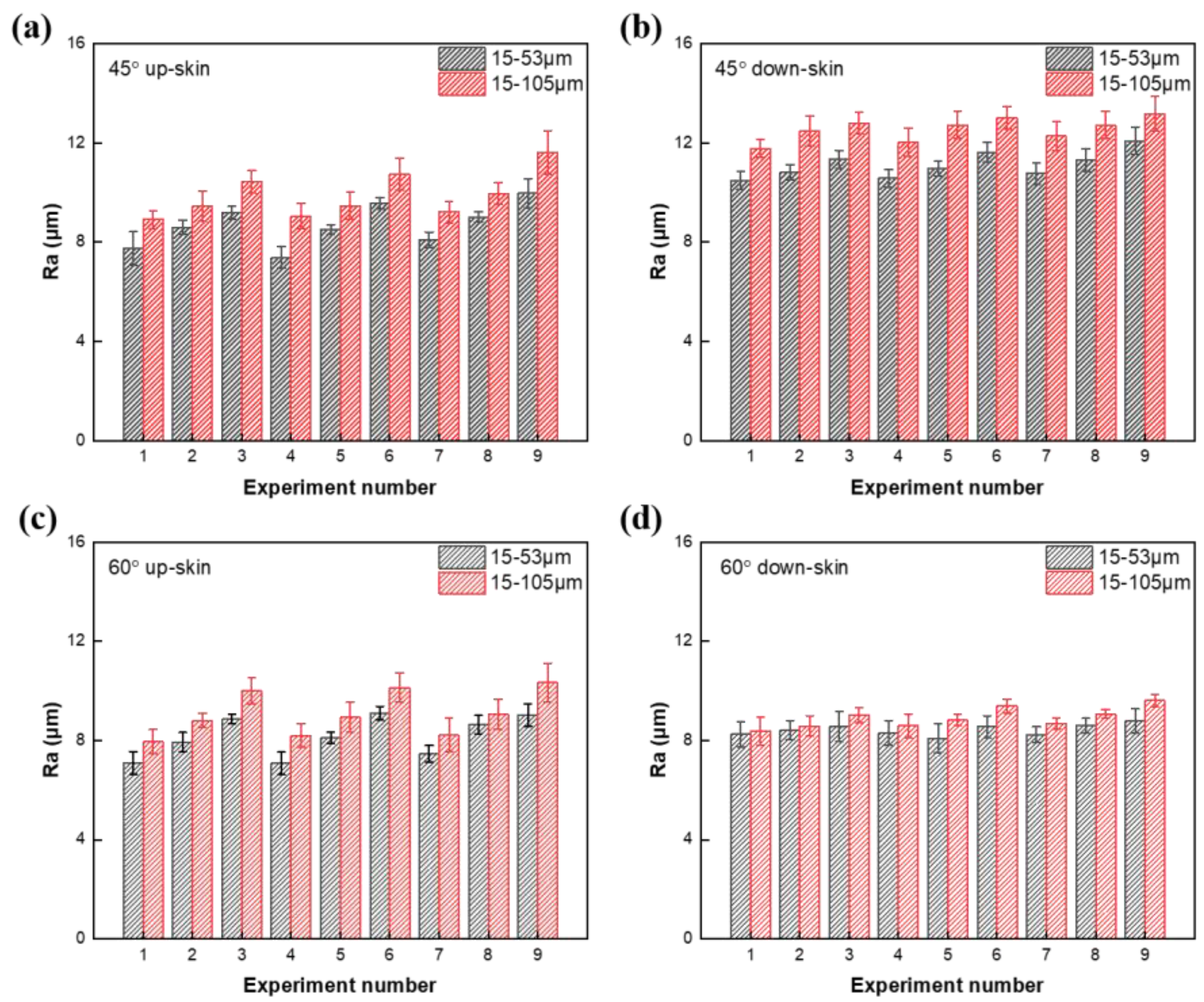

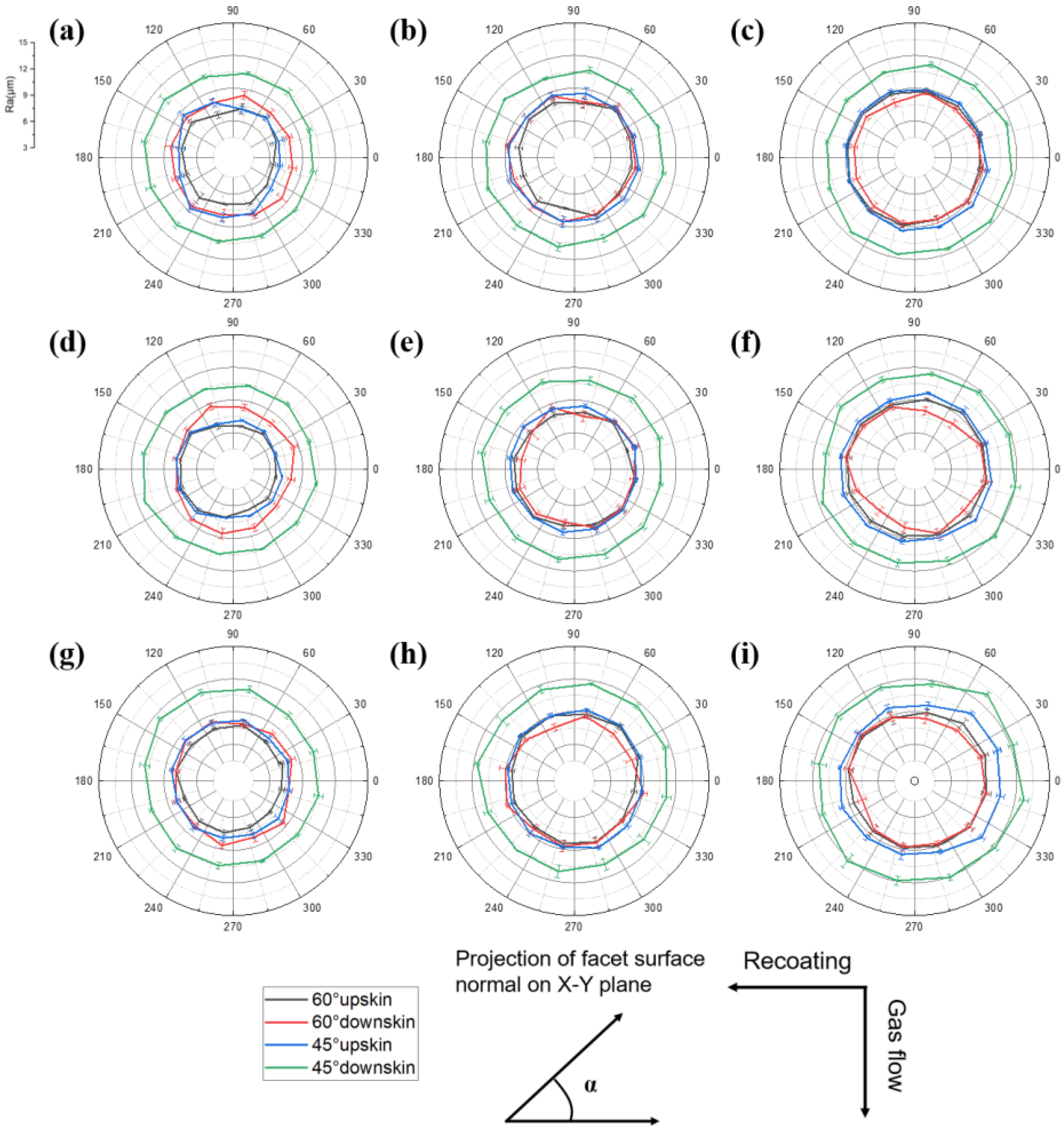

3.3. Surface Roughness

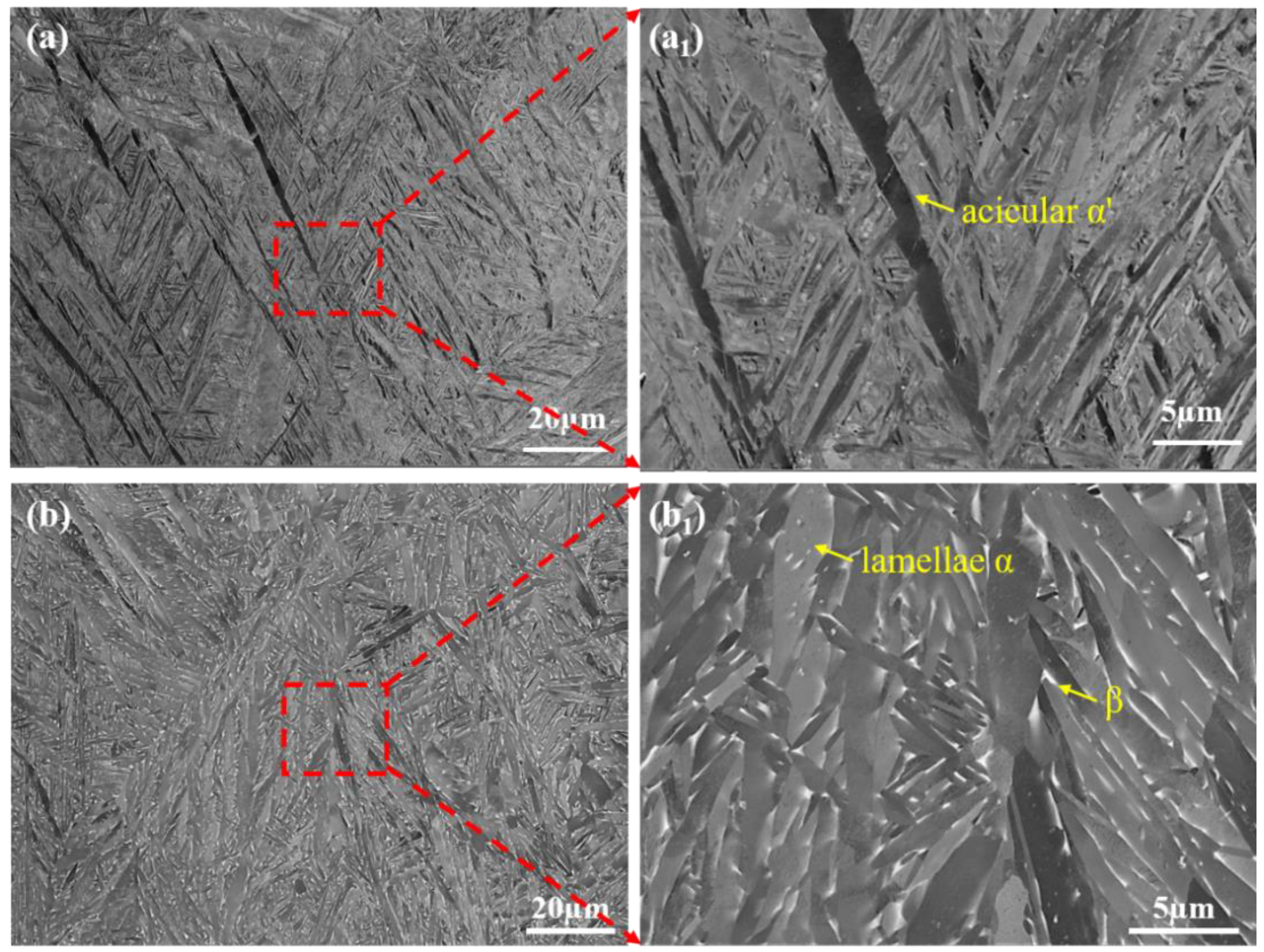

3.4. Microstructural Characterization

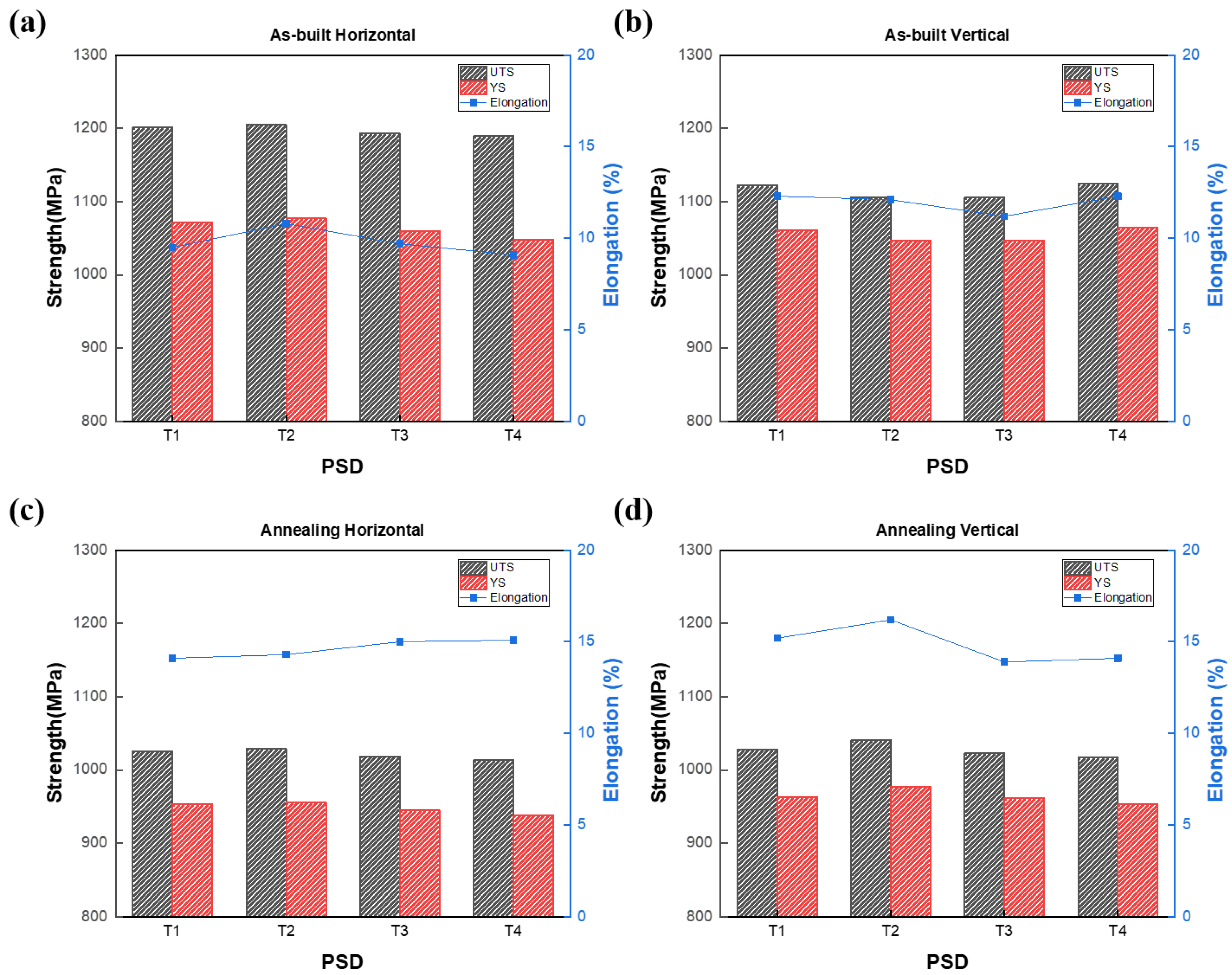

3.5. Mechanical Properties

4. Conclusions

- (1)

- The process window (VED range) that allows for the successful fabrication of fully dense parts using the coarse powders (T4 powder: 15–105 μm) is relatively narrower compared to the other three powders due to the higher laser energy required for completely melting the large particles. Nevertheless, a high density of over 99.9% was still achieved in the VED range of 39–58 J/mm3 at the layer thickness of 60 μm. This suggests that coarser powders can still be used for fabricating dense specimens when the parameters are properly regulated.

- (2)

- Among these fully dense specimens, the surface roughness varies slightly with the variation of VED and PSD. In the case of proper parameter selection, specimens made of coarse powder can still achieve a low surface roughness, which is comparable to the case at layer thickness of 30 μm. The down-skin surface and the lesser formation angle decrease the forming quality due to the step effect.

- (3)

- The fully dense specimens fabricated using four different powders demonstrated comparable tensile properties. The anisotropy in tensile properties of the as-built Ti-6Al-4V can be fully improved by annealing treatment at 800 °C for 2 h. The tensile properties, with UTS > 1000 MPa, YS > 900 MPa, and elongation > 10% in the annealed state, meet the application criteria for industrial production.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2018, 35, 270–284. [Google Scholar] [CrossRef]

- Liu, X.; Hu, R.; Zou, H.; Yang, C.; Luo, X.; Bai, J.; Ma, R. Investigation of cracking mechanism and yield strength associated with scanning strategy for an additively manufactured nickel-based superalloy. J. Alloys Compd. 2023, 938, 168532. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef] [Green Version]

- Mower, T.M.; Long, M.J. Mechanical behavior of additive manufactured, powder-bed laser-fused materials. Mater. Sci. Eng. A 2016, 651, 198–213. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2018, 164, 107552. [Google Scholar] [CrossRef]

- Shipley, H.; McDonnell, D.; Culleton, M.; Coull, R.; Lupoi, R.; O’Donnell, G.; Trimble, D. Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V: A review. Int. J. Mach. Tools Manuf. 2018, 128, 1–20. [Google Scholar] [CrossRef]

- Tan, C.; Weng, F.; Sui, S.; Chew, Y.; Bi, G. Progress and perspectives in laser additive manufacturing of key aeroengine materials. Int. J. Mach. Tools Manuf. 2021, 170, 103804. [Google Scholar] [CrossRef]

- Rovetta, R.; Ginestra, P.; Ferraro, R.M.; Zohar-Hauber, K.; Giliani, S.; Ceretti, E. Building Orientation and Post Processing of Ti6Al4V Produced by Laser Powder Bed Fusion Process. J. Manuf. Mater. Process. 2023, 7, 43. [Google Scholar] [CrossRef]

- Strondl, A.; Lyckfeldt, O.; Brodin, H.; Ackelid, U. Characterization and Control of Powder Properties for Additive Manufacturing. JOM 2015, 67, 549–554. [Google Scholar] [CrossRef]

- Ali, U.; Mahmoodkhani, Y.; Shahabad, S.I.; Esmaeilizadeh, R.; Liravi, F.; Sheydaeian, E.; Huang, K.Y.; Marzbanrad, E.; Vlasea, M.; Toyserkani, E. On the measurement of relative powder-bed compaction density in powder-bed additive manufacturing processes. Mater. Des. 2018, 155, 495–501. [Google Scholar] [CrossRef]

- He, Y.; Hassanpour, A.; Bayly, A.E. Combined effect of particle size and surface cohesiveness on powder spreadability for additive manufacturing. Powder Technol. 2021, 392, 191–203. [Google Scholar] [CrossRef]

- Spierings, A.B.; Levy, G. Comparison of Density of Stainless Steel 316L Parts Produced with Selective Laser Melting Using Different Powder Grades. Solid Free Fabr. Proc. 2009, 342–353. Available online: https://www.icvr.ethz.ch/ConfiguratorJM/publications/Comparison_129067143709656/Spierings__2009____Comparison_of_density_of_316L_parts_produced_with_SLM_using_different_powder_grades.pdf (accessed on 12 February 2023).

- Tan, J.H.; Wong, W.L.E.; Dalgarno, K.W. An overview of powder granulometry on feedstock and part performance in the selective laser melting process. Addit. Manuf. 2017, 18, 228–255. [Google Scholar] [CrossRef] [Green Version]

- Olakanmi, E. Selective laser sintering/melting (SLS/SLM) of pure Al, Al–Mg, and Al–Si powders: Effect of processing conditions and powder properties. J. Mater. Process. Technol. 2013, 213, 1387–1405. [Google Scholar] [CrossRef]

- Yánez, A.; Fiorucci, M.P.; Martel, O.; Cuadrado, A. The Influence of Dimensions and Powder Recycling on the Roughness and Mechanical Properties of Ti-6Al-4V Parts Fabricated by Laser Powder Bed Fusion. Materials 2022, 15, 5787. [Google Scholar] [CrossRef] [PubMed]

- Soltani-Tehrani, A.; Habibnejad-Korayem, M.; Shao, S.; Haghshenas, M.; Shamsaei, N. Ti-6Al-4V powder characteristics in laser powder bed fusion: The effect on tensile and fatigue behavior. Addit. Manuf. 2022, 51, 102584. [Google Scholar] [CrossRef]

- Riener, K.; Albrecht, N.; Ziegelmeier, S.; Ramakrishnan, R.; Haferkamp, L.; Spierings, A.B.; Leichtfried, G.J. Influence of particle size distribution and morphology on the properties of the powder feedstock as well as of AlSi10Mg parts produced by laser powder bed fusion (LPBF). Addit. Manuf. 2020, 34, 101286. [Google Scholar] [CrossRef]

- Balbaa, M.; Ghasemi, A.; Fereiduni, E.; Elbestawi, M.; Jadhav, S.; Kruth, J.-P. Role of powder particle size on laser powder bed fusion processability of AlSi10mg alloy. Addit. Manuf. 2021, 37, 101630. [Google Scholar] [CrossRef]

- Pleass, C.; Jothi, S. Influence of powder characteristics and additive manufacturing process parameters on the microstructure and mechanical behaviour of Inconel 625 fabricated by Selective Laser Melting. Addit. Manuf. 2018, 24, 419–431. [Google Scholar] [CrossRef]

- Spierings, A.; Herres, N.; Levy, G. Influence of the particle size distribution on surface quality and mechanical properties in AM steel parts. Rapid Prototyp. J. 2011, 17, 195–202. [Google Scholar] [CrossRef] [Green Version]

- Gu, H.; Gong, H.; Dilip, J.J.S.; Pal, D.; Hicks, A.; Doak, H.; Stucker, B. Effects of Powder Variation on the Microstructure and Tensile Strength of Ti6Al4V Parts Fabricated by Selective Laser Melting. Solid Free. Fabr. Symp. 2014, 470–483. [Google Scholar]

- Brika, S.E.; Letenneur, M.; Dion, C.A.; Brailovski, V. Influence of particle morphology and size distribution on the powder flowability and laser powder bed fusion manufacturability of Ti-6Al-4V alloy. Addit. Manuf. 2019, 31, 100929. [Google Scholar] [CrossRef]

- Irrinki, H.; Dexter, M.; Barmore, B.; Enneti, R.K.; Pasebani, S.; Badwe, S.; Stitzel, J.; Malhotra, R.; Atre, S.V. Effects of Powder Attributes and Laser Powder Bed Fusion (L-PBF) Process Conditions on the Densification and Mechanical Properties of 17-4 PH Stainless Steel. JOM 2016, 68, 860–868. [Google Scholar] [CrossRef]

- Liu, B.; Wildman, R.; Tuck, C.; Ashcroft, I.; Hague, R. Investigation the effect of particle size distribution on processing parameters optimization in selective laser melting process. SFF 2011, 227–238. [Google Scholar]

- Gullane, A.; Murray, J.W.; Hyde, C.J.; Sankare, S.; Evirgen, A.; Clare, A.T. Failure modes in dual layer thickness Laser Powder Bed Fusion components using a novel post-mortem reconstruction technique. Addit. Manuf. 2022, 59, 103186. [Google Scholar] [CrossRef]

- Gullane, A.; Murray, J.W.; Hyde, C.J.; Sankare, S.; Evirgen, A.; Clare, A.T. On the use of multiple layer thicknesses within laser powder bed fusion and the effect on mechanical properties. Mater. Des. 2021, 212, 110256. [Google Scholar] [CrossRef]

- Pal, S.; Lojen, G.; Kokol, V.; Drstvensek, I. Evolution of metallurgical properties of Ti-6Al-4V alloy fabricated in different energy densities in the Selective Laser Melting technique. J. Manuf. Process. 2018, 35, 538–546. [Google Scholar] [CrossRef]

- Gordon, J.V.; Narra, S.P.; Cunningham, R.W.; Liu, H.; Chen, H.; Suter, R.M.; Beuth, J.L.; Rollett, A.D. Defect structure process maps for laser powder bed fusion additive manufacturing. Addit. Manuf. 2020, 36, 101552. [Google Scholar] [CrossRef]

- Panwisawas, C.; Qiu, C.; Anderson, M.J.; Sovani, Y.; Turner, R.P.; Attallah, M.M.; Brooks, J.W.; Basoalto, H.C. Mesoscale modelling of selective laser melting: Thermal fluid dynamics and microstructural evolution. Comput. Mater. Sci. 2017, 126, 479–490. [Google Scholar] [CrossRef]

- Qiu, C.; Panwisawas, C.; Ward, M.; Basoalto, H.C.; Brooks, J.W.; Attallah, M.M. On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater. 2015, 96, 72–79. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, Q.; Luu, D.; Nai, S.; Zhu, Z.; Chen, Z.; Wei, J. The role of powder layer thickness on the quality of SLM printed parts. Arch. Civ. Mech. Eng. 2018, 18, 948–955. [Google Scholar] [CrossRef]

- Cai, J.; Li, F.; Liu, T.; Chen, B.; He, M. Constitutive equations for elevated temperature flow stress of Ti–6Al–4V alloy considering the effect of strain. Mater. Des. 2011, 32, 1144–1151. [Google Scholar] [CrossRef]

- Min, D.; Shen, J.; Lai, S.; Chen, J.; Xu, N.; Liu, H. Effects of heat input on the low power Nd:YAG pulse laser conduction weldability of magnesium alloy AZ61. Opt. Lasers Eng. 2011, 49, 89–96. [Google Scholar] [CrossRef]

- Jallo, L.J.; Chen, Y.; Bowen, J.; Etzler, F.; Dave, R. Prediction of Inter-particle Adhesion Force from Surface Energy and Surface Roughness. J. Adhes. Sci. Technol. 2012, 25, 367–384. [Google Scholar] [CrossRef]

- Baesso, I.; Karl, D.; Spitzer, A.; Gurlo, A.; Günster, J.; Zocca, A. Characterization of powder flow behavior for additive manufacturing. Addit. Manuf. 2021, 47, 102250. [Google Scholar] [CrossRef]

- Kalman, H. Quantification of mechanisms governing the angle of repose, angle of tilting, and Hausner ratio to estimate the flowability of particulate materials. Powder Technol. 2021, 382, 573–593. [Google Scholar] [CrossRef]

- Wang, D.; Wu, S.; Fu, F.; Mai, S.; Yang, Y.; Liu, Y.; Song, C. Mechanisms and characteristics of spatter generation in SLM processing and its effect on the properties. Mater. Des. 2017, 117, 121–130. [Google Scholar] [CrossRef]

- Wang, S.; Ning, J.; Zhu, L.; Yang, Z.; Yan, W.; Dun, Y.; Xue, P.; Xu, P.; Bose, S.; Bandyopadhyay, A. Role of porosity defects in metal 3D printing: Formation mechanisms, impacts on properties and mitigation strategies. Mater. Today 2022, 59, 133–160. [Google Scholar] [CrossRef]

- Bustillos, J.; Kim, J.; Moridi, A. Exploiting lack of fusion defects for microstructural engineering in additive manufacturing. Addit. Manuf. 2021, 48, 102399. [Google Scholar] [CrossRef]

- Huang, Y.; Fleming, T.G.; Clark, S.J.; Marussi, S.; Fezzaa, K.; Thiyagalingam, J.; Leung, C.L.A.; Lee, P.D. Keyhole fluctuation and pore formation mechanisms during laser powder bed fusion additive manufacturing. Nat. Commun. 2022, 13, 1170. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, X.; Tomus, D.; Davies, C.H. Surface roughness of Selective Laser Melted Ti-6Al-4V alloy components. Addit. Manuf. 2018, 21, 91–103. [Google Scholar] [CrossRef]

- Abele, E.; Kniepkamp, M. Analysis and optimisation of vertical surface roughness in micro selective laser melting. Surf. Topogr. Metrol. Prop. 2015, 3, 34007. [Google Scholar] [CrossRef]

- Strano, G.; Hao, L.; Everson, R.M.; Evans, K.E. Surface roughness analysis, modelling and prediction in selective laser melting. J. Mater. Process. Technol. 2013, 213, 589–597. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, X.; Davies, C.H. Process variation in Laser Powder Bed Fusion of Ti-6Al-4V. Addit. Manuf. 2021, 41, 101987. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Kovalev, E.P. Model of thermal conductivity in powder beds. Phys. Rev. B 2009, 80, 024202. [Google Scholar] [CrossRef]

- Wang, D.; Yang, Y.; Yi, Z.; Su, X. Research on the fabricating quality optimization of the overhanging surface in SLM process. Int. J. Adv. Manuf. Technol. 2012, 65, 1471–1484. [Google Scholar] [CrossRef]

- Ilin, A.; Logvinov, R.; Kulikov, A.; Prihodovsky, A.; Xu, H.; Ploshikhin, V.; Günther, B.; Bechmann, F. Computer Aided Optimisation of the Thermal Management During Laser Beam Melting Process. Phys. Procedia 2014, 56, 390–399. [Google Scholar] [CrossRef] [Green Version]

- Huang, W.; He, D.; Wang, H.; Qin, S.; Wang, L.; Xu, X. The Effect of Heat Treatment on the Anisotropy of Ti-6Al-4V by Selective Laser Melting. JOM 2022, 74, 2724–2732. [Google Scholar] [CrossRef]

- Xu, W.; Brandt, M.; Sun, S.; Elambasseril, J.; Liu, Q.; Latham, K.; Xia, K.; Qian, M. Additive manufacturing of strong and ductile Ti–6Al–4V by selective laser melting via in situ martensite decomposition. Acta Mater. 2014, 85, 74–84. [Google Scholar] [CrossRef]

- Wang, H.; Chao, Q.; Chen, H.; Chen, Z.; Primig, S.; Xu, W.; Ringer, S.; Liao, X. Formation of a transition V-rich structure during the α’ to α + β phase transformation process in additively manufactured Ti-6Al-4 V. Acta Mater. 2022, 235, 118104. [Google Scholar] [CrossRef]

- Sun, S.; Zhang, D.; Palanisamy, S.; Liu, Q.; Dargusch, M.S. Mechanical properties and deformation mechanisms of martensitic Ti6Al4V alloy processed by laser powder bed fusion and water quenching. Mater. Sci. Eng. A 2022, 839, 142817. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting. Mater. Des. 2016, 108, 308–318. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Wang, Y.N.; Huang, J.C. Texture analysis in hexagonal materials. Mater. Chem. Phys. 2003, 81, 11–26. [Google Scholar] [CrossRef]

- Ren, S.; Chen, Y.; Liu, T.; Qu, X. Effect of Build Orientation on Mechanical Properties and Microstructure of Ti-6Al-4V Manufactured by Selective Laser Melting. Met. Mater. Trans. A 2019, 50, 4388–4409. [Google Scholar] [CrossRef]

- Matsumoto, H.; Yoneda, H.; Sato, K.; Kurosu, S.; Maire, E.; Fabregue, D.; Konno, T.J.; Chiba, A. Room-temperature ductility of Ti–6Al–4V alloy with α′ martensite microstructure. Mater. Sci. Eng. A 2010, 528, 1512–1520. [Google Scholar] [CrossRef]

- Chao, Q.; Cizek, P.; Wang, J.; Hodgson, P.D.; Beladi, H. Enhanced mechanical response of an ultrafine grained Ti–6Al–4V alloy produced through warm symmetric and asymmetric rolling. Mater. Sci. Eng. A 2016, 650, 404–413. [Google Scholar] [CrossRef]

| Manufacturing Parameters | Values | |

|---|---|---|

| Laser power/W | 200–400 | 280 |

| Scanning speed/mm·s−1 | 1200 | 600–1800 |

| VED/J·mm−3 | 27.8–55.6 | 77.8–25.9 |

| Specimens | Laser Power (W) | Scanning Speed (mmꞏs−1) | VED (J·mm−3) |

|---|---|---|---|

| 1 | 320 | 900 | 59.3 |

| 2 | 320 | 1200 | 44.4 |

| 3 | 320 | 1500 | 35.6 |

| 4 | 280 | 900 | 51.9 |

| 5 | 280 | 1200 | 38.9 |

| 6 | 280 | 1500 | 31.1 |

| 7 | 240 | 900 | 44.4 |

| 8 | 240 | 1200 | 33.3 |

| 9 | 240 | 1500 | 26.7 |

| Types | Average Particle Diameter (μm) | Fluidity (s/50g) | Apparent Density (g/cm3) | Tap Density (g/cm3) | Hausner Ratio |

|---|---|---|---|---|---|

| T1 | 33 | 36.72 | 2.30 | 2.86 | 1.243 |

| T2 | 35 | 34.29 | 2.30 | 2.84 | 1.235 |

| T3 | 45 | 29.94 | 2.32 | 2.84 | 1.224 |

| T4 | 59 | 24.30 | 2.41 | 2.92 | 1.211 |

| Sample | UTS (MPa) | YS (MPa) | Elongation (%) | |

|---|---|---|---|---|

| As-built Horizontal | T1 | 1201 | 1072 | 9.5 |

| T2 | 1206 | 1077 | 10.8 | |

| T3 | 1193 | 1060 | 9.7 | |

| T4 | 1189 | 1048 | 9.1 | |

| As-built Vertical | T1 | 1122 | 1062 | 12.3 |

| T2 | 1106 | 1047 | 12.1 | |

| T3 | 1106 | 1047 | 11.2 | |

| T4 | 1124 | 1064 | 12.3 | |

| Annealing Horizontal | T1 | 1026 | 953 | 14.1 |

| T2 | 1029 | 956 | 14.3 | |

| T3 | 1019 | 945 | 15.0 | |

| T4 | 1014 | 938 | 15.1 | |

| Annealing Vertical | T1 | 1028 | 963 | 15.2 |

| T2 | 1041 | 978 | 16.2 | |

| T3 | 1023 | 961 | 13.9 | |

| T4 | 1017 | 954 | 14.1 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, M.; Chen, X.; Ji, X.; Xie, X.; Chao, Q.; Fan, G. Effect of Particle Size Distribution on the Printing Quality and Tensile Properties of Ti-6Al-4V Alloy Produced by LPBF Process. Metals 2023, 13, 604. https://doi.org/10.3390/met13030604

Xue M, Chen X, Ji X, Xie X, Chao Q, Fan G. Effect of Particle Size Distribution on the Printing Quality and Tensile Properties of Ti-6Al-4V Alloy Produced by LPBF Process. Metals. 2023; 13(3):604. https://doi.org/10.3390/met13030604

Chicago/Turabian StyleXue, Muhan, Xinyue Chen, Xia Ji, Xinliang Xie, Qi Chao, and Guohua Fan. 2023. "Effect of Particle Size Distribution on the Printing Quality and Tensile Properties of Ti-6Al-4V Alloy Produced by LPBF Process" Metals 13, no. 3: 604. https://doi.org/10.3390/met13030604