Effect of Process Parameters on Spinning Force and Forming Quality of Deep Cylinder Parts in Multi-Pass Spinning Process

Abstract

:1. Introduction

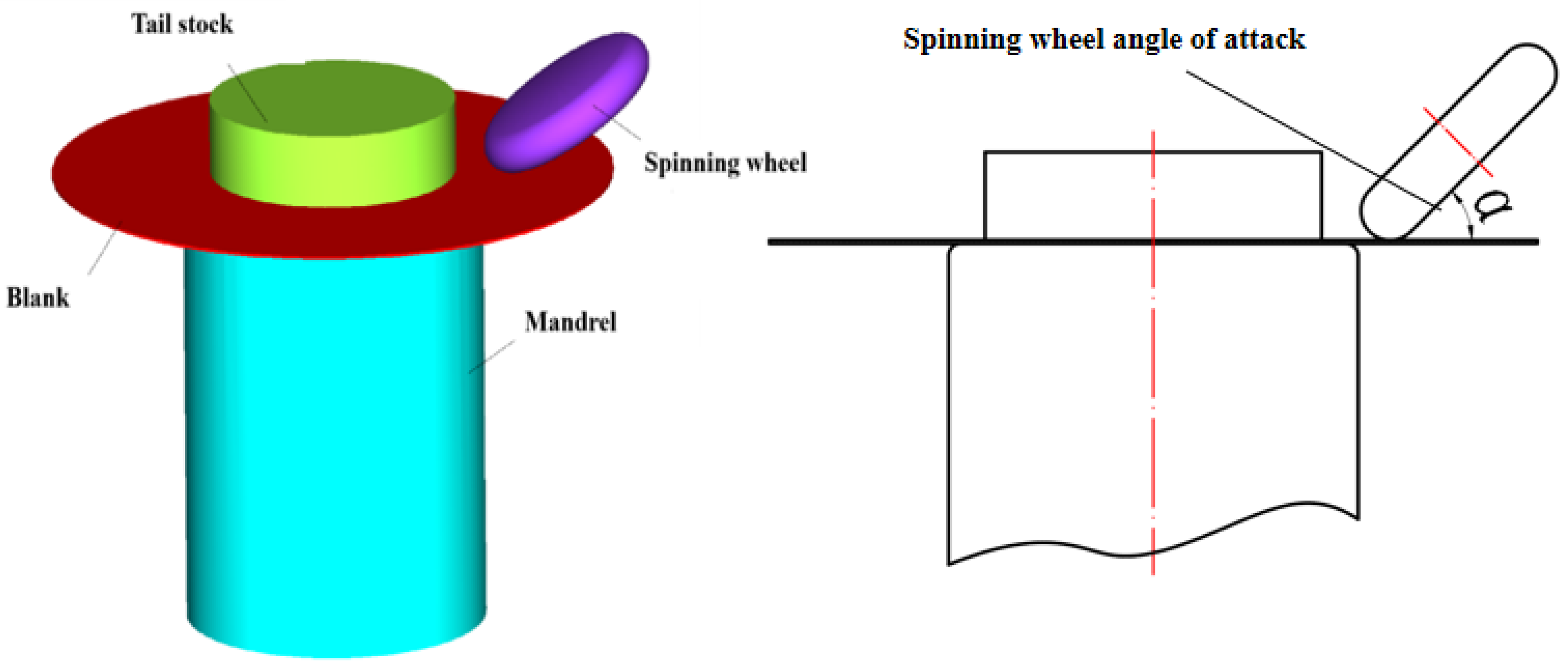

2. Finite Element Model and Feasibility Analysis of Deep Cylinder Spinning

2.1. Model

2.2. Feasibility and Verification of the Model

3. Simulation Results and Analysis

3.1. Effect of Process Parameters on Spinning Force

3.1.1. Mandrel Speed

3.1.2. Feed Rate

3.1.3. Spinning Wheel Fillet Radius

3.1.4. Wheel Installation Angle

3.1.5. Instability and Wrinkling Phenomenon

3.2. Effect of Process Parameters on Wall Thickness Deviation

4. Conclusions

- (1)

- Under the influence of different process parameters and different levels, the radial spinning force and the tangential spinning force maintain the same trend. When the mandrel speed, feed rate, roller fillet radius and spinning wheel angle of attack are 500 rpm, 1 mm/rev, 6 mm and 35°, respectively, the radial spinning force and the tangential spinning force are the smallest. At this time, the spinning efficiency is the highest and the workpiece is not prone to defects. If the single-pass reduction is too large, the workpiece is prone to instability and wrinkling. A reasonable reduction will increase the stability of spinning.

- (2)

- The wall thickness deviation of the workpiece decreases with the increase in the mandrel speed. With the increase in the feed rate, the wall thickness deviation increases first and then decreases. With the increase in the roller fillet radius, the wall thickness deviation increases first and then decreases. With the increase in the spinning wheel angle of attack, the wall thickness deviation increases first and then decreases. When spinning with the process parameters obtained under the minimum spinning force of Conclusion 1, the wall thickness deviation of the workpiece is also small, indicating that the wall thickness deviation of the workpiece is closely related to the spinning force.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, Y. Simulation Study on Power Spinning Dynamics of Cylindrical Parts; Changchun University of Science and Technology: Changchun, China, 2014. [Google Scholar]

- Lu, L. Numerical Simulation of Spinning Forming of Elliptical Tube Shaped Parts based on Deform. Mod. Manuf. Technol. Equip. 2016, 8, 53–55+82. [Google Scholar]

- Lu, Y.L.; Wang, H.Q. Numerical Simulation on Spinning Manufacturing for 1060 Aluminum Alloy Cylinder Part. Mach. Tool Hydraul. 2018, 46, 39–42. [Google Scholar]

- Wang, X.X.; Zhan, M.; Guo, J.; Zhao, B. Evaluating the Applicability of GTN Damage Model in Forward Tube Spinning of Aluminum Alloy. Metals 2016, 6, 136. [Google Scholar] [CrossRef] [Green Version]

- Shi, L.; Xiao, H.; Xia, Q.X. Study on Forming Mechanism of DP600 High Strength Steel Multi-pass Deep Drawing Spinning. In Proceedings of the 11th China Iron and Steel Annual Conference, Beijing, China, 21–22 September 2017; pp. 48–53. [Google Scholar]

- Li, F.G.; Yuan, X.; Hao, X.H.; Liu, T.; Wang, M.J. Influence of the number of power spinning wheels on forming quality for cylindrical parts based on Simufact. Forg. Stamp. Technol. 2019, 44, 86–91. [Google Scholar]

- Zeng, C.; Zhang, S.J.; Xia, Q.X.; Xie, H.X. Research on effect of roller-races and process parameters on multi-pass drawing spinning quality. Forg. Stamp. Technol. 2014, 39, 58–63. [Google Scholar]

- Mei, Y.; Liu, B.; Niu, Z.B.; Zhang, C. Analysis of Forward Spinning for Aluminium Alloy Tube. Adv. Mater. Res. 2011, 1336, 295–297. [Google Scholar] [CrossRef]

- Zhang, T.; Li, X.H.; Wei, Z.; Chang, S.W. Influence of process parameters on the flow forming quality of thin-walled tube with large diameter-thickness ratio. J. Plast. Eng. 2017, 24, 75–81. [Google Scholar]

- Zhang, H.P.; Ouyang, Z.G.; Li, L.; Ma, W.; Liu, Y.; Chen, F.H.; Xiao, X.H. Numerical Study on Welding Residual Stress Distribution of Corrugated Steel Webs. Metals 2022, 12, 1831. [Google Scholar] [CrossRef]

- Ma, Z.P.; Li, Y.; Sun, C.G.; Yu, D.T.; Hu, J.Z. Influence analysis of conventional spinning pass curve on forming. Forg. Stamp. Technol. 1999, 24, 21–24. [Google Scholar]

- Pan, G.J.; Li, Y.; Wang, J.; Lu, G.D. Review of conventional spinning process and its roller path design development. J. Zhejiang Univ. 2015, 49, 644–654. [Google Scholar]

- Li, X.B.; Han, Z.R.; Gao, T.J.; Liu, B.M.; Jia, Z. Finite element simulation of multi-pass spinning forming oflargecomplex thin-wall cylinder. J. Shenyang Aerosp. Univ. 2016, 33, 32–37. [Google Scholar]

- Wang, L.; Long, H. A study of effects of roller path profiles on tool forces and part wall thickness variation in conventional metal spinning. J. Mater. Process. Technol. 2011, 211, 2140–2151. [Google Scholar] [CrossRef]

- Chen, J.; Wan, M.; Li, W.D.; Xu, C.X.; Xu, X.D.; Huang, Z.B. Design of the involute trace of multi-pass conventional spinning and application in numerical simulation. J. Plast. Eng. 2008, 15, 53–57. [Google Scholar]

- He, J.C.; Zhu, S.P.; Luo, C.; Niu, X.; Wang, Q. Size effect in fatigue modelling of defective materials: Application of the calibrated weakest-link theory. Int. J. Fatigue 2022, 165, 107213. [Google Scholar] [CrossRef]

- Liang, L.; Xu, M.; Chen, Y.; Zhang, T.; Tong, W.; Liu, H.; Wang, H.; Li, H. Effect of welding thermal treatment on the microstructure and mechanical properties of nickel-based superalloy fabricated by selective laser melting. Mater. Sci. Eng. A 2021, 819, 141507. [Google Scholar] [CrossRef]

- Han, Z.R.; Li, L.; Xiao, Y.; Jia, Z. Effect of feed rate on wall thickness distribution in multi-pass deep drawing spinning. Light Alloy. Fabr. Technol. 2019, 47, 67–71. [Google Scholar]

- He, Q.Z.; Li, H.; Zhao, L.D. Research on dimensional accuracy of multi-step ironing based on Simufact. Forg. Stamp. Technol. 2018, 43, 108–112. [Google Scholar]

- Li, X.M.; Xiao, S.H. Experimental research on one-step drawing and spinning of thin-walled cup. Die Mould. Ind. 2014, 40, 46–50. [Google Scholar]

- Ebrahimi, M.; Tabei, K.H.; Naseri, R.; Djavanroodi, F. Effect of flow-forming parameters on surface quality, geometrical precision and mechanical properties of titanium tube. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2018, 232, 702–708. [Google Scholar] [CrossRef]

- Molladavoudi, H.R.; Djavanroodi, F. Experimental study of thickness reduction effects on mechanical properties and spinning accuracy of aluminum 7075 during flow forming. The Int. J. Adv. Manuf. Technol. 2011, 52, 949–957. [Google Scholar] [CrossRef]

- Wang, D.L.; Guo, Y.M.; Li, Y.N.; Huang, T.; Gao, W.L.; Zheng, H.W.; Xu, H.Q. Numerical simulation and forming precision analysis on counter-roller spinning for large thin-walled cylindrical parts. Forg. Stamp. Technol. 2020, 45, 47–55. [Google Scholar]

- Dahms, F.; Homberg, W. Manufacture of Defined Residual Stress Distributions in the Friction-Spinning Process. Investigations and Run-to-Run Predictive Control. Metals 2022, 12, 158. [Google Scholar] [CrossRef]

- Du, F.; Xia, Q.X.; Xiao, H.; Shi, L. Analysis on forming quality of high strength steel DP600 cup-shaped part during single-pass deep drawing spinning. Forg. Stamp. Technol. 2017, 42, 54–59. [Google Scholar]

- Gao, S.; Zhao, J.S.; Li, Z.W.; Gao, C.; Li, X.C.; Xie, R. Study on forming accuracy of hot power spinning connecting rod bushing based on Simufact. J. Plast. Eng. 2020, 27, 40–47. [Google Scholar]

- Tang, C.Y.; Fan, W.X.; Yin, X.Y. Forming quality study of power backspinning connecting rod bushing under different rotating wheel parameters based on Simufact. J. Plast. Eng. 2018, 25, 102–107. [Google Scholar]

| Parameters | Young’s Modulus (E/GPa) (20 °C) | Poisson’s Ratio | Yield Strength σ (MPa) | Density ρ (Kg·mm−3) |

|---|---|---|---|---|

| Number | 69 | 0.25 | 130.111 | 2725 |

| Parameters | Mandrel Speed (rpm) | Feed Rate (f) (mm/rev) | The Spinning Wheel Angle of Attack (°) | The Fillet Radius of the Spinning Wheel (mm) |

|---|---|---|---|---|

| Number | 300 | 3 | 30° | 9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Chen, S.; Lu, Q.; Shu, X.; Zhang, J.; Shen, W. Effect of Process Parameters on Spinning Force and Forming Quality of Deep Cylinder Parts in Multi-Pass Spinning Process. Metals 2023, 13, 620. https://doi.org/10.3390/met13030620

Li L, Chen S, Lu Q, Shu X, Zhang J, Shen W. Effect of Process Parameters on Spinning Force and Forming Quality of Deep Cylinder Parts in Multi-Pass Spinning Process. Metals. 2023; 13(3):620. https://doi.org/10.3390/met13030620

Chicago/Turabian StyleLi, Libo, Siyuan Chen, Qinying Lu, Xuedao Shu, Jun Zhang, and Weiwei Shen. 2023. "Effect of Process Parameters on Spinning Force and Forming Quality of Deep Cylinder Parts in Multi-Pass Spinning Process" Metals 13, no. 3: 620. https://doi.org/10.3390/met13030620

APA StyleLi, L., Chen, S., Lu, Q., Shu, X., Zhang, J., & Shen, W. (2023). Effect of Process Parameters on Spinning Force and Forming Quality of Deep Cylinder Parts in Multi-Pass Spinning Process. Metals, 13(3), 620. https://doi.org/10.3390/met13030620